Fire resistance of waterborne intumescent fire-retardant coatings reinforced by fly ash-chitosan composites

-

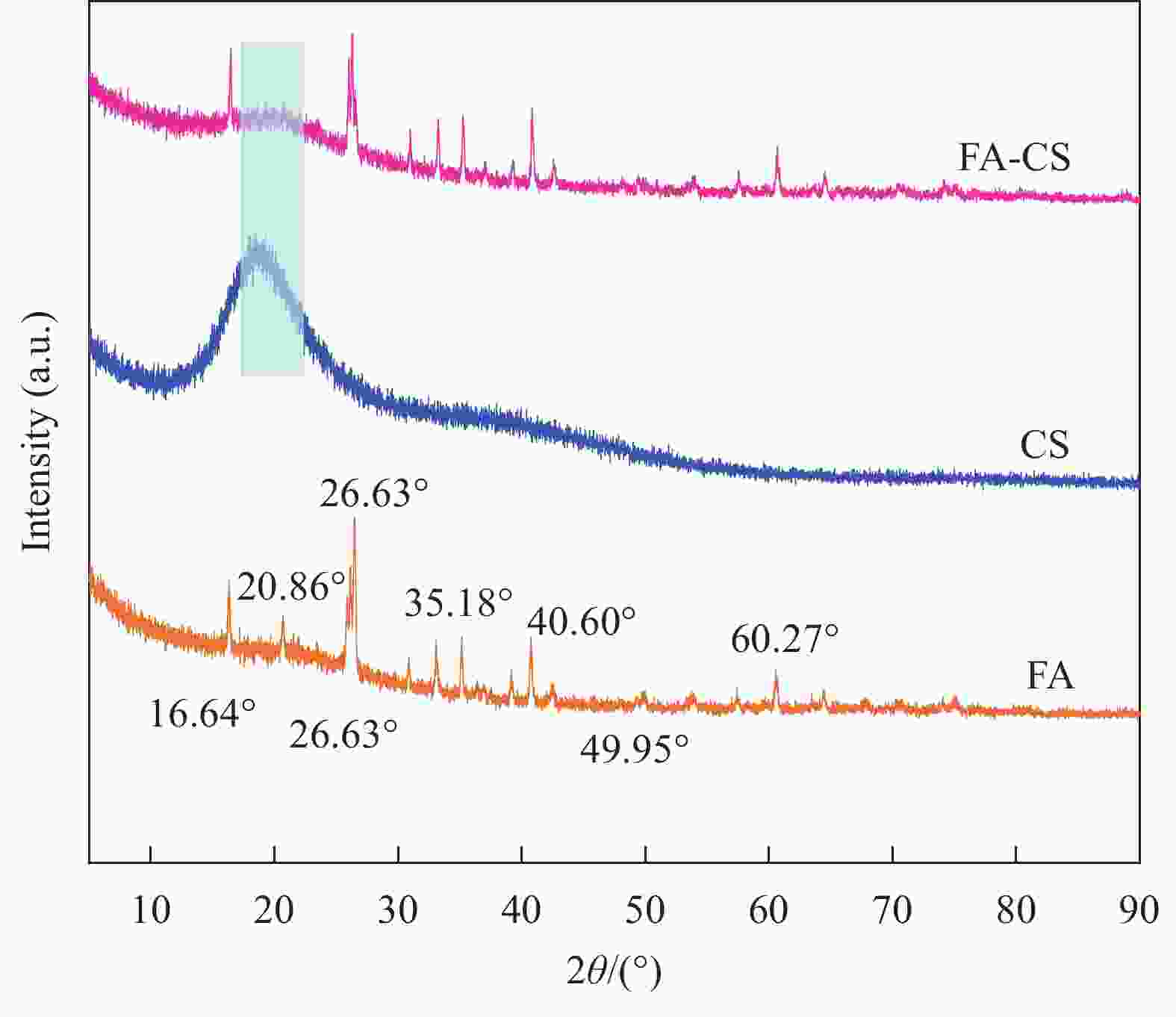

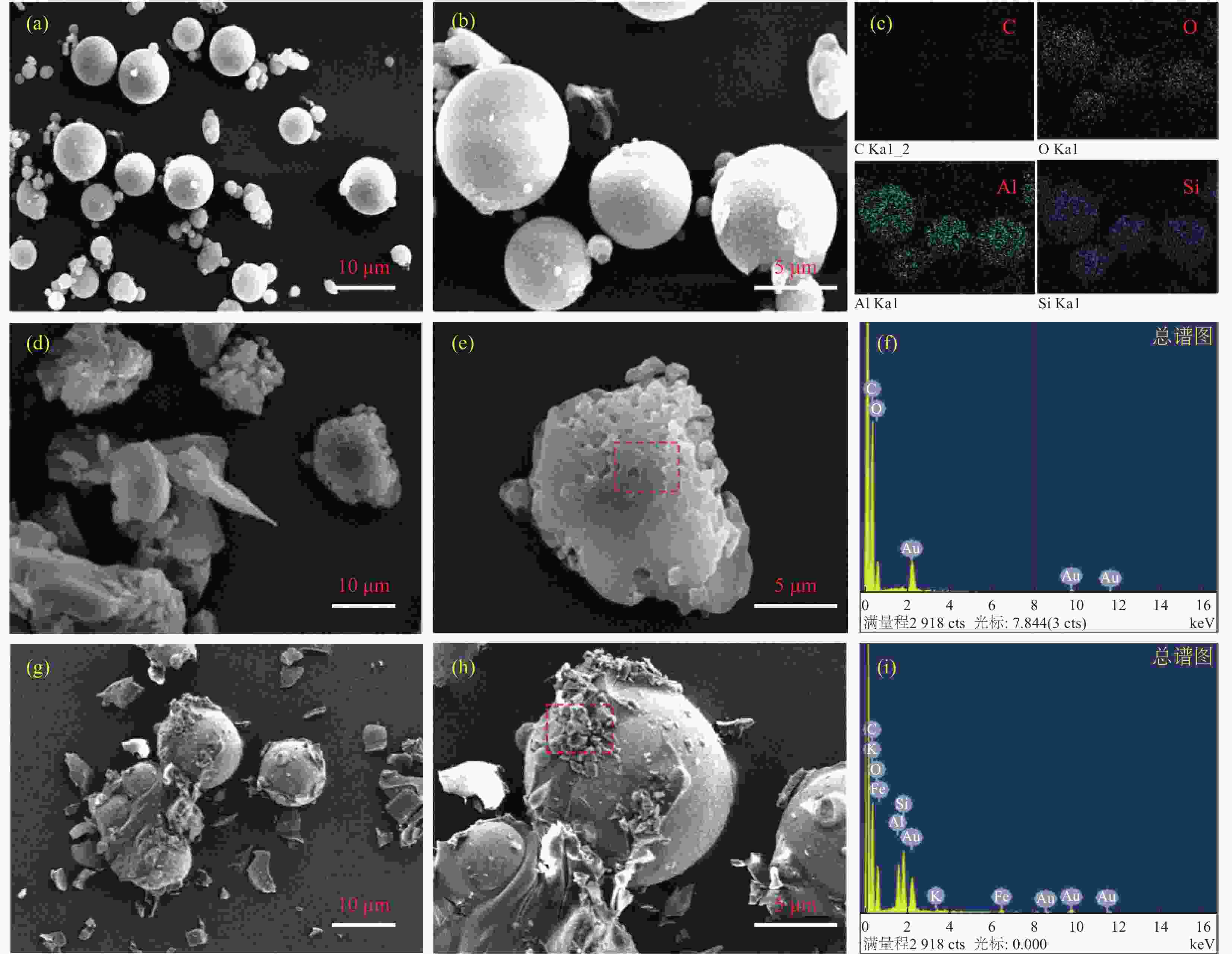

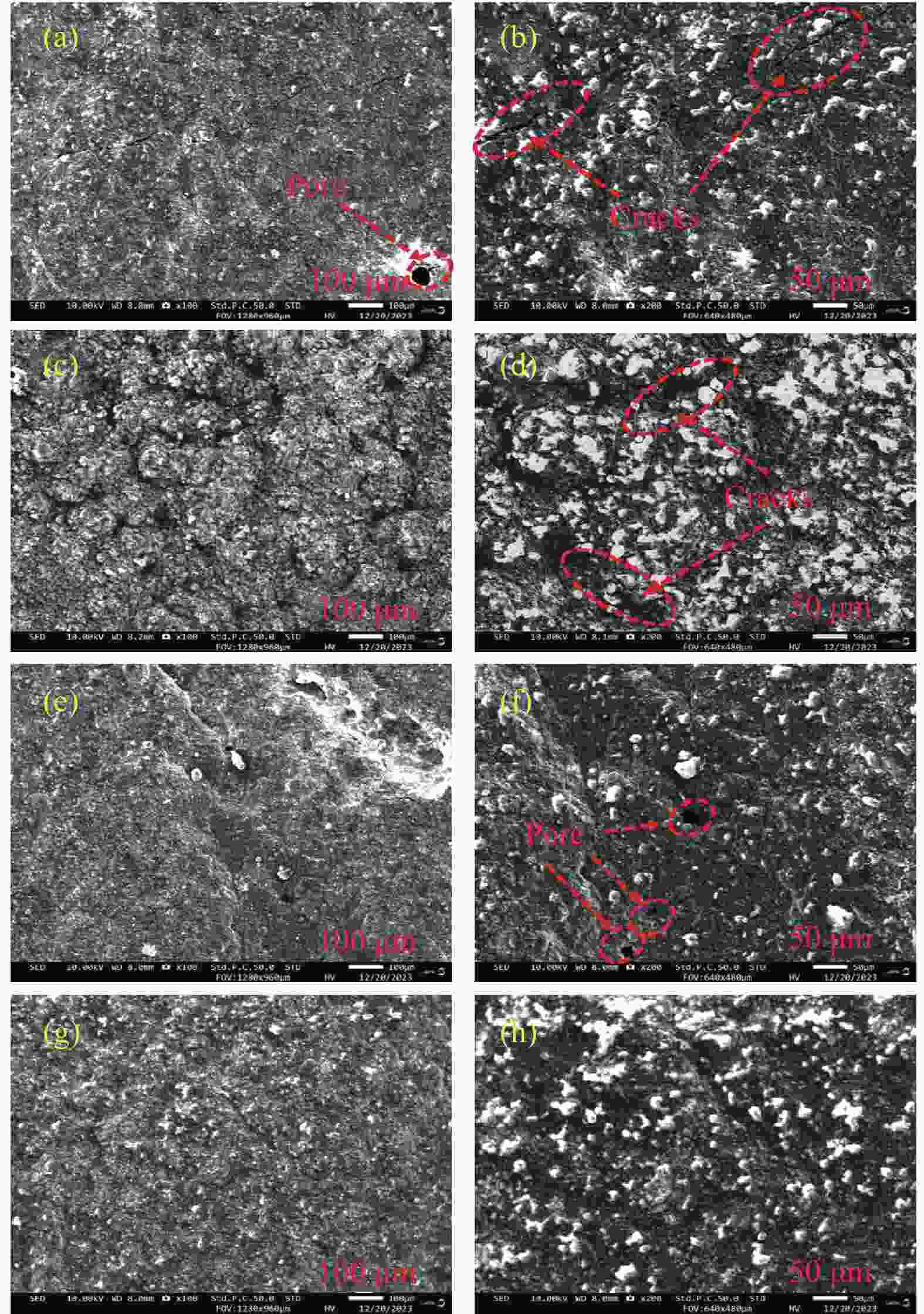

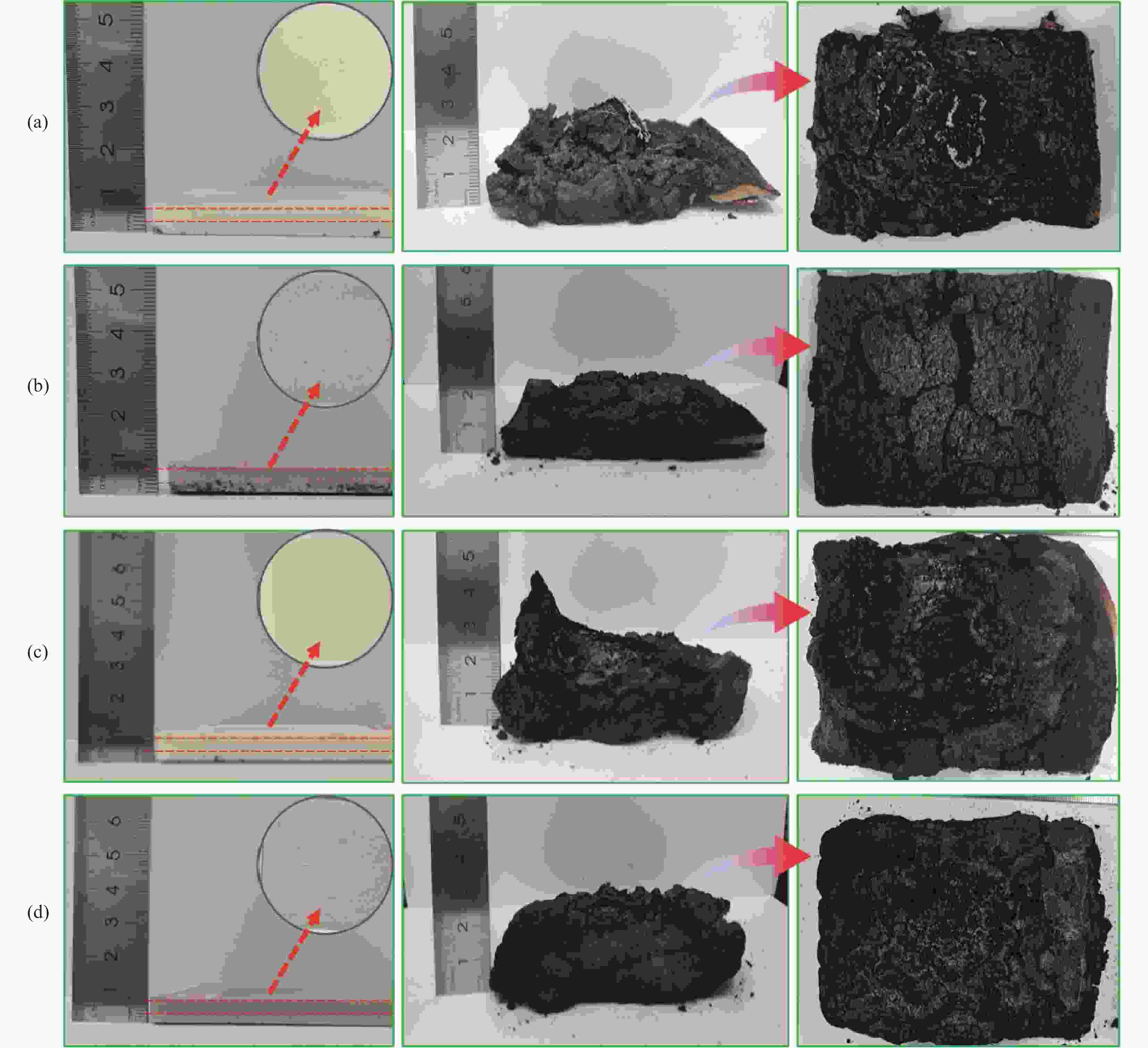

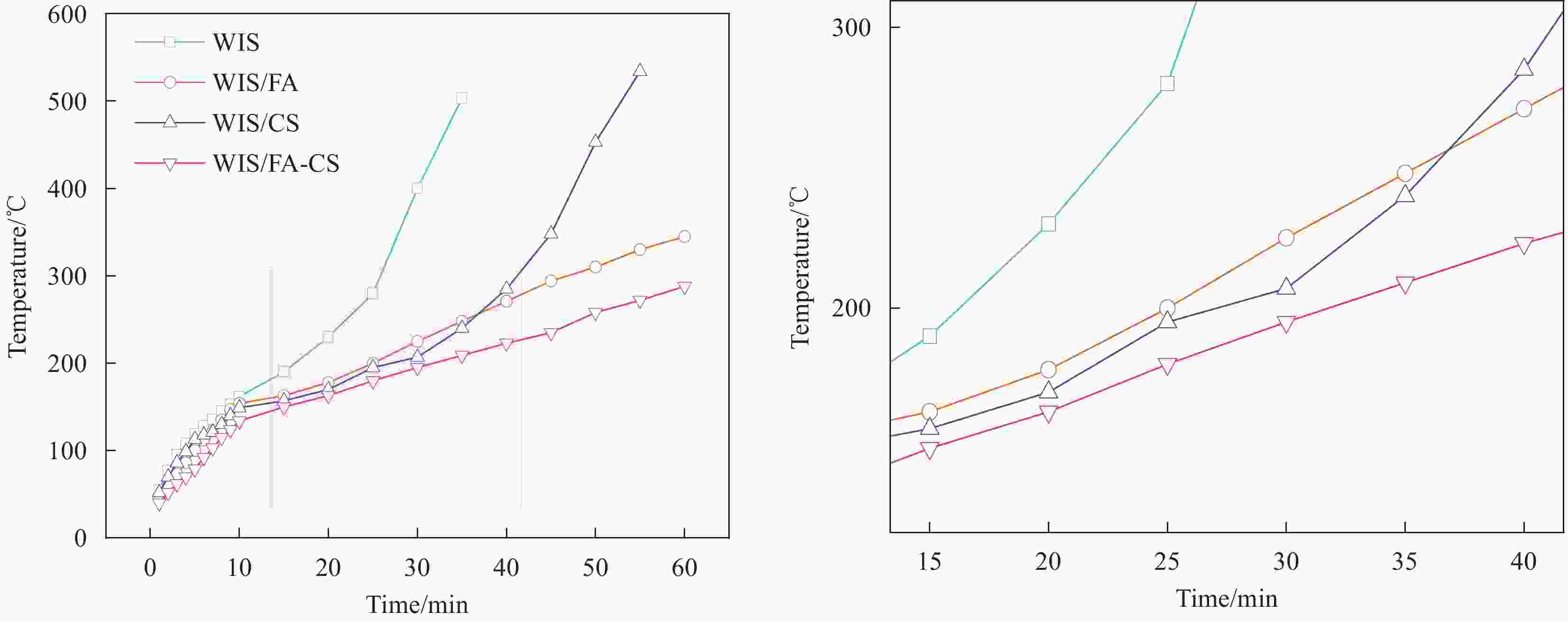

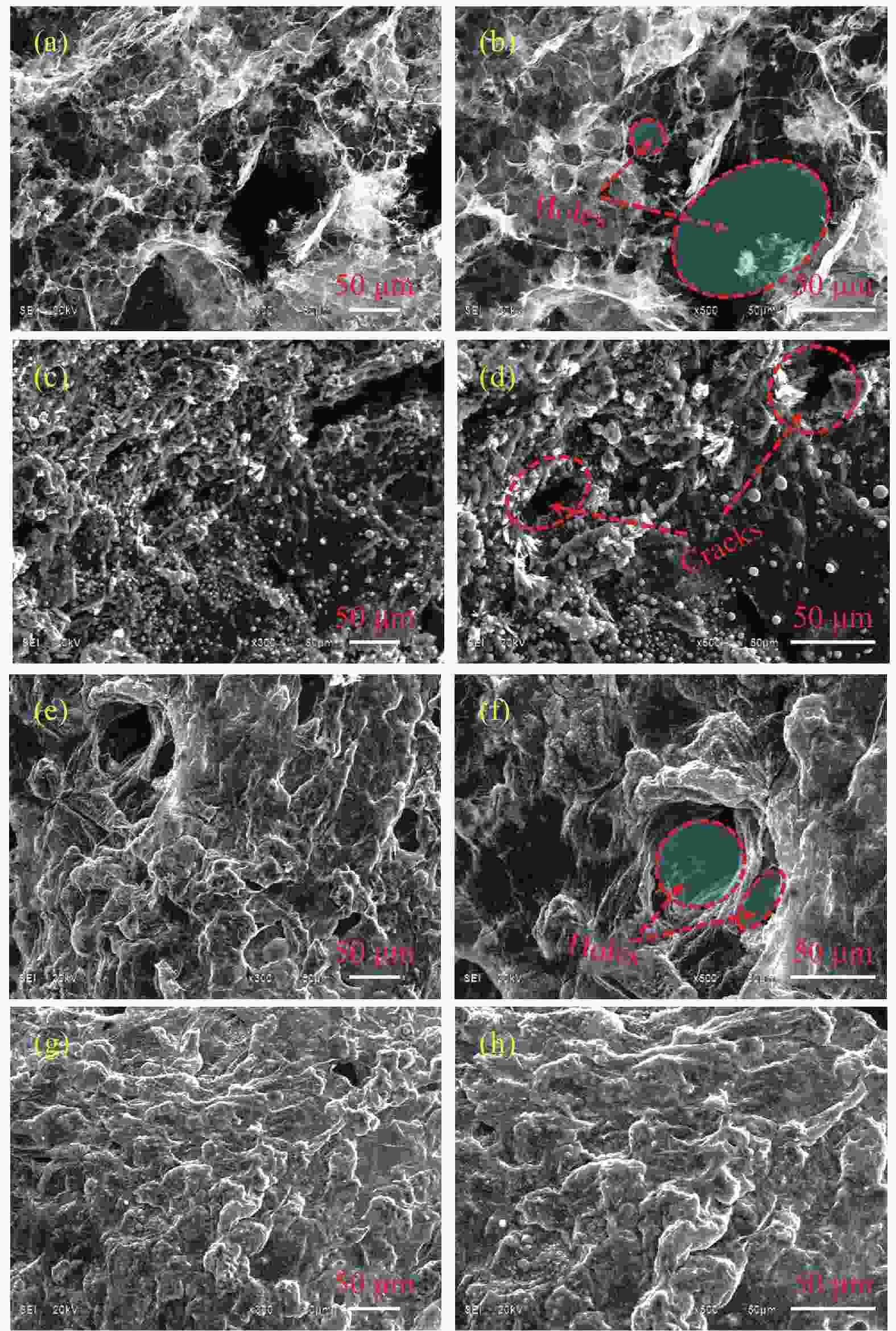

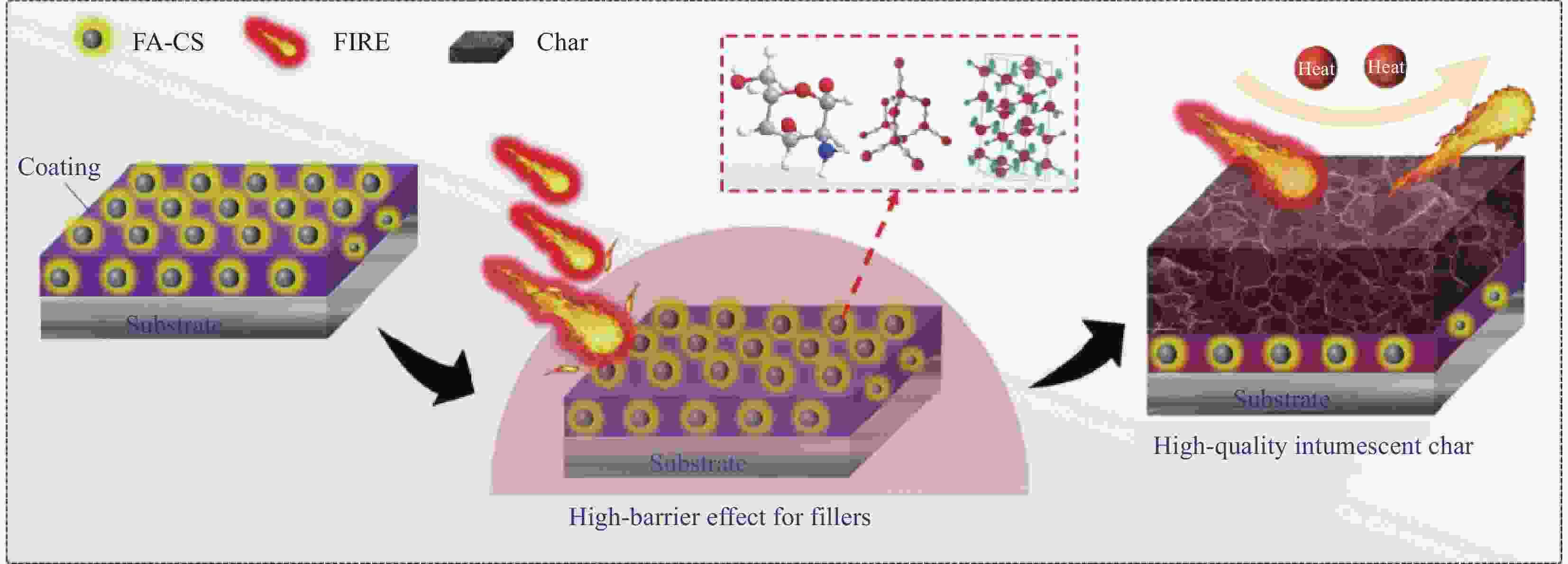

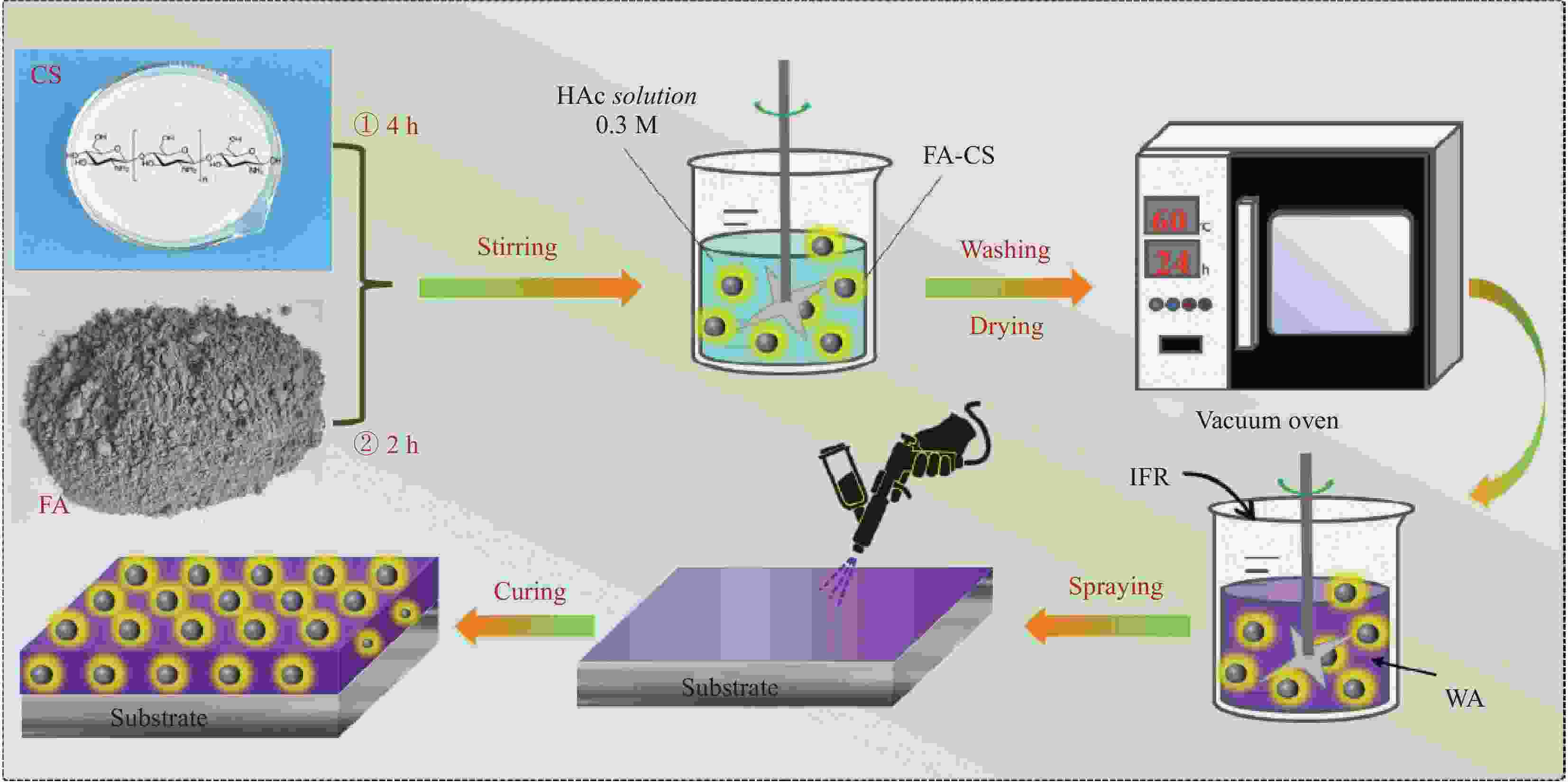

摘要: 以粉煤灰(FA)和壳聚糖(CS)等废弃物为原料,制备了FA-CS复合阻燃填料,并将其引入水性膨胀型防火涂料体系中,以强化涂层的耐火极限和隔热性能,采用FT-IR、XRD、SEM等技术对复合阻燃填料进行观察分析。再通过大板实验、背温曲线和微观组织结构等考察了涂层的耐火性能和隔热能力,从而揭示其防火阻燃机制。大板实验显示在外焰温度维持在1000±50 ℃,燃烧时间为60 min的前提下,相比水性膨胀体系(WIS)、FA/WIS、CS/WIS涂层,FA-CS/WIS涂层具有较高的膨胀倍率(10.2倍)和更低的背面温度(279 ℃),表现出优异的阻隔热量传递和抗火焰冲刷的能力。此外,采用SEM技术对涂层膨胀层表面形貌进行分析,结果显示相比其他涂层,FA-CS/WIS涂层具有更致密光滑的表面。FA-CS/WIS涂层表现出优异的阻燃耐火性能,主要归因于:(a)涂层材料中膨胀阻燃体系的酸化、气化等反应,逐渐形成膨胀层;(b)CS参与了膨胀层的成炭反应,促进了膨胀倍率的提升;(c)具有优异耐热性能的FA在燃烧后的残炭中作为耐温材料填补在膨胀层的孔隙中,增加了膨胀层的热稳定性和阻隔能力。Abstract: Based on the wastes of fly ash (FA) and chitosan (CS), FA-CS composite flame-retardant filler was prepared and introduced into the water-based intumescent fireproof coating system to strengthen the fire-resistant limit and heat-insulating property of the coating. The FA-CS composite was observed and characterized by the techniques of FT-IR, XRD, SEM, etc. Then the fire resistance and heat insulation ability of the coating were evaluated by large-plate experiments, back-temperature curves and microstructure and thus revealed its fire-retardant and flame-retardant mechanism. Large-plate experiments showed that on the premise that the external flame temperature was maintained at 1000±50℃ and the combustion time is 60 min, compared with the Waterborne intumescent system(WIS), FA/WIS, and CS/WIS coatings, the FA-CS/WIS coating exhibited a higher expansion multiplier (10.2 times) and lower backside temperature (279℃), thus demonstrating excellent ability to block the heat transfer and flame washout. In addition, SEM analysis of the surface morphology of the intumescent layer of the coating showed that the FA-CS/WIS coating had a denser and smoother surface compared with the other coatings. In brief, The excellent flame retardant and fire-resistant properties of the FA-CS/WIS coating were mainly attributed to (a) the acidification and gasification of the intumescent flame retardant system of the coating material, which gradually formed the intumescent layer; (b) the participation of chitosan in the charcoal-forming reaction of the intumescent layer, which promoted the intumescent multiplication; and (c) Fly ash with excellent heat-resistant properties in the residual charcoal after combustion is used as a temperature-resistant material to fill in the pores of the expansion layer, which increases the thermal stability and barrier capacity of the expansion layer.

-

Key words:

- Fly ash (FA) /

- Chitosan (CS) /

- Waste utilization /

- Thermal insulation /

- Expansion ratio /

- Flame retardant mechanism

-

表 1 水性膨胀型防火涂层的组成比例(wt %)

Table 1. Composition ratio of water-based intumescent flame-retardant coatings (wt %)

Coatings WA APP PER MEL FA CS FA-CS H2O WIS 45 26 13 13 / / / 3 FA/WIS 40 26 13 13 5 / / 3 CS/WIS 40 26 13 13 / 5 / 3 FA-CS/WIS 40 26 13 13 / / 5 3 Notes: WA, Waterborne emulsions; APP, Ammonium polyphosphate; PER, pentaerythritol; MEL melamine; FA Fly ash; CS Chitosan; FA-CS, Fly ash- Chitosan; WIS, Waterborne Intumescent System; FA/WIS, Fly ash/ Waterborne Intumescent System; CS/WIS, Chitosan/ Waterborne Intumescent System; FA-CS/WIS, Fly ash- Chitosan/Waterborne Intumescent System -

[1] ZHAO W, ZHAO H-B, CHENG J-B, et al. A green, durable and effective flame-retardant coating for expandable polystyrene foams[J]. Chem Eng J, 2022, 440: 135807. doi: 10.1016/j.cej.2022.135807 [2] YANG Z, XIAO G, CHEN C, et al. Mussel inspired polydopamine@KH560-linked hexagonal boron nitride and CNTs nanoflame retardants improve fire performance of composite coatings[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2021, 631: 127717. doi: 10.1016/j.colsurfa.2021.127717 [3] ZHONG F, CHEN C, YANG X, et al. Self-assembly of zinc hydroxystannate on polyethyleneimine supported boron nitride to improve the flame protection properties of waterborne epoxy coatings[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2022, 650: 129557. doi: 10.1016/j.colsurfa.2022.129557 [4] HU X, ZHU X, SUN Z. Fireproof performance of the intumescent fire retardant coatings with layered double hydroxides additives[J]. Construction and Building Materials, 2020, 256: 119445. doi: 10.1016/j.conbuildmat.2020.119445 [5] CHEN C, XIAO G, ZHONG F, et al. Dendritic-hydroxyzinc stannate loaded carbon nanotubes for enhancing flame retardancy of composite coatings[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2022, 648: 129329. doi: 10.1016/j.colsurfa.2022.129329 [6] JIN S-A, SPONTAK R J. Fundamentals of and advances in nanocellulose and nanochitin systems[J]. Advanced Industrial and Engineering Polymer Research, 2023, 6(4): 356-381. doi: 10.1016/j.aiepr.2023.04.003 [7] WANG M, YIN G-Z, YANG Y, et al. Bio-based flame retardants to polymers: A review[J]. Advanced Industrial and Engineering Polymer Research, 2023, 6(2): 132-155. doi: 10.1016/j.aiepr.2022.07.003 [8] WANG M, XIAO G, CHEN C, et al. Combining layered double hydroxides and carbon nanotubes to synergistically enhance the flame retardant properties of composite coatings[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2022, 638: 128315. doi: 10.1016/j.colsurfa.2022.128315 [9] SAMIEE R, MONTAZERI S, RAMEZANZADEH B, et al. Ce-MOF nanorods/aluminum hydroxide (AlTH) synergism effect on the fire-retardancy/smoke-release and thermo-mechanical properties of a novel thermoplastic acrylic intumescent composite coating[J]. Chem Eng J, 2022, 428: 132533. doi: 10.1016/j.cej.2021.132533 [10] HU X, ZHU X, SUN Z. Effect of CaAlCO3-LDHs on fire resistant properties of intumescent fireproof coatings for steel structure[J]. Appl Surf Sci, 2018, 457: 164-169. doi: 10.1016/j.apsusc.2018.06.165 [11] KIM Y, HWANG S, CHOI J, et al. Valorization of fly ash as a harmless flame retardant via carbonation treatment for enhanced fire-proofing performance and mechanical properties of silicone composites[J]. J Hazard Mater, 2021, 404: 124202. doi: 10.1016/j.jhazmat.2020.124202 [12] BATISTELLA M, ROUX J-C, LE SAOUT G, et al. Use of fly ash as synergistic and reactive component of flame retardant system in polylactide[J]. Polym Degrad Stab, 2023, 211. [13] ZHOU Y, WANG Y, YU K, et al. Synergistic flame retardancy of piperazine pyrophosphate/magnesium hydroxide/fly ash cenospheres-doped rigid polyurethane foams[J]. Construction and Building Materials, 2023, 408: 133670. doi: 10.1016/j.conbuildmat.2023.133670 [14] YU K, WANG Y, QU C, et al. Multifunctional Si-C-P flame-retardant coatings blended by chitosan hydrochloride/melamine polyphosphate/ammonium phosphomolybdate in spodumene tailings geopolymer[J]. Construction and Building Materials, 2023, 405: 133340. doi: 10.1016/j.conbuildmat.2023.133340 [15] 常娟, 程爱华. FeS/壳聚糖基碳气凝胶复合材料的制备及对Cr(VI)的吸附[J]. 化工进展: 2023, 42(11): 6042-6052.CHANG Juan, CHENG Aihua. Preparation and Cr(Ⅵ) adsorption properties of FeS/chitosan-based carbon aerogel composites[J]. Chemical Industry and Engineering Progress, 2023, 42(11): 6042-6052. (in Chinese) [16] 范佳璇, 赵奕, 柯勤飞, 等. 壳聚糖/植酸静电纺涂层阻燃疏水棉织物的制备及其性能[J]. 印染, 2023, 49(9): 1-6+18.FAN Jiaxuan, ZHAO Yi, KE Qinfei, et. al. Fabrication and properties of flame-retardant and hydrophobic cotton fabric based on electro-spuncoating of chitosan/phytic acid[J]. Printing and Dyeing, 2023, 49(9): 1-6+18(in Chinese). [17] 王娜, 王树伟, 滕海伟, 等. 壳聚糖基阻燃剂制备及其在防火涂层中应用[J]. 精细化工, 2018, 35(11): 1968-1973.WANG Na, WANG Shu-Wei, TENG Hai-Wei, et al. Preparation of a Chitosan-based Flame Retardant and Its Application in Fireproofing Coating[J]. Fine Chemicals, 2018, 35(11): 1968-1973(in Chinese). [18] WU J, WONG H S, ZHANG H, et al. Improvement of cemented rockfill by premixing low-alkalinity activator and fly ash for recycling gangue and partially replacing cement[J]. Cem Concr Compos, 2024, 145: 105345. doi: 10.1016/j.cemconcomp.2023.105345 [19] HEIDARI F, JAFARI S M, ZIAIIFAR A M, et al. Surface modification of silica nanoparticles by chitosan for stabilization of water-in-oil Pickering emulsions[J]. Carbohydrate Polymer Technologies and Applications, 2023, 6: 100381. doi: 10.1016/j.carpta.2023.100381 [20] UL HAQ E, KUNJALUKKAL PADMANABHAN S, LICCIULLI A. Synthesis and characteristics of fly ash and bottom ash based geopolymers–A comparative study[J]. Ceram Int, 2014, 40(2): 2965-2971. doi: 10.1016/j.ceramint.2013.10.012 [21] 曾春芽, 单慧媚, 赵超然, 等. 纳米铁-氧化石墨烯/壳聚糖复合材料的制备及其力学性能[J]. 复合材料学报, 2022, 39(04): 1739-1747.ZENG Chunya , SHAN Huimei , ZHAO Chaoran, et al. Preparation and mechanical properties of nano-iron-graphene oxide/chitosan composites[J]. Acta Materiae Compositae Sinica, 2022, 39(04): 1739-1747. (in Chinese) [22] MOKHTAR A, DJELAD A, BENGUEDDACH A, et al. CuNPs-magadiite/chitosan nanocomposite beads as advanced antibacterial agent: Synthetic path and characterization[J]. Int J Biol Macromol, 2018, 118: 2149-2155. doi: 10.1016/j.ijbiomac.2018.07.058 [23] LI Q, LI H, LIANG T. Effect of non-intumescent fireproof coating on the durability of concrete exposed to elevated temperature[J]. Construction and Building Materials, 2023, 404: 133211. doi: 10.1016/j.conbuildmat.2023.133211 [24] TASI T-P, HSIEH C-T, YANG H-C, et al. Enhanced fireproof performance of construction coatings by adding hexagonal boron nitride nanosheets[J]. Ceram Int, 2022, 48(14): 20809-20816. doi: 10.1016/j.ceramint.2022.04.065 [25] CAI Z, LIU F, YU J, et al. Development of ultra-high ductility engineered cementitious composites as a novel and resilient fireproof coating[J]. Construction and Building Materials, 2021, 288: 123090. doi: 10.1016/j.conbuildmat.2021.123090 [26] HADAŁA B, ZYGMUNT-KOWALSKA B, KUŹNIA M, et al. Thermal insulation properties of rigid polyurethane foam modified with fly ash- a comparative study[J]. Thermochim Acta, 2024, 731: 179659. doi: 10.1016/j.tca.2023.179659 [27] HU S, SONG L, PAN H, et al. Thermal properties and combustion behaviors of flame retarded epoxy acrylate with a chitosan based flame retardant containing phosphorus and acrylate structure[J]. J Anal Appl Pyrolysis, 2012, 97: 109-115. doi: 10.1016/j.jaap.2012.06.003 [28] QI P, WANG S, WANG W, et al. Chitosan/sodium polyborate based micro-nano coating with high flame retardancy and superhydrophobicity for cotton fabric[J]. Int J Biol Macromol, 2022, 205: 261-273. doi: 10.1016/j.ijbiomac.2022.02.062 -

点击查看大图

点击查看大图

计量

- 文章访问数: 52

- HTML全文浏览量: 51

- 被引次数: 0

下载:

下载: