Property assessment of wood-based photothermal evaporator with 2D+3D water supplying

-

摘要:

近年来,随着经济和社会快速发展,全球淡水资源需求量不断增加,导致全球淡水资源愈加紧缺。海水淡化是目前解决淡水短缺问题最好的方式之一。为实现海水的快速蒸发,本文制备了高度为20 mm、碳化层厚度为3 mm的脱木素轻木木基光热材料(CDW),通过SEM、FTIR、Raman光谱、UV-Vis-NIR吸收光谱等表征实验证实所制备的材料具有丰富的孔道和良好的吸光性能,有利于水的光热蒸发。构建2D+3D供水的小型光热蒸发器,采用吸水纸向光热材料供水,对所制备的CDW材料进行了光热水蒸发性能评价,所获得的平均蒸发速率为

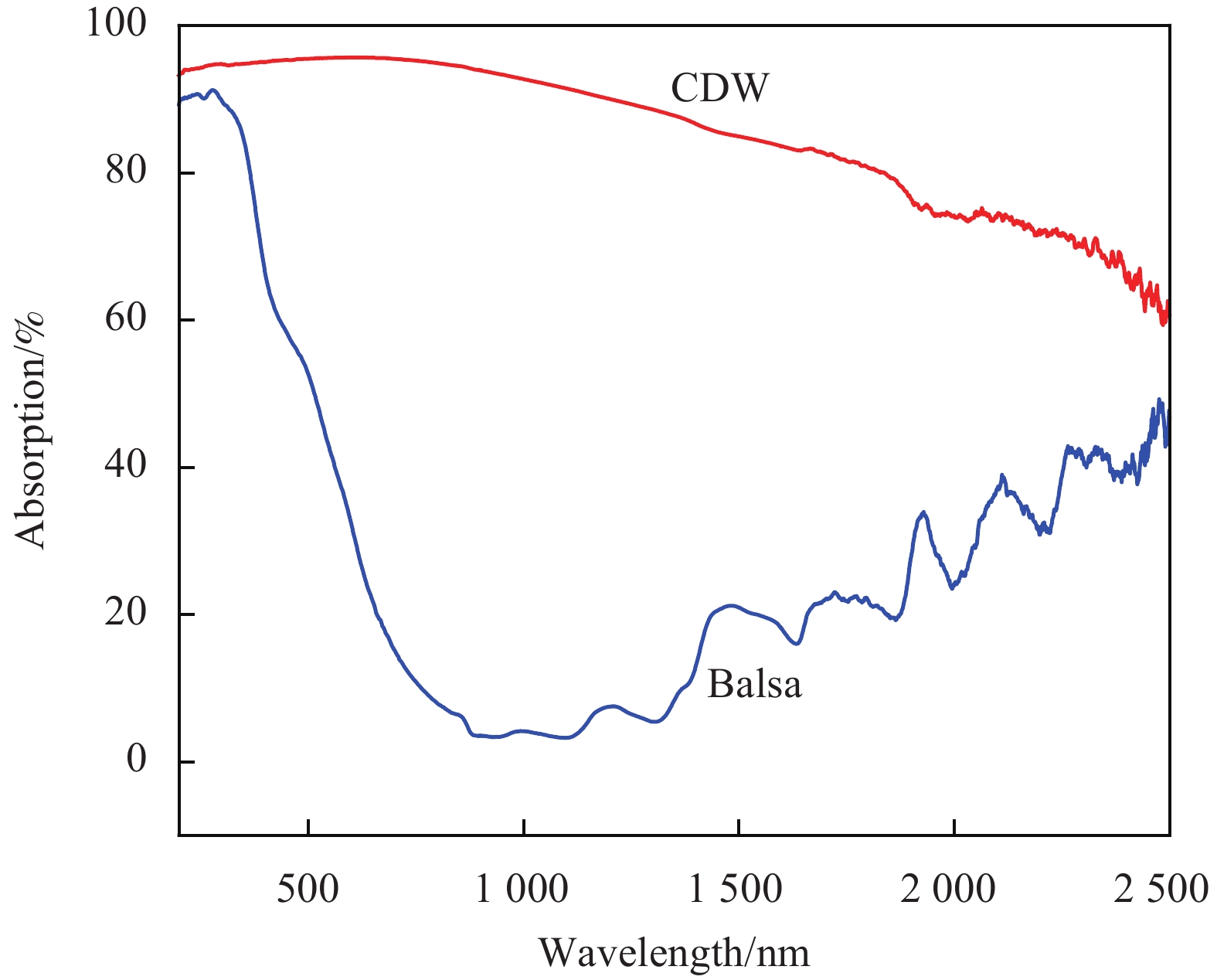

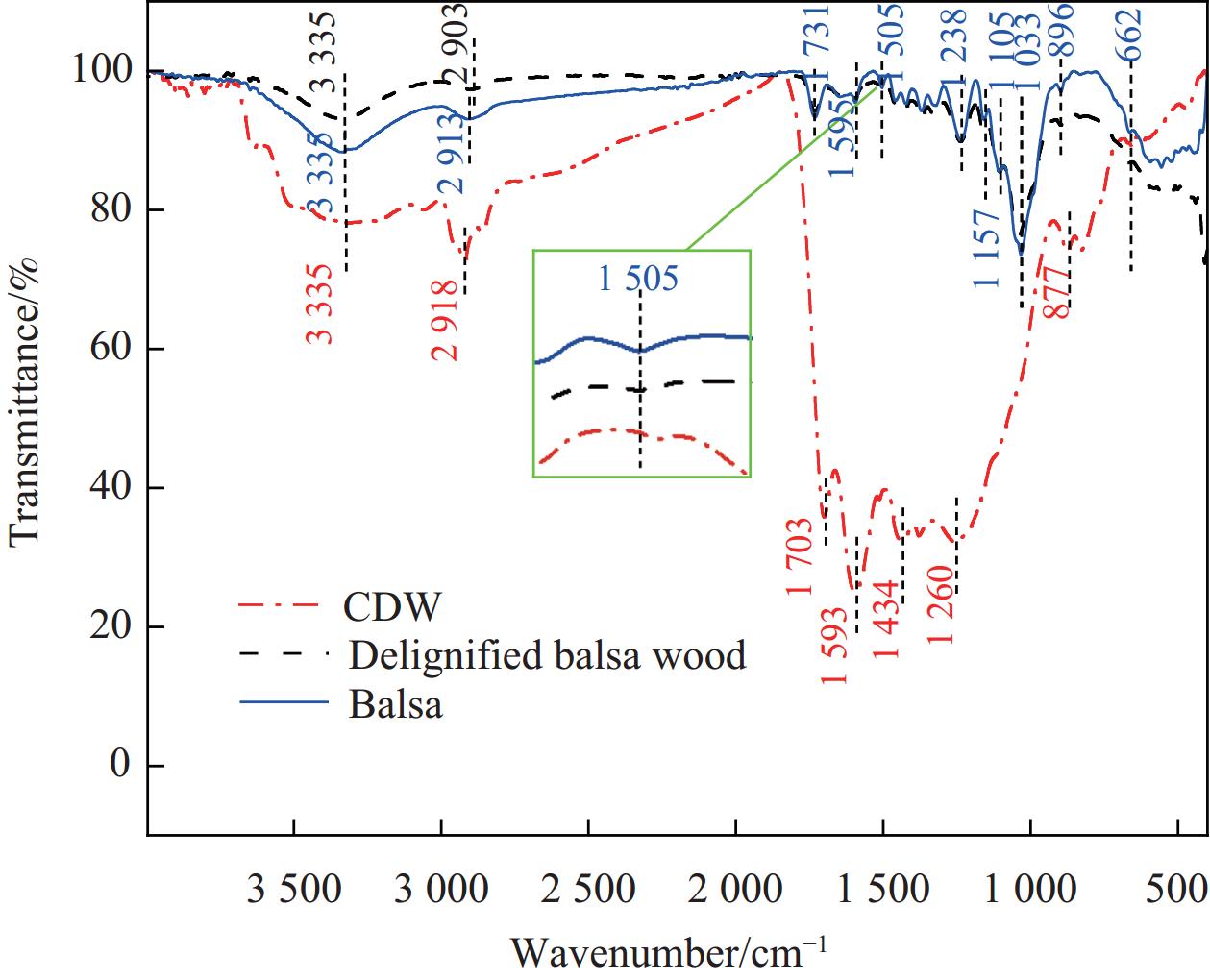

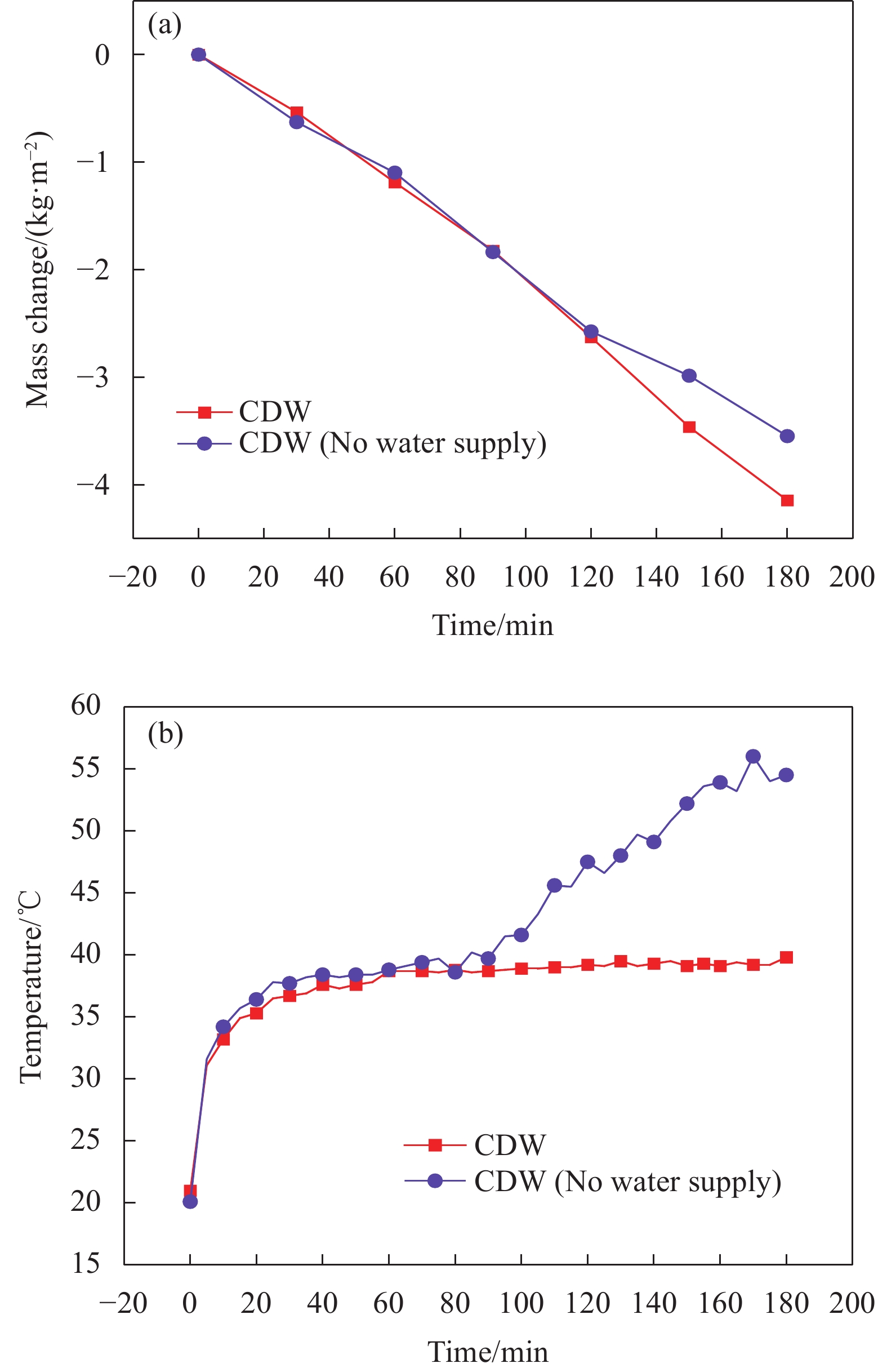

1.5310 kg/(m2·h),较碳化原木有明显提升。通过与无供水情况下的光热实验对比,证实吸水纸能够稳定给材料提供水源;通过与材料直接接触水面的3D供水情况作对比,证实了2D+3D供水结构的优越性。Abstract:In recent years, with the rapid development of the economy and society, the global demand for freshwater resources has been continuously increasing, leading to an increasing shortage of freshwater resources worldwide. Desalination of seawater is one of the best ways to solve the problem of freshwater shortage recently. In order to achieve rapid evaporation of seawater, a photothermal material based on a delignified balsa wood (CDW) was prepared, which had a height of 20 mm and a carbonization layer with thickness of 3 mm. Characterization experiments such as SEM, FTIR, Raman, and UV-Vis-NIR absorption spectrum have confirmed that the prepared material has abundant pores and high solar absorbance, which is beneficial for photothermal evaporation. A small photothermal evaporator with 2D+3D water supplying paths, transferring water to the photothermal material using absorbent paper, was used to evaluate the evaporation performance of CDW. The average evaporation rate of the prepared CDW material is

1.5310 kg/(m2·h). The evaporation rate is higher than the directly carbonized balsa wood. The comparison between the above results and that without water supply confirmed that the absorbent paper can steadily supply water to the material. The advantages of the 2D+3D water supplying structure are also observed when compared with the 3D water supplying structure.-

Keywords:

- balsa wood /

- evaporation /

- solar energy /

- carbonized wood /

- seawater desalination /

- composite

-

强韧、轻质复合多级结构材料在能源储存转化、环境治理、生物医学及航天等战略领域的应用越来越受关注[1-4],其中二维多级层状结构材料独特的电子限域效应赋予这类材料独特的物理、化学性质及丰富的科学内涵,在众多的领域都有重要的应用前景,特别是电子器件、光电器件等方面[5-6]。但人工合成材料不能像天然材料(贝壳、骨骼等)一样通过大量的相互作用对结构基元进行精准的调控,以致各结构基元在受力时应力不能有效传递导致材料断裂,影响力学性质、进而限制材料的应用[7-10]。

受自然界启发,研究工作者发展了大量具有强韧力学性能的二维层状结构材料,通常采取的方案是将高强度的无机纳米片与高柔性的有机聚合物通过层-层(LBL)组装、真空抽滤组装、空气诱导组装、冰模板等方法复合,得到类贝壳珍珠层的“砖-泥”结构[11-13]。如Shin等[14]将还原石墨烯氧化物(RGOF)与碳纳米管(SWNT)复合,用RGOF-SWNT复合体填充聚乙烯醇(PVA),获得了具有强韧性的RGOF-SWNT-PVA复合膜材料。Cao等[15]鉴于电磁屏蔽材料对厚度与力学性能的需要,选择Ti3C2Tx (MXene)与纤维素纳米纤维(CNF)为功能基元通过真空抽滤自组装的方法得到了高电磁屏蔽效率的复合膜材料,同时保证了材料的强度和韧性。Yoo等[16]通过静电组装氮化硼(BNNS)与明胶获得机械强度媲美人体骨密质的复合膜,且表现出优异的生物相容性,有望应用于组织工程与骨内植入领域。Woo等[17]利用交联剂(CA) 将片层氧化石墨烯(GO)通过化学键相连,形成仿贝壳结构的GO/CA层状复合薄膜,由于GO之间强大的共价键网络,复合薄膜表现出优异的力学性能,在航空航天、电子保护器、渗透膜等领域有潜在应用。过去研究者们采用纳米填充质增强聚合物薄膜的工作在拉伸强度上都有明显的提升,但断裂伸长率却变化不大甚至有所降低,导致复合薄膜的韧性提升被限制。究其原因在于结构基元之间可作为牺牲性成键的相互作用力较少,也将其归结为应力传递效率较低。综上所述,发展一种普适性的复合膜增强增韧方法仍然具有一定的挑战性[18-20]。

利用聚乙烯亚胺(PEI)修饰过后的纤维素纳米晶(PCNC)与蒙脱土纳米片(MMT)静电自组装得到MMT-PCNC组装体,将其分散到PVA水溶液中并搅拌均匀,随后倒入培养皿中利用溶剂蒸发法成膜。得到的MMT-PCNC/PVA复合膜拉伸强度与断裂伸长率同步增加,性能平衡。此法提高了材料的应力传递效率,有效增加了复合膜的拉伸强度;同时利用多重弱相互作用实现了断裂强度、断裂伸长率以及韧性的同步提升。

1. 实验材料及方法

1.1 原材料

蒙脱土粉末购买于浙江丰虹新材料有限公司,棉浆浆板购买于河北中国纸业公司,浓硫酸(98%)购买于北京化学试剂厂,聚乙烯醇(PVA,醇解度为87%~89%,AR)在阿拉丁上海有限公司购买,聚乙烯亚胺(PEI,Mw=10000,AR)购买于阿达玛斯试剂有限公司。实验过程中所用到的试剂都未经任何处理。

1.2 PCNC的制备

晶态纳米纤维素(Cellulose nanocrystals, CNC)悬浮液制备方法参考文献[21]制得,PEI修饰的CNC具体制备过程如下:取10 mL PEI水溶液(3.0wt%)加入到5 mL CNC悬浮液(3.0wt%)中,室温下连续搅拌1 h,随后用浓盐酸将混合溶液pH调到1.3以增强CNC与PEI之间的离子相互作用。继续搅拌十分钟后,将混合溶液高速离心20 min(13000 r/min),弃去上层清液,将沉淀用超纯水(18.2 MΩ·cm,Mill-Q Corp)洗涤三次,去掉未发生相互作用的游离PEI聚合物。最后再将沉淀加入水中,超声30 min重新分散,8000 r/min低速离心8 min,去掉CNC聚集体,收集上层清液得到单分散的CNC悬浮液,浓度为1.0wt%,命名为PCNC。

1.3 MMT悬浮液的制备

将2 g MMT粉末加入到500 mL超纯水中,连续溶解搅拌一周后静置72 h,收集上层清液得到剥离充分的MMT纳米片备用,浓度为0.2wt%。

1.4 MMT-PCNC组装体的制备

将MMT (0.2wt%)悬浮溶液逐滴加入到PCNC (1.0wt%)悬浮溶液中,持续搅拌24 h,得到MMT-PCNC组装体悬浮液,控制MMT与PCNC的质量比分别为1∶1、1∶2、1∶4。得到不同MMT、PCNC质量比的组装体,分别命名为1MMT-1PCNC、1MMT-2PCNC、1MMT-4PCNC,具体组成见表1。

1.5 MMT-PCNC/PVA复合膜的制备

将上述组装体悬浮液加入到PVA水溶液中,搅拌过夜,使组装体分散均匀,组装体含量控制为PVA质量的20%。将混合液置于直径为60 mm的聚乙烯塑料培养皿中室温干燥2天,得到柔性MMT-PCNC/PVA复合膜。

表 1 蒙脱土-纤维素纳米晶(MMT-PCNC)组装体的组成Table 1. Compositions of the montmorillonite-cellulose nanocrystal (MMT-PCNC) assembliesSample 1MMT-1PCNC 1MMT-2PCNC 1MMT-4PCNC Composition Mass fraction Mass ratio Mass ratio Mass ratio MMT 0.2% 1 1 1 PCNC 1.0% 1 2 4 1.6 样品性能及表征

SEM结果在JSM-6510A上获得,样品用导电胶粘贴于样品台表面,喷金60 s,电压设置为20 kV,电流设置为86 μA[22]。TEM结果在FEI Tecnai G2S-Twin上获得,样品滴于200 mm铜网上,室温晾干,加速电压为200 kV。溶液的Zeta电势常温下在Malvern Zetasizer Nano-ZS90上获得,样品浓度为0.1wt%[23]。傅立叶红外光谱(FTIR)测试在Bruker IFS 66v/S红外光谱仪上进行,扫描范围为 400~4000 cm−1,扫描速度为4 cm−1,制样过程参考文献[24],样品采用KBr压片,测试前置于60℃烘箱干燥1 h。力学性能测试在万能材料测试机(Instron 5944, UK)上进行,所用传感器为2000 N,拉伸速率为5 mm·min−1,夹距为10 mm。所有的样品测试均在常温下进行,样品长度约为50 mm、宽度约为5 mm、厚度约为0.3 mm,每组样品重复测量3次。

2. 结果与讨论

2.1 MMT-PCNC组装体的形成过程

图1(a)~1(c)分别为CNC、PCNC、MMT悬浮溶液置于室温下一个月之后的光学照片,从图中可以看到溶液基本都呈乳白色,无沉淀产生,说明所有的溶液均非常稳定。CNC由硫酸水解制得,表面含有磺酸基,带负电,Zeta电势分析得到CNC的电势值为−21.3 mV。加入PEI对其进行修饰后,在其表面引入了氨基,带正电,Zeta电势分析显示,PEI修饰过后的CNC (PCNC)电势值由−21.3 mV增加到35.4 mV。对MMT进行Zeta电势表征得到,其电势值为−31.3 mV,与PCNC所带电荷相反,数值匹配,为静电相互作用驱动形成MMT-PCNC组装体提供了必要的条件(图1(d))。

对修饰前后的CNC进行TEM表征,可以看到PCNC仍为棒状结构,长度与直径相比较CNC有明显的增加(图2)。经过统计,平均长度由164 nm增加到206 nm,平均直径由22 nm增加到26 nm (图3),说明PEI聚电解质已成功包覆于CNC的表面,形成PCNC。

将不同质量比的PCNC与MMT悬浮液混合,得到不同质量比的MMT-PCNC组装体悬浮液(1MMT-2PCNC、1MMT-1PCNC、1MMT-4PCNC),组装后发现三组不同配比的溶液均不同程度的发生聚沉,出现明显颗粒感,说明两种结构基元发生相互作用,且组装以后尺寸变大。以1MMT-2PCNC组装体为例,分别对组装前后的结构基元(MMT纳米片、PCNC纳米棒和1MMT-2PCNC组装体)进行TEM表征(图4)。如图4(a)所示,MMT呈分散、不规则片层结构,横向尺寸大约有100~1000 nm。在1MMT-2PCNC组装体的TEM图像中可以看到PCNC纳米棒附着于MMT纳米片的表面及边缘上,取向各异,在MMT表面上形成一层稠密的PCNC层(图4(c)及插图)。组装体的尺寸取决于原始MMT与PCNC的尺寸。

2.2 MMT-PCNC/PVA复合膜的形貌

图5为不同MMT-PCNC/PVA复合膜的SEM图像。如图所示,纯PVA薄膜截面致密,无有序结构。而由不同MMT、PCNC质量比的组装体所构成的复合膜均具有明显层状结构,为干燥成膜过程中MMT纳米片组装而成,由图5(c)、5(d)可见,层间具有明显PCNC附着(图中箭头所指),表明由于较强的静电相互作用,使MMT-PCNC组装体在成膜过程中得以有效保存,但由于层间还存在PVA分子,使得PCNC被部分覆盖,电镜下只观察到棒状尖端。图5(b)中,由于PCNC含量相对较少,未在截面处观察到明显PCNC结构。

2.3 MMT-PCNC/PVA复合膜的力学性能

对复合膜及纯PVA膜进行力学性能的测试(图6),测试结果总结于表2中。如图6所示,相比较纯PVA膜,MMT-PCNC作为增强质对复合膜的力学性能产生正影响,拉伸强度、断裂伸长率、韧性都不同程度的增加,杨氏模量均略有下降;其中,1MMT-1PCNC/PVA复合膜拉伸强度增长最为明显,为196%;1MMT-2PCNC/PVA复合膜的断裂伸长率、韧性增加最为明显(图6插图),分别为175%和900%。这些均得益于复合膜内部的弱相互作用[25-26]:MMT与PCNC之间通过静电组装,使组装体内部存在大量静电相互作用;MMT-PCNC组装体表面携带羟基和氨基,易与PVA分子侧基羟基形成氢键,增加了组装体与基体的界面相互作用[27]。这些弱相互作用在复合膜受到拉伸时首先断裂,充当牺牲性成键,使复合膜内部的MMT、PCNC产生滑移,断裂伸长率提高,进而提升韧性[28-29];其次,附着于MMT表面的PCNC通过静电与氢键相互作用将MMT与PVA连接,形成具有砖-泥结构的片层复合膜,当应力作用于膜上时,可在这些刚性结构基元之间有效传递,从而增加复合膜的强度。二者协同作用使材料单位应变时所需的应力减小,即刚性减小。

表 2 MMT-PCNC/PVA复合膜的力学性能Table 2. Mechanical properties of the MMT-PCNC/PVA hybrid filmsHybrid films of filler/PVA Elongation-at-break

/%Tensile strength

/MPaYoung’s modulus

/MPaToughness

/(MJ·m−3)PVA 28±3 26±3 101±13 3±1 1MMT-1PCNC/PVA 50±4 77±7 97±6 27±6 1MMT-2PCNC/PVA 77±4 63±8 100±3 30±9 1MMT-4PCNC/PVA 42±2 54±9 92±7 13±2 为了证实氢键的存在,对1MMT-2PCNC/PVA复合膜、纯PVA膜以及冷冻干燥的纯CNC进行了红外分析。如图7所示,在3000~3500 cm−1区域内出现的透过峰归属于PVA羟基伸缩振动,对比几个样品—OH的透过峰峰位可以发现,1MMT-2PCNC/PVA复合膜的峰位较纯CNC和PVA向低波数方向移动。过去研究表明[30-33],氢键的形成是导致羟基峰位发生偏移的主要原因。PEI修饰的CNC表面存在大量的氨基,MMT表面也有一定量的羟基,因此组装体1MMT-2PCNC与PVA之间势必会形成氢键,导致羟基峰发生移动。在1025 cm−1、1733 cm−1以及2945 cm−1波数处出现的峰分别归属于PVA的C—OH、C=O以及脂肪质C—H的伸缩振动[34],在1256 cm−1、1370 cm−1以及1446 cm−1处出现的峰分别归属于PVA的C—H、O—H的弯曲振动以及C—H非平面摇摆振动[35-37]。CNC在3382 cm−1、2915 cm−1、1649 cm−1及1055 cm−1处分别出现明显的透过峰,其中3382 cm−1、2915 cm−1归属于CNC的O—H与C—H的伸缩振动,1649 cm−1归属于CNC吡喃糖环的伸缩振动,而1055 cm−1归属于CNC中吸附了水分子的羟基伸缩振动[38]。

为了进一步研究自组装体改善聚合物薄膜力学性能的强韧化机制,人为破坏薄膜表面造成裂纹进行SEM测试。如图8(a)所示,裂纹均非直线传播,而是随着主裂纹的扩展出现了明显的微裂纹偏转(图8(a)中白色折线),说明MMT、PCNC、PVA之间存在强烈的相互作用,与之前分析一致。存在于片层之间的PCNC通过静电以及氢键作用将PVA和MMT相互连接,当应力施加时充当桥连剂,阻止裂纹扩展,随着应力增大,裂纹将沿着纳米纤维发生偏转,直至最终断裂,这一过程将导致裂纹路径增大,消耗更多的能量,实现复合材料的强韧化[26, 39]。

![]() 图 8 1MMT-2PCNC/PVA复合膜断裂形态的SEM图像和断裂示意图:(a) 断裂过程中裂纹扩展的SEM图像(白色折线表示裂纹偏转);(b) 断裂模型示意图Figure 8. SEM image of fracture morphologies of 1MMT-2PCNC/PVA hybrid films and the proposed fracture model: (a) SEM image of crack propagation occurred during fracture (White line indicate crack propagation); (b) Schematic illustration of the fracture model

图 8 1MMT-2PCNC/PVA复合膜断裂形态的SEM图像和断裂示意图:(a) 断裂过程中裂纹扩展的SEM图像(白色折线表示裂纹偏转);(b) 断裂模型示意图Figure 8. SEM image of fracture morphologies of 1MMT-2PCNC/PVA hybrid films and the proposed fracture model: (a) SEM image of crack propagation occurred during fracture (White line indicate crack propagation); (b) Schematic illustration of the fracture model通过观察组装体中MMT与PCNC的不同比例组装体对薄膜力学性能的影响发现,随着组装体中PCNC含量的增加,拉伸强度逐渐减弱,当MMT与PCNC比例为1∶4时,断裂伸长率也明显下降(图6),原因可能是随着PCNC含量的增加,组装体质量加重,更易发生聚沉,且当其分布于聚合物基体中时,不易分散均匀,导致复合膜力学性能下降[40-41]。

3. 结 论

(1) 组装体1MMT(蒙脱土)-1PCNC(纤维素纳米晶)和1MMT-2PCNC对PVA(聚乙烯醇)力学性能增强较为明显,拉伸强度分别增加196%、142%;断裂伸长率增幅分别为79%、175%;韧性增幅分别为800%、900%;复合膜杨氏模量略有下降。

(2) MMT-PCNC/PVA复合膜中存在多种弱相互作用(静电相互作用、氢键),给应力的传递提供了有效的途径,同时引起裂纹偏转,达到消耗能量的目的,使其在拉伸强度提高的同时断裂伸长率也得到提升。本文提出了一种新的合理设计构筑先进复合纳米材料的思路,即用自组装的方法制备组装体,并利用组装体中存在的大量弱相互作用提升聚合物薄膜的力学性质,从而拓展其应用。

-

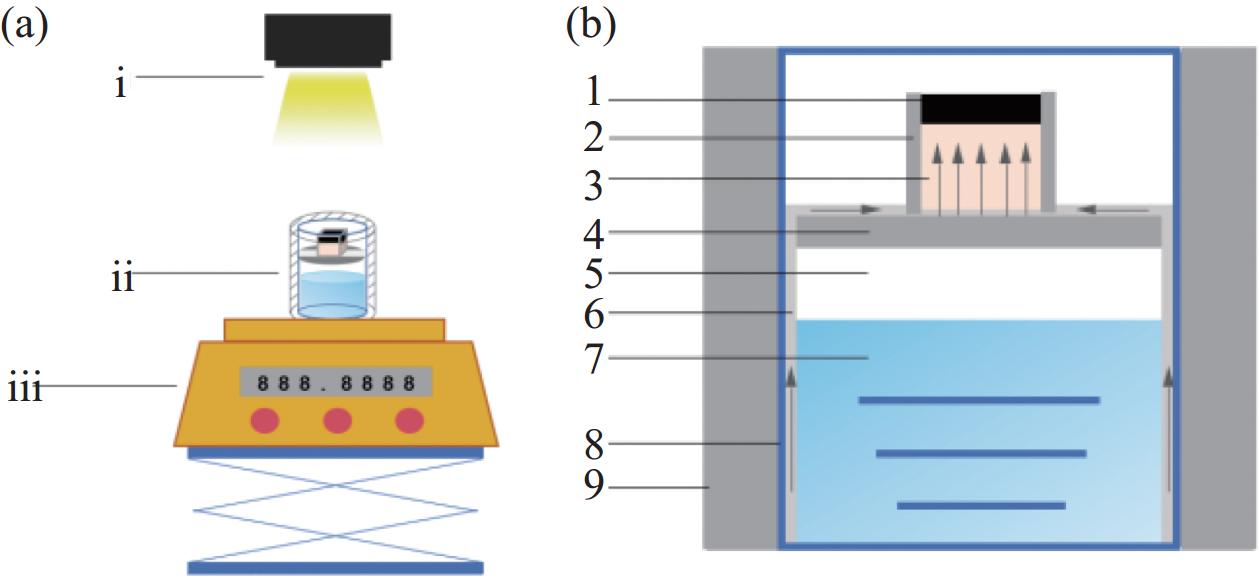

图 1 光热实验示意图:(a)装置整体;(b) 2D+3D供水通道示意图

i—Xenon lamp; ii—Small evaporator, iii—Electronic balance; 1—Carbonization layer; 2, 4, 9—Polystyrene (PS) insulated foam; 3—Material water transport layer; 5—Air; 6—Absorbent paper; 7—Water; 8—Beaker

Figure 1. Schematic diagram of photothermal experiment: (a) Apparatus; (b) Schematic diagram of 2D+3D water supply channel

表 1 CDW与其他文献工作报道的材料对比

Table 1 Comparison of materials reported by CDW and other literatures

Material Evaporation

rate/

(kg·(m2·h)−1)Evaporation

efficiency/%Ref. APDA-Wood 0.91 77.0 Zou et al. (2021)[37] CS-Wood 0.95 67.9 Wang et al. (2019)[39] F-Wood 1.05 72.0 Xue et al. (2020)[42] CPS 1.20 82.2 Lu et al. (2020)[41] Fe-D-Wood 1.30 73.0 Song et al. (2021)[36] ALD/

Chinese Ink-

coated Wood1.31 82.2 Yang et al. (2019)[40] PPy-Wood 1.33 83.0 Huang et al. (2019)[38] Wood@ATP 1.42 90.8 Chen et al. (2017)[43] CDW 1.53 91.5 This work Notes:APDA-Wood—Wood-based material modified with arginine polydopamine; CS-Wood—Candle soot-decorated wood; F-Wood—Wood treated with alcohol flame; CPS—Carbonized pencil shaving; Fe-D-Wood—Fe3O4/polyvinyl alcohol decorated delignified wood; ALD/Chinese Ink-coated Wood—Wood-based material loaded with Chinese ink; PPy-Wood—Wood loaded with polypyrrole; Wood@ATP—Aluminophosphate-treated wood. -

[1] 白炳林. 基于碳复合材料光热转换太阳能蒸汽海水淡化实验研究[D]. 呼和浩特: 内蒙古工业大学, 2020. BAI Binglin. Experimental study on seawater desalination of solar steam generation based on photothermal conversion of carbon composites[D]. Hohhot: Inner Mongolia University of Technology, 2020(in Chinese).

[2] WANG Z H, LIU Y M, TAO P, et al. Bio-inspired evaporation through plasmonic film of nanoparticles at the air-water interface[J]. Small, 2014, 10(16): 3234-3239. DOI: 10.1002/smll.201401071

[3] GHASEMI H, NI G, MARCONNET A M, et al. Solar steam generation by heat localization[J]. Nature Communications, 2014, 5(1): 4449. DOI: 10.1038/ncomms5449

[4] NI G, LI G, BORISKINA SVETLANA V, et al. Steam generation under one sun enabled by a floating structure with thermal concentration[J]. Nature Energy, 2016, 1(9): 16126. DOI: 10.1038/nenergy.2016.126

[5] 王哲, 王喜明. 木材多尺度孔隙结构及表征方法研究进展[J]. 林业科学, 2014, 50(10): 123-133. WANG Zhe, WANG Ximing. Research progress of multi-scale pore structure and characterization methods of wood[J]. Scientia Silvae Sinicae, 2014, 50(10): 123-133(in Chinese).

[6] 王小青, 戴鑫建, 管浩, 等. 木基太阳能界面蒸发器研究进展[J]. 林业工程学报, 2023, 8(3): 1-10. WANG Xiaoqing, DAI Xinjian, GUAN Hao, et al. Research progress of wood-based interfacial solar steam generator[J]. Journal of Forestry Engineering, 2023, 8(3): 1-10(in Chinese).

[7] 杨林涛. 木基光热转化材料的制备及海水淡化性能研究[D]. 哈尔滨: 东北林业大学, 2020. YANG Lintao. Preparation of wood-based photothermal conversion materials and their seawater desalination performance[D]. Harbin: Northeast Forestry University, 2020(in Chinese).

[8] 施镭, 周凝宇, 杨青峰, 等. 木基光热复合材料用于海水淡化的研究进展[J]. 化工新型材料, 2022, 50(S1): 66-74, 82. SHI Lei, ZHOU Ningyu, YANG Qingfeng, et al. Research progress on wood-based photothermal composite for seawater desalination[J]. New Chemical Materials, 2022, 50(S1): 66-74, 82(in Chinese).

[9] 于郑月. 植物光热转换材料的制备及水处理性能研究[D]. 哈尔滨: 哈尔滨师范大学, 2022. YU Zhengyue. Preparation of plant photothermal conversion materials and study on water treatment performance[D]. Harbin: Harbin Normal University, 2022(in Chinese).

[10] LI Y J, GAO T T, YANG Z, et al. Graphene oxide-based evaporator with one-dimensional water transport enabling high-efficiency solar desalination[J]. Nano Energy, 2017, 41: 201-209. DOI: 10.1016/j.nanoen.2017.09.034

[11] LI W G, ZHENG L, BERTELSMANN K, et al. Portable low-pressure solar steaming-collection unisystem with polypyrrole origamis[J]. Advanced Materials, 2019, 31(29): 1900720. DOI: 10.1002/adma.201900720

[12] LI X Q, XU W C, TANG M Y, et al. Graphene oxide-based efficient and scalable solar desalination under one sun with a confined 2D water path[J]. Proceedings of the National Academy of Sciences, 2016, 113(49): 13953-13958. DOI: 10.1073/pnas.1613031113

[13] ZHOU X Y, ZHAO F, GUO Y H, et al. A hydrogel-based antifouling solar evaporator for highly efficient water desalination[J]. Energy & Environmental Science, 2018, 11(8): 1985-1992.

[14] JIANG Q, GHOLAMI DERAMI H, GHIM D, et al. Polydopamine-filled bacterial nanocellulose as a biodegradable interfacial photothermal evaporator for highly efficient solar steam generation[J]. Journal of Materials Chemistry A, 2017, 5(35): 18397-18402. DOI: 10.1039/C7TA04834C

[15] ZHAO F, ZHOU X Y, SHI Y, et al. Highly efficient solar vapour generation via hierarchically nanostructured gels[J]. Nature Nanotechnology, 2018, 13(6): 489-495. DOI: 10.1038/s41565-018-0097-z

[16] STORER D P, PHELPS J L, WU X, et al. Graphene and rice-straw-fiber-based 3D photothermal aerogels for highly efficient solar evaporation[J]. ACS Applied Materials & Intefaces, 2020, 12(13): 15279-15287.

[17] GU Y J, WANG D N, GAO Y, et al. Solar-powered high-performance lignin-wood evaporator for solar steam generation[J]. Advanced Functional Materials, 2023, 33: 2306947. DOI: 10.1002/adfm.202306947

[18] 石晓桐, 郝晓峰, 孙德林, 等. 脱木质素处理对木材组分和物化性能的影响研究[J]. 林产工业, 2023, 60(5): 21-25, 44. SHI Xiaotong, HAO Xiaofeng, SUN Delin, et al. Effects of delignification treatment on wood composition and physicochemical properties[J]. China Forest Products Industry, 2023, 60(5): 21-25, 44(in Chinese).

[19] 刘慧滢, 杜金保, 印青, 等. 木材用于太阳能界面蒸发器的研究进展[J]. 化工新型材料, 2023, 51(S2): 588-595. LIU Huiying, DU Jinbao, YIN Qing, et al. Research progress on wood for solar interface evaporators[J]. New Chemical Materials, 2023, 51(S2): 588-595(in Chinese).

[20] 杨林涛, 李淑君, 张显权, 等. 太阳能驱动的木基表面水蒸气发生器的制备及性能测试[J]. 东北林业大学学报, 2020, 48(6): 100-104. DOI: 10.3969/j.issn.1000-5382.2020.06.019 YANG Lintao, LI Shujun, ZHANG Xianquan, et al. Preparation and performance test of solar-powered wood-based surface water vapor generator[J]. Journal of Northeast Forestry University, 2020, 48(6): 100-104(in Chinese). DOI: 10.3969/j.issn.1000-5382.2020.06.019

[21] WINDEISEN E, STROBEL C, WEGENER G. Chemical changes during the production of thermo-treated beech wood[J]. Wood Science and Technology, 2007, 41(6): 523-536. DOI: 10.1007/s00226-007-0146-5

[22] YAMAUCHI S, IIJIMA Y, DOI S. Spectrochemical characterization by FT-Raman spectroscopy of wood heat-treated at low temperatures: Japanese larch and beech[J]. Journal of Wood Science, 2005, 51(5): 498-506.

[23] AGARWAL U P, MCSWEENY J D, RALPH S A. FT-Raman investigation of milled-wood lignins: Softwood, hardwood, and chemically modified black spruce lignins[J]. Journal of Wood Chemistry and Technology, 2011, 31(4): 324-344. DOI: 10.1080/02773813.2011.562338

[24] STEWART D, WILSON H M, HENDRA P J, et al. Fourier-transform infrared and raman spectroscopic study of biochemical and chemical treatments of oak wood (quercus rubra) and barley (hordeum vulgare) straw[J]. Journal of Agricultural and Food Chemistry, 1995, 43(8): 2219-2225. DOI: 10.1021/jf00056a047

[25] YABLONOYITCH E. Statistical ray optics[J]. Journal of the Optical Society of America, 1982, 72(7): 1917-1983.

[26] YABLONOYITCH E. Intensity enhancement in textured optical sheets for solar cells[J]. Conference Record of the IEEE Photovoltaic Specialists Conference, 1982, 29(2): 501-506.

[27] WANG C Y, ZHANG M, XU Y, et al. One-step synthesis of unique silica particles for the fabrication of bionic and stably superhydrophobic coatings on wood surface[J]. Advanced Powder Technology, 2014, 25(2): 530-535. DOI: 10.1016/j.apt.2013.08.007

[28] TRAORE M, KAAL J, MARTINEZ CORTIZAS A. Differentiation between pine woods according to species and growing location using FTIR-ATR[J]. Wood Science and Technology, 2018, 52(2): 487-504. DOI: 10.1007/s00226-017-0967-9

[29] CONG M Y, WANG F, ZHANG Y L, et al. An array structure of polydopamine/wood solar interfacial evaporator for high-efficiency water generation and desalination[J]. Solar Energy Materials and Solar Cells, 2023, 249: 112052. DOI: 10.1016/j.solmat.2022.112052

[30] LI Y Y, FU Q L, ROJAS R, et al. Lignin-retaining transparent wood[J]. ChemSusChem, 2017, 10(17): 3445-3451. DOI: 10.1002/cssc.201701089

[31] ZHANG M, SHI L, DU X L, et al. Janus mesoporous wood-based membrane for simultaneous oil/water separation, aromatic dyes removal, and seawater desalination[J]. Industrial Crops and Products, 2022, 188: 115643. DOI: 10.1016/j.indcrop.2022.115643

[32] 宋莲. 木材表面亲疏水调控策略及高效太阳能蒸发材料的制备[D]. 南京: 南京林业大学, 2022. SONG Lian. Wood surface wettability control strategy and high efficiency solar evaporative materials preparation[D]. Nanjing: Nanjing Forestry University, 2022(in Chinese).

[33] DELDICQUE D, ROUZAUD J N, VELDE B. A Raman-HRTEM study of the carbonization of wood: A new Raman-based paleothermometer dedicated to archaeometry[J]. Carbon, 2016, 102: 319-329. DOI: 10.1016/j.carbon.2016.02.042

[34] ÖZGENC Ö, DURMAZ S, BOYACI I H, et al. Determination of chemical changes in heat-treated wood using ATR-FTIR and FT Raman spectrometry[J]. Spectrochimica Acta Part A: Molecular and Biomolecular Spectroscopy, 2017, 171: 395-400. DOI: 10.1016/j.saa.2016.08.026

[35] JIN K X, WANG K, CUI H S, et al. Application of Raman spectroscopy to the research on lignin[J]. Scientia Silvae Sinicae, 2018, 54(3): 144-151.

[36] SONG L, ZHANG X F, WANG Z, et al. Fe3O4/polyvinyl alcohol decorated delignified wood evaporator for continuous solar steam generation[J]. Desalination, 2021, 507: 115024. DOI: 10.1016/j.desal.2021.115024

[37] ZOU Y, YANG P, YANG L, et al. Boosting solar steam generation by photothermal enhanced polydopamine/wood composites[J]. Polymer, 2021, 217: 123464. DOI: 10.1016/j.polymer.2021.123464

[38] HUANG W, HU G, TIAN C, et al. Nature-inspired salt resistant polypyrrole-wood for highly efficient solar steam generation[J]. Sustainable Energy & Fuels, 2019, 3(11): 3000-3008.

[39] WANG Z, YAN Y, SHEN X, et al. Candle soot nanoparticle-decorated wood for efficient solar vapor generation[J]. Sustain Energy Fuels, 2019, 4(1): 354-361.

[40] YANG H C, CHEN Z, XIE Y, et al. Chinese ink: A powerful photothermal material for solar steam generation[J]. Advanced Materials Interfaces, 2019, 6(1): 1801252.

[41] LU Y, DAI T, FAN D, et al. Turning trash into treasure: Pencil waste-derived materials for solar-powered water evaporation[J]. Energy Technology, 2020, 8(10): 2000567. DOI: 10.1002/ente.202000567

[42] XUE G, LIU K, CHEN Q, et al. Robust and low-cost flame-treated wood for high-performance solar steam generation[J]. ACS Applied Materials & Interfaces, 2017, 9(17): 15052-15057.

[43] CHEN T, WU Z, LIU Z, et al. Hierarchical porous aluminophosphate-treated wood for high-efficiency solar steam generation[J]. ACS Applied Materials & Interfaces, 2020, 12(17): 19511-19518.

-

目的

随着经济和社会的快速发展,全球淡水资源需求量不算增加,导致全球淡水资源严重短缺。海水淡化技术成为解决目前的淡水资源短缺问题的重要途径,本文通过制备性能良好的光热材料、设计具有2D+3D结合供水结构的小型蒸发器来实现高效率的水蒸发。

方法①材料的制备:配制亚氯酸钠溶液作为脱木素溶液,将规格为20×20×20 mm的轻木木块放入盛有脱木素溶液的锥形瓶中,之后将锥形瓶放入预热好的油浴锅中90℃加热1小时,瓶口用保鲜膜封住。1小时后取出木块,用去离子水和无水乙醇反复洗涤,于40℃烘箱中干燥48小时后取出,得脱木素木块。用铝箔包住一定范围的木块侧面,于500℃的高温加热板表面对脱木素木块的顶表面进行碳化,得碳化脱木素轻木木基光热材料(CDW)。②具有2D+3D供水结构的小型蒸发器的设计:将浸满水的材料用PS泡沫包裹保温,仅留出上、下表面。小烧杯中盛有去离子水,在水面上方10 mm处放入PS泡沫隔热板。将两张吸水纸沿杯壁插入小烧杯的水中(二者直线距离为小烧杯的直径),高出烧杯中隔热板的部分向隔热板中心弯折,水平重叠搭接。将保温好的材料放入隔热板表面的吸水纸重叠搭接处,隔热板及其下方的空气层共同组成蒸发器的隔热层,材料的非碳化部分作为3D供水通道,吸水纸作为2D供水通道,材料表面碳化部分为吸光层。将整个烧杯放置于电子天平上,烧杯外部由PS泡沫进行保温。

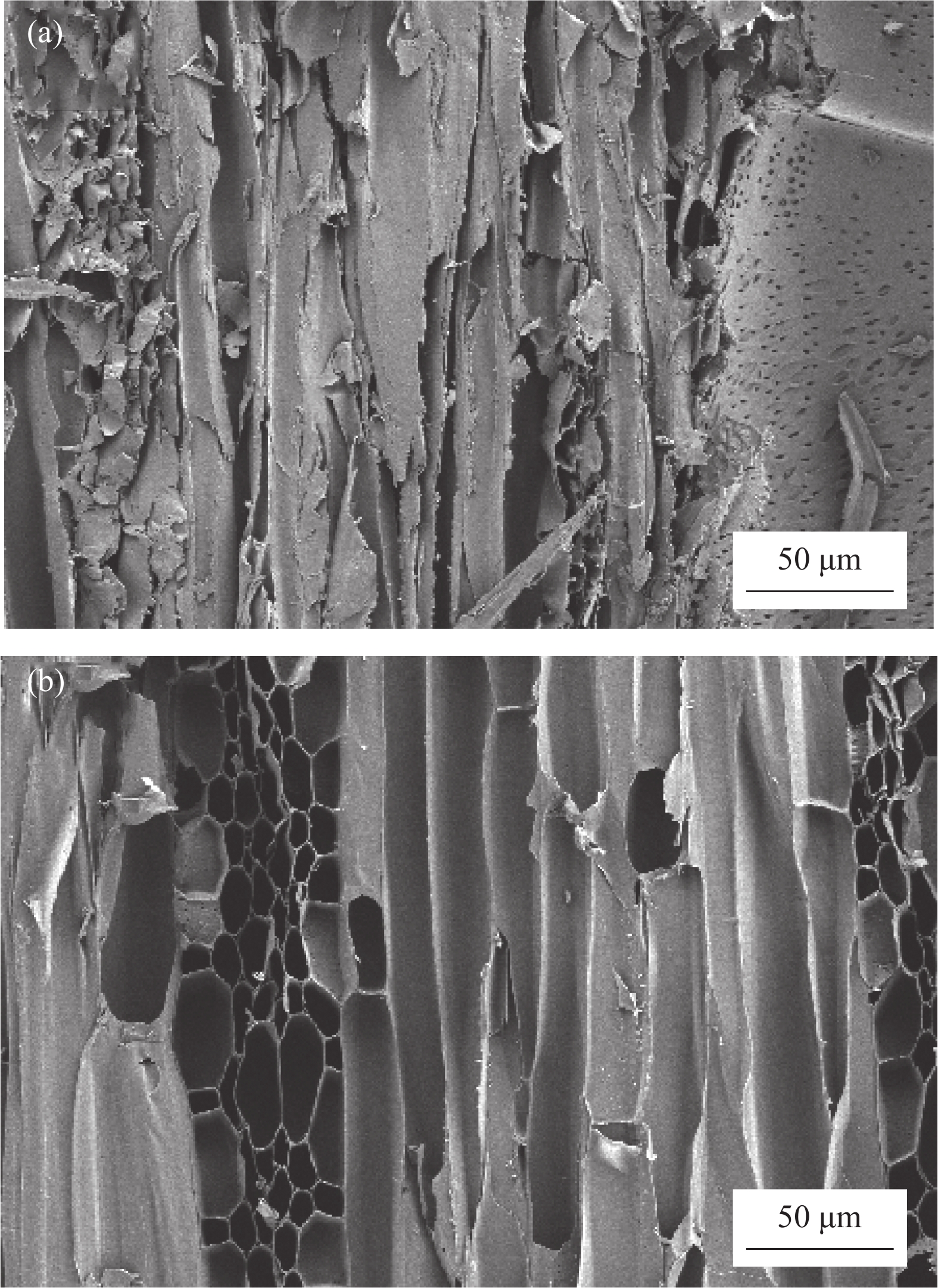

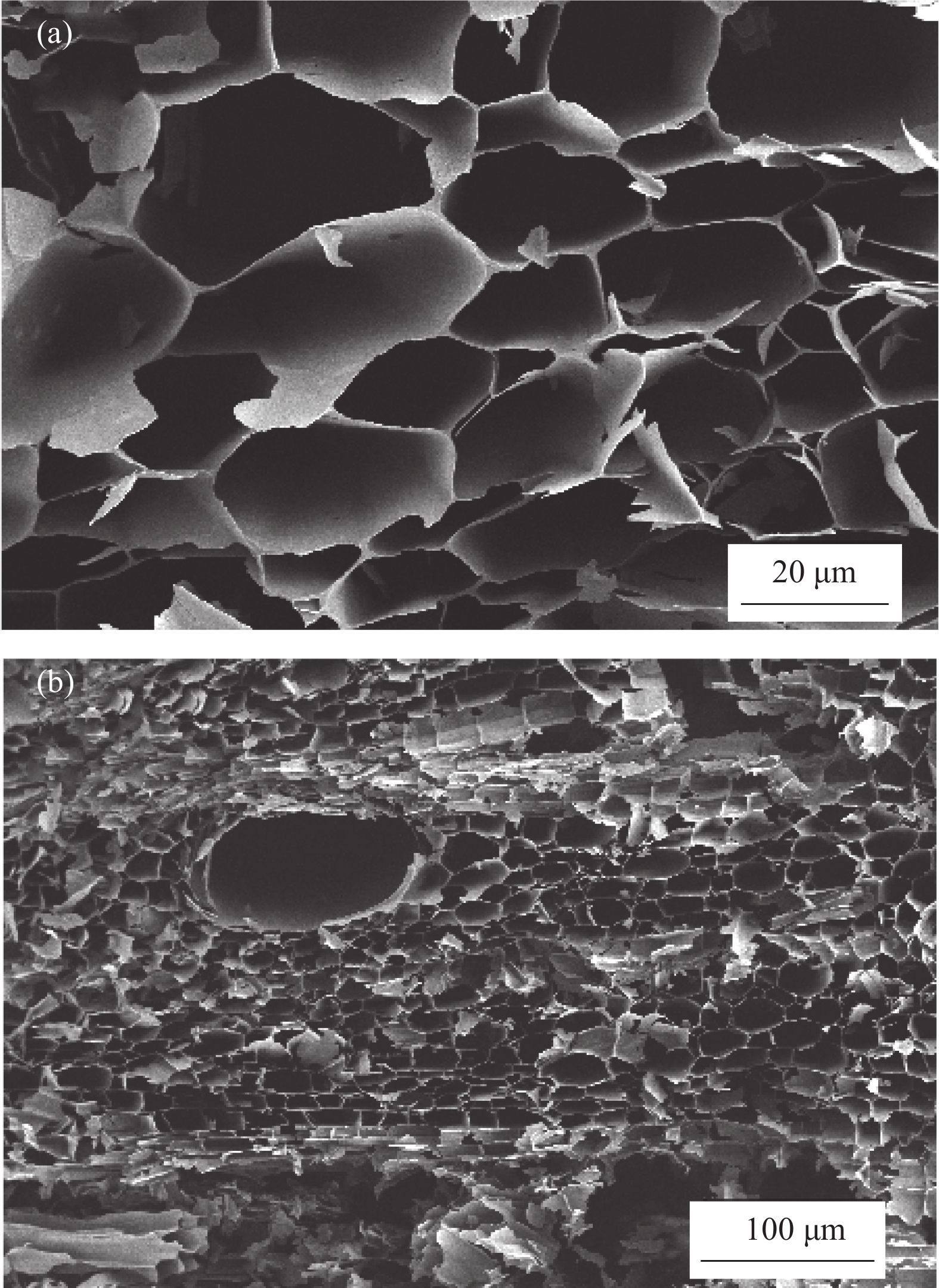

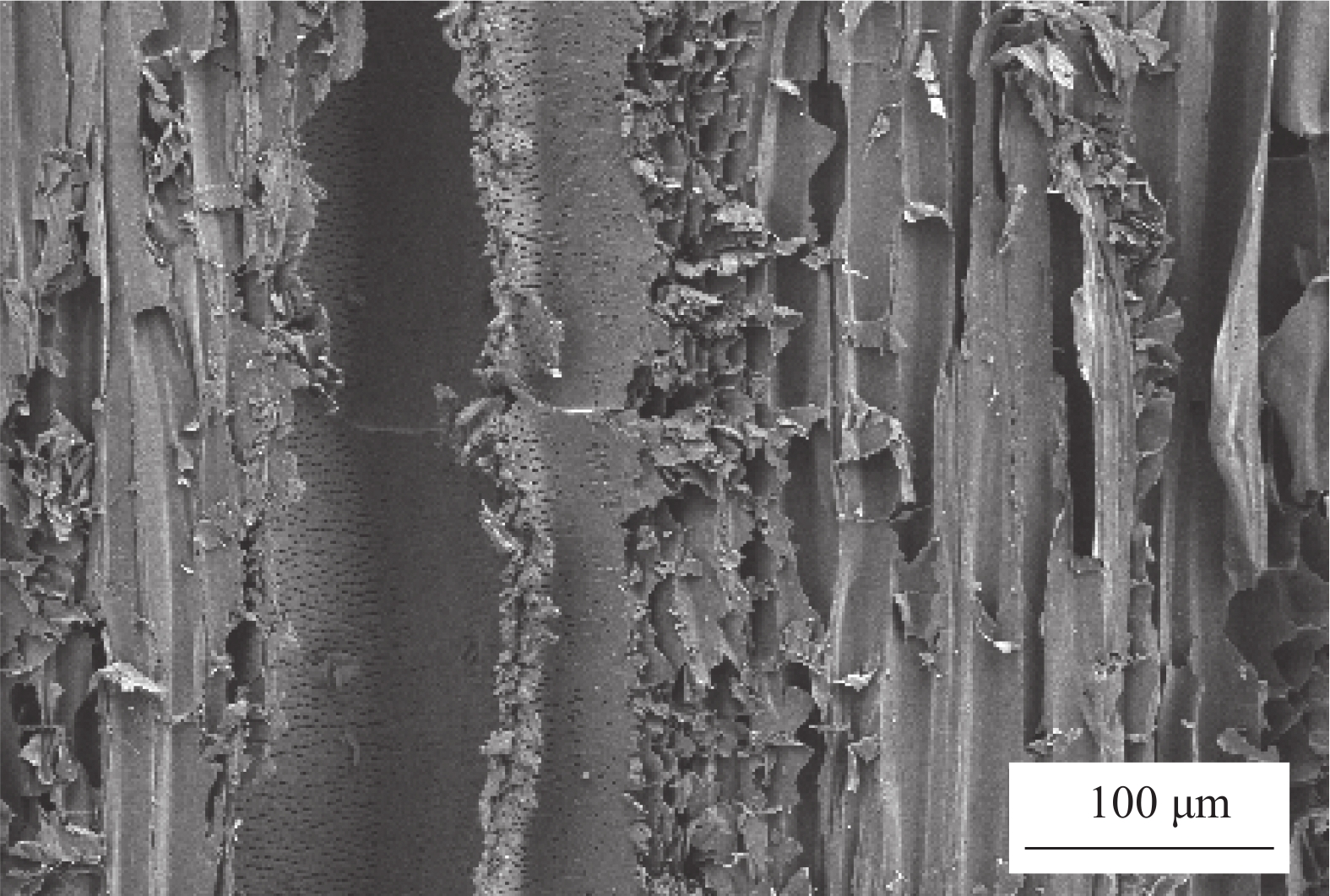

结果①SEM、FT-IR、Uv-Vis-NIR、Raman光谱四种表征表明制备的碳化脱木素轻木木基光热材料仍保留轻木的部分导管及大小孔结构,且毛细管作用增强,有利于输水;材料的碳化层具有缺陷结构且疏水,有利于吸光。②采用具有2D+3D供水结构的小型蒸发器进行光热水蒸发实验,计算发现水蒸发所需的潜热较低,所得光热蒸发速率较高,达1.5310 kg/(m·h),光热转换效率较高,达91.5%。通过与无供水情况下的光热实验对比,证实吸水纸能够稳定给材料提供水源;通过与原木、脱木素木、碳化原木的光热水蒸发实验作对比,证实了CDW具有良好的输水性、吸光性及高光热转换能力;通过与材料直接接触水的3D供水情况作对比,证实了2D+3D供水结构具有一定的优越性。与其他文献工作报道的材料对比,本文的蒸发器在蒸发速率和蒸发效率方面具有一定优势。

结论利用本文制备的材料,采用2D+3D供水结构,实现了较高的光热蒸发速率,达1.5310 kg/(m·h),材料所需的水蒸发潜热较低,光热转换效率达91.5%。具有一定的优越性。与其他文献的材料对比,本文依托CDW所建立的2D+3D供水结构蒸发器在蒸发速率和蒸发效率方面具有一定优势,有必要进一步开展循环运行实验及脱盐实验并用于海水淡化。

下载:

下载: