Mechanical properties and microstructure of nano-reinforced concrete containing etched fly ash cenosphere

-

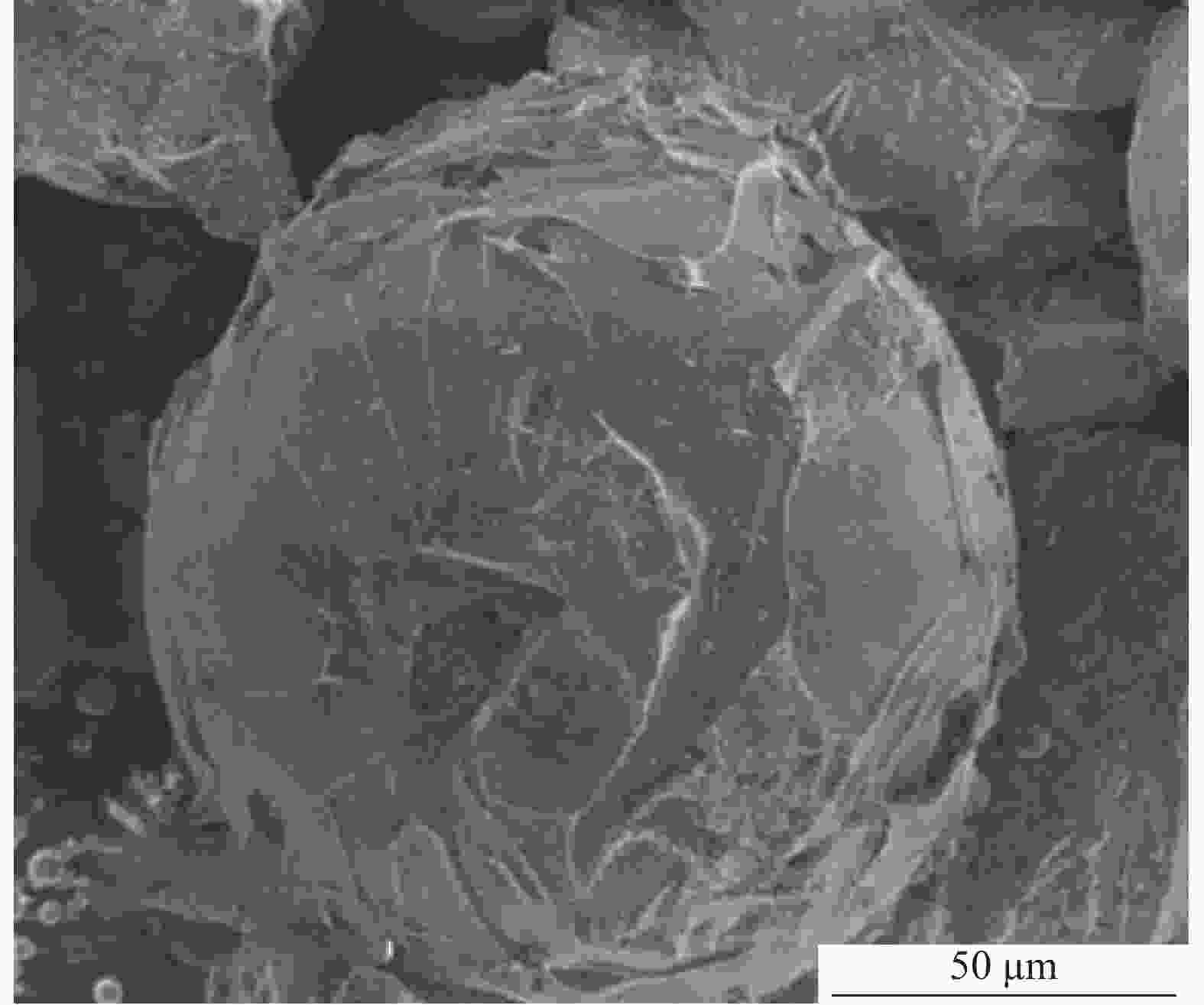

摘要: 粉煤灰漂珠是煤炭燃烧废弃物,用于替代水泥制备混凝土可有效降低环境负荷。本文提出针对粉煤灰漂珠的表面蚀刻工艺,并协同纳米SiO2以增强混凝土性能。通过扫描电子显微镜和X射线衍射仪对比了漂珠蚀刻前后的微观形貌和物相组成,利用热重试验表征蚀刻漂珠对浆体水化特征的影响,确定蚀刻方法的有效性。基于抗压、劈裂抗拉试验和扫描电子显微镜-能谱仪研究了蚀刻漂珠和纳米SiO2对混凝土力学和微观性能的影响规律与改性机制。结果表明,本文采用的蚀刻工艺加速了粉煤灰漂珠中Si和Al元素的释放,蚀刻的细微孔为水分迁移提供了有效路径,使漂珠具有内养护效应的同时提高了其反应活性,因此显著改善了浆体水化,提高了混凝土力学性能,但掺量增至40%时,粉煤灰漂珠中空结构的负面影响更为显著,混凝土强度下降。此外,蚀刻漂珠与纳米SiO2的协同增强效果显著,提高了界面Si/Ca和Al/Ca比率,改善了水化产物组成,优化了界面过渡区,有利于混凝土的致密稳定和强度发展。Abstract: Utilizing fly ash cenosphere, which is a coal-based waste, as a substitute for cement to prepare concrete can effectively mitigate its negative environmental effect. A surface etching process for fly ash cenosphere was proposed in this paper, and nano-silica was also adopted to coordinatively reinforce concrete performance. The microstructure morphology and phase composition of the cenosphere before and after surface etching were compared using scanning electron microscopy and X-ray diffraction and the influence of the surface etched cenosphere on the hydration properties was characterized by thermogravimetric testing to determine the effectiveness of the proposed etching procedure. The effects of surface etched cenosphere and nano silica were studied using compression and split-tensile tests and scanning electron microscopy-energy dispersive spectroscopy. Results show that the etching procedure proposed in this paper accelerates the release of Si and Al elements inside fly ash cenosphere. The etched micro-pores provide effective paths for water migration, enabling fly ash cenosphere to have internal curing effect and increased pozzolanic activity. Thus, cement hydration and mechanical properties of concrete are significantly improved. However, when the dosage of fly ash cenosphere increases to 40%, the negative impact of the hollow structure of fly ash cenosphere is more significant, resulting in decreased concrete strengths. Furthermore, the synergistic enhancing effect of surface etched cenosphere and nano silica is significant with increased Si/Ca and Al/Ca ratios at the interface, which improves the composition of hydration products and optimizes the interfacial transition zone and thus benefits the microstructure and strength development of concrete.

-

表 1 纳米SiO2的物理性能

Table 1. Physical properties of nano-silica

Purity/% Particle size/nm Specific surface area/(m2·g) Density/(g·cm−3) Bulk density/(g·cm−3) >99.99 20 >240 2.3 0.06 表 2 蚀刻粉煤灰漂珠(SEFAC)的吸水率和释水率

Table 2. Water absorption and water desorption of surface etched fly ash cenosphere (SEFAC)

Time/h Water absorption/% Water desorption/% RH=85.1% RH=75.5% RH=43.2% 1 63.2 12.4 20.8 31.8 6 66.5 40.5 50.6 63.9 12 67.4 55.3 73.8 82.5 24 68.7 66.4 83.5 92.4 48 70.2 76.2 92.1 98.9 Note: RH—Relative humidity 表 3 混凝土配合比

Table 3. Mix proportions of concrete mixtures

Mixture ID Water/kg Cement/kg Gravel/kg Sand/kg FAC/kg SEFAC/kg NS/kg 20wt%FAC 147 310 1119 746 76 - - 20wt%SEFAC 147 310 1119 746 - 76 - 40wt%SEFAC 147 234 1119 746 - 152 - 1wt%NS/20wt%SEFAC 147 306.14 1119 746 - 76 3.86 2wt%NS/20wt%SEFAC 147 302.28 1119 746 - 76 7.72 1wt%NS/40wt%SEFAC 147 230.14 1119 746 - 152 3.86 2wt%NS/40wt%SEFAC 147 226.28 1119 746 - 152 7.72 Notes: NS—nano-silica; Example: 1wt%NS/20wt%SEFAC is that the concrete mixture was added with 20wt% SEFAC and 1wt% nano-silica. 表 4 Ca(OH)2和结合水含量

Table 4. Ca(OH)2 and non-evaporable water contents

Mixture ID Ca(OH)2 content/% Non-evaporable water content/% 3 d 28 d 3 d 28 d 20wt%FAC 7.1 15.2 3.7 5.8 20wt%SEFAC 10.8 19.8 7.3 8.6 -

[1] FERNANDO S, GUNASEKARA C, LAW D W, et al. Long-term mechanical properties of blended fly ash-rice husk ash alkali-activated concrete[J]. ACI Materials Journal, 2022, 119(5): 174-186. [2] GU C P, YAO J K, HUANG S L, et al. Study on early-age tensile properties of high volume fly ash concrete[J]. Materials and Structures, 2022, 55(5): 135. doi: 10.1617/s11527-022-01977-x [3] MEENA A, SINGH N, SINGH S P. High-volume fly ash self consolidating concrete with coal bottom ash and recycled concrete aggregates: Fresh, mechanical and microstructural properties[J]. Journal of Building Engineering, 2023, 63: 105447. doi: 10.1016/j.jobe.2022.105447 [4] HASIM A M, SHAHID K A, ARIFFIN N F, et al. Coal bottom ash concrete: Mechanical properties and cracking mechanism of concrete subjected to cyclic load test[J]. Construction and Building Materials, 2022, 346: 128464. doi: 10.1016/j.conbuildmat.2022.128464 [5] ZHANG Y T, FAN Z W, SUN X W, et al. Utilization of surface-modified fly ash cenosphere waste as an internal curing material to intensify concrete performance[J]. Journal of Cleaner Production, 2022, 358: 132042. doi: 10.1016/j.jclepro.2022.132042 [6] RHEINHEIMER V, WU Y P, WU T, et al. Multi-scale study of high-strength low-thermal-conductivity cement composites containing cenospheres[J] Cement and Concrete Composites, 2017, 80: 91-103. [7] BROOKS A L, SHEN Z L, ZHOU H Y. Development of a high-temperature inorganic synthetic foam with recycled fly-ash cenospheres for thermal insulation brick manufacturing[J]. Journal of Cleaner Production, 2020, 246: 118748. doi: 10.1016/j.jclepro.2019.118748 [8] HUANG X Y, RANADE R, ZHANG Q, et al. Mechanical and thermal properties of green lightweight engineered cementitious composites[J]. Construction and Building Materials, 2013, 48: 954-960. doi: 10.1016/j.conbuildmat.2013.07.104 [9] ZHOU Y W, XI B, SUI L L, et al. Development of high strain-hardening lightweight engineered cementitious composites: Design and performance[J]. Cement and Concrete Composites, 2019, 104: 103370. doi: 10.1016/j.cemconcomp.2019.103370 [10] HANIF A, LU Z Y, LI Z J. Utilization of fly ash cenosphere as lightweight filler in cement-based composites - a review[J]. Construction and Building Materials, 2017, 144: 373-384. doi: 10.1016/j.conbuildmat.2017.03.188 [11] WANG J Y, ZHANG M H, LI W, et al. Stability of cenospheres in lightweight cement composites in terms of alkali-silica reaction[J]. Cement and Concrete Research, 2012, 42(5): 721-727. doi: 10.1016/j.cemconres.2012.02.010 [12] LIU F J, WANG J L, QIAN X, et al. Internal curing of high performance concrete using cenospheres[J]. Cement and Concrete Research, 2017, 95: 39-46. doi: 10.1016/j.cemconres.2017.02.023 [13] ZHANG Y T, SUN X W, ZHU X Y, et al. Multi-criteria optimization of concrete mixes incorporating cenosphere waste and multi-minerals[J]. Journal of Cleaner Production, 2022, 367: 133102. doi: 10.1016/j.jclepro.2022.133102 [14] CHEN P Y, TAN W B, QIAN X, et al. Improving the pore structure of perforated cenospheres for better internal curing performance[J]. Materials and Design, 2022, 222: 111047. doi: 10.1016/j.matdes.2022.111047 [15] 梁圣, 崔宏志, 徐丹玥. 纳米SiO2改性轻骨料混凝土性能[J]. 复合材料学报, 2019, 36(2): 498-505.LIANG Sheng, CUI Hongzhi, XU Danyue. Properties of nano-SiO2 modified lightweight aggregate concrete[J]. Acta Materiae Compositae Sinica, 2019, 36(2): 498-505. [16] WEI Y, KONG W K, WANG Y Q. Strengthening mechanism of fracture properties by nano materials for cementitious materials subject to early-age frost attack[J]. Cement and Concrete Composites, 2021, 119: 104025. doi: 10.1016/j.cemconcomp.2021.104025 [17] WANG X Y, DONG S F, ASHOUR A, et al. Effect and mechanisms of nanomaterials on interface between aggregates and cement mortars[J]. Construction and Building Materials, 2020, 240: 117942. doi: 10.1016/j.conbuildmat.2019.117942 [18] YAZDI M A, GRUYAERT E, TITTELBOOM K V, et al. Treatment with nano-silica and bacteria to restore the reduced bond strength between concrete and repair mortar caused by aggressive removal techniques[J]. Cement and Concrete Composites, 2021, 120: 104064. doi: 10.1016/j.cemconcomp.2021.104064 [19] LI L, XUAN D X, CHU S H, et al. Efficiency and mechanism of nano-silica pre-spraying treatment in performance enhancement of recycled aggregate concrete[J]. Construction and Building Materials, 2021, 301: 124093. doi: 10.1016/j.conbuildmat.2021.124093 [20] 姚贤华, 郭晓宁, 韩瑞聪, 等. 纳米SiO2和聚丙烯纤维对全煤矸石骨料混凝土力学性能与微观结构的影响[J]. 复合材料学报, 2024, 41(3): 1402-1419.YAO Xianhua, GUO Xiaoning, HAN Ruicong, et al. Effect of nano-SiO2 and popypropylene fibers on the mechanical properties and microscopic properties of all coal gangue aggregate concrete[J]. Acta Materiae Compositae Sinica, 2024, 41(3): 1402-1419. [21] ZHANG P Y, XIE N, CHENG X, et al. Low dosage nano-silica modification on lightweight aggregate concrete[J]. Nanomaterials and Nanotechnology, 2018, 8: 1847980418761283. [22] SONG X B, LI C Z, CHEN D D, et al. Interfacial mechanical properties of recycled aggregate concrete reinforced by nano-materials[J]. Construction and Building Materials, 2021, 270: 121446. doi: 10.1016/j.conbuildmat.2020.121446 [23] SAFIUDDIN M, GONZALEZ M, CAO J W, et al. State-of-the-art report on use of nano-materials in concrete[J]. International Journal of Pavement Engineering, 2014, 15(10): 940-949. doi: 10.1080/10298436.2014.893327 [24] ZHAO Z F, QI T Q, ZHOU W, et al. A review on the properties, reinforcing effects, and commercialization of nanomaterials for cement-based materials[J]. Nanotechnology Reviews, 2020, 9(1): 303-322. doi: 10.1515/ntrev-2020-0023 [25] ZHANG Y T, ZHU X Y. Effect of nano-silica on the mechanical performance and microstructure of silicon-aluminum-based internal-cured concrete[J]. Journal of Building Engineering, 2023, 65: 105735. doi: 10.1016/j.jobe.2022.105735 [26] ZHANG Y T, SUN X W. Synergistic effects of nano-silica and fly ash on the mechanical properties and durability of internal-cured concrete incorporating artificial shale ceramsite[J]. Journal of Building Engineering, 2023, 66: 105905. doi: 10.1016/j.jobe.2023.105905 [27] 中华人民共和国交通运输部. 公路工程水泥及水泥混凝土试验规程: JTG 3420-2020 [S]. 北京: 人民交通出版社, 2020.Ministry of Transport of the People’s Republic of China. Testing Methods of Cement and Concrete for Highway Engineering: JTG 3420-2020 [S]. Beijing: China Communications Press, 2020 (in Chinese). [28] LI X S, SHUI Z H, YU R, et al. Magnesium induced hydration kinetics of ultra-high performance concrete (UHPC) served in marine environment: Experiments and modelling[J]. Construction and Building Materials, 2019, 224: 1056-1068. doi: 10.1016/j.conbuildmat.2019.07.273 [29] MISHRA G, WARDA A, SHAH S P. Carbon sequestration in graphene oxide modified cementitious system[J]. Journal of Building Engineering, 2022, 62: 105356. doi: 10.1016/j.jobe.2022.105356 [30] 王冲, 张聪, 刘俊超, 等. CaCO3对硅酸盐水泥水化特性的影响[J]. 硅酸盐通报, 2016, 35(3): 824-830.WANG Chong, ZHANG Cong, LIU Junchao, et al. Influence of Nano-CaCO3 on hydration characteristic of portland cement[J]. Bulletin of the Chinese Ceramic Society, 2016, 35(3): 824-830(in Chinese). [31] MEHDIZADEH H, JIA X X, MO KH, et al. Effect of water-to cement ratio induced hydration on the accelerated carbonation of cement pastes[J]. Environmental Pollution, 2021, 280: 116914. doi: 10.1016/j.envpol.2021.116914 [32] BAI S, GUAN X C, LI G Y. Early-age hydration heat evolution and kinetics of Portland cement containing nano-silica at different temperatures[J]. Construction and Building Materials, 2022, 334: 127363. doi: 10.1016/j.conbuildmat.2022.127363 [33] YANG L, SHI C J, LIU J H, et al. Factors affecting the effectiveness of internal curing: A review[J]. Construction and Building Materials, 2021, 267: 121017. doi: 10.1016/j.conbuildmat.2020.121017 [34] ZHANG Y T, SUN X W. A comprehensive assessment of nanomaterials reinforced lightweight aggregate concrete containing high-volume artificial shale ceramsite[J]. Journal of Building Engineering, 2024, 84: 108696. doi: 10.1016/j.jobe.2024.108696 [35] 肖杰, 龙晨杰, 何建刚, 等. 大掺量激活钢渣微粉-水泥稳定碎石性能及围观特性[J]. 中国公路学报, 2021, 34(10): 204-215. doi: 10.3969/j.issn.1001-7372.2021.10.017XIAO Jie, LONG Chenjie, HE Jiangang, et al. Performance and micro characteristics of cement stabilized macadam with a large amount of activated steel slag powder[J]. China Journal of Highway and Transport, 2021, 34(10): 204-215(in Chinese). doi: 10.3969/j.issn.1001-7372.2021.10.017 [36] NIE S, HU S G, WANG F Z, et al. Pozzolanic reaction of lightweight fine aggregate and its influence on the hydration of cement[J]. Construction and Building Materials, 2017, 153: 165-173. doi: 10.1016/j.conbuildmat.2017.07.111 -

点击查看大图

点击查看大图

计量

- 文章访问数: 51

- HTML全文浏览量: 28

- 被引次数: 0

下载:

下载: