Effect of BFRP mesh cloth on bonding properties of ultra-high performance concrete

-

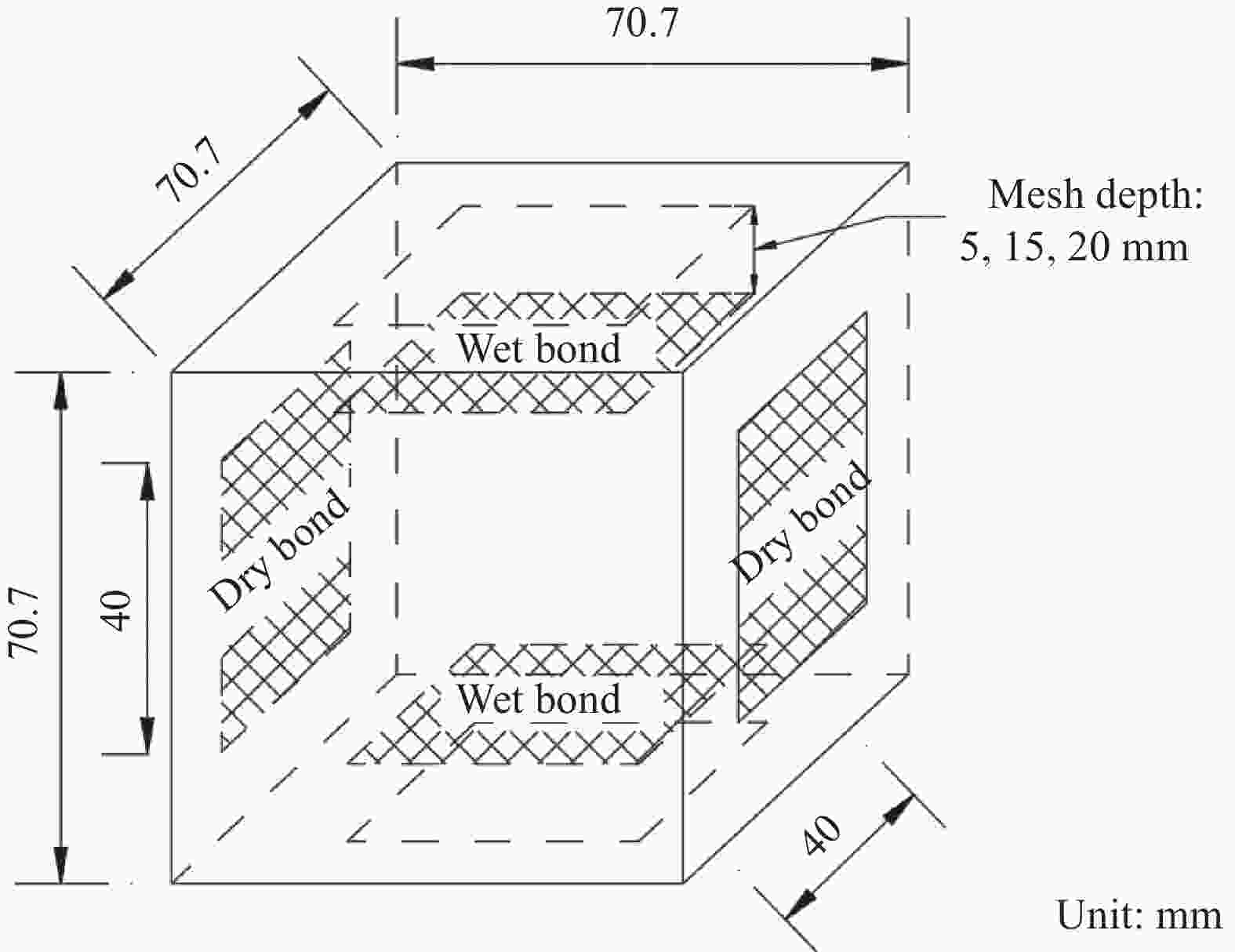

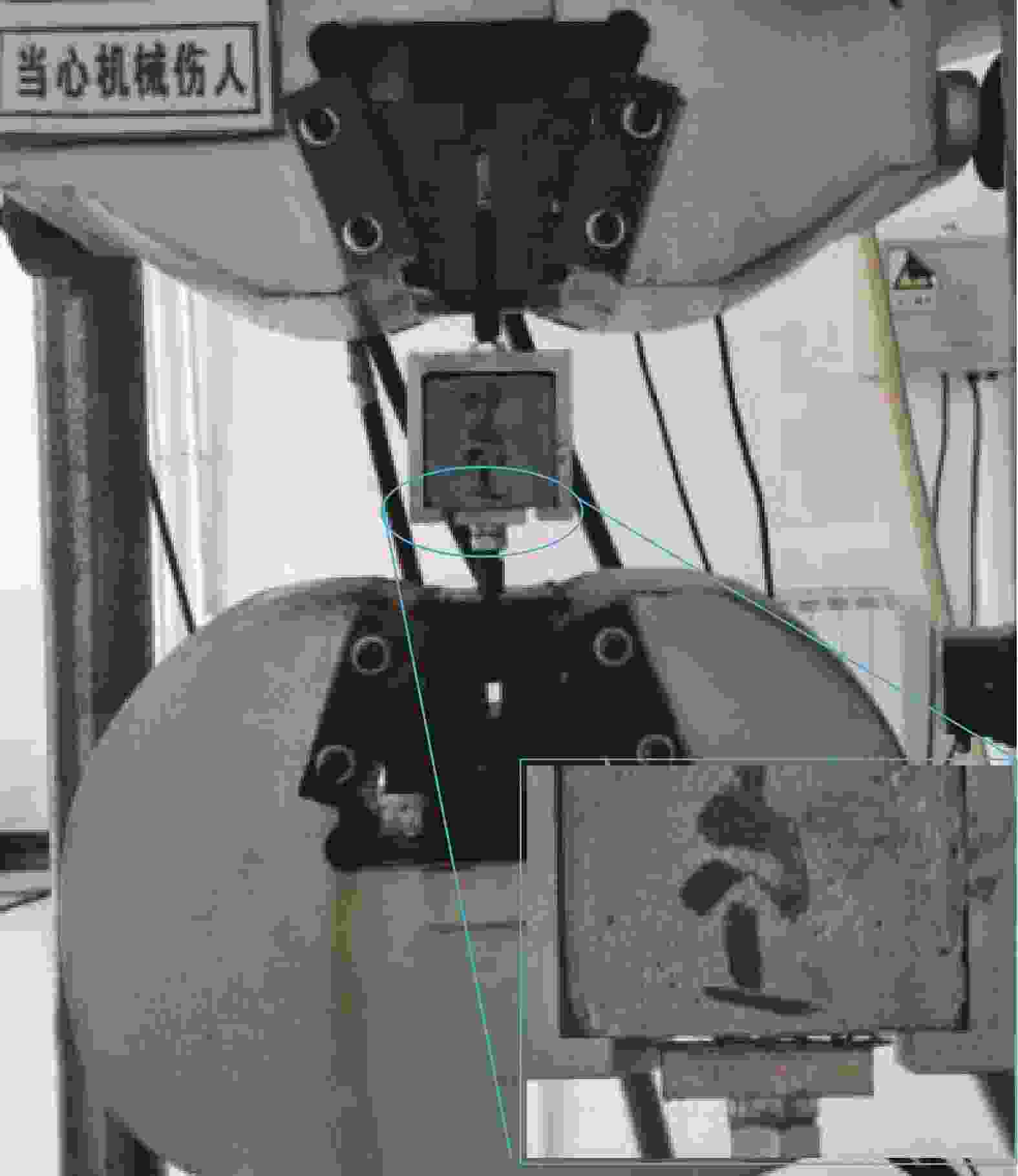

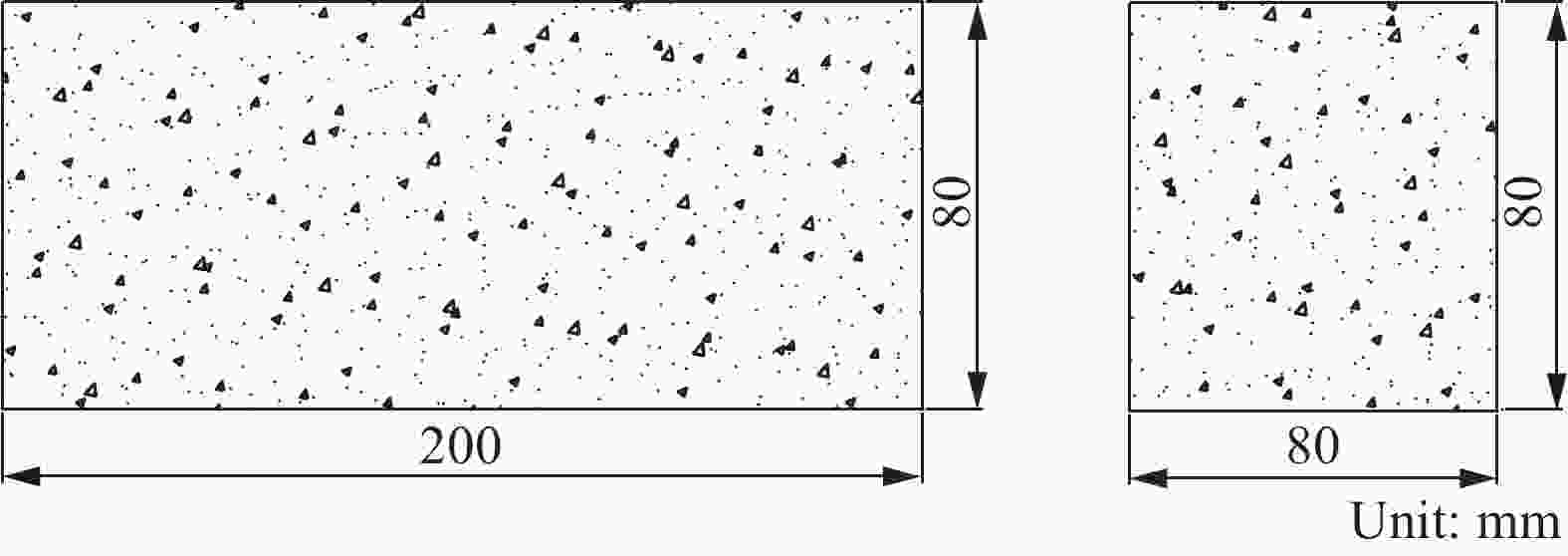

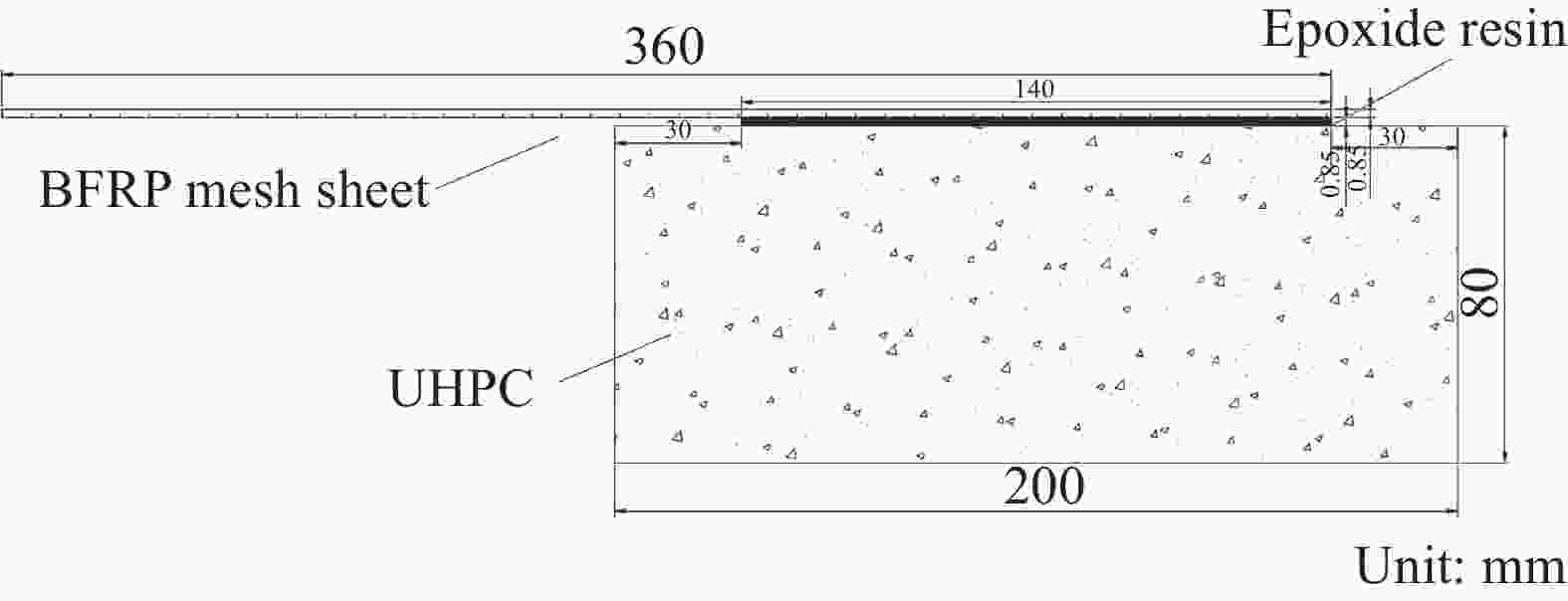

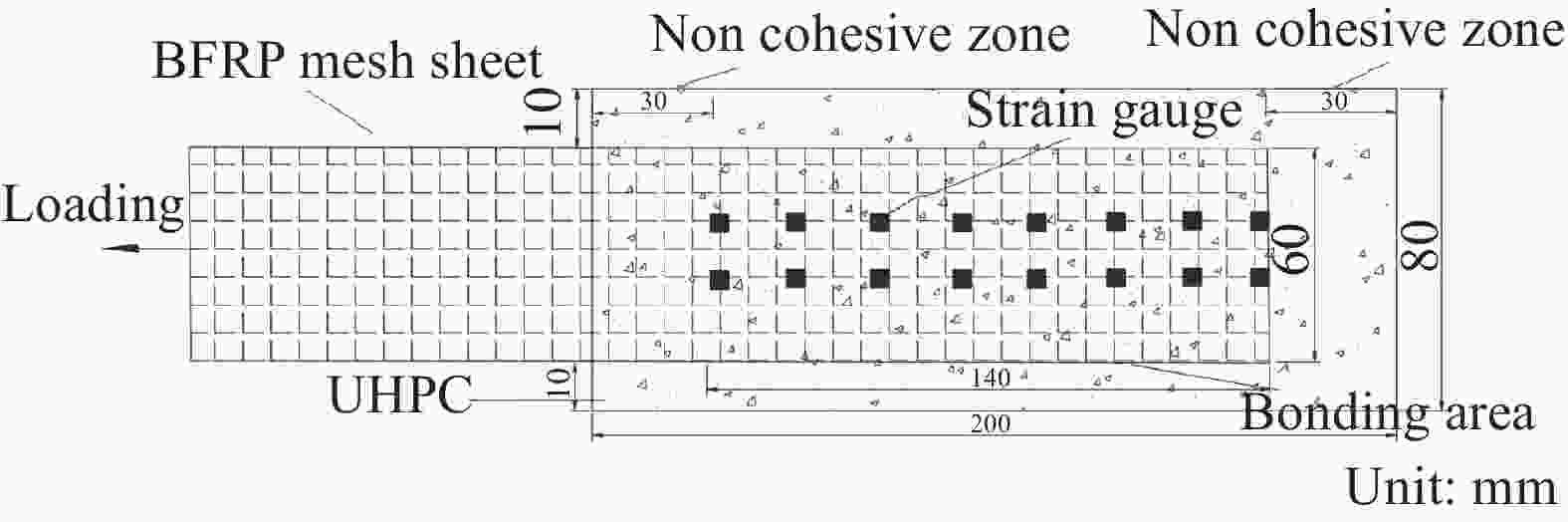

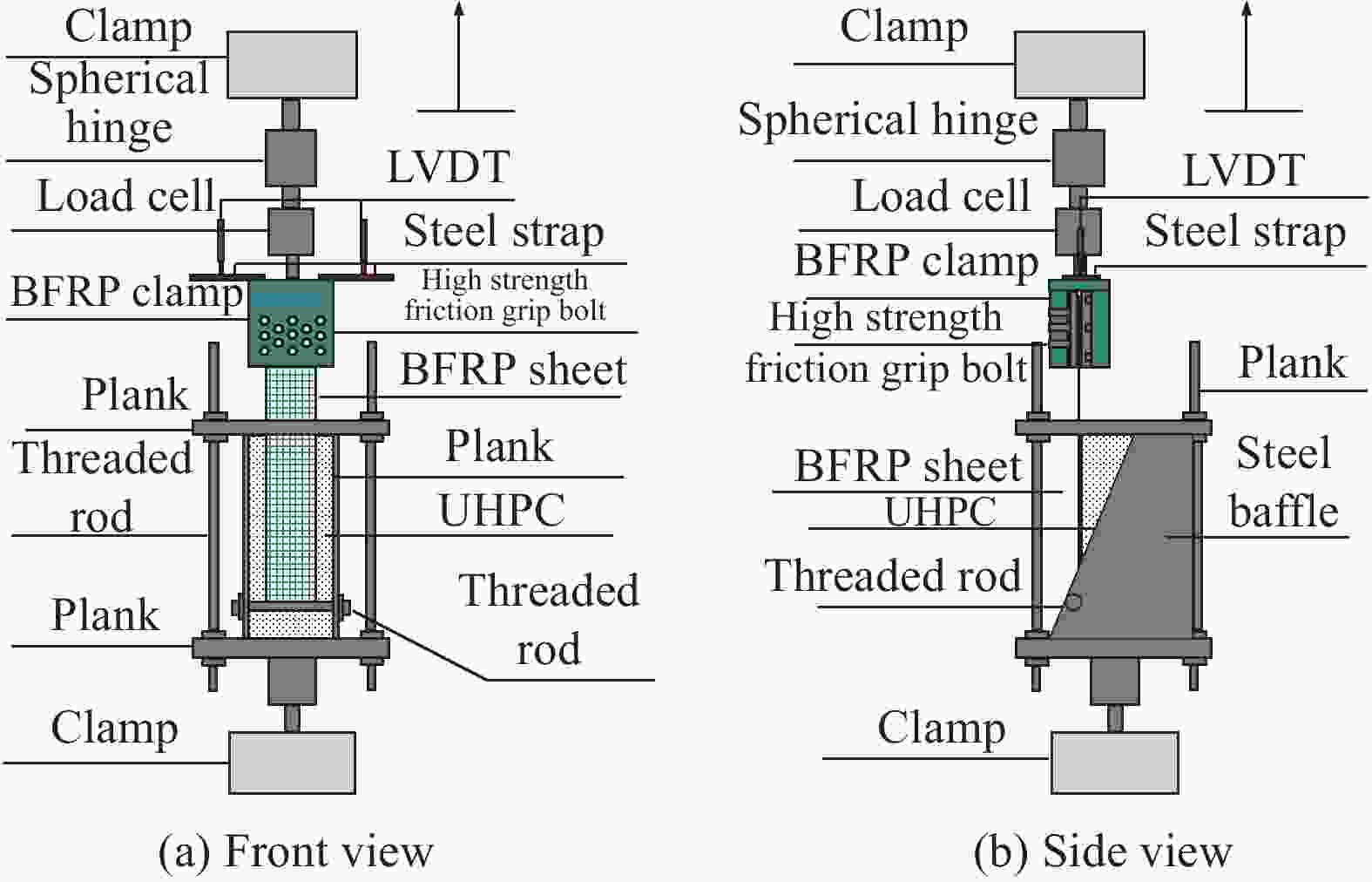

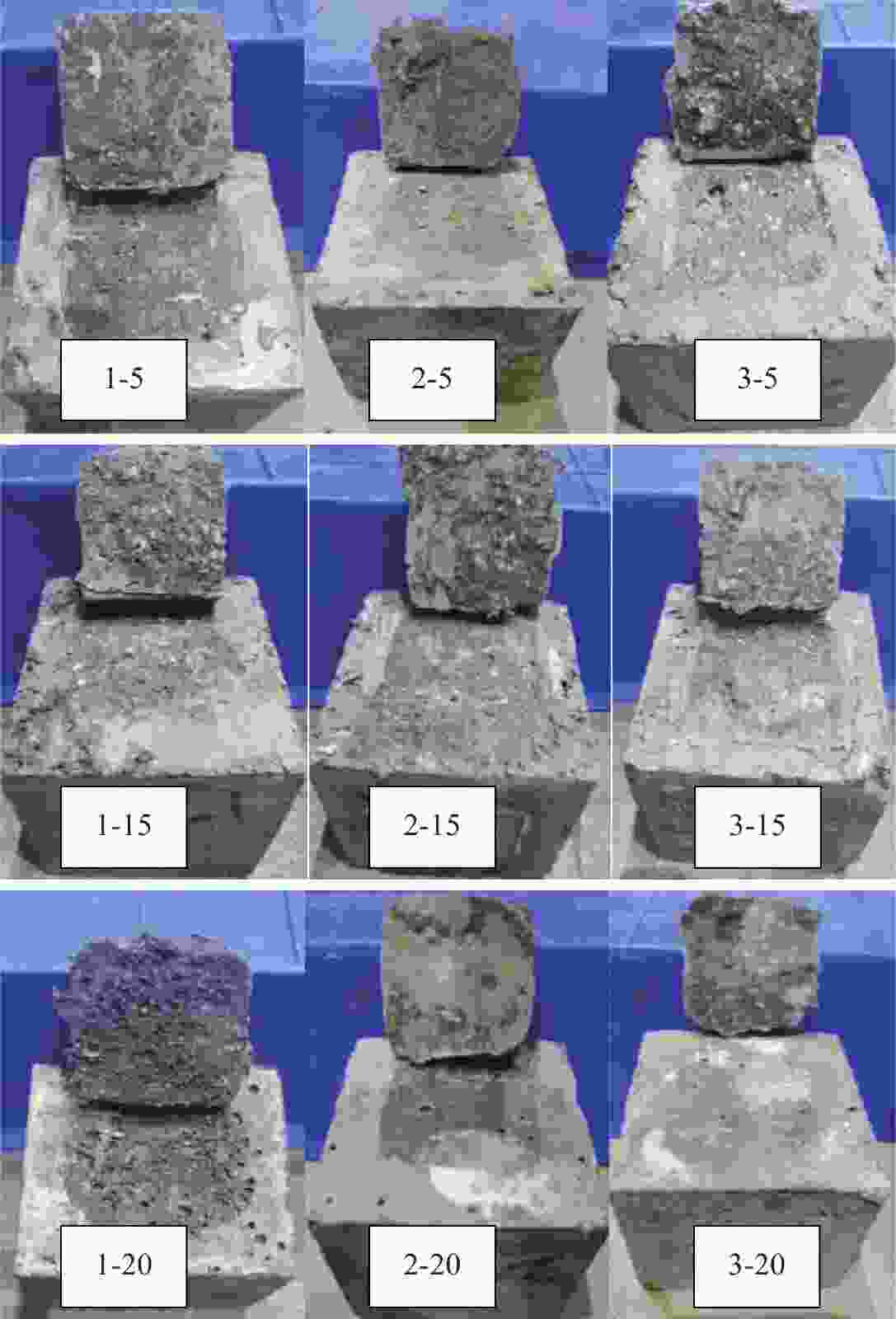

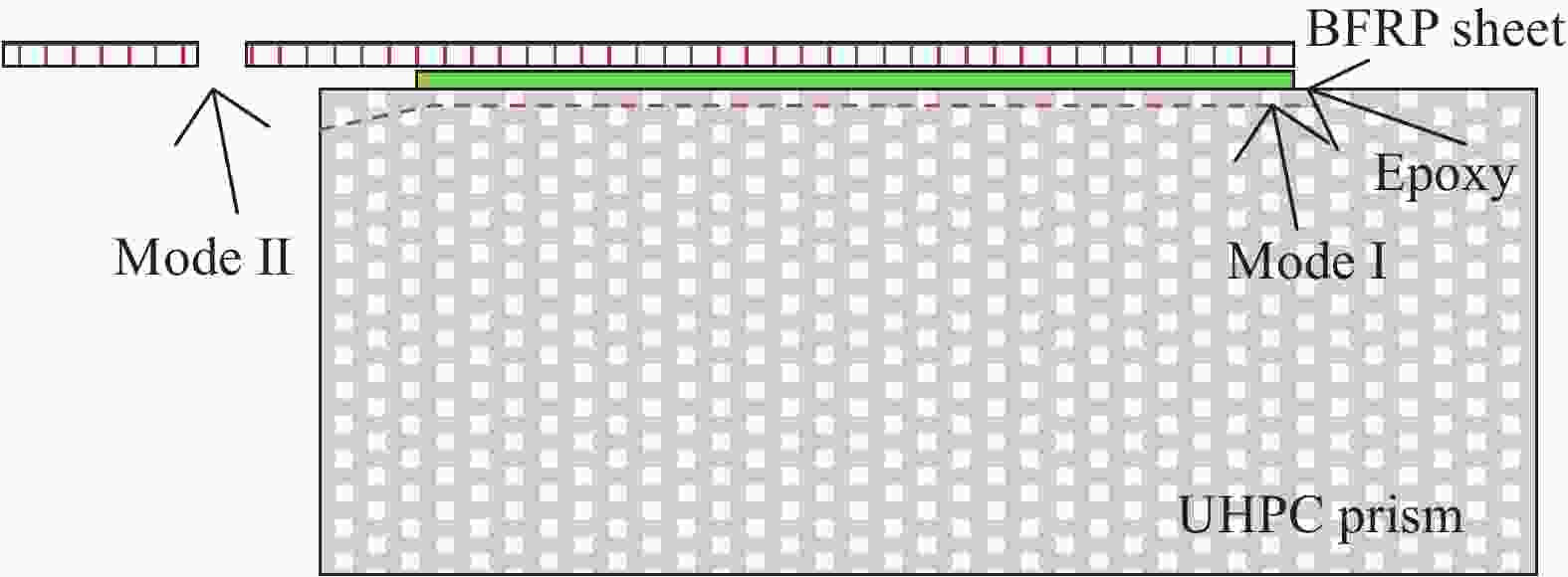

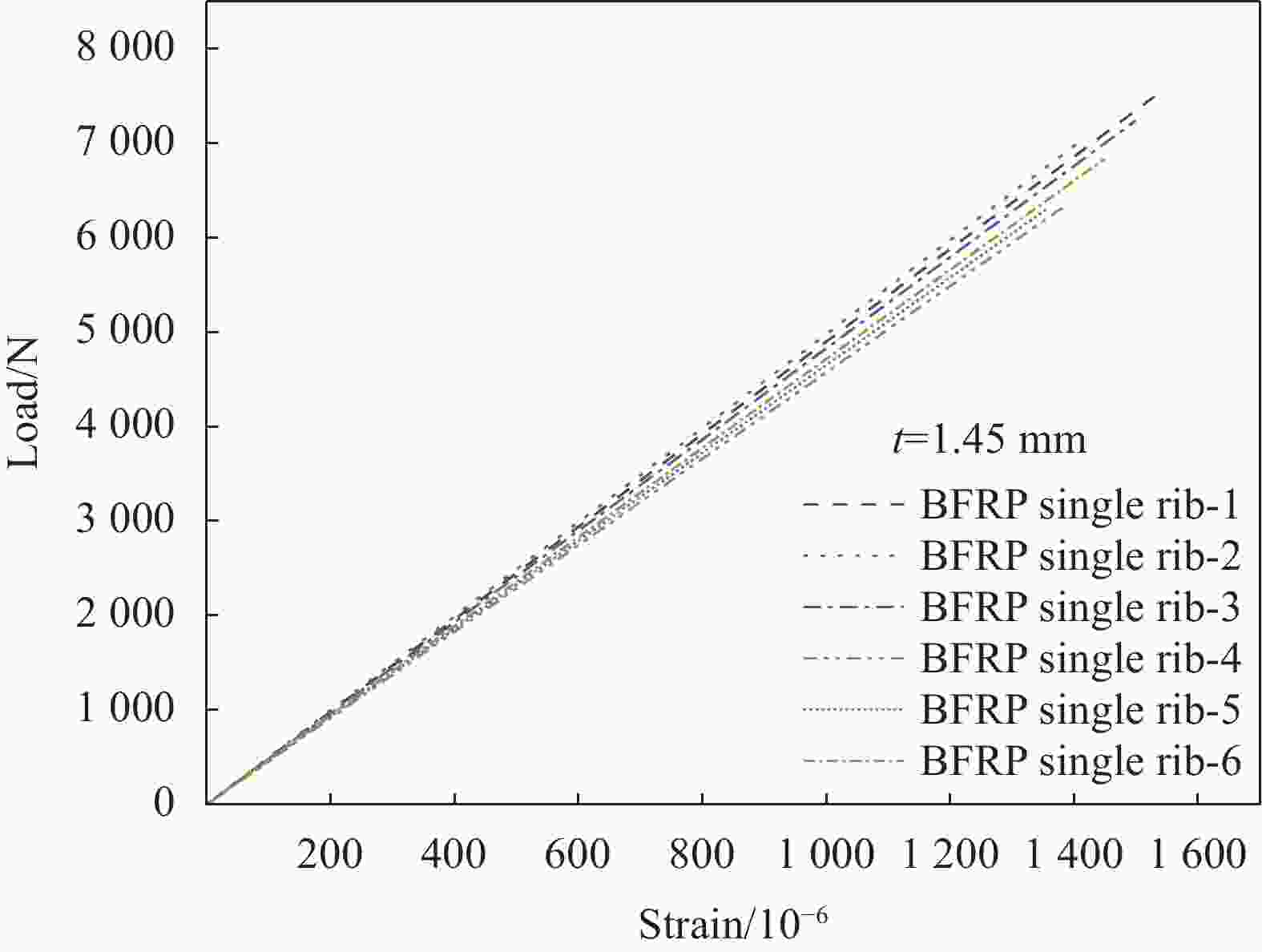

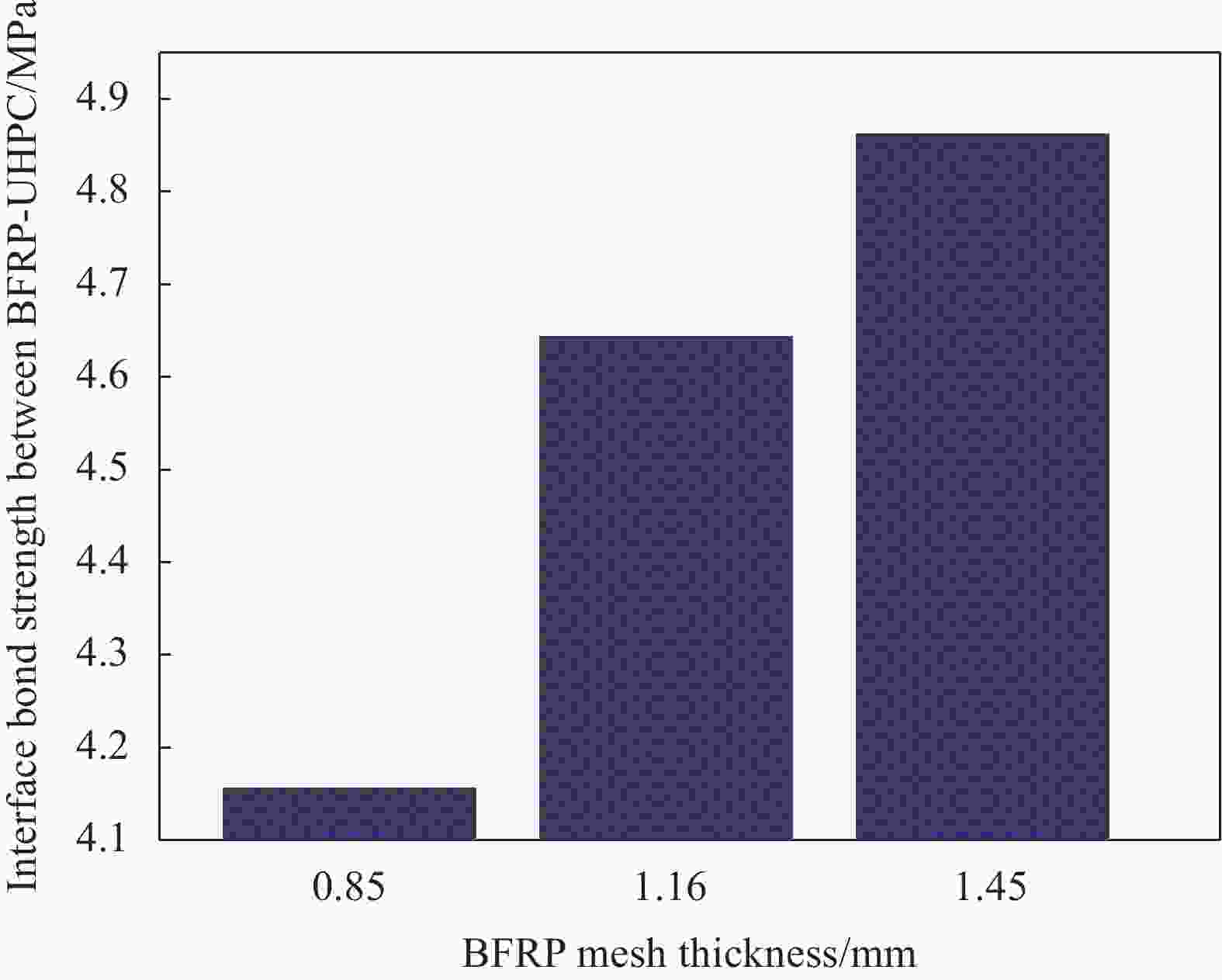

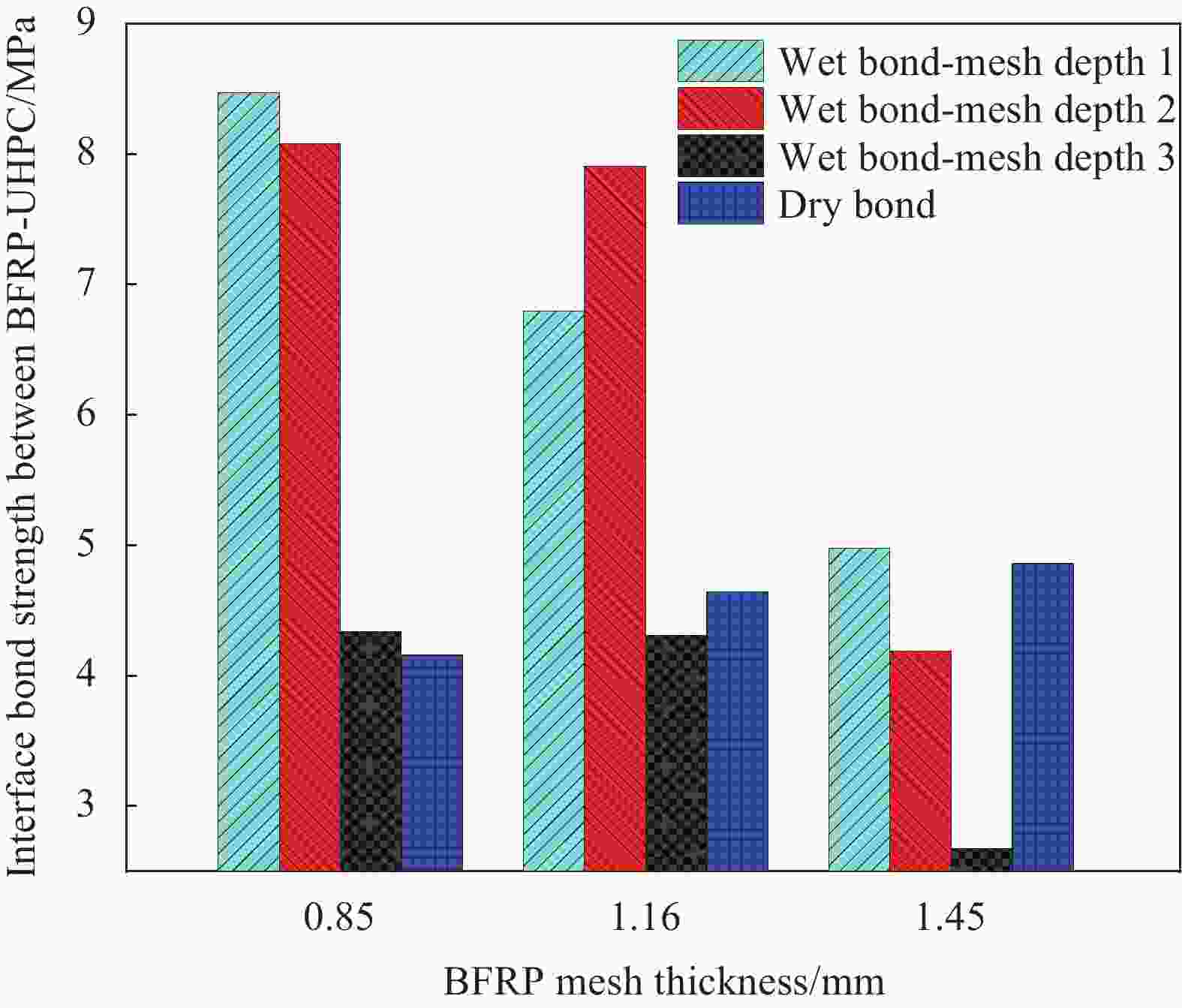

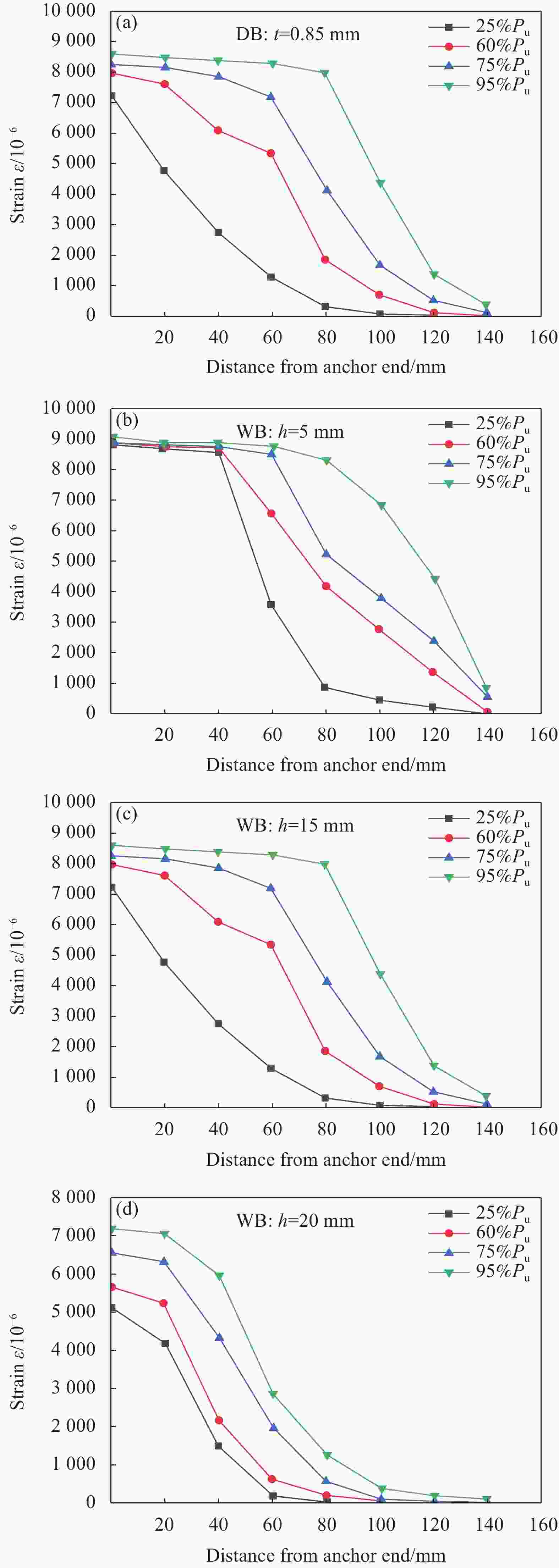

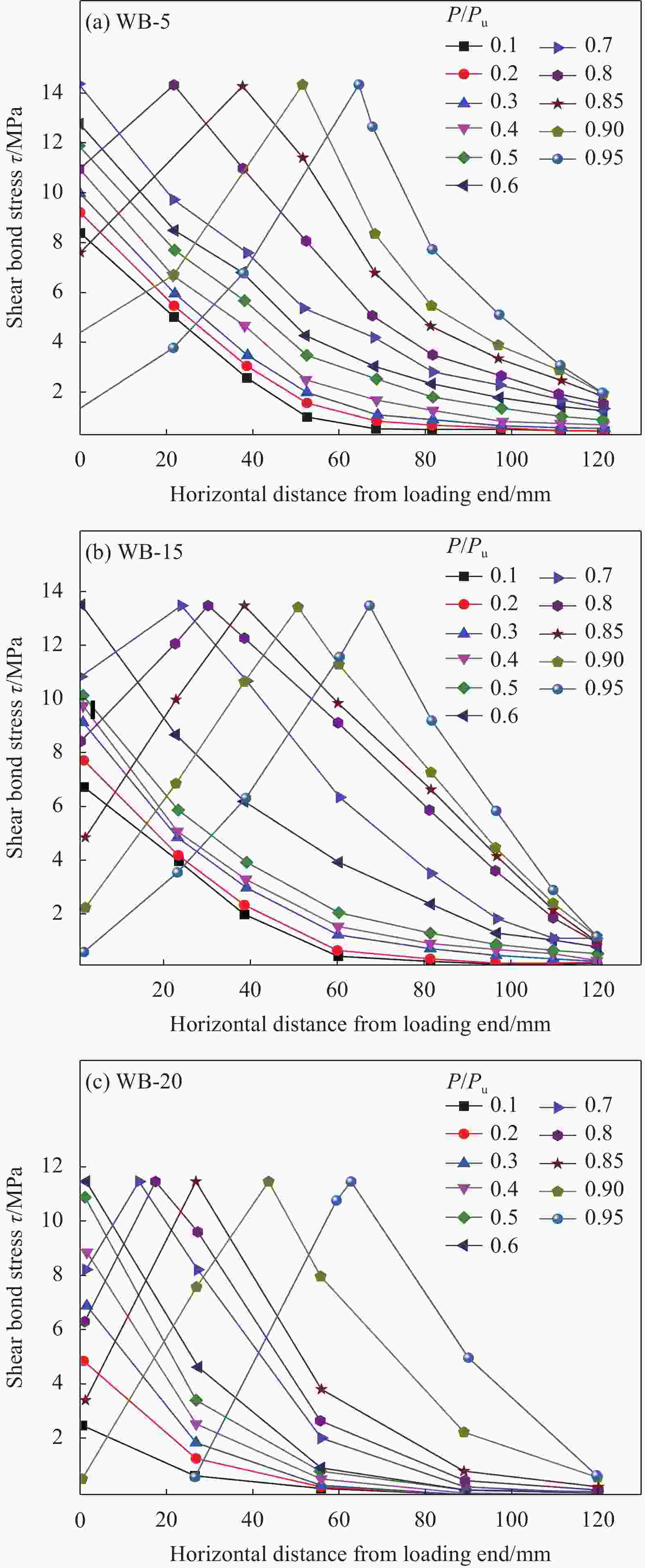

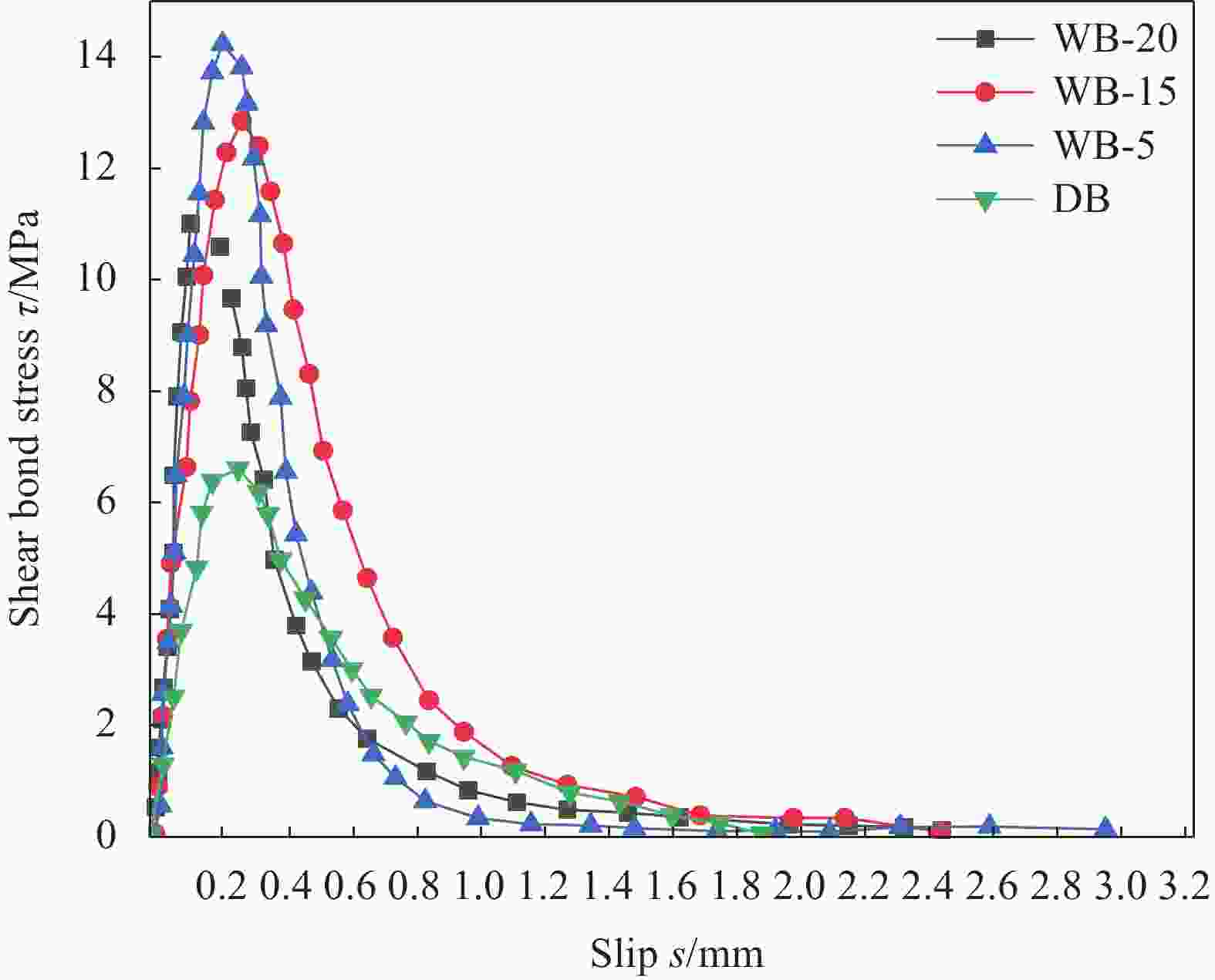

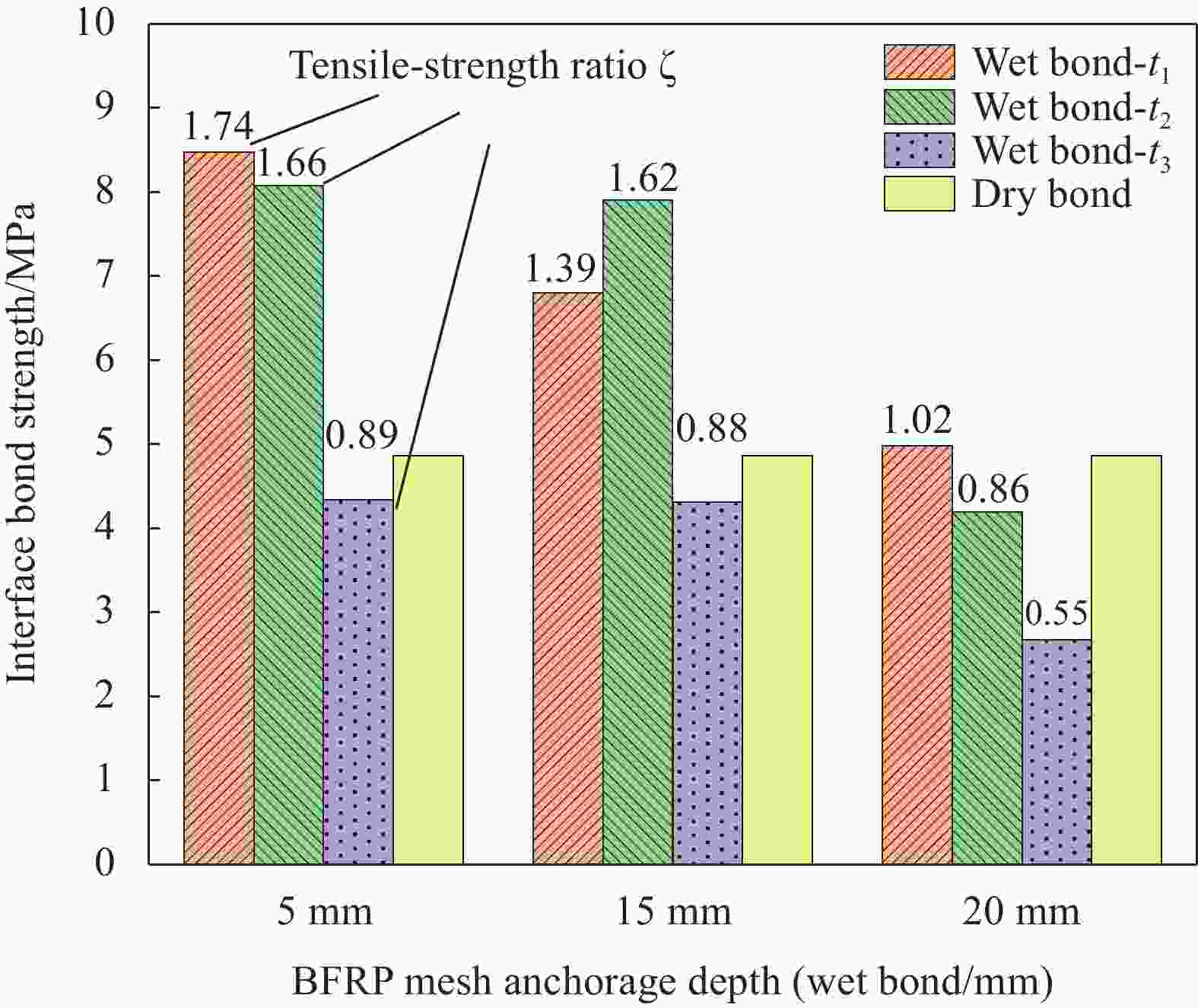

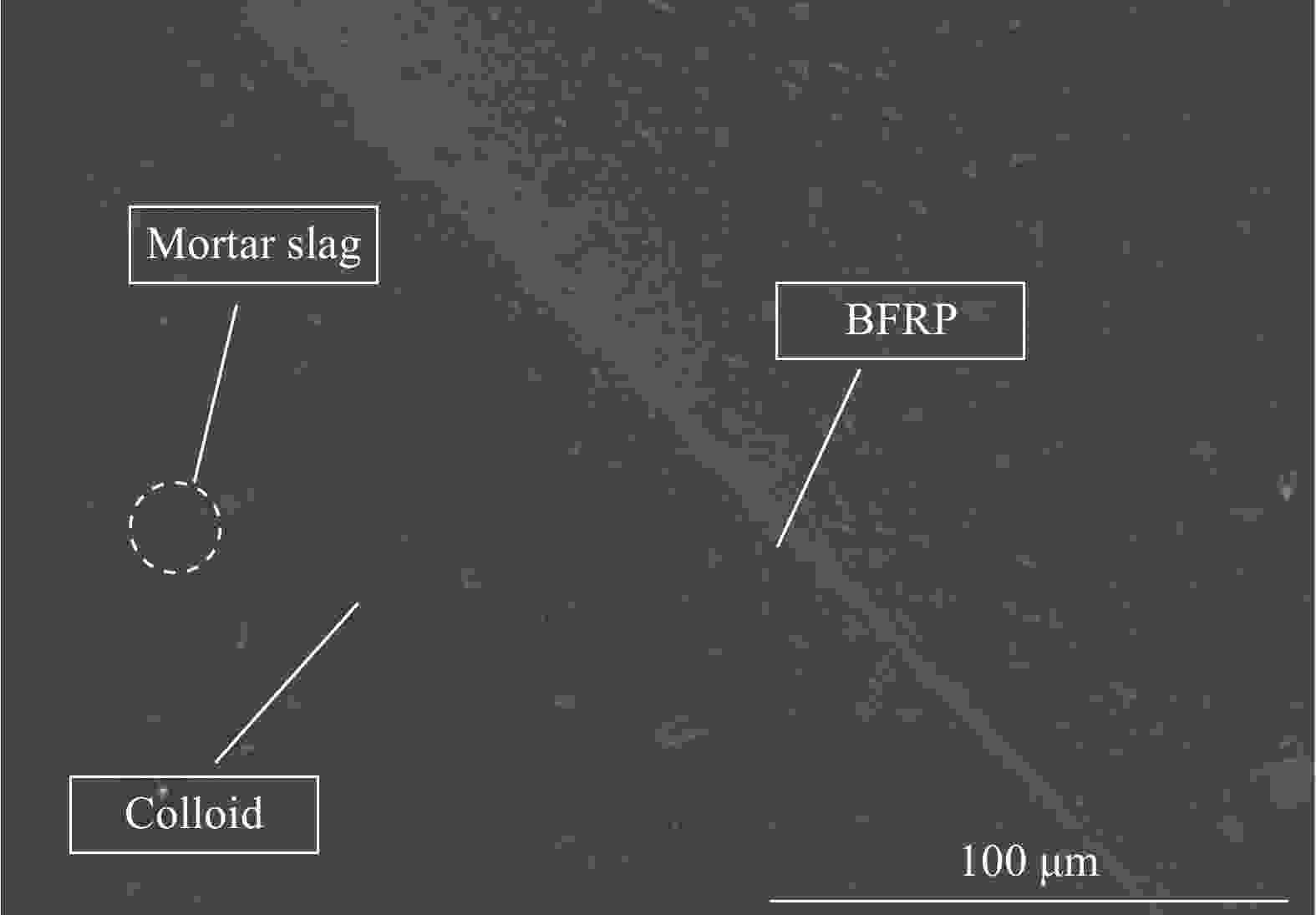

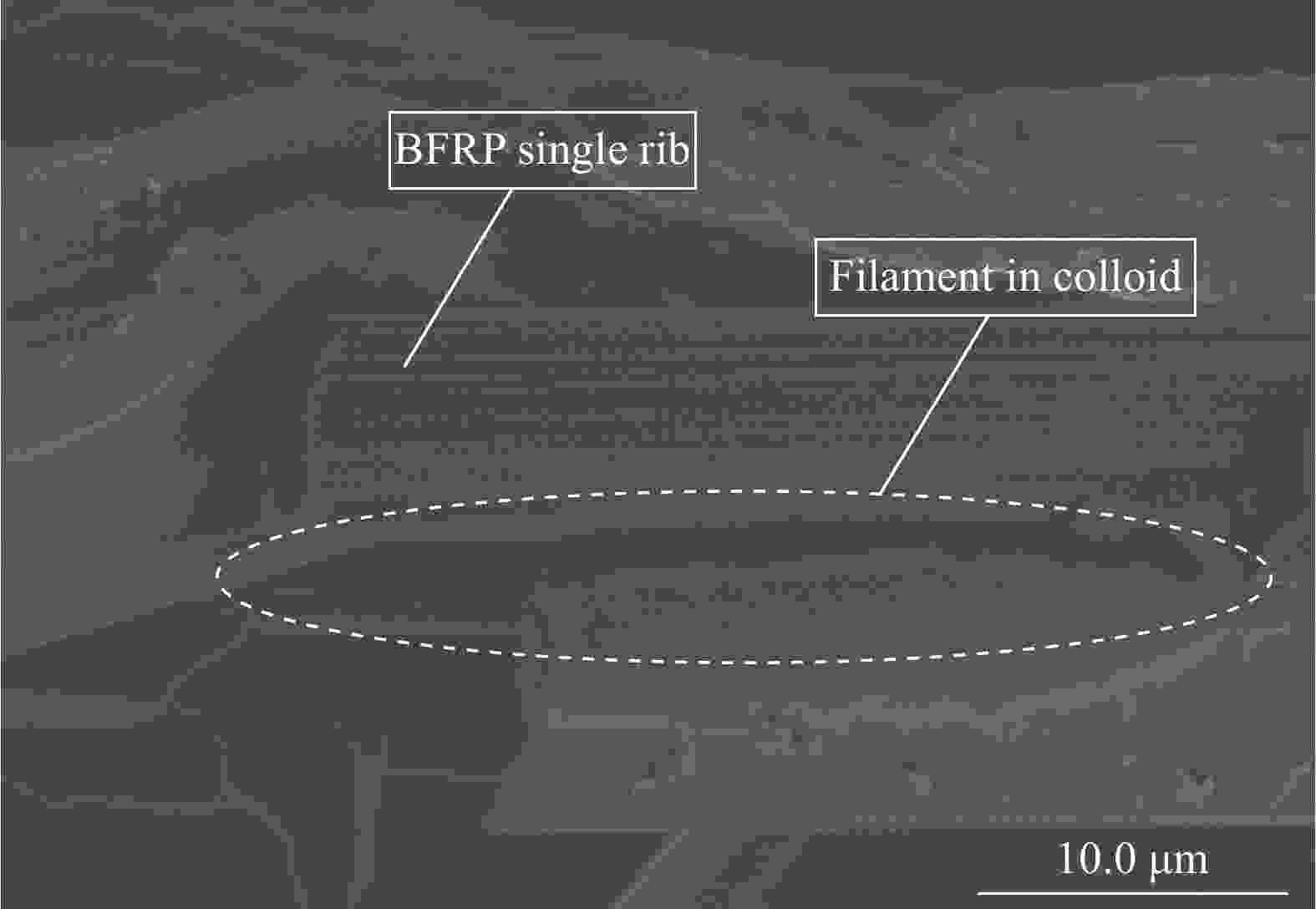

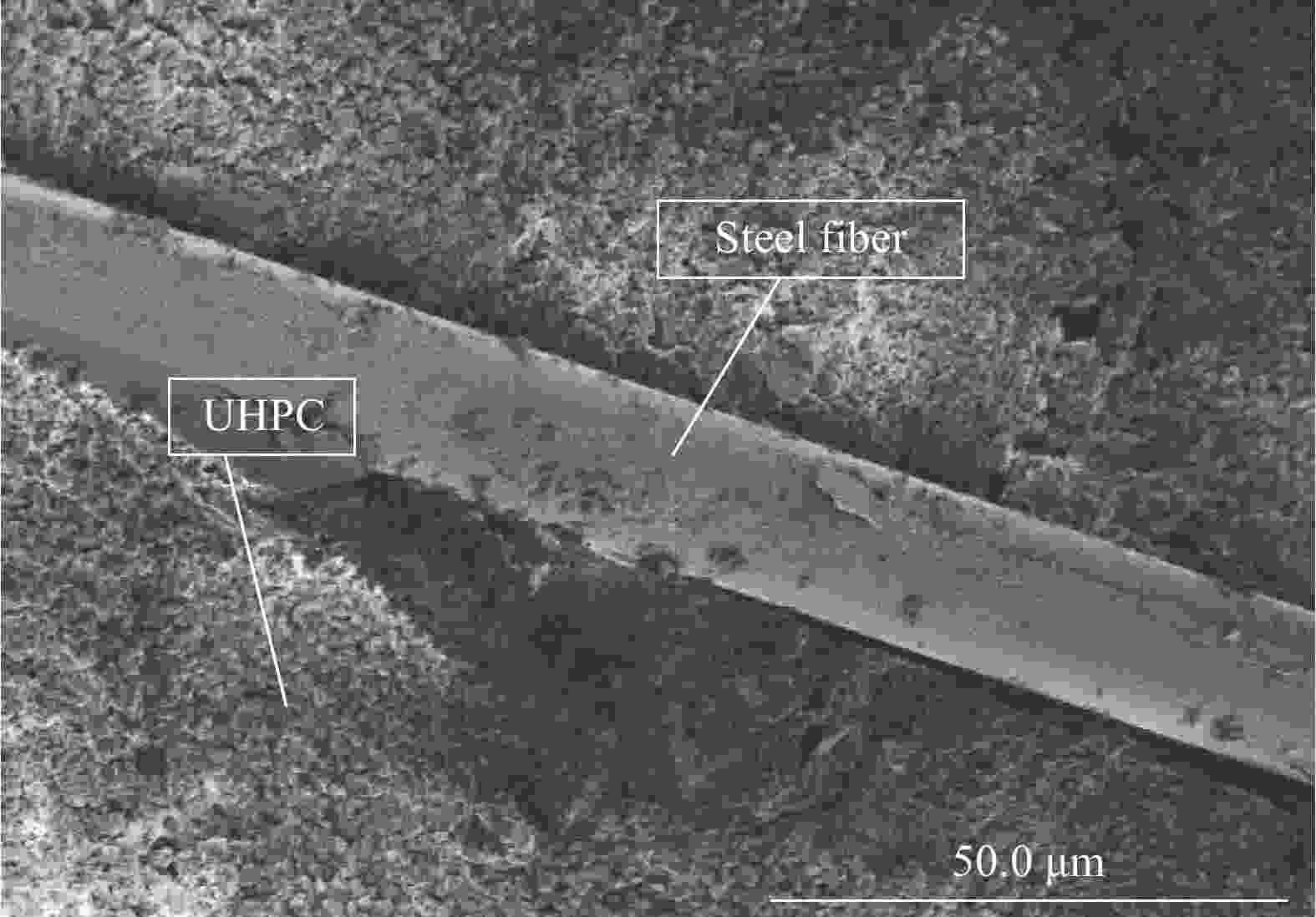

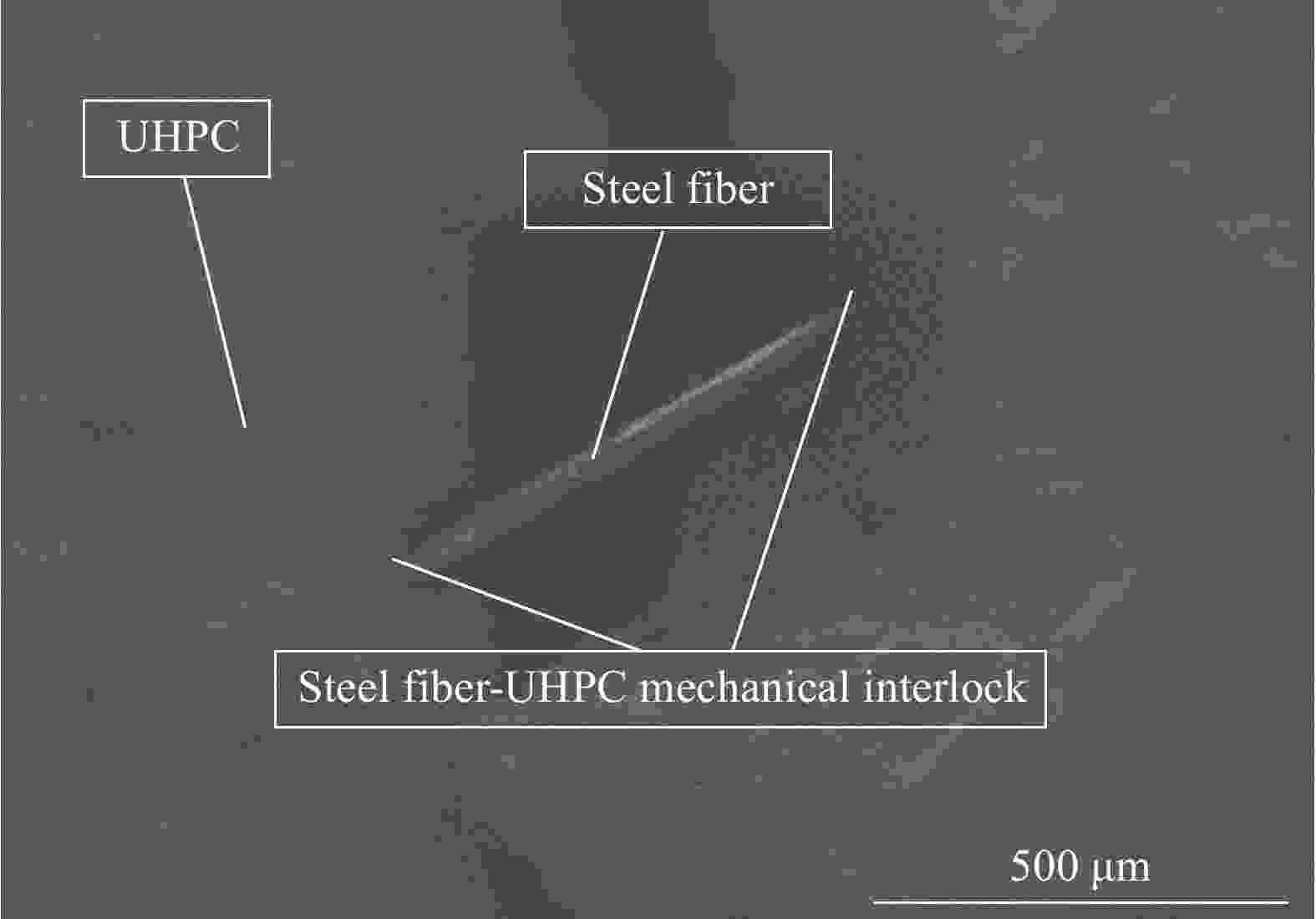

摘要: 为分析玄武岩纤维增强树脂复合材料(BFRP)网格布对超高性能混凝土(UHPC)粘结性能的影响,以干/湿粘结类型、BFRP网格布锚固深度和网格布厚度3个参数,分别开展BFRP-UHPC界面正拉粘结试验(48块)和切向剪切试验(21块),研究了BFRP网格布对其与UHPC界面破坏模态、粘结性能、剪应力-滑移曲线、拉伸比和韧性的影响,同时利用SEM,揭示BFRP-UHPC界面破坏机制。结果表明:锚固深度直接决定BFRP-UHPC界面破坏模式;法向粘结应力和切向粘结应力在界面变化规律上具有正向相关性;BFRP-UHPC界面湿粘结强度高于干粘结工艺水平;随着BFRP厚度和锚固深度逐渐增加,BFRP与UHPC界面粘结应力均呈现逐渐减小的规律;钢纤维对BFRP-UHPC界面增韧效果显著,其端勾构造使UHPC损伤后仍具有残余刚度和强度;当BFRP锚固深度为5 mm时,此时界面粘结应力达到最大,正拉粘结试验中粘结应力最大提升幅度达到74%,拉伸强度比高达1.74。Abstract: In order to analyze the influence of basalt fiber reinforced polymer (BFRP) mesh on the bonding performance of ultra-high performance concrete (UHPC), the BFRP-UHPC interface pull-out bonding test (48 pieces) and shear test (21 pieces) were carried out respectively with three parameters of dry/wet bonding type, BFRP mesh anchorage depth and mesh thickness. The effects of BFRP mesh on the failure mode, bonding performance, shear stress slip curve, tensile ratio and toughness were studied. At the same time, the failure mechanism of BFRP-UHPC interface was revealed by SEM. The results show that the anchoring depth directly determines the failure mode of BFRP-UHPC interface. There is a positive correlation between tangential bonding stress and normal bonding stress. The wet bonding strength of BFRP-UHPC interface is higher than that of dry bonding process. With the increase of BFRP thickness and anchorage depth, the interfacial bonding stress between BFRP and UHPC shows a decreasing trend. Steel fiber has remarkable toughening effect on BFRP-UHPC interface, its end hook structure makes UHPC still have residual stiffness and strength after damage. When the anchoring depth of BFRP is 5 mm, the interface bonding stress reaches the maximum, the maximum increase of interface in the pull out bonding stress reaches 74%, and the tensile strength ratio is 1.74.

-

Key words:

- ultra-high performance concrete /

- BFRP /

- wet bonding /

- dry bonding /

- pull-out test /

- shear test /

- interface

-

表 1 超高性能混凝土(UHPC)配合比(相对质量比)

Table 1. Ultra-high performance concrete (UHPC) mix proportion (Relative mass ratio)

Portland cement Silica fume Water Water reducer Steel fiber Fine sand Crushed stone W/C 1 0.225 0.225 0.017 0.177 0.900 0.225 0.184 Notes: W—Water; C—Cement. 表 2 UHPC力学性能

Table 2. Mechanical properties of UHPC

Item Compressive strength

/MPaElastic modulus

/GPaInitial crack strength/MPa UHPC 136 40.2 8.3 表 3 其他材料性能参数

Table 3. Performance parameters of other materials

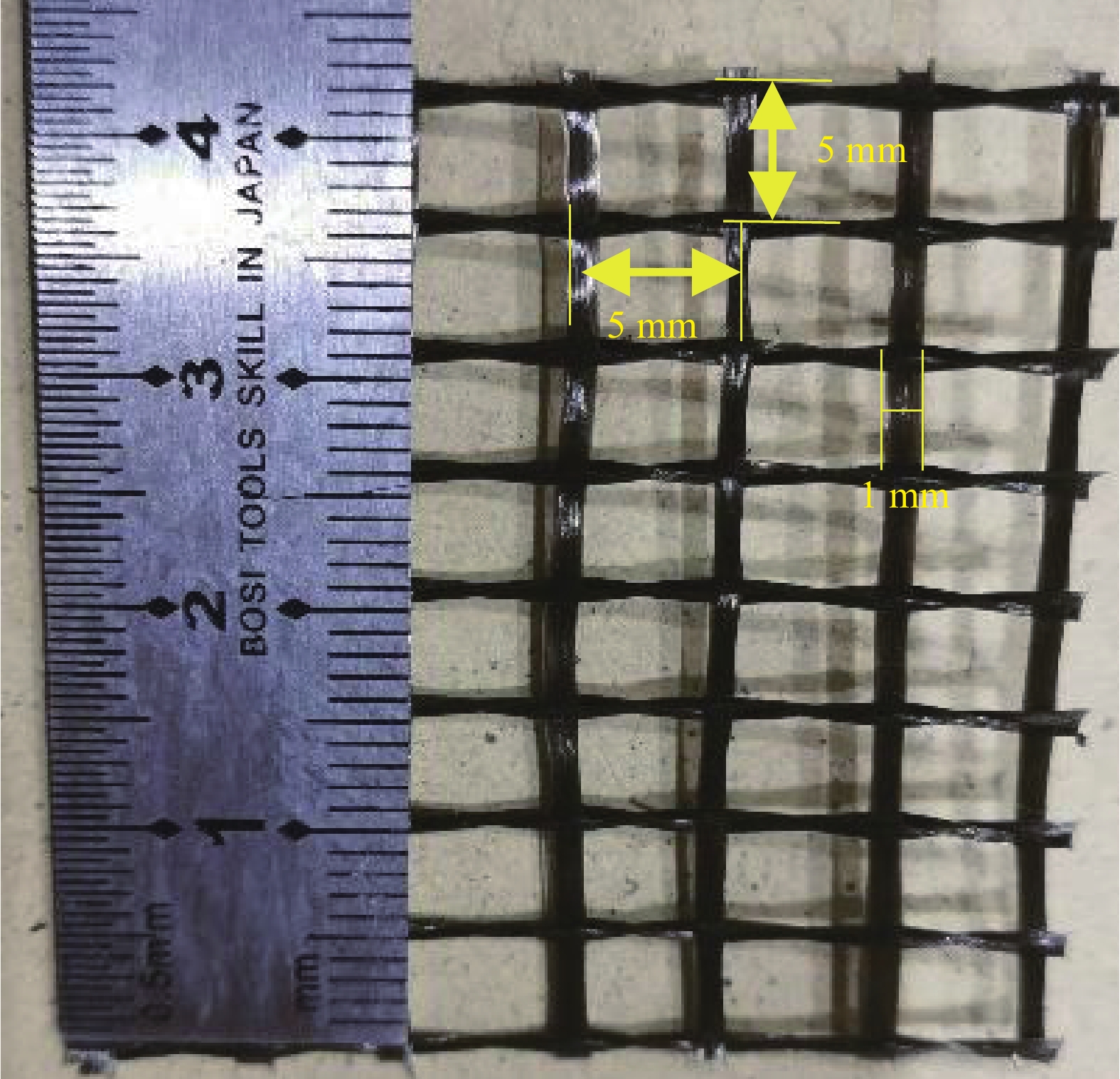

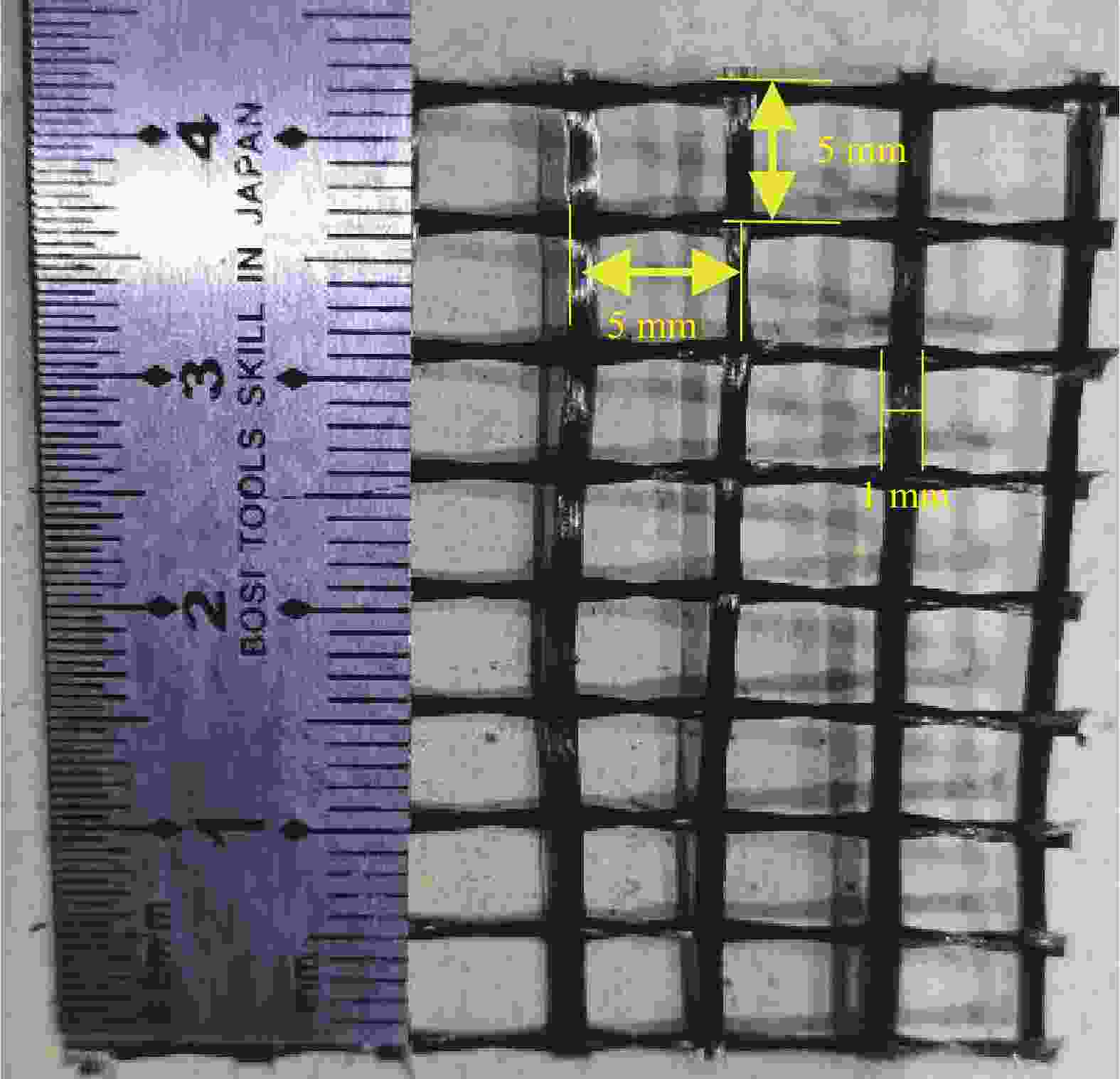

Designation Tensile strength/MPa Thickness

t1, t2, t3/mmMass/

(g·m−2)Mesh size

/mmElastic modulus

/MPaElongation

/%BFRP 1848, 2887, 5377 0.85, 1.16, 1.45 200/372/582 5×5 81500, 82300, 83100 2.76, 2.88, 2.97 Colloid 38 — — — 2.4×103 — Steel colloid 30 — — — 1.2×104 — 表 4 BFRP-UHPC切向剪切试验数据值

Table 4. Shear test values of BFRP-UHPC

Designation Series $ {p_{\text{u}}} $/kN $ {\tau _{\text{u}}} $/MPa $ {s_{\text{u}}} $/mm DB 9.81 7.02 1.48 t=0.85 mm WB-5 19.88 14.23 3.00 WB-15 16.65 12.00 2.60 WB-20 14.00 11.02 2.20 h=15 mm WB0.85 16.65 12.00 2.60 WB1.16 15.35 11.06 2.40 WB1.45 16.22 11.69 2.53 Notes: $ {p_{\text{u}}} $—Interface ultimate load; $ {\tau _{\text{u}}} $—Interfacial adhesion strength; $ {s_{\text{u}}} $—Local maximum slip value of the interface; DB—Adhesion; WB—Wet bonding; WB-a—Anchorage depth of mesh cloth under wet bonding condition; WBb—Thickness of mesh cloth under wet bonding condition; h—Anchorage depth. -

[1] 周傲, 李烁, 刘铁军, 等. 疏水改性玄武岩纤维增强树脂复合材料筋的力学性能及耐久性[J]. 复合材料学报, 2022, 39(11): 5228-5238.ZHOU Ao, LI Shuo, LIU Tiejun, et al. Mechanical properties and durability of hydrophobically modified basalt fiber reinforced polymer bars[J]. Acta Materiae Compositae Sinica Materials, 2022, 39(11): 5228-5238(in Chinese). [2] 潘毅, 刘茜, 任宇, 等. 基于不同黏结材的CFRP链-混凝土界面黏结性能试验研究[J]. 土木工程学报, 2021, 54 (1): 26-37, 96.PAN Yi, LIU Qian, REN Yu, et al. Experimental study on bonding performance of CFRP chain concrete interface based on different bonding materials[J]. Journal of Civil Engineering, 2021, 54 (1): 26-37, 96(in Chinese). [3] 连德攀, 郭广磊, 梅迎军, 等. 材料特征对新浇筑混凝土与基体混凝土界面黏结性能的影响[J]. 公路, 2022, 67(3):306-311.LIAN Depan, GUO Guanglei, MEI Yingjun, et al. Effect of material characteristics on the interfacial adhesion between newly poured concrete and matrix concrete[J]. Highway,2022,67(3):306-311(in Chinese). [4] DESKOVIC N, TRIANTAFILLOU T, MEIER U. Innovative design of FRP combined with concrete: Short-term behavior[J]. Journal of Structural Engineering,1995,121(7):1069-1078. doi: 10.1061/(ASCE)0733-9445(1995)121:7(1069) [5] 张普, 高丹盈, 朱虹. FRP板-混凝土湿黏结界面性能的试验研究与数值模拟[J]. 土木工程学报, 2013, 46(2):108-113.ZHANG Pu, GAO Danying, ZHU Hong. Experimental study and numerical simulation of wet bonding interface between FRP plate and concrete[J]. Journal of Civil Engi-neering,2013,46(2):108-113(in Chinese). [6] HULATT J, HOLLAWAY L, THORNE A. Short term testing of hybrid beam made of new material[J]. Journal of Compo-sites for Construction,2003,7(2):133-144. [7] ZHANG P, WU G, ZHU H, et al. Mechanical performance of the wet-bond interface between FRP plates and cast-in-place concrete[J]. Journal of Composites for Construction,2014,18(6):1121-1137. [8] ZHANG P, LIU H N, GAO D Y, et al. Shear-bond behavior of the interface between FRP profiles and concrete by the double-lap push shear method[J]. Journal of Composites for Construction,2017,21(4):963-978. [9] 任翔, 王怡, 余兴, 等. 冻融/干湿环境影响下CFRP板-钢界面黏结性能试验[J]. 中国公路学报, 2022, 35(2): 247-258.REN Xiang, WANG Yi, YU Xing, et al. Experimental study on interfacial bonding performance of CFRP plate steel under freeze-thaw/dry wet environment[J]. Chinese Jour-nal of Highway, 2022, 35(2): 247-258(in Chinese). [10] 张普, 朱虹, 孟少平. 混杂FRP-混凝土T形组合梁受弯性能试验研究[J]. 东南大学学报(自然科学版), 2010, 40(3): 548-553.ZHANG Pu, ZHU Hong, MENG Shaoping. Experimental study on flexural behavior of hybrid FRP concrete T-shaped composite beams[J]. Journal of Southeast University (Natural Science Edition), 2010, 40 (3): 548-553(in Chinese). [11] 吕国栋. 桥梁湿接缝施工工艺对混凝土界面黏结力的影响研究[J]. 公路, 2020, 65(9):113-118.LYU Guodong. Study on the influence of bridge wet joint construction technology on concrete interface adhesion[J]. Highway,2020,65(9):113-118(in Chinese). [12] CANNING L, HOLLAWAY L, THORNE A M. Aninvestigation of the composite action of an FRP/concrete prismatic beam[J]. Construction and Building Materials,1999,13(8):417-426. doi: 10.1016/S0950-0618(99)00050-1 [13] CHOI S, GARTNER A L, ETTEN N V, et al. Durability of concrete beams externally reinforced with CFRP composites exposed to various environments[J]. Journal of Compo-sites for Construction,2012,10(10):61-71. [14] HUANG H, WANG W, ZHAO F. Experimental study on thebond behavior at the GFRP-concrete interface under wet bonding technique[J]. Industry Construction,2013,43:192-195. [15] ZHU H T, ZHANG Q M, TIAN X Y, et al. Analysis on effective bonding length between hybrid fiber reinforced plastics and casting-in-place concrete[C]//Proceedings of the Tenth International Symposium on Structural Engineering for Young Experts. Changsha: Hunan University Press, 2008: 766-775. [16] WU Z, LI W, SAKUMA N. Innovative externally bonded FRP/concrete hybrid flexural members[J]. Composite Structures,2006,72(3):289-300. doi: 10.1016/j.compstruct.2004.12.002 [17] ZHANG P, ZHU H, WU G, et al. Flexural performance of HFRP-RC composite T-beams with different interfaces[J]. Journal of Composites for Construction,2017,21(3):1956-1977. [18] 殷雨时, 范颖芳, 徐义洪. 粗糙度对CFRP-混凝土界面剪切黏结性能的影响[J]. 建筑材料学报, 2018, 21(2):202-207. doi: 10.3969/j.issn.1007-9629.2018.02.005YIN Yushi, FAN Yingfang, XU Yihong. Effect of roughness on shear bond properties of CFRP concrete interface[J]. Journal of Building Materials,2018,21(2):202-207(in Chinese). doi: 10.3969/j.issn.1007-9629.2018.02.005 [19] 殷雨时, 范颖芳, 郭馨艳. 粗糙度对FRP-混凝土界面黏结性能的影响[J]. 华南理工大学学报(自然科学版), 2019, 47(5):130-138.YIN Yushi, FAN Yingfang, GUO Xinyan. Effect of roughness on FRP concrete interface bonding performance[J]. Journal of South China University of Technology (Natural Science Edition),2019,47(5):130-138(in Chinese). [20] 中华人民共和国交通运输部. 碳纤维片材加固混凝土结构技术规程: CECS 146: 2003[S]. 北京: 人民交通出版社, 2002.Ministry of Transport of the People's Republic of China. Technical specification for strengthening concrete structures with carbon fiber sheets: CECS 146: 2003[S]. Beijing: People's Communications Press, 2002(in Chinese). [21] 任小明. 扫描电镜/能谱原理及特殊分析技术[M]. 北京: 化学工业出版社, 2020.REN Xiaoming. Scanning electron microscope/energy spectrum principle and special analysis technology[M]. Beijing: Chemical Industry Press, 2020(in Chinese). [22] 马莹, 高磊, 张峰. 钢筋混凝土T梁HU-FRP抗剪加固试验和数值模拟[J]. 建筑材料学报, 2021, 24(5):1073-1081.MA Ying, GAO Lei, ZHANG Feng. Test and numerical simulation of shear strengthening of reinforced concrete T-beam with HU-FRP[J]. Journal of Building Materials,2021,24(5):1073-1081(in Chinese). [23] 李晓林, 樊新波, 王建锋. 加工芳纶纳米纤维/聚乙烯醇水凝胶制备高强度复合薄膜[J]. 复合材料学报, 2021, 38(12):3986-3995. doi: 10.13801/j.cnki.fhclxb.20210205.001LI Xiaolin, FAN Xinbo, WANG Jianfeng. Preparation of high strength composite films by processing aramid nanofibers/polyvinyl alcohol hydrogels[J]. Acta Materiae Compositae Sinica Materials,2021,38(12):3986-3995(in Chinese). doi: 10.13801/j.cnki.fhclxb.20210205.001 [24] 江培成, 郎利辉, 邱超斌, 等. 拉伸比对2 A16铝合金板材双向拉伸性能的影响[J]. 塑性工程学报, 2022, 29(1):126-132. doi: 10.3969/j.issn.1007-2012.2022.01.018JIANG Peicheng, LANG Lihui, QIU Chaobin, et al. Effect of tensile ratio on biaxial tensile properties of 2 A16 aluminum alloy sheet[J]. Journal of Plastic Engineering,2022,29(1):126-132(in Chinese). doi: 10.3969/j.issn.1007-2012.2022.01.018 [25] 刘加平, 汤金辉, 韩方玉. 现代混凝土增韧防裂原理及应用[J]. 土木工程学报, 2021, 54(10):47-54, 63.LIU Jiaping, TANG Jinhui, HAN Fangyu. Toughening and crack prevention of modern concrete: Mechanisms and applications[J]. China Civil Engineering Journal,2021,54(10):47-54, 63(in Chinese). -

下载:

下载: