Research progress and prospect of laser shock wave testing technology for bonding interface of composite materials

-

摘要: 纤维增强树脂基复合材料因比强度/比模量高、抗疲劳/抗腐蚀性能好等优势,广泛应用于军/民用飞机上。为避免铆钉/螺栓连接时打孔造成纤维断裂、基体开裂和分层等损伤,常用胶粘方式进行连接。胶粘界面污染、粘接剂不均匀/老化等因素会导致“吻接”和“弱粘接”问题,而现有超声波、红外等无损检测技术无法检测评估,已成为复合材料结构安全隐患。激光冲击波界面结合强度检测技术(Laser bond inspection,LBI)是一种利用激光冲击波反射拉伸波的力学效应进行界面结合强度定量性评估的新型检测技术,可有效解决“吻接”和“弱粘接”的检测难题。本文介绍了激光冲击波界面结合强度检测的技术原理、特点及发展应用情况;分别从脉冲激光诱导冲击波特性、冲击波传播规律及材料动态响应、激光冲击层裂及损伤特征、界面结合强度检测方法4个方面总结了国内外研究进展及亟待解决的关键问题。从发展大脉宽/均能量/高功率的纳秒激光器、建立多变量激光冲击波时空压力模型、构建复合材料高应变率力学模型、发明快速/准确/智能的检测方法和建立规范、统一的研究体系等方面进行展望。综合分析国内研究不足和技术差距,建议解决思路与方案,希望通过加强基础研究和关键技术突破,推动激光冲击波界面结合强度检测技术的快速发展和工程应用。

-

关键词:

- 复合材料 /

- 界面结合强度 /

- 吻接与弱粘接 /

- 无损检测方法 /

- 激光冲击波结合力检测

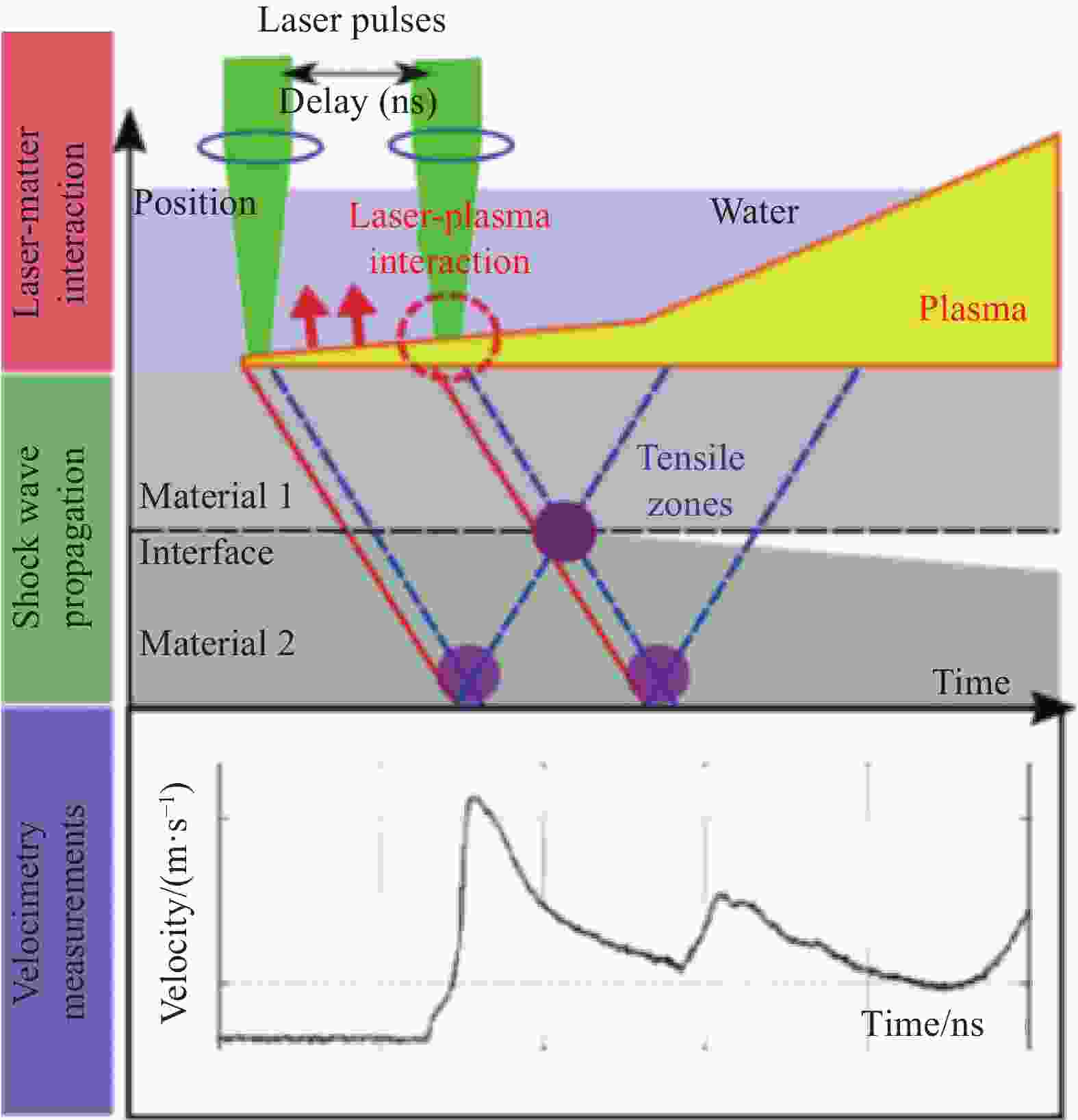

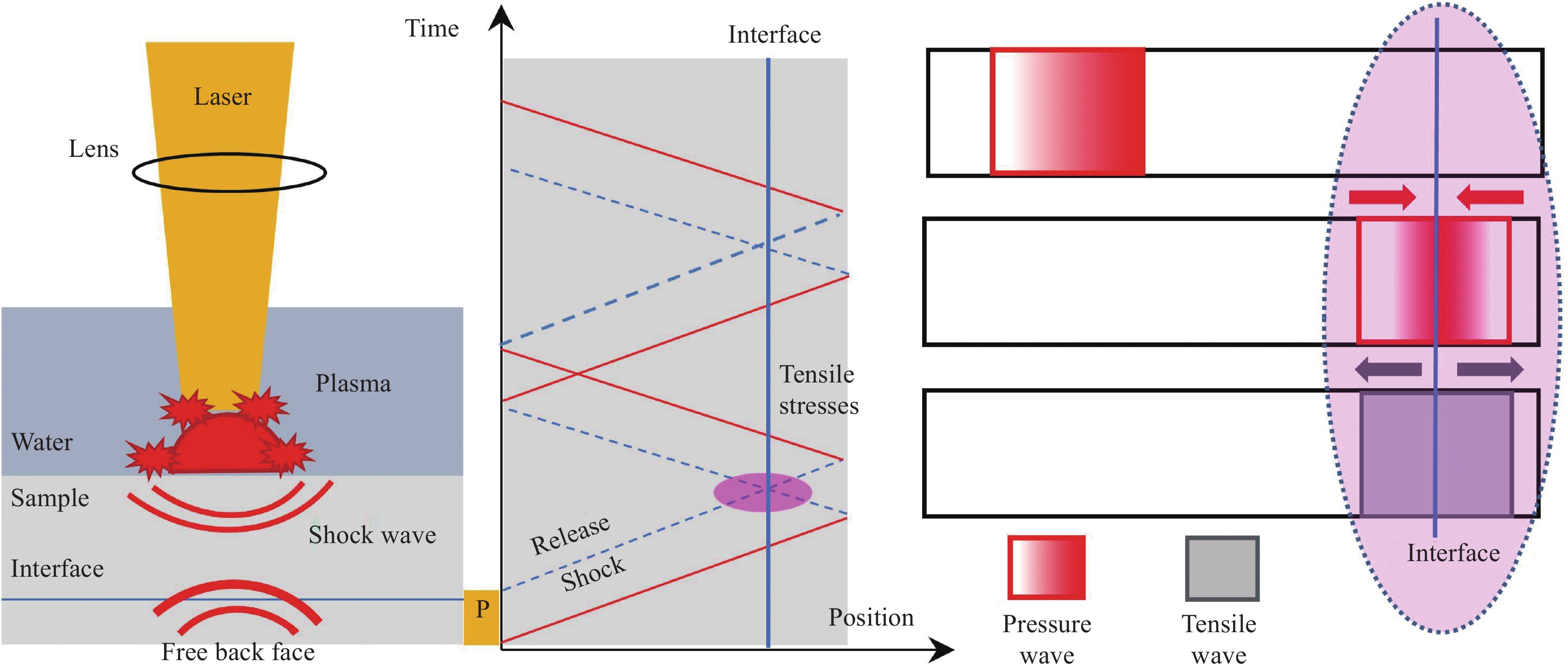

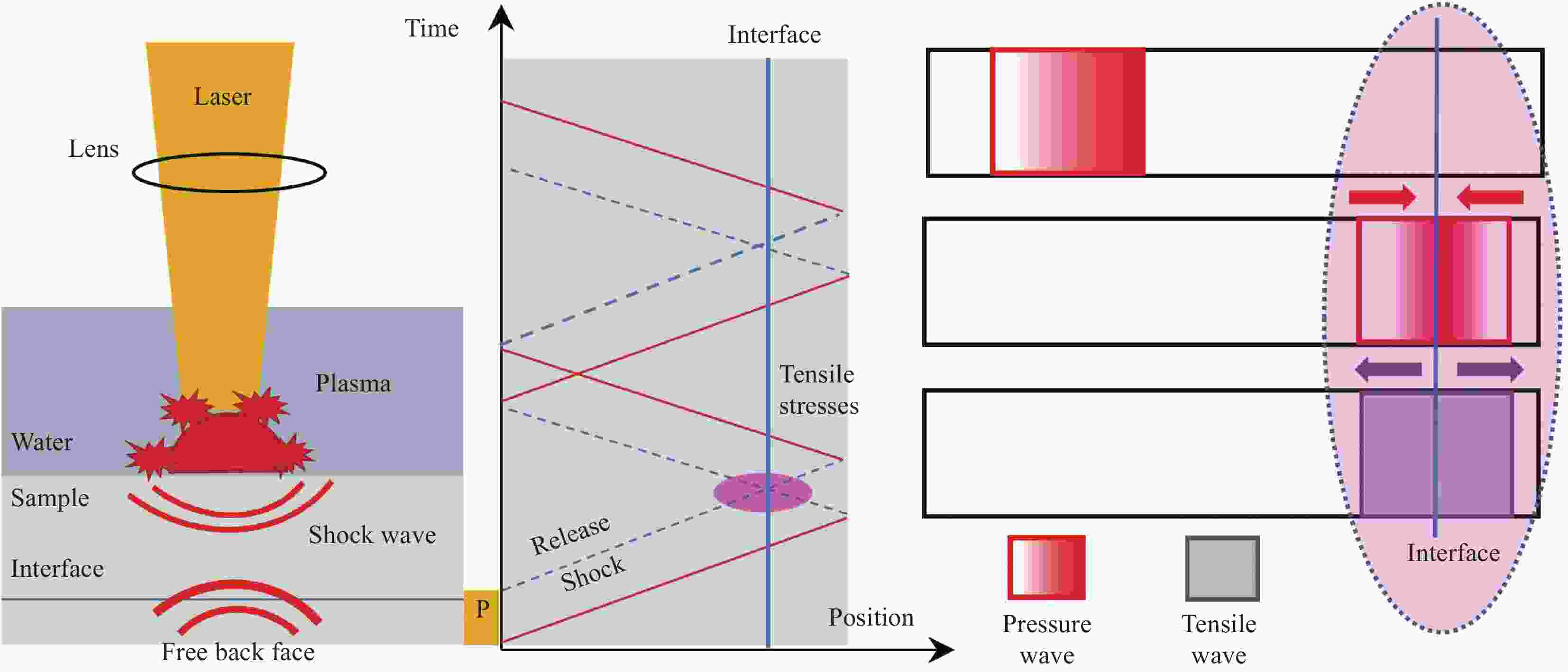

Abstract: Fibre-reinforced resin matrix composites are widely used in military/civilian aircraft due to their high specific strength/modulus and good fatigue/corrosion resistance. To avoid damage such as fibre breakage, matrix cracking and delamination caused by riveting/bolting, gluing is often used. Contamination of the adhesive interface, unevenness/ageing of the adhesive can lead to "kissing" and "weak bonding" problems, which cannot be detected and assessed by existing non-destructive testing techniques such as ultrasonic and infrared, and have become a safety hazard for composite structures. Laser bond inspection (LBI) is a new type of inspection technology that uses the mechanical effect of laser shock waves to reflect tensile waves for quantitative assessment of interface bond strength. It can effectively solve the problem of "kissing" and "weak bonding". This paper introduces the technical principles, characteristics and applications of laser shock wave interface bond strength testing; Summarises the progress of domestic and international research and the key issues to be solved from four aspects: Pulsed laser induced shock wave characteristics, shock wave propagation law and dynamic response of materials, laser shock layer cracking and damage characteristics, and interface bond strength testing methods. The outlook is from the development of nanosecond lasers with large pulse width/even energy/high power, the establishment of multivariable laser shock wave spatio-temporal pressure models, the construction of high strain rate mechanical models for composite materials, the invention of fast/accurate/intelligent detection methods and the establishment of a standardized and unified research system. A comprehensive analysis of domestic research deficiencies and technology gaps, suggested solutions and solutions, and hoped to promote the rapid development and engineering applications of laser shock wave interface bond strength testing technology by strengthening basic research and key technology breakthroughs. -

表 1 国内外同类技术对比

Table 1. Comparison of similar technologies at home and abroad

United States France Air Force Engineering University Laser devices Solid resonant chambers+Enlarge;

100-300 ns, 10-50 J;

Waveform non-adjustable[8]Solid resonant chambers+

Enlarge; Pulse width, waveform non-adjustable[8]Fiber optic seed source enlargement; 10-300 ns, 1-50 J;

Arbitrary waveform adjustment[9]Laser shock wave properties and propagation VISAR/PDV testing; Finite element analysis[10] VISAR/PDV testing; Finite element analysis[11] VISAR/PDV testing; Finite element analysis[12] Interface stress regulation methods Pulse width, energy adjustment Energy adjustment Pulse width, waveform and energy adjustment Shockwave dyna-

mic monitoringEMAT for vibration signal monitor-

ing (engineered applications)[13]VIASR/PDV

(Laboratory)[14-15]VIASR/PDV(Laboratory)[14-15] surface ultrasound monitoring (in engineering-oriented development) Laser lamination crack determina-

tion methodHigh-low-high triple impact test method Ultrasonic and radiographic inspection method after laser impact[8-11] Two laser impact signal characteristics contrast detection method[16] Notes: VISAR—Velocity interferometer system for any reflector; PDV—Photon doppler velocimetry; EMAT—Magnetoprobe. -

[1] RICCIO A, SAPUTO S, SELLITTO A, et al. On the mechanical behavior of laminated composite plates subjected to compression after impact tests[J]. Materials Today: Proceedings, 2020, 34(12): 53-56. [2] KATUNIN A, KRUKIEWICZ K, HEREGA A, et al. Concept of a conducting composite material for lightning strike protection[J]. Advances in Materials Science, 2016, 16(2): 32-46. [3] MIYAKE T, MUKAE K, FUTAMURA M. Evaluation of machining damage around drilled holes in a CFRP by fiber residual stresses measured using micro-raman spectroscopy[J]. Mechanical Engineering Journal, 2018, 3(6): 16-00301. [4] EHRHART B, ECAULT R, TOUCHARD F, et al. Development of a laser shock adhesion test for the assessment of weak adhesive bonded CFRP structures[J]. International Journal of Adhesion and Adhesives,2014,52:57-65. doi: 10.1016/j.ijadhadh.2014.04.002 [5] ECAULT R, TOUCHARD F, BOUSTIE M, et al. Numerical modeling of laser-induced shock experiments for the development of the adhesion test for bonded composite materials[J]. Composite Structures,2016,152:382-394. doi: 10.1016/j.compstruct.2016.05.032 [6] ZHENG S, ZHANG S, LUO Y, et al. Nondestructive analysis of debonding in composite/rubber/rubber structure using ultrasonic pulse-echo method[J]. Nondestructive Testing and Evaluation, 2021, 36(5): 515-527. [7] SUN R J, CHE Z G, CAO Z W, et al. Fatigue behavior of Ti-17 titanium alloy subjected to different laser shock peened regions and its microstructural response[J]. Surface & Coatings Technology,2020,383:125284. [8] 张伟毅. 高功率掺镱光纤主振荡功率放大系统研究[D]. 天津: 天津大学, 2012.ZHANG Weiyi. Study on main oscillation power amplifier system of ytterbium-doped fiber with high power[D]. Tianjin: Tianjin University, 2012(in Chinese). [9] 朱晶. 光纤放大器种子源的研究[D]. 北京: 中国科学院大学, 2010.ZHU Jing. Research on seed source of fiber amplifier[D]. Beijing: University of Chinese Academy of Sciences, 2010(in Chinese). [10] PERTON M, BLOUIN A, MONCHALIN J, et al. Adhesive bond testing by laser shock waves and laser interferometry[C]//Abstracts of 17th World Conference on Non-destructive Testing. Shanghai: International Committee for Non-Destructive Testing (ICNDT), 2010: 1258-1268. [11] ECAULT R, TOUCHARD F, BERTHE L, et al. Laser shock adhesion test numerical optimization for composite bonding assessment[J]. Composite Structures,2020,247:112441. doi: 10.1016/j.compstruct.2020.112441 [12] NIE X F, TANG Y Y, ZHAO F F, et al. Formation mechanism and control method of residual stress profile by laser shock peening in thin titanium alloy component[J]. Materials,2021,14(8):1878. [13] 聂祥樊, 李应红, 何卫锋, 等. 一种用于非导电材料激光冲击波结合力检测的电磁感应胶带: 中国, CN109142215 A[P]. 2019-01-05.NIE Xiangfan, LI Yinghong, HE Weifeng, et al. A kind of electromagnetic induction tape for detecting laser shock wave bonding force of non-conductive materials: China, CN109142215 A[P]. 2019-01-05(in Chinese). [14] TAN H. Experimental shock wave physics guidance[M]. Beijing: National Defense Industry Press, 2007. [15] MEYERS M A. Dynamic behavior of materials[M]. New York: John Wiley & Sons, Inc., 1994. [16] 李应红, 何卫锋, 聂祥樊. 一种基于激光冲击波的复合材料粘接力在线快速检测方法: 中国, CN107561004 B[P]. 2018-01-09.LI Yinghong, HE Weifeng, NIE Xiangfan. A fast online detection method for adhesion of composite materials based on laser shock wave: China, CN107561004 B[P]. 2018-01-09(in Chinese). [17] LOOMIS E, PERALTA P, SWIFT D, et al. Cross-sectional TEM studies of plastic wave attenuation in shock loaded NiAl[J]. Materials Science and Engineering A,2006,437:212-221. doi: 10.1016/j.msea.2006.07.116 [18] CELLARD C, RETRAINT D, FRANCOIS C, et al. Laser shock peening of Ti-17 titanium alloy: Influence of process parameters[J]. Materials Science and Engineering A,2012,532:362-372. doi: 10.1016/j.msea.2011.10.104 [19] YAN Q, XU R, LU J, et al. Experimental study on laser-induced plasma shock waves in transparent solid media[J]. Chinese Optics Letters,2005,3:372-374. [20] 张永康. 激光冲击处理提高航空铝合金疲劳寿命研究[D]. 南京: 南京航空航天大学, 1995.ZHANG Yongkang. Study on fatigue life improvement of aviation aluminum alloy by laser shock treatment[D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 1995(in Chinese). [21] FABBRO R, FOURNIER J, BALLARD P, et al. Physical study of laser-produced plasma in confined geometry[J]. Journal of Applied Physics,1990,68(2):775-784. doi: 10.1063/1.346783 [22] GUO D, ZHANG Y. Study on the mechanism of laser shock enhancement[J]. Science in China Series E,1999,29(3):222-226. [23] MIAO R C, LI F J, DONG J, et al. Diffraction effect of thin laser beam from liquid surface waves at low-frequency[J]. Acta Photonica Sinica, 2007, 36(5): 877-880. [24] NG A, PARFENIUK D, DASILVA L. Hugoniot measurements for laser-generated shock waves in aluminum.[J]. Physical Review Letters,1985,54(24):2604-2607. doi: 10.1103/PhysRevLett.54.2604 [25] TOLLIER L, FABBRO R, BARTNICKI E. Study of the laser-driven spallation process by the velocity interferometer system for any reflector interferometry technique. I. Laser-shock characterization[J]. Journal of Applied Physics,1998,83(3):1224-1230. doi: 10.1063/1.366819 [26] TOLLIER L, FABBRO R. Study of the laser-driven spallation process by the VISAR interferometry technique. II. Experiment and simulation of the spallation process[J]. Journal of Applied Physics,1998,83(3):1231-1237. doi: 10.1063/1.366820 [27] LI Z, ZHANG D, YU B, et al. Characteristics of plasma shock waves generated in the pulsed laser ablation process[J]. European Physical Journal Applied Physics, 2002(12): 1841-1843. [28] FAIRAND B P, CLAUER A H, WILCOX B A. Pulsed laser induced deformation in an Fe-3 Wt Pct Si alloy[J]. Metallurgical Transactions A,1977,8A:119-125. [29] FAIRAND B P, CLAUER A H. Effect of water and paint coatings on the magnitude of laser-generated shock[J]. Optics Communications,1976,18(4):588-591. doi: 10.1016/0030-4018(76)90327-8 [30] CLAUER A H, FAIRAND B P. Interaction of laser-induced stress waves with metals[C]//Applications of Lasers in Materials Processing. Washington: NTRS, 1979, 330: 291-315. [31] ZHU W H, YU T X, LI Z Y, et al. Laser-induced shock waves in PMMA confined foils[J]. International Journal of Impact Engineering, 2000, 24(6-7): 641-657. [32] AUROUX E, BOUSTIE M, ROMAIN J P, et al. Improvement of the laser spallation technique using an amplifying layer. Experimental and numerical approach[J]. AIP Conference Proceedings,2000,505(1):1211. [33] ARRIGONI M, BOUSTIE M, BOLIS C, et al. Evolutions of the laser adhesion test (LASAT) for the debonding of coatings on substrates above the millimeter range thickness[J]. Journal de Physique IV,2007,134(2):42-51. [34] RADZIEJEWSKA J, STRZELEC M, OSTROWSKI R, et al. Experimental investigation of shock wave pressure induced by a ns laser pulse under varying confined regimes[J]. Optics and Lasers in Engineering,2020,126:105913. doi: 10.1016/j.optlaseng.2019.105913 [35] SANO Y, MUKAI N, OKAZAKI K, et al. Residual stress improvement in metal surface by under water laser irradiation[J]. Nuclear Instruments and Methods in Physics Prsearch Section,1997,121(1-4):432-436. doi: 10.1016/S0168-583X(96)00551-4 [36] JIANG X, YU X, DENG X, et al. Investigation on laser-induced shock pressure with condensed matter model and experimental verification[J]. Experimental Techniques,2019,43:161-167. doi: 10.1007/s40799-018-291-9 [37] BERTHE L, FABBRO R, PEYRE P, et al. Wavelength dependent of laser shock-wave generation in the water-confinement regime[J]. Journal of Applied Physics,1999,85(11):7552-7555. doi: 10.1063/1.370553 [38] BERTHE L, SOLLIER A, PEYRE P, et al. The generation of laser shock waves in a water-confinement regime with 50 ns and 150 ns xecl excimer laser pulses[J]. Journal of Physics D—Applied Physics,2000,33(17):2142-2145. doi: 10.1088/0022-3727/33/17/308 [39] FABBRO R, FARAL B, VIRMONT J, et al. Experimental study of ablation pressures and target velocities obtained in 0.26 m wavelength laser experiments in planar geometry[J]. Archiv Für Psychologie, 1985, 129(1): 1-24. [40] BERTHE L, FABBRO R, PEYRE P, et al. Shock waves from a water-confined laser-generated plasma[J]. Journal of Applied Physics,1997,82(6):2826-2832. doi: 10.1063/1.366113 [41] FABBRO R, PEYRE P, BERTHE L, et al. Physics and applications of laser-shock processing[J]. Journal of Laser Applications,1998,10(6):265-279. doi: 10.2351/1.521861 [42] ENGEBRETSEN C C, PALAZOTTO A N, LANGER K. Integrated finite element & optimization model for laser shock pressure impulse shape determination[J]. Engineering Research Express, 2019, 1(1): 1-11. [43] GOLABI S, VAKIL M R, AMIRSALARI B. Multi-objective optimization of residual stress and cost in laser shock peening process using finite element analysis and pso algorithm[J]. Lasers in Manufacturing and Materials Processing,2019,6(4):398-423. doi: 10.1007/s40516-019-00102-1 [44] MATHEW J, KSHIRSAGAR R, ZABEEN S, et al. Machine learning-based prediction and optimisation system for laser shock peening[J]. Applied Sciences,2021,11(7):2888. [45] WELSH L M, HARDING J. Mechanical and physical behavior of material under dynamic loading[J]. Journal de Physique IV, 1985, Colloque C5: 405-414. [46] GERLACH R, SIVIOUR C R, PETRINIC N, et al. Experimental characterisation and constitutive modelling of RTM-6 resin under impact loading[J]. Polymer,2008,49(11):2728-2737. doi: 10.1016/j.polymer.2008.04.018 [47] NAIK N K, GADIPATRI R, THORAM N M, et al. Shear properties of epoxy under high strain rate loading[J]. Polymer Engineering and Science,2010,50(4):780-788. doi: 10.1002/pen.21585 [48] NAIK N K, SHANKAR P J, KAVALA V R, et al. High strain rate mechanical behavior of epoxy under compressive loading: Experimental and modeling studies[J]. Materials Science and Engineering A—Structural Materials Properties Microstructure and Processing,2011,528(3):846-854. doi: 10.1016/j.msea.2010.10.099 [49] MONTEAL D M, WILLIAMS C J. A method for evaluating the high strain rate compressive properties of composite materials[M]//Composite materials: Testing and Design (tenth volume) ASTM STP 1120. Philadelphia: American Society for Testing and Materials, 1992: 54-65. [50] GILAT A, GOLDBERG R K, ROBERTS G D. High strain rate response of epoxy in tensile and shear loading[J]. Journal de Physique IV,2003,110:123-127. [51] WAAS A M, TAKEDA N, YUAN J, et al. Static and dynamic compressive behavior of glass fiber reinforced unidirectional composites[C]//Proceedings 12nd Annual Technical American Society for Composites Conference. Dearborn: Destech Publications, 1997: 552-561. [52] HSIAO H M, DANIEL I M, CORDES R D. Strain rate effects on the transverse compression and shear behavior of unidirectional composites[J]. Journal of Composite Materials, 1999, 33(17): 1620-1642. [53] JIAO T, CLIFTON R J. Measurement of the response of an elastomer at pressures up to 9 GPa and shear-rates of 105-106 s-1[C]//Joint Conference APS Topical Group on Shock Compression of Condensed Matter. Washington: APS Topical Group on Shock Compression of Condensed Matter, 2014. [54] WANG X, QU Y, PENG G, et al. Research progress on mechanical properties of resin based fiber reinforced composites at high strain rate[J]. Engineering Plastics Application,2019(11):83-86. doi: 10.3969/j.issn.1001-3539.2009.11.023 [55] MILLETT J, BOURNE C F N K, BARNES N R. The behavior of an epoxy resin under one-dimensional shock loading[J]. Journal of Applied Physics,2002,92(11):6590-6594. doi: 10.1063/1.1506389 [56] BOURNE N K, MILLETT J, BARNES N, et al. The deviatoric response of an epoxy resin to one-dimensional shock loading[J]. American Institute of Physics, 2002, 620(49): 649-652. [57] APPLEBY-THOMAS G J, HAZELL P J, STENNETT C. The variation in lateral and longitudinal stress gauge response within an rtm 6 epoxy resin under one-dimensional shock loading[J]. Journal of Materials Science,2009,44(22):6187-6198. doi: 10.1007/s10853-009-3859-z [58] MILLETT J C F , DEAS D N K, BOURNE N K, et al. The deviatoric response of an alumina filled epoxy composite during shock loading[J]. Journal of Applied Physics, 2007, 102(6): 419-428. [59] HAN X, HAN S. Study on rate-dependent constitutive model of composite materials[J]. Mechanical Science and Technology for Aerospace Engineering, 1999(1): 125-126. [60] ECAULT R, BERTHE L, BOUSTIE F, et al. Observation of the shock wave propagation induced by a high-power laser irradiation into an epoxy material[J]. Journal of Physics D-Applied Physics, 2013, 46(23): 235501. [61] ECAULT R, BERTHE L, TOUCHARD F, et al. Experimental and numerical investigations of shock and shear wave propagation induced by femtosecond laser irradiation in epoxy resins[J]. Journal of Physics D-Applied Physics, 2015, 48(9): 9-16. [62] ARAI M, CHIBA T, GOTO K, et al. Inverse analysis of interlaminar strength in CFRP laminates using pulse laser spallation method[J]. Composites Science and Technology,2021(10):108938. [63] GAY E, BERTHE L, BOUSTIE M, et al. Study of the response of CFRP composite laminates to a laser-induced shock[J]. Composites Part B: Engineering,2014,64:111-114. [64] COTTET F, NG A S, SILVA L, et al. Spallation under the action of a laser induced shock wave[J]. Le Journal de Physique Colloques, 1988, 49(C3): 419-424. [65] COTTET F, BOUSTIE M. Spallation studies in aluminum targets using shock-waves induced by laser irradiation at various pulse durations[J]. Journal of Applied Physics, 1989, 66(9): 4067-4073. [66] BOUSTIE M, COTTET F. Experimental and numerical study of laser-induced spallation into aluminum and copper targets[J]. Journal of Applied Physics,1991,69(11):7533-7538. doi: 10.1063/1.347570 [67] FORTOV V E, KOSTIN V V, ELIEZER S. Spallation of metals under laser irradiation[J]. Journal of Applied Physics,1991,70(8):4524-4531. doi: 10.1063/1.349087 [68] BURAVOVA S N, GONCHAROV A A, KISELEV J N. Surface damage under dynamic loading[J]. Tribology International,1996,29(5):357-363. doi: 10.1016/0301-679X(95)00062-9 [69] LACOMME M, CAZALIS B, DAVID J, et al. Laser-induced damage and spall[J]. Journal de Physique IV,1994,4(C8):77-82. [70] VOSSEN J L. Adhesion measurement of thin films, thick film, and bulk coatings: ASTM STP 640[S]. West Conshohocken: ASTM, 1978. [71] GUPTA V. System and method for measuring the interface tensile strength of planar interfaces: USA, US08/026682[P]. 1995-08-01. [72] COURAPIED D, KROMER R, BERTHE L, et al. Laser adhesion test for thermal sprayed coatings on textured surface by laser[J]. Journal of Laser Applications, 2016, 28(2): 022509. [73] SARTORI C, OLRA R, DUBIEF P. A pulsed laser technique for an evaluation of the spall resistance of sputtered oxide films: Diagnostic by interferometric probing[J]. Surface & Coatings Technology,1998,106(2-3):251-261. [74] GUPTA V, ARGON A S, PARKS D M, et al. Measurement of interface strength by a laser spallation technique[J]. Journal of the Mechanics & Physics of Solids,1992,40(1):141-180. [75] NUTT G L, KING W E. Comments on the bond strength measurements of Gupta and co-workers[J]. Materials Science and Engineering A,1992,159(2):135-142. doi: 10.1016/0921-5093(92)90281-5 [76] MING Z. Theoretic analysis and numerical simulation on quantitative evaluation of interface strength by pulsed-laser technology[J]. Proceedings of SPIE-The International Society for Optical Engineering,1999,3862:433-437. [77] HUANG Y, JIANG Y F, JIN H, et al. Propagation of shock wave induced by ring laser and its effect on spallation[J]. Laser Technology,2013,37(3):301-305. [78] BOUSTIE M, CUQ-LELANDAIS J P, BOLIS C, et al. Study of damage phenomena induced by edge effects into materials under laser driven shocks[J]. Journal of Physics D-Applied Physics, 2017, 40: 7103. [79] TAHAN G, ARRIGONI M, BIDAUD P, et al. Evolution of failure pattern by laser induced shockwave within an adhesive bond[J]. Optics & Laser Technology,2020,129:106224. [80] BÉGUÉ G, FABRE G, GUIPONT V, et al. Laser shock adhesion test (lasat) of eb-pvd tbcs: Towards an industrial application[J]. Surface & Coatings Technology,2013,237:305-312. [81] PERRIER A, ECAULT R, TOUCHARD F, et al. Towards the development of laser shock test for mechanical characterisation of fibre/matrix interface in eco-composites[J]. Polymer Testing,2015,44:125-134. doi: 10.1016/j.polymertesting.2015.04.003 [82] ABDALLAH E A, BOUVET C, RIVALLANT S, et al. Experimental analysis of damage creation and permanent indentation on highly oriented plates[J]. Composites Science and Technology, 2009, 69: 1238-1245. [83] LACHAUD F, ESPINOSA C, MICHEL L. Impact damage of carbone-epoxy laminates[C]//In: 17th JNC Conference. Poitiers: Journée Nationale des Composites, 2011. [84] PETIT S, BOUVET C, BERGEROT A, et al. Impact and compression after impact experimental study of a composite laminate with a cork thermal shield[J]. Composites Science and Technology, 2007, 67: 3286-3299. [85] HONGKARNJANAKUL N, BOUVET C, RIVALLANT S. The effect of stacking sequence on the low-velocity impact response of composite laminates[C]//In: 15th European Conference on Composite Materials. Venice: ECCM15, 2012. [86] YEN C F. Ballistic impact modeling of composite materials[C]//In: 7th International LS-DYNA Users Conference. Salzburg: 7th International LS-DYNA Users Conference, 2006. [87] LOIKKANEN M, PRAVEEN G, POWELL D. Simulation of ballistic impact on composite panels[C]//In: 10th International LS-DYNA Users Conference. Dearborn: 10th International LS-DYNA Users Conference, 2008. [88] CRAVEN R, IANNUCCI L, OLSSON R. Delamination buckling: A finite element study woth realistic delamination shapes, multiple delaminations and fibre fracture cracks[J]. Composites Part A: Applied Science and Manufacturing, 2010, 41: 684-692. [89] SCHIPPEREN J H A. Validation of a progressive failure prediction tool for a dynamically loaded three dimensional composite ship structure[C]//In: 15th European Conference on Composite Materials. Venice: ECCM15, 2012. [90] YOSHIMURA A, NAGAKURA K, OKABE T, et al. 3D simulation of high-velocity impact damage progress in the CFRP laminates[C]//In: 15th European Conference on Composite Materials. Venice: ECCM15, 2012. [91] ZHOU M, ZHANG Y, CAI L. Quantitative determination of interfacial bonding strength of thin films by laser lamination method[J]. Science China Technical Sciences,2002,32(1):28-36. [92] ECAULT R, BOUSTIE M, TOUCHARD F, et al. A study of composite material damage induced by laser shock waves[J]. Composites Part A: Applied Science and Manufacturing,2013,53:54-64. doi: 10.1016/j.compositesa.2013.05.015 [93] GHRIB M, BERTHE L, MECHBAL N, et al. Generation of controlled delaminations in composites using symmetrical laser shock configuration[J]. Composite Structures,2017,171:288-292. [94] 谷卓伟, PERTON M, SILVIO E, 等. 激光冲击波检测碳纤维材料中的粘接质量[J]. 中国激光, 2011, 38(3):0308002.GU Z W, PERTON M, SILVIO E, et al. Bonding quality detection of composite structure by laser shock wave[J]. Chinese Journal of Lasers,2011,38(3):0308002(in Chinese). [95] PERTON M, BLOUIN A, MONCHALIN J P. Adhesive bond testing of carbon-epoxy composites by laser shockwave[J]. Journal of Physics D-Applied Physics, 2010, 44: 034012. [96] ECAULT R, BOUSTIE M, BERTHE L, et al. Development of the laser shock wave adhesion test on bonded CFRP composite[J]. International Journal of Structural Integrity,2014,5(4):253-261. doi: 10.1108/IJSI-10-2013-0032 [97] EHRHART B, ECAULT R, TOUCHARD F, et al. Development of a laser shock adhesion test for the assessment of weak adhesive bonded CFRP structures[J]. International Journal of Adhesion & Adhesives,2014,52:62-64. [98] GAY E, BERTHE L, BUZAUD E, et al. Shock adhesion test for composite bonded assembly using a high pulsed power generator[J]. Journal of Applied Physics, 2013, 114(1): 208-222. [99] GILATH I, ELIEZER S, SHKOLNIK S. Spall behavior of carbon epoxy unidirectional composites as compared to aluminum and iron[J]. Journal of Composite Materials,2018,24(11):1138-1151. [100] GILATH I, ELIEZER S, BARNOY T, et al. Material response at hypervelocity impact conditions using laser-induced shock-waves[J]. International Journal of Impact Engineering,2019,14(1-4):279-289. [101] ZOBEIRY N, REINER J, VAZIRI R. Theory-guided machine learning for damage characterization of composites[J]. Composite Structures,2020,246:112407. doi: 10.1016/j.compstruct.2020.112407 [102] LIU Z. Deep material network with cohesive layers: Multi-stage training and interfacial failure analysis[J]. Computer Methods in Applied Mechanics and Engineering,2020,363:112913. doi: 10.1016/j.cma.2020.112913 [103] YANG H, QIU H, XIANG Q, et al. Exploring elastoplastic constitutive law of microstructured materials through artificial neural network—A mechanistic-based data-driven approach[J]. Journal of Applied Mechanics,2020,87:1-9. [104] RICKY T, CHEN Q, RUBANOVA Y, et al, Neural ordinary differential equations[C]//Advances in Neural Information Processing Systems 31, Montréal: Annual Conference on Neural Information Processing Systems, 2018. [105] ZHAN X, ZHAO W. Identification of defect types in carbon fiber composites based on one-dimensional CNN[J]. Laser and Optoelectronics Progress, 2020, 57(10): 143-151. -

下载:

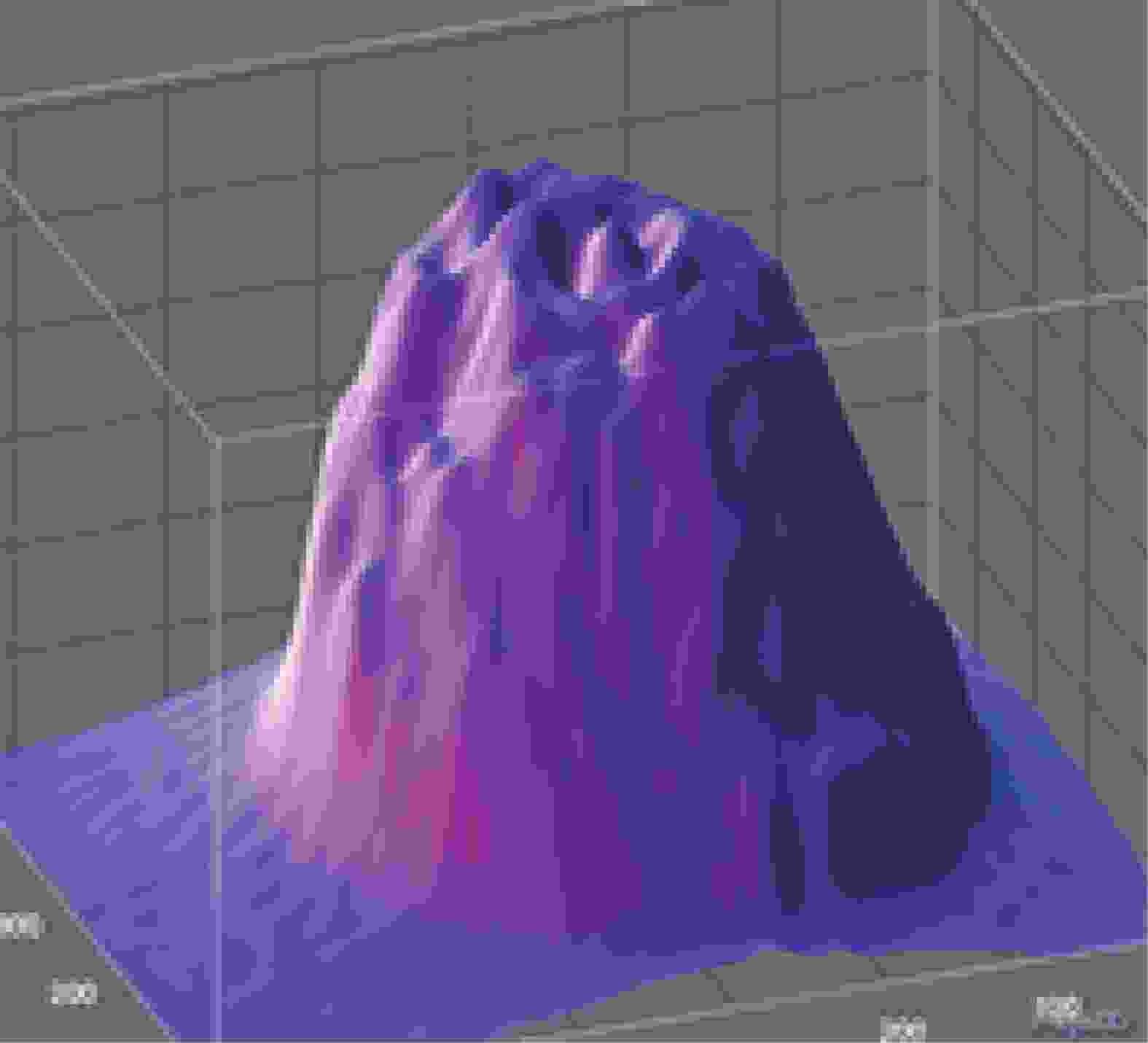

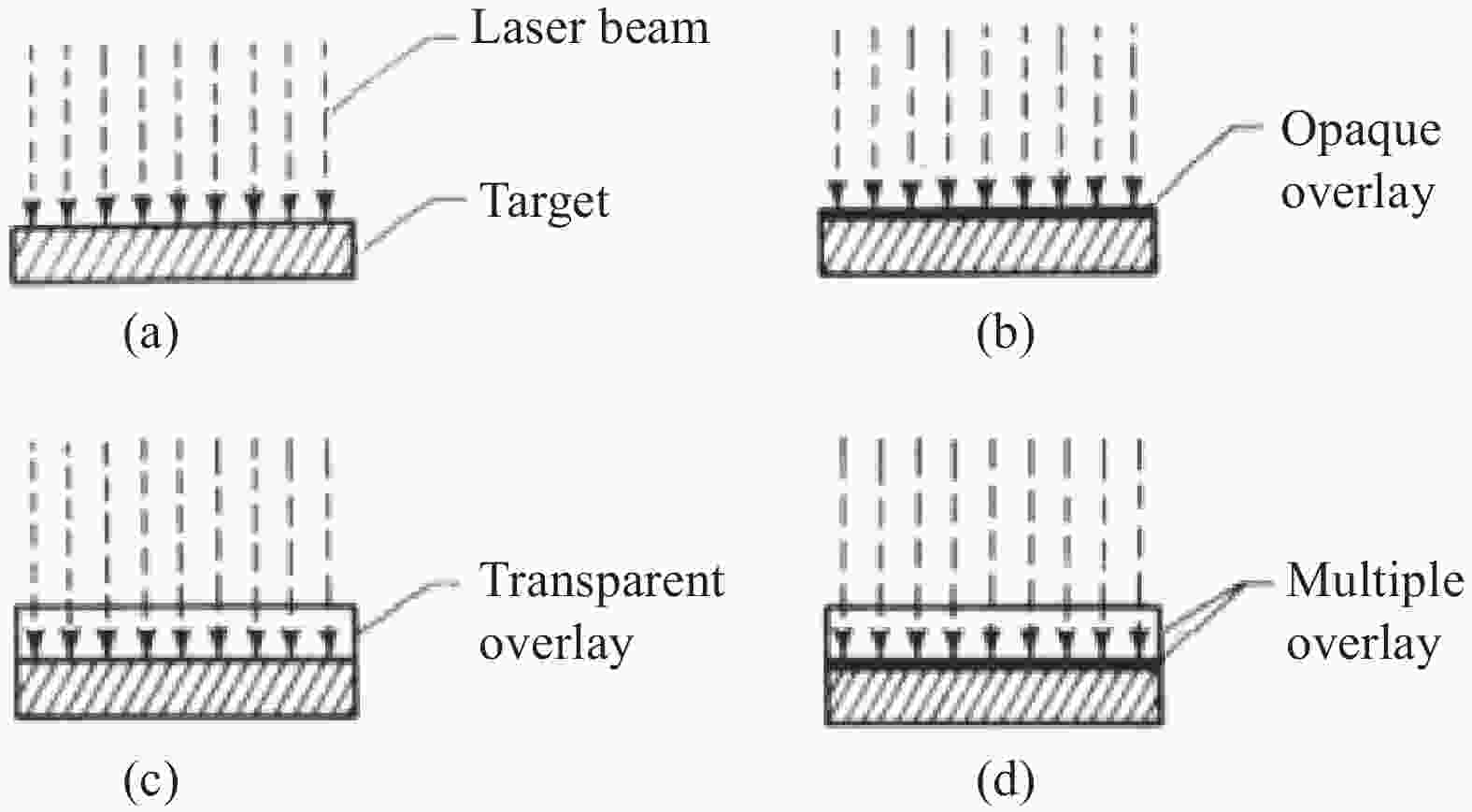

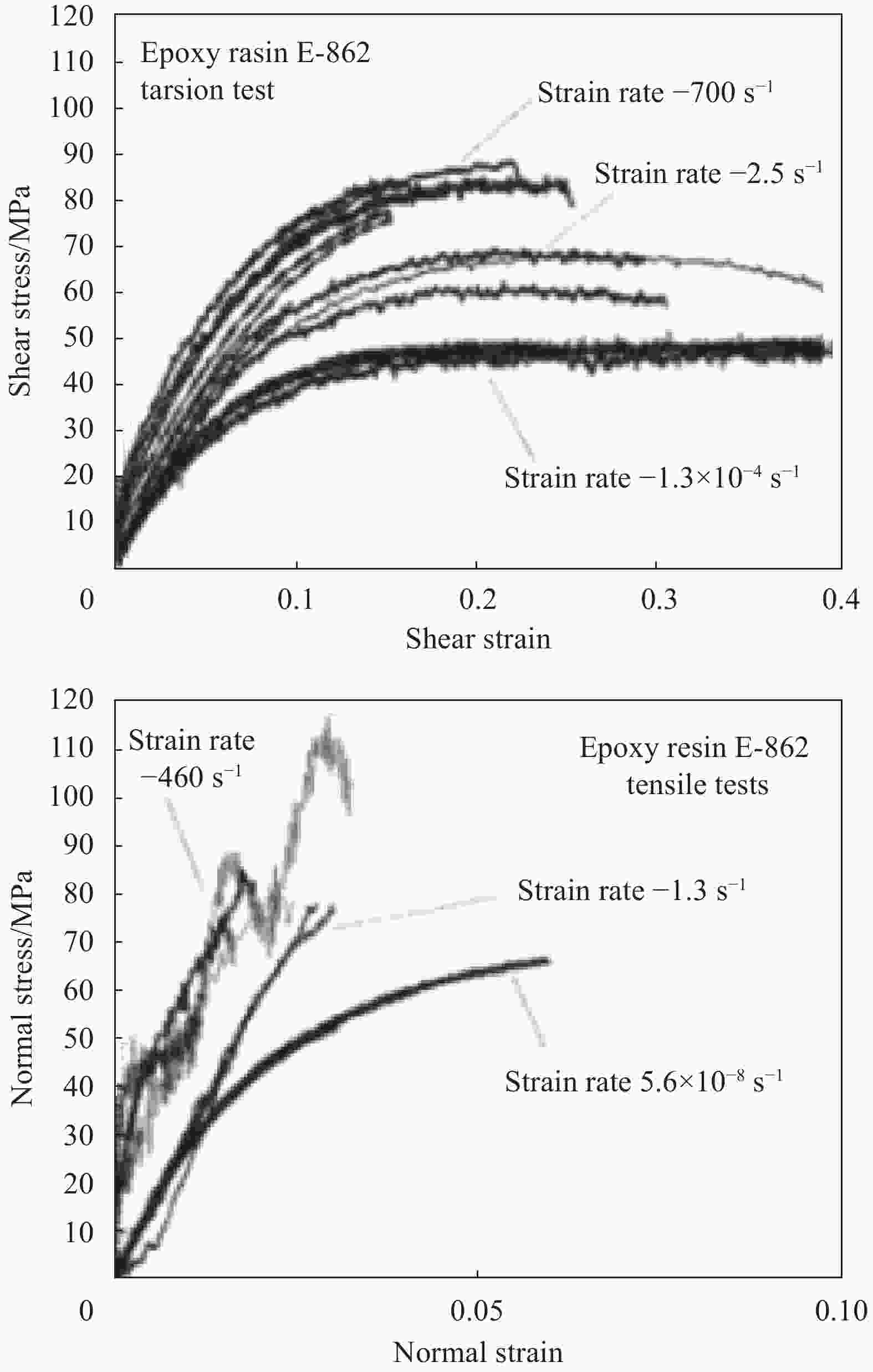

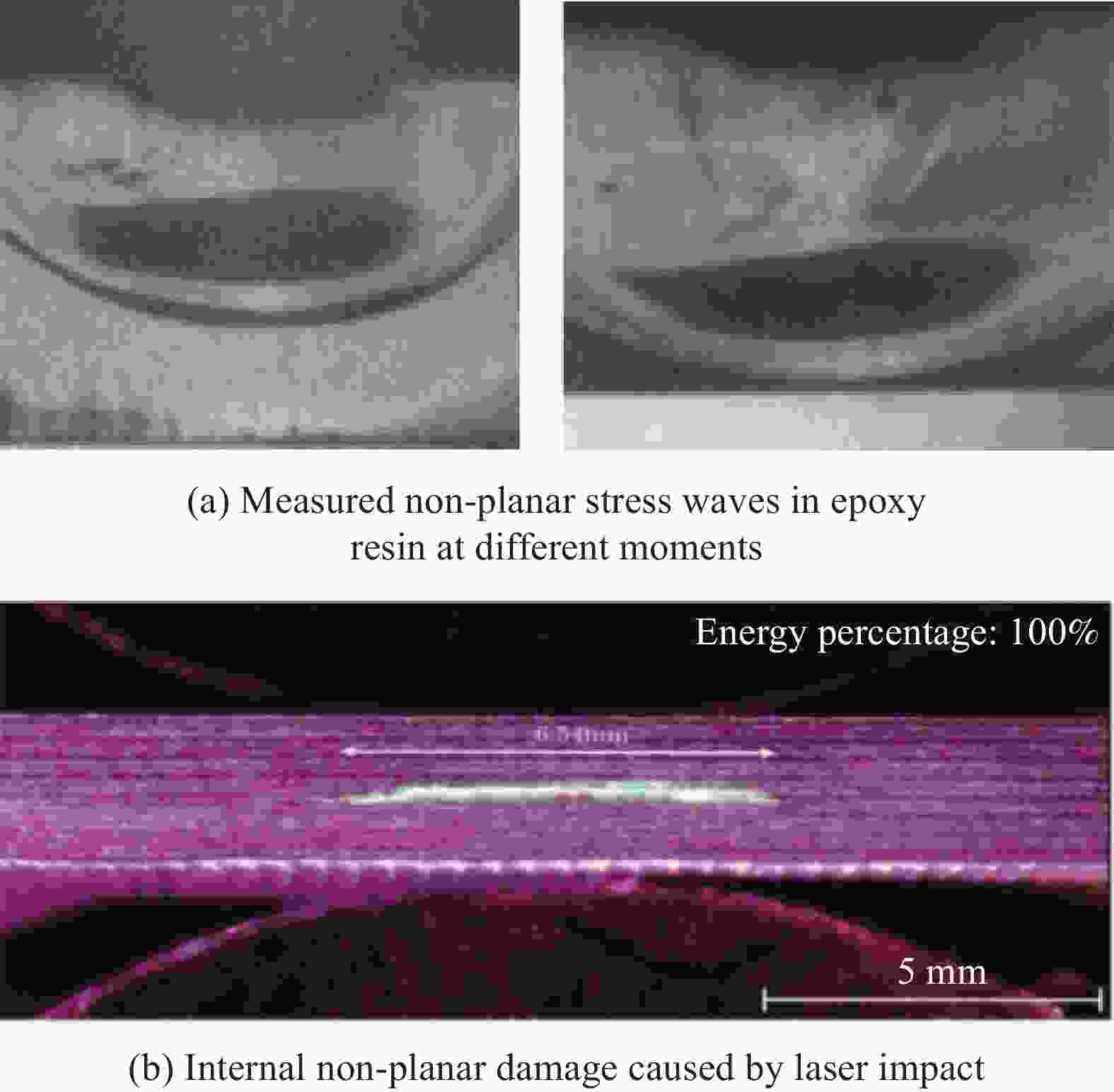

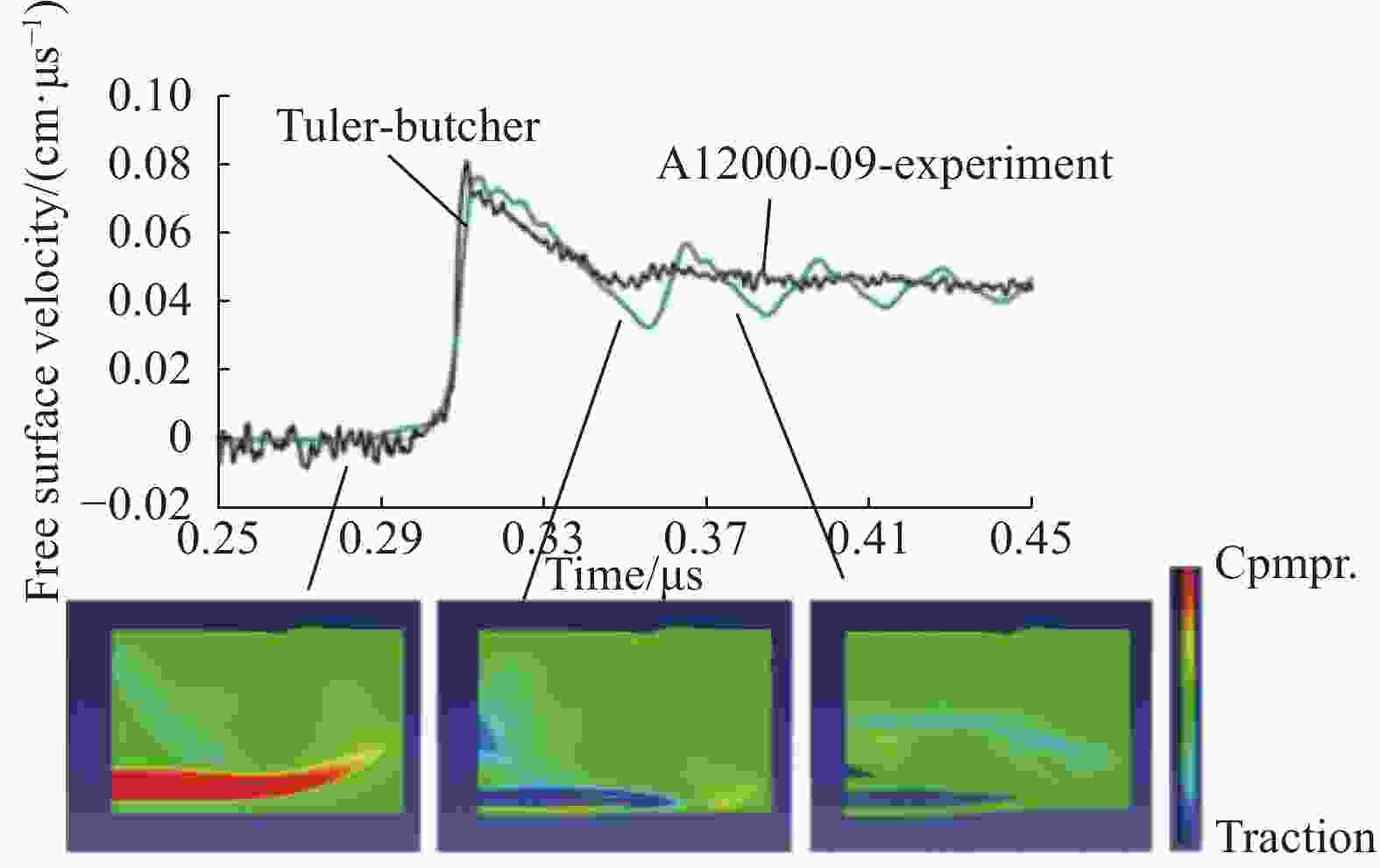

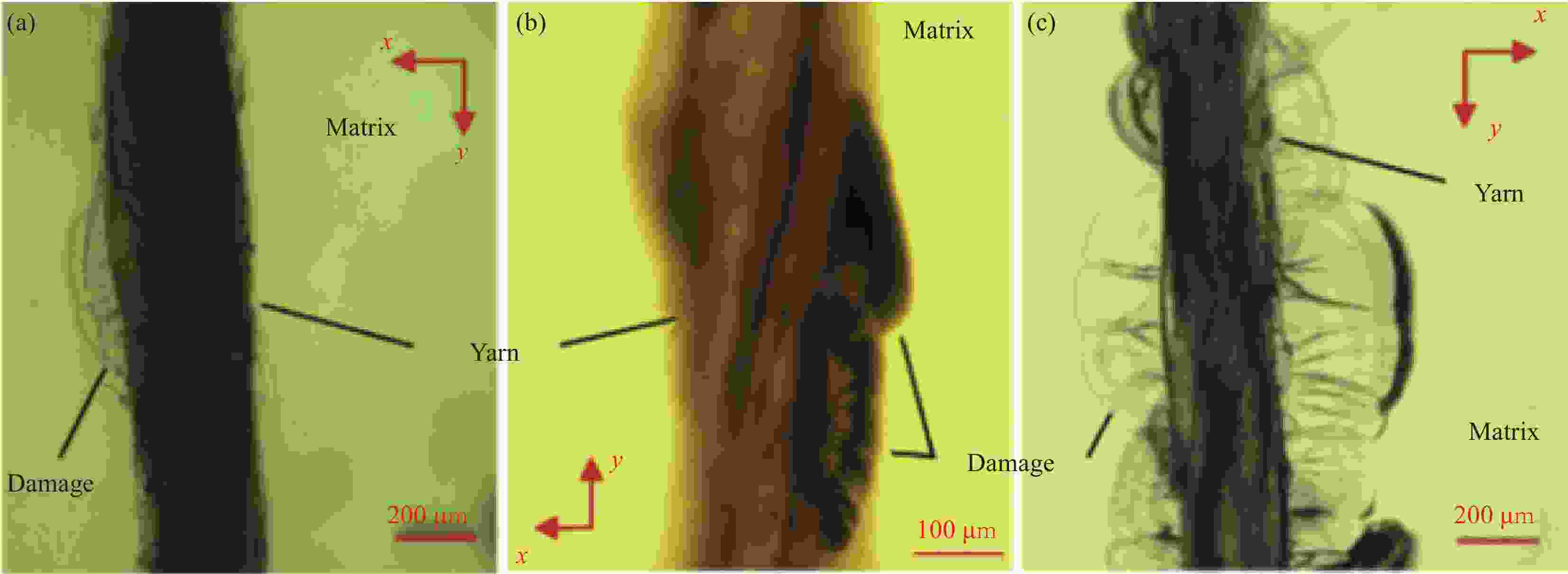

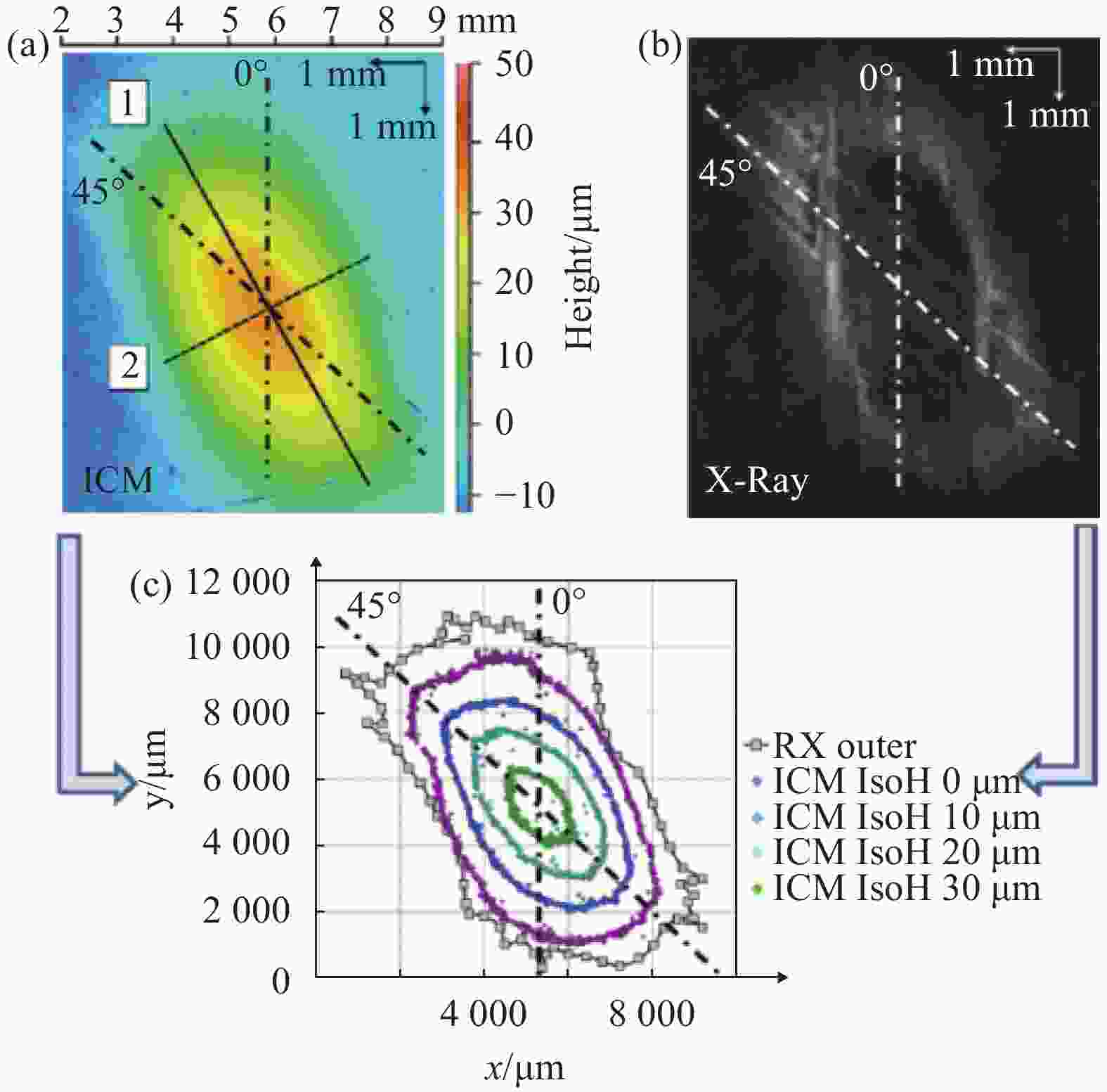

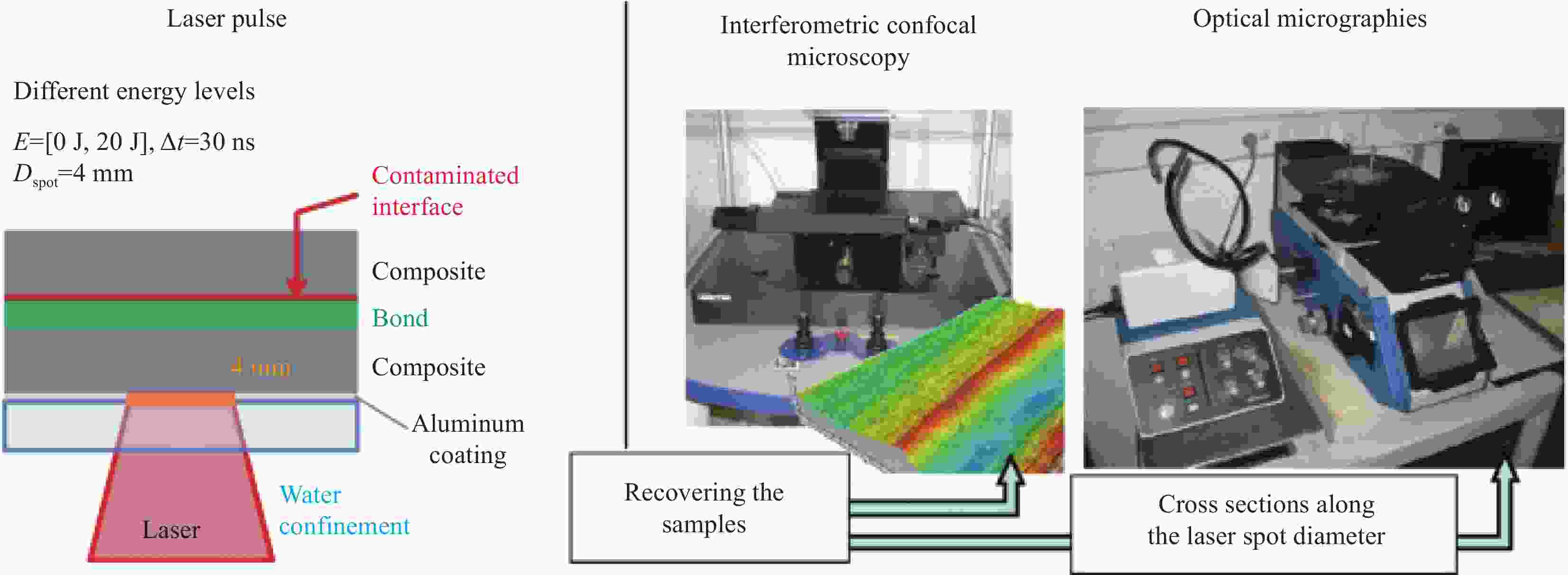

下载: