A review of rheological properties and influencing factors of 3D printed concrete

-

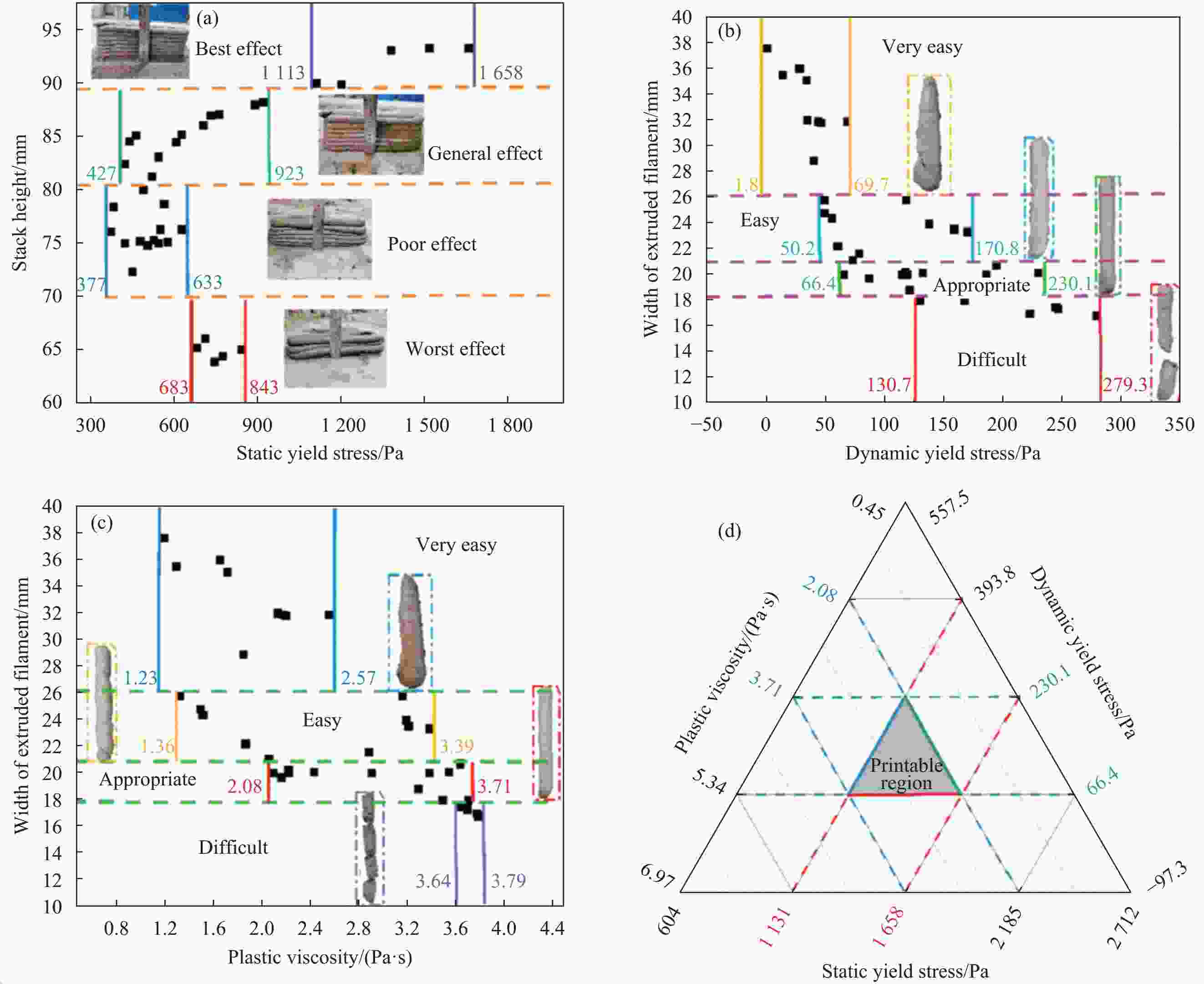

摘要: 3D打印混凝土具有绿色环保、生产高效智能、节约人力、无需模板等优势,是推动建筑行业工业化升级向智慧化和数字化发展的重要途径之一。对应混凝土3D打印的3个重要阶段:泵送、挤出和建造,决定其制备成功的可打印性主要包含可泵送性、可挤出性和可建造性,然而,这些特性之间存在着矛盾与平衡,且与流变性能密切相关。因此,混凝土流变性能是3D打印混凝土的重要影响因素,也是制约3D打印技术在土木工程中广泛应用的主要因素。目前,已有许多关于3D打印混凝土流变性能的研究,但对于3D打印混凝土流变性能的测试方案和影响因素等关键研究方向尚未形成全面的认识。基于此,本文首先汇总分析了3D打印混凝土流变参数(屈服应力、塑性黏度和触变性)的测试方案、测量范围和表征模型。其次,对3D打印混凝土流变性能的影响因素(原材料性能与配合比、打印参数和温度)进行了分析,提出了调控流变参数的方法。最后,展望了3D打印混凝土流变性能研究的未来发展方向。Abstract: 3D printed concrete has the advantages of green environmental protection, efficient and intelligent production, labor saving, and no formwork, and is one of the important ways to promote the industrialization and upgrading of the construction industry to intelligent and digital development. Corresponding to the three important stages of 3D printing for concrete: Pumping, extrusion and construction, the printability that determines the success of its preparation mainly includes pumpability, extrudability and buildability. However, there are contradictions and balances between these characteristics, and they are closely related to rheological properties. Therefore, the rheological properties of concrete are vital important factors for 3D printed concrete, and it is also the main factor restricting the wide application of 3D printing technology in civil engineering. At present, there are many researches on the rheological properties of 3D printed concrete, however, there is still no comprehensive understanding for the key research directions such as the test scheme and influencing factors of the rheological properties of 3D printed concrete. Therefore, this paper first reviewed the test protocols, measuring ranges and models for rheological parameters (yield stress, plastic viscosity and thixotropy) of 3D printed concrete. Secondly, the factors affecting rheological properties of 3D printed concrete were analyzed, influencing factors include raw material properties, mix proportion, printing parameters and temperature, and the method of controlling rheological parameters is obtained. Finally, the problems in the research of 3D printed concrete rheological properties are pointed out and improvement measures are proposed, as well as its development trend and application prospect are prospected.

-

Key words:

- 3D printed concrete /

- rheological property /

- yield stress /

- plastic viscosity /

- thixotropy

-

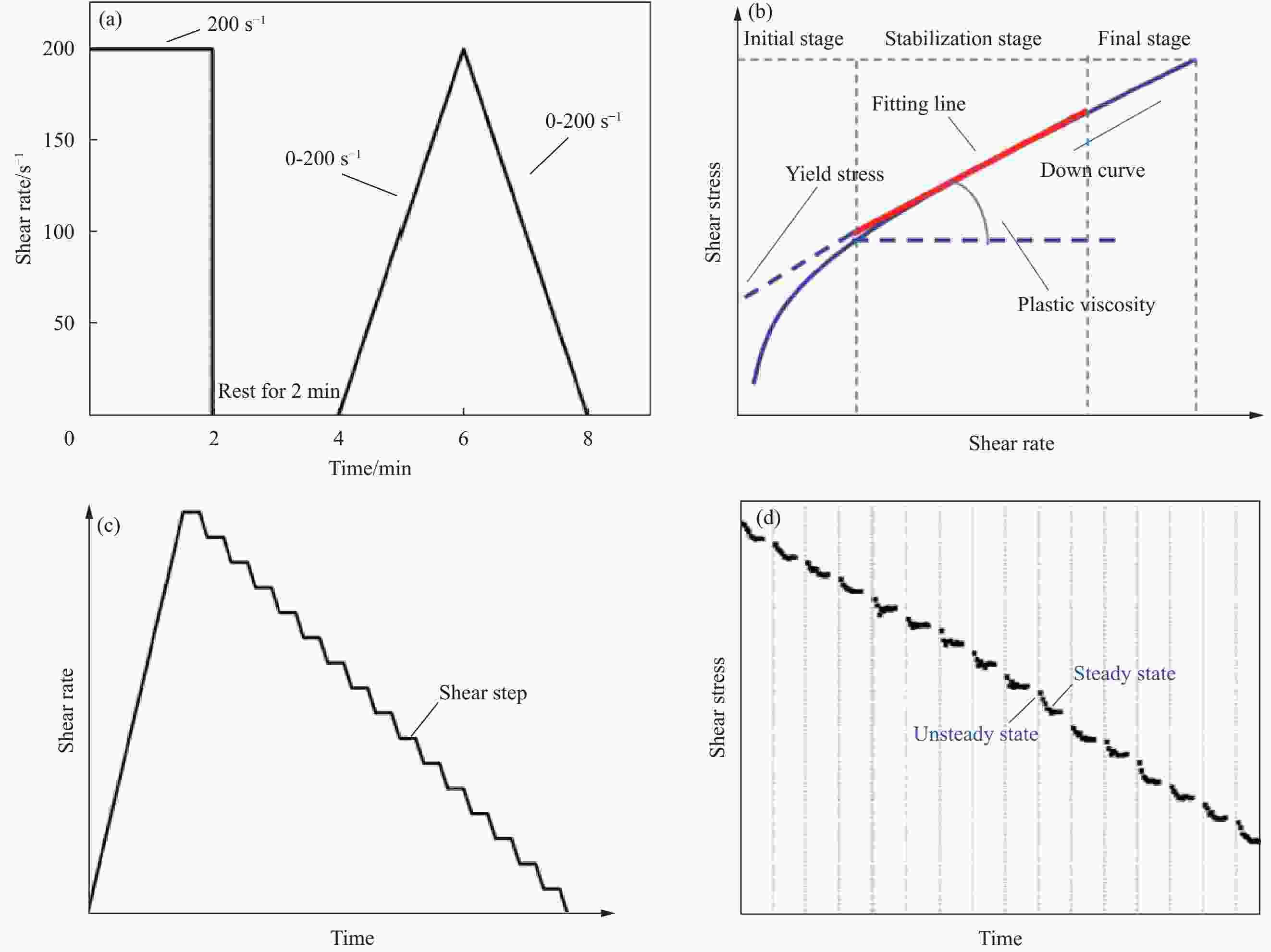

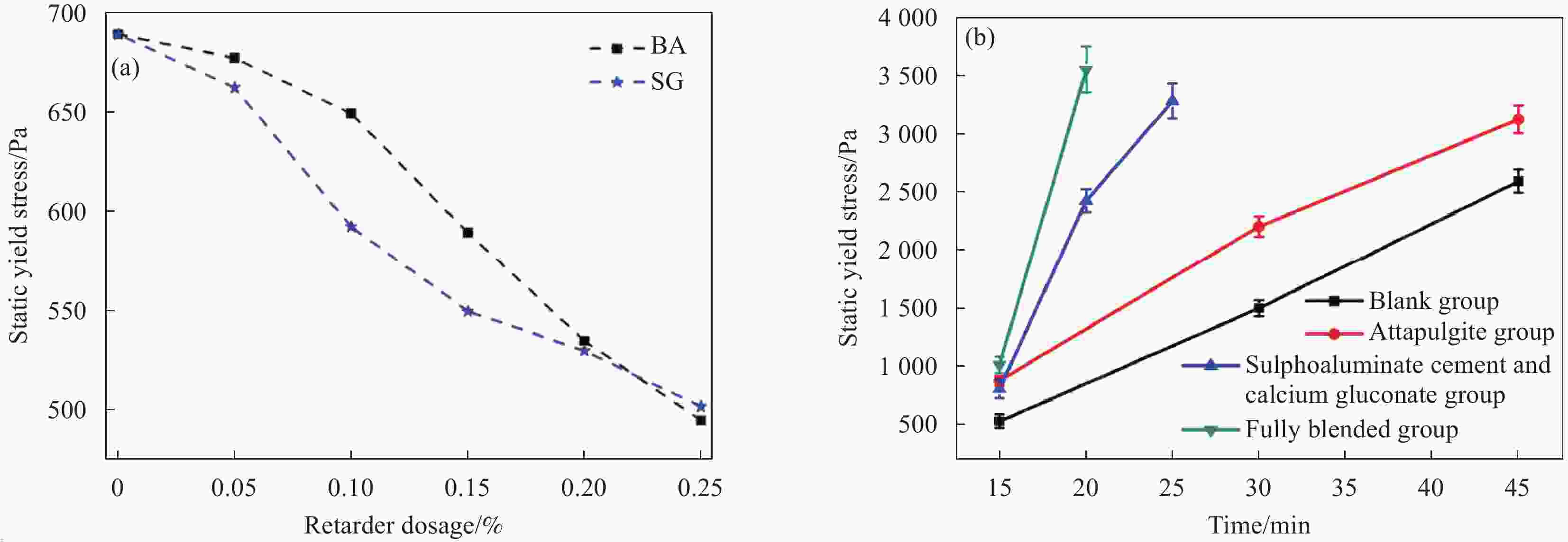

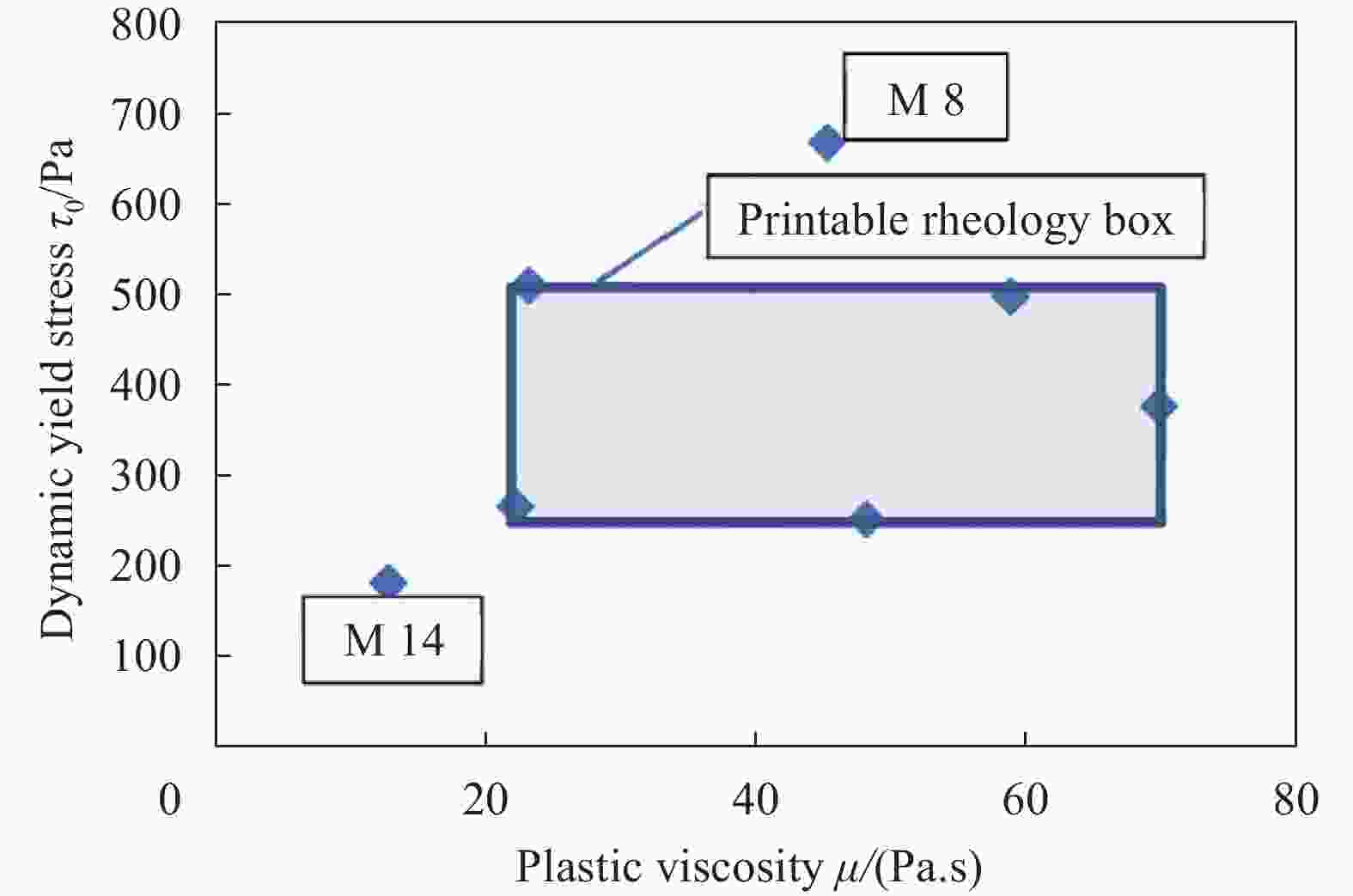

图 2 动态屈服应力和塑性黏度测试方法及其流变曲线:((a), (b)) 线性剪切法及其剪切应力-剪切速率曲线[53];((c), (d)) 阶梯式剪切法及其剪切应力-剪切速率曲线[81]

Figure 2. Test method and rheological curves of dynamic yield stress and plastic viscosity: ((a), (b)) Test method and shear stress-shear rate curves of linear shear method[53]; ((c), (d)) Test method and shear stress-shear rate curve of step shear method[81]

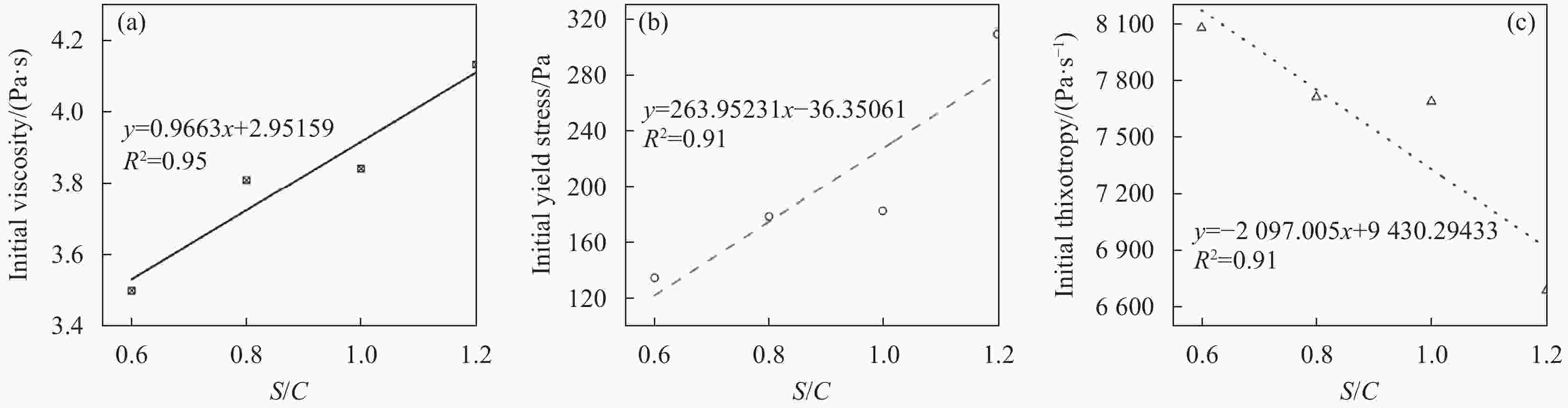

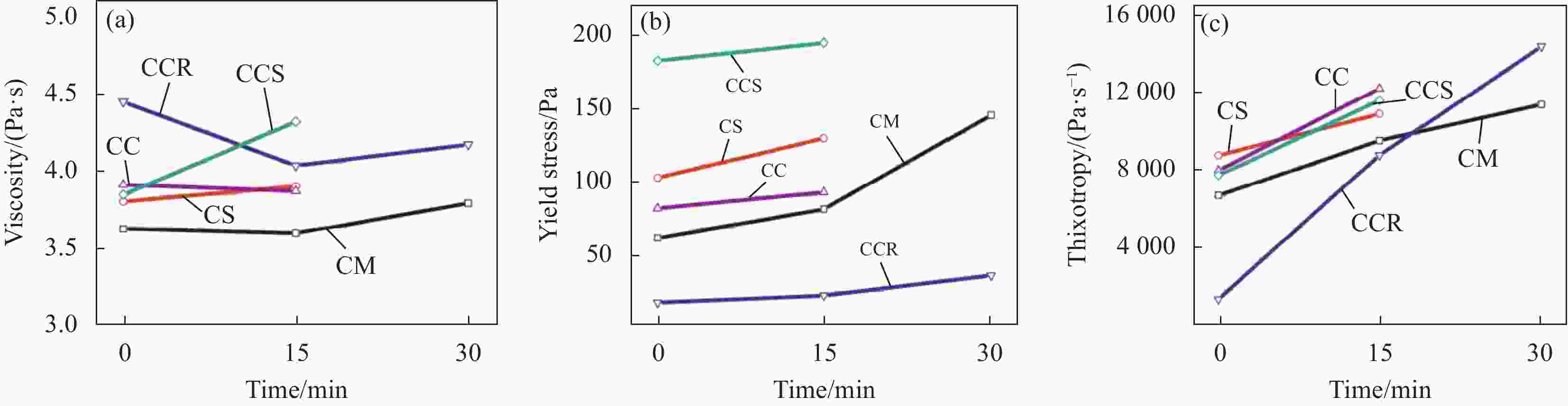

图 7 纳米黏土对3D打印混凝土流变性能影响:(a)塑性黏度;(b)动态屈服应力;(c)触变性 [35]

CM, CS, CC, CCS—Blank group, silica fume group, nanoclay group, silica fume-nanoclay group, respectively; CCR—Silica fume, nanoclay and retarder group

Figure 7. Effect of nano clay on rheological properties of 3D printed concrete: (a) Plasticity viscosity; (b) Dynamic yield stress; (c) Thixotropy[35]

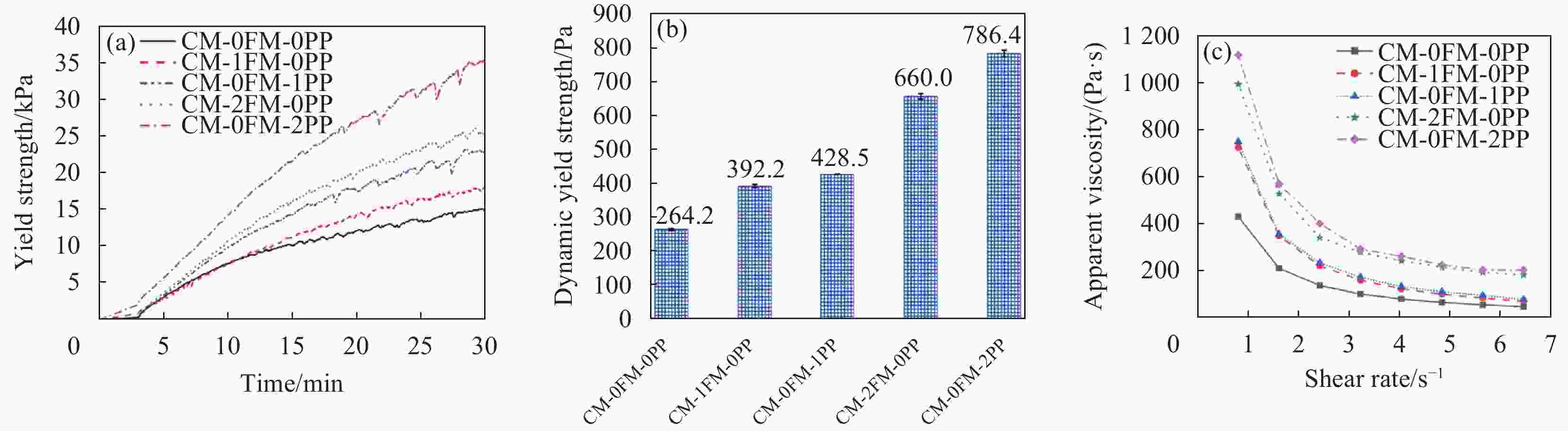

图 8 口罩回收纤维和聚丙烯(PP)纤维对3D打印混凝土流变性能的影响:(a)静态屈服应力;(b)动态屈服应力;(c)表观黏度[149]

CM, FM, PP—Control mix, face mask and polypropylene fiber respectively; e.g. CM-1FM-0PP stands for 1vol% face mask and no polypropylene fiber

Figure 8. Effects of mask recycled fibers and polypropylene (PP) fibers on rheological properties of 3D printed concrete: (a) Static yield stress; (b) Dynamic yield stress; (c) Apparent viscosity[149]

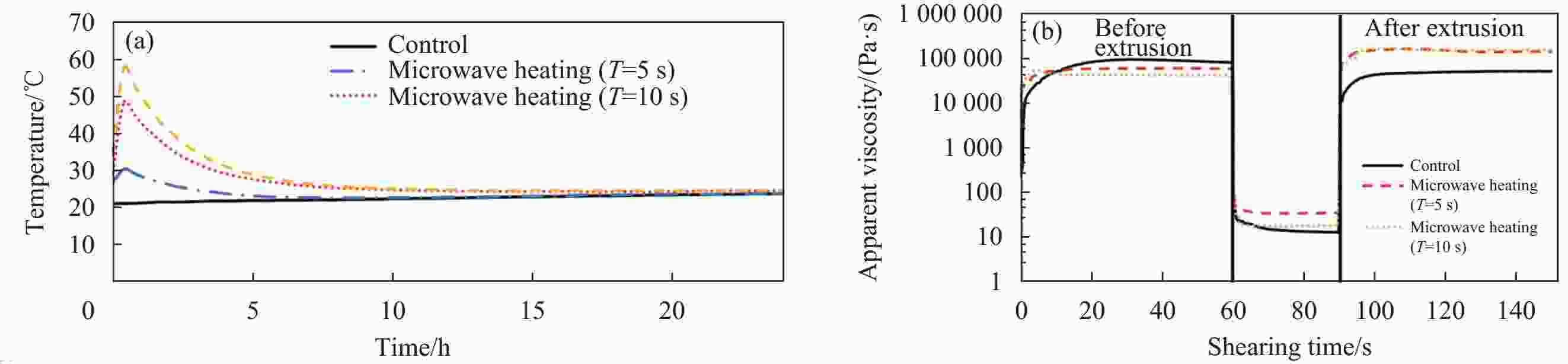

图 11 微波加热在3D打印地聚物混凝土的应用:(a) 微波加热前后打印层层间温度;(b) 微波加热前后的黏度恢复率[188]

T—Heating time

Figure 11. Application of microwave heating in 3D printed geopolymer concrete: (a) Layers temperature of printing layers before and after microwave heating; (b) Viscosity recovery rate before and after microwave heating[188]

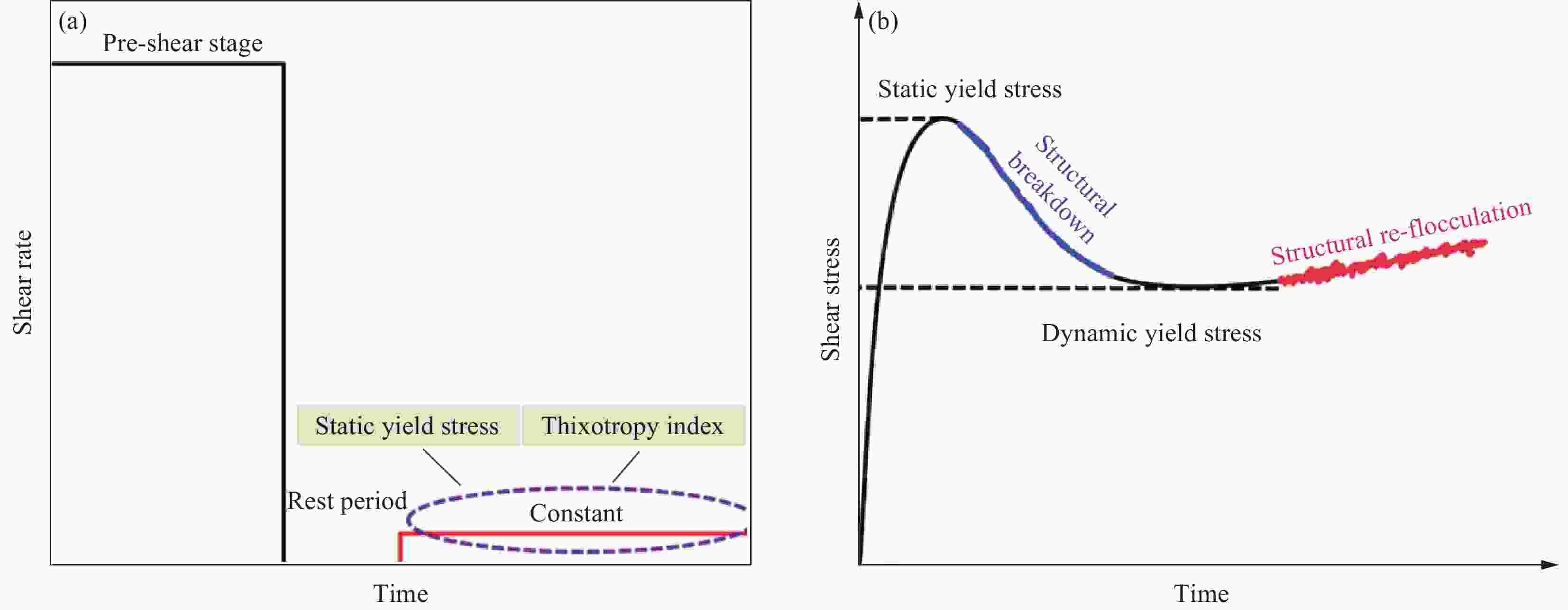

表 1 静态屈服应力演化模型对比

Table 1. Comparison of static yield stress evolution models

Model Equation Fitting time Disadvantage Fitting cases of 3D

printed concreteRoussel[65] $ \tau_0\left(t\right)=\tau_{\mathrm{0,0}}+A_{\mathrm{thix}}t\mathrm{_{rest}} $

$ A\mathrm{_{thix}}=\dfrac{\tau_0}{\mathrm{\mathit{T}}} $Within 40 min after resting Its fitting time is short Perrot et al[69] Perrot[66] $ \tau_0\left(t\right)=\tau_{\mathrm{0,0}}+A_{\mathrm{thix}}t_{\mathrm{c}}\left(\mathrm{e}^{t\mathrm{_{rest}}/t_{\mathrm{c}}}-1\right) $ From resting to printable time limit It lacks the fitting of the

re-flocculation periodPerrot et al[69],

Shahmirzadi

et al[70]Kruger[52] $ \tau\mathrm{_S}\left(t\right)=\tau_{\mathrm{D,i}}+R\mathrm{_{thix}}t $ (t≤trf$)

$ t\mathrm{_{rf}}=\dfrac{\tau_{\mathrm{S,i}}-\tau_{\mathrm{D,i}}}{R_{\mathrm{thix}}} $

$ \tau_{\mathrm{S}}\left(t\right)=\tau\mathrm{_{S,i}}+A\mathrm{_{thix}}(t-t_{\mathrm{rf}}) $ (t>$ t_{\mathrm{rf}} $)Period of re-flocculation

and after 40 min of restingIt needs to derive trf and can only fit the time of resting for 40 min Kruger et al[52, 58],

De Vlieger et al[40]Notes: τ0,0—Initial static yield stress; trest—Resting time; T—Thixotropic parameter; τ0(t)—Time-varying static yield stress; tc— Characteristic time; τS(t)—Time-varying static yield stress; Rthix—Re-flocculation rate; τD,i—Initial dynamic yield stress; τS,i—Initial static yield stress; t—Time since cessation of agitation; trf—Time period over which re-flocculation occurs; Athix—Structuration rate. 表 2 Bingham模型、改进Bingham模型和Herschel-Bulkley 模型对比

Table 2. Comparison of Bingham model, modified Bingham model and Herschel-Bulkley model

Model Equation Advantage Disadvantage Ref. Bingham $ \tau ={\tau }_{0}+\eta \gamma $ It is a linear model to facilitate

data processingIt is not suitable for shear-thinning and

shear-thickening fluids[36, 42, 74, 79-80] Modified Bingham $ \tau ={\tau }_{0}+\eta \gamma +c{\gamma }^{2} $ It has high fitting accuracy and

avoids the case of τ0 < 0It sometimes lacks of transformation

formulae[76, 81-83] Herschel-Bulkley $ \tau ={\tau }_{0}+m{\gamma }^{n} $ It can fit most experimental data

with high fitting accuracyIt has mathematical limitations on shear-

thickening fluids, sometimes fitting τ0<0[36, 42, 61, 76, 83-84] Notes: τ—Shear stress; γ—Shear rate; τ0—Dynamic yield stress; η—Plastic viscosity; c—Second order parameter; m—Consistency factor; n—Flow index (n < 1: Shear thinning fluid; n > 1: Shear thickening fluid). 表 3 塑性黏度表征模型

Table 3. Plastic viscosity characterization models

Plastic viscosity

characterization modelEquation Notes Hu and De Larrard[90] $ \eta ={\eta }_{0}\left(1+{k}_{{\mathrm{s}}}{p}_{{\mathrm{s}}}\right){\left(1-\dfrac{{\phi }_{{\mathrm{F}}}}{{\alpha }_{{\mathrm{F}}}}\right)}^{-2.5{\alpha }_{{\mathrm{F}}}}{\left(1-\dfrac{{\phi }_{{\mathrm{C}}}}{{\alpha }_{{\mathrm{C}}}}\right)}^{-k{\alpha }_{{\mathrm{C}}}}{\left(1-\dfrac{{\phi }_{{\mathrm{G}}}}{{\alpha }_{{\mathrm{G}}}}\right)}^{-k{\alpha }_{{\mathrm{G}}}} $

$ {\phi }_{{\mathrm{F}}}=\dfrac{{V}_{{\mathrm{F}}}}{{V}_{0}+{V}_{{\mathrm{F}}}} $,$ {\phi }_{{\mathrm{C}}}=\dfrac{{V}_{{\mathrm{C}}}}{{V}_{0}+{V}_{{\mathrm{F}}}+{V}_{{\mathrm{C}}}} $,$ {\phi }_{{\mathrm{G}}}=\dfrac{{V}_{{\mathrm{G}}}}{{V}_{0}+{V}_{{\mathrm{F}}}+{V}_{{\mathrm{C}}}+{V}_{{\mathrm{G}}}} $$

$ \alpha\mathrm{_{\mathit{x}max}}=1-0.45\left(\dfrac{d_{\mathrm{\mathit{x}}}}{D_{\mathrm{\mathit{x}}}}\right)^{0.19} $ ,x=F, C, GIt fits with general accuracy Mahmoodzadeh and Chidiac[95] $ \eta_{\mathrm{r}}=1+\eta\mathrm{_i}\lambda $

$ \lambda ={y}^{3}\dfrac{4\left(1-{y}^{7}\right)}{4(1+{y}^{10})-25{y}^{3}(1+{y}^{4})+42{y}^{5}} $$

$ y\left(\phi \right)={\left(\phi /{\phi }_{\max}\right)}^{1/3}\left(1-{K}_{{\mathrm{P}}}\right) $$

$ {K}_{{\mathrm{P}}}={C}_{{\mathrm{P}}}\dfrac{{m}_{{\mathrm{c}}}}{{m}_{{\mathrm{w}}}} $It is more accurate to fit than the former Zhao et al[93] $ \eta =46.8 F-21.09 A-24.71 R+147.09 $ It is not widely applicable Li et al[94] $ \eta_{\mathrm{r}}=\dfrac{D}{\mathrm{PFT}}\dfrac{\left(1-\phi_{\mathrm{Fa}}/\phi_{\mathrm{m}}\right)^{-4}}{\left(a+b\phi_{\mathrm{Fa}}/\phi_{\mathrm{m}}\right)\mathit{^{\mathrm{c}}}} $ It is a semiquantitative model Notes: η0—Plastic viscosity of water; ks, k—Fit by curve; ps—Maximum proportion of water reducing agent; F, C, G—Silica fume, cement, aggregate, respectively; $\phi $—Volume concentration; $\phi_F $, $\phi_C $, $\phi_G $—Volume concentration of silica fume, cement, aggregate, respectively; αF, αC, αG—Maximum packing density of silica fume, cement, aggregate, respectively; V—Volume fraction; V0, VF, VC, VG—Volume fraction of water, silica fume, cement, aggregate, respectively; $ \alpha_{x\mathrm{max}} $—Maximum packing density; dx, Dx—Sieve sizes corresponding of 10%, 90%, respectively; ηr—Relative plastic viscosity; ηi—Intrinsic viscosity; $\phi_{\max} $—Maximum packing density; λ—A function of y; y—Ratio of the particle radius to the cell radius; KP—A calibration parameter; CP—Fitting parameter; mc, mw—Mass of cement and water in the mixture respectively; F—Flatness; A—Angularity; R—Roughness; D—Equivalent diameter; PFT—Paste film thickness; $ \phi\mathrm{_F\mathrm{_a}} $—Fine aggregate volume fraction; $ \phi_{\mathrm{m}} $—Packing density; a, b, c—Dimensionless fitting parameters obtained from the regression analysis. 表 4 材料比例对3D打印混凝土流变性能的影响

Table 4. Effect of material ratio on rheological properties of 3D printed concrete

Material ratio Rheological parameter Ratio Growth rate/% Ref. Sand-binder ratio Static yield stress 0.8→1.2 847 [70] 0→1.5 130 [57] Dynamic yield stress 0.6→1.5 173 [45] 1.0→1.8 23 [102] Dlastic viscosity 0.6→1.5 29 [45] 1.0→1.8 153 [102] Thixotropy 0.6→1.5 −22 [45] 0→0.67 213 [57] 0.8→1.2 180 [70] Water-binder ratio Static yield stress 0.38→0.40 −35 [38] 0.22→0.28 −90 [34] Plastic viscosity 0.22→0.28 −97 Thixotropy 0.38→0.40 −33 [38] 表 5 化学外加剂对3D打印混凝土流变性能影响

Table 5. Effect of chemical admixtures on rheological properties of 3D printed concrete

Chemical admixtures Rheological parameter Content/wt% Growth rate/% Ref. Superplasticizer Static yield stress 6.1→6.9 −33 [59] 1.26→1.48 −73 [52] Dynamic yield stress 1.26→1.48 −130 6.1→6.9 −32 [59] Viscosity modifier Shear yield stress 0→0.4 1000 [106] 0.14→0.48 150 [107] Tensile yield stress 0.14→0.48 100 Bulk yield stress 0→0.4 141 [106] Static yield stress 0→0.3 81 [74] Dynamic yield stress 0→0.3 105611 Plastic viscosity 0→0.3 176 Dynamic yield stress 0→1 190 [80] Plastic viscosity 0→1 21 Thixotropy 0→1 130 Retarder Static yield stress 0→0.25 −36 [53] Dynamic yield stress 0→0.25 −24 Plastic viscosity 0→0.25 −14 Static yield stress 0→0.25 −37 Dynamic yield stress 0→0.25 −27 Plastic viscosity 0→0.25 −15 0→0.25 15 [35] Dynamic yield stress 0→0.1 −80 Thixotropy 0→0.1 −85 Accelerator Static yield stress 0→10 50 [39] Note: If it is not specified in detail, the content in the table defaults to the quality content of the cementing material. 表 6 纳米填料对3D打印混凝土流变性能的影响

Table 6. Effect of nanofillers on rheological properties of 3D printed concrete

Nanofillers type Rheological parameter Content/wt% Growth rate/% Ref. Nano silica Static yield stress 0→3 137 [138] 0→1 900 [139] Dynamic yield stress 0→3 145 [138] Thixotropy −44 0→1 800 [139] Nano calcium carbonate Static yield stress 0→4 188 [62] Nano clay Static yield stress 0→0.5 57 [56] 0→1 494 [28] 0→2 755 [29] Dynamic yield stress 0→1 140 [28] Plastic viscosity 220 Apparent viscosity 0→0.5 39 [56] 0→2 101 [29] Thixotropy 0→0.5 176 [56] 0→1 105 [28] Carbon nano tube Static yield stress 0→0.1 143 [15] Dynamic yield stress 122 表 7 纤维对3D打印混凝土流变性能的影响

Table 7. Effect of fibers on rheological properties of 3D printed concrete

Fiber type Rheological parameter Content Growth rate/% Ref. Polyvinyl alcohol fiber Bulk yield stress 0→2.2wt% 81 [106] Shear yield stress 0→1.6wt% 75 Dynamic yield stress 0→0.5wt% 25 [135] Polypropylene fiber Static yield stress 0→9wt% 69 [59] Dynamic yield stress 97 Dynamic yield stress 0→5.4 kg/m3 1667 [34] Plastic viscosity 107 Steel fiber Initial shear yield stress 0→2vol% 395 [29] Thixotropic stress 494 Thixotropy 293 表 8 矿物掺和料对3D打印混凝土流变性能的影响

Table 8. Effect of mineral admixtures on rheological properties of 3D printed concrete

Types of mineral admixtures Rheological parameter Content/wt% Growth rate/% Ref. Silica fume Static yield stress 0→10 140 [153] Dynamic yield stress 0→2 70 [35] 0→10 650 [43] Plastic viscosity 0→2 30 [35] 0→16 1320 [74] Thixotropy 0→2 33 [35] 0→10 185 [153] 0→10 767 [43] Fly ash Static yield stress 50→80 −57 [154] 0→20 −45 [61] Dynamic yield stress 0→40 −62 [30] 0→20 −73 [61] Apparent viscosity 0→40 −201 [30] 50→80 −20 [154] Thixotropy 0→20 −90 [61] Limestone packing Static yield stress 0→15 44 [155] 0→70 123 [55] Dynamic yield stress 0→70

0→30141

182[55]

[152]Plastic viscosity 0→70 238 [55] 0→30 30 [152] Blast furnace slag Static yield stress 0→10 128

726[153]

[43]Dynamic yield stress 0→10 61 [43] Plastic viscosity 0→10 196 [43] Metakaolin Static yield stress 0→3 75 [36] 0→10 285 [31] Dynamic yield stress 0→3

0→1027

129[36] Plastic viscosity 0→10 49 [31] Thixotropy 0→3 62 [36] 0→10 5457 [31] Note: If it is not specified in detail, the content in the table defaults to the quality content of the cementing material. -

[1] NGO T D, KASHANI A, IMBALZANO G, et al. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges[J]. Composites Part B: Engineering, 2018, 143: 172-196. doi: 10.1016/j.compositesb.2018.02.012 [2] 张超, 邓智聪, 侯泽宇, 等. 混凝土3D打印研究进展[J]. 工业建筑, 2020, 50(8): 16-21.ZHANG Chao, DENG Zhicong, HOU Zeyu, et al. Research progress of 3D printing for concrete[J]. Industrial Construction, 2020, 50(8): 16-21(in Chinese). [3] 龙昱, 李岩, 付昆昆. 3D打印纤维增强复合材料工艺和力学性能研究进展[J]. 复合材料学报, 2022, 39(9): 4196-4212.LONG Yu, LI Yan, FU Kunkun. Recent advances in 3D printed fiber reinforced composites: Processing technique and mechanical performance[J]. Acta Materiae Compositae Sinica, 2022, 39(9): 4196-4212(in Chinese). [4] DE SCHUTTER G, LESAGE K, MECHTCHERINE V, et al. Vision of 3D printing with concrete — Technical, economic and environmental potentials[J]. Cement and Concrete Research, 2018, 112: 25-36. doi: 10.1016/j.cemconres.2018.06.001 [5] LIM J H, WENG Y W, PHAM Q C. 3D printing of curved concrete surfaces using adaptable membrane formwork[J]. Construction and Building Materials, 2020, 232: 117075. doi: 10.1016/j.conbuildmat.2019.117075 [6] CARNEAU P, MESNIL R, ROUSSEL N, et al. Additive manufacturing of cantilever - Fom masonry to concrete 3D printing[J]. Automation in Construction, 2020, 116: 103184. doi: 10.1016/j.autcon.2020.103184 [7] RUBIN A P, QUINTANILHA L C, REPETTE W L. Influence of structuration rate, with hydration accelerating admixture, on the physical and mechanical properties of concrete for 3D printing[J]. Construction and Building Materials, 2023, 363: 129826. doi: 10.1016/j.conbuildmat.2022.129826 [8] 李西敏, 杨韬, 彭必友, 等. 二氧化钛陶瓷浆料的制备及其直写成型3D打印[J]. 复合材料学报, 2022, 39(7): 3510-3517.LI Ximin, YANG Tao, PENG Biyou, et al. Preparation of titanium dioxide ceramic slurry and its 3D printing for direct-ink-writing[J]. Acta Materiae Compositae Sinica, 2022, 39(7): 3510-3517(in Chinese). [9] PIMENTEL TINOCO M, GOUVÊA L, DE CÁSSIA MAGALHÃES MARTINS K, et al. The use of rice husk particles to adjust the rheological properties of 3D printable cementitious composites through water sorption[J]. Construction and Building Materials, 2023, 365: 130046. doi: 10.1016/j.conbuildmat.2022.130046 [10] KRISTOMBU BADUGE S, NAVARATNAM S, ABU-ZIDAN Y, et al. Improving performance of additive manufactured (3D printed) concrete: A review on material mix design, processing, interlayer bonding, and reinforcing methods[J]. Structures, 2021, 29: 1597-1609. doi: 10.1016/j.istruc.2020.12.061 [11] DAS A, REITER L, MANTELLATO S, et al. Early-age rheology and hydration control of ternary binders for 3D printing applications[J]. Cement and Concrete Research, 2022, 162: 107004. doi: 10.1016/j.cemconres.2022.107004 [12] 常西栋, 李维红, 王乾. 3D打印混凝土材料及性能测试研究进展[J]. 硅酸盐通报, 2019, 38(8): 2435-2441.CHANG Xidong, LI Weihong, WANG Qian. Research progress of 3D printed concrete materials and its performance test[J]. Bulletin of the Chinese Ceramic Society, 2019, 38(8): 2435-2441(in Chinese). [13] 黄宏, 曾建涛, 王伊. 取代率对再生陶瓷粗骨料混凝土抗压强度的影响[J]. 华东交通大学学报, 2022, 39(2): 27-34. doi: 10.3969/j.issn.1005-0523.2022.2.hdjtdxxb202202004HUANG Hong, ZENG Jiantao, WANG Yi. Influence of replacement rate on compressive strength of recycled ceramic coarse aggregate concrete[J]. Journal of East China Jiaotong University, 2022, 39(2): 27-34(in Chinese). doi: 10.3969/j.issn.1005-0523.2022.2.hdjtdxxb202202004 [14] 张立卿, 肖振荣, 刘莎, 等. 废弃陶瓷对水泥基复合材料力学性能影响与机制的研究综述[J]. 复合材料学报, 2024, 41(6): 2829-2844.ZHANG Liqing, XIAO Zhenrong, LIU Sha, et al. A review of the effect of ceramic wastes on mechanical properties and mechanisms of cementitious composites[J]. Acta Materiae Compositae Sinica, 2024, 41(6): 2829-2844(in Chinese). [15] 赵宇, 武喜凯, 朱伶俐, 等. 碳纳米管对3D打印混凝土流变性能及力学性能的影响[J]. 材料导报, 2023(6): 1-10.ZHAO Yu, WU Xikai, ZHU Lingli, et al. Effect of carbon nanotubes on the rheological and mechanical properties of 3D printed concrete[J]. Materials Reports, 2023(6): 1-10(in Chinese). [16] ILCAN H, SAHIN O, KUL A, et al. Rheological property and extrudability performance assessment of construction and demolition waste-based geopolymer mortars with varied testing protocols[J]. Cement and Concrete Composites, 2023, 136: 104891. doi: 10.1016/j.cemconcomp.2022.104891 [17] WANG D, ZHANG T T, GUO X D, et al. The potential of 3D printing in facilitating carbon neutrality[J]. Journal of Environmental Sciences, 2023, 130: 85-91. doi: 10.1016/j.jes.2022.10.024 [18] ILCAN H, SAHIN O, KUL A, et al. Rheological properties and compressive strength of construction and demolition waste-based geopolymer mortars for 3D-printing[J]. Construction and Building Materials, 2022, 328: 127114. doi: 10.1016/j.conbuildmat.2022.127114 [19] LI V C, BOS F P, YU K Q, et al. On the emergence of 3D printable engineered, strain hardening cementitious composites (ECC/SHCC)[J]. Cement and Concrete Research, 2020, 132: 106038. doi: 10.1016/j.cemconres.2020.106038 [20] MA G W, LI Z J, WANG L, et al. Mechanical anisotropy of aligned fiber reinforced composite for extrusion-based 3D printing[J]. Construction and Building Materials, 2019, 202: 770-783. doi: 10.1016/j.conbuildmat.2019.01.008 [21] ZHONG H, ZHANG M Z. 3D printing geopolymers: A review[J]. Cement and Concrete Composites, 2022, 128: 104455. doi: 10.1016/j.cemconcomp.2022.104455 [22] HOU S D, DUAN Z H, XIAO J Z, et al. A review of 3D printed concrete: Performance requirements, testing measurements and mix design[J]. Construction and Building Materials, 2021, 273: 121745. doi: 10.1016/j.conbuildmat.2020.121745 [23] REHMAN A U, KIM J. 3D concrete printing: A systematic review of rheology, mix designs, mechanical, microstructural, and durability characteristics[J]. Materials, 2021, 14(14): 3800. doi: 10.3390/ma14143800 [24] 张超, 邓智聪, 马蕾, 等. 3D打印混凝土研究进展及其应用[J]. 硅酸盐通报, 2021, 40(6): 1769-1795.ZHANG Chao, DENG Zhicong, MA Lei, et al. Research progress and application of 3D printing concrete[J]. Bulletin of the Chinese Ceramic Society, 2021, 40(6): 1769-1795(in Chinese). [25] 焦泽坤, 王栋民, 王启宝, 等. 3D打印混凝土材料可打印性的影响因素与测试方法[J]. 硅酸盐通报, 2021, 40(6): 1821-1831.JIAO Zekun, WANG Dongming, WANG Qibao, et al. Influencing factors and testing methods of printability of 3D printing concrete materials[J]. Bulletin of the Chinese Ceramic Society, 2021, 40(6): 1821-1831(in Chinese). [26] SOUZA M T, FERREIRA I M, GUZI DE MORAES E, et al. 3D printed concrete for large-scale buildings: An overview of rheology, printing parameters, chemical admixtures, reinforcements, and economic and environmental prospects[J]. Journal of Building Engineering, 2020, 32: 101833. doi: 10.1016/j.jobe.2020.101833 [27] XIAO J Z, HOU S D, DUAN Z H, et al. Rheology of 3D printable concrete prepared by secondary mixing of ready-mix concrete[J]. Cement and Concrete Composites, 2023, 138: 104958. doi: 10.1016/j.cemconcomp.2023.104958 [28] DAI X D, TAO Y X, VAN TITTELBOOM K, et al. Rheological and mechanical properties of 3D printable alkali-activated slag mixtures with addition of nano clay[J]. Cement and Concrete Composites, 2023, 139: 104995. doi: 10.1016/j.cemconcomp.2023.104995 [29] ARUNOTHAYAN A R, NEMATOLLAHI B, KHAYAT K H, et al. Rheological characterization of ultra-high performance concrete for 3D printing[J]. Cement and Concrete Composites, 2023, 136: 104854. doi: 10.1016/j.cemconcomp.2022.104854 [30] XU Z Y, ZHANG D W, LI H, et al. Effect of FA and GGBFS on compressive strength, rheology, and printing properties of cement-based 3D printing material[J]. Construction and Building Materials, 2022, 339: 127685. doi: 10.1016/j.conbuildmat.2022.127685 [31] DUAN Z H, LI L, YAO Q Y, et al. Effect of metakaolin on the fresh and hardened properties of 3D printed cementitious composite[J]. Construction and Building Materials, 2022, 350: 128808. doi: 10.1016/j.conbuildmat.2022.128808 [32] ZHANG J C, WANG J L, DONG S F, et al. A review of the current progress and application of 3D printed concrete[J]. Composites Part A: Applied Science and Manufacturing, 2019, 125: 105533. doi: 10.1016/j.compositesa.2019.105533 [33] 赵宇, 武喜凯, 朱伶俐, 等. 玄武岩纤维对3D打印水泥基材料可打印性的影响[J]. 复合材料学报, 2022, 39(11): 5537-5547.ZHAO Yu, WU Xikai, ZHU Lingli, et al. Influence of basalt fiber on the printability of 3D printing cement-based materials[J]. Acta Materiae Compositae Sinica, 2022, 39(11): 5537-5547(in Chinese). [34] TRAN M V, CU Y T H, LE C V H. Rheology and shrinkage of concrete using polypropylene fiber for 3D concrete printing[J]. Journal of Building Engineering, 2021, 44: 103400. doi: 10.1016/j.jobe.2021.103400 [35] ZHANG Y, ZHANG Y S, LIU G J, et al. Fresh properties of a novel 3D printing concrete ink[J]. Construction and Building Materials, 2018, 174: 263-271. doi: 10.1016/j.conbuildmat.2018.04.115 [36] CHEN M X, YANG L, ZHENG Y, et al. Yield stress and thixotropy control of 3D-printed calcium sulfoaluminate cement composites with metakaolin related to structural build-up[J]. Construction and Building Materials, 2020, 252: 119090. doi: 10.1016/j.conbuildmat.2020.119090 [37] ROUSSEL N. Rheological requirements for printable concretes[J]. Cement and Concrete Research, 2018, 112: 76-85. doi: 10.1016/j.cemconres.2018.04.005 [38] MAZHOUD B, PERROT A, PICANDET V, et al. Underwater 3D printing of cement-based mortar[J]. Construction and Building Materials, 2019, 214: 458-467. doi: 10.1016/j.conbuildmat.2019.04.134 [39] YUAN Q, LI Z M, ZHOU D J, et al. A feasible method for measuring the buildability of fresh 3D printing mortar[J]. Construction and Building Materials, 2019, 227: 116600. doi: 10.1016/j.conbuildmat.2019.07.326 [40] DE VLIEGER J, BOEHME L, BLAAKMEER J, et al. Buildability assessment of mortar with fine recycled aggregates for 3D printing[J]. Construction and Building Materials, 2023, 367: 130313. doi: 10.1016/j.conbuildmat.2023.130313 [41] DENG Z C, JIA Z J, ZHANG C, et al. 3D printing lightweight aggregate concrete prepared with shell-packing-aggregate method—Printability, mechanical properties and pore structure[J]. Journal of Building Engineering, 2022, 62: 105404. doi: 10.1016/j.jobe.2022.105404 [42] ZHAO Z H, CHEN M X, XU J B, et al. Mix design and rheological properties of magnesium potassium phosphate cement composites based on the 3D printing extrusion system[J]. Construction and Building Materials, 2021, 284: 122797. doi: 10.1016/j.conbuildmat.2021.122797 [43] GUO X L, YANG J Y, XIONG G Y. Influence of supplementary cementitious materials on rheological properties of 3D printed fly ash based geopolymer[J]. Cement and Concrete Composites, 2020, 114: 103820. doi: 10.1016/j.cemconcomp.2020.103820 [44] LI K K, LENG Y, XU L L, et al. Rheological characteristics of ultra-high performance concrete (UHPC) incorporating bentonite[J]. Construction and Building Materials, 2022, 349: 128793. [45] ZHANG Y, ZHANG Y S, SHE W, et al. Rheological and harden properties of the high-thixotropy 3D printing concrete[J]. Construction and Building Materials, 2019, 201: 278-285. doi: 10.1016/j.conbuildmat.2018.12.061 [46] 朱江. 石粉对水泥浆体流变性能的影响及作用机制[D]. 重庆: 重庆大学, 2022.ZHU Jiang. Influence of microfines from manufactured sand on the rheological properties of cement paste and its mechanism [D]. Chongqing: Chongqing University, 2022(in Chinese). [47] QIAN Y, KAWASHIMA S. Use of creep recovery protocol to measure static yield stress and structural rebuilding of fresh cement pastes[J]. Cement and Concrete Research, 2016, 90: 73-79. doi: 10.1016/j.cemconres.2016.09.005 [48] PANDA B, LIM J H, TAN M J. Mechanical properties and deformation behaviour of early age concrete in the context of digital construction[J]. Composites Part B: Engineering, 2019, 165: 563-571. doi: 10.1016/j.compositesb.2019.02.040 [49] WALLEVIK J E. Rheological properties of cement paste: Thixotropic behavior and structural breakdown[J]. Cement and Concrete Research, 2009, 39(1): 14-29. doi: 10.1016/j.cemconres.2008.10.001 [50] ROUSSEL N, OVARLEZ G, GARRAULT S, et al. The origins of thixotropy of fresh cement pastes[J]. Cement and Concrete Research, 2012, 42(1): 148-157. doi: 10.1016/j.cemconres.2011.09.004 [51] REITER L, WANGLER T, ROUSSEL N, et al. The role of early age structural build-up in digital fabrication with concrete[J]. Cement and Concrete Research, 2018, 112: 86-95. doi: 10.1016/j.cemconres.2018.05.011 [52] KRUGER J, ZERANKA S, VAN ZIJL G. An ab initio approach for thixotropy characterisation of (nanoparticle-infused) 3D printable concrete[J]. Construction and Building Materials, 2019, 224: 372-386. doi: 10.1016/j.conbuildmat.2019.07.078 [53] CHEN M X, LI L B, WANG J A, et al. Rheological parameters and building time of 3D printing sulphoaluminate cement paste modified by retarder and diatomite[J]. Construction and Building Materials, 2020, 234: 117391. doi: 10.1016/j.conbuildmat.2019.117391 [54] ZHANG Z D, JIA Z J, SHI J Y, et al. Clarifying and quantifying the driving force for the evolution of static yield stress of cement pastes[J]. Cement and Concrete Research, 2023, 167: 107129. doi: 10.1016/j.cemconres.2023.107129 [55] WANG X G, JIA L T, JIA Z J, et al. Optimization of 3D printing concrete with coarse aggregate via proper mix design and printing process[J]. Journal of Building Engineering, 2022, 56: 104745. doi: 10.1016/j.jobe.2022.104745 [56] PANDA B, RUAN S, UNLUER C, et al. Improving the 3D printability of high volume fly ash mixtures via the use of nano attapulgite clay[J]. Composites Part B: Engineering, 2019, 165: 75-83. doi: 10.1016/j.compositesb.2018.11.109 [57] LIU C, CHEN Y N, ZHANG Z D, et al. Study of the influence of sand on rheological properties, bubble features and buildability of fresh foamed concrete for 3D printing[J]. Construction and Building Materials, 2022, 356: 129292. doi: 10.1016/j.conbuildmat.2022.129292 [58] KRUGER J, ZERANKA S, VAN ZIJL G. 3D concrete printing: A lower bound analytical model for buildability performance quantification[J]. Automation in Construction, 2019, 106: 102904. doi: 10.1016/j.autcon.2019.102904 [59] IBRAHIM K A, VAN ZIJL G P A G, BABAFEMI A J. Influence of limestone calcined clay cement on properties of 3D printed concrete for sustainable construction[J]. Journal of Building Engineering, 2023, 69: 106186. [60] ZHU L L, YAO J, ZHAO Y, et al. Effects of composite cementation system on rheological and working performances of fresh 3D-printable engineered cementitious composites[J]. Journal of Building Engineering, 2023, 65: 105801. doi: 10.1016/j.jobe.2022.105801 [61] AYDIN E M, KARA B, BUNDUR Z B, et al. A comparative evaluation of sepiolite and nano-montmorillonite on the rheology of cementitious materials for 3D printing[J]. Construction and Building Materials, 2022, 350: 128935. doi: 10.1016/j.conbuildmat.2022.128935 [62] LIU Q, JIANG Q, ZHOU Z H, et al. The printable and hardened properties of nano-calcium carbonate with modified polypropylene fibers for cement-based 3D printing[J]. Construction and Building Materials, 2023, 369: 130594. doi: 10.1016/j.conbuildmat.2023.130594 [63] ZHU B R, PAN J L, NEMATOLLAHI B, et al. Development of 3D printable engineered cementitious composites with ultra-high tensile ductility for digital construction[J]. Materials and Design, 2019, 181: 108088. doi: 10.1016/j.matdes.2019.108088 [64] RAHUL A V, SANTHANAM M, MEENA H, et al. 3D printable concrete: Mixture design and test methods[J]. Cement and Concrete Composites, 2019, 97: 13-23. doi: 10.1016/j.cemconcomp.2018.12.014 [65] ROUSSEL N. A thixotropy model for fresh fluid concretes: Theory, validation and applications[J]. Cement and Concrete Research, 2006, 36(10): 1797-1806. doi: 10.1016/j.cemconres.2006.05.025 [66] PERROT A, PIERRE A, VITALONI S, et al. Prediction of lateral form pressure exerted by concrete at low casting rates[J]. Materials and Structures, 2015, 48(7): 2315-2322. doi: 10.1617/s11527-014-0313-8 [67] ROUSSEL N. Steady and transient flow behaviour of fresh cement pastes[J]. Cement and Concrete Research, 2005, 35(9): 1656-1664. doi: 10.1016/j.cemconres.2004.08.001 [68] MARCHON D, KAWASHIMA S, BESSAIES-BEY H, et al. Hydration and rheology control of concrete for digital fabrication: Potential admixtures and cement chemistry[J]. Cement and Concrete Research, 2018, 112: 96-110. doi: 10.1016/j.cemconres.2018.05.014 [69] PERROT A, RANGEARD D, PIERRE A. Structural built-up of cement-based materials used for 3D-printing extrusion techniques[J]. Materials and Structures, 2016, 49(4): 1213-1220. doi: 10.1617/s11527-015-0571-0 [70] SHAHMIRZADI M R, GHOLAMPOUR A, KASHANI A, et al. Shrinkage behavior of cementitious 3D printing materials: Effect of temperature and relative humidity[J]. Cement and Concrete Composites, 2021, 124: 104238. doi: 10.1016/j.cemconcomp.2021.104238 [71] PAUL S C, TAY Y W D, PANDA B, et al. Fresh and hardened properties of 3D printable cementitious materials for building and construction[J]. Archives of Civil and Mechanical Engineering, 2018, 18(1): 311-319. doi: 10.1016/j.acme.2017.02.008 [72] 刘宇. 复合胶凝材料浆体的结构建立与流变性能研究[D]. 北京: 清华大学, 2022.LIU Yu. Study on the structural build-up and rheological property of composite cementitious materials paste [D]. Beijing: Tsinghua University, 2022(in Chinese). [73] WALLEVIK J. Rheology of particle suspensions: Fresh concrete, mortar and cement paste with various types of lignosulfonates[D]. Trondheim: The Norwegian University of Science and Technology, 2003. [74] LIU C, WANG X G, CHEN Y N, et al. Influence of hydroxypropyl methylcellulose and silica fume on stability, rheological properties, and printability of 3D printing foam concrete[J]. Cement and Concrete Composites, 2021, 122: 104158. doi: 10.1016/j.cemconcomp.2021.104158 [75] ZHANG N, SANJAYAN J. Extrusion nozzle design and print parameter selections for 3D concrete printing[J]. Cement and Concrete Composites, 2023, 137: 104939. doi: 10.1016/j.cemconcomp.2023.104939 [76] 张俊逸. 低温环境与外加剂对水泥基材料流变行为的影响研究[D]. 哈尔滨: 哈尔滨工业大学, 2022.ZHANG Junyi. Effects of low temperature and admixtures on rheological behavior of cement-based materials [D]. Harbin: Harbin Institute of Technology, 2022(in Chinese). [77] PANDA B, PAUL S C, MOHAMED N A N, et al. Measurement of tensile bond strength of 3D printed geopolymer mortar[J]. Journal of the International Measurement Confederation, 2018, 113: 108-116. [78] 姜波, 郭新宇, 焦欢, 等. 木质素基复合材料的直写式3D打印及其功能应用[J]. 复合材料学报, 2023, 40(4): 1913-1923.JIANG Bo, GUO Xinyu, JIAO Huan, et al. Direct ink writing of lignin-based composites and their applications[J]. Acta Materiae Compositae Sinica, 2023, 40(4): 1913-1923(in Chinese). [79] CHEN M X, LIU B, LI L B, et al. Rheological parameters, thixotropy and creep of 3D-printed calcium sulfoaluminate cement composites modified by bentonite[J]. Composites Part B: Engineering, 2020, 186: 107821. doi: 10.1016/j.compositesb.2020.107821 [80] LONG W J, TAO J L, LIN C, et al. Rheology and buildability of sustainable cement-based composites containing micro-crystalline cellulose for 3D-printing[J]. Journal of Cleaner Production, 2019, 239: 118054. doi: 10.1016/j.jclepro.2019.118054 [81] PENG Y M, MA K L, UNLUER C, et al. Method for calculating dynamic yield stress of fresh cement pastes using a coaxial cylinder system[J]. Journal of the American Ceramic Society, 2021, 104: 5557-5570. [82] GÜNEYISI E, GESOGLU M, ALGıN Z, et al. Rheological and fresh properties of self-compacting concretes containing coarse and fine recycled concrete aggregates[J]. Construction and Building Materials, 2016, 113: 622-630. doi: 10.1016/j.conbuildmat.2016.03.073 [83] FEYS D, VERHOEVEN R, DE SCHUTTER G. Fresh self compacting concrete, a shear thickening material[J]. Cement and Concrete Research, 2008, 38(7): 920-929. doi: 10.1016/j.cemconres.2008.02.008 [84] BURROUGHS J F, WEISS J, HADDOCK J E. Influence of high volumes of silica fume on the rheological behavior of oil well cement pastes[J]. Construction and Building Materials, 2019, 203: 401-407. doi: 10.1016/j.conbuildmat.2019.01.027 [85] MARCHON D, JUILLAND P, GALLUCCI E, et al. Molecular and submolecular scale effects of comb-copolymers on tri-calcium silicate reactivity: Toward molecular design[J]. Journal of the American Ceramic Society, 2017, 100(3): 817-841. doi: 10.1111/jace.14695 [86] KOVLER K, ROUSSEL N. Properties of fresh and hardened concrete[J]. Cement and Concrete Research, 2011, 41(7): 775-792. doi: 10.1016/j.cemconres.2011.03.009 [87] JIAO D W, SHI C J, YUAN Q, et al. Effect of constituents on rheological properties of fresh concrete—A review[J]. Cement and Concrete Composites, 2017, 83: 146-159. doi: 10.1016/j.cemconcomp.2017.07.016 [88] LI H Y, ZHANG L Q, DING S Q, et al. Effects and mechanisms of incorporated nanoparticles on the rheological performance of cement pastes[J]. Journal of Building Engineering, 2023, 73: 106694. doi: 10.1016/j.jobe.2023.106694 [89] FERRARIS C, DELARRARD F. Testing and modeling of fresh concrete rheology [R]. Gaithersburg: National Institute of Standards and Technology, 1998. [90] HU C, DE LARRARD F. The rheology of fresh high-performance concrete[J]. Cement and Concrete Research, 1996, 26(2): 283-294. doi: 10.1016/0008-8846(95)00213-8 [91] ORR C, BLOCKER H G. The viscosity of suspensions of spheres[J]. Journal of Colloid Science, 1955, 10(1): 24-28. doi: 10.1016/0095-8522(55)90074-X [92] CHIDIAC S E, MAHMOODZADEH F. Plastic viscosity of fresh concrete—A critical review of predictions methods[J]. Cement and Concrete Composites, 2009, 31(8): 535-544. doi: 10.1016/j.cemconcomp.2009.02.004 [93] ZHAO Y, DUAN Y H, ZHU L L, et al. Characterization of coarse aggregate morphology and its effect on rheological and mechanical properties of fresh concrete[J]. Construction and Building Materials, 2021, 286: 122940. doi: 10.1016/j.conbuildmat.2021.122940 [94] LI T, NOGUEIRA R, DE BRITO J, et al. Underlying mechanisms of the influence of fine aggregates' content and properties on mortar's plastic viscosity[J]. Journal of Building Engineering, 2023, 67: 106016. doi: 10.1016/j.jobe.2023.106016 [95] MAHMOODZADEH F, CHIDIAC S E. Rheological models for predicting plastic viscosity and yield stress of fresh concrete[J]. Cement and Concrete Research, 2013, 49: 1-9. doi: 10.1016/j.cemconres.2013.03.004 [96] QIAN Y, DE SCHUTTER G. Enhancing thixotropy of fresh cement pastes with nanoclay in presence of polycarboxylate ether superplasticizer (PCE)[J]. Cement and Concrete Research, 2018, 111: 15-22. doi: 10.1016/j.cemconres.2018.06.013 [97] PANDA B, UNLUER C, TAN M J. Extrusion and rheology characterization of geopolymer nanocomposites used in 3D printing[J]. Composites Part B: Engineering, 2019, 176: 107290. doi: 10.1016/j.compositesb.2019.107290 [98] ASSAAD J J, KHAYAT K H. Assessment of thixotropy of self-consolidating concrete and concrete-equivalent-mortar—Effect of binder composition and content[J]. Materials, 2004, 101: 400-408. [99] QIAN Y, LESAGE K, EL CHEIKH K, et al. Effect of polycarboxylate ether superplasticizer (PCE) on dynamic yield stress, thixotropy and flocculation state of fresh cement pastes in consideration of the critical micelle concentration (CMC)[J]. Cement and Concrete Research, 2018, 107: 75-84. doi: 10.1016/j.cemconres.2018.02.019 [100] 叶焕. 不同胶凝材料体系的絮凝特性及流变性能[D]. 哈尔滨: 哈尔滨工业大学, 2019.YE Huan. Flocculation and rheological performance of variable cementitious systems [D]. Harbin: Harbin Institute of Technology, 2019(in Chinese). [101] JIAO D W, DE SCHRYVER R, SHI C J, et al. Thixotropic structural build-up of cement-based materials: A state-of-the-art review[J]. Cement and Concrete Composites, 2021, 122: 104152. doi: 10.1016/j.cemconcomp.2021.104152 [102] MOHAN M K, RAHUL A V, VAN TITTELBOOM K, et al. Rheological and pumping behaviour of 3D printable cementitious materials with varying aggregate content[J]. Cement and Concrete Research, 2021, 139: 106258. doi: 10.1016/j.cemconres.2020.106258 [103] ZHANG Y S, LIU C, LIU Z Y, et al. Modelling of diffusion behavior of ions in low-density and high-density calcium silicate hydrate[J]. Construction and Building Materials, 2017, 155: 965-980. doi: 10.1016/j.conbuildmat.2017.08.128 [104] QUANJI Z J, LOMBOY G R, WANG K. Influence of nano-sized highly purified magnesium alumino silicate clay on thixotropic behavior of fresh cement pastes[J]. Construction and Building Materials, 2014, 69: 295-300. doi: 10.1016/j.conbuildmat.2014.07.050 [105] WENG Y, LU B, LI M, et al. Empirical models to predict rheological properties of fiber reinforced cementitious composites for 3D printing[J]. Construction and Building Materials, 2018, 189: 676-685. doi: 10.1016/j.conbuildmat.2018.09.039 [106] CHAVES FIGUEIREDO S, ROMERO RODRÍGUEZ C, AHMED Z Y, et al. An approach to develop printable strain hardening cementitious composites[J]. Materials & Design, 2019, 169: 107651. [107] CHEN Y, CHAVES FIGUEIREDO S, YALÇINKAYA Ç, et al. The effect of viscosity-modifying admixture on the extrudability of limestone and calcined clay-based cementitious material for extrusion-based 3D concrete printing[J]. Materials, 2019, 12(9): 1374. doi: 10.3390/ma12091374 [108] SARUHAN V, KESKINATEŞ M, FELEKOĞLU B. A comprehensive review on fresh state rheological properties of extrusion mortars designed for 3D printing applications[J]. Construction and Building Materials, 2022, 337: 127629. doi: 10.1016/j.conbuildmat.2022.127629 [109] LU B, WENG Y W, LI M Y, et al. A systematical review of 3D printable cementitious materials[J]. Construction and Building Materials, 2019, 207: 477-490. doi: 10.1016/j.conbuildmat.2019.02.144 [110] SAKAI E, KASUGA T, SUGIYAMA T, et al. Influence of superplasticizers on the hydration of cement and the pore structure of hardened cement[J]. Cement and Concrete Research, 2006, 36(11): 2049-2053. doi: 10.1016/j.cemconres.2006.08.003 [111] CHENG D C. Thixotropy[J]. International Journal of Cosmetic Science, 1987, 9(4): 151-191. doi: 10.1111/j.1467-2494.1987.tb00472.x [112] LE T T, AUSTIN S A, LIM S, et al. Mix design and fresh properties for high-performance printing concrete[J]. Materials and Structures, 2012, 45(8): 1221-1232. doi: 10.1617/s11527-012-9828-z [113] CHEN Y, CHAVES FIGUEIREDO S, LI Z M, et al. Improving printability of limestone-calcined clay-based cementitious materials by using viscosity-modifying admixture[J]. Cement and Concrete Research, 2020, 132: 106040. doi: 10.1016/j.cemconres.2020.106040 [114] SOLTAN D G, LI V C. A self-reinforced cementitious composite for building-scale 3D printing[J]. Cement and Concrete Composites, 2018, 90: 1-13. doi: 10.1016/j.cemconcomp.2018.03.017 [115] BRUMAUD C, BAUMANN R, SCHMITZ M, et al. Cellulose ethers and yield stress of cement pastes[J]. Cement and Concrete Research, 2014, 55: 14-21. doi: 10.1016/j.cemconres.2013.06.013 [116] YUN K, CHOI S, YEON J H. Effects of admixtures on the rheological properties of high-performance wet-mix shotcrete mixtures[J]. Construction and Building Materials, 2015, 78: 194-202. doi: 10.1016/j.conbuildmat.2014.12.117 [117] CHEUNG J, JEKNAVORIAN A, ROBERTS L, et al. Impact of admixtures on the hydration kinetics of Portland cement[J]. Cement and Concrete Research, 2011, 41(12): 1289-1309. doi: 10.1016/j.cemconres.2011.03.005 [118] WENG Y W, RUAN S Q, LI M Y, et al. Feasibility study on sustainable magnesium potassium phosphate cement paste for 3D printing[J]. Construction and Building Materials, 2019, 221: 595-603. doi: 10.1016/j.conbuildmat.2019.05.053 [119] MUTHUKRISHNAN S, RAMAKRISHNAN S, SANJAYAN J. Technologies for improving buildability in 3D concrete printing[J]. Cement and Concrete Composites, 2021, 122: 104144. doi: 10.1016/j.cemconcomp.2021.104144 [120] MALAEB Z, HACHEM H, TOURBAH A, et al. 3D concrete printing: Machine and mix design[J]. International Journal of Civil Engineering and Technology, 2015, 6: 14-22. [121] BENTZ D P, JONES S Z, BENTZ I R, et al. Towards the formulation of robust and sustainable cementitious binders for 3D additive construction by extrusion[J]. Construction and Building Materials, 2018, 175: 215-224. doi: 10.1016/j.conbuildmat.2018.04.167 [122] TARHAN Y, ŞAHIN R. Fresh and rheological performances of air-entrained 3D printable mortars[J]. Materials, 2021, 14(9): 2409. doi: 10.3390/ma14092409 [123] SHANTANU B, SMRATI J, MANU S. Criticality of binder-aggregate interaction for buildability of 3D printed concrete containing limestone calcined clay[J]. Cement and Concrete Composites, 2023, 136: 104853. doi: 10.1016/j.cemconcomp.2022.104853 [124] ZHANG C, JIA Z J, WANG X G, et al. A two-phase design strategy based on the composite of mortar and coarse aggregate for 3D printable concrete with coarse aggregate[J]. Journal of Building Engineering, 2022, 54: 104672. doi: 10.1016/j.jobe.2022.104672 [125] HU J, WANG K J. Effect of coarse aggregate characteristics on concrete rheology[J]. Construction and Building Materials, 2011, 25(3): 1196-1204. doi: 10.1016/j.conbuildmat.2010.09.035 [126] DUAN Z H, HOU S D, XIAO J Z, et al. Rheological properties of mortar containing recycled powders from construction and demolition wastes[J]. Construction and Building Materials, 2020, 237: 117622. doi: 10.1016/j.conbuildmat.2019.117622 [127] YANG H, CHE Y. Recycling of aggregate micro fines as a partial replacement for fly ash in 3D printing cementitious materials[J]. Construction and Building Materials, 2022, 321: 126372. doi: 10.1016/j.conbuildmat.2022.126372 [128] WENG Y, LI M, TAN M J, et al. Design 3D printing cementitious materials via Fuller Thompson theory and Marson-Percy model[J]. Construction and Building Materials, 2018, 163: 600-610. doi: 10.1016/j.conbuildmat.2017.12.112 [129] DILS J, BOEL V, DE SCHUTTER G. Influence of cement type and mixing pressure on air content, rheology and mechanical properties of UHPC[J]. Construction and Building Materials, 2013, 41: 455-463. doi: 10.1016/j.conbuildmat.2012.12.050 [130] KHALIL N, AOUAD G, EL CHEIKH K, et al. Use of calcium sulfoaluminate cements for setting control of 3D-printing mortars[J]. Construction and Building Materials, 2017, 157: 382-391. doi: 10.1016/j.conbuildmat.2017.09.109 [131] 徐卓越, 李辉, 张大旺, 等. 建筑3D打印用胶凝材料及其相关性能研究进展[J]. 材料导报, 2023, 37(12): 93-106. doi: 10.11896/cldb.21080117XU Zhuoyue, LI Hui, ZHANG Dawang, et al. Research progress of cementitious materials and related properties for building 3D printing[J]. Materials Reports, 2023, 37(12): 93-106(in Chinese). doi: 10.11896/cldb.21080117 [132] MA G W, SALMAN N M, WANG L, et al. A novel additive mortar leveraging internal curing for enhancing interlayer bonding of cementitious composite for 3D printing[J]. Construction and Building Materials, 2020, 244: 118305. doi: 10.1016/j.conbuildmat.2020.118305 [133] 崔天龙, 王里, 马国伟, 等. HB-CSA与膨胀剂对3D打印混凝土收缩开裂性能的影响[J]. 材料导报, 2022, 36(2): 76-82. doi: 10.11896/cldb.20120078CUI Tianlong, WANG Li, MA Guowei, et al. Effect of HB-CSA and expansion agent on shrinkage and cracking performance of 3D printing concrete[J]. Materials Reports, 2022, 36(2): 76-82(in Chinese). doi: 10.11896/cldb.20120078 [134] KHALIL A, WANG X Y, CELIK K. 3D printable magnesium oxide concrete: Towards sustainable modern architecture[J]. Additive Manufacturing, 2020, 33: 101145. doi: 10.1016/j.addma.2020.101145 [135] CHOUGAN M, GHAFFAR S H, SIKORA P, et al. Investigation of additive incorporation on rheological, microstructural and mechanical properties of 3D printable alkali-activated materials[J]. Materials & Design, 2021, 202: 109574. [136] PANDA B, RUAN S, UNLUER C, et al. Investigation of the properties of alkali-activated slag mixes involving the use of nanoclay and nucleation seeds for 3D printing[J]. Composites Part B: Engineering, 2020, 186: 107826. doi: 10.1016/j.compositesb.2020.107826 [137] GARCÍA-TAENGUA E, SONEBI M, HOSSAIN K M A, et al. Effects of the addition of nanosilica on the rheology, hydration and development of the compressive strength of cement mortars[J]. Composites Part B: Engineering, 2015, 81: 120-129. doi: 10.1016/j.compositesb.2015.07.009 [138] KRUGER J, VAN DEN HEEVER M S, CHO S Z, et al. High-performance 3D printable concrete enhanced with nanomaterials [C]//SERDAR M. International Conference on Sustainable Materials, Systems and Structures. Croatia: Curran Associates Inc, 2019: 533. [139] MENDOZA REALES O A, DUDA P, SILVA E C C M, et al. Nanosilica particles as structural buildup agents for 3D printing with Portland cement pastes[J]. Construction and Building Materials, 2019, 219: 91-100. doi: 10.1016/j.conbuildmat.2019.05.174 [140] 刘雄飞, 侯冠宇, 蔡华崇, 等. 协同连续布筋增韧喷射3D打印混凝土抗弯性能研究[J]. 材料导报, 2024(1): 1-17.LIU Xiongfei, HOU Guanyu, CAI Huachong, et al. Flexural performance of spray-based 3D printed concrete with continuous micro-cable[J]. Materials Reports, 2024(1): 1-17(in Chinese). [141] 白刚, 王里, 王芳, 等. 3D打印UHPC的制备和力学性能试验研究[J]. 材料导报, 2021, 35(12): 12063-12069. doi: 10.11896/cldb.20040209BAI Gang, WANG Li, WANG Fang, et al. Investigation of the printability and mechanical properties of 3D printing UHPC[J]. Materials Reports, 2021, 35(12): 12063-12069 (in Chinese). doi: 10.11896/cldb.20040209 [142] LI L G, XIAO B F, FANG Z Q, et al. Feasibility of glass/basalt fiber reinforced seawater coral sand mortar for 3D printing[J]. Additive Manufacturing, 2021, 37: 101684. doi: 10.1016/j.addma.2020.101684 [143] ZHAO Y, YANG G, ZHU L L, et al. Effects of rheological properties and printing speed on molding accuracy of 3D printing basalt fiber cementitious materials[J]. Journal of Materials Research and Technology, 2022, 21: 3462-3475. doi: 10.1016/j.jmrt.2022.10.124 [144] CHU S H, LI L G, KWAN A K H. Development of extrudable high strength fiber reinforced concrete incorporating nano calcium carbonate[J]. Additive Manufacturing, 2021, 37: 101617. doi: 10.1016/j.addma.2020.101617 [145] 周港明, 杭美艳, 路兰, 等. 风积沙3D打印砂浆材料参数与各向异性研究[J]. 材料导报, 2022, 36(9): 105-109. doi: 10.11896/cldb.21020081ZHOU Gangming, HANG Meiyan, LU Lan, et al. Material parameters and anisotropy research of 3D printing mortar after incorporating with aeolian sand[J]. Materials Reports, 2022, 36(9): 105-109(in Chinese). doi: 10.11896/cldb.21020081 [146] PANG Z, LU C, LI B, et al. A multiscale model for quantifying fiber orientation effects on the tensile properties of 3D printed engineered cementitious composites (3DP-ECC)[J]. Journal of Building Engineering, 2023, 68: 106090. [147] WANG L, LI Q, HU Y, et al. Shrinkage and cracking properties of cellulose fiber-concrete composites for 3D printing by leveraging internal curing[J]. 3D Printing and Additive Manufacturing, 2022, 11(1): 50-59. [148] KHAYAT K H, MENG W, VALLURUPALLI K, et al. Rheological properties of ultra-high-performance concrete—An overview[J]. Cement and Concrete Research, 2019, 124: 105828. doi: 10.1016/j.cemconres.2019.105828 [149] RAJEEV P, RAMESH A, NAVARATNAM S, et al. Using fibre recovered from face mask waste to improve printability in 3D concrete printing[J]. Cement and Concrete Composites, 2023, 139: 105047. doi: 10.1016/j.cemconcomp.2023.105047 [150] 张立卿, 潘延念, 胡文兵, 等. 废弃瓷砖粉对超高性能混凝土的抗压强度影响规律与机制[J]. 复合材料学报, 2023, 40(3): 1611-1623.ZHANG Liqing, PAN Yannian, HU Wenbing, et al. Effect law and mechanism of ceramic tile powder on compressive strength of ultra high performance concrete[J]. Acta Materiae Compositae Sinica, 2023, 40(3): 1611-1623(in Chinese). [151] 陈梦成, 张锐, 赵旺平, 等. 养护温度对陶瓷粉-水泥复合胶体水化的影响[J]. 华东交通大学学报, 2021, 38(5): 48-55.CHEN Mengcheng, ZHANG Rui, ZHAO Wangping, et al. Effect of curing temperature on hydration of ceramic powder-cement composite colloid[J]. Journal of East China Jiaotong University, 2021, 38(5): 48-55(in Chinese). [152] NAIR S A O, PANDA S, SANTHANAM M, et al. A critical examination of the influence of material characteristics and extruder geometry on 3D printing of cementitious binders[J]. Cement and Concrete Composites, 2020, 112: 103671. doi: 10.1016/j.cemconcomp.2020.103671 [153] PANDA B, UNLUER C, TAN M J. Investigation of the rheology and strength of geopolymer mixtures for extrusion-based 3D printing[J]. Cement and Concrete Composites, 2018, 94: 307-314. doi: 10.1016/j.cemconcomp.2018.10.002 [154] PANDA B, TAN M J. Rheological behavior of high volume fly ash mixtures containing micro silica for digital construction application[J]. Materials Letters, 2019, 237: 348-351. [155] DEY D, SRINIVAS D, BODDEPALLI U, et al. 3D printability of ternary Portland cement mixes containing fly ash and limestone[J]. Materials Today: Proceedings, 2022, 70: 195-200. doi: 10.1016/j.matpr.2022.09.020 [156] KAZEMIAN A, YUAN X, COCHRAN E, et al. Cementitious materials for construction-scale 3D printing: Laboratory testing of fresh printing mixture[J]. Construction and Building Materials, 2017, 145: 639-647. doi: 10.1016/j.conbuildmat.2017.04.015 [157] 刘一帆, 吴泽媚, 张轩翰, 等. 超高性能混凝土流变特性及调控研究进展[J]. 硅酸盐学报, 2023, 51(11): 3025-3038.LIU Yifan, WU Zemei, ZHANG Xuanhan, et al. Rheological properties and their regulation of ultra-high performance concrete—A short review[J]. Journal of the Chinese Ceramic Society, 2023, 51(11): 3025-3038. [158] AHARI R S, ERDEM T K, RAMYAR K. Thixotropy and structural breakdown properties of self consolidating concrete containing various supplementary cementitious materials[J]. Cement and Concrete Composites, 2015, 59: 26-37. doi: 10.1016/j.cemconcomp.2015.03.009 [159] PARK C K, NOH M H, PARK T H. Rheological properties of cementitious materials containing mineral admixtures[J]. Cement and Concrete Research, 2005, 35(5): 842-849. doi: 10.1016/j.cemconres.2004.11.002 [160] BENTZ D P, FERRARIS C F, GALLER M A, et al. Influence of particle size distributions on yield stress and viscosity of cement-fly ash pastes[J]. Cement and Concrete Research, 2012, 42(2): 404-409. doi: 10.1016/j.cemconres.2011.11.006 [161] CHEN Y, HE S, GAN Y D, et al. A review of printing strategies, sustainable cementitious materials and characterization methods in the context of extrusion-based 3D concrete printing[J]. Journal of Building Engineering, 2022, 45: 103599. doi: 10.1016/j.jobe.2021.103599 [162] VANCE K, KUMAR A, SANT G, et al. The rheological properties of ternary binders containing Portland cement, limestone, and metakaolin or fly ash[J]. Cement and Concrete Research, 2013, 52: 196-207. doi: 10.1016/j.cemconres.2013.07.007 [163] UYSAL M, YILMAZ K. Effect of mineral admixtures on properties of self-compacting concrete[J]. Cement and Concrete Composites, 2011, 33: 771-776. doi: 10.1016/j.cemconcomp.2011.04.005 [164] BONG S H, XIA M, NEMATOLLAHI B, et al. Ambient temperature cured ‘just-add-water’ geopolymer for 3D concrete printing applications[J]. Cement and Concrete Composites, 2021, 121: 104060. doi: 10.1016/j.cemconcomp.2021.104060 [165] 朱伶俐, 杨章, 赵宇, 等. 钢渣-矿渣复合水泥基材料3D打印性能[J]. 材料导报, 2023, 37(12): 107-112. doi: 10.11896/cldb.21100196ZHU Lingli, YANG Zhang, ZHAO Yu, et al. 3D printing performance of composite cement-based materials with blast furnace slag and steel slag[J]. Materials Reports, 2023, 37(12): 107-112 (in Chinese). doi: 10.11896/cldb.21100196 [166] DINIZ H A A, MARTINELLI A E, CABRAL K C, et al. Synergistic effects of the use of metakaolin, sand and water on the properties of cementitious composites for 3D printing[J]. Construction and Building Materials, 2023, 366: 130277. doi: 10.1016/j.conbuildmat.2022.130277 [167] NAIR S A O, ALGHAMDI H, ARORA A, et al. Linking fresh paste microstructure, rheology and extrusion characteristics of cementitious binders for 3D printing[J]. Journal of the American Ceramic Society, 2019, 102(7): 3951-3964. doi: 10.1111/jace.16305 [168] CHEN Y, HE S, ZHANG Y, et al. 3D printing of calcined clay-limestone-based cementitious materials[J]. Cement and Concrete Research, 2021, 149: 106553. doi: 10.1016/j.cemconres.2021.106553 [169] LI Y, KWAN A K H. Ternary blending of cement with fly ash microsphere and condensed silica fume to improve the performance of mortar[J]. Cement and Concrete Composites, 2014, 49: 26-35. doi: 10.1016/j.cemconcomp.2014.02.002 [170] KASHANI A, SAN NICOLAS R, QIAO G, et al. Modelling the yield stress of ternary cement-slag-fly ash pastes based on particle size distribution[J]. Powder Technology, 2014, 266: 203-209. doi: 10.1016/j.powtec.2014.06.041 [171] TAY Y W D, LI M Y, TAN M J. Effect of printing parameters in 3D concrete printing: Printing region and support structures[J]. Journal of Materials Processing Technology, 2019, 271: 261-270. doi: 10.1016/j.jmatprotec.2019.04.007 [172] CHEN Y, JANSEN K, ZHANG H Z, et al. Effect of printing parameters on interlayer bond strength of 3D printed limestone-calcined clay-based cementitious materials: An experimental and numerical study[J]. Construction and Building Materials, 2020, 262: 120094. doi: 10.1016/j.conbuildmat.2020.120094 [173] SHAKOR P, NEJADI S, PAUL G. A study into the effect of different nozzles shapes and fibre-reinforcement in 3D printed mortar[J]. Materials, 2019, 12(10): 1708. [174] 武雷, 郭潞杰, 康强. 3D打印混凝土工艺参数对成型精度的影响[J]. 混凝土与水泥制品, 2020(11): 1-5.WU Lei, GUO Lujie, KANG Qiang. The influence of 3D printed concrete process parameters on forming precision[J]. China Concrete and Cement Products, 2020(11): 1-5 (in Chinese). [175] 史庆轩, 万胜木, 王秋维, 等. 喷嘴行进速度及高度对3D打印混凝土力学性能影响的试验[J]. 复合材料学报, 2023, 40(4): 2273-2284.SHI Qingxuan, WAN Shengmu, WANG Qiuwei, et al. Experimental investigations on the influence of nozzle travel speed and height on the mechanical properties of 3D printed concrete[J]. Acta Materiae Compositae Sinica, 2023, 40(4): 2273-2284(in Chinese). [176] EL CHEIKH K, RÉMOND S, KHALIL N, et al. Numerical and experimental studies of aggregate blocking in mortar extrusion[J]. Construction and Building Materials, 2017, 145: 452-463. doi: 10.1016/j.conbuildmat.2017.04.032 [177] XU J, DING L Y, CAI L X, et al. Volume-forming 3D concrete printing using a variable-size square nozzle[J]. Automation in Construction, 2019, 104: 95-106. doi: 10.1016/j.autcon.2019.03.008 [178] YANG L M, SEPASGOZAR S M E, SHIROWZHAN S, et al. Nozzle criteria for enhancing extrudability, buildability and interlayer bonding in 3D printing concrete[J]. Automation in Construction, 2023, 146: 104671. doi: 10.1016/j.autcon.2022.104671 [179] ZHANG C, NERELLA V N, KRISHNA A, et al. Mix design concepts for 3D printable concrete: A review[J]. Cement and Concrete Composites, 2021, 122: 104155. doi: 10.1016/j.cemconcomp.2021.104155 [180] WENG Y W, LI M Y, ZHANG D, et al. Investigation of interlayer adhesion of 3D printable cementitious material from the aspect of printing process[J]. Cement and Concrete Research, 2021, 143: 106386. doi: 10.1016/j.cemconres.2021.106386 [181] JOH C, LEE J, BUI T Q, et al. Buildability and mechanical properties of 3D printed concrete[J]. Materials, 2020, 13(21): 4919. doi: 10.3390/ma13214919 [182] LIU X F, CAI H C, MA G W, et al. Spray-based 3D concrete printing parameter design model: Actionable insight for high printing quality[J]. Cement and Concrete Composites, 2024, 147: 105446. doi: 10.1016/j.cemconcomp.2024.105446 [183] COMMINAL R, DA SILVA W R L, ANDERSEN T J, et al. Influence of processing parameters on the layer geometry in 3D concrete printing: Experiments and modelling[C]. Cham: Springer International Publishing, 2020. [184] XU W B, ZHANG Y L, ZUO X H, et al. Time-dependent rheological and mechanical properties of silica fume modified cemented tailings backfill in low temperature environment[J]. Cement and Concrete Composites, 2020, 114: 103804. doi: 10.1016/j.cemconcomp.2020.103804 [185] DU J, GUO P W, MENG W N. Effect of water-based nanoclay and ambient temperature on rheological properties of UHPC pastes[J]. Construction and Building Materials, 2023, 370: 130733. doi: 10.1016/j.conbuildmat.2023.130733 [186] CHENG H Y, WU S C, LI H, et al. Influence of time and temperature on rheology and flow performance of cemented paste backfill[J]. Construction and Building Materials, 2020, 231: 117117. doi: 10.1016/j.conbuildmat.2019.117117 [187] HONG S, KIM H. Effects of microwave energy on fast compressive strength development of coal bottom ash-based geopolymers[J]. Scientific Reports, 2019, 9(1): 15694. doi: 10.1038/s41598-019-52160-2 [188] MUTHUKRISHNAN S, RAMAKRISHNAN S, SANJAYAN J. Effect of microwave heating on interlayer bonding and buildability of geopolymer 3D concrete printing[J]. Construction and Building Materials, 2020, 265: 120786. doi: 10.1016/j.conbuildmat.2020.120786 -

下载:

下载: