Effect of modified basalt fiber on the sulfate resistance of concrete

-

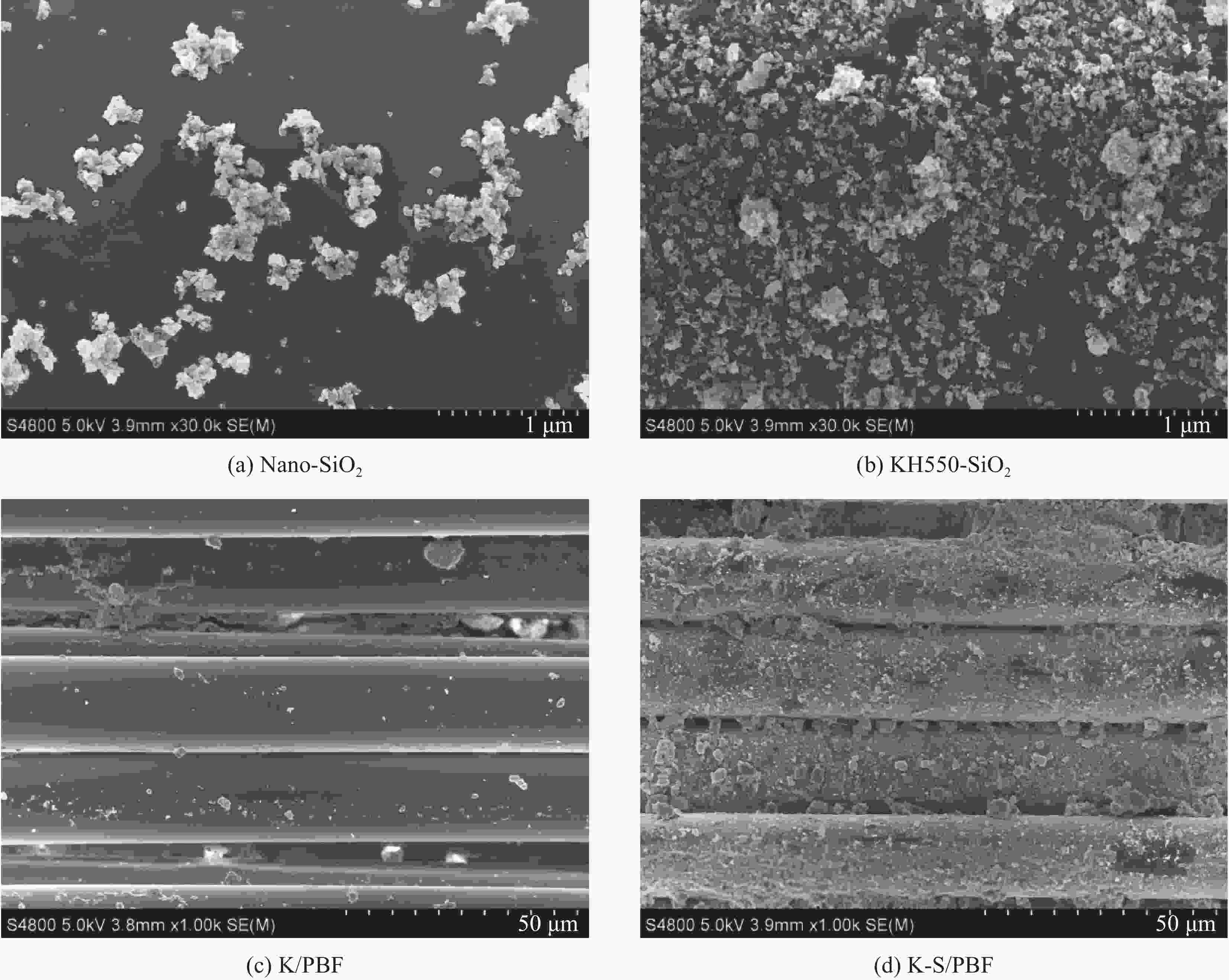

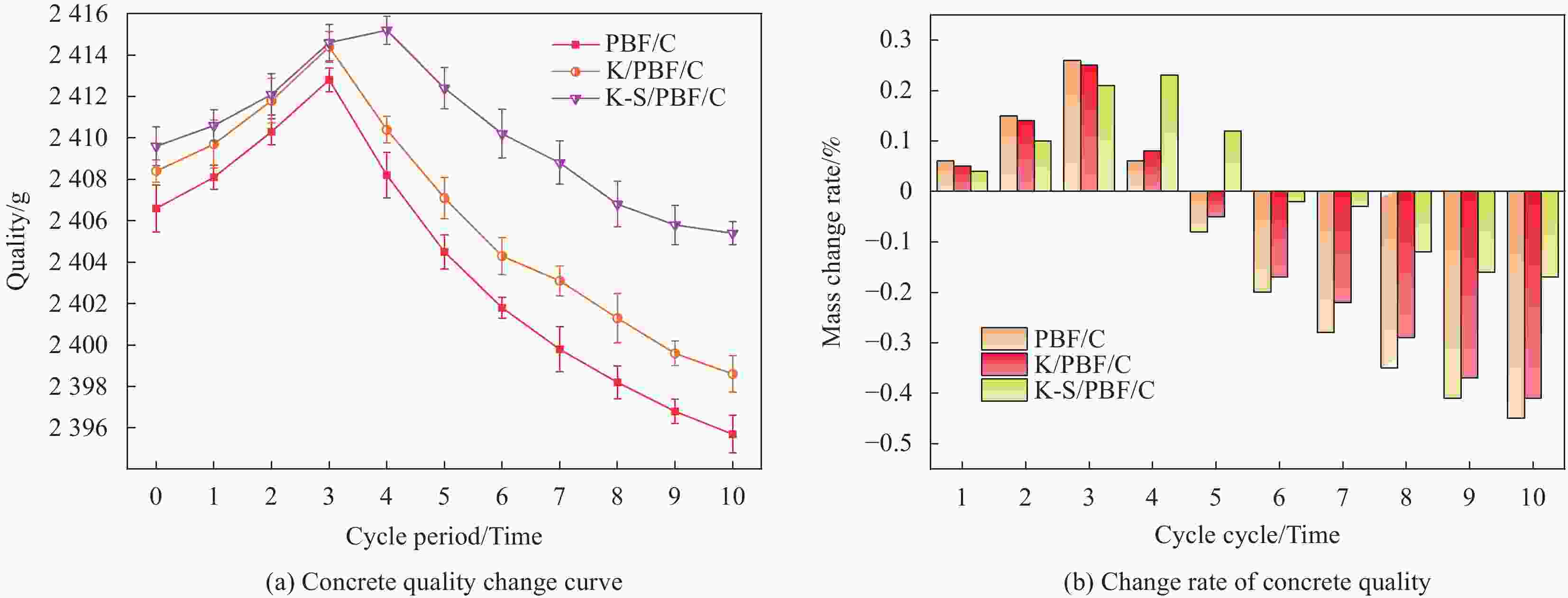

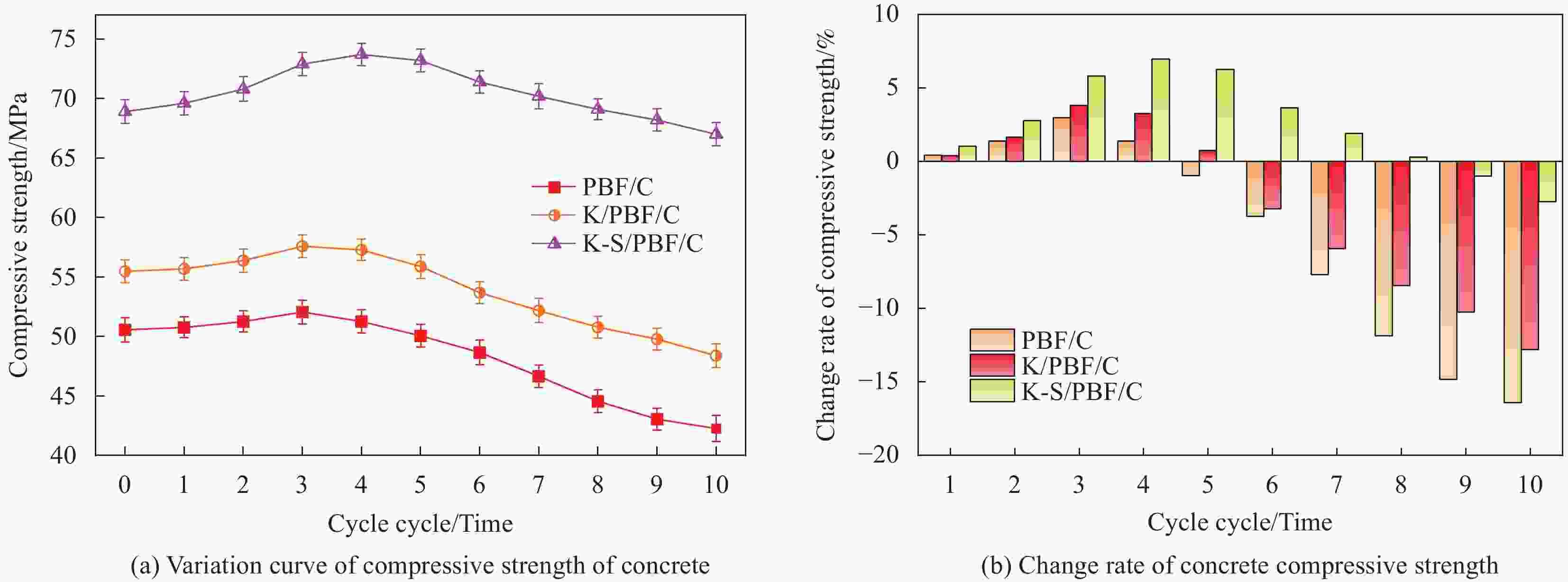

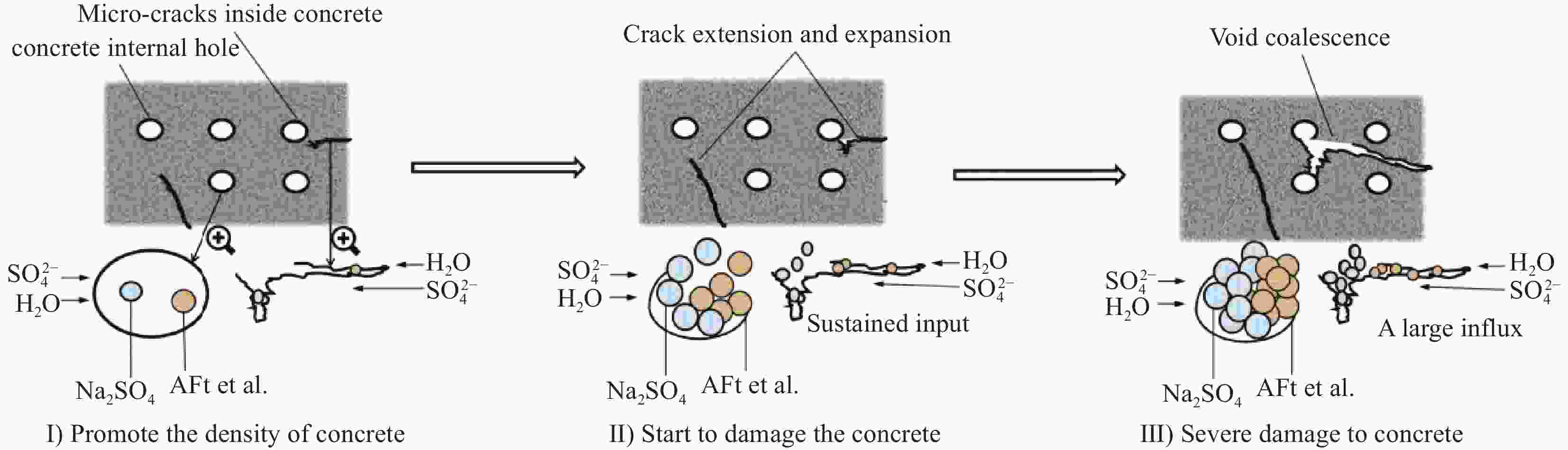

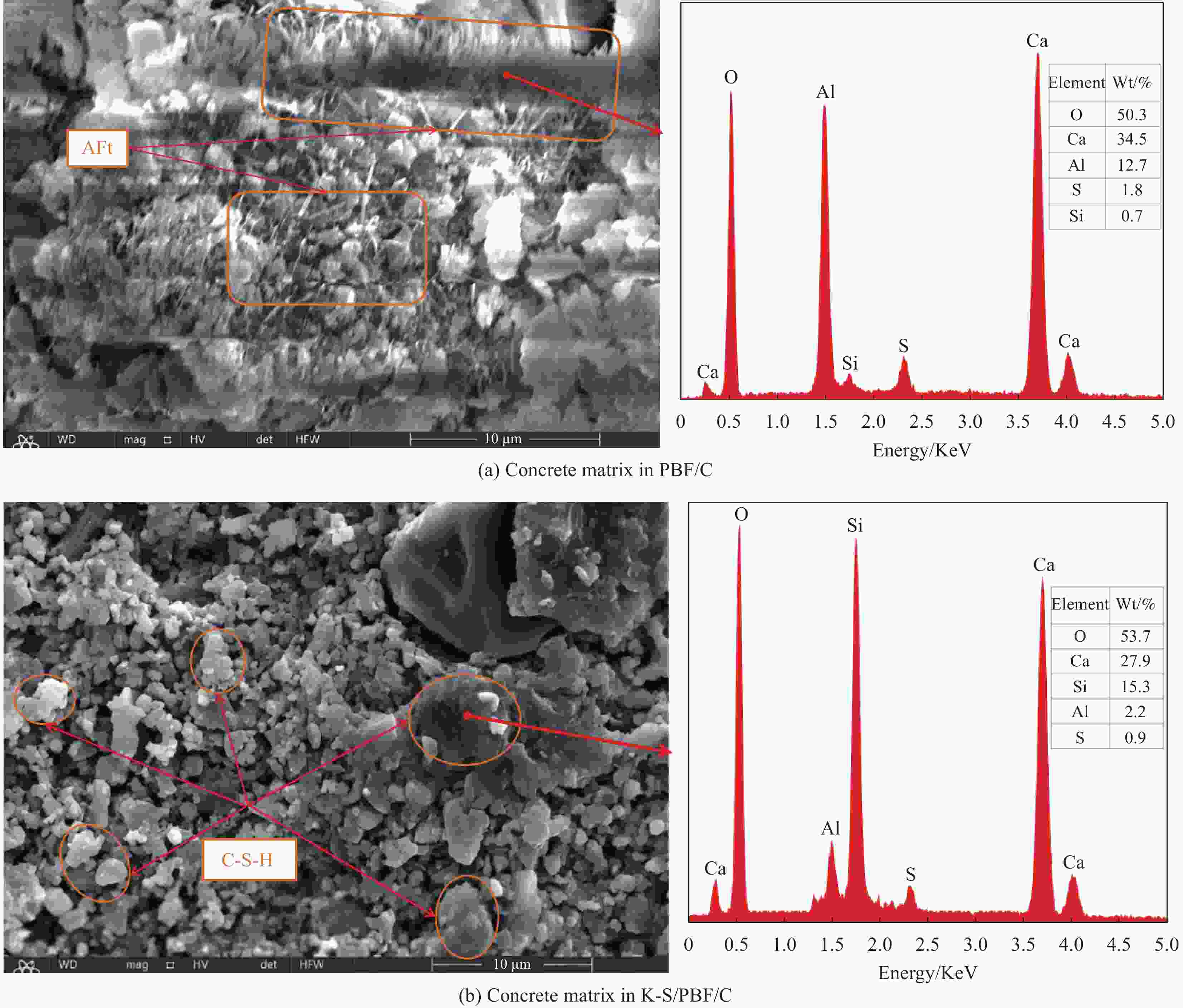

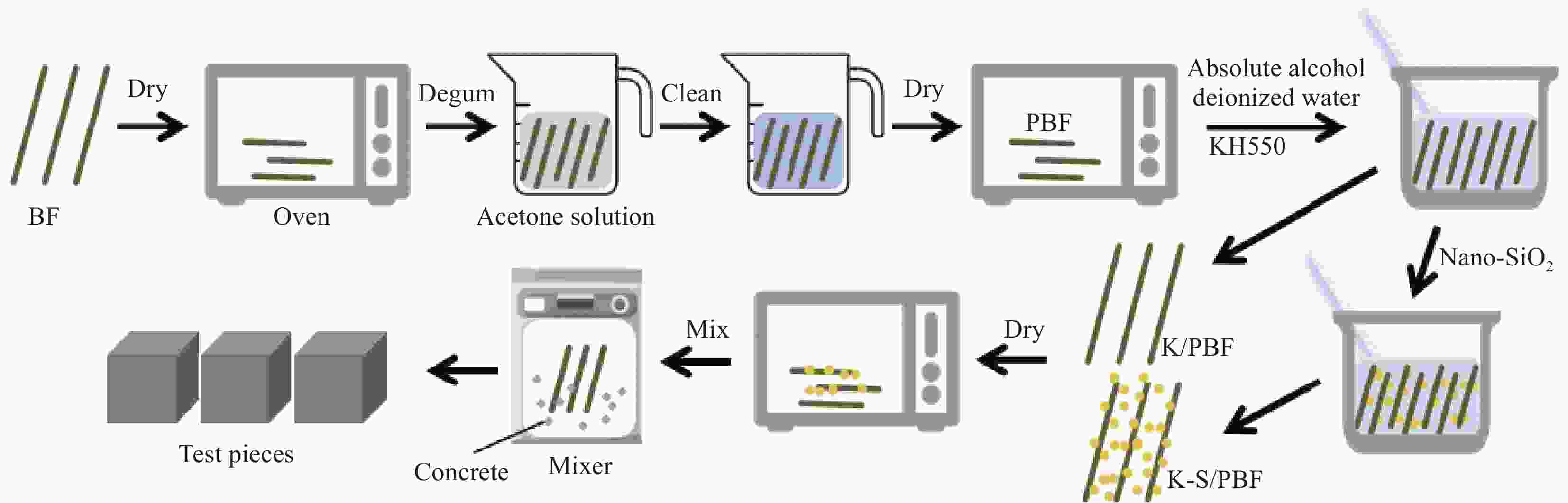

摘要: 为探究玄武岩纤维(BF)表面改性对混凝土抗硫酸盐性能的影响。本文利用γ-氨丙基三乙氧基硅烷偶联剂(KH550)和纳米二氧化硅(nano-SiO2)对BF表面进行改性。通过微观表征技术和混凝土硫酸盐侵蚀试验揭示改性机制并对在硫酸盐侵蚀环境下的耐久性进行评估。结果表明:KH550使nano-SiO2分布均匀,有利于BF表面附着的nano-SiO2与水泥中的Ca(OH)2反应,促进水泥的水化反应,增强了BF与水泥基体的界面黏结性。在硫酸盐侵蚀的条件下,与其他种类混凝土相比,加入了纳米改性纤维的混凝土表现出最佳的抗盐和抗压性能。在侵蚀280 d后,混凝土的质量和抗压强度仅损失了0.23%和2.76%。硫酸盐-干湿循环对混凝土试件的侵蚀过程可大致分为促进混凝土密实、开始损坏混凝土和剧烈损坏混凝土三个阶段。Nano-SiO2充填了混凝土中纤维与基体界面区的微缝隙,发生的二次水化反应可生成密实且耐久的C-S-H凝胶,可有效抑制化学物质与水分进一步对混凝土的渗透,阻碍更多AFt与石膏等膨胀类物质的产生,显著提高混凝土的抗盐侵蚀能力。Abstract: To explore the effect of surface modification of basalt fibers (BF) on the sulfate resistance of concrete,γ-aminopropyltriethoxysilane coupling agent (KH550) and nano-silica (nano-SiO2) were used to modify the surface of basalt fibers (BF). The modification mechanisms were revealed through micro-characterization techniques and concrete sulfate erosion tests, and the durability in a sulfate erosion environment was assessed. The results show: KH550 can facilitate the uniform distribution of nano-SiO2, which aids in the reaction between nano-SiO2 adhered to the BF surface and Ca(OH)2 in cement, enhancing the hydration of cement and the interfacial adhesion between BF and the cement matrix. Under sulfate attack conditions, concrete that incorporates nano-modified fibers outperforms other types of concrete in terms of salt resistance and compressive strength. After 280 days of erosion, there is merely a 0.23% reduction in the mass of the concrete and a 2.76% decline in its compressive strength. The erosion process of concrete specimens under sulfate dry-wet cycling can generally be divided into three phases: enhancing the compaction of concrete, starting concrete deterioration, and severe degradation of concrete. Nano-SiO2 fills the micro-cracks at the interface between fibers and the matrix in concrete, leading to secondary hydration reactions that produce dense and durable C-S-H gel. This effectively inhibits the further penetration of chemicals and moisture into the concrete, impedes the production of expansive materials such as AFt and gypsum, significantly improving the concrete’s resistance to salt-induced erosion.

-

Key words:

- basalt fiber /

- nano-SiO2 /

- microscopic /

- concrete /

- salt tolerance

-

表 1 BF的性能指标

Table 1. Performance indicators of BF

Diameter/μm Length/mm Density/(g·cm−3) Tensile strength/MPa Elastic modulus/GPa Elongation/% 17 6 2.65 3200 -4500 95-115 2.4-3.0 表 2 水泥和粉煤灰的主要化学成分

Table 2. Main chemical composition of cement and fly ash

Oxide CaO SiO2 Al2O3 Fe2O3 SO3 K2O MgO SiO3 Cement/% 62.77 19.93 4.97 3.82 2.32 2.07 1.68 — Fly ash/% 4.73 43.26 32.78 8.35 0.73 — 0.92 1.21 表 3 纤维混凝土原材料的配合比

Table 3. Mixing ratio of fiber concrete raw materials

Raw material Cement Fly ash Granite Sand Fiber Deionized water Water Mix proportion/(kg·m−3) 376 94 740 1022 7.95 4.68 164 表 4 BF、PBF、K/PBF和K-S/PBF的拉伸强度和伸长率

Table 4. Tensile strength and elongation of BF, PBF, K/PBF and K-S/PBF

Fiber class Tensile strength/MPa Elongation/% BF 3845 2.81 PBF 3925 2.74 K/PBF 4083 2.74 K-S/PBF 4132 2.74 Notes: BF—Basalt fiber; PBF—Pretreated basalt fiber; K/PBF—KH550 modified pretreated basalt fiber; K-S/PBF—KH550-SiO2 modified pretreated basalt fiber. -

[1] LI V C. High-performance and multifunctional cement-based composite material[J]. Engineering, 2019, 5(2): 250-260. doi: 10.1016/j.eng.2018.11.031 [2] 谢发祥, 韩旭, 蔡定鹏, 等. 高性能水泥基复合材料的压剪性能和破坏准则[J]. 复合材料学报, 2022, 39(11): 5311-5320.XIE Faxiang, HAN Xu, CAI Dingpeng, et al. Compression-shear performance and failure criteria of the high-performance cement-based composite[J]. Acta Materiae Compositae Sinica, 2022, 39(11): 5311-5320 (in Chinese). [3] YOO D Y, BANTHIA N. High-performance strain-hardening cementitious composites with tensile strain capacity exceeding 4%: A review[J]. Cement and Concrete Composites, 2022, 125: 104325. doi: 10.1016/j.cemconcomp.2021.104325 [4] 朱俊涛, 李志强, 王新玲, 等. 工程用水泥基复合材料单轴受拉本构关系模型[J]. 应用基础与工程科学学报, 2021, 29(2): 471-482.ZHU Juntao, LI Ziqiang, WANG Xinling, et al. Constitutive relationship model of engineered cementitious composites under uniaxial tension[J]. Journal of Basic Science and Engineering, 2021, 29(2): 471-482 (in Chinese). [5] 李安令, 郭帅成, 朱德举. 高韧性水泥基复合材料拉伸和弯曲性能的相关性[J]. 土木工程学报, 2021, 54(7): 54-61+132.LI Anling, GUO Suaicheng, ZHU Deju. Correlation of tensile and flexural behaviors of high toughness cementitious composites[J]. China Civil Engineering Journal, 2021, 54(7): 54-61+132 (in Chinese). [6] 高峰, 郝贠洪, 吴安利, 等. 低模量聚酯纤维/水泥基复合材料抗冲击性能及损伤机制[J]. 复合材料学报, 2021, 38(11): 3838-3849.GAO Feng, HAO Yunhong, WU Anli, et al. Impact resistance and damage mechanism of low modulus polyester fiber/cement matrix composites[J]. Acta Materiae Compositae Sinica, 2021, 38(11): 3838-3849 (in Chinese). [7] 陆振乾, 杨雅茹, 荀勇. 纤维对水泥基复合材料性能影响研究进展[J]. 纺织学报, 2021, 42(4): 177-183.LU Zenqian, YANG Yaru, XUN Yong. Research review of fiber effect on properties of cement-based composite[J]. Journal of Textile Research, 2021, 42(4): 177-183 (in Chinese). [8] ADESINA A. Performance of cementitious composites reinforced with chopped basalt fibres–An overview[J]. Construction and Building Materials, 2021, 266: 120970. doi: 10.1016/j.conbuildmat.2020.120970 [9] 吴智深, 汪昕, 史健喆. 玄武岩纤维复合材料性能提升及其新型结构[J]. 工程力学, 2020, 37(5): 1-14.WU Zhishen, WANG Xin, SHI Jianzhe. Advancement of basalt fiber-reinforced polymers (bfrps) and the novel structures reinforced with bfrps[J]. Engineering Mechanics, 2020, 37(5): 1-14 (in Chinese). [10] 王晓荣. 粗糙化玄武岩纤维的制备及其对PP基复合材料结构与性能的影响 [D]. 宜宾: 西华大学, 2022.WANG Xiaorong. Preparation of roughened basalt fiber and its effect on the structure and properties of PP matrix composites [D]. Yibin: Xihua University, 2022 (in Chinese). [11] 孙泽阳, 付林晨, 冯德成, 等. 集束玄武岩纤维筋黏结性能试验研究[J]. 建筑结构学报, 2019, 40(S1): 378-385.SUN Zeyang, FU Linchen, FENG Decheng, et al. Bond behavior between bundled basalt fiber reinforced bar and concrete by eccentric pull-out test[J]. Journal of Building Structures, 2019, 40(S1): 378-385 (in Chinese). [12] 邱军, 陈典兵, 邱挺挺, 等. 碳纤维/碳纳米管-环氧树脂复合材料的耐老化性能[J]. 材料研究学报, 2013, 27(2): 131-138.QIU Jun, CHENG Dianbing, QIU Tingting, et al. Aging Properties of Carbon Nanotubes/Carbon Fiber/Epoxy Resin Composites[J]. Chinese Journal of Materials Research, 2013, 27(2): 131-138 (in Chinese). [13] 张颜锋, 朱四荣, 别依诺, 等. 连续玄武岩纤维/环氧树脂复合材料的润湿渗透剂表面改性及其非线性蠕变性能[J]. 复合材料学报, 2024, 41(4): 1798-1808.ZHANG Yanfeng, ZHU Sirong, BIE Yinuo, et al. Study on the surface modification of wetting penetrant and nonlinear creep of continuous basalt fiber/epoxy resin composites[J]. Acta Materiae Compositae Sinica, 2024, 41(4): 1798-1808 (in Chinese). [14] 刘寒冰, 高鑫, 宫亚峰, 等. 表面处理对玄武岩纤维活性粉末混凝土力学性能的影响及断裂特性[J]. 吉林大学学报(工学版), 2021, 51(3): 936-945.LIU Hanbing, GAO Xin, GONG Yafeng, et al. Influence of surface treatment on basalt fiber reactive powder concrete mechanical properties and fracture characteristics[J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(3): 936-945 (in Chinese). [15] 王晓东, 云斯宁, 张太宏, 等. 硅烷偶联剂表面改性玄武岩纤维增强复合材料研究进展[J]. 材料导报, 2017, 31(5): 77-83.WANG Xiaodong, YUN Sining, ZHANG Taihong, et al. Advances in basalt fiber-reinforced composites modified by silane coupling agents[J]. Materials Reports, 2017, 31(5): 77-83 (in Chinese). [16] 张运华, 姚丽萍, 徐仕进, 等. 表面处理玄武岩纤维增强水泥基复合材料力学性能[J]. 复合材料学报, 2017, 34(5): 1159-1166.ZHANG Yunhua, YAO Liping, XU Shijin, et al. Mechanical properties of cement matrix composites reinforced with surface treated basalt fibers[J]. Acta Materiae Compositae Sinica, 2017, 34(5): 1159-1166 (in Chinese). [17] 李福洲, 李贵超, 王浩明, 等. 酸/碱腐蚀对玄武岩纤维纱线特性的影响[J]. 材料导报, 2015, 29(2): 110-113.LI Fuzhou, LI Guichao, WANG Haoming, et al. Effect of acid/alkali corrosion on properties of basalt fiber yarn[J]. Materials Reports, 2015, 29(2): 110-113 (in Chinese). [18] 严燕钫, 沈艳琴, 武海良, 等. 玄武岩长丝表面低温等离子体处理及其浆丝集束性能[J]. 纺织学报, 2018, 39(12): 24-29.YANG Yanfang, Shen Yanqin, Wu Hauliang, et al. Low temperature plasma treatment of basalt filament surface and sizing strand integrity thereof[J]. Journal of Textile Research, 2018, 39(12): 24-29 (in Chinese). [19] PARK O K, KIM W Y, KIM S M, et al. Effect of oxygen plasma treatment on the mechanical properties of carbon nanotube fibers[J]. Materials Letters, 2015, 156: 17-20. doi: 10.1016/j.matlet.2015.04.141 [20] ZHANG W, ZOU X S, WEI F Y, et al. Grafting SiO2 nanoparticles on polyvinyl alcohol fibers to enhance the interfacial bonding strength with cement[J]. Composites Part B: Engineering, 2019, 162: 500-507. doi: 10.1016/j.compositesb.2019.01.034 [21] LI X, LIU T, LIN P, et al. A review on mechanisms and recent developments of nanomaterials based carbon fiber reinforced composites for enhanced interface performance[J]. Materialwissenschaft und Werkstofftechnik, 2023, 54(1): 98-108. doi: 10.1002/mawe.202200072 [22] 杜常博, 朱明皓, 易富, 等. 玄武岩纤维表面改性对混凝土力学性能的影响[J]. 建筑材料学报, 2024, 1-12.DU Cangbo, ZHU Minghao YI Fu, et al. Effect of basalt fiber surface modification on the mechanical properties of concrete[J]. Journal of Building Materials, 2024, 1-12 (in Chinese). [23] 中华人民共和国住房和城乡建设部, 国家市场监督管理总局. 混凝土物理力学性能试验方法标准: GB/T 50081-2019 [S]. 北京: 中国建筑工业出版社, 2019.Ministry of Housing and Urban-Rural Development of the People's Republic of China, State Administration for Market Regulation. Standard for test methods of concrete physical and mechanical properties: GB/T 50081-2019 [S]. Beijing: China Architecture & Building Press, 2019 (in Chinese). [24] 韦小碧, 顾佩, 柳志军, 等. 纤维水泥稳定碎石室内拌和工艺试验研究[J]. 公路, 2017, 62(11): 19-24.WEI Xiaobo, GU Pei, LIU Zhijun, et al. Experimental study on mixing process of fiber cement stabilized macadam[J]. Journal of Tongji Highway, 2017, 62(11): 19-24 (in Chinese). [25] 国家质量监督检验检疫总局, 国家标准化管理委员会. 碳纤维单丝拉伸性能的测定: GB/T 31290-2022 [S]. 北京: 中国标准出版社, 2022.General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, Standardization Administration of the People's Republic of China. Carbon fibre—Determination of the tensile properties of single-filament specimens: GB/T 31290-2022 [S]. Beijing: Standards Press of China, 2022 (in Chinese). [26] 中华人民共和国国家质量监督检验检疫总局, 中华人民共和国国家标准化管理委员会. 碳纤维复丝拉伸性能试验方法: GB/T 3362-2017 [S]. 北京: 中国标准出版社, 2017.General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, Standardization Administration of the People's Republic of China. Test methods for tensile properties of carbon fiber multifilament: GB/T 3362-2017 [S]. Beijing: Standards Press of China, 2017 (in Chinese). [27] DEMATOS P R, ANDRADENETO J S, SAKATA R D, et al. Strategies for XRD quantitative phase analysis of ordinary and blended Portland cements[J]. Cement and Concrete Composites, 2022, 131: 104571. doi: 10.1016/j.cemconcomp.2022.104571 [28] LEE B, LEE S, KIM B, et al. Advanced characterization of IGCC slag by automated SEM-EDS analysis[J]. Waste Manage, 2020, 116: 140. doi: 10.1016/j.wasman.2020.08.001 [29] 中华人民共和国住房和城乡建设部, 中华人民共和国国家质量监督检验检疫总局. 普通混凝土长期性能和耐久性能试验方法标准: GB/T 50082-2009 [S]. 北京: 中国建筑工业出版社, 2009.Ministry of Housing and Urban-Rural Development of the People's Republic of China, State Administration for Market Regulation. Standard for test methods of long-term performance and durability of ordinary concrete: GB/T 50082-2009 [S]. China Architecture & Building Press, 2009 (in Chinese). [30] 于利超. 玄武岩纤维表面处理对其复合材料力学性能的影响 [D]. 上海: 东华大学, 2015.YU Lichao. Effect of basalt fiber surface treatment on composite performance [D]. Shanghai: Donghua University, 2015 (in Chinese). [31] 景芳达, 韩松, 葛晶, 等. 改性玄武岩纤维/聚氨酯阻尼材料的制备及性能[J]. 精细化工, 2022, 39(7): 1369-1375+1456.JING Fangda, HAN Song, GE Jing, et al. Preparation and properties of modified basalt fiber/polyurethane damping material[J]. Fine Chemicals, 2022, 39(7): 1369-1375+1456 (in Chinese). [32] 刘淑强, 武捷, 吴改红, 等. 纳米SiO2对玄武岩纤维的表面改性[J]. 纺织学报, 2020, 41(12): 37-41.LIU Shuqiang, WU Jie, WU Gaihong, et al. Surface modification of basalt fiber using nano-SiO2[J]. Journal of Textile Research, 2020, 41(12): 37-41 (in Chinese). [33] 郭耀东, 刘元珍, 王文婧, 等. 玄武岩纤维特征参数对混凝土单轴受拉性能的影响[J]. 复合材料学报, 2023, 40(5): 2897-2912.GUO Yaodong, LIU Yuanzhen, WANG Wenjing, et al. Influence of basalt fiber characteristic parameters on uniaxial tensile properties of concrete[J]. Acta Materiae Compositae Sinica, 2023, 40(5): 2897-2912 (in Chinese). [34] MA Y, DI H H, YU Z X, et al. Fabrication of silica-decorated graphene oxide nanohybrids and the properties of composite epoxy coatings research[J]. Applied surface science, 2016, 360: 936-945. doi: 10.1016/j.apsusc.2015.11.088 [35] 朱耿增, 李文静, 王晓明, 等. KH550改性微米二氧化硅的条件优化[J]. 中国粉体技术, 2020, 26(04): 33-37.ZHU Gengzeng, LI Wenjing, WANG Xiaoming, et al. Condition optimization of KH550 modified micron silica[J]. China Powder Science and Technology, 2016, 360: 936-945 (in Chinese). [36] 李刊, 魏智强, 乔宏霞, 等. 纳米SiO2改性聚合物水泥基材料性能试验研究[J]. 湖南大学学报(自然科学版), 2021, 48(11): 150-159.LI Kan, WEI Zhiqiang, QIAO Hongxia, et al. Experimental Study on Property of Polymer Cement Based Composite Modified by Nano-SiO2[J]. Journal of Hunan University(Natural Sciences), 2021, 48(11): 150-159 (in Chinese). -

点击查看大图

点击查看大图

计量

- 文章访问数: 38

- HTML全文浏览量: 64

- 被引次数: 0

下载:

下载: