Effect of low-temperature plasma surface modification on the adhesive performance of CFRP

-

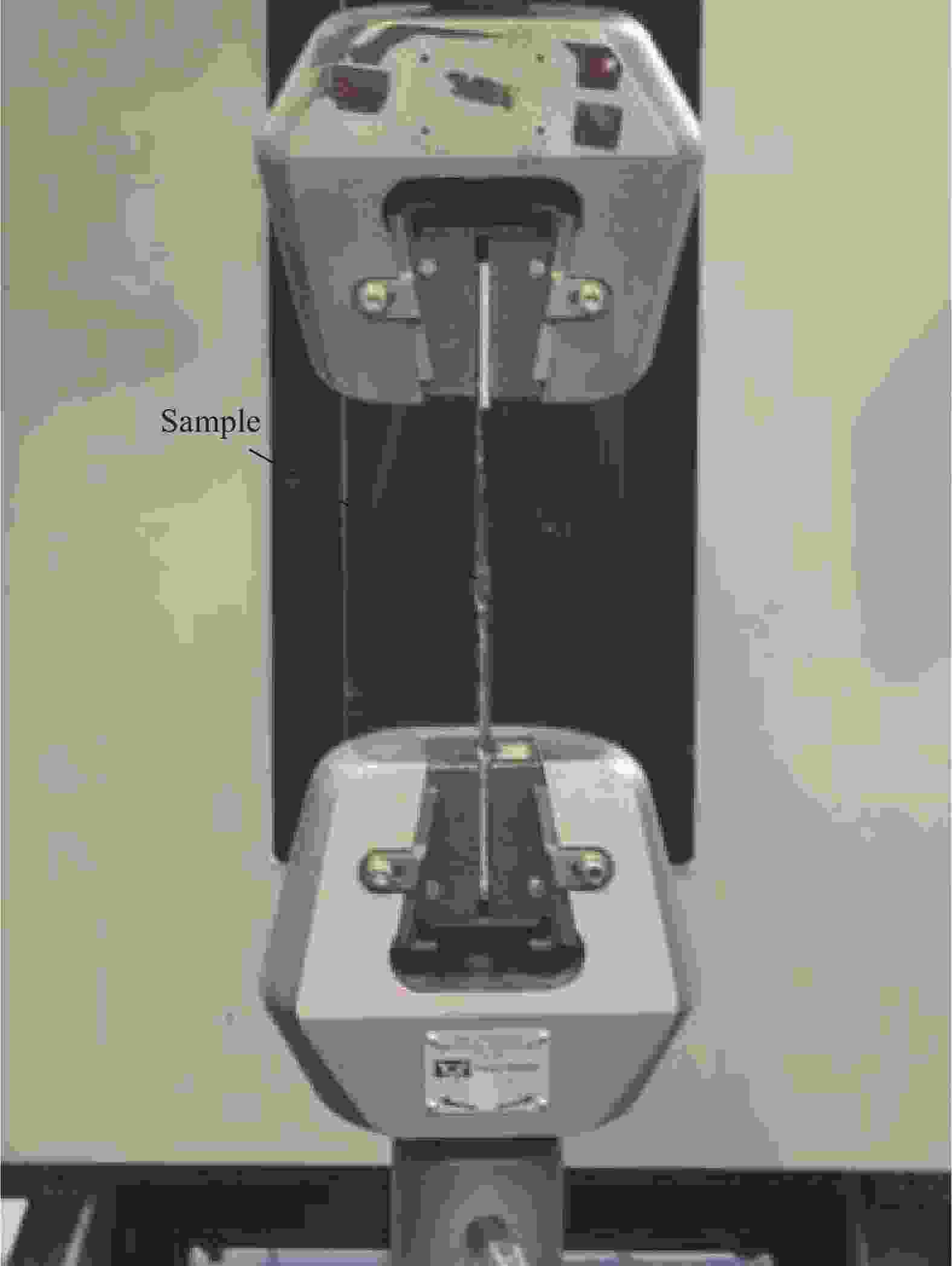

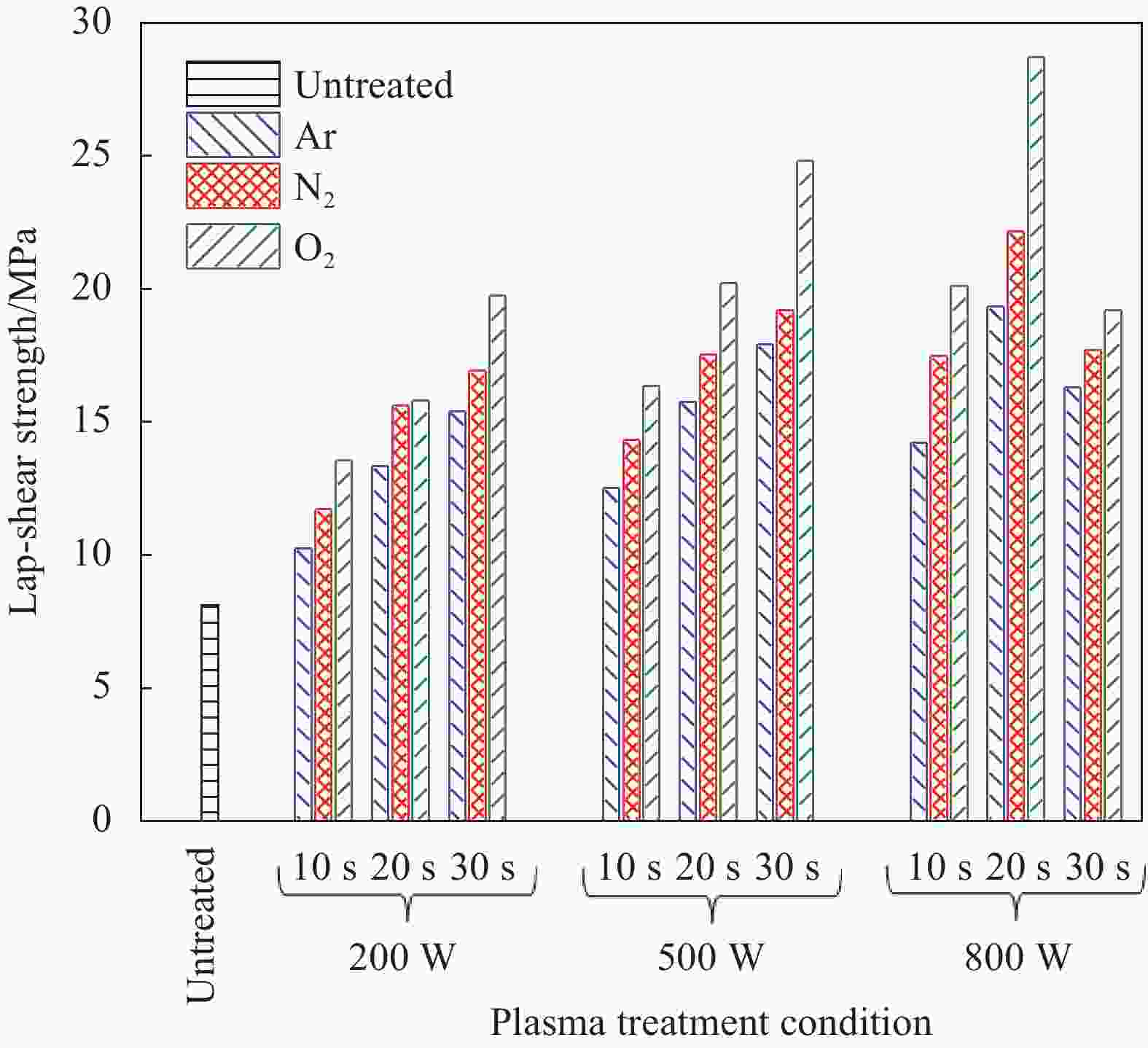

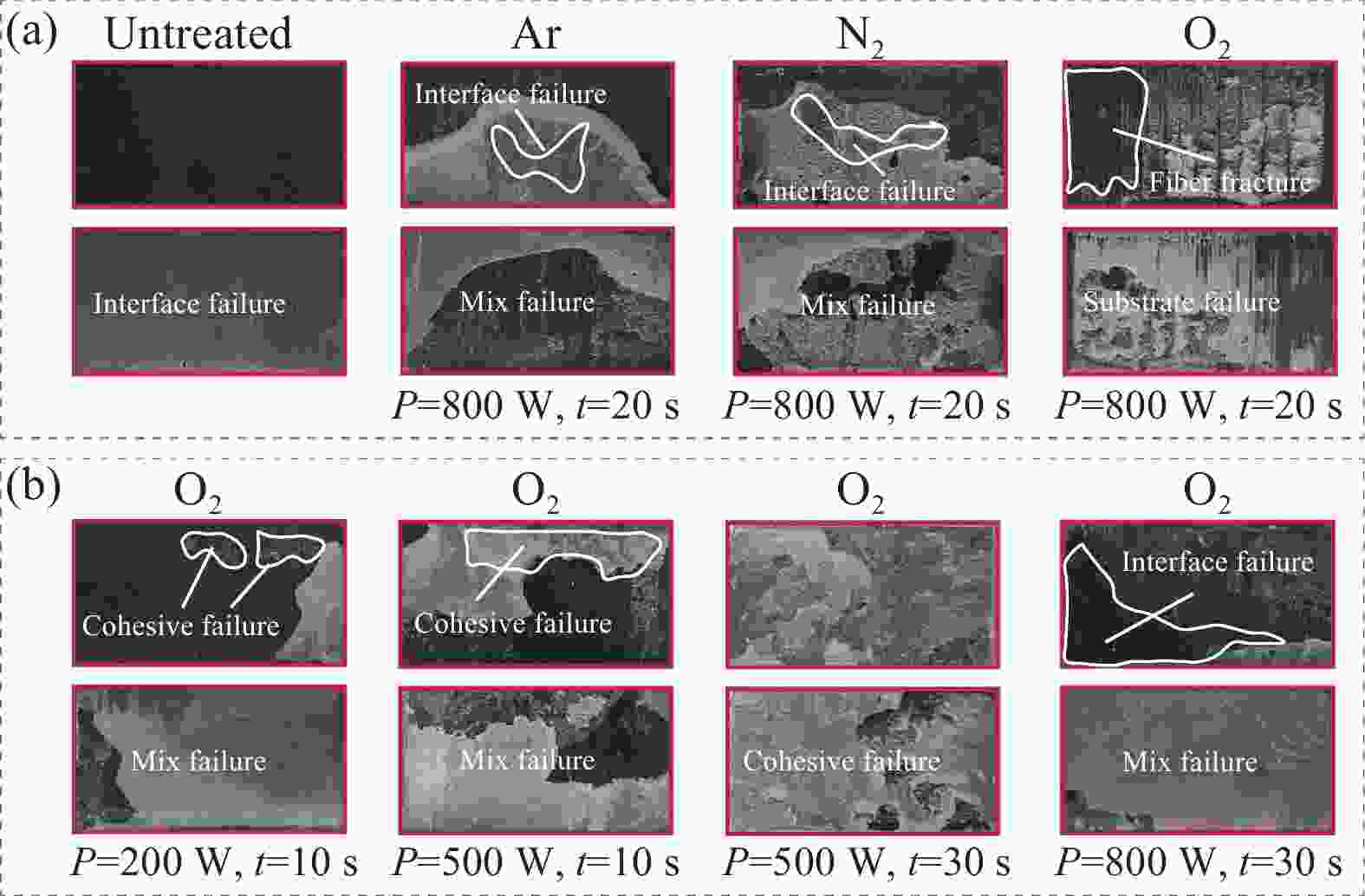

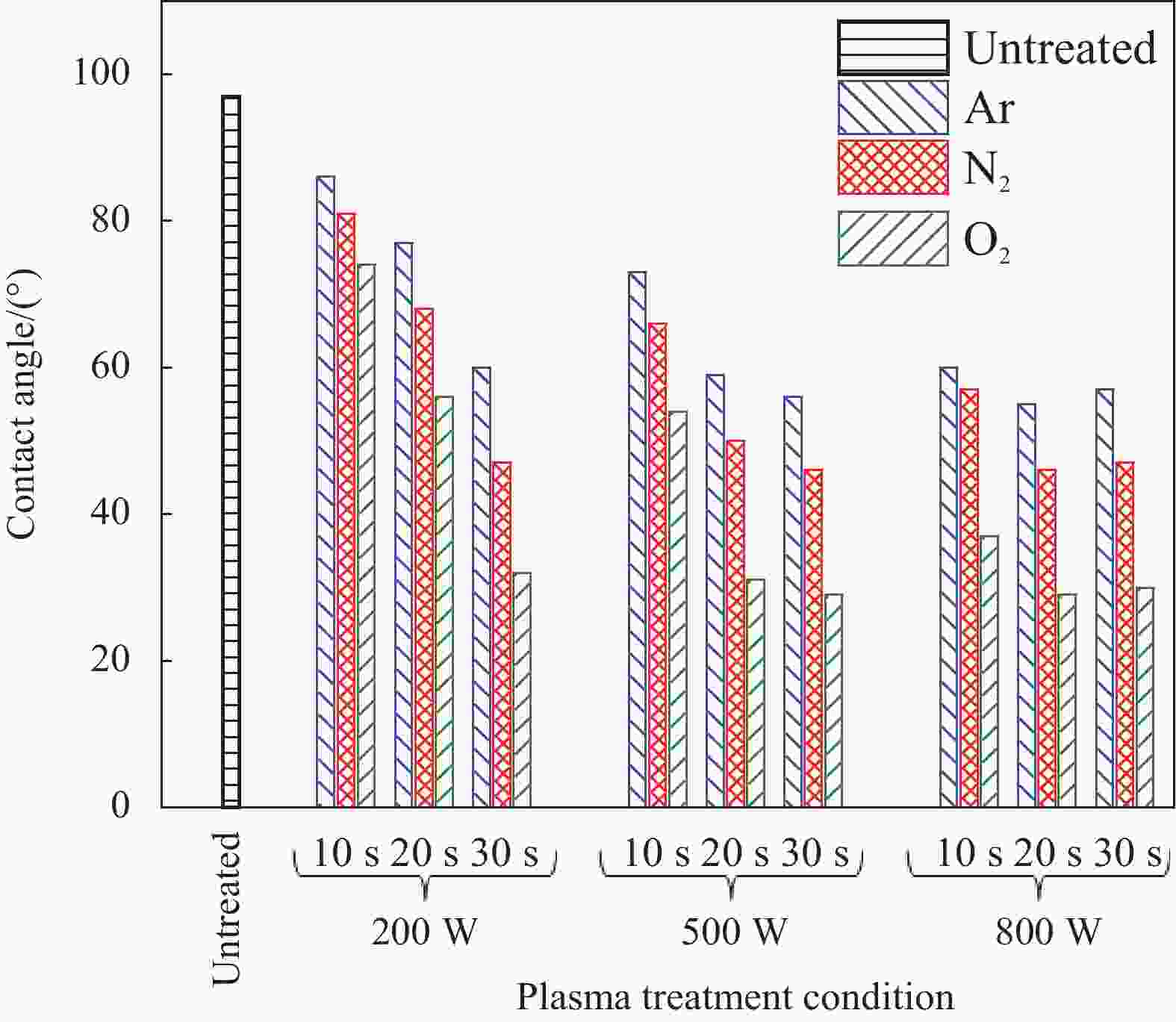

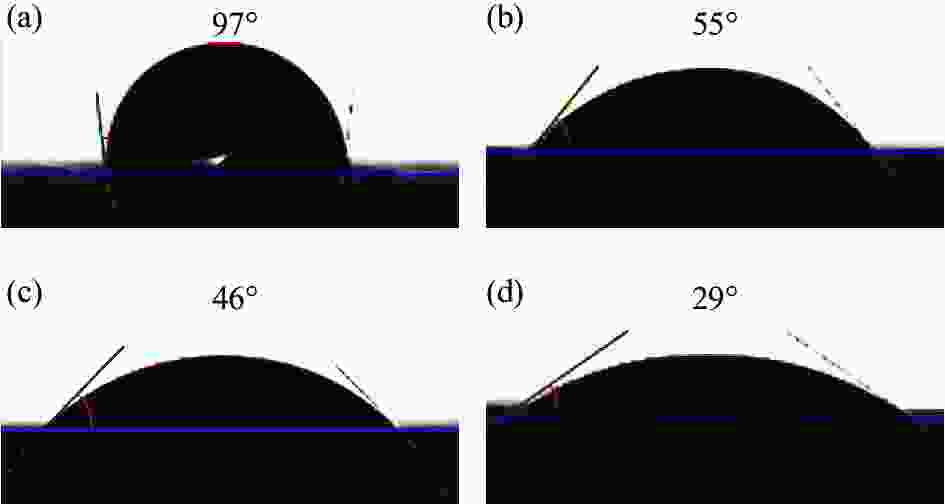

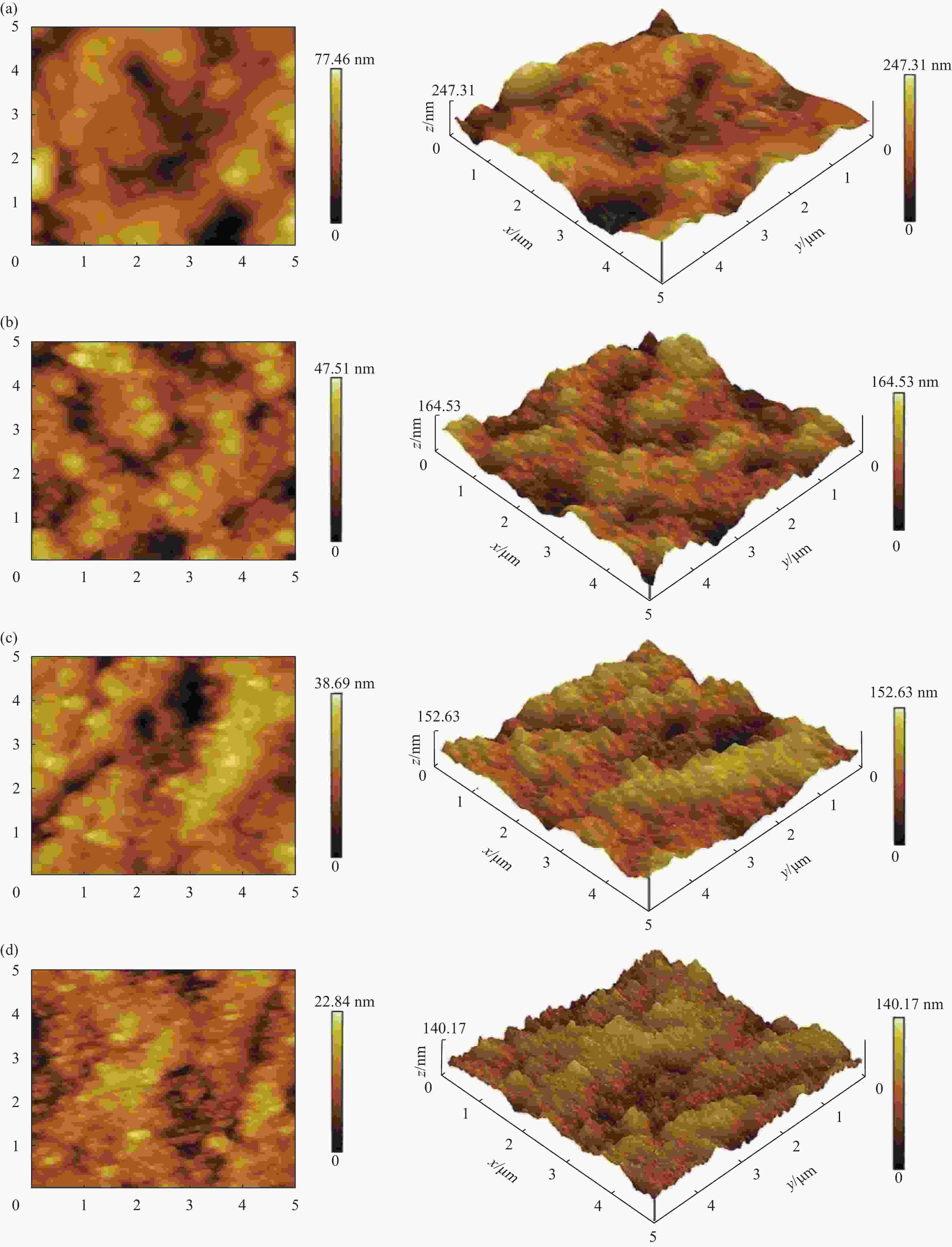

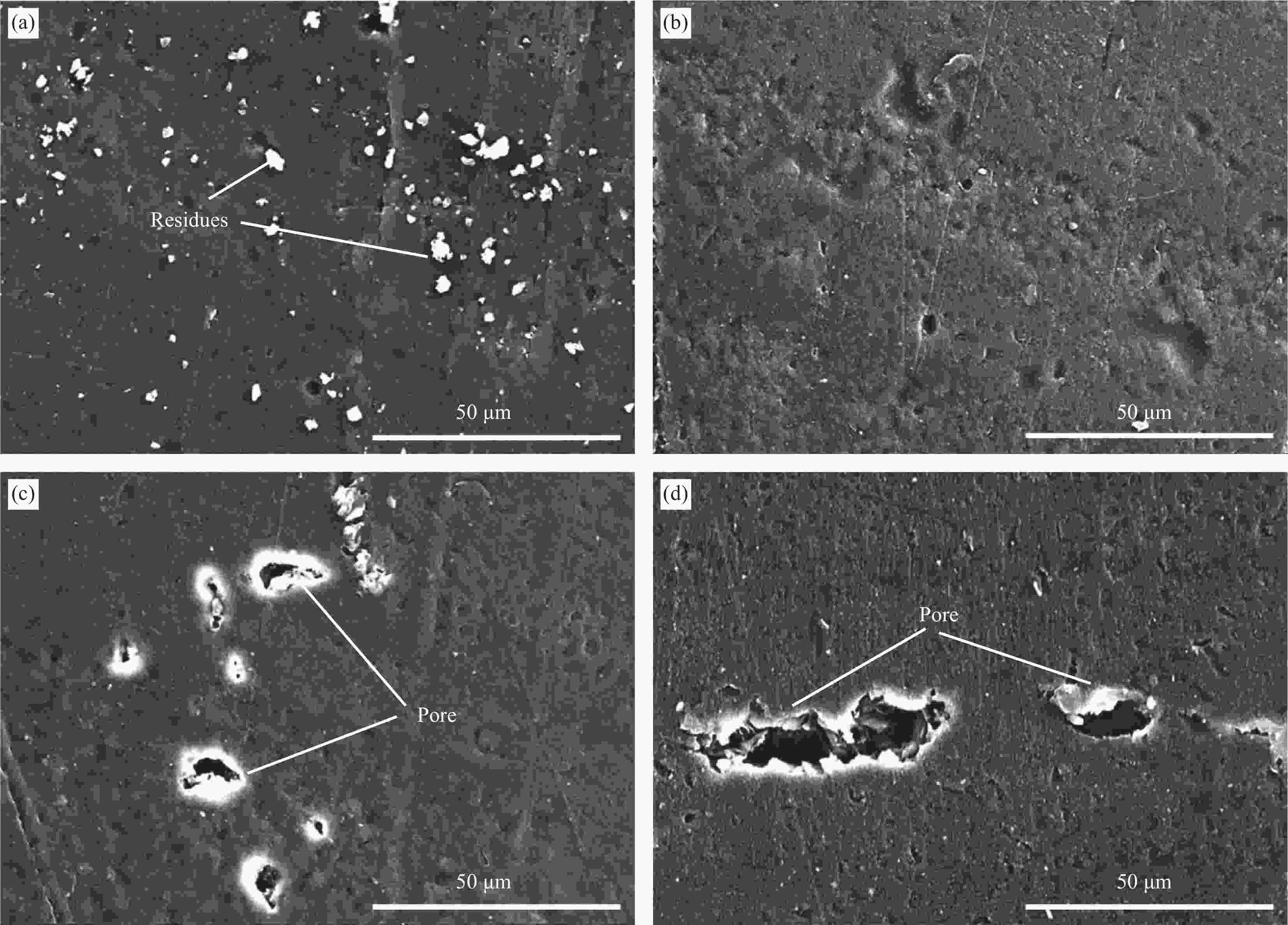

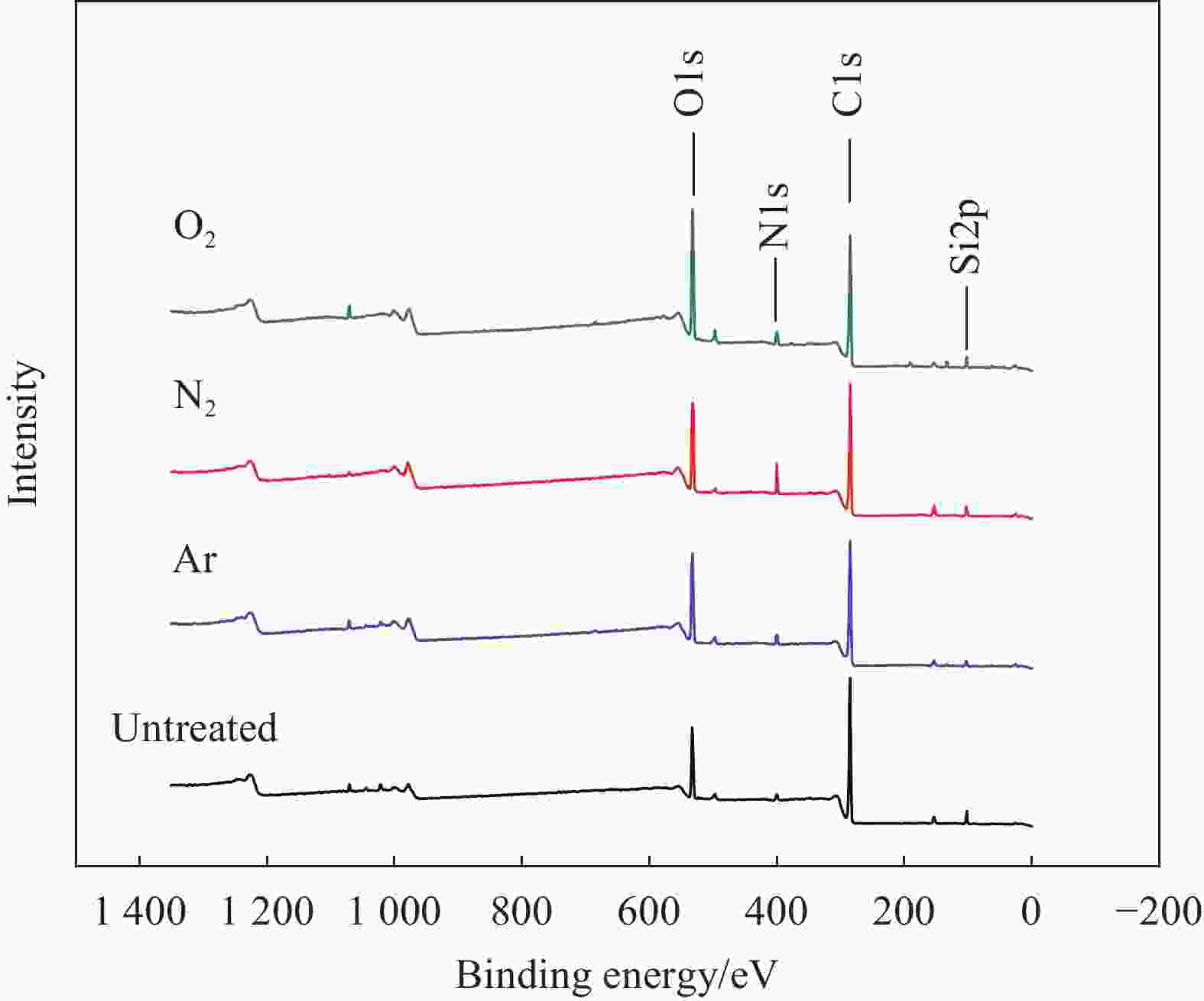

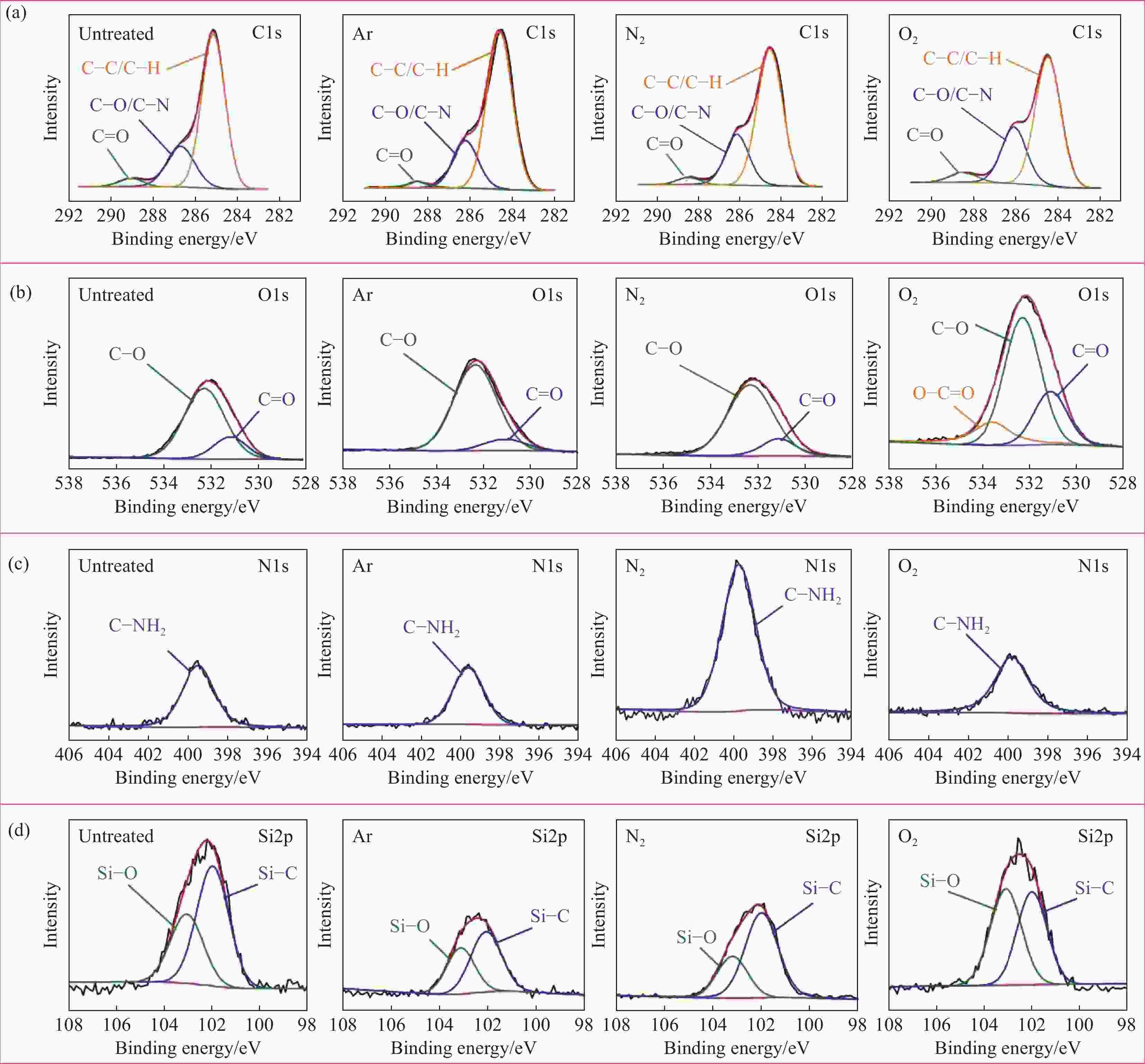

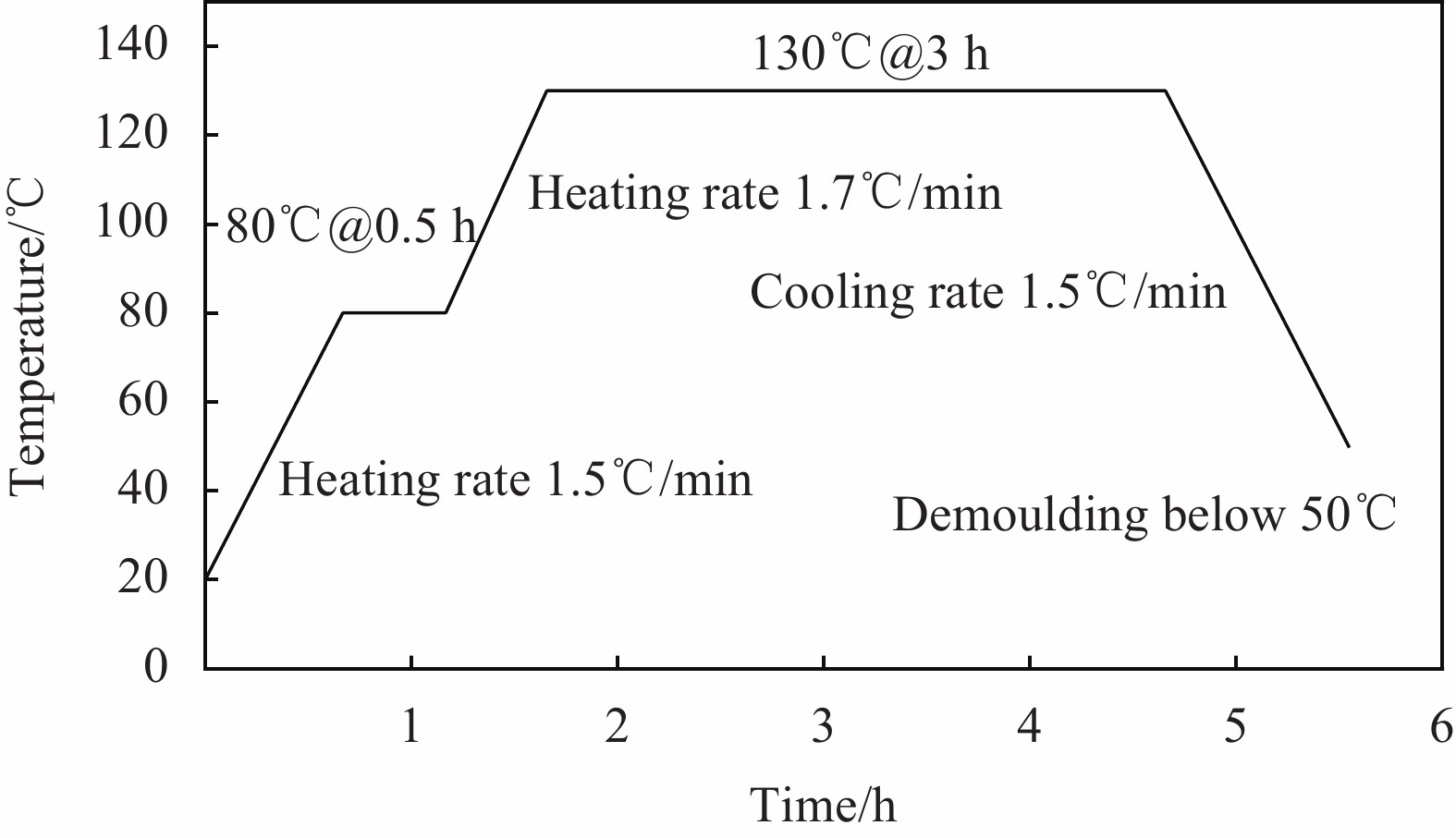

摘要: 采用低温等离子体处理技术对碳纤维增强树脂复合材料(CFRP)表面进行处理,以氩气(Ar)、N2和O2作为等离子体激发气体,通过接触角测量仪、AFM、SEM和XPS等测试分析手段,对CFRP表面的润湿性、粗糙度、微观形貌和化学组分进行表征,并结合拉伸剪切试验测试和失效形貌分析,研究了等离子体气体类型、放电功率P和处理时间t对CFRP表面理化特性和胶接性能的影响。结果表明:Ar、N2和O2等离子体处理可以显著改善CFRP胶接性能,当P=800 W,t=20 s时,与未处理相比,CFRP胶接强度分别提高了138%、172%和253%。表面测试分析可知,Ar等离子体处理后,CFRP胶接强度的增加主要是通过提高表面清洁度和增大界面粘接表面积,试样失效模式由界面失效转变为内聚失效为主的混合失效模式。与Ar相比,N2等离子体处理后,CFRP表面生成了较多—NH2极性基团,表面活性增加,进一步提高了CFRP和胶粘剂之间界面的结合力。与以上两种气体相比,O2等离子体刻蚀CFRP表面更为剧烈,并对表层基团进行重组,形成了极性较强—COOH官能团,试样胶接强度提高效果最佳,试样失效模式由界面失效转变为基板失效。此外,当活性粒子的密度和能量过高时,较大的等离子体刻蚀孔隙,在一定程度上会降低胶接性能。Abstract: Ar, N2 and O2 were used as low-temperature plasma excitation gases to treat the surface of carbon fiber reinforced plastics (CFRP). The effects of plasma gas, discharge power and treatment time on the physicochemical properties, including wettability, roughness, microscopic morphology and chemical components of CFRP surface, were characterized by contact angle measurement, AFM, SEM and XPS. The adhesive joint property was investigated through tensile shear experiment and failure morphology analysis. Compared with untreated, the tensile shear strength of CFRP adhesive joints after Ar, N2 and O2 plasma treatment can significantly improve the bonding performance of CFRP, and when the plasma discharge power is 800 W and treatment time is 20 s, the adhesive joint strength increases by 138%, 172% and 253%, respectively. The surface test analysis shows that the improvement of CFRP adhesive strength after argon plasma treatment is mainly induced by improving the surface cleanliness and increasing the surface area for interfacial adhesive, and the failure modes of samples changes from interfacial failure to mixed failure mode with cohesive failure as the main mode. Compared with Ar, a greater number of polar chemical groups (—NH2) are generated on the CFRP surface after N2 plasma treatment, which increase the surface activity and further improve the interfacial adhesive strength between CFRP and adhesive. Compared with the above two gases, O2 plasma etch the CFRP surface more vigorously, as well as reorganize the surface chemical groups, forming a more polar —COOH functional group, so that the specimen adhesive strength is improved most effectively, and the specimen failure mode changes from interface failure to substrate failure. In addition, under the excessively high density and energy of the active particles, the adhesive performance will be reduced to some extent with the expansion of the pores by plasma etching.

-

Key words:

- CFRP /

- low temperature plasma /

- adhesive property /

- surface modification /

- wettability

-

图 7 (a) 不同气体等离子体处理后CFRP试样的拉伸断裂形貌(放电功率P=800 W,处理时间t=20 s);(b) 不同P和t下O2等离子体处理后CFRP的拉伸断裂形貌

Figure 7. (a) Effect of plasma treatment with different gases on the tensile fracture morphologies of the CFRP samples (Discharge power P=800 W, treatment time t=20 s); (b) Tensile fracture morphologies of the CFRP samples under O2 plasma treatment with different P and t

图 11 不同放电功率和处理时间下O2等离子体处理后CFRP样品表面的SEM图像:(a)未处理;(b) P=200 W, t=30 s;(c) P=800 W, t=20 s;(d) P=800 W, t=30 s

Figure 11. SEM images of CFRP samples surface treated under O2 plasma treatment with different discharge powers and processing time: (a) Untreated; (b) P=200 W, t=30 s; (c) P=800 W, t=20 s; (d) P=800 W, t=30 s

表 1 CFRP复合材料主要性能参数

Table 1. Main performance parameters of CFRP composites

Mechanical property Value E11/GPa 121 E22/GPa 8.6 E33/GPa 8.6 G12/MPa 3450 G13/MPa 3450 G23/MPa 2800 Poisson’s ratio 0.3 Density/(kg·m−3) 1467 Notes: E—Young’s modulus; i (i=1, 2, 3)—Direction; G—Shear modulus. 表 2 Araldite 2015主要力学性能参数

Table 2. Main mechanical property parameters of the Araldite 2015

Araldite 2015 Value Tensile strength/MPa 21.63 Shear strength/MPa 17.90 Elongation/% 0.33 表 3 低压等离子体处理工艺参数

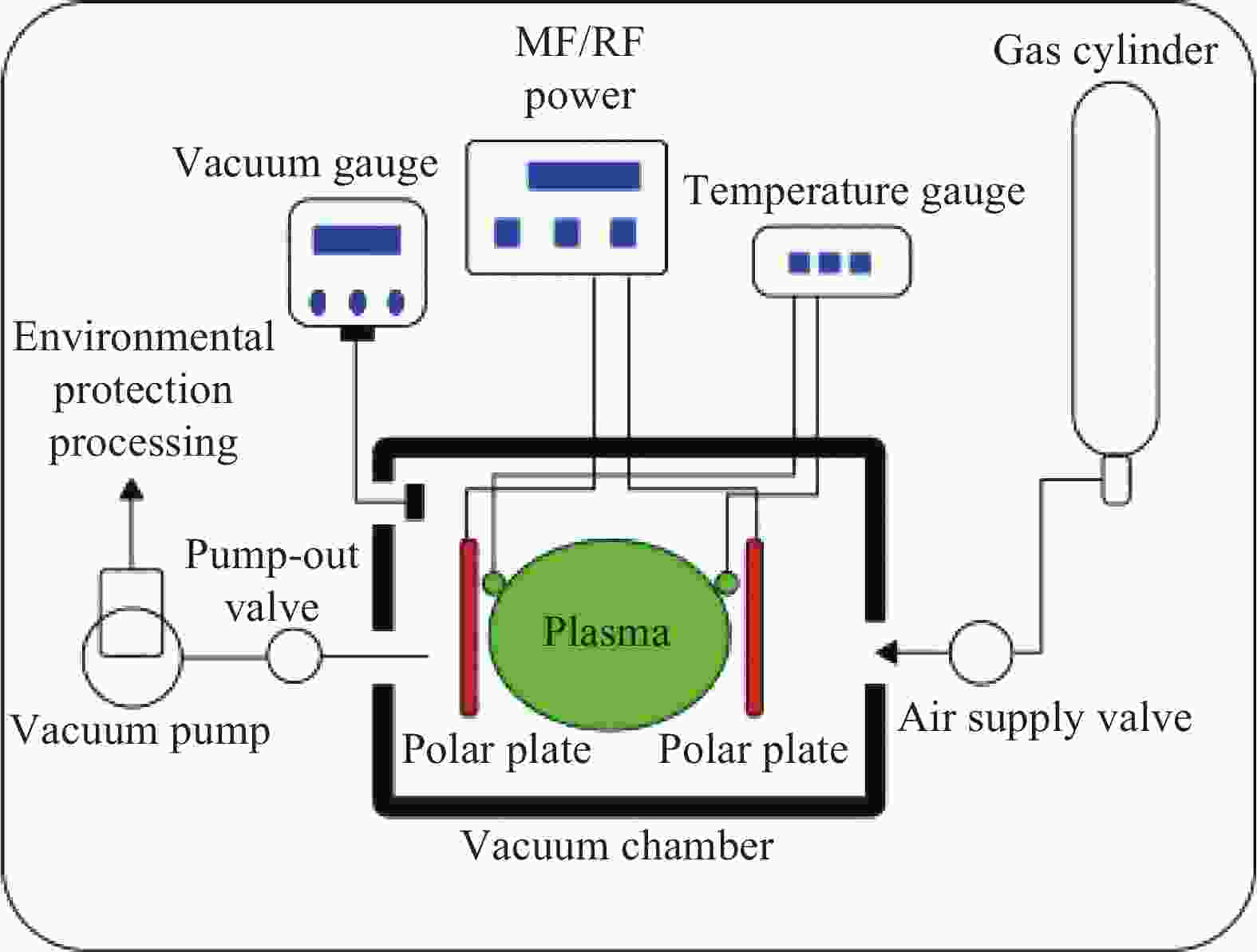

Table 3. Process parameters of low pressure plasma treatment

Item Nominal parameter value Plasma frequency/MHz 13.56 Power input/W 0-1000 Process pressure/Pa 100 Speed/(mL·min−1) 150 表 4 不同气体等离子体处理后CFRP试样表面化学元素组成及其所占比例(P=800 W,t=20 s)

Table 4. Surface chemical composition and proportion of CFRP samples under plasma treatment with different gases (P=800 W, t=20 s)

Surface treatment C/at% O/at% N/at% Si/at% O/C/% N/C/% Untreated 74.52 17.85 3.87 3.76 23.95 5.19 Ar 72.89 21.42 3.46 2.23 29.39 4.75 N2 66.54 19.61 11.48 2.37 29.47 17.25 O2 62.47 30.89 3.17 3.47 49.45 5.07 表 5 不同气体等离子体处理后CFRP试样XPS的C1s、O1s、N1s和Si2p分峰表面基团相对含量拟合数据(P=800 W,t=20 s)

Table 5. C1s, O1s, N1s and Si2p peak-differentiating and imitating data of relative content of surface groups for XPS of CFRP samples surface under plasma treatment with different gases (P=800 W, t=20 s)

at% Element Surface group Surface treatment Untreated Ar N2 O2 C1s C—C/C—H 71.92 70.95 68.01 60.36 C—O/C—N 23.71 25.49 27.96 33.37 C=O 4.37 3.56 4.03 6.27 O1s C—O 79.57 86.13 81.28 61.76 C=O 20.43 13.87 18.72 25.96 O=C—O 0.00 0.00 0.00 12.28 N1s C—NH2 100.00 100.00 100.00 100.00 Si2p Si—C 69.21 66.32 67.17 45.47 Si—O 30.79 33.68 32.83 54.53 -

[1] 马立敏, 张嘉振, 岳广全, 等. 复合材料在新一代大型民用飞机中的应用[J]. 复合材料学报, 2015, 32(2):317-322. doi: 10.13801/j.cnki.fhclxb.20150122.001MA Limin, ZHANG Jiazhen, YUE Guangquan, et al. Application of composite in new generation of large civil aircraft[J]. Acta Materiae Compositae Sinica,2015,32(2):317-322(in Chinese). doi: 10.13801/j.cnki.fhclxb.20150122.001 [2] KATNAM K B, DA SILVA L F M, YOUNG T M. Bonded repair of composite aircraft structures: A review of scientific challenges and opportunities[J]. Progress in Aerospace Sciences,2013,61:26-42. doi: 10.1016/j.paerosci.2013.03.003 [3] BARILE C, CASAVOLA C, DE C F. Mechanical comparison of new composite materials for aerospace applications[J]. Composites Part B: Engineering,2019,162:122-128. doi: 10.1016/j.compositesb.2018.10.101 [4] 孙振起, 吴安如. 先进复合材料在飞机结构中的应用[J]. 材料导报, 2015, 29(11):61-64, 69.SUN Zhenqi, WU Anru. Application of advanced composite in aircraft structures[J]. Materials Reports,2015,29(11):61-64, 69(in Chinese). [5] DENG S, DJUKIC L, PATON R, et al. Thermoplastic-epoxy interactions and their potential applications in joining composite structures—A review[J]. Composites Part A: Applied Science and Manufacturing,2015,68:121-132. doi: 10.1016/j.compositesa.2014.09.027 [6] QIN G, NA J, MU W, et al. Effect of continuous high temperature exposure on the adhesive strength of epoxy adhesive CFRP and adhesively bonded CFRP-aluminum alloy joints[J]. Composites Part B: Engineering,2018,154:43-55. doi: 10.1016/j.compositesb.2018.07.059 [7] PARK S M, ROY R, KWEON J H, et al. Strength and failure modes of surface treated CFRP secondary bonded single-lap joints in static and fatigue tensile loading regimes[J]. Composites Part A: Applied Science and Manufacturing,2020,134:105897. doi: 10.1016/j.compositesa.2020.105897 [8] DI B Y, JOSHI S C, ONG L S. Interfacial bonding between CFRP and mechanically-treated aluminum liner surfaces for risers[J]. Composite Structures,2018,188:374-386. doi: 10.1016/j.compstruct.2018.01.047 [9] BUCHMANN C, LANGER S, FILSINGER J, et al. Analysis of the removal of peel ply from CFRP surfaces[J]. Composites Part B: Engineering,2016,89:352-361. doi: 10.1016/j.compositesb.2015.11.019 [10] HU Y, YUAN B, CHENG F, et al. NaOH etching and resin pre-coating treatments for stronger adhesive bonding between CFRP and aluminium alloy[J]. Composites Part B: Engineering,2019,178:107478. doi: 10.1016/j.compositesb.2019.107478 [11] 尚文翰, 李姜. 旧橡胶颗粒的表面改性及粘接性能[J]. 高分子材料科学与工程, 2018, 34(10):99-104.SHANG Wenhan, LI jiang. Surface modification of ground tire rubber and its adhesion property[J]. Polymer Materials Science & Engineering,2018,34(10):99-104(in Chinese). [12] AKMAN E, ERDOĞAN Y, BORA M Ö, et al. Investigation of accumulated laser fluence and bondline thickness effects on adhesive joint performance of CFRP composites[J]. International Journal of Adhesion and Adhesives,2019,89:109-116. doi: 10.1016/j.ijadhadh.2018.12.003 [13] ZALDIVAR R J, NOKES J, STECKEL G L, et al. The effect of atmospheric plasma treatment on the chemistry, morphology and resultant bonding behavior of a PAN-based carbon fiber-reinforced epoxy composite[J]. Journal of Composite Materials,2010,44(2):137-156. doi: 10.1177/0021998309345343 [14] HOLTMANNSPÖTTER J. How surfaces of carbon fiber reinforced plastics with thermoset matrices need to be treated for structural adhesive bonding[J]. The Journal of Adhesion,2018,96(9):839-854. [15] PROLONGO S G, GUDE M R, DEL R G, et al. Surface pretreatments for composite joints: Study of surface profile by SEM image analysis[J]. Journal of Adhesion Science and Technology,2010,24(11-12):1855-1867. doi: 10.1163/016942410X507623 [16] LIU G, XU Y, YANG W, et al. Bonding repair of CFRP based on cold plasma treatment surface modification[J]. Journal of Adhesion Science and Technology,2020,34(16):1796-1808. doi: 10.1080/01694243.2020.1730663 [17] SUNDRIYAL P, PANDEY M, BHATTACHARYA S. Plasma-assisted surface alteration of industrial polymers for improved adhesive bonding[J]. International Journal of Adhesion and Adhesives,2020,101:102626. doi: 10.1016/j.ijadhadh.2020.102626 [18] CHO B G, HWANG S H, PARK M, et al. The effects of plasma surface treatment on the mechanical properties of polycarbonate/carbon nanotube/carbon fiber composites[J]. Composites Part B: Engineering,2019,160:436-445. doi: 10.1016/j.compositesb.2018.12.062 [19] YOOZBASHIZADEH M, CHARTOSIAS M, VICTORINO C, et al. Investigation on the effect of process parameters in atmospheric pressure plasma treatment on carbon fiber reinforced polymer surfaces for bonding[J]. Materials and Manufacturing Processes,2019,34(6):660-669. doi: 10.1080/10426914.2019.1566613 [20] 翟全胜, 苗春卉, 崔海超, 等. 基于表面改性的国产T800碳纤维/高韧性环氧树脂复合材料胶接性能[J]. 复合材料学报, 2021, 38(7):2162-2171.ZHAI Quansheng, MIAO Chunhui, CUI Haichao, et al. Bonding performance of domestic T800/high toughness epoxy resin composites based on surface modification[J]. Acta Materiae Compositae Sinica,2021,38(7):2162-2171(in Chinese). [21] SUN C, MIN J, LIN J, et al. Effect of atmospheric pressure plasma treatment on adhesive bonding of carbon fiber reinforced polymer[J]. Polymers,2019,11(1):139. doi: 10.3390/polym11010139 [22] LIN J, SUN C, MIN J, et al. Effect of atmospheric pressure plasma treatment on surface physicochemical properties of carbon fiber reinforced polymer and its interfacial bonding strength with adhesive[J]. Composites Part B: Engi-neering,2020,199:108237. doi: 10.1016/j.compositesb.2020.108237 [23] PIZZORNI M, LERTORA E, MANDOLFINO C. Low pressure plasma treatment of CFRP substrates for adhesive bonding: An investigation of joint durability under severe temperature-moisture conditioning[J]. International Journal of Adhesion and Adhesives,2020,99:102592. doi: 10.1016/j.ijadhadh.2020.102592 [24] ASTM International. Standard test method for apparent shear strength of single-lap-joint adhesively bonded metal specimens by tension loading: ASTM D1002-10[S]. West Conshohocken: ASTM International, 2010. [25] ASTM International. Standard test method for lab shear adhesion for fiber reinforced plastic (FRP) bonding: ASTM D5868-01[S]. West Conshohocken: ASTM International, 2014. [26] HARTWIG A, VITR G, DIECKHOFF S, et al. Surface treatment of an epoxy resin by CO2 laser irradition[J]. Die Angewandte Makromolekulare Chemie: Applied Macromolecular Chemistry and Physics,1996,238(1):177-189. doi: 10.1002/apmc.1996.052380115 [27] YANG D, ZHOU L, CHEN L, et al. Chemically modified graphene oxides as a hole transport layer in organic solar cells[J]. Chemical Communications,2012,48(65):8078-8080. doi: 10.1039/c2cc33829g [28] JIANG L, DING H, LU S, et al. Photoactivated fluorescence enhancement in F, N-doped carbon dots with piezochromic behavior[J]. Angewandte Chemie,2020,132(25):10072-10077. doi: 10.1002/ange.201913800 [29] ZHANG L, LI Y, ZHANG L, et al. Electrocatalytic oxidation of NADH on graphene oxide and reduced graphene oxide modified screen-printed electrode[J]. International Journal of Electrochemical Science,2011,6(3):819-829. [30] LI X, ZHANG P, HUANG H, et al. Etched carbon fiber/polyaniline composite with p-n heterojunction for high-energy electrochemical supercapacitor[J]. ECS Journal of Solid State Science and Technology,2021,10(1):013005. doi: 10.1149/2162-8777/abdd84 [31] ZHAO X, MAGTOTO N P, KELBER J A. Chemical vapor deposition of tantalum nitride with tertbutylimino tris(diethylamino) tantalum and atomic hydrogen[J]. Thin Solid Films,2005,478(1-2):188-195. doi: 10.1016/j.tsf.2004.10.042 -

下载:

下载: