Research on dry friction and wear characteristics of SiC/AZ91D composites based on Archard wear mode

-

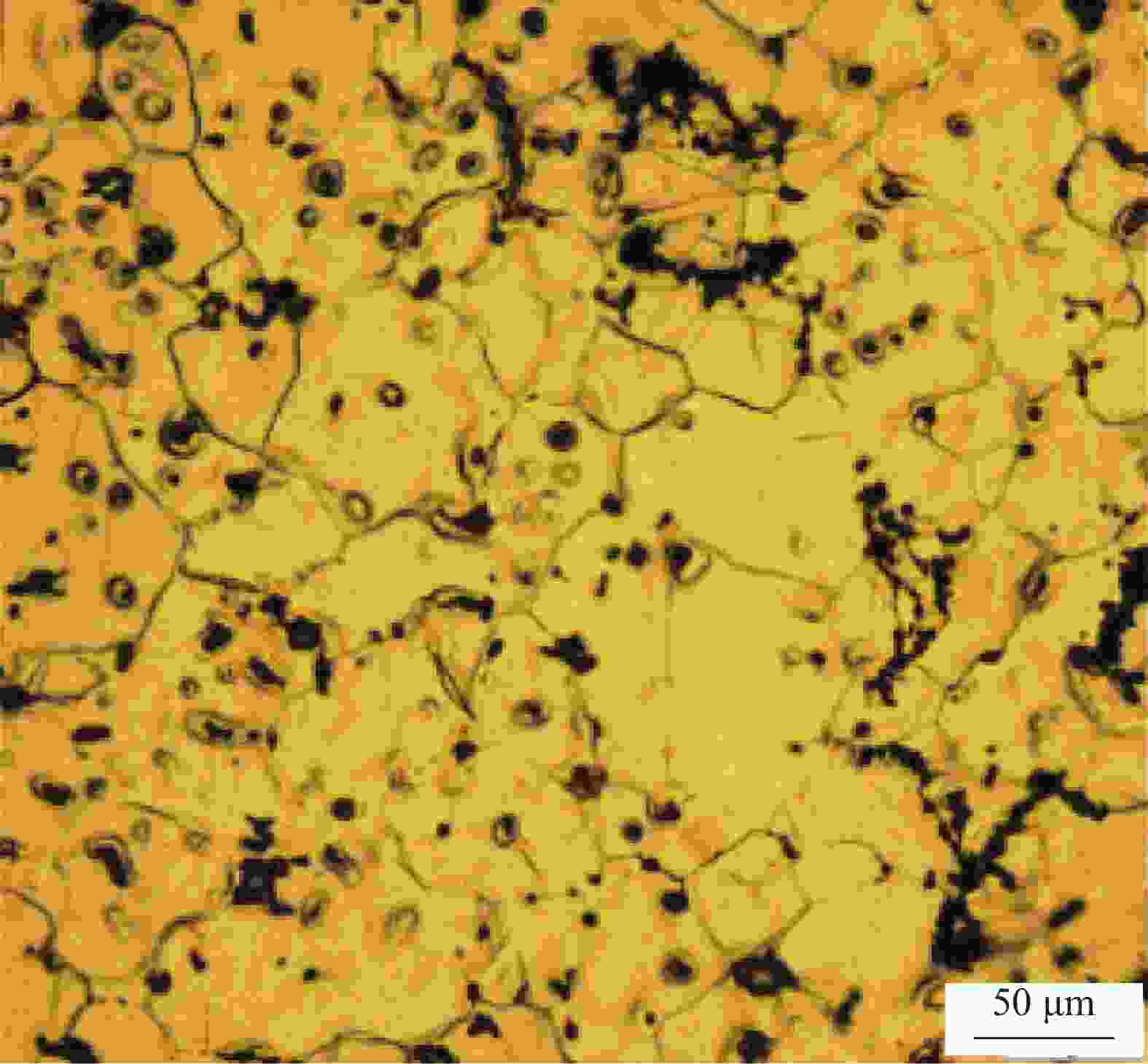

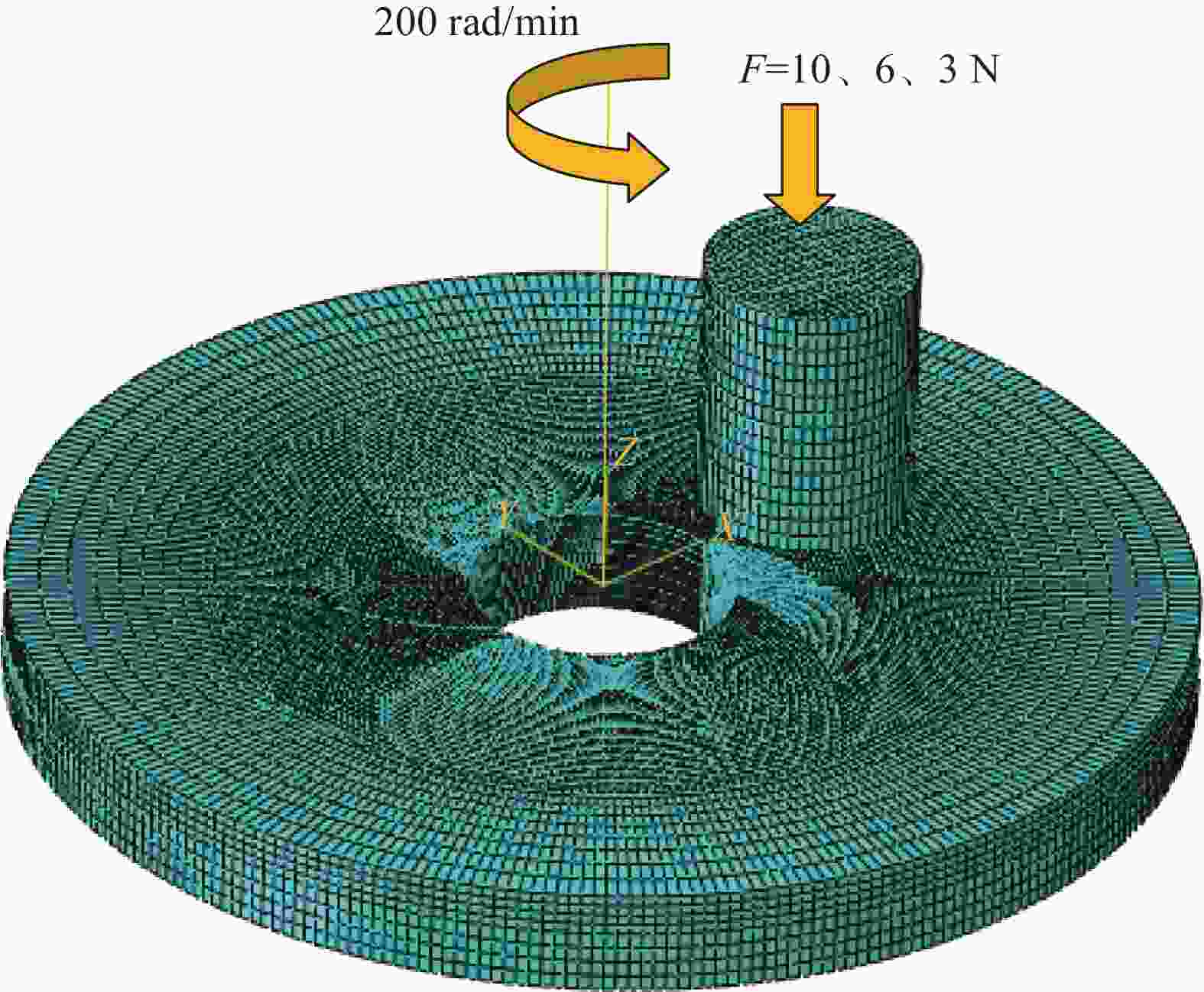

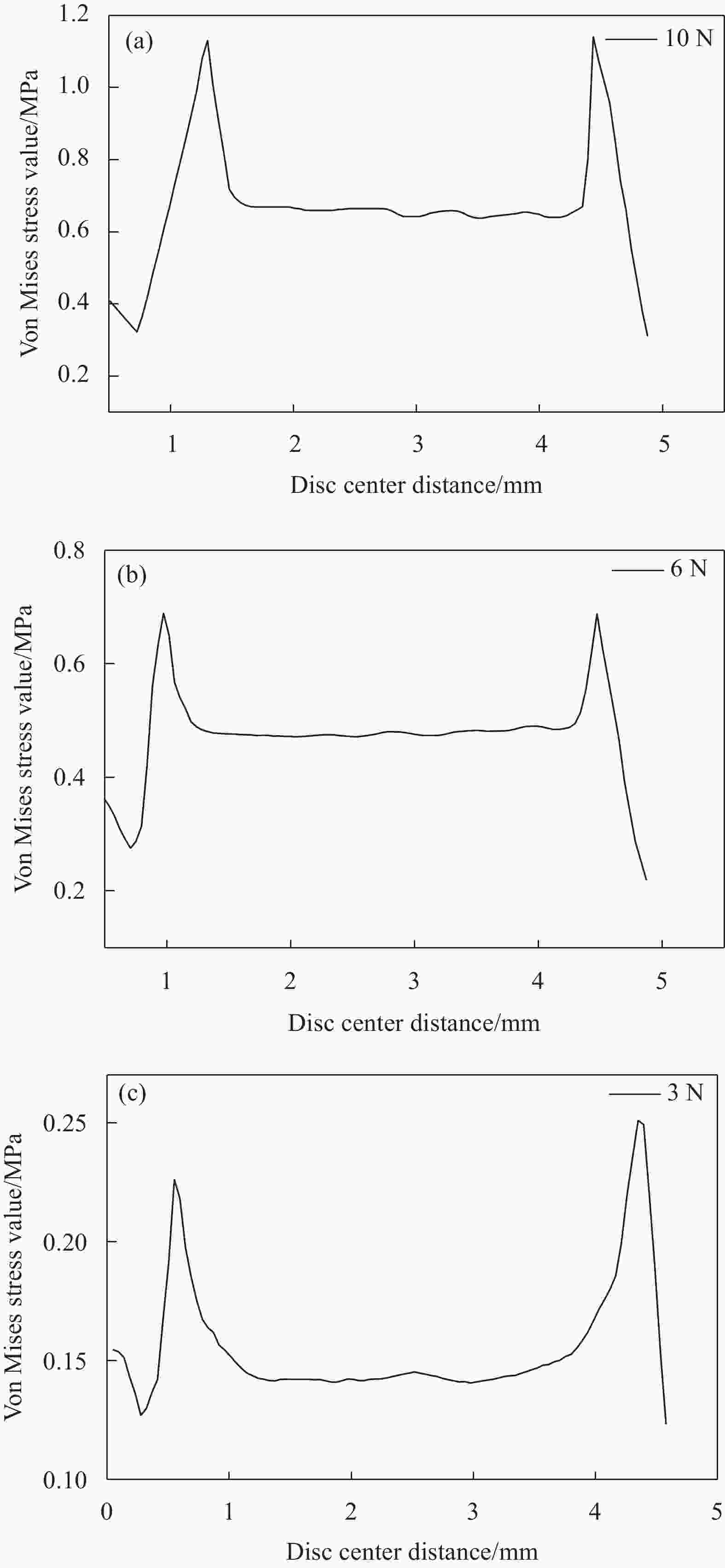

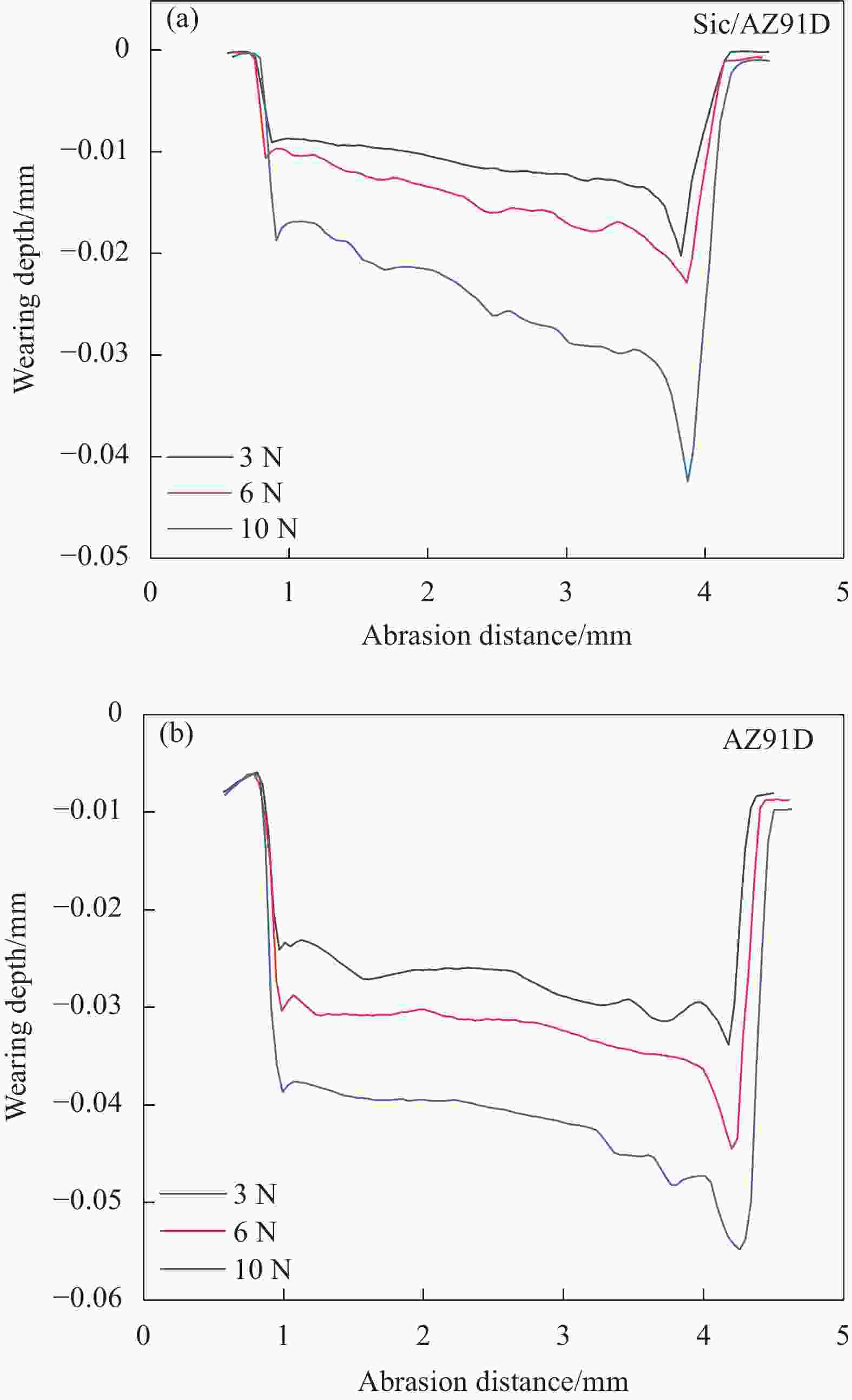

摘要: 颗粒增强镁基复合材料在活塞制造中具有重要意义,活塞使用寿命与其材料的摩擦磨损性能关系密切,为预测镁基复合材料活塞耐磨性。基于Archard磨损模型结合自适应网格技术,建立SiC/AZ91D镁基复合材料及其基体有限元模型,探究其在不同载荷下的磨损行为,考察其应力场分布、磨损深度,进行了试验验证,揭示磨损机理。结果表明:在不同载荷下,盘销的接触面均表现出距盘轴心最近与最远处应力值较大,其它径向区域较小。随着载荷增加,盘销接触区域各处均表现出应力值增大。在不同载荷下,盘销接触面均表现出距盘轴心最近处磨损深度较小,离盘轴心径向距离增加,磨损深度越来越大。随着载荷增加,盘销接触区域各处均表现出磨损深度数值增大。但复合材料的磨损深度小于基体,表现出较好的耐磨性能。磨粒磨损和剥层磨损为复合材料主要磨损机制,粘着磨损为基体合金的主要磨损机理,模拟结果与试验结果吻合较好。

-

关键词:

- 镁基复合材料 /

- 有限元模拟 /

- 摩擦磨损 /

- Archard磨损模型

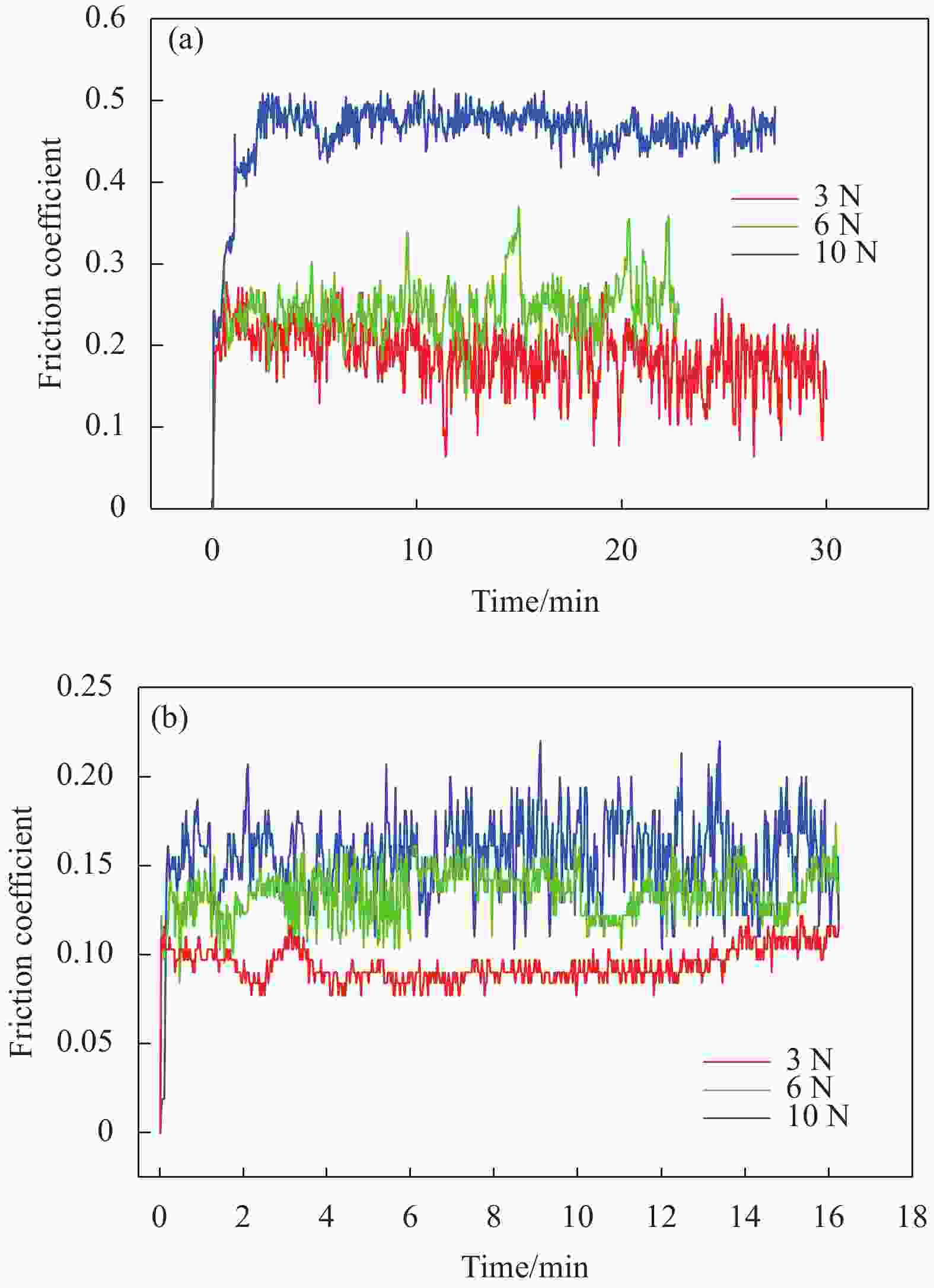

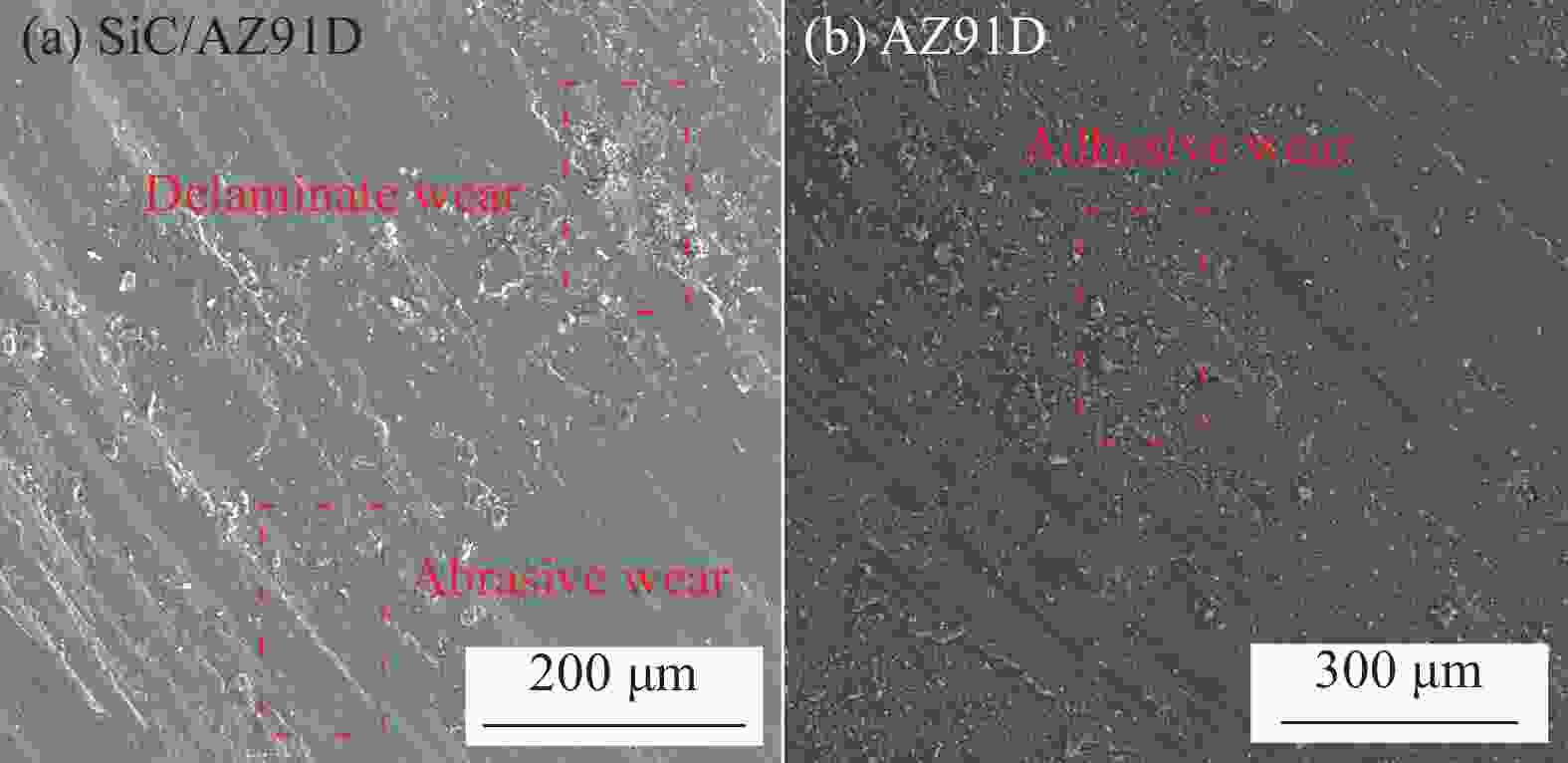

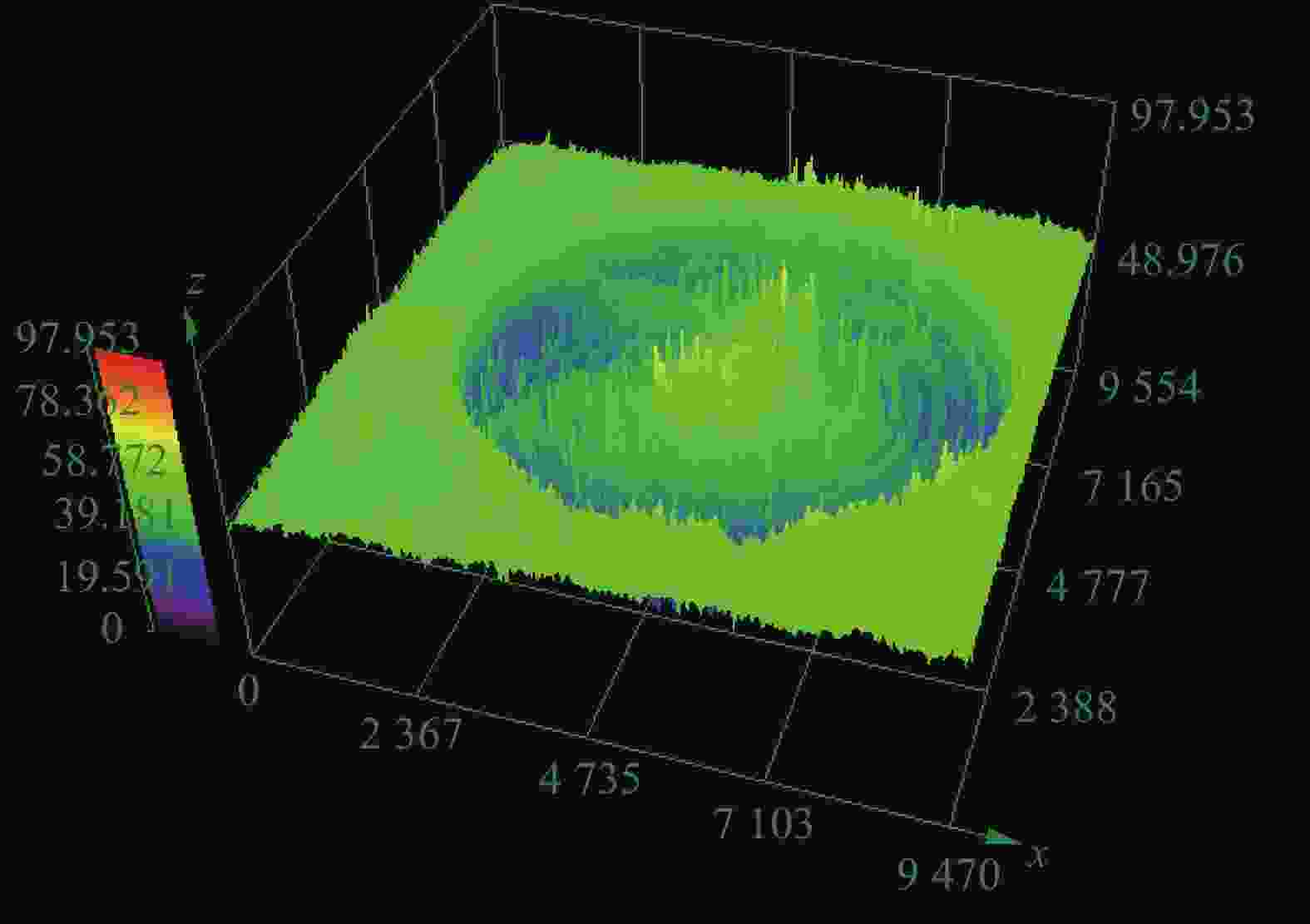

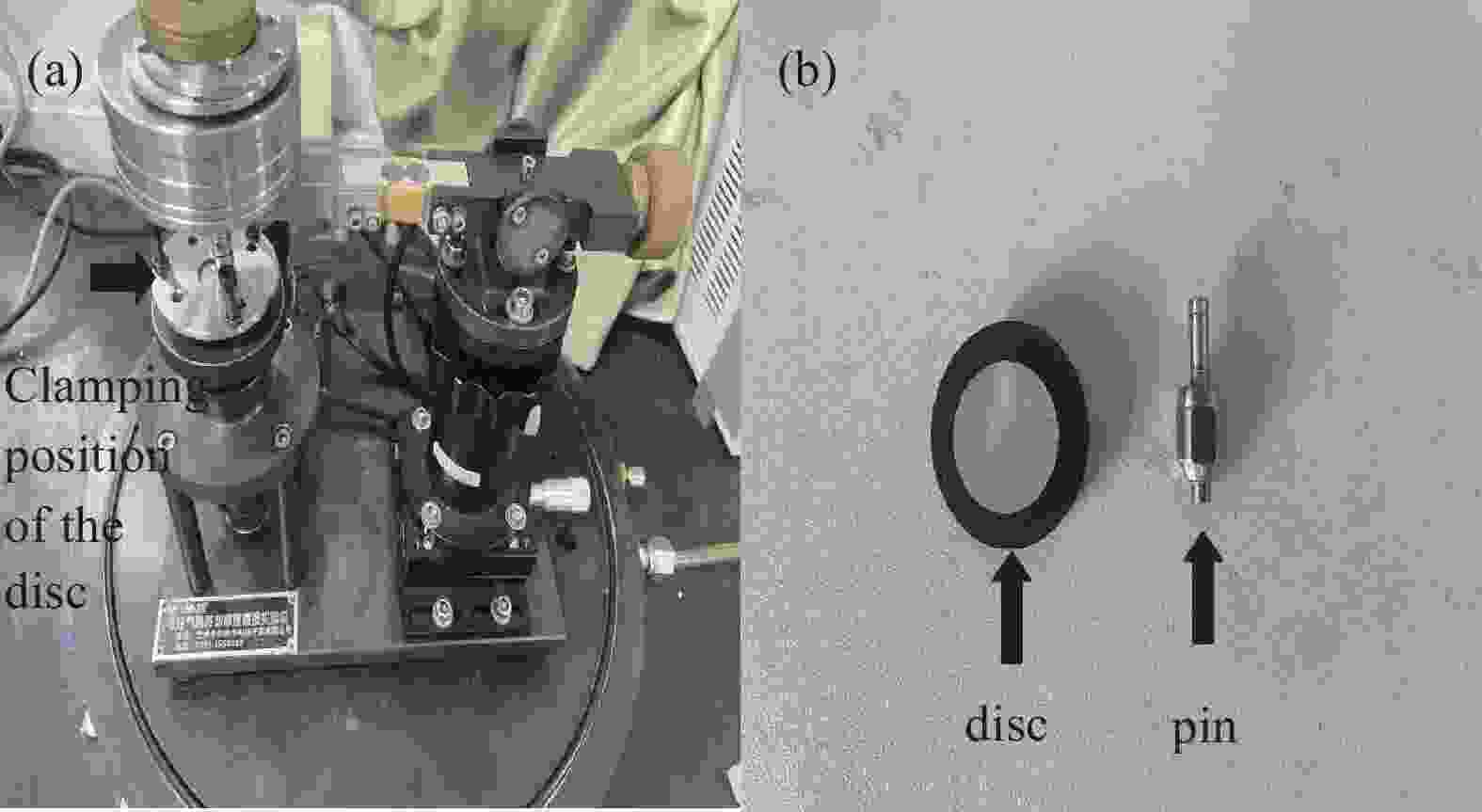

Abstract: The particle reinforced magnesium matrix composite is of great significance in the manufacture of piston. The service life of piston is closely related to the friction and wear properties of the material, so it can predict the wear resistance of magnesium matrix composite piston. Based on Archard wear model and adaptive mesh technology, a finite element model of SiC/AZ91D magnesium matrix composite and its matrix was established to explore its wear behavior under different loads, investigate its stress field distribution and wear depth, and conduct experimental verification to reveal the wear mechanism. The results show that, under different loads, the stress values of the nearest and furthest distance from the disc axis are larger on the contact surface of the disc pin, while other radial regions are smaller. With the increase of load, the stress values in all parts of the disc and pin contact area increase. Under different loads, the wear depth of the contact surface of the disc pin is smaller at the closest point to the disc axis, and the wear depth is larger and larger with the increase of the radial distance from the disc axis. With the increase of load, the wear depth increases in all parts of the disc and pin contact area. However, the wear depth of the composite is less than that of the matrix, which shows better wear resistance. Abrasive wear and peeling wear are the main wear mechanisms of the composite, adhesive wear is the main wear mechanism of the matrix alloy, and the simulation results are in good agreement with the experimental results. -

表 1 材料的基本参数

Table 1. Basic parameters of the materials

Material $ \rho $/(kg·m−3) $ \sigma_{\mathrm{S}} $/MPa $ \mu $ E/MPa HB GCr15 7.18 518.5 0.3 20800 248 SiC/AZ91D 1.84 204 0.35 62000 65 AZ91D 1.82 160 0.3 44800 58 Notes: $ \rho $ is the material density; E is the modulus of elasticity; $ \mu $ is Poisson's ratio; $ \sigma_{\mathrm{S}} $ is the yield strength; HB is Brinell hardness number. 表 2 实验条件

Table 2. Experiment condition

No. Load/N Rtation speed/

(rad·min−1)Time/min Material 1 3 200 20 SiC/AZ91D 2 6 200 20 SiC/AZ91D 3 10 200 20 SiC/AZ91D 4 3 200 20 AZ91D 5 6 200 20 AZ91D 6 10 200 20 AZ91D -

[1] 李紫阳, 薄文杰, 张清林, 等. 外场对SiCp/AZ91D 镁基复合材料组织和性能的影响[J]. 复合材料学报, 2022, 39(1): 275-284.LI Ziyang, BO Wenjie, ZHANG Qinglin, et al. Effect of compound field on microstructure and properties of SiCp/AZ91D magnesium matrix composites[J]. Acta Materiae Compositae Sinica, 2022, 39(1): 275-284(in Chinese). [2] 李怡然, 尧军平, 黄浩, 等. SiC/AZ91D镁基复合材料单轴拉伸过程中裂纹萌生扩展机制[J]. 塑性工程学报, 2023, 30(2): 185-196. doi: 10.3969/j.issn.1007-2012.2023.02.022LI Yiran, YAO Junping, HUANG Hao, et al. Crack initiation and propagation mechanism of SiC/ AZ91D magnesium matrix composites during uniaxial tension[J]. Journal of Plasticity Engineering, 2023, 30(2): 185-196(in Chinese). doi: 10.3969/j.issn.1007-2012.2023.02.022 [3] YU, Xiaowen, JIANG, Bin, He, Junjie, et al. Oxidation resistance of Mg-Y alloys at elevated temperatures and the protection performance of the oxide films[J]. Journal of Alloys and Compound: 2018, 749: 1054-1062 [4] 吕鑫, 邓坤坤, 王翠菊, 等. SiCp/尺寸对铸态AZ91 镁合金显微组织与腐蚀性能的影响[J]. 中国腐蚀与防护学报, 2023, 43(1): 136-142.Lv Xin, Deng Kunkun, Wang Cuiju, et al. Effect of SiCp size on microstructure and corrosion properties of as-cast AZ91 magnesium alloy[J]. Journal of Chinese Society for Corrosion and Protection, 2023, 43(1): 136-142(in Chinese). [5] 刘世英, 李文珍, 张琼元, 等. SiCp/AZ91D 纳米复合材料的摩擦磨损行为研究[J]. 稀有金属材料与工程, 2012, 41(1): 110-114.LI Shiying, LI Wenzhen, ZHANG Qingyuan, et al. Study on friction and wear behavior of SiCp/AZ91D nanocomposites[J]. Rare Metal Materials and Engineering, 2012, 41(1): 110-114(in Chinese). [6] Arjmandi, M. , Ramezani, M. , Giordano, M, et al. Finite Element Modelling of Sliding Wear in Three-Dimensional Woven Textiles[J]. Tribology Internationa, 2017, 115: 452-460. [7] Ajit Bastola a, David Stewart b, Daniele Dini. Three-dimensional finite element simulation and experimental validation of sliding wear[J]. Wear, 2022, 204402: 504-505. [8] Ashish Soni a, Pankaj Kumar Das, Tribological characterizations and numerical simulations of thermoplastic composites in pin-on-disc configuration[J], Materials Today, 2023, 79: 92–99. [9] R. Suresh. , M. Prasanna Kumar, S. Basavarajappa, et al. Numerical Simulation & Experimental study of wear depth and Contact pressure distribution Of Aluminum MMC Pin on Disc Tribometer[J]. Materials Today, 2017, 4: 11218–11228. [10] E. Falconnet, H. Makich, J. C. Monteil, Numerical and experimental analyses of punch wear in the blanking of copper alloy thin sheet[J]. Wear, 2012, 296: 598-606. doi: 10.1016/j.wear.2012.07.031 [11] 吕景儒, 殷玉枫, 张锦, 等. 基于C17200与34CrNiMo6材料的摩擦磨损特性与数值模拟研究[J]. 表面技术, 2023, 52(04): 176-177.LYU Jing-ru, YIN Yu-feng, ZHANG Jin, et al. Frictional Wear Properties and Numerical Simulation of C17200 and 34CrNiMo6 Materials[J]. Surface Technology, 2023, 52(4): 172-183. (in Chinese) [12] Kunal Kumar Bose, Ramkumar Penchaliah. 3-D FEM Wear Prediction of Brass Sliding against Bearing Steel Using Constant Contact Pressure Approximation Technique[J]. Tribology Online, 2019, 14: 194-207. doi: 10.2474/trol.14.194 [13] V. Hegadekattea, N. Huberb. Modeling and simulation of wear in a pin on disc tribometer[J]. Tribology Letters, 2006, 10(24): 1-10. [14] WANG Ye-qing, PASILIAO C L. Modeling Ablation of Laminated Composites: A Novel Manual Mesh Moving Finite Element Analysis Procedure with ABAQUS[J]. International Journal of Heat and Mass Transfer, 2018, 116: 306-313. doi: 10.1016/j.ijheatmasstransfer.2017.09.038 [15] CAI Mingxin, ZHANG Po, XIONG Qiwen. Finite Element Analysis of Fretting Wear under Variable Coefficient of Friction and Different Contact Regimes[J]. Tribology International, 2023, 177: 107930. doi: 10.1016/j.triboint.2022.107930 [16] MilošStankovi c, Aleksandar Marinkovi c, Aleksandar Grbovi c, Determination of Archard’s wear coefficient and wear simulation of sliding bearings[J]. Industrial Lubrication and Tribology, 2018, 71: 119-125 [17] Arvin Taghizadeh Tabrizi a, Hossein Aghajani b, Hasan Saghafian c. Correction of Archard equation for wear behavior of modified pure titanium[J]. Tribology International, 2021, 115: 106772. [18] E. M. Bortoleto, A. C. Rovani, V. Seriacopi, Experimental and numerical analysis of dry contact in the pinon disc test[J]. Wea, 2013, 301: 19–26 [19] ZHANG Wenchao, ZHANG Yu, GUO Haoliang. An investigation on the tribological properties of nano-tungsten carbide coating by ESD[J]. Journal of Engineering Research, 2023, 8: Available online [20] 李宏伟, 李增权. SiC颗粒增强镁基复合材料的制备与组织性能研究[J]. 精密成形工程, 2023, 15(5): 36-43LI Hongwei, LI Zengquan. Preparation and microstructure properties of SiC particle reinforced magnesium matrix composites[J]. Precision forming engineering, 2023, 15(5): 36-43(in Chinese). [21] Priit Po˜dra a, So¨ren Andersson b. Simulating sliding wear with finite element method[J]. Tribology International, 1999, 8: 71-81 [22] Ashish Soni, Pankaj Kumar Das. Tribological characterizations and numerical simulations of thermoplastic composites in pin-on-dis configuration[J]. Materials Today, 2023, 79: 92-99 [23] 肖博升, 王新宇. 基于修正Archard模型的聚醚醚酮磨损数值模拟[J]. 工程塑料应, 2017, 45(09): 91-92XIAO Bosheng, WANG Xinyu. Numerical simulation of polyether ether ketone wear based on modified Archard model[J]. Engineering plastics application, 2017, 45(09): 88-104. (in Chinese) [24] G. Straffelini, M. Pellizzari, A. Molinari, Influence of load and temperature on the dry sliding behaviour of Al-based metal-matrix-composites against friction material[J]. Wear, 2004, 256: 7-8. [25] 卢楠楠, SiCp_AZ91D镁基复合材料的摩擦磨损行为研究[D]. 哈尔滨工业大学, 2015.Lv Nannan, Study on friction and wear behavior of SiCp AZ91D magnesium matrix composites[D]. HIT(Harbin Institute of Technology), 2015. [26] 张永振, 邱明, 上官宝, 等. 高速干摩擦条件下铝基复合材料的摩擦磨损行为研究[J]. 摩擦学学报, 2005, 25(4): 343-347.ZHANG Yongzhen, QIU Ming, SHANGGUAN Bao, et al. Study on friction and wear behavior of aluminum matrix composites under high speed dry friction[J]. Tribology, 2005, 25(4): 343-347(in Chinese). [27] 梁超群, 尧军平, 李怡然, 等. SiC/AZ91D 镁基复合材料单轴压缩过程中裂纹萌生扩展机制[J]. 复合材料学报, 2023, 40(7): 4282-4293.LIANG Chaoqun, YAO Junping, LI Yiran, et al. Crack initiation and propagation mechanism during uniaxial compression of SiC/AZ91Dmagnesium matrix composites[J]. Acta Materiae Compositae Sinica, 2023, 40(7): 4282-4293(in Chinese). -

点击查看大图

点击查看大图

计量

- 文章访问数: 264

- HTML全文浏览量: 91

- 被引次数: 0

下载:

下载: