Ballistic limit velocities of carbon fiber material target plate against fragment penetration

-

摘要: 碳纤维复合材料(CFRPs)在国防科技中广泛应用,已经成为主承力构件及部分结构的防护材料,研究其抗破片侵彻性能为科研人员提高碳纤维复合材料性能、进行防护结构设计提供依据。为研究碳纤维复合材料靶板受破片侵彻的毁伤机理及弹道极限速度,进行8 g立方体钢破片分别侵彻厚5 mm、10 mm、15 mm碳纤维复合材料靶板数值仿真与试验,得到破片侵彻碳纤维复合材料靶板的数值仿真弹道极限与六射弹弹道极限速度,数值仿真弹道极限与六射弹弹道极限最大误差为6.21%。利用数值仿真方法得到大量不同着靶速度与对应的剩余速度,基于THOR公式建立破片侵彻碳纤维复合材料靶板剩余速度模型与弹道极限计算公式。对弹道极限公式进行试验验证,选取不同工况下的六射弹弹道极限,与理论计算值进行对比,结果表明,同一工况下,试验结果与计算结果最大误差为4.54%。

-

关键词:

- 碳纤维复合材料(CFRPs) /

- 弹道侵彻试验 /

- 毁伤模式 /

- 弹道极限

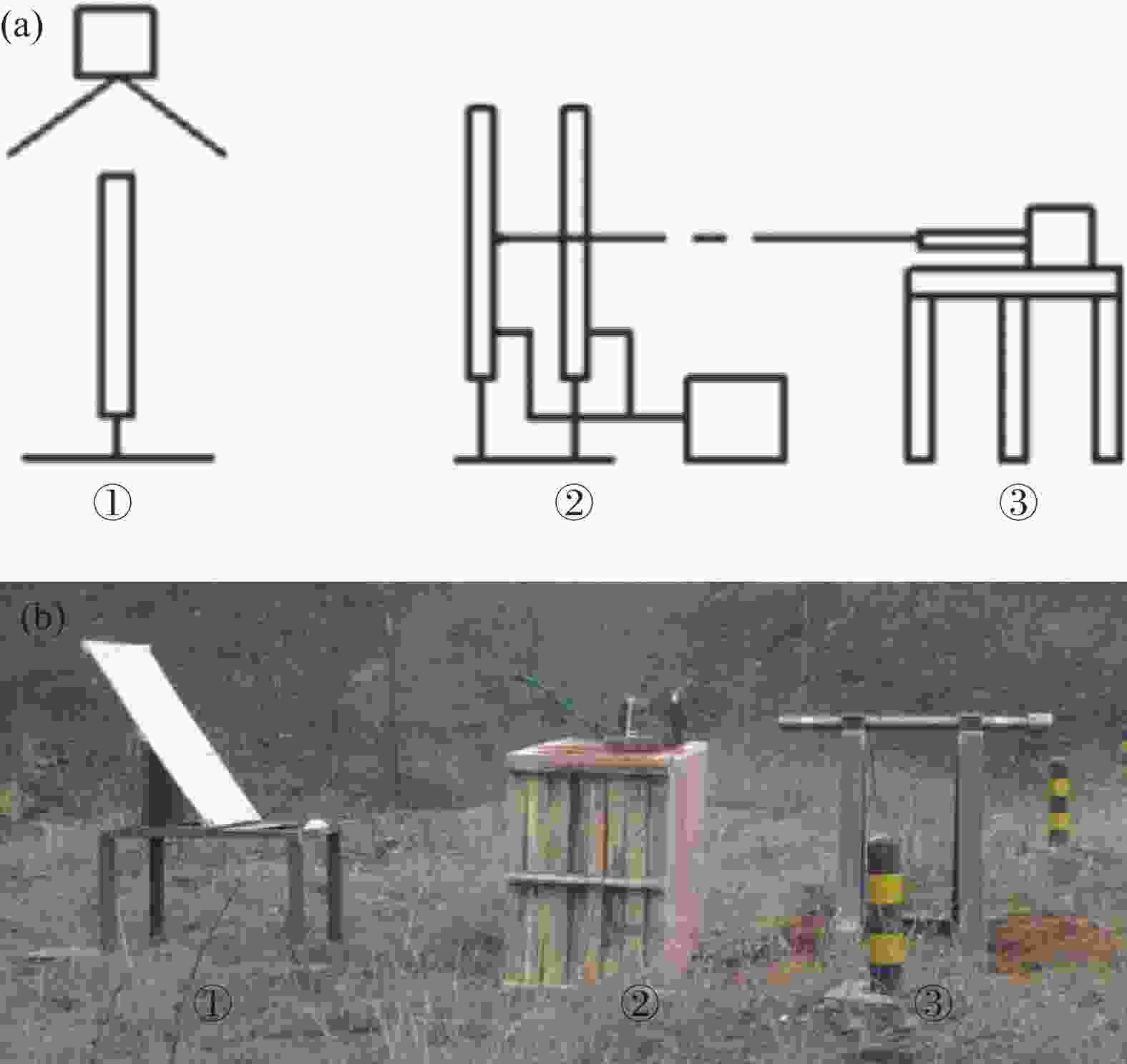

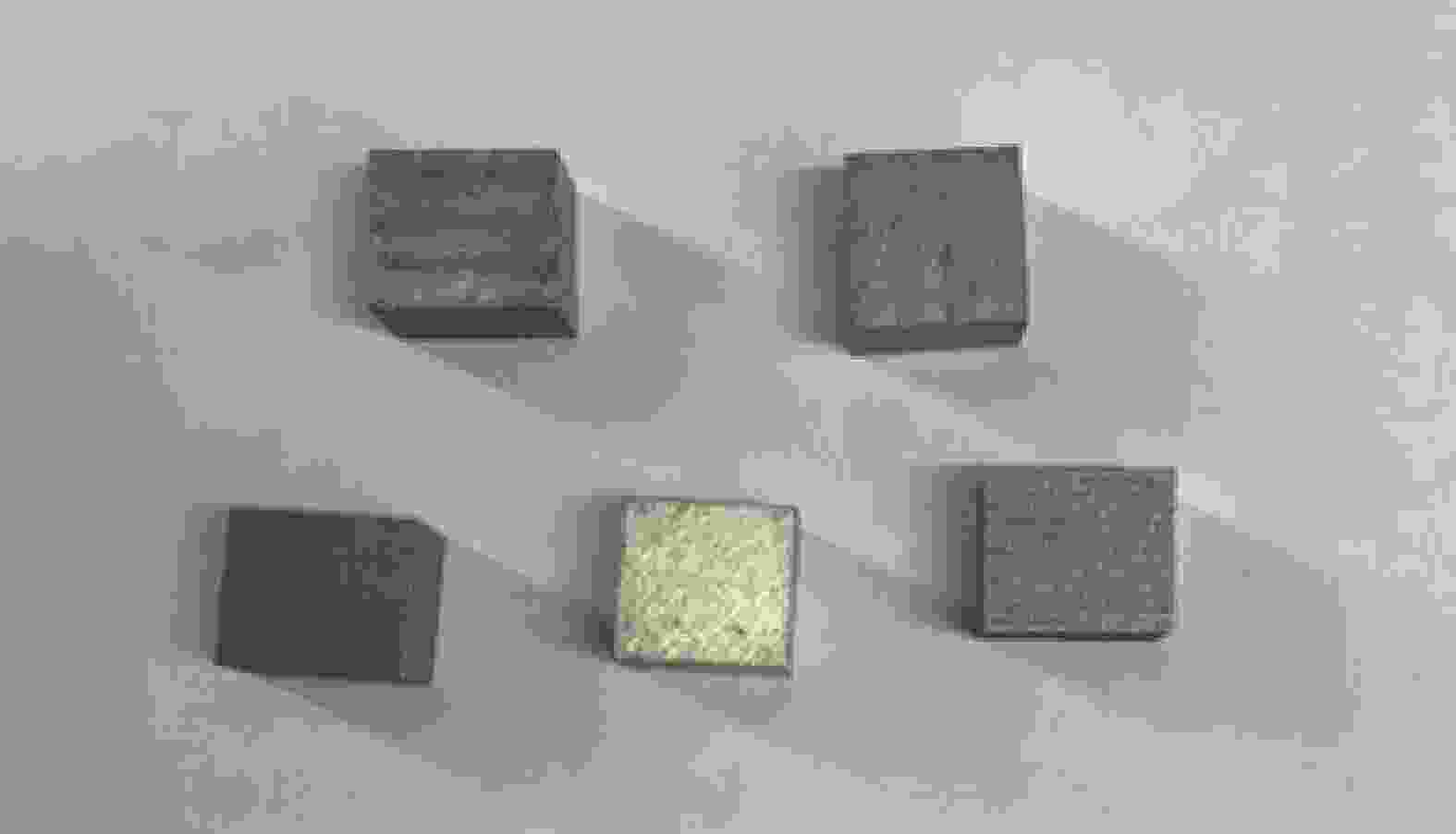

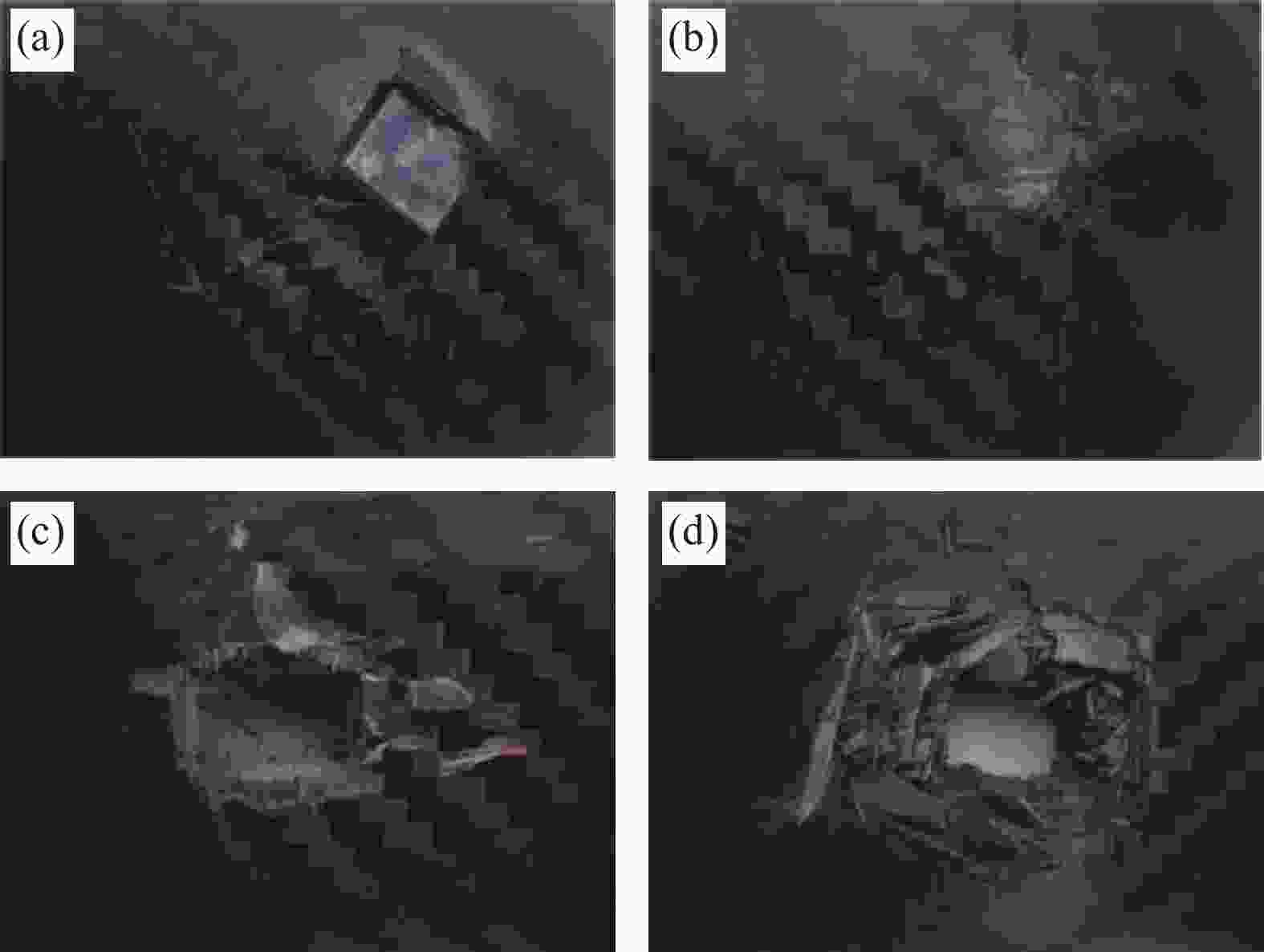

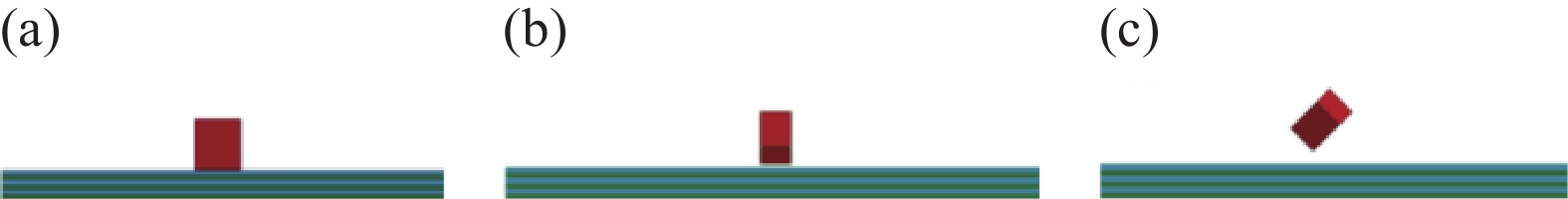

Abstract: Carbon fiber reinforced plastics (CFRPs) are widely used in national defense science and technology and have become the protective materials for main load-bearing components and some structures. Research on their fragment penetration resistance provides a basis for scientific researchers to improve the performance of CFRPs and design protective structures. To study the damage mechanism and ballistic limit velocity of CFRP target plates penetrated by fragments, numerical simulations and tests were conducted on 8g cubic steel fragments penetrating CFRP target plates with thicknesses of 5 mm, 10 mm and 15 mm, respectively. The numerical simulation of the ballistic limit velocities of the fragments penetrating CFRP target plates and the six-projectile ballistic limit velocities were obtained, and the maximum error between the numerical simulation of the ballistic limit velocity and the six-projectile ballistic limit velocity was 6.21%. A large number of different impact velocities and corresponding residual velocities were obtained by numerical simulations. Based on the THOR formula, the residual velocity model of the fragments penetrating CFRP target plates and the ballistic limit calculation formula were established. The ballistic limit formula was verified experimentally, and the six-projectile ballistic limits under different working conditions were selected and compared with the theoretical calculated values. The results show that under the same working condition, the maximum error between the test and calculated results is 4.54%. -

表 1 钢破片材料参数

Table 1. Material parameters of the steel fragment

ρ/(g·cm−3) G/GPa σ/MPa B/MPa n 7.83 0.77 792 510 0.26 c M TM/K TR/K 0.014 1.03 1793 294 Notes: ρ is density ; G is the shear modulus ; σis the yield stress ; B is the hardening coefficient ; n is the hardening index ; c is the strain rate coefficient; M is the temperature coefficient ; TM is the melting temperature ; TR is the ambient temperature. 表 2 数值仿真弹道极限

Table 2. Numerical simulation of ballistic limit

Target thickness/mm Simulation of ballistic limit velocity/ (m·s-1) 5 307.76 10 394.78 15 437.55 表 3 发射药量与破片着靶速度

Table 3. Amount of propellant and the velocity of fragment hitting the target

Target

thickness/mmDosage of

propellant/gRange of speed/

((m·s−1))5 2.5-3 290-340 10 3.5-4 370-420 15 4.5-5 425-460 表 4 碳纤维复合材料力学性能

Table 4. Mechanical properties of CFRPs

Mechanical property Parameter Longitudinal tensile strength $ {\sigma }_{\mathrm{x}\mathrm{t}} $ /MPa 1755 Longitudinal tensile modulus $ {E}_{1\mathrm{t}} $ / GPa 138 Main Poisson's ratio $ {V}_{12} $ 0.27 Transverse tensile strength $ {\sigma }_{\mathrm{y}\mathrm{t}} $ /MPa 48 Transverse tensile modulus $ {E}_{2\mathrm{t}} $ /GPa 8.36 Longitudinal compressive strength $ {\sigma }_{\mathrm{x}\mathrm{c}} $ /MPa 1248 Longitudinal compression modulus $ {E}_{1\mathrm{C}} $ /GPa 128 Transverse compressive strength$ {\sigma }_{\mathrm{y}\mathrm{c}} $ /MPa 214 Transverse compression modulus $ {E}_{2\mathrm{C}} $ /GPa 8.48 Longitudinal and transverse shear strength $ {\tau }_{12} $ /MPa 113 Longitudinal and transverse shear modulus $ {G}_{12} $ /GPa 4.51 Shear strength of bonded structure $ {\tau }_{\mathrm{J}} $/MPa 21.5 表 5 六射弹弹道极限

Table 5. Six-shot limit velocity

Target thickness/mm Experimental data/ (m·s-1) Six-shot limit velocity/(m·s-1) Local penetration Complete penetration 5 312 335 328.17 318 340 318 342 10 379 404 394.67 384 406 386 409 15 423 439 436.50 429 447 432 449 表 6 数值仿真与试验结果误差表

Table 6. Error table between numerical simulation and test results

Target

thickness/mmBallistic limit

velocity/(m·s−1)Six-shot limit

velocity/(m·s−1)Deviation/% 5 307.76 328.17 6.21 10 394.78 394.67 0 15 437.55 436.50 0.23 表 7 不同速度碳纤维复合靶板破坏形式

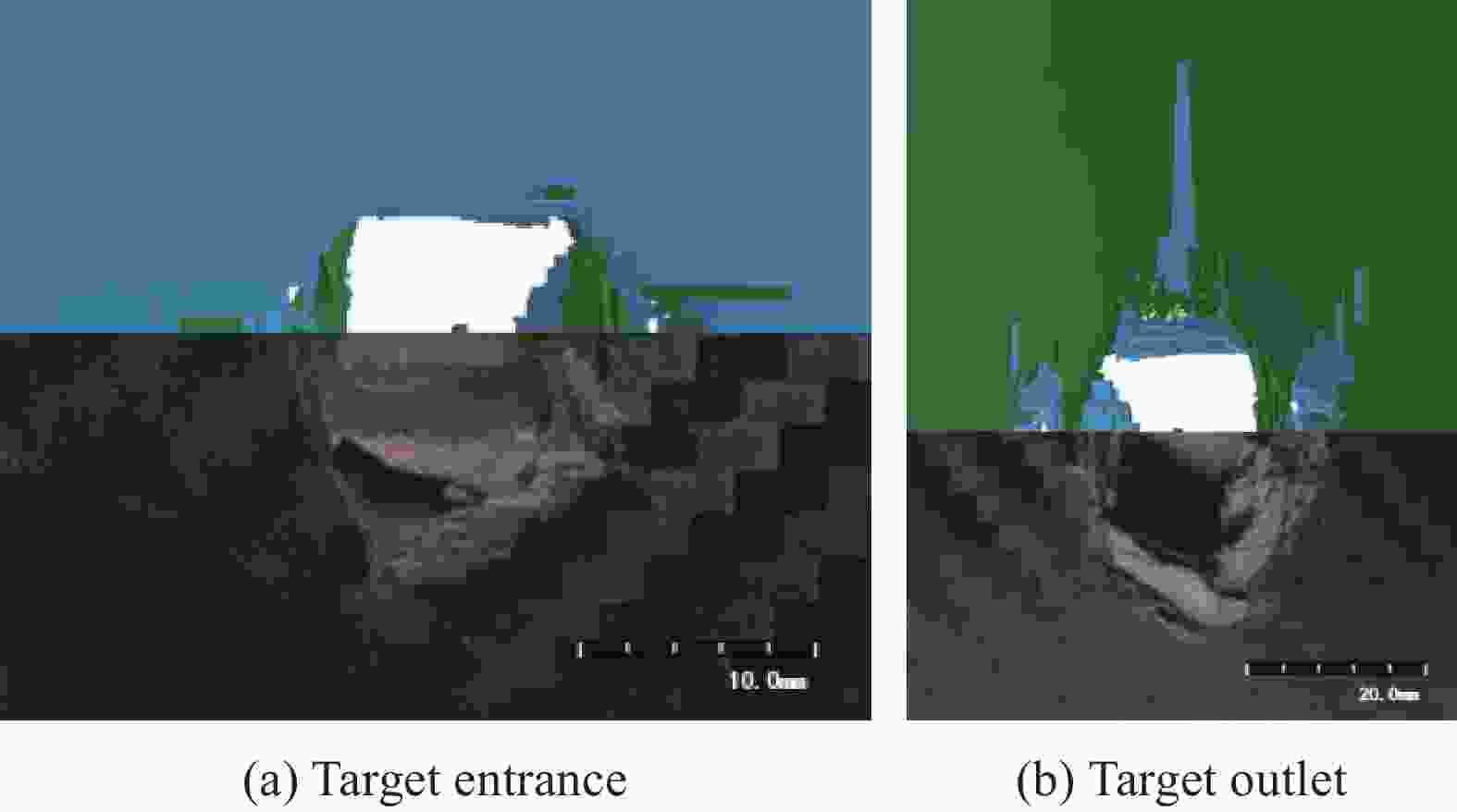

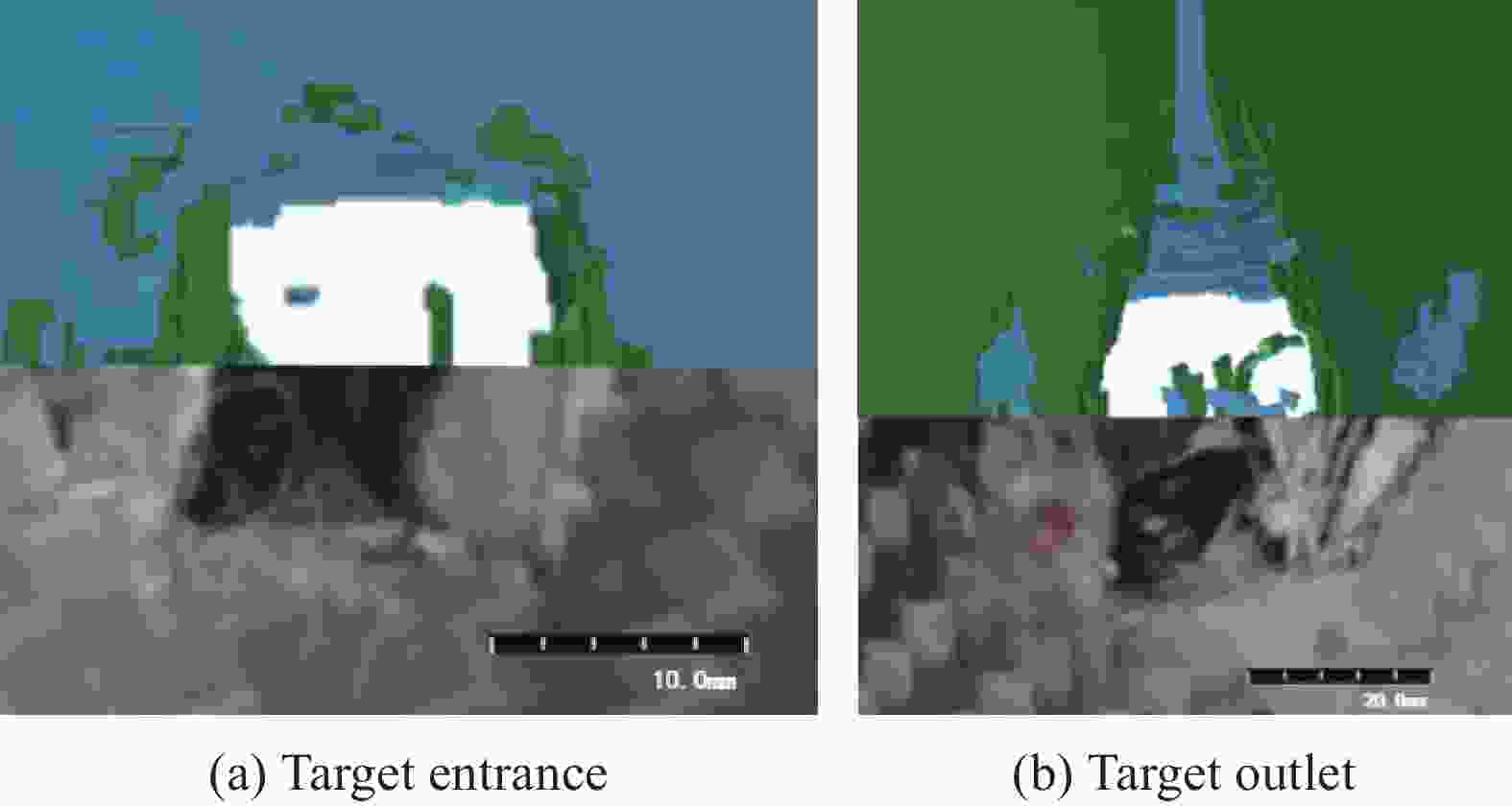

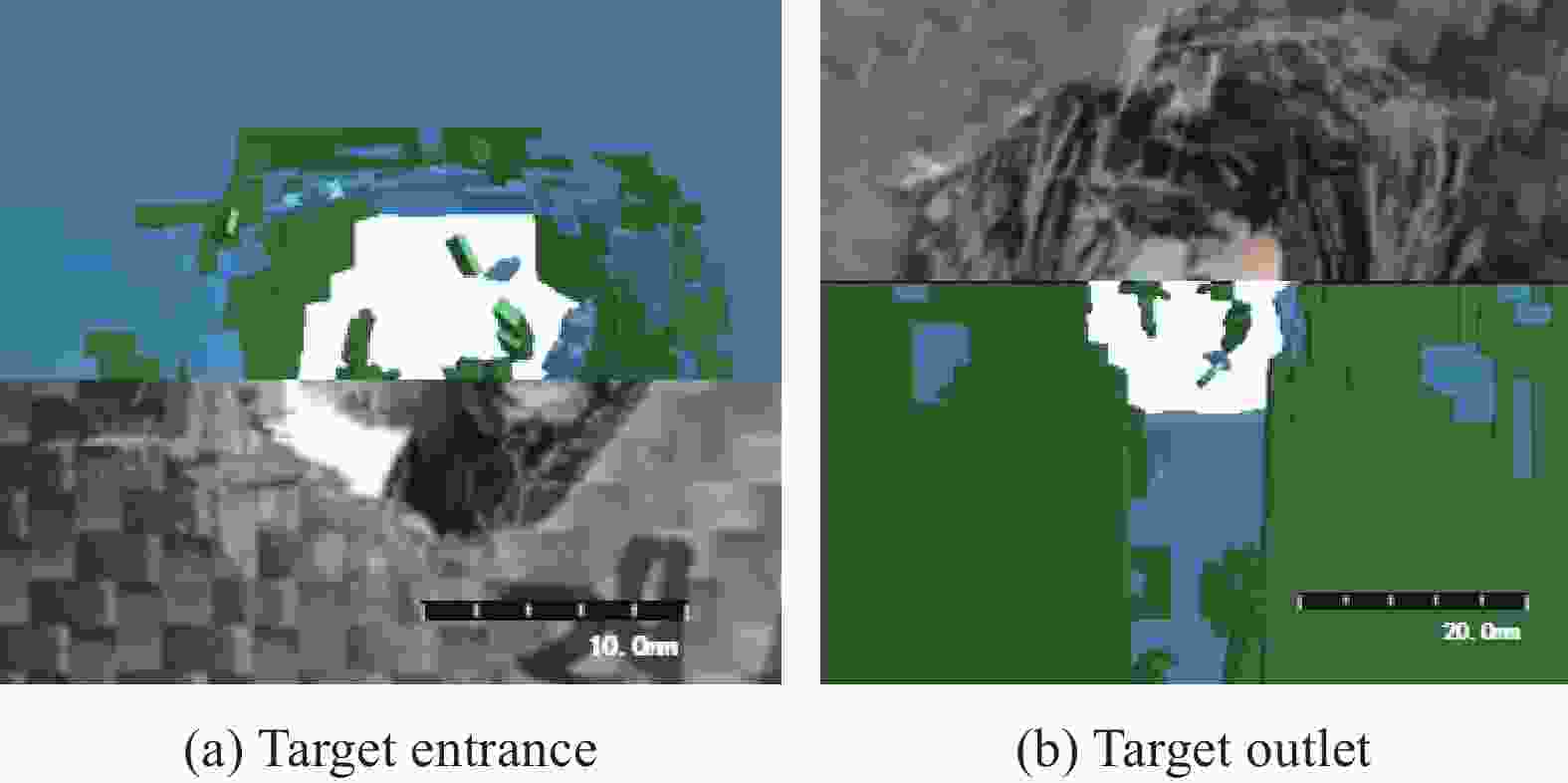

Table 7. Failure modes of CFRPs with different velocities

Velocity Damage pattern Shear failure Fiber tensile failure Matrix damage Delamination damage (bulging) >limit velocity √ =limit velocity √ √ <imit velocity √ √ Multiple minor collisions √ 表 8 拟合系数

Table 8. Fit coefficient

$ {C}_{1} $ $ {C}_{2} $ $ {C}_{3} $ $ {C}_{4} $ $ {C}_{5} $ 6.422 0.302 −0.968 1.254 −0.306 表 9 碳纤维复合靶板弹道极限理论计算值

Table 9. Ballistic limit calculation value of CFRPs

Target thickness/mm Theoretical calculation of ballistic

limit velocity/(m·s−1)5 323.32 10 379.46 15 416.72 表 10 理论计算与试验结果误差

Table 10. Error between theoretical calculation and test results

Target

thickness/mmTheoretical

velocity /(m·s−1)Six-shot limit

velocity/(m·s−1)Deviation/% 5 323.32 328.17 1.47 10 379.46 394.67 3.88 15 416.72 436.50 4.54 -

[1] 周锦地. 基于多尺度方法的碳纤维复合材料温度环境下力学行为研究[D]. 哈尔滨工业大学, 2022: 1-3.ZHOU Jindi. Study of mechanical behavior ofcarbon fiber composites undertemperature environment based onmultlscale approach[D]. Harbin Institute of Technology , 2022: 1-3. (in Chinese). [2] Anuse Vaibhav Somaji, Shankar Krishnapillai, Velmurugan Ramachandran, Ha Sung Kyu. LVI and CAI Analysis of Woven Carbon Fiber Reinforced Composite Laminates with Different Stacking Sequence[J]. Key Engineering Materials, 2023, 969: 93-100 doi: 10.4028/p-n2McuG [3] 常新龙, 孙超凡, 齐重阳, 等. 集成于碳纤维复合材料的fsFBG响应特性研究[J/OL]. 兵器装备工程学报;2023, 45(01): 1-9.CHANG Xinlong, SUN Chaofan, QI Chongyang, et al. Response characteristics of fsFBG sensor based on carbon fiber composite laminate[J/OL]. Journal of Ordnance Equipment Engineering;2023, 45(01): 1-9. (in Chinese). [4] 贾宝华, 刘翔, 顾永强, 等. 复合材料层合板的抗弹性能模拟分析[J]. 兵器装备工程学报, 2017, 37(8): 147-152. doi: 10.11809/scbgxb2017.08.031JIA Baohua, LIU Xiang, GU Yongqiang, et al. Numerical Si mulation of the Anti-Bullet Property for Composite Laminated Plates[J]. Journal of Ordnance Equipment Engineering, 2017, 37(8): 147-152(in Chinese). doi: 10.11809/scbgxb2017.08.031 [5] ABRATE S. Impact on laminated composites-recent advances[J]. Applied Mechanics Reviews, 1994: 517-544. [6] 金子明, 隋金玲, 张菡英, 等. 纤维增强复合防弹板研究进展及抗弹性能研究[J]. 玻璃钢, 2001, 01: 1-6.JIN Ziming, SUI Jinling, ZHANG Hanying, et al. Research progress and anti-elastic properties of fiber reinforced composite bulletproof panels[J]. Fiber Reinforced Plastics, 2001, 01: 1-6(in Chinese). [7] Guoqi Z, Goldsmith W, Dharan Ck H. Penetration of laminated Kevlar by projectiles—I. Experimental investigation[J]. International Journal of Solids and Structures, 1992, 29(4): 399-420. doi: 10.1016/0020-7683(92)90207-A [8] Guoqi Z, Goldsmith W, Dharan C K H. Penetration of laminated Kevlar by projectiles—II. Analytical model[J]. International Journal of Solids and Structures, 1992, 29(4): 421-436. doi: 10.1016/0020-7683(92)90208-B [9] 李春昀, 孙颖, 张典堂, 等. 缝合铺层碳/环氧复合材料动态压缩性能实验研究[J]. 天津工业大学学报, 2013, 32(1): 1-4. doi: 10.3969/j.issn.1671-024X.2013.01.001LI Chunyun, SUN Ying, ZHANG Diantang, et al. Study on dynamic compressive behavior of stitched carbon/epoxy composite laminates[J]. Journal of Tiangong University, 2013, 32(1): 1-4(in Chinese). doi: 10.3969/j.issn.1671-024X.2013.01.001 [10] Hosur M V, Alexander J, Jeelani S, et al. High Strain Compression Response of Affordable Woven Carbon/Epoxy Composites[J]. Journal of Reinforced Plastics and Composites, 2003, 22(3): 271-296. doi: 10.1177/0731684403022003844 [11] Xiao L, Wang G, Qiu S, et al. Exploration of energy absorption and viscoelastic behavior of CFRPs subjected to low velocity impact[J]. Composites Part B: Engineering, 2019, 165: 247-254. doi: 10.1016/j.compositesb.2018.11.126 [12] Kim H, Welch D A, Kedward K T. Experimental investigation of high velocity ice impacts on woven carbon/epoxy composite panels[J]. Composites Part A: Applied Science and Manufacturing, 2003, 34(1): 25-41. doi: 10.1016/S1359-835X(02)00258-0 [13] 赵九州. 三维编织复合材料冲击行为与动态强度研究[D]. 哈尔滨工业大学, 2016.ZHAO Jiuzhou. Research on the impact behavior anddynamic strength of 3-d woven compositeHarbin Institute of Technology, 2016. (in Chinese). [14] 马小敏, 李世强, 李鑫, 等. 编织Kevlar/Epoxy复合材料层合板在冲击荷载下的动态响应[J]. 爆炸与冲击, 2016, 36(2): 170-176. doi: 10.11883/1001-1455(2016)02-0170-07MA Xiaomin, LI Shiqiang, LI Xin, et al. Dynamic response of woven Kevlar/Epoxy composite laminates under impact loadino[J]. Explosion and Shock Waves, 2016, 36(2): 170-176(in Chinese). doi: 10.11883/1001-1455(2016)02-0170-07 [15] Zhou J, Liao B, Shi Y, et al. Low-velocity impact behavior and residual tensile strength of CFRP laminates[J]. Composites Part B: Engineering, 2019, 161: 300-313. doi: 10.1016/j.compositesb.2018.10.090 [16] MORYESS, HINEPJ, DUCKETTR A, et al. Modelling of the energy absorption by polymer composites upon ballistic impacts[J]. Composites Science and Technology, 2000: 2631-2642. [17] LIU P F, ZHENG J Y. Recent developments on damage modeling and finite element analysis for composite laminates: A review[J]. Materials & Design, 2010: 3825-3834. [18] 赵云, 杨波, 陶子伟, 等. 纤维增强树脂基防弹复合材料吸能机制及损伤模式研究进展[J/OL]. 复合材料学报, 1-16[2024-03-31].ZHAO Yun, YANG Bo, TAO Ziwei, et al. Research progress on energy absorption mechanism and damage mode of fiber reinforced resinbased bulletproof composites[J/OL]. Acta Materiae Compositae Sinica, 1-16[2024-03-31]. (in Chinese). [19] 俞鸣明, 朱雪莉, 刘雪强, 等. 低速多次冲击下碳纤维/环氧树脂基复合材料层合板失效机制及剩余强度评估[J]. 复合材料学报, 2023, 40(9): 5359-5370.YU Mingming, ZHU Xueli, LIU Xueqiang, et al. Failure mechanism and assessment of residual strength of carbon fiber/epoxy resin matrix composite laminates under multiple impacts at low velocities[J]. Acta Materiae Compositae Sinica, 2023, 40(9): 5359-5370(in Chinese). [20] 王东哲. 纤维增强复合材料抗弹丸侵彻性能的多尺度数值模拟研究[D]. 山东大学, 2021.WANG Dongzhe. Multi-scale Numerical Simulation of Anti-penetration Performance of Fiber Reinforced Composites[D]. Shandong University, 2021. (in Chinese). [21] 许明明. 碳纤维增强金属层合板抗高速冲击特性研究[D]. 北京理工大学, 2018.XU Mingming. High Velocity Impact Resistance of CarbonFiber-reinforced Metal Laminates[D]. Beijing Institute of Technology, 2018. (in Chinese). [22] 秦溶蔓, 朱波, 乔琨等. 复合结构碳纤维防弹板的防弹性能仿真[J]. 工程科学学报, 2021, 43(10): 1346-1354.QIN Rongman, ZHU Bo, QIAO Kun, et al. Simulation study of the protective performance of composite structure carbon fiber bulletproof board[J]. Chinese Journal of Engineering, 2021, 43(10): 1346-1354(in Chinese). [23] 徐豫新, 任杰, 王树山. 钨球正撞击下低碳钢板的极限贯穿厚度研究[J]. 北京理工大学学报, 2017, 37(6): 551-556.XU Yuxin, REN Jie, WANG Shushan. Research on Perforation Limit Thickness of Low Carbon Steel Plates Impacted Normally by Tungsten Spheres[J]. Transactions of Beijing Institute of Technology, 2017, 37(6): 551-556(in Chinese). [24] 蒋志刚, 曾首义, 周建平. 分析金属靶板弹道极限的延性扩孔模型[J]. 弹道学报, 2004, (1): 54-59. doi: 10.3969/j.issn.1004-499X.2004.01.011JIANG Zhigang, ZENG Shouyi, ZHOU Jianping. A Model for Ballistic Limit of Thick Metallic Targets STRUCK by Projectiles with Conical or Ogival Nose[J]. Journal of Ballistics, 2004, (1): 54-59(in Chinese). doi: 10.3969/j.issn.1004-499X.2004.01.011 [25] 周冰, 李良春, 宋桂飞. 仿真预测泡沫铝弹道极限和弹丸侵彻冲击力[J]. 兵工自动化, 2018, 37(6): 10-13.ZHOU Bing, LI Liangchun, SONG Guifei. Numerical Stimulation for Predicting Ballistic Limit and Impact Force in Penetration of Aluminum Foam by Blunt-nosed Projectile[J]. Ordnance Industry Automation, 2018, 37(6): 10-13(in Chinese). [26] 武一丁, 高光发, 王晓东. 不同速度下B4C陶瓷/铝合金轻型复合靶板抗侵彻行为研究[J]. 南京理工大学学报, 2023, 47(4): 503-513.WU Yiding, GAO Guangfa, WANG Xiaodng. Research on the penetration resistance behavior of B, C ceramic/aluminum alloy lightweightcomposite target at different speeds[J]. Journal of Nanjing University of Science and Technology, 2023, 47(4): 503-513(in Chinese). [27] 姜春兰, 李明, 张庆明等. 碳纤维织物增强复合材料的冲击响应特性(英文)[J]. Journal of Beijing Institute of Technology (English Edition), 2000, (3): 225-230.JIANG Chunlan, LI Ming, ZHANG Qingming, et al. lmpact Responses of the Carbon Fiber Fabric Reinforced Composites[J]. Journal of Beijing Institute of Technology(English Edition), 2000, (3): 225-230(in Chinese). [28] 罗锡林, 魏建辉, 李飘等. 碳纤维编织复合材料层合板抗侵彻性能研究[J]. 材料开发与应用, 2023, 38(4): 61-68. doi: 10.19515/j.cnki.1003-1545.2023.04.004LUO Xilin, WEI Jianhui, LI Piao, et al. Study on Penetration Resistance of Carbon Fiber Braided Composite Laminates[J]. Development and Application of Materials, 2023, 38(4): 61-68 (in Chinese). doi: 10.19515/j.cnki.1003-1545.2023.04.004 [29] 李明, 姜春兰, 王在成. 钨球贯穿陶瓷 /铝复合靶的弹道极限分析模型(英文)[J]. Journal of Beijing Institute of Technology(English Edition), 2002, (4): 389-392.LI Ming, JIANG Chunlan, WANG Zaicheng. A Ballistic Limit Analytical Model of Tungsten Ball Perforating Ceramic/Aluminum Composite Target[J]. Journal of Beijing Institute of Technology(English Edition), 2002, (4): 389-392(in Chinese). [30] Qi S , Huang G , Zhi X , et al. External blast flow field evolution and response mechanism of single-layer reticulated dome structure[J]. Defence Technology, 2023, 24(06): 241-253. [31] 钟正. 碳纤维复合材料力学行为及断裂失效模式仿真[D]. 大连理工大学, 2021.ZHONGZheng. CFRP Mechanical behavior and fracture failure mode simulation of CFRP. [D]. Dalian University of Technology , 2021. (in Chinese). [32] Shirvanimoghaddam K, Hamim S U, Karbalaei Akbari M, et al. Carbon fiber reinforced metal matrix composites: Fabrication processes and properties[J]. Composites Part A: Applied Science and Manufacturing, 2017, 92: 70-96. doi: 10.1016/j.compositesa.2016.10.032 [33] 隋树元, 王树山. 终点效应学[M]. 北京: 国防工业出版社, 2000.SUI Shuyuan, WANG Shushan. Terminal effect[M]. Beijing: National Defence Industry Press. (in Chinese) [34] 赵国志. 穿甲工程力学[M]. 北京: 兵器工业出版社, 1992.ZHAO Zhiguo, Armor-piercing engineering mechanics[M]. Beijing: Weapons Industry Press, 1992. (in Chinese). -

点击查看大图

点击查看大图

计量

- 文章访问数: 95

- HTML全文浏览量: 36

- 被引次数: 0

下载:

下载: