Studies on toughening modification and the properties of phenolic resin by carbon nanotubes in collaboration with hexamethylenetetramine

-

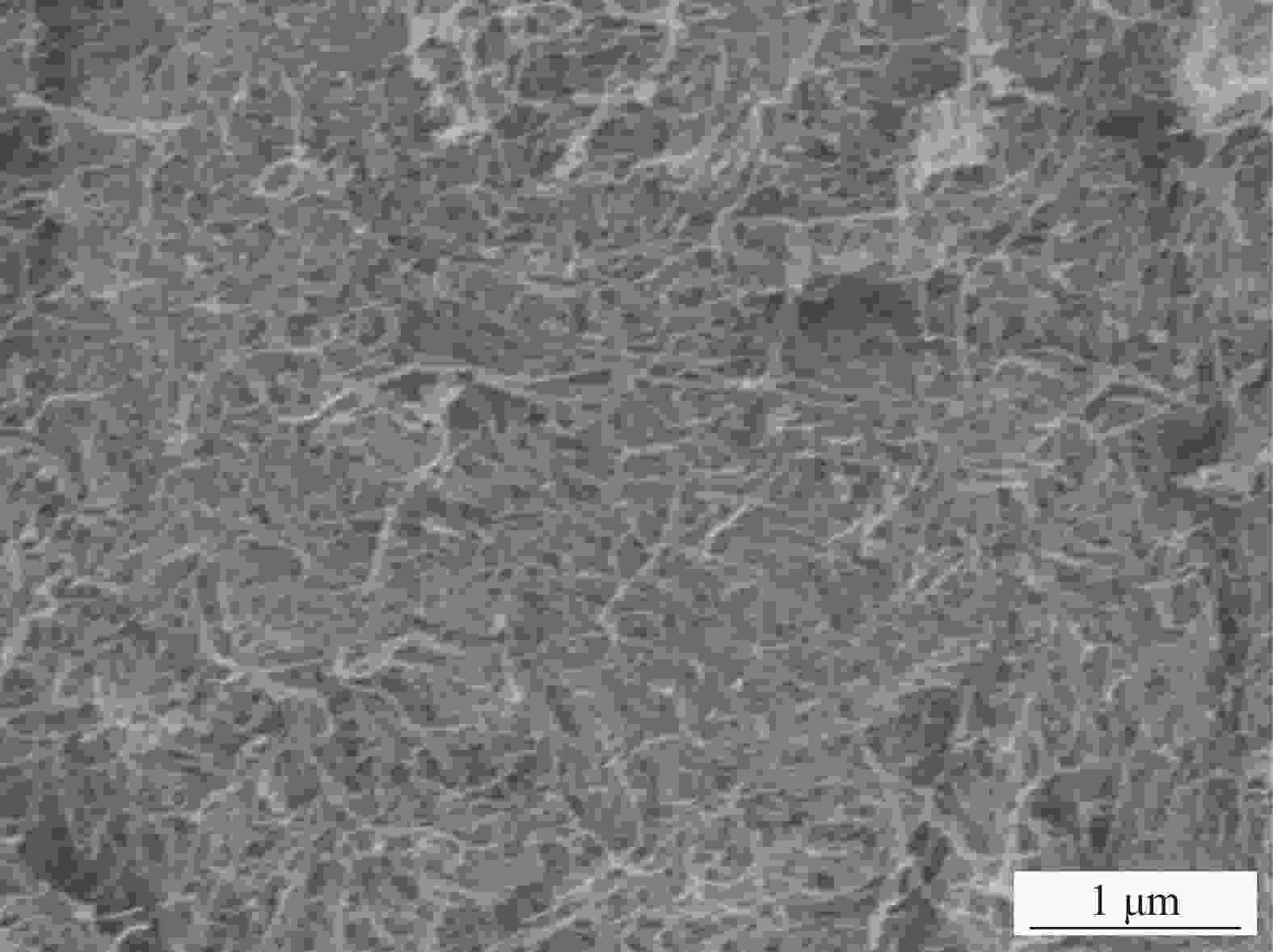

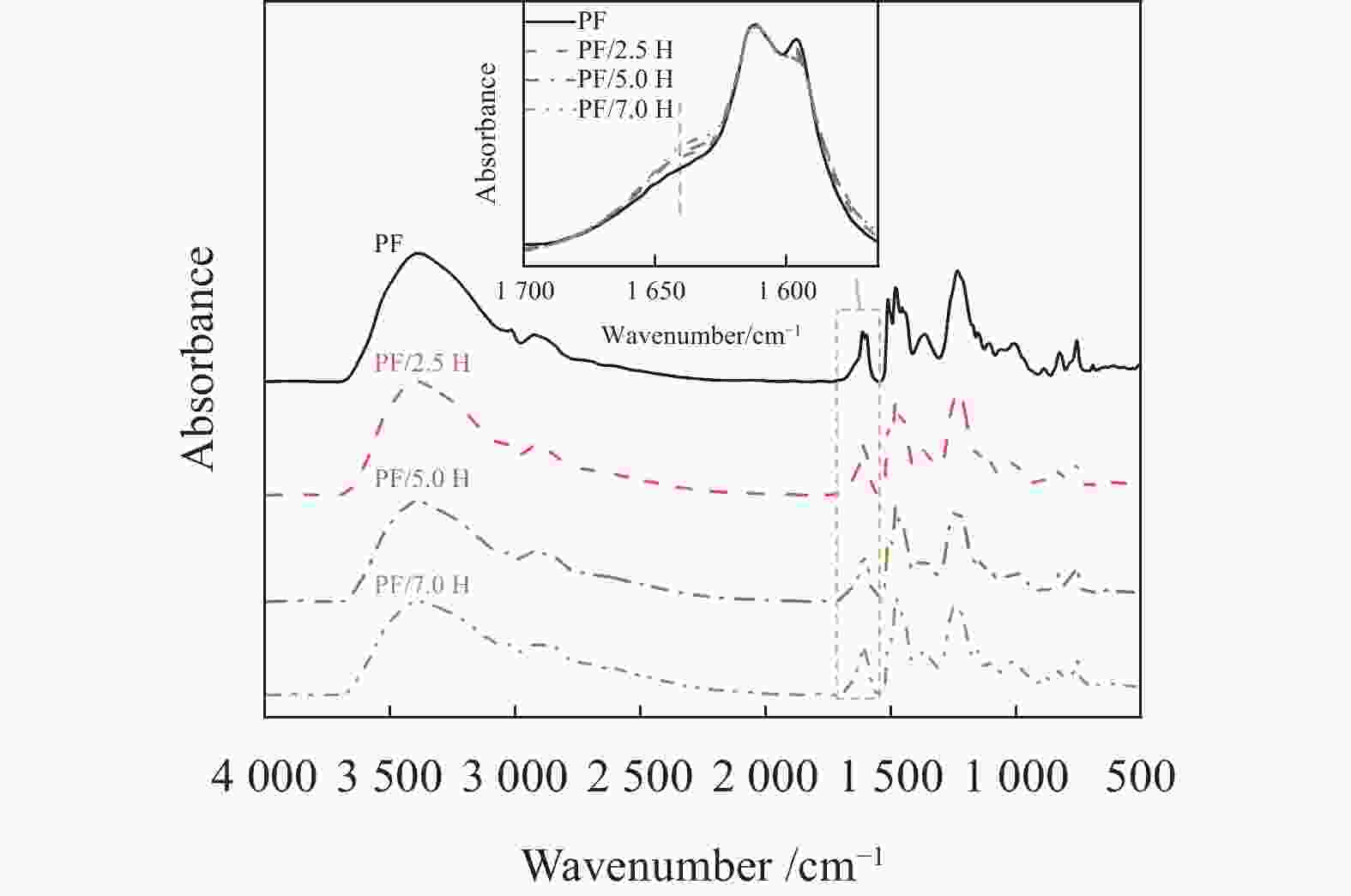

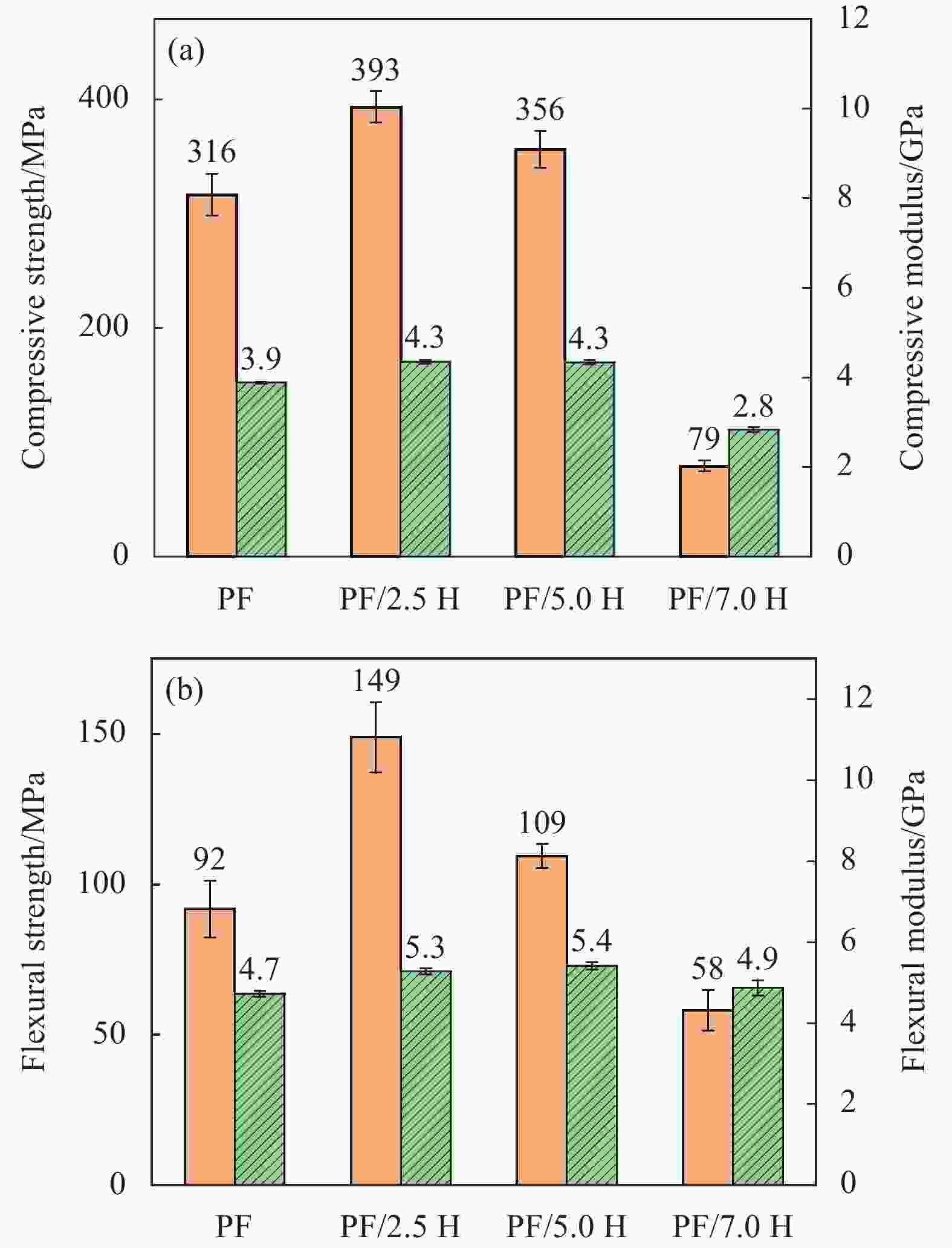

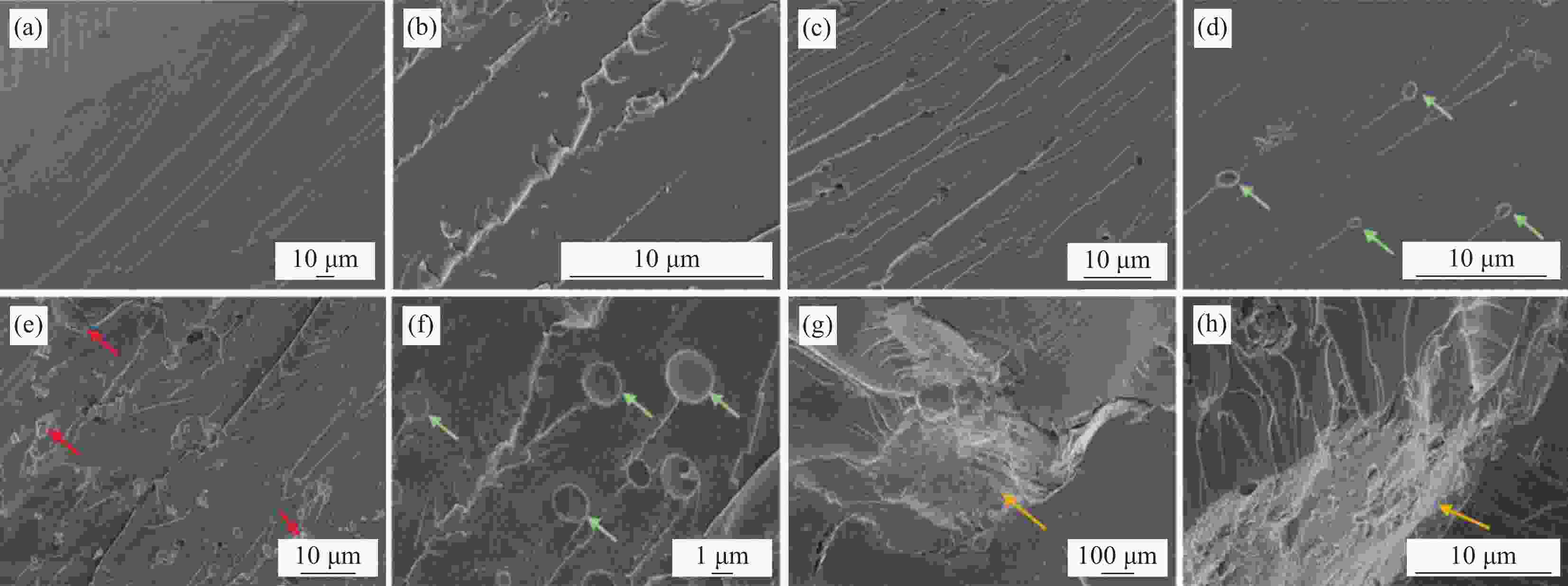

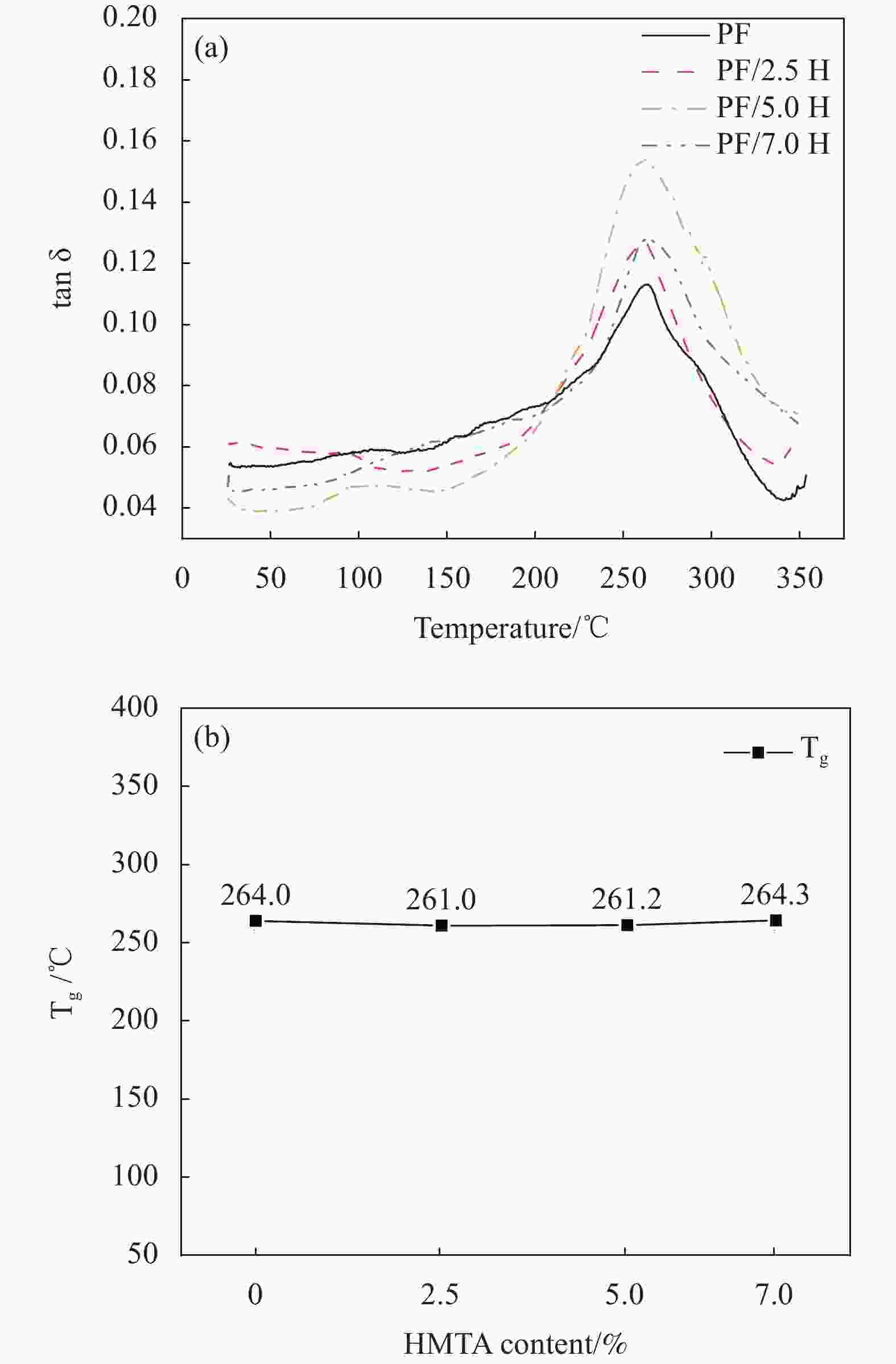

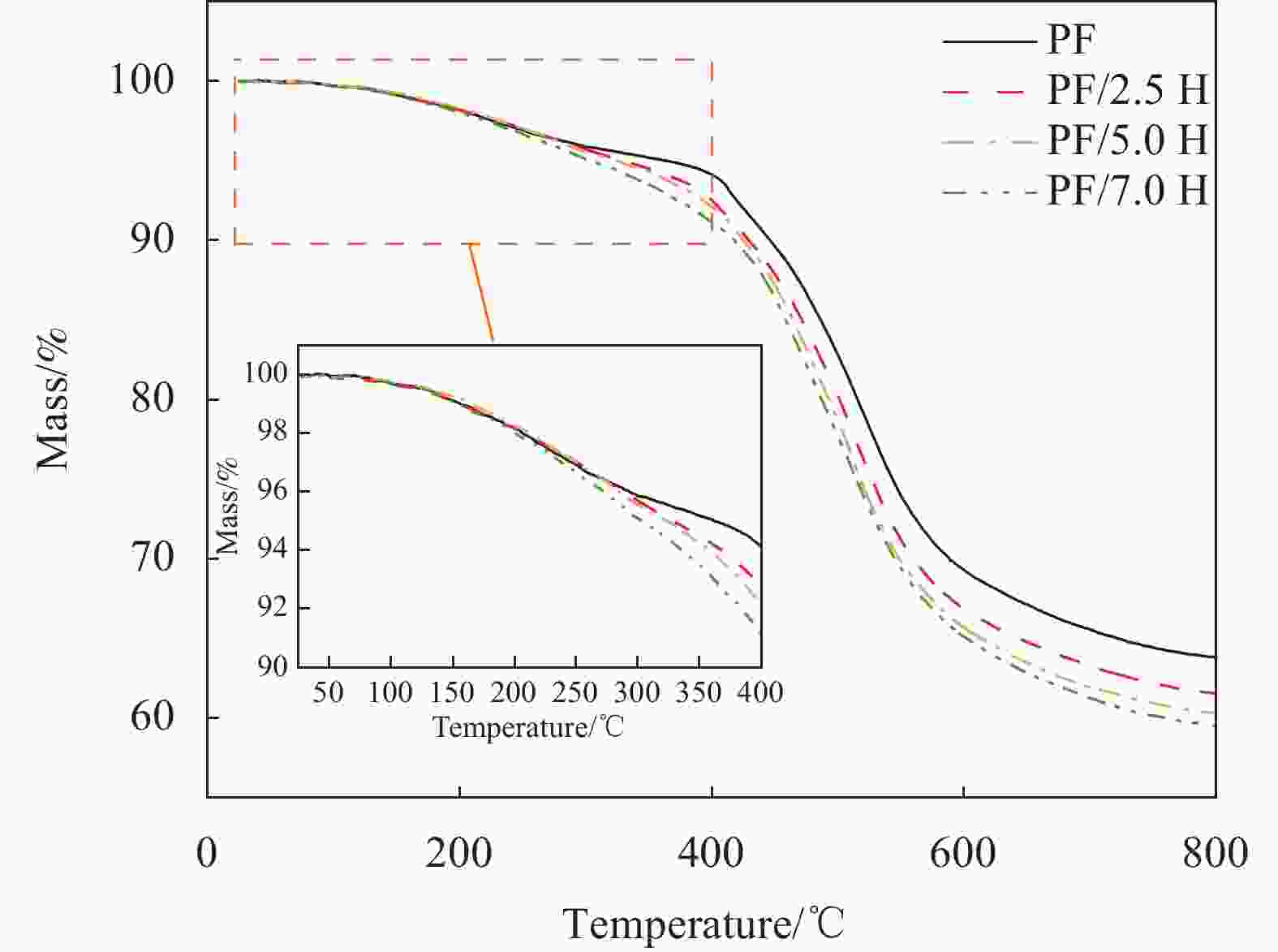

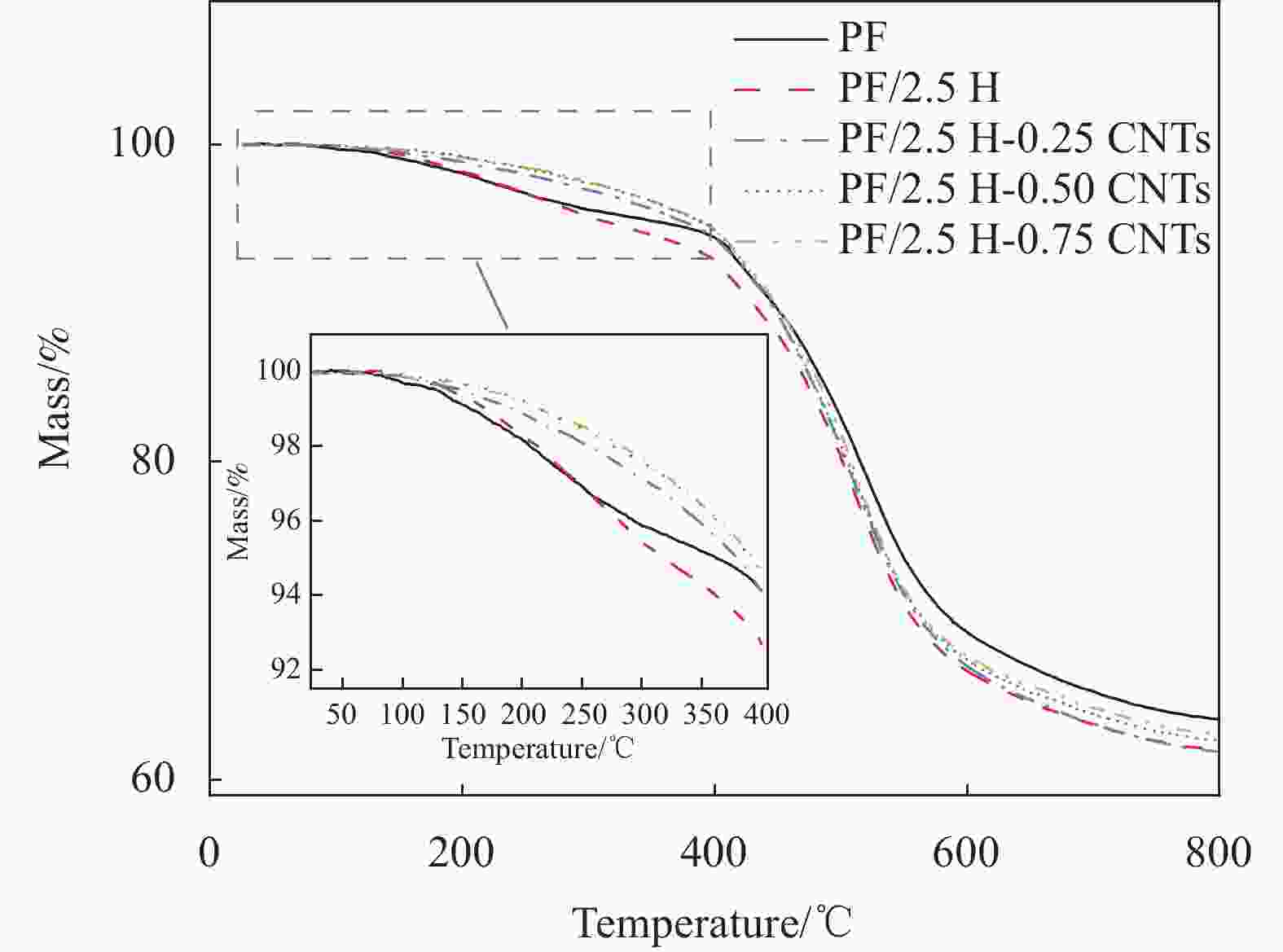

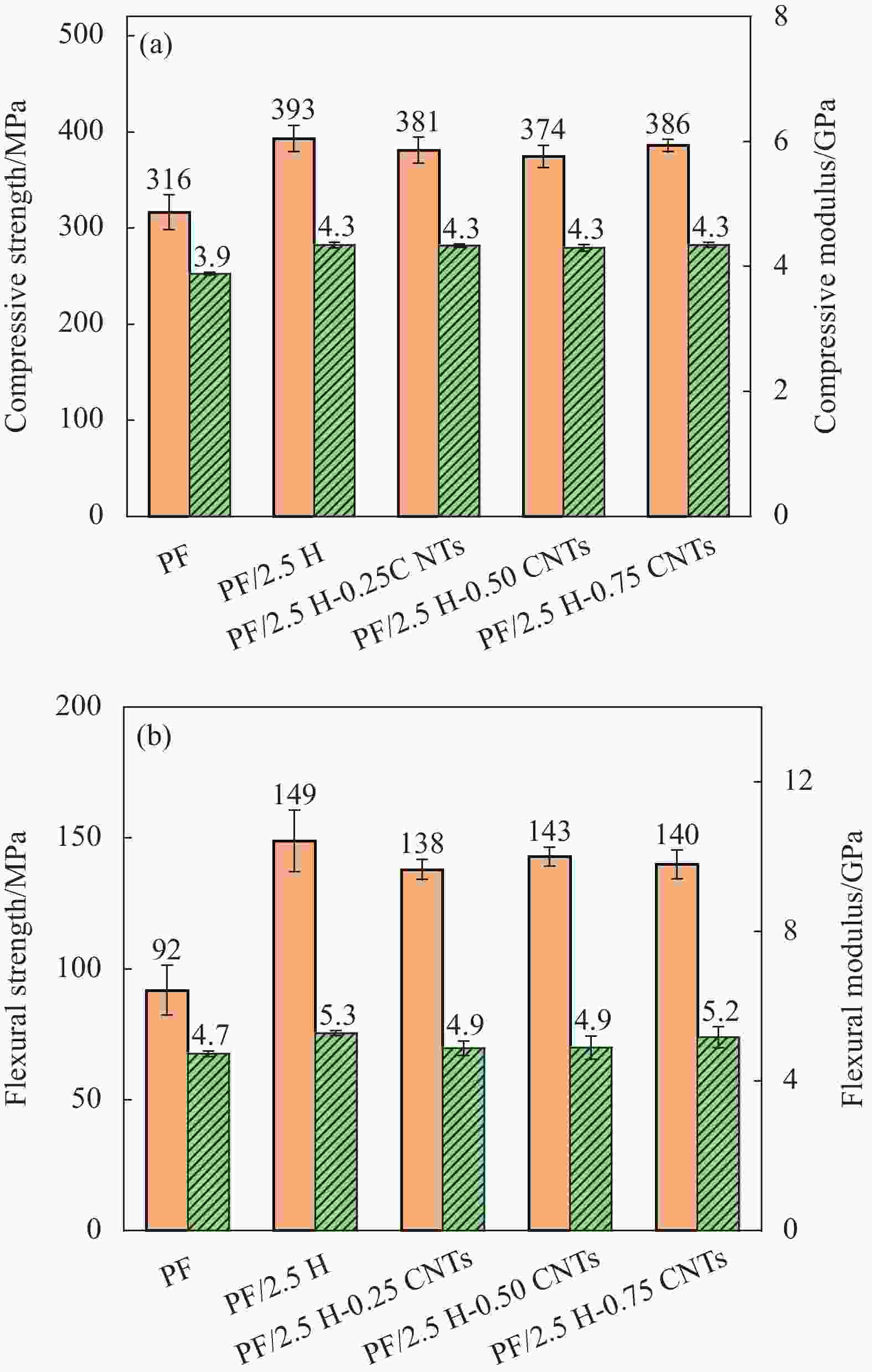

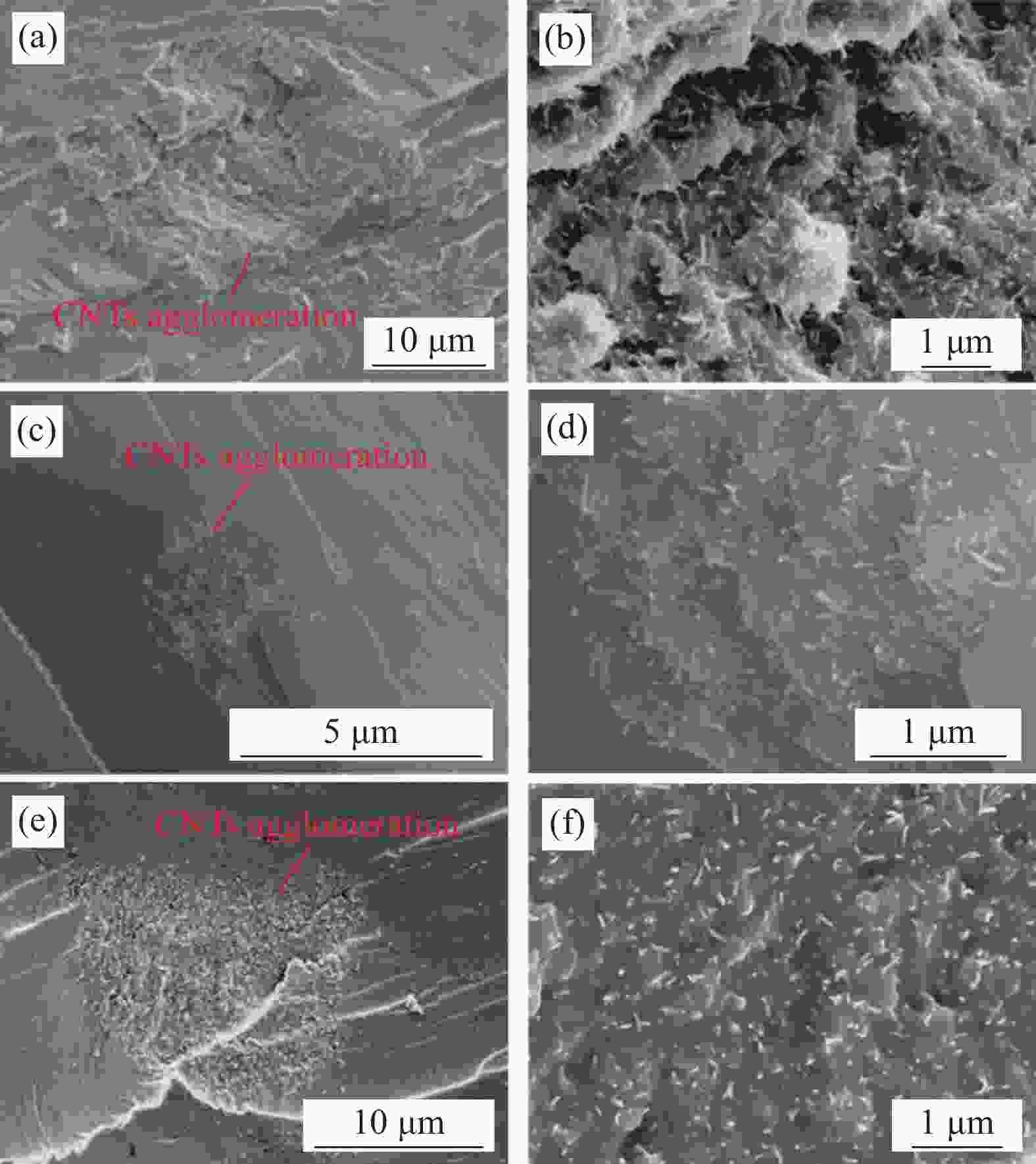

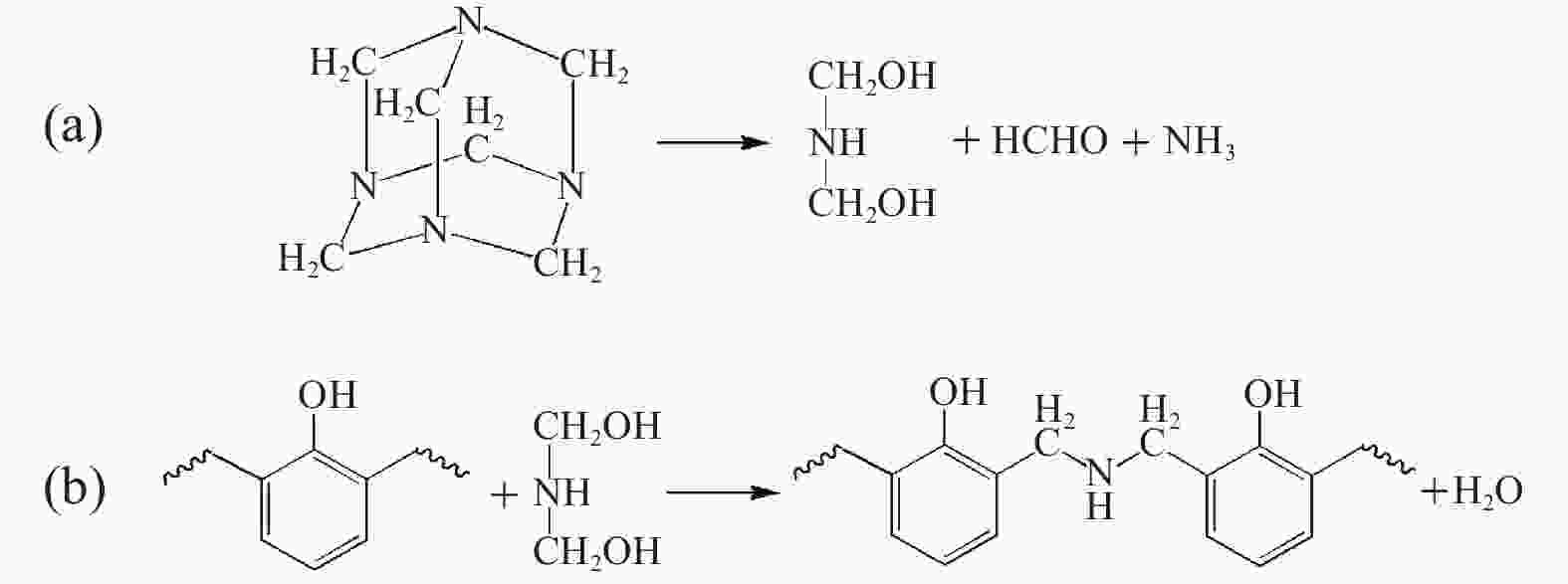

摘要: 传统热固性酚醛树脂脆性大,本文采用六亚甲基四胺(HMTA)对酚醛树脂进行了化学增韧改性,并考察了碳纳米管协同改性提高酚醛树脂耐热性能的综合效应。研究发现,不同含量HMTA对酚醛树脂力学性能影响规律呈先增长后下降趋势,2.5wt%HMTA改性酚醛的力学性能最为突出,其压缩强度达到393 MPa,弯曲强度为149 MPa,相比未改性酚醛树脂分别提升24%与62%,断口分析表明增韧体系中形成的“海-岛”结构显著提升了树脂基体的力学性能。但是,HMTA导致酚醛树脂的耐热性能明显下降,在2.5wt%HMTA增韧酚醛体系中加入碳纳米管可将树脂体系的Td5提升至初始酚醛树脂的水平,同时兼具优异的增韧后力学性能。这一结果对结构/防热一体化新型酚醛树脂基体的设计研制具有重要参考价值。Abstract: The conventional thermosetting phenolic resin exhibits significant brittleness. This paper utilized hexamethylenetetramine (HMTA) to chemically toughen phenolic resins. And the comprehensive effect of carbon nanotube synergistic modification on improving the heat-resistant properties of the phenolic resin was also examined. The results indicate that the mechanical properties of the HMTA-modified phenolic resin present a tendency of first increasing and then decreasing with the increase of the HMTA content. The highest mechanical properties are observed in the modified phenolic resin with 2.5wt% HMTA, as its compression strength reaches up to 393 MPa and the bending strength up to 149 MPa, representing increases of 24% and 62%, respectively, compared to the unmodified phenolic resin matrix. The fracture morphology reveals that the low content of HMTA creates numerous "sea-island" structures within the modified phenolic matrix, which significantly contributes to the improvement of the mechanical properties of the phenolic matrix. However, HMTA can lead to an obvious decrease in the heat-resistance of phenolic resins. Adding carbon nanotubes to the 2.5wt% HMTA toughened phenolic system can increase the Td5 of the resin system to the level of the unmodified phenolic resin, while also exhibiting excellent toughened mechanical properties. This lays an important foundation for the design and development of new structural/thermal protection integrated phenolic resin matrices and their composites.

-

Key words:

- phenolic resin /

- chemical toughening /

- carbon nanotubes /

- heat resistant performance

-

表 1 改性酚醛树脂(PF)的样品名称与组成

Table 1. Nominations and compositions of modified phenolic resins (PF)

Nominations PF/g HMTA/g CNTs/g PF 100 0 0 PF/2.5H 97.5 2.5 0 PF/5.0H 95.0 5.0 0 PF/7.0H 93.0 7.0 0 PF/2.5H-0.25CNTs 97.5 2.5 0.25 PF/2.5H-0.50CNTs 97.5 2.5 0.50 PF/2.5H-0.75CNTs 97.5 2.5 0.75 表 2 不同含量HMTA改性酚醛树脂固化后的热性能参数

Table 2. Thermogravimetric analysis data of cured phenolic resins modified with different contents of HMTA

Designation Td5/℃ Td10/℃ Residue

at 800℃/%PF 362 446 63.8 PF/2.5H 329 430 61.6 PF/5.0H 324 425 60.3 PF/7.0H 304 417 59.5 Notes:Td5 is the pyrolysis temperature at 5% mass loss; Td10 is the pyrolysis temperature at 10% mass loss. 表 3 CNTs与HMTA协同改性酚醛树脂固化后的热性能参数

Table 3. Thermogravimetric analysis data of cured phenolic resins co-modified with CNTs and HMTA

Designation Td5/℃ Td10/℃ Residue

at 800℃/%PF 362 446 63.8 PF/2.5H 329 430 61.6 PF/2.5H-0.25CNTs 380 444 61.8 PF/2.5H-0.50CNTs 392 446 62.5 PF/2.5H-0.75CNTs 394 449 62.9 -

[1] UYANNA O, NAJAFI H. Thermal protection systems for space vehicles: A review on technology development, current challenges and future prospects[J]. Acta Astronautica, 2020, 176: 341-356. doi: 10.1016/j.actaastro.2020.06.047 [2] PELIN G, PELIN C E, STEFAN A, et al. Oxy-Butane Ablation Testing of Thermal Protection Systems Based on Nanomodified Phenolic Resin Matrix Materials[J]. Polymers, 2023, 15(19): 4016. doi: 10.3390/polym15194016 [3] GE T, TANG K, YU Y, et al. Preparation and properties of the 3-pentadecyl-phenol in situ modified foamable phenolic resin[J]. Polymers, 2018, 10(10): 1124. doi: 10.3390/polym10101124 [4] BO C, SHI Z, HU L, et al. Cardanol derived P, Si and N based precursors to develop flame retardant phenolic foam[J]. Scientific Reports, 2020, 10(1): 12082. doi: 10.1038/s41598-020-68910-6 [5] HU L, WANG Z, ZHAO Q. Flame retardant and mechanical properties of toughened phenolic foams containing a melamine phosphate borate[J]. Polymer-Plastics Technology and Engineering, 2017, 56(6): 678-686. doi: 10.1080/03602559.2016.1227844 [6] TANG K, TANG X, LIU X, et al. Phenolic Foams Toughened with Triethylene Glycol by In Situ Polymerization and Prepolymerization Processes[J]. ACS Applied Polymer Materials, 2022, 4(11): 8303-8314. doi: 10.1021/acsapm.2c01277 [7] LI X, WANG Z, WU L. Preparation of a silica nanospheres/graphene oxide hybrid and its application in phenolic foams with improved mechanical strengths, friability and flame retardancy[J]. Rsc Advances, 2015, 5(121): 99907-99913. doi: 10.1039/C5RA19830E [8] WANG Z, LI X. Synthesis of CoAl-layered double hydroxide/graphene oxide nanohybrid and its reinforcing effect in phenolic foams[J]. High Performance Polymers, 2018, 30(6): 688-698. doi: 10.1177/0954008317716976 [9] YU Y, WANG Y, XU P, et al. Preparation and characterization of phenolic foam modified with bio-oil[J]. Materials, 2018, 11(11): 2228. doi: 10.3390/ma11112228 [10] JING S, LI T, LI X, et al. Phenolic foams modified by cardanol through bisphenol modification[J]. Journal of Applied Polymer Science, 2014, 131(4): 39942. doi: 10.1002/app.39942 [11] YANG H, WANG X, YU B, et al. A novel polyurethane prepolymer as toughening agent: Preparation, characterization, and its influence on mechanical and flame retardant properties of phenolic foam[J]. Journal of applied polymer science, 2013, 128(5): 2720-2728. doi: 10.1002/app.38399 [12] WANG J, WANG R, JI X, et al. Enhancing and toughening bamboo interfacial bonding strength by reactive hyperbranched polyethyleneimine modified phenol formaldehyde resin adhesive[J]. Journal of Materials Research and Technology, 2023, 26: 8213-8228. doi: 10.1016/j.jmrt.2023.09.176 [13] YANG W, Rallini M, Natali M, et al. Preparation and properties of adhesives based on phenolic resin containing lignin micro and nanoparticles: A comparative study[J]. Materials & Design, 2019, 161: 55-63. [14] 张丽青, 张国利, 王伟伟等. 聚乙烯醇缩丁醛改性酚醛树脂的耐热与增韧性能[J]. 高分子材料科学与工程, 2021, 37(6): 85-93.ZHANG Liqing, ZHANG Guoli, WANG Weiwei, et al. Heat Resistance and Toughening Properties of Polyvinyl Butyral Modified Phenolic Resin[J]. Polymer Materials Science and Engineering, 2021, 37(6): 85-93(in Chinese). [15] LIU L, FU M, WANG Z. Synthesis of boron-containing toughening agents and their application in phenolic foams[J]. Industrial & Engineering Chemistry Research, 2015, 54(7): 1962-1970. [16] GAO M, WU W, WANG Y, et al. Phenolic foam modified with dicyandiamide as toughening agent[J]. Journal of thermal analysis and calorimetry, 2016, 124: 189-195. doi: 10.1007/s10973-015-5156-1 [17] SONG F, JIA P, BO C, et al. Preparation and characterization of tung oil toughened modified phenolic foams with enhanced mechanical properties and smoke suppression[J]. Journal of Renewable Materials, 2020, 8(5): 535-547. doi: 10.32604/jrm.2020.09304 [18] YU Z, LI J, YANG L, et al. Synthesis and properties of nano carboxylic acrylonitrile butadiene rubber latex toughened phenolic resin[J]. Journal of Applied Polymer Science, 2012, 123(2): 1079-1084. doi: 10.1002/app.34573 [19] LIU W W, MA J J, ZHAN M S, et al. The toughening effect and mechanism of styrene-butadiene rubber nanoparticles for novolac resin[J]. Journal of Applied Polymer Science, 2015, 132(9): 41533. doi: 10.1002/app.41533 [20] LIU D, WANG H, JIANG H, et al. Improving the heat-resistance and toughness performance of phenolic resins by adding a rigid aromatic hyperbranched polyester[J]. Journal of Applied Polymer Science, 2016, 133(4): 42734. doi: 10.1002/app.42734 [21] RAVINDRAN L, MS S, ANILKUMAR S, et al. Mechanical, Morphological Behaviour and Electrical Conductivity of Phenol Formaldehyde-Flax Fabric (PF-F) Hybrid Composites Reinforced with Rice Husk Derived Nano-silica[J]. Silicon, 2023, 15(7): 3237-3250. doi: 10.1007/s12633-022-02193-6 [22] LIU L, WANG Z. Facile synthesis of a novel magnesium amino-tris-(methylene phosphonate)-reduced graphene oxide hybrid and its high performance in mechanical strength, thermal stability, smoke suppression and flame retardancy in phenolic foam[J]. Journal of hazardous materials, 2018, 357: 89-99. doi: 10.1016/j.jhazmat.2018.05.052 [23] LI X, WANG Z, WU L, et al. One-step in situ synthesis of a novel α-zirconium phosphate/graphene oxide hybrid and its application in phenolic foam with enhanced mechanical strength, flame retardancy and thermal stability[J]. RSC advances, 2016, 6(78): 74903-74912. doi: 10.1039/C6RA12208F [24] ZHU Y, WANG Z. Phenolic foams, modified by nano-metallic oxides, improved in mechanical strengths and friability[J]. Iranian Polymer Journal, 2016, 25: 579-587. doi: 10.1007/s13726-016-0447-3 [25] TANG K, ZHANG A, Ge T, et al. Research progress on modification of phenolic resin[J]. Materials Today Communications, 2021, 26: 101879. doi: 10.1016/j.mtcomm.2020.101879 [26] ZHANG W, JIANG N, ZHANG T, et al. Thermal stability and thermal degradation study of phenolic resin modified by cardanol[J]. Emerging Materials Research, 2020, 9(1): 180-185. [27] 中国国家标准化管理委员会. 树脂浇铸体性能试验方法: GB/T 2567-2008[S]. 北京: 中国标准出版社, 2008.Standardization Administration of the People's Republic of China. Test methods for properties of resin casting body: GB/T 2567-2008[S]. Beijing: China Standards Press, 2008(in Chinese). [28] CORCIONE C E, FRIGIONE M. Characterization of nanocomposites by thermal analysis[J]. Materials, 2012, 5(12): 2960-2980. doi: 10.3390/ma5122960 -

点击查看大图

点击查看大图

计量

- 文章访问数: 124

- HTML全文浏览量: 37

- 被引次数: 0

下载:

下载: