Effect of high-temperature gas-phase oxidation of carbon fiber on tensile and interlaminar shear properties of PEEK composites

-

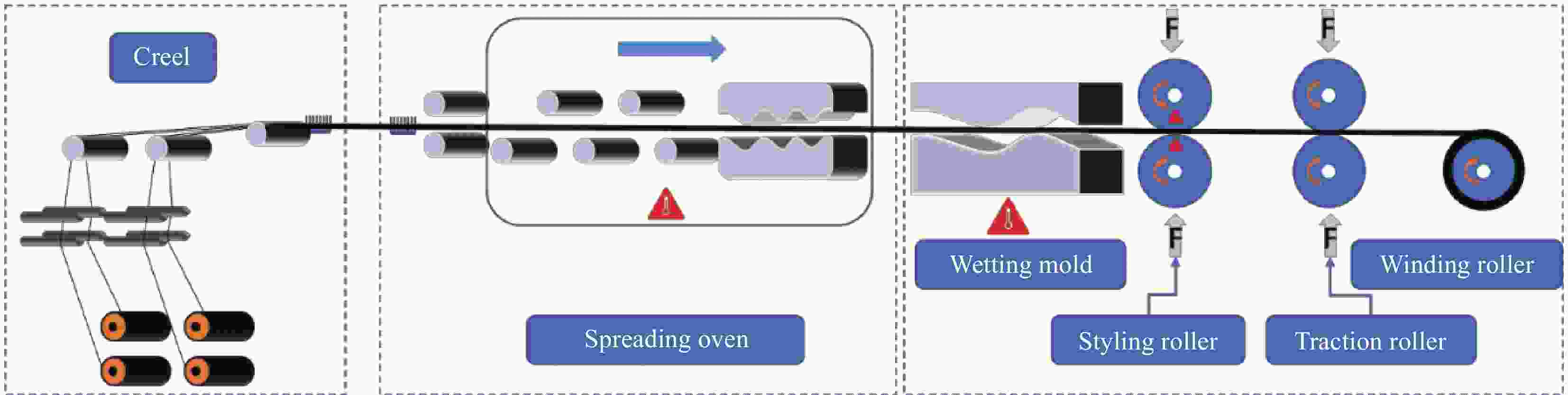

摘要: 聚醚醚酮(PEEK)复合材料具有优异的抗冲击性能,在航空领域具有重要的应用价值。然而,聚醚醚酮复合材料成型温度高,成型过程中可能存在环氧上浆剂分解残留,导致界面强度降低、载荷传递变差等问题,影响其使用性能。系统地研究了碳纤维(CF)高温气相氧化对CF/PEEK复合材料拉伸和层间剪切性能的影响。首先采用不同氧化工艺处理碳纤维,采用XPS、IGC、复丝拉伸等方法表征了碳纤维表面活性、表面能以及拉伸性能。结果表明,合适的氧化条件有利于改善纤维表面活性和表面能,但同时会降低纤维拉伸强度。采用熔体法制备了CF/PEEK预浸料,研究了高温气相氧化对CF/PEEK复合材料拉伸和层间剪切性能的影响。结果表明,纤维高温氧化后CF/PEEK复合材料0°拉伸强度下降超过20%,表明高温氧化会导致纤维严重损伤;90°拉伸强度变化不超过10%,层间剪切强度变化小于5%,表明碳纤维高温氧化未能实现复合材料界面性能改善。上述结果表明,在预浸料制备工艺中增加碳纤维高温氧化工序,不利于改善复合材料性能。Abstract: Polyetheretherketone (PEEK) composites have excellent impact resistance and thus have important potential application value in aviation field. However, the molding temperature of PEEK composites is too high for carbon fiber (CF) with epoxy sizing agent, which will result in the decomposition of sizing agent and further cause the reduction of interface strength and deterioration of load transfer. It will affect the application of PEEK composites. The effect of high-temperature gas-phase oxidation of CFs on the tensile and interlaminar shear properties of PEEK composites was systematically studied. CFs oxidized under different conditions were firstly prepared and characterized by XPS, IGC, bundle tensile testing to study the effect of oxidation on surface activity, surface energy and mechanical properties of CFs. The results show that appropriate oxidation conditions are beneficial to improving surface activity and surface energy of the CFs, while oxidation will decrease the tensile strength of CFs. CF/PEEK prepregs were prepared using the melt method, and the tensile properties and interlaminar shear properties of the composites were compared between untreated fibers and oxidized fibers. The results show that after oxidation, the 0° tensile strength decreases by more than 20%, indicating that high-temperature oxidation of CFs will cause fiber damage; the difference in 90° tensile strength does not exceed 10%, and the difference in interlaminar shear strength is less than 5%, indicating that the high-temperature oxidation of CFs failed to improve the interface properties of the composites. The above results show that adding the high-temperature oxidation process of CFs to the prepreg preparation process is not conducive to improve composite properties.

-

表 1 碳纤维(CF)表面处理方法

Table 1. Surface treatment method of carbon fiber (CF)

Sample Method Temperature Time 1# Untreated — — 2# Oxidized 300℃ 60 s 3# Oxidized 300℃ 120 s 4# Oxidized 300℃ 600 s 5# Oxidized 350℃ 60 s 6# Acetone dissolved — — 表 2 碳纤维表面元素含量

Table 2. Surface element content of CFs

Sample Conditions Element content /mol % O/C C O Si N 1# Untreated 92.01 6.91 0.00 1.08 0.08 2# 300℃,60 s 93.65 6.35 0.00 0.00 0.07 3# 300℃,120 s 91.87 7.27 0.86 0.00 0.08 4# 300℃,600 s 88.49 8.54 0.97 1.20 0.10 5# 350℃,60 s 91.91 7.08 0.00 0.99 0.08 6# Acetone dissolved 94.39 5.61 0.00 0.00 0.06 表 3 不同处理条件碳纤维表面官能团含量

Table 3. Content of CF surface functional groups under different conditions

sample conditions functional group content(mol%) —C—C—

or —C—H—C—OH

or —C—OR—COOH

or —COORratio of active functional

groups (mol%)1# untreated 83.08 16.13 0.79 16.92 2# 300℃,60 s 74.93 20.26 4.81 25.07 3# 300℃,120 s 65.34 26.67 7.99 34.66 4# 300℃,600 s 69.4 25.44 6.05 30.6 5# 350℃,60 s 64.95 30.21 4.84 35.05 6# acetone dissolved 82.37 9.84 7.80 17.64 表 4 不同处理条件下碳纤维表面能

Table 4. Surface energy of CFs under different conditions

Sample Conditions γd/(mJ·m−2) γp/(mJ·m−2) γ/(mJ·m−2) 1# Untreated 38.33 7.33 45.66 2# 300℃,60 s 41.68 6.47 48.15 3# 300℃,120 s 42.58 6.34 48.92 4# 300℃,600 s 44.87 8.92 53.79 5# 350℃,60 s 42.68 6.86 49.54 6# Acetone dissolved 46.12 5.60 51.72 Note: γd: dispersion component,γp: polar component,γ: total surface energy -

[1] 邢丽英, 包建文, 礼嵩明, 陈祥宝. 先进树脂基复合材料发展现状和面临的挑战[J]. 复合材料学报, 2016, 33(7): 1327-1338.XING Liying, BAO Jianwen, LI Songming, et al. Development status and facing challenge of advanced polymer matrix composites[J]. Acta Materiae Compositae Sinica, 2016, 33(7): 1327-1338(in Chinese). [2] 邢丽英, 李亚锋, 陈祥宝. 先进复合材料在航空装备发展中的地位与作用[J]. 复合材料学报, 2022, 39(9): 4179-4186XING Liying, LI Yafeng, CHEN Xiangbao. Status and role of the advanced composite materials in the development of aviation equipment[J]. Acta Materiae Compositae Sinica, 2022, 39(9): 4179-4186(in Chinese). [3] 肇研, 孙铭辰, 张思益, 等. 连续碳纤维增强高性能热塑性复合材料的研究进展[J]. 复合材料学报, 2022, 39(9): 4274-4285.ZHAO Yan, SUN Mingchen, ZHANG Siyi, et al. Advance in continuous carbon fiber reinforced high performance thermoplastic composites[J]. Acta Materiae Compositae Sinica, 2022, 39(9): 4274-4285(in Chinese). [4] 张婷. 高性能热塑性复合材料在大型客机结构件上的应用[J]. 航空制造技术, 2013, (15): 32-35. doi: 10.3969/j.issn.1671-833X.2013.15.003ZHANG Ting. Applications of high performance thermoplastic composites for commercial airplane structural component[J]. Aeronautical Manufacturing Technology, 2013, (15): 32-35(in Chinese). doi: 10.3969/j.issn.1671-833X.2013.15.003 [5] 罗云烽, 姚佳楠. 高性能热塑性复合材料在民用航空领域中的应用[J]. 航空制造技术, 2021, 64(16): 93-102.LUO Yunfeng, YAO Jianan. Applications of high performance thermoplastic composites in civil aviation[J]. Aeronautical Manufacturing Technology, 2021, 64(16): 93-10(in Chinese). [6] 滕凌虹, 曹伟伟, 朱波, 等. 纤维增强热塑性树脂预浸料的制备工艺及研究进展[J]. 材料工程, 2021, 49(2): 42-53. doi: 10.11868/j.issn.1001-4381.2020.000358TENG Linghong, CAO Weiwei, ZU Bo, et al. Research progress in the preparation of fiber reinforced thermoplastic resin prepreg[J]. Journal of Materials Engineering, 2021, 49(2): 42-53(in Chinese). doi: 10.11868/j.issn.1001-4381.2020.000358 [7] YAO S S, JIN F L, RHEE K Y, et al. Recent advances in carbon-fiber-reinforced thermoplastic composites: A review[J]. Composites Part B: Engineering, 2018, 142: 241-250. doi: 10.1016/j.compositesb.2017.12.007 [8] MARTIN I, SAENZ del Castillo D, FERNANDEZ A, et al. Advanced thermoplastic composite manufacturing by in-situ consolidation: a review[J]. Journal of Composites Science, 2020, 4(4): 149-184. doi: 10.3390/jcs4040149 [9] 张照. 碳纤维织物增强聚醚醚酮基(CFF/PEEK)航空复合材料的制备及其界面改性[D]. 上海: 东华大学, 2017.ZHANG Zhao. Preparations and interface modifications for carbon fiber fabrics reinforced polyetheretherketone (CFF/PEEK) aeronautical composites[D]. Shanghai: Donghua University, 2017(in Chinese). [10] VAIDYA U K, CHAWLA K K. Processing of fibre reinforced thermoplastic composites[J]. International Materials Reviews, 2008, 53(4): 185-218. doi: 10.1179/174328008X325223 [11] THIRUCHITRAMBALAM M, BUBESH Kumar D, SHANMUGAM D, et al. A review on PEEK composites-Manufacturing methods, properties and applications[J]. Materials Today: Proceedings, 2020, 33: 1085-1092. doi: 10.1016/j.matpr.2020.07.124 [12] 周典瑞, 高亮, 霍红宇, 等. 热塑性树脂基复合材料用碳纤维上浆剂研究进展[J]. 复合材料学报, 2020, 37(8): 1785-1795ZHOU Dianrui, GAO Liang, HUO Hongyu, et al. Research progress of carbon fiber sizing agents for thermoplastic composites[J]. Acta Materiae Compositae Sinica, 2020, 37(8): 1785-1795(in Chinese). [13] 邢宇, 张代军, 王成博, 等. PEEK复合材料用碳纤维上浆剂研究进展[J]. 材料工程, 2022, 50(8): 70-81. doi: 10.11868/j.issn.1001-4381.2021.000852XING Yu, ZHANG Daijun, WANG Chengbo, et al. Research progress in carbon fiber sizing agents for PEEK composites[J]. Journal of Materials Engineering, 2022, 50(8): 70-81(in Chinese). doi: 10.11868/j.issn.1001-4381.2021.000852 [14] SHARMA M, Gao S, MÄDER E, et al. Carbon fiber surfaces and composite interphases[J]. Composites Science and Technology, 2014, 102: 35-50. doi: 10.1016/j.compscitech.2014.07.005 [15] LIU L, YAN F, LI M, et al. A novel thermoplastic sizing containing graphene oxide functionalized with structural analogs of matrix for improving interfacial adhesion of CF/PES composites[J]. Composites Part A: Applied Science and Manufacturing, 2018, 114: 418-428. doi: 10.1016/j.compositesa.2018.09.004 [16] YANG Y, WANG T, WANG S, et al. Strong interface construction of carbon fiber-reinforced PEEK composites: an efficient method for modifying carbon fiber with crystalline PEEK[J]. Macromolecular Rapid Communications, 2020, 41(24): 2000001-2000007. doi: 10.1002/marc.202000001 [17] YAN T, YAN F, LI S, et al. Interfacial enhancement of CF/PEEK composites by modifying water-based PEEK-NH2 sizing agent[J]. Composites Part B: Engineering, 2020, 199: 108258-108265. doi: 10.1016/j.compositesb.2020.108258 [18] HASSAN E A M, GE D, YANG L, et al. Highly boosting the interlaminar shear strength of CF/PEEK composites via introduction of PEKK onto activated CF[J]. Composites Part A: Applied Science and Manufacturing, 2018, 112: 155-160. doi: 10.1016/j.compositesa.2018.05.029 [19] LIU H, ZHAO Y, LI N, et al. Effect of polyetherimide sizing on surface properties of carbon fiber and interfacial strength of carbon fiber/polyetheretherketone composites[J]. Polymer Composites, 2021, 42(2): 931-943. doi: 10.1002/pc.25876 [20] 杨砚超. 基于结晶性聚醚醚酮的碳纤维上浆剂的研究及复合材料界面构筑[D]. 吉林: 吉林大学, 2020.YANG Chaoxian. The research of carbon fiber sizing agent based on crystalline polyetheretherketone and composite interface construction[D]. Jilin: Jilin University, 2020(in Chinese). [21] REN T, ZHU G, HOU X, et al. Improvement of interfacial interactions in CF/PEEK composites by an s-PSF/graphene oxide compound sizing agent[J]. Journal of Applied Polymer Science, 2021, 138(45): 51327-51339. doi: 10.1002/app.51327 [22] TIWARI S, BIJWE J. Surface treatment of carbon fibers-a review[J]. Procedia Technology, 2014, 14: 505-512. doi: 10.1016/j.protcy.2014.08.064 [23] LI W, LI R, LI C, et al. Surface characterization and electrical property of carbon fibers modified by air oxidation[J]. Surface and Interface analysis, 2015, 47(3): 325-330. doi: 10.1002/sia.5711 [24] LI J. Interfacial studies on the O3 modified carbon fiber-reinforced polyamide 6 composites[J]. Applied Surface Science, 2008, 255(5): 2822-2824. doi: 10.1016/j.apsusc.2008.08.013 [25] 中国国家标准化管理委员. 碳纤维复丝拉伸性能试验方法: GB/T 3362—2017 [S]. 北京: 中国标准出版社, 2017.China National Standardization Administration. Test methods for tensile properties of carbon fiber multifilaments: GB/T 3362-2017 [S]. Beijing: China Standards Press, 2017. [26] American Society for Testing and Materials. ASTM D 3039-14 Standard test method for tensile properties of polymer matrix composite materials [S]. USA: ASTM International, 2014. [27] American Society of Testing and Materials. ASTM D2344-2016 Standard test method for short-beam strength of polymer matrix composite materials and their laminates [S]. USA: ASTM International, 2016. [28] 陈平, 陈辉. 先进聚合物基复合材料界面及纤维表面改性[M]. 科学出版社, 2010.CHEN Ping, CHEN Hui. Advanced polymer matrix composite interface and fiber surface modification[M]. Science Press, 2010. [29] XIAO J, ZHANG X, ZHAO Z, et al. Rapid and continuous atmospheric plasma surface modification of PAN-based carbon fibers[J]. ACS omega, 2022, 7(13): 10963-10969. doi: 10.1021/acsomega.1c06818 [30] SANTOS A L, BOTELHO E C, KOSTOV K G, et al. Carbon fiber surface modification by plasma treatment for interface adhesion improvements of aerospace composites[J]. Advanced materials research, 2016, 1135: 75-87. doi: 10.4028/www.scientific.net/AMR.1135.75 [31] PANERAI F, COCHELL T, MARTIN A, et al. Experimental measurements of the high-temperature oxidation of carbon fibers[J]. International Journal of Heat and Mass Transfer, 2019, 136: 972-986. doi: 10.1016/j.ijheatmasstransfer.2019.03.018 [32] ZHANG X, FAN X, YAN C, et al. Interfacial microstructure and properties of carbon fiber composites modified with graphene oxide[J]. ACS applied materials & interfaces, 2012, 4(3): 1543-1552. [33] MA J, JIANG L, DAN Y, et al. Study on the inter-laminar shear properties of carbon fiber reinforced epoxy composite materials with different interface structures[J]. Materials & Design, 2022, 214: 110417. -

点击查看大图

点击查看大图

计量

- 文章访问数: 108

- HTML全文浏览量: 65

- 被引次数: 0

下载:

下载: