Evolution behavior of major Poisson's ratio of 2D-C/SiC composites

-

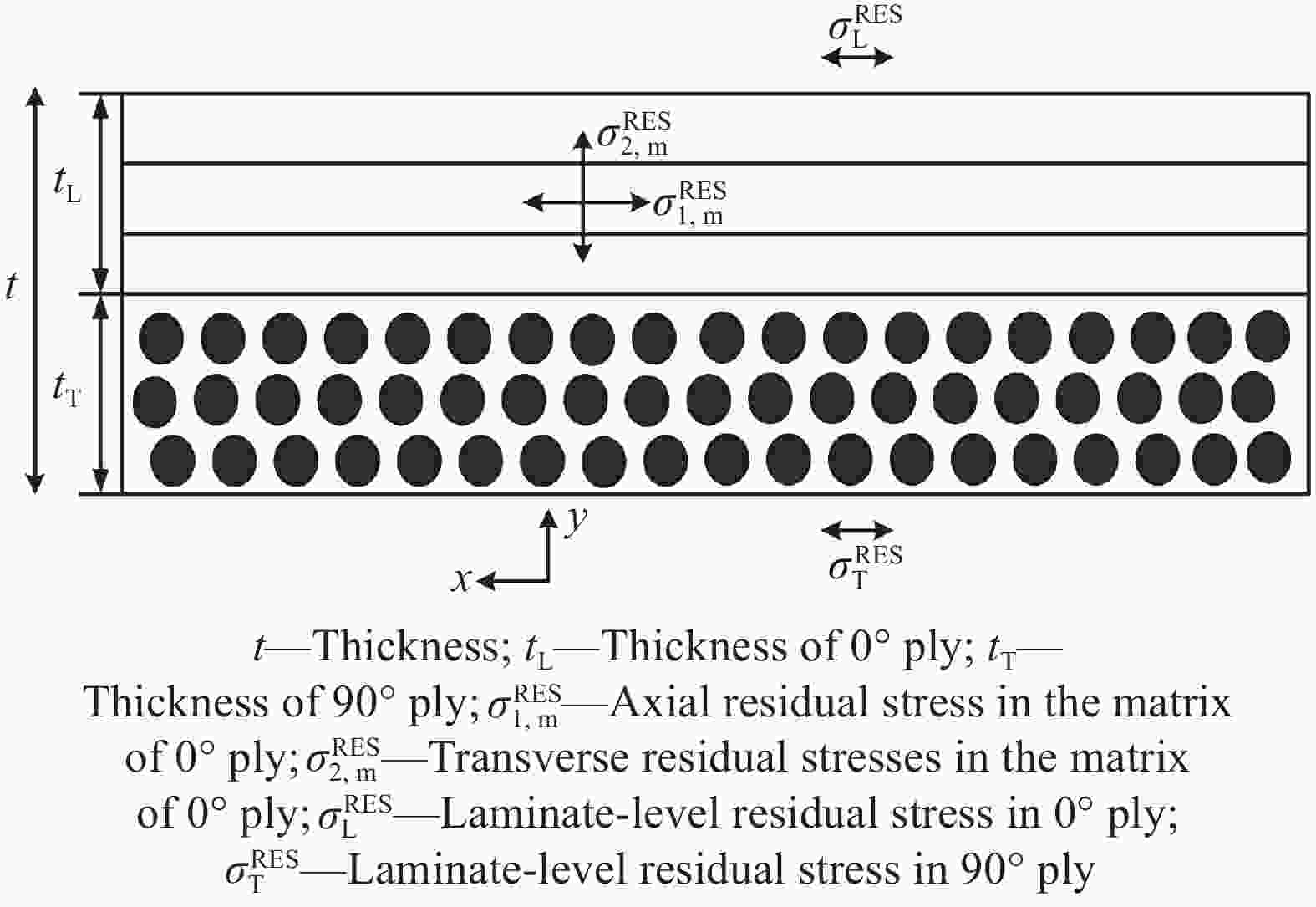

摘要: 泊松比是材料及其结构力学性能分析的重要参数之一。本文旨在研究2D-C/SiC复合材料主泊松比的非线性演化行为。首先,基于Mini复合材料模型与正交层压板模型,考虑纤维的横观各向同性性质,建立了2D-C/SiC复合材料的热残余应力计算模型;其次,应用剪滞理论与经典层压板理论,考虑材料的损伤与热残余应力释放机制,建立了2D-C/SiC复合材料的主泊松比计算模型;最后,通过试验表征了材料的应变响应及泊松比演化规律,并对理论模型进行了分析验证。结果表明,2D-C/SiC复合材料内部热残余应力较大,拉伸损伤过程中的热残余应力释放是负泊松比产生的原因;应力-应变曲线及泊松比演化曲线的模型预测结果均与试验曲线吻合较好,表明了理论分析模型的准确性与合理性。

-

关键词:

- 陶瓷基复合材料 /

- 泊松比 /

- Mini复合材料模型 /

- 热残余应力

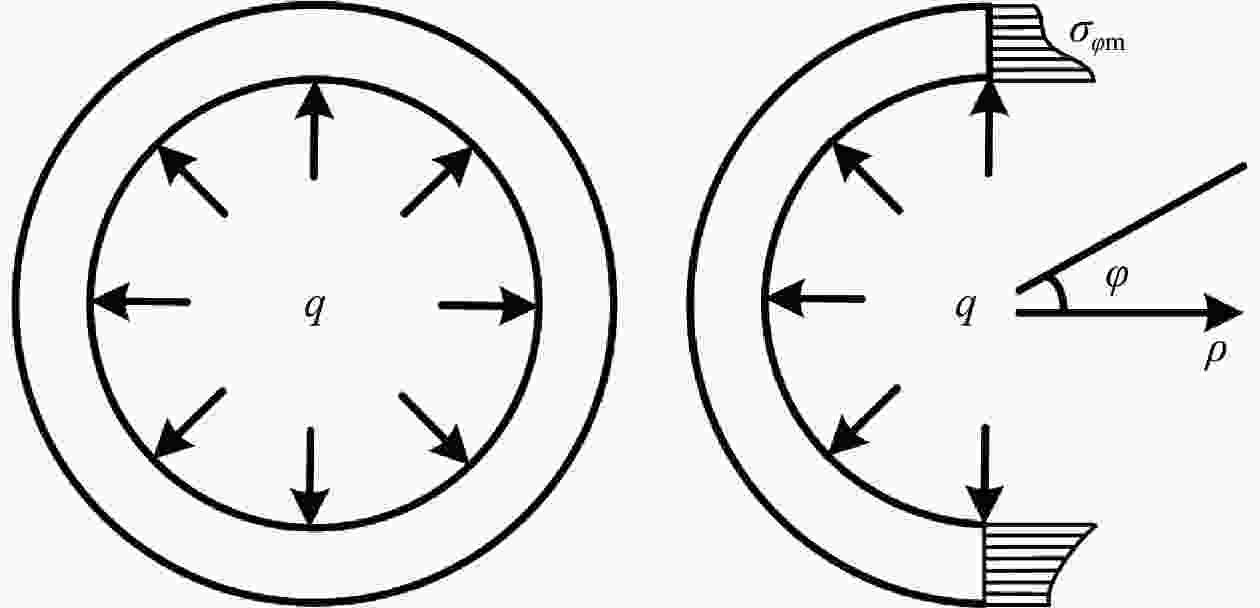

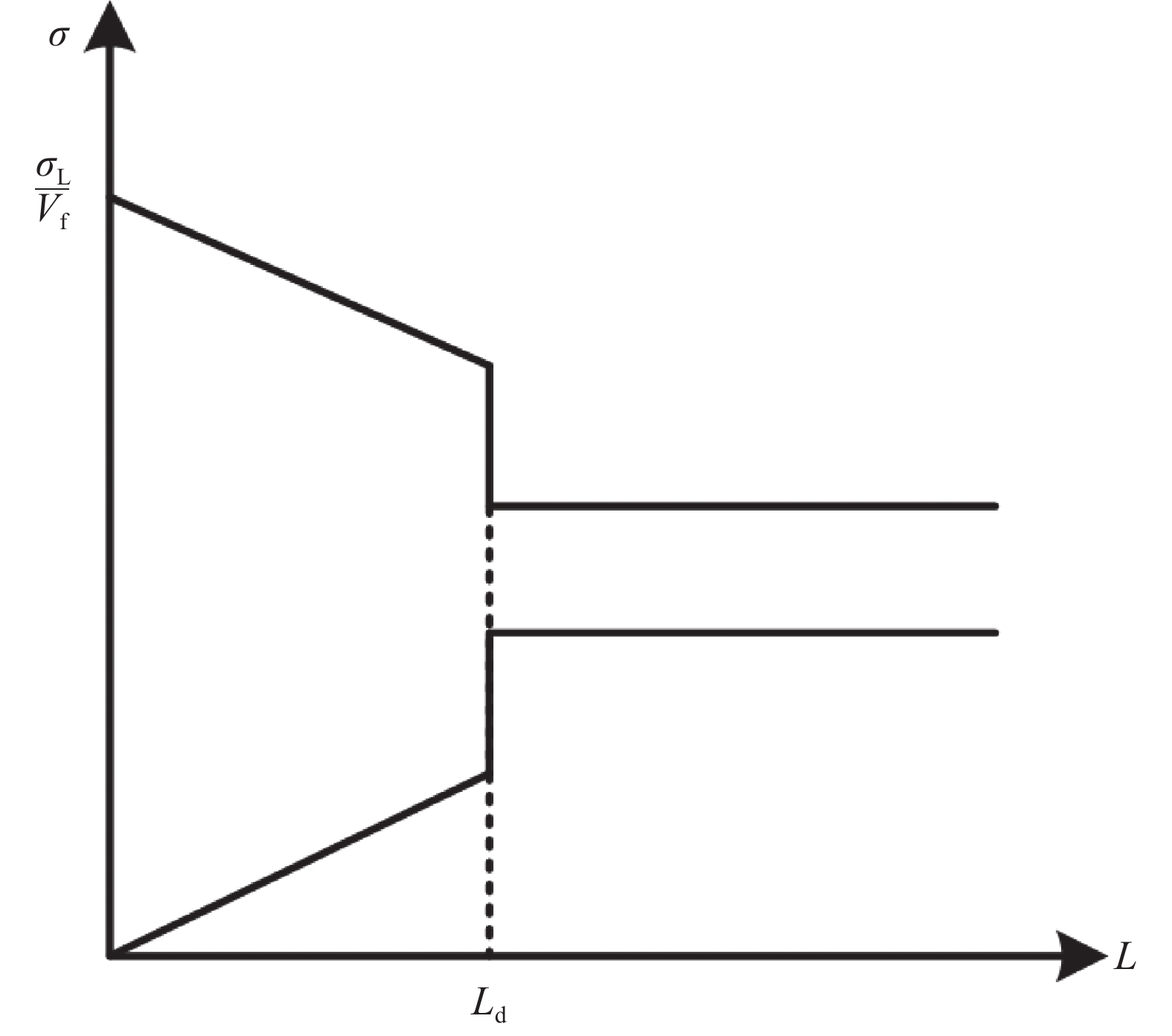

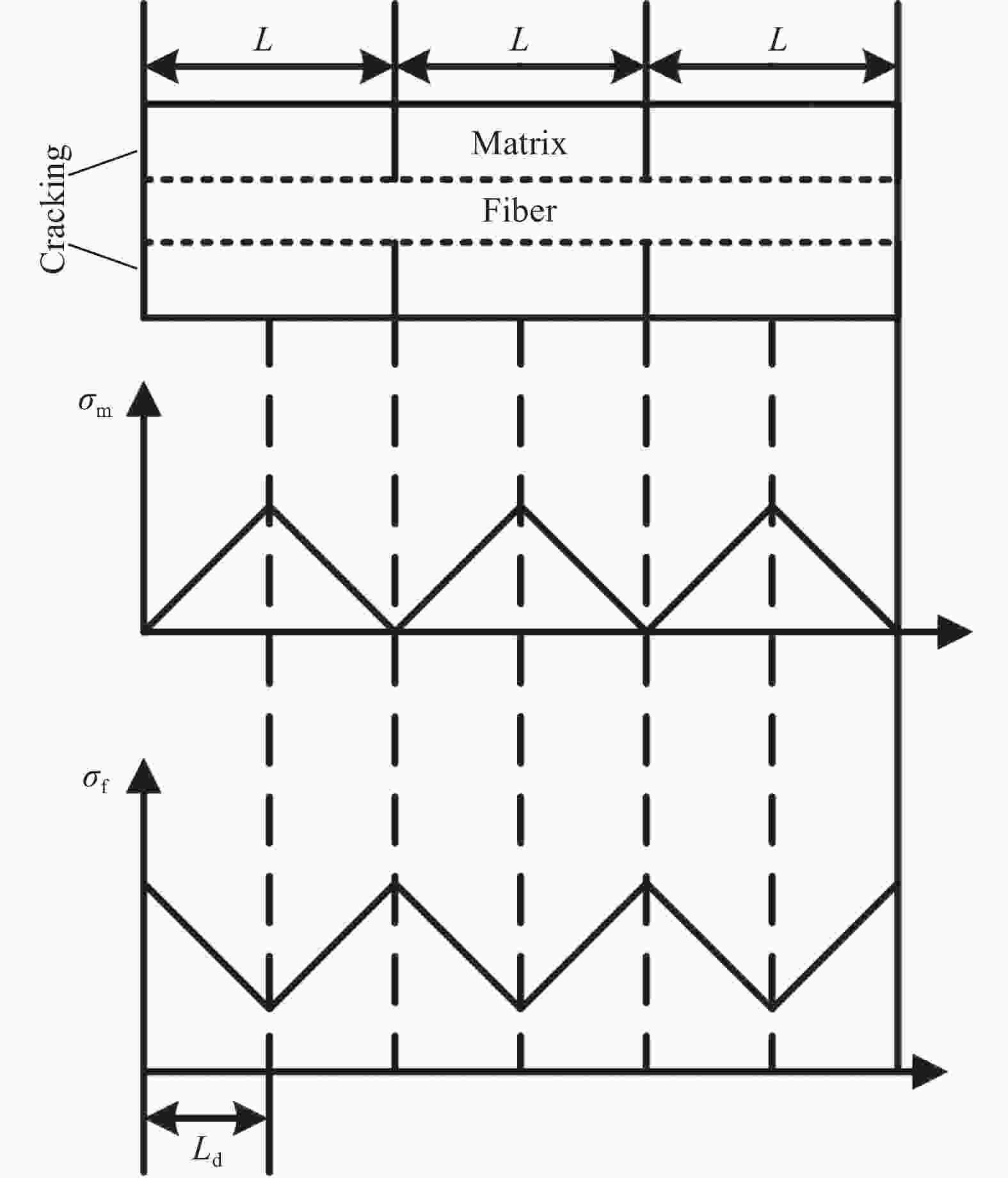

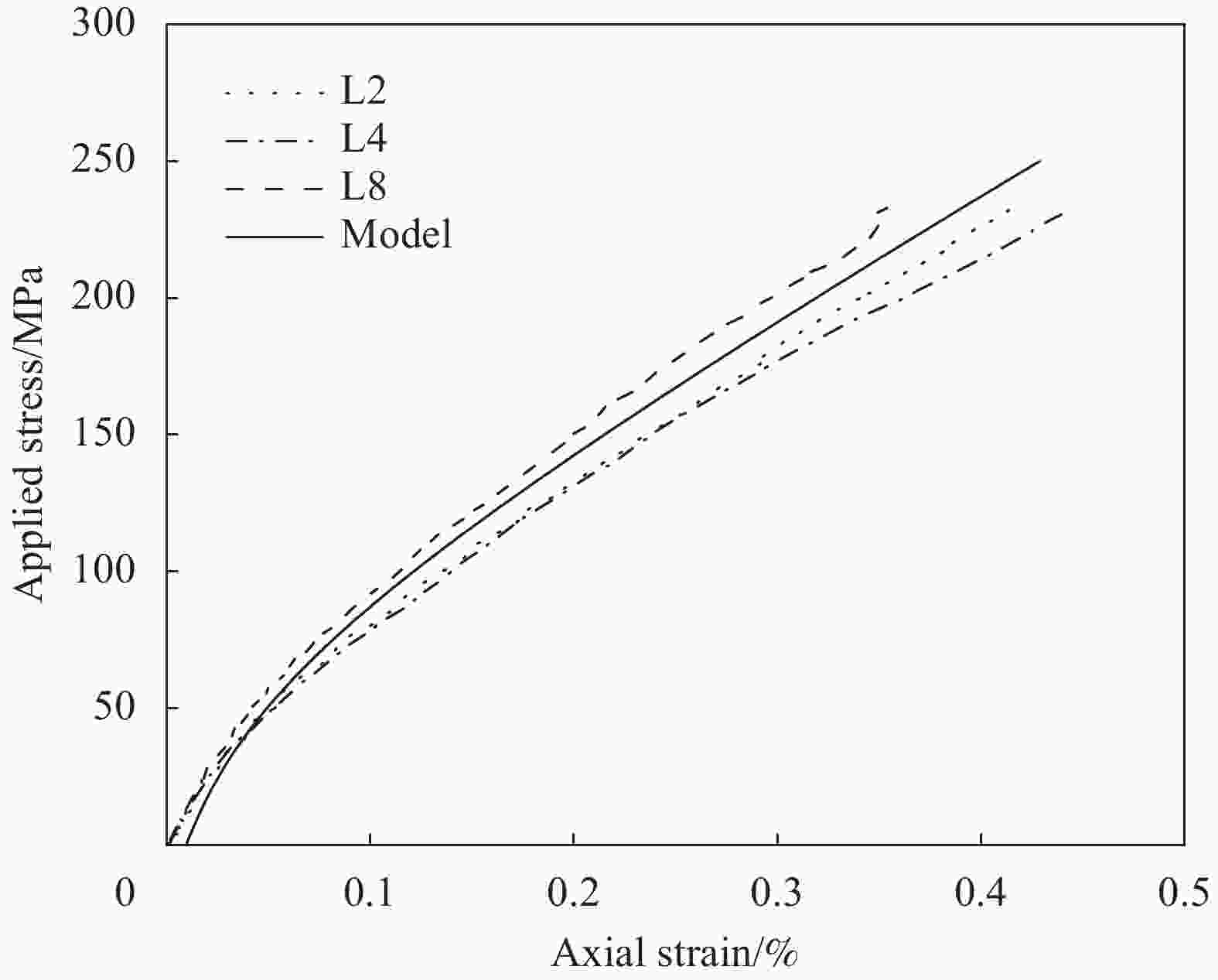

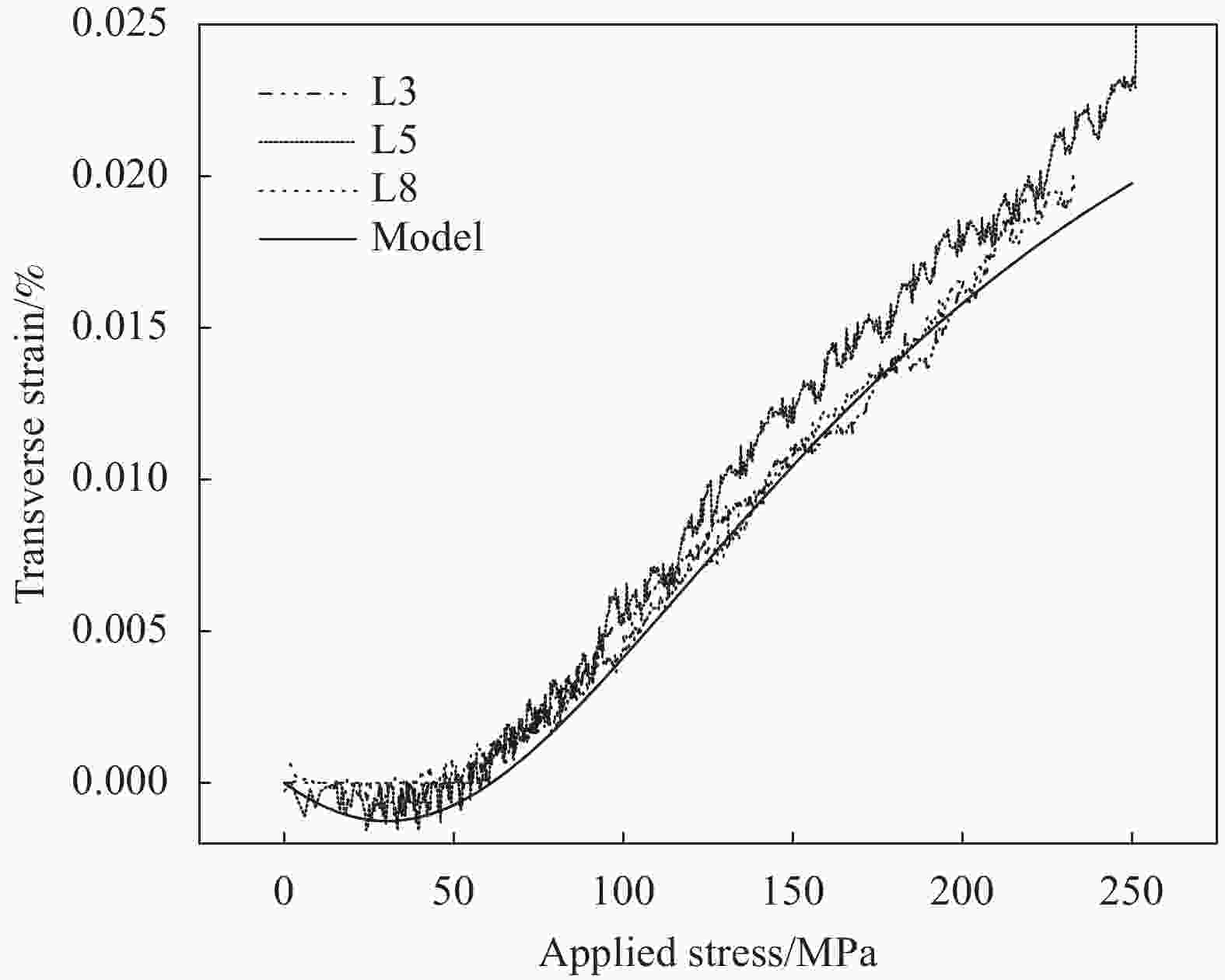

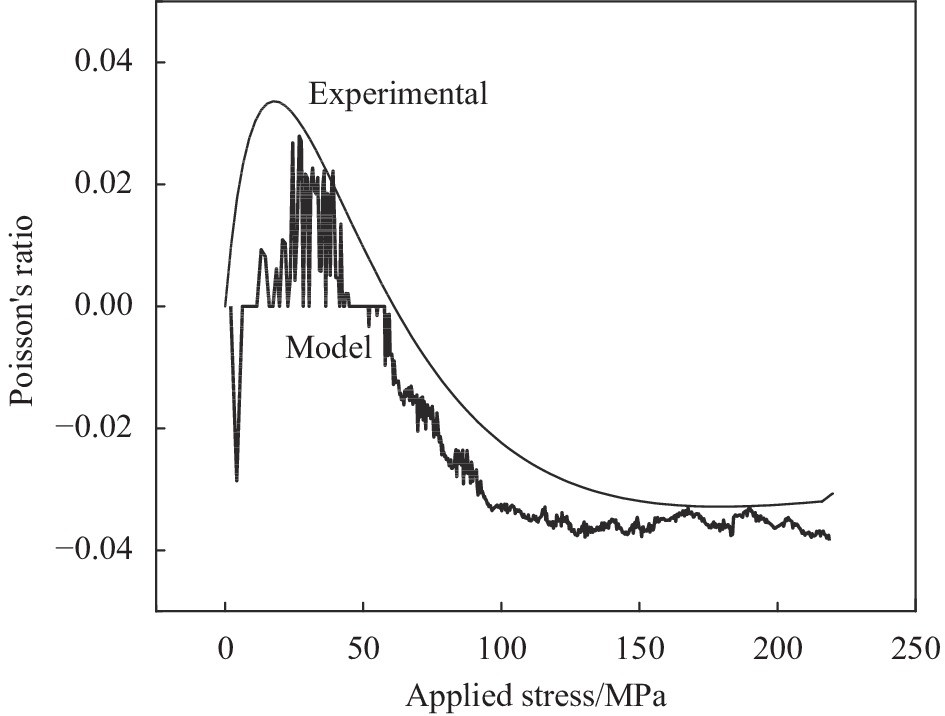

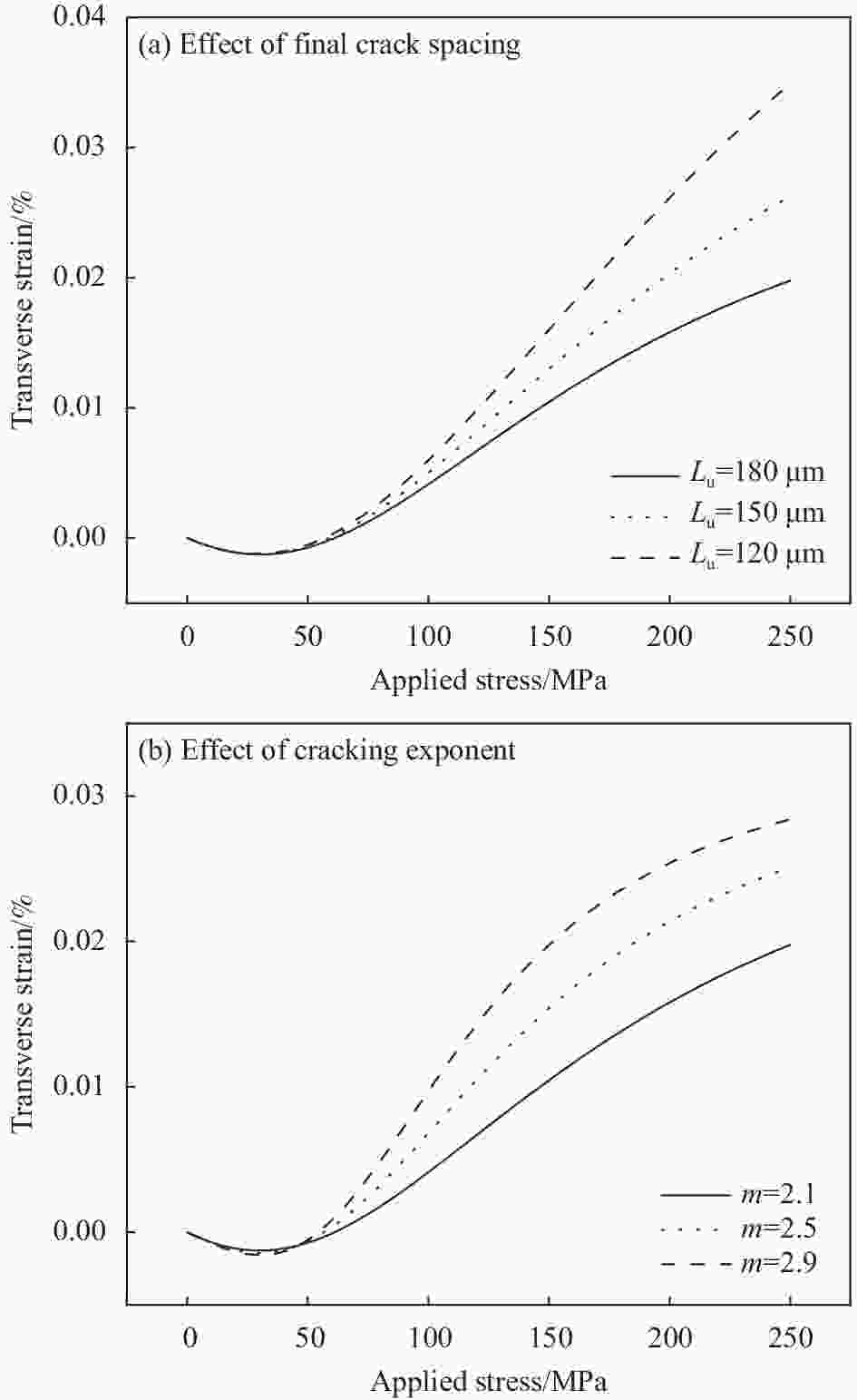

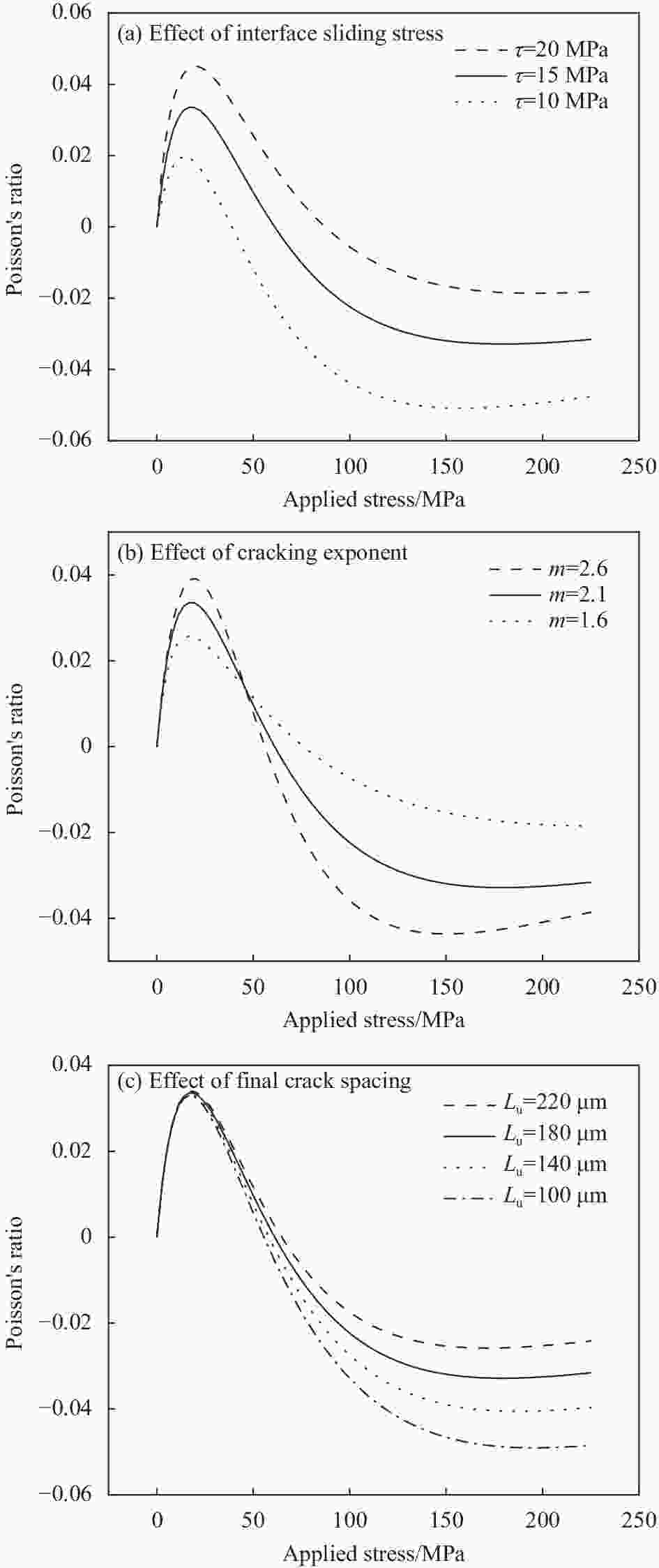

Abstract: Poisson's ratio is one of the important parameters in the analysis of mechanical properties of materials and structures. In this paper, the nonlinear evolution behavior of major Poisson's ratio of 2D-C/SiC composites was studied. Firstly, based on Mini composite model and cross-ply laminate model, the thermal residual stress calculation model of 2D-C/SiC composites was established considering the transverse isotropic property of fiber. Secondly, the major Poisson's ratio calculation model of 2D-C/SiC composites was established by using shear-lag theory and classical laminate theory while considering the damage and thermal residual stress release mechanisms of the material. Finally, the strain response and Poisson's ratio evolution of the material were characterized by experiments, and the theoretical model was analyzed and verified. The results show that the internal thermal residual stress of 2D-C/SiC composites is large, and the release of thermal residual stress during tensile damage is responsible for the negative Poisson's ratio. The model prediction results of stress-strain curve and Poisson's ratio evolution curve are in good agreement with the tested curves, which indicates the accuracy and reasonability of the theoretical analysis model. -

表 1 2D-C/SiC复合材料模型基本参数

Table 1. Basic parameters of 2D-C/SiC composites model

Parameter Value Longitudinal modulus of fiber $ {E}_{1\mathrm{f}} $/GPa 230 Transverse modulus of fiber $ {E}_{2\mathrm{f}} $/GPa 14 Matrix modulus $ {E}_{\mathrm{m}} $/GPa 350 Fiber volume fraction $ {V}_{\mathrm{f}} $/vol% 40 Matrix volume fraction $ {V}_{\mathrm{m}} $/vol% 60 Fiber volume fraction in bundle $ {V}_{\mathrm{f}\mathrm{b}} $/vol% 70 Matrix volume fraction in bundle $ {V}_{\mathrm{m}\mathrm{b}} $/vol% 30 Axial Poisson's ratio of fiber $ {\nu }_{1\mathrm{f}} $ 20 Transverse Poisson's ratio of fiber $ {\nu }_{2\mathrm{f}} $ 0.07 Matrix Poisson's ratio $ {\nu }_{\mathrm{m}} $ 0.2 CTE of matrix $ {\alpha }_{\mathrm{m}} $/$ {(10}^{-6}\;{\mathrm{K}}^{-1}) $ 4.6 Axial CTE of fiber $ {\alpha }_{1\mathrm{f}} $/$ {(10}^{-6}\;{\mathrm{K}}^{-1}) $ 0 Transverse CTE of fiber $ {\alpha }_{2\mathrm{f}} $/$ {(10}^{-6}\;{\mathrm{K}}^{-1}) $ 8.8 Interface sliding stress $ \tau $/MPa 15 Final crack spacing $ {L}_{\mathrm{u}} $/μm 180 Initial crack spacing $ {L}_{0} $/μm 2000 Reference stress of matrix cracking $ {\sigma }_{\mathrm{R}} $/MPa 46 Minimum cracking stress $ {\sigma }^{*} $/MPa 256 Cracking exponent $ m $ 2.1 Note: CTE—Coefficient of thermal expansion. 表 2 2D-C/SiC复合材料试件尺寸和拉伸试验结果

Table 2. Specimen size and tensile test results of 2D-C/SiC composites

No. Width

/mmThickness

/mmModulus

/GPaStrength

/MPaL1 10.10 3.70 80.29 177.80 L2 10.12 3.68 99.86 232.20 L3 10.28 3.64 91.63 218.76 L4 10.14 3.66 117.42 231.48 L5 10.16 3.64 112.70 251.36 L6 10.22 3.62 126.83 256.80 L7 10.08 3.68 106.10 205.75 L8 10.12 3.66 91.49 233.00 Average − − 103.29 225.89 -

[1] 张立同, 成来飞, 徐永东. 新型碳化硅陶瓷基复合材料的研究进展[J]. 航空制造技术, 2003, 1:24-32. doi: 10.3969/j.issn.1671-833X.2003.10.012ZHANG Litong, CHENG Laifei, XU Yongdong. Progress in research work of new CMC-SiC[J]. Aeronautical Manufacturing Technology,2003,1:24-32(in Chinese). doi: 10.3969/j.issn.1671-833X.2003.10.012 [2] 何柏林, 孙佳. 碳纤维增强碳化硅陶瓷基复合材料的研究进展及应用[J]. 硅酸盐通报, 2009, 28(6):1197-1202, 1207. doi: 10.16552/j.cnki.issn1001-1625.2009.06.025HE Bolin, SUN Jia. Progress and application of carbon fibers reinforced silicon carbide ceramic matrix composites[J]. Bulletin of The Chinese Ceramic Society,2009,28(6):1197-1202, 1207(in Chinese). doi: 10.16552/j.cnki.issn1001-1625.2009.06.025 [3] WILKINS P H, LYNCH S P, THOLE K A, et al. Effect of a ceramic matrix composite surface on film cooling[J]. Journal of Turbomachinery,2022,144(8):081014. doi: 10.1115/1.4053842 [4] 蔡兴瑞, 万逸飞, 李翰超, 等. 连续碳化硅纤维增韧陶瓷基复合材料微结构数字化建模和宏观各向异性模量预测[J]. 材料导报, 2023, 37(13):1-12.CAI Xingrui, WAN Yifei, LI Hanchao, et al. Digital modeling of the natural microstructures and evaluation of the overall anisotropic moduli of ceramic matrix composites toughened by continuous SiC fiber bundles[J]. Materials Reports,2023,37(13):1-12(in Chinese). [5] 李俊, 矫桂琼, 王波, 等. 二维编织C/SiC复合材料非线性损伤本构模型与应用[J]. 复合材料学报, 2013, 30(1):165-171. doi: 10.13801/j.cnki.fhclxb.2013.01.034LI Jun, JIAO Guiqiong, WANG Bo, et al. A non-linear damage constitutive model for 2D woven C/SiC composite material and its application[J]. Acta Materiae Compositae Sinica,2013,30(1):165-171(in Chinese). doi: 10.13801/j.cnki.fhclxb.2013.01.034 [6] BASTE S. Inelastic behaviour of ceramic-matrix composites[J]. Composites Science and Technology,2001,61(15):2285-2297. doi: 10.1016/S0266-3538(01)00122-1 [7] 杨成鹏, 矫桂琼. 界面对纤维增强陶瓷基复合材料拉伸性能的影响[J]. 复合材料学报, 2010, 27(3):116-121. doi: 10.13801/j.cnki.fhclxb.2010.03.020YANG Chengpeng, JIAO Guiqiong. Effects of interface on tensile properties of fiber reinforced ceramic matrix composites[J]. Acta Materiae Compositae Sinica,2010,27(3):116-121(in Chinese). doi: 10.13801/j.cnki.fhclxb.2010.03.020 [8] NARDONE V C, PREWO K M. Tensile performance of carbon-fibre-reinforced glass[J] Journal of Materials Science, 1988, 23(1): 168-180. [9] SORENSEN B F, TALREJA R, SORENSEN O T. Micromechanical analysis of damage mechanisms in ceramic matrix composites during mechanical and thermal cycling[J]. Composites,1993,24(2):129-140. doi: 10.1016/0010-4361(93)90009-W [10] 梅辉, 成来飞, 张立同, 等. 2维C/SiC复合材料的拉伸损伤演变过程和微观结构特征[J]. 硅酸盐学报, 2007, 35(2):137-143. doi: 10.3321/j.issn:0454-5648.2007.02.002MEI Hui, CHENG Laifei, ZHANG Litong, et al. Damage evolution and microstructural characterization of a cross-woven C/SiC composite under tensile loading[J]. Journal of The Chinese Ceramic Society,2007,35(2):137-143(in Chinese). doi: 10.3321/j.issn:0454-5648.2007.02.002 [11] 杨成鹏, 矫桂琼, 王波. 2D-C/SiC复合材料的单轴拉伸力学行为及其强度[J]. 力学学报, 2011, 43(2):137-143.YANG Chengpeng, JIAO Guiqiong, WANG Bo. Uniaxial tensile stress-strain behavior and strength of plain woven C/SiC composite[J]. Chinese Journal of Theoretical and Applied Mechanics,2011,43(2):137-143(in Chinese). [12] VANSWIJGENHOVEN E, WEVERS M, BIEST O V D. The transverse strain response of cross-plied fibre-reinforced ceramic-matrix composites[J]. Composites Science and Technology,1999,59(10):1469-1481. doi: 10.1016/S0266-3538(98)00186-9 [13] CADDOCK B D, EVANS K E. Microporous materials with negative Poisson's ratios: I. Microstructure and mechanical properties[J]. Journal of Physics D: Applied Physics,1989,22(12):1877-1882. doi: 10.1088/0022-3727/22/12/012 [14] ALDERSON K L, FITZGERALD A, EVANS K E. The strain dependent indentation resilience of auxetic microporous polyethylene[J]. Journal of Materials Science,2000,35(16):4039-4047. doi: 10.1023/A:1004830103411 [15] HABIB F A, TAYLOR R A J, COOKE R G, et al. Fatigue damage in SiC/CAS composites[J]. Composites,1993,24(2):157-165. doi: 10.1016/0010-4361(93)90012-W [16] HARRIS B, HABIB F A, COOKE R G. Matrix cracking and the mechanical behaviour of SiC-CAS composites[J]. Proceedings of the Royal Society A: Mathematical, Physical and Engineering Sciences,1992,437(1899):109-131. [17] CAMUS G, GUILLAUMAT L, BASTE S. Development of damage in a 2D woven C/SiC composite under mechanical loading: I. Mechanical characterization[J]. Composites Science and Technology,1996,56(12):1363-1372. doi: 10.1016/S0266-3538(96)00094-2 [18] 郭洪宝, 洪智亮, 李开元, 等. 2D-C/SiC复合材料轴向加载泊松效应[J]. 材料工程, 2021, 49(8):178-183. doi: 10.11868/j.issn.1001-4381.2019.001217GUO Hongbao, HONG Zhiliang, LI Kaiyuan, et al. Poisson effects of 2D-C/SiC composite under axial loading conditions[J]. Journals of Materials Engineering,2021,49(8):178-183(in Chinese). doi: 10.11868/j.issn.1001-4381.2019.001217 [19] VEDULA M, PANGBORN R N, QUEENEY R A. Fibre anisotropic thermal expansion and residual thermal stress in a graphite/aluminium composite[J]. Composites,1988,19(1):55-60. doi: 10.1016/0010-4361(88)90544-7 [20] KASTRITSEAS C, SMITH P A, YEOMANS J A. Thermal shock fracture in cross-ply fibre-reinforced ceramicmatrix composites[J]. Philosophical Magazine,2010,90(31-32):4209-4226. doi: 10.1080/14786431003785621 [21] YANG C P, ZHANG L, WANG B, et al. Tensile behavior of 2D-C/SiC composites at elevated temperatures: Experiment and modeling[J]. Journal of the European Ceramic Society,2017,37(4):1281-1290. doi: 10.1016/j.jeurceramsoc.2016.11.011 [22] KASTRITSEAS C, SMITH P A, YEOMANS J A. Thermal shock fracture in unidirectional fibre-reinforced ceramic-matrix composites[J]. Composites Science and Technology,2005,65(11):1880-1890. [23] RAN Z G, YAN Y, LI J F, et al. Determination of thermal expansion coefficients for unidirectional fiber-reinforced composites[J]. Chinese Journal of Aeronautics,2014,27(5):1180-1187. doi: 10.1016/j.cja.2014.03.010 [24] HSUEH C H. Crack-wake interfacial debonding criteria for fiber-reinforced ceramic composites[J]. Acta Materialia,1996,44(6):2211-2216. doi: 10.1016/1359-6454(95)00369-X [25] AHN B K, CURTIN W A. Strain and hysteresis by stochastic matrix cracking in ceramic matrix composites[J]. Journal of the Mechanics and Physics of Solids,1997,45(2):177-209. doi: 10.1016/S0022-5096(96)00081-6 -

下载:

下载: