Tensile performance of fluorocarbon/polyurethane-coated GFRP bars exposed to southern marine environment

-

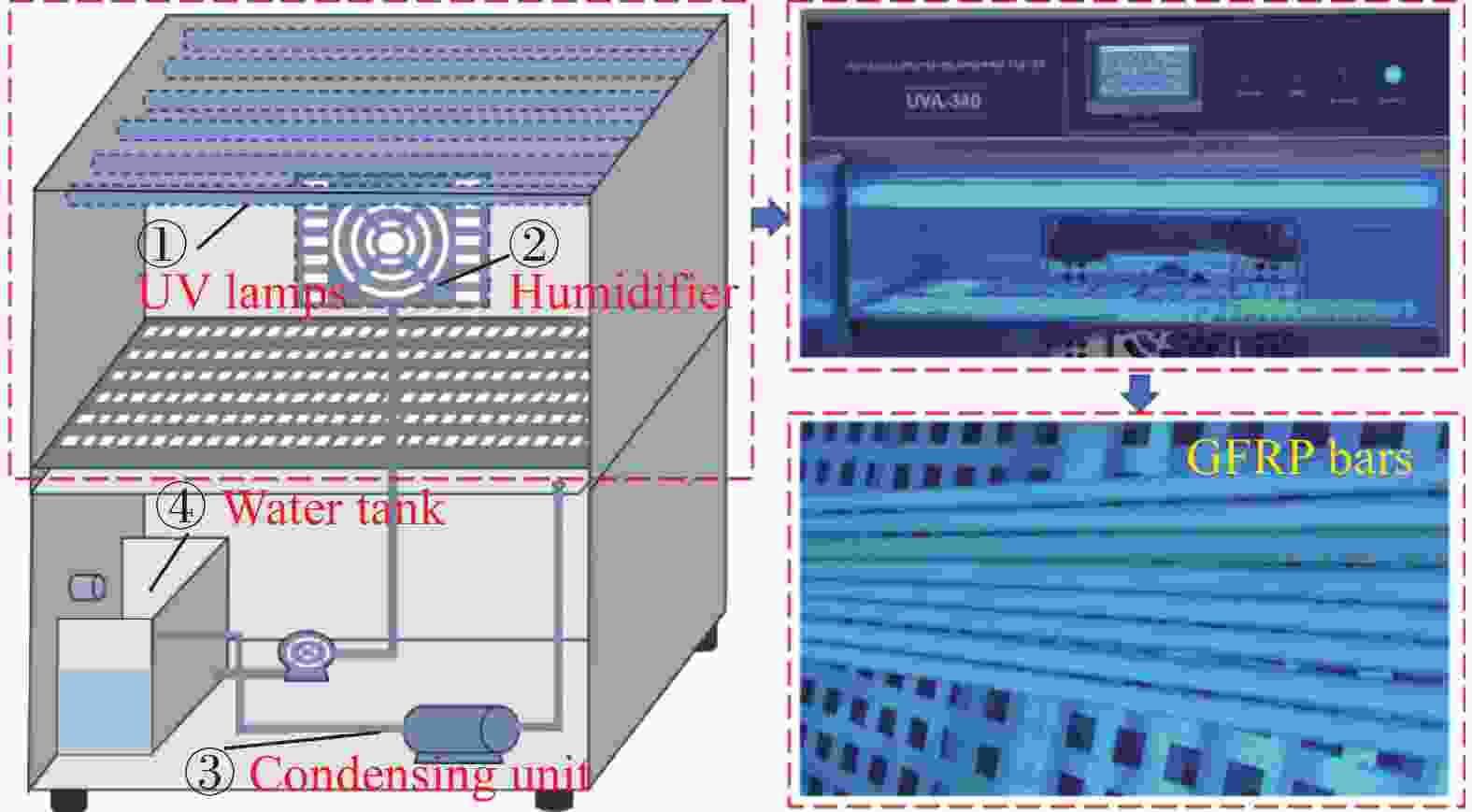

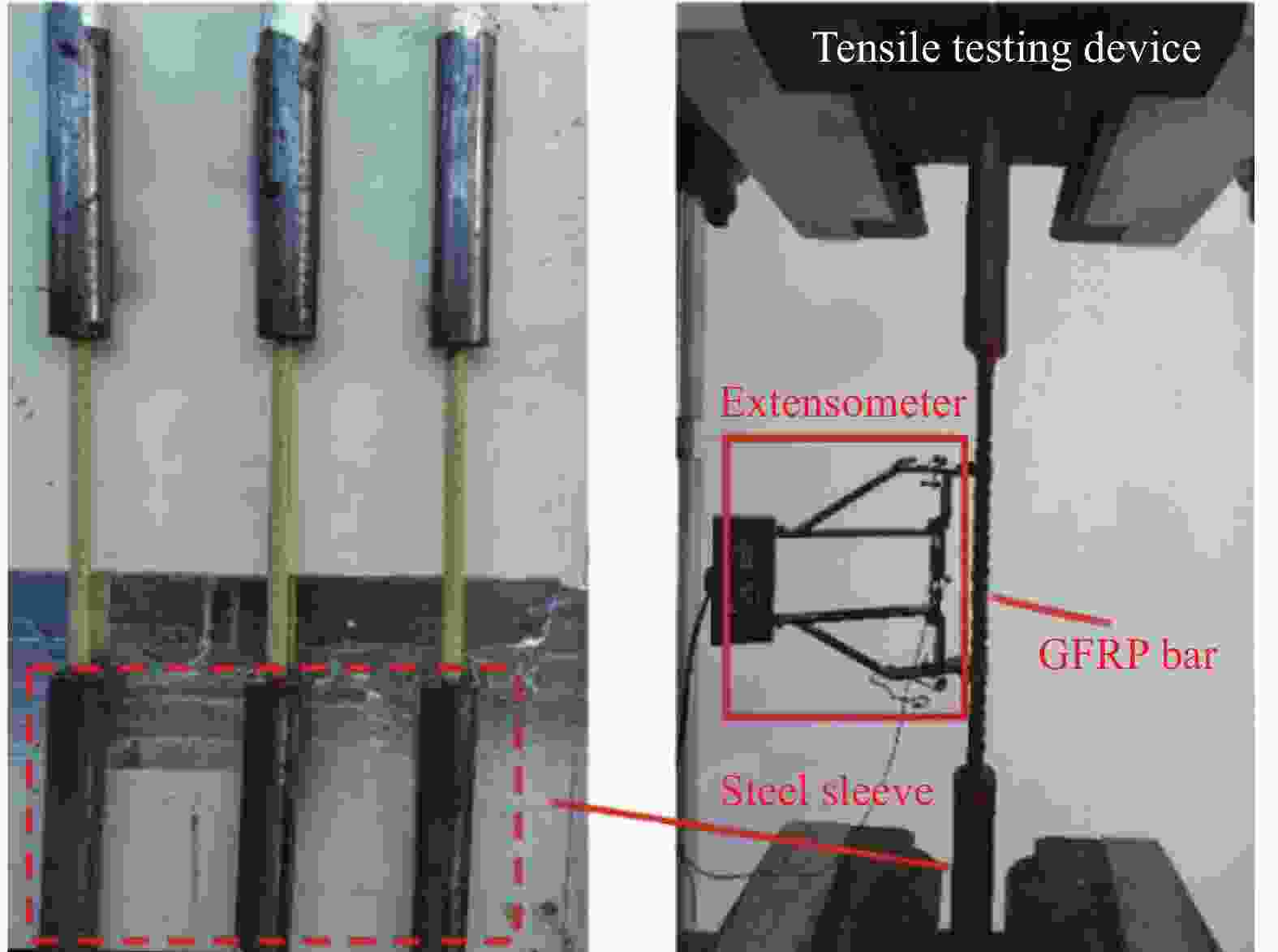

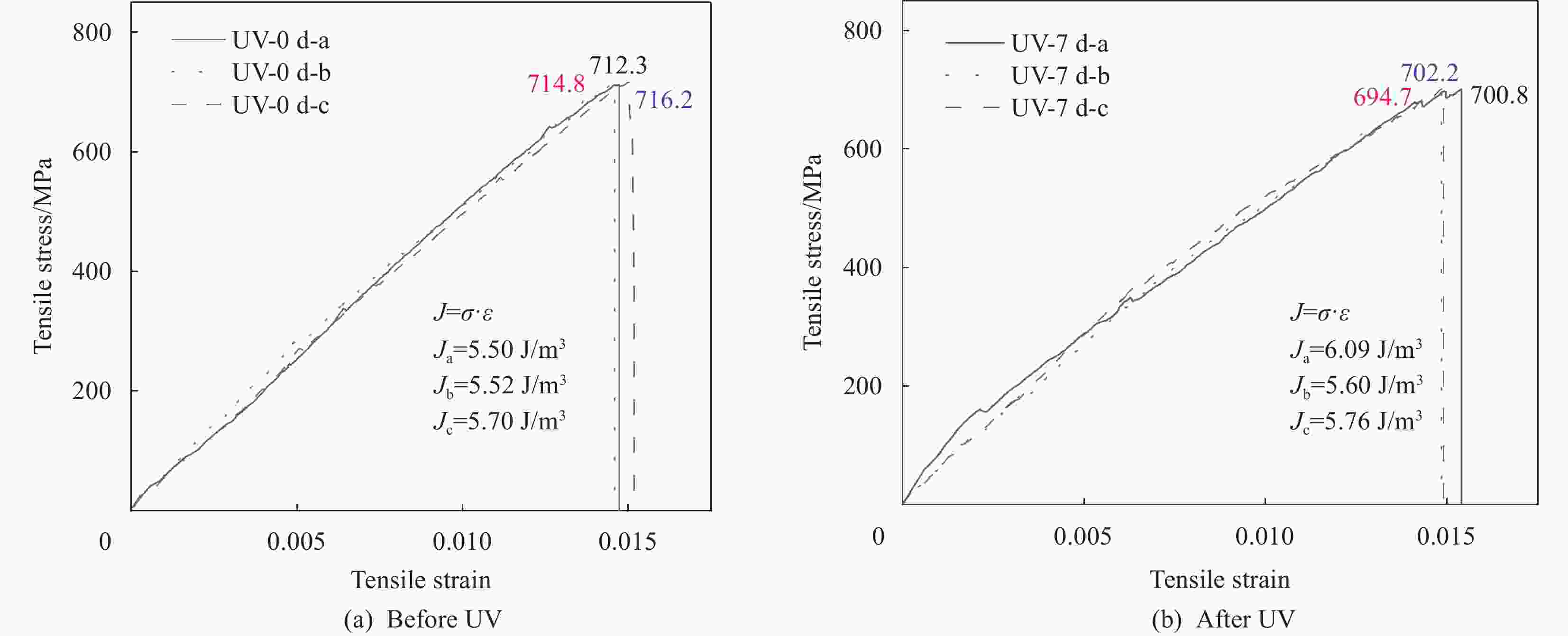

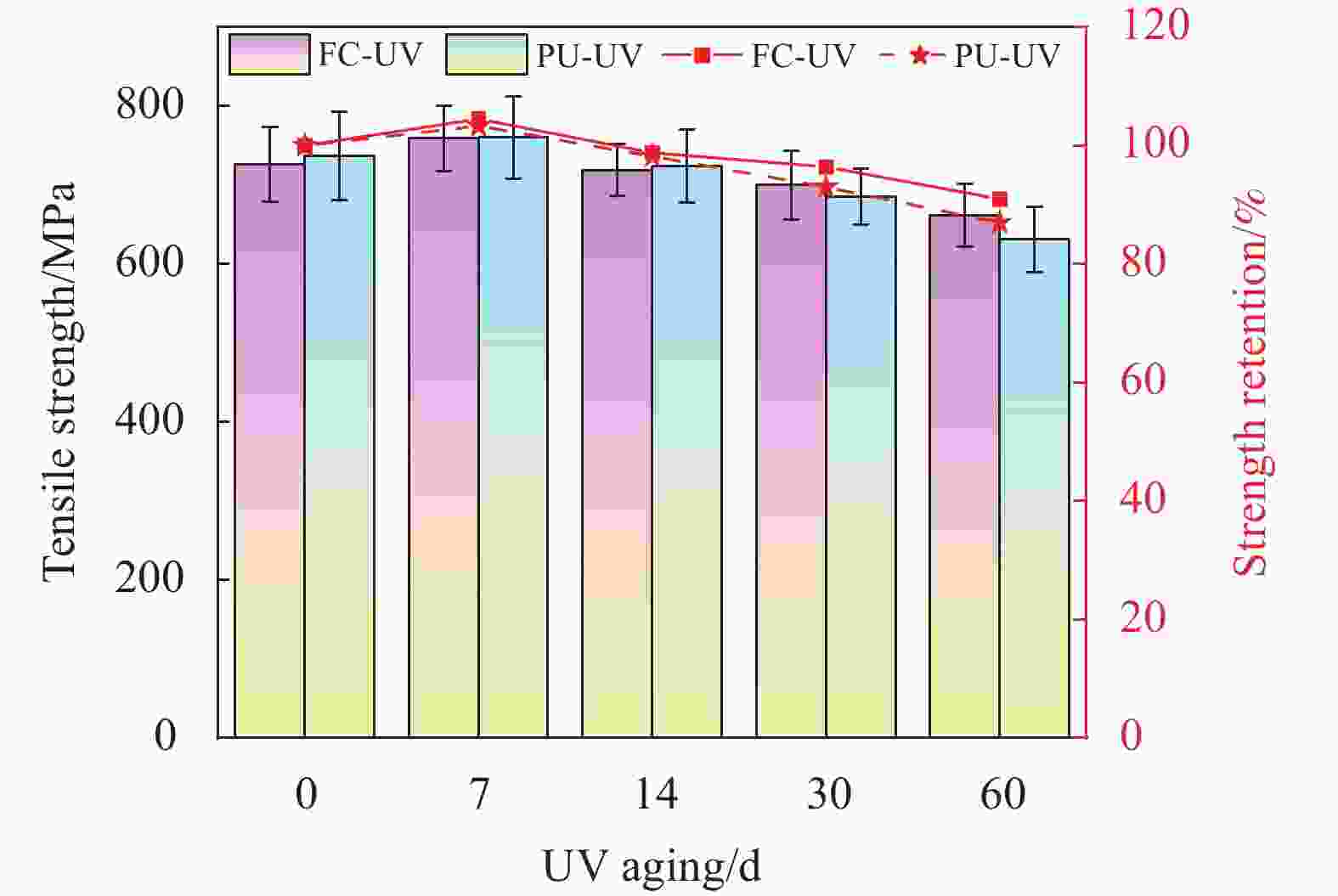

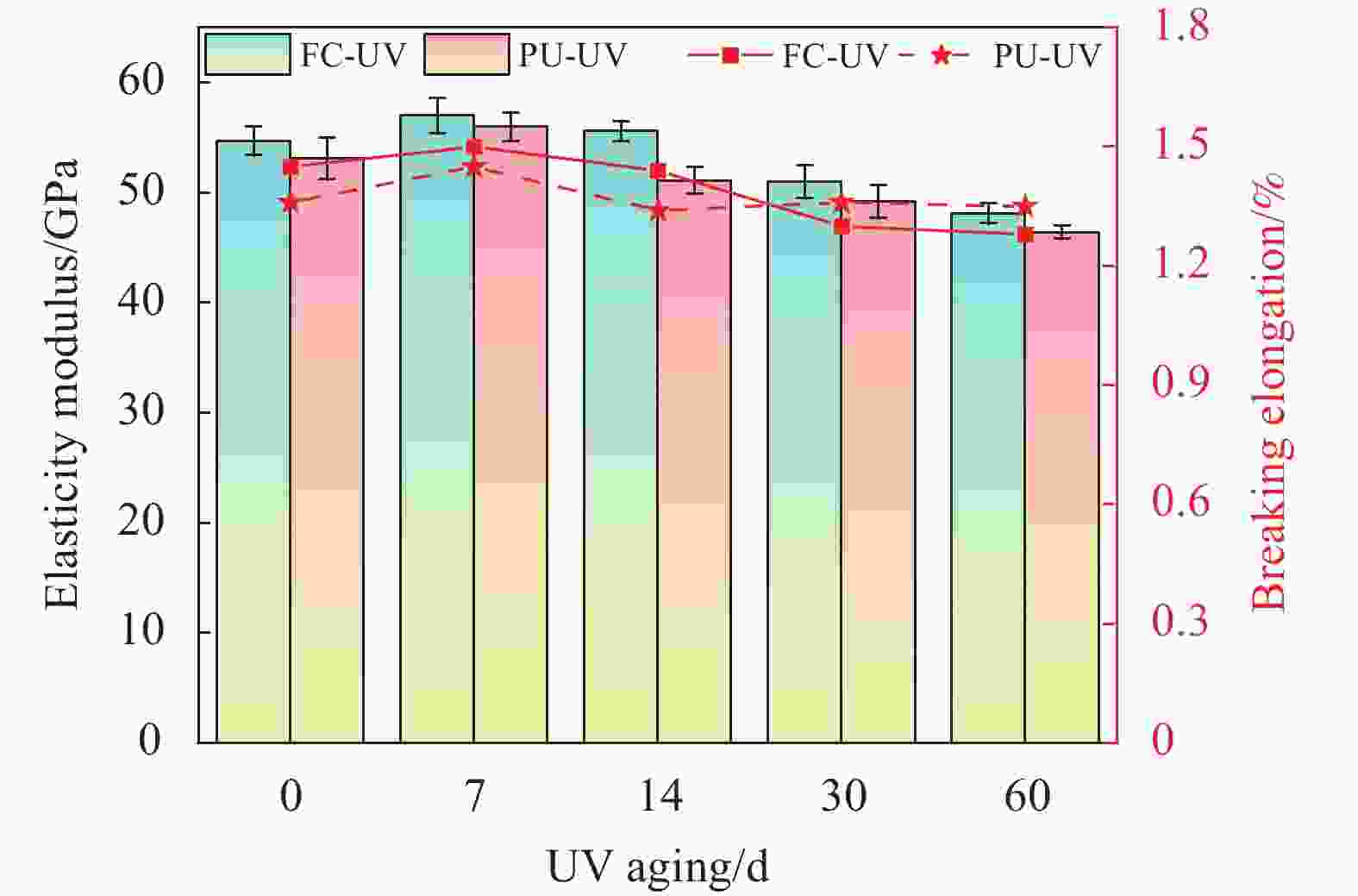

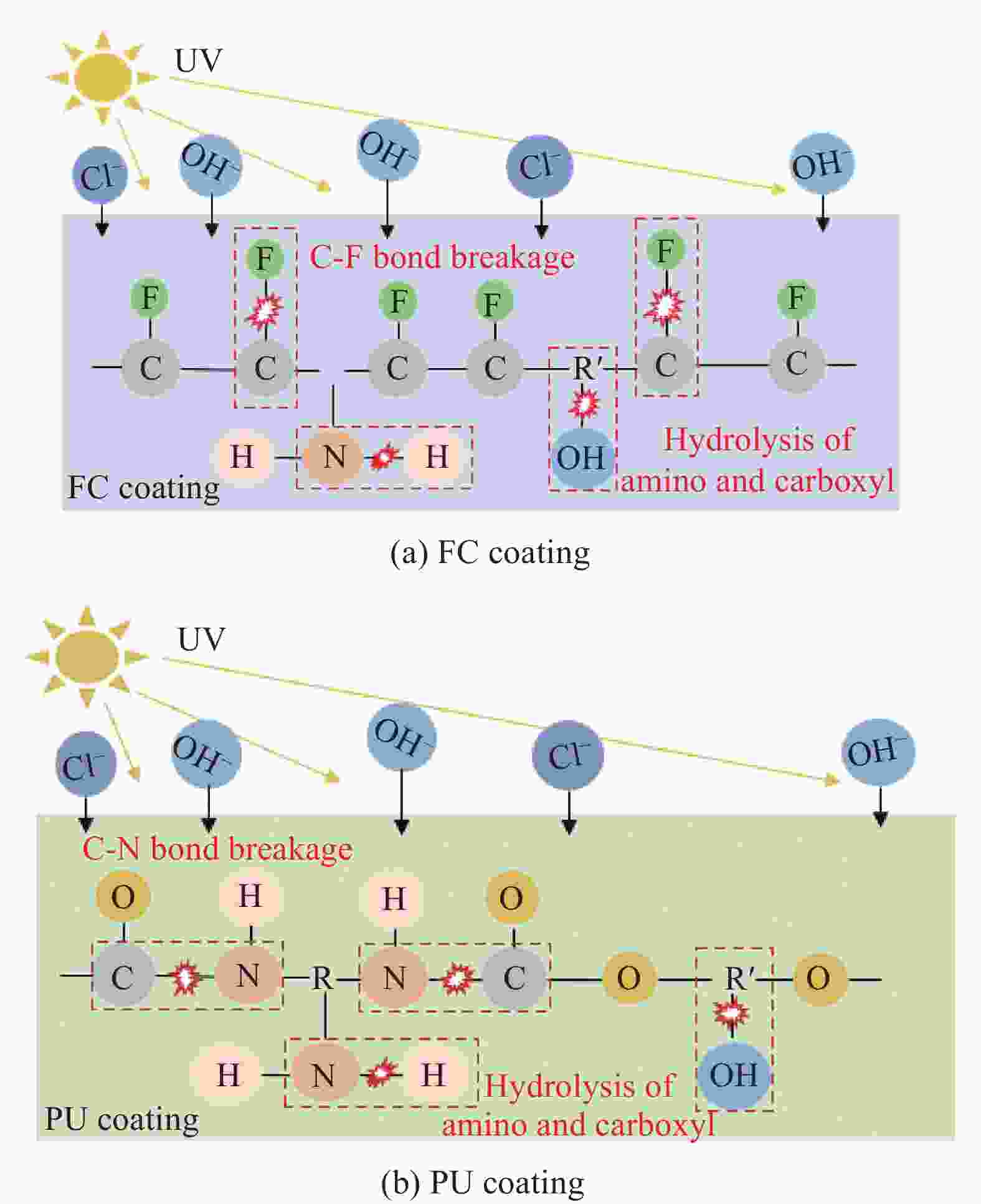

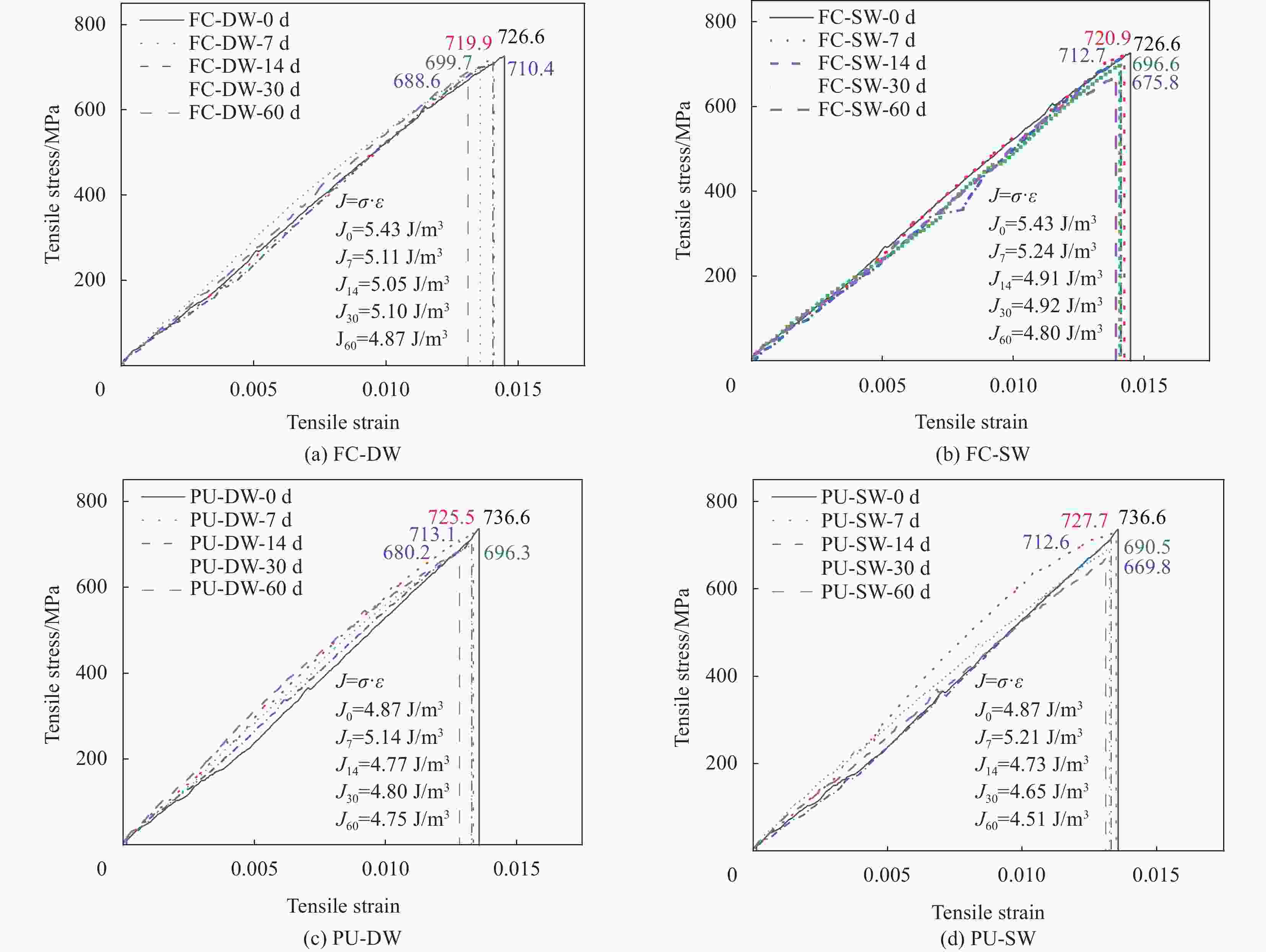

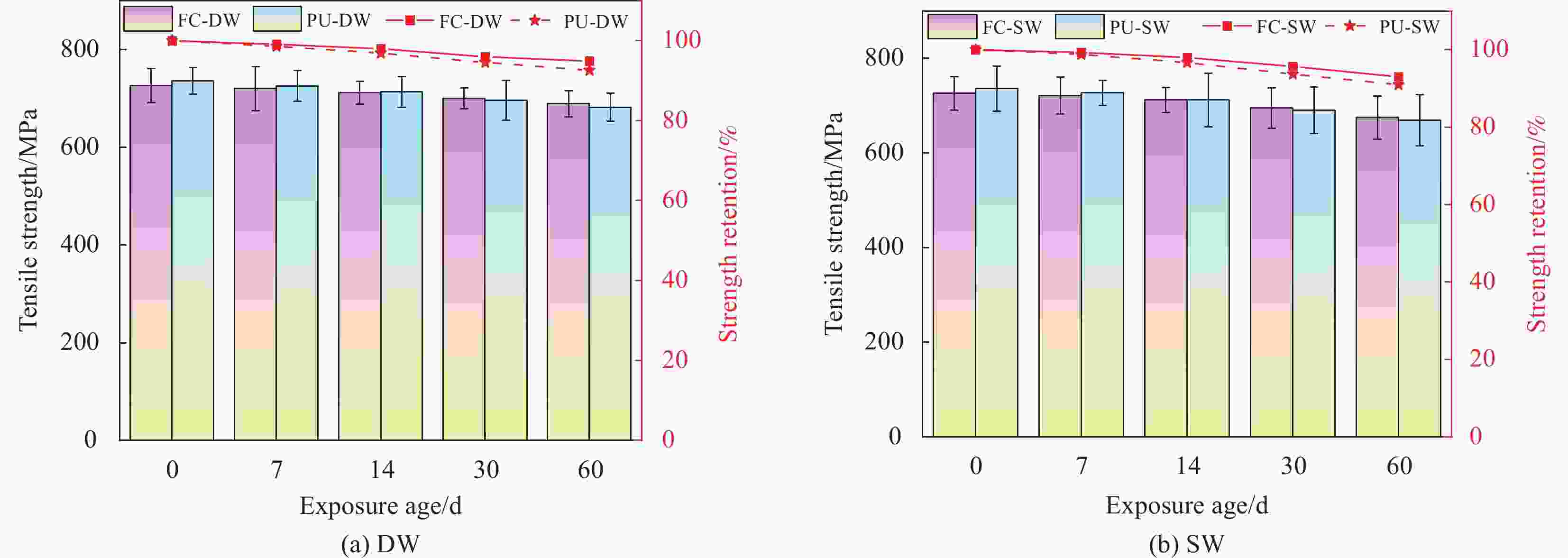

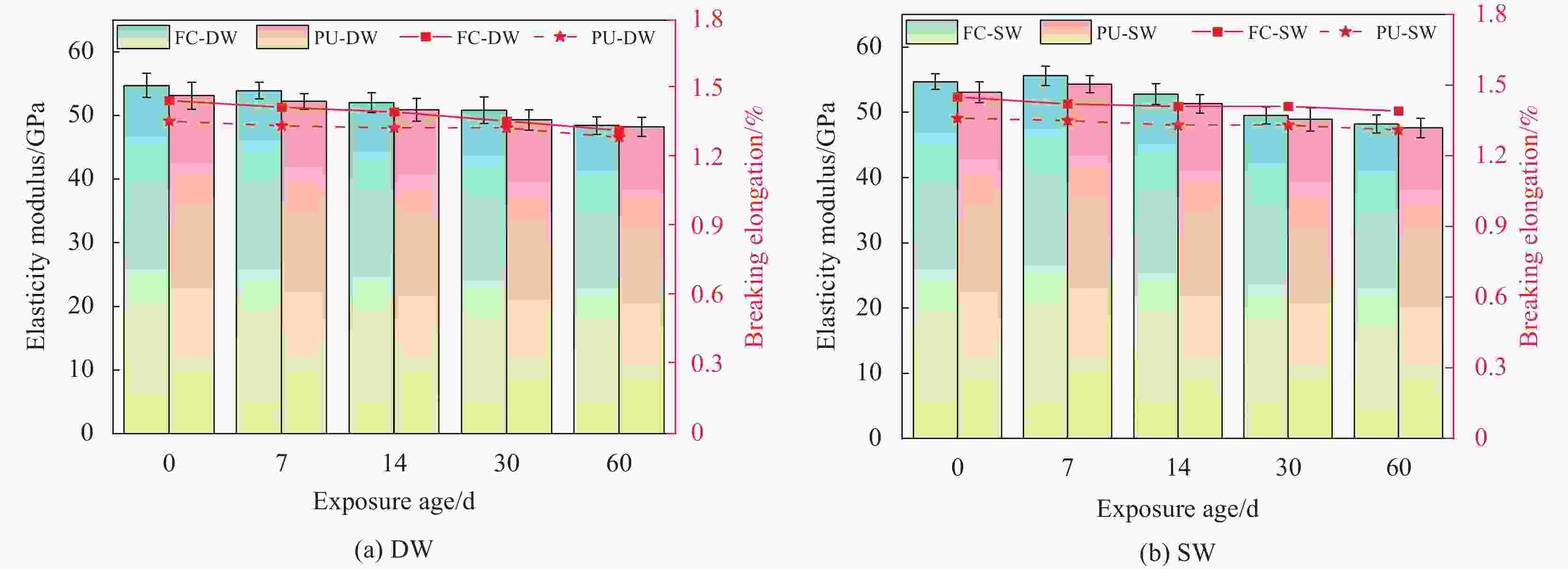

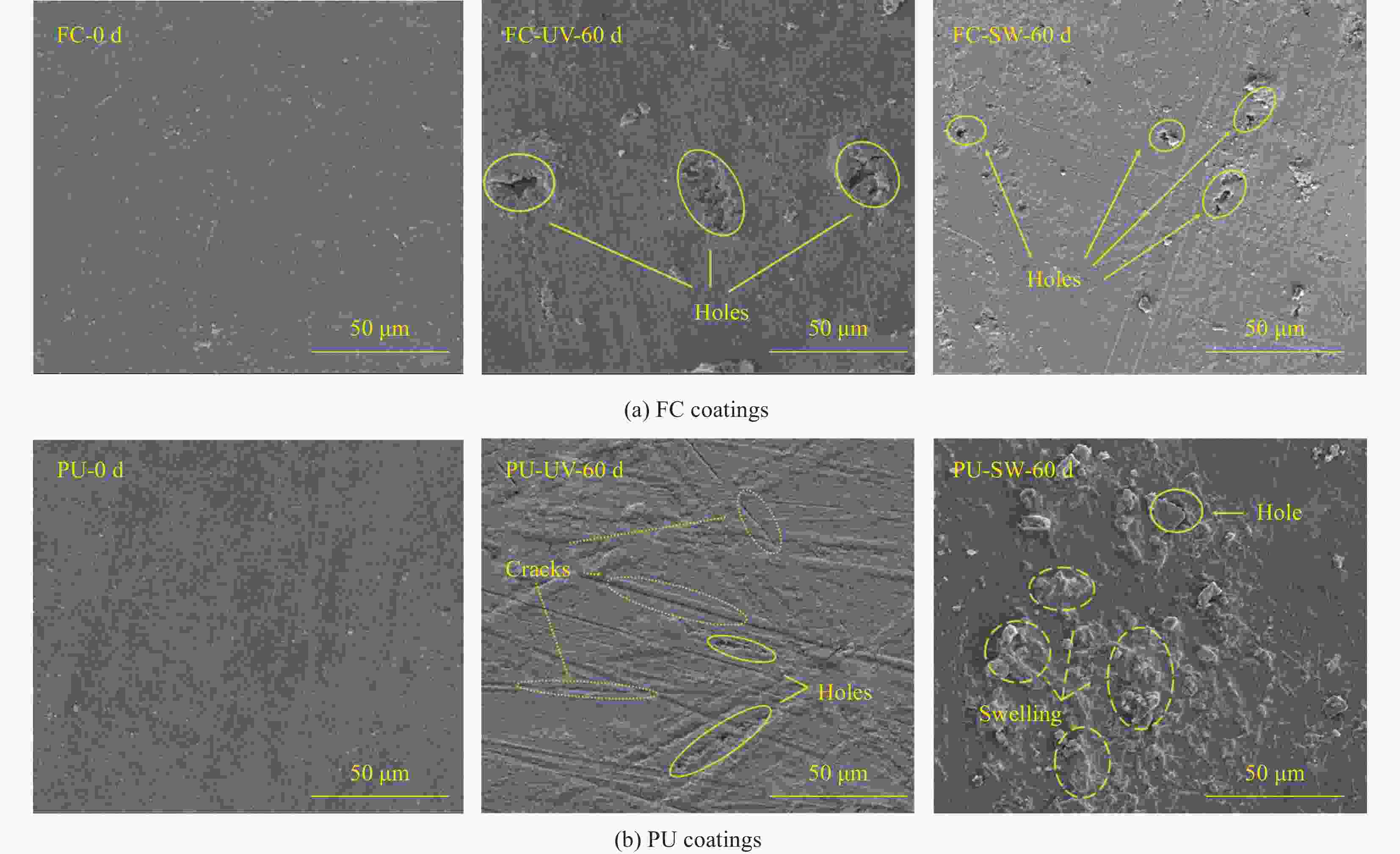

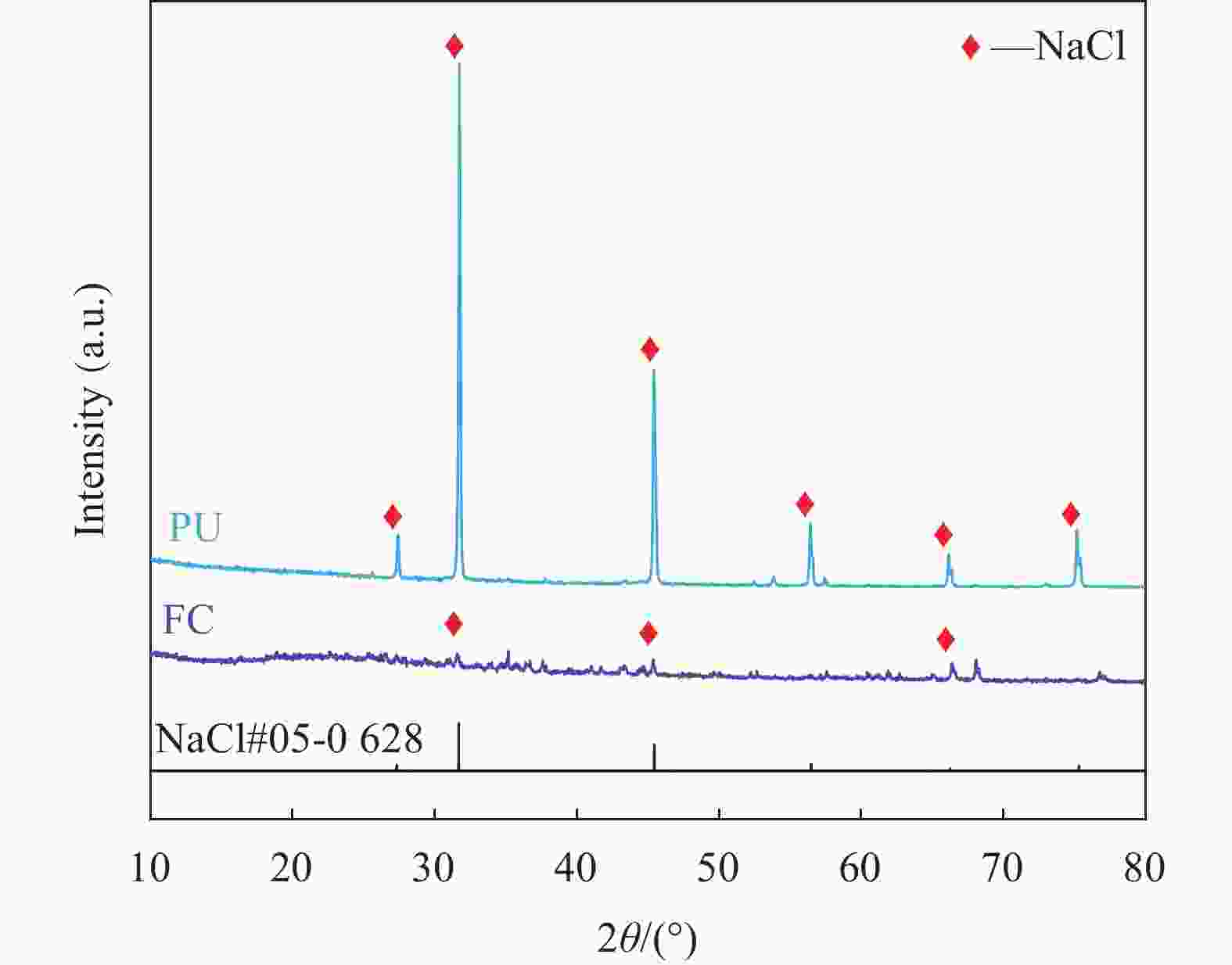

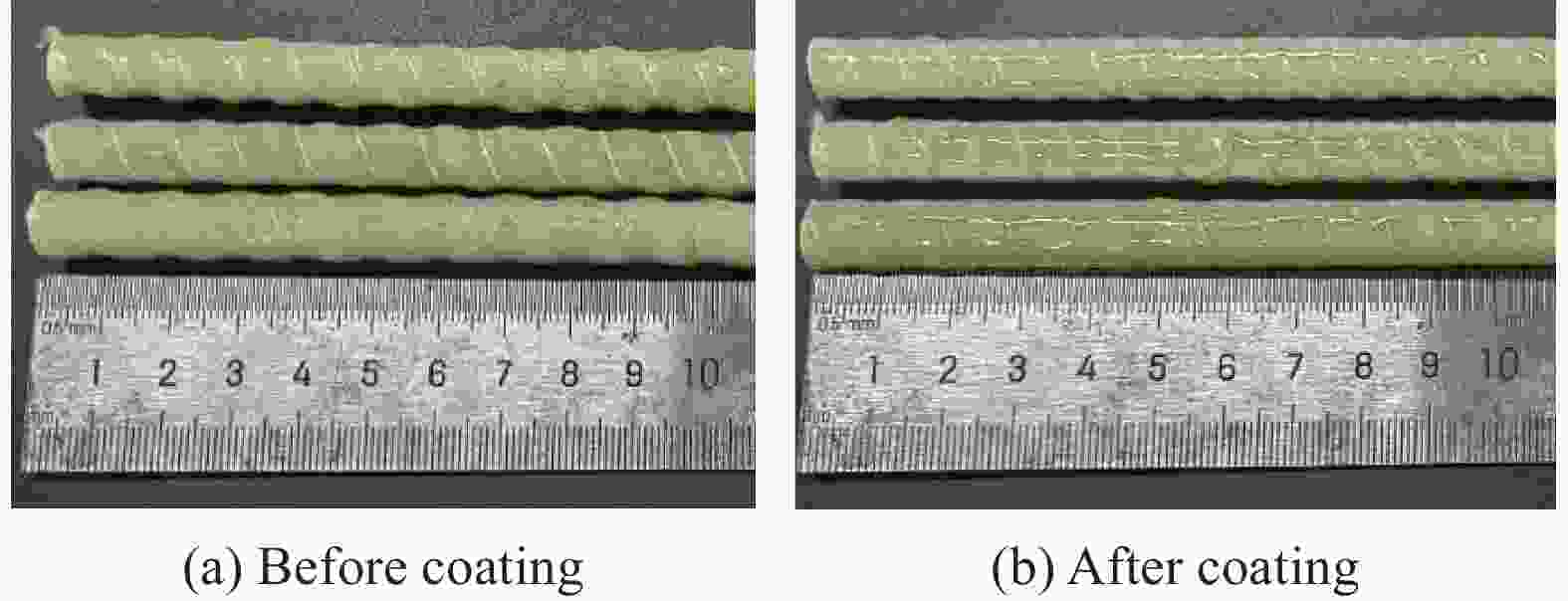

摘要: 传统金属材料在海洋环境下存在锈蚀问题,而纤维增强聚合物(FRP)筋材具有轻质高强、抗疲劳、耐腐蚀等优势,利用FRP筋替代钢筋已成为提高海洋混凝土结构耐久性的一种有效选择,但长期处于高紫外线、高盐和高湿等环境中,其树脂基体较为脆弱,材料化学结构易产生变化,造成FRP复合材料性能失效,从而降低其刚度和耐久性,利用涂层进行防护可有效提高FRP的抗老化和耐腐蚀能力。基于此,考虑高辐射、高盐和高湿的南方海洋环境因素,研究了紫外线老化及不同腐蚀介质(去离子水和真实海水)作用氟碳和聚氨酯涂层防护玻璃纤维增强复合材料(GFRP)筋材拉伸性能的退化规律,分析了不同暴露龄期(0、7、14、30、60 d)下两种涂层体系防护GFRP筋材的拉伸性能影响规律,并通过扫描电子显微镜(SEM)表征了腐蚀前后涂层的微观形貌及性能退化规律。结果表明:紫外线老化7 d后因涂层发生残余交联使GFRP筋拉伸强度提高了3%~5%,而之后涂层化学结构破坏与分子链断裂,紫外线老化60 d后其拉伸强度保留率为85%~90%;在去离子水和海水中浸泡60 d后,抗拉强度保留率范围分别为92%~95%、91%~93%;与聚氨酯涂层相比,氟碳涂层的耐久性相对优异,在相同劣化条件下具有更高的拉伸强度保留率,这是由于氟碳涂层具有优越的F-C键结构,氟原子紧密排列在聚合物碳链的周围起到了良好的保护作用,赋予含氟聚合物优异的耐久性。Abstract: Traditional metal materials have serous corrosion problems when exposed to marine environment, while fiber reinforced Composite (FRP) bars have the advantages of light weight, high strength, fatigue resistance, and corrosion resistance, etc. The application of FRP bars to replace steel bars has become an effective choice to improve the durability of marine concrete structures. However, for the long-term exposure to high ultraviolet (UV), high salt, high humidity and other environments, the resin matrix of FRP is relatively fragile, and the chemical structure of materials is prone to be changed, resulting in the performance failure of FRP composite materials to cause the decline of the stiffness and durability. The application of coating protection can effectively improve the resistance to aging and corrosion of FRP materials. Based on this, considering high radiation, high salinity, and high humidity southern marine environmental factors, the degradation law for the tensile performance of glass fiber reinforced Composite (GFRP) bars protected by fluorocarbon and polyurethane coatings under the action of ultraviolet radiation and different corrosive media (deionized water and real seawater) was studied. And the effect of different exposure ages (0, 7, 14, 30, and 60 d) on the tensile performance of GFRP bars coated by two systems was analyzed. The microstructure and performance degradation law of the coatings before and after corrosion were characterized by scanning electron microscopy (SEM). The results showed that after 7-days UV aging, the residual crosslinking actions of coatings increased the tensile strength of GFRP bars by 3% to 5%. After then, the chemical structures of the coatings were destroyed and molecular chains were broken. After 60-days UV aging, the retention rate of GFRP tensile strength was 85% to 90%. After soaking in deionized water and seawater for the duration of 60 days, the retention rates of tensile strength ranged from 92% to 95% and 91% to 93%, respectively. Compared to polyurethane coatings, fluorocarbon coatings have relatively excellent durability and higher retention of tensile strength under the same degradation conditions. This is due to the superior F-C bonding structure of fluorocarbon coatings, where fluorine atoms are tightly arranged around the polymer carbon chain, providing the good protection and endowing fluoropolymers with excellent durability.

-

Key words:

- GFRP bar /

- Fluorocarbon/Polyurethane coating /

- Tensile performance /

- UV aging /

- Corrosion deterioration

-

表 1 实测玻璃纤维增强复合材料(GFRP)筋材基本性能指标

Table 1. Measured basic performance index of glass fiber reinforced Composite (GFRP) bars

Performance index GFRP bars Tensile strength/MPa 714.30 Elasticity modulus/GPa 50.08 Breaking elongation/% 1.48 -

[1] SHOKRIEH M M, BAYAT A. Effects of ultraviolet radiation on mechanical properties of glass/polyester composites[J]. Journal of Composite Materials, 2007, 41(20): 2443-2455. doi: 10.1177/0021998307075441 [2] CABRAL-FONSECA S, CORREIA J R, RODRIGUES M P, et al. Artificial accelerated ageing of GFRP pultruded profiles made of polyester and vinylester resins: characterisation of physical-chemical and mechanical damage[J]. Strain, 2012, 48(2): 162-173. doi: 10.1111/j.1475-1305.2011.00810.x [3] 刘兴. FRP拉挤型材在海洋环境中的长期性能及预测方法研究[D]. 北京: 清华大学, 2023.LIU Xing. Study on long-term performance and prediction of pultruded FRP in marine environment [D]. Beijing: Tsinghua University, 2023. (in Chinese) [4] HARLE S M. Durability and long-term performance of fiber reinforced polymer (FRP) composites: A review[J]. Structures, 2024, 60: 105881. doi: 10.1016/j.istruc.2024.105881 [5] 李茜, 李景育, 孙茂钧, 等. 三种涂层在模拟热带海洋大气环境中的性能退化研究[J]. 环境技术, 2023, 41(3): 11-16. doi: 10.3969/j.issn.1004-7204.2023.03.005LI Qian, LI Jingyu, SUN Maojun, et al. Performance degradation of three coatings in simulated tropical marine atmospheric environment[J]. Environmental Technology, 2023, 41(3): 11-16(in Chinese). doi: 10.3969/j.issn.1004-7204.2023.03.005 [6] ALI S I, AHMAD S N. Tribo-corrosion behavior of Zn-Ni-Cu and Zn-Ni-Cu-TiB2 coated mild steel[J]. Arabian Journal of Chemistry, 2023, 16(5): 104648. doi: 10.1016/j.arabjc.2023.104648 [7] AL-NEGHEIMISH A, HUSSAIN R R, ALHOZAIMY A, et al. Corrosion performance of hot-dip galvanized zinc-aluminum coated steel rebars in comparison to the conventional pure zinc coated rebars in concrete environment[J]. Construction and Building Materials, 2021, 274: 121921. doi: 10.1016/j.conbuildmat.2020.121921 [8] KHANEGHAHI M H, NAJAFABADI E P, SHOAEI P, et al. Effect of intumescent paint coating on mechanical properties of FRP bars at elevated temperature[J]. Polymer testing, 2018, 71: 72-86. doi: 10.1016/j.polymertesting.2018.08.020 [9] 胡涛. 水工混凝土表面氟碳纳米复合涂层的制备及防护耐久性研究[D]. 武汉: 长江科学院, 2017.HU Tao. Preparation and durability of fluorocarbon nanocomposite coating on hydraulic concrete surface[D]. Wuhan: Changjiang River Scientific Research Institute, 2017. (in Chinese) [10] 柴武, 王媛媛, 王广超, 等. FEVE氟碳涂料研究进展[J]. 化工新型材料, 2022, 50(S1): 126-129.CHAI Wu, WANG Yuanyuan, WANG Guangchao, et al. Research progress on fluorocarbon coating with FEVE[J]. New Chemical Materials, 2022, 50(S1): 126-129(in Chinese). [11] 吴士军. 海洋钢筋混凝土结构氟碳涂层防护效果研究[D]. 青岛: 青岛理工大学, 2014.WU Shijun. Study on the protective effect of fluorocarbon coating for marine reinforced concrete structure[D]. Qingdao: Qingdao University of Technology, 2014. (in Chinese) [12] 李伟华, 廖晓, 季涛, 等. 氟碳涂层对海洋环境下混凝土抗氯离子渗透性能的影响[J]. 表面技术, 2017, 46(12): 43-47.LI Weihua, LIAO Xiao, JI Tao, et al. Effects of fluorocarbon coating on resistance to chloride ion penetration of concrete in marine environment[J]. Surface Technology, 2017, 46(12): 43-47(in Chinese). [13] 朱晓明, 周学杰, 纪方奇, 等. 氟碳涂层体系在严酷自然环境中的腐蚀行为[J]. 涂料技术与文摘, 2012, 33(10): 32-39.ZHU Xiaoming, ZHOU Xuejie, JI Fangqi, et al. Anticorrosion performance of fluorocarbon coatings system in severe natural environment[J]. Coatings Technology & Abstracts, 2012, 33(10): 32-39(in Chinese). [14] 杨明达, 王来发, 吴永畅, 等. 盐分环境下水性混凝土防腐涂层失效规律对比研究[J]. 公路交通科技, 2024, 41(1): 44-53. doi: 10.3969/j.issn.1002-0268.2024.01.006YANG Mingda, WANG Laifa, WU Yongchang, et al. Comparative study on failure regularity of anti-corrosive coating for waterborne concrete in salinity environment[J]. Journal of Highway and Transportation Research and Development, 2024, 41(1): 44-53(in Chinese). doi: 10.3969/j.issn.1002-0268.2024.01.006 [15] 於林锋. 防护涂层对混凝土力学性能和耐久性的影响[J]. 新型建筑材料, 2021, 48(11): 68-72.YU Lingfeng. Effect of protective coating on mechanical properties and durability of concrete[J]. New Building Materials, 2021, 48(11): 68-72(in Chinese). [16] 黄微波, 车凯圆, 吕平, 等. 聚氨酯涂层老化研究进展[J]. 聚氨酯工业, 2018, 33(6): 1-4. doi: 10.3969/j.issn.1005-1902.2018.06.001HUANG Weibo, CHE Kaiyuan, LYU Ping, et al. Research progress on aging of polyurethane coatings[J]. Polyurethane Industry, 2018, 33(6): 1-4(in Chinese). doi: 10.3969/j.issn.1005-1902.2018.06.001 [17] ZHENG H, LIU L, MENG F, et al. Multifunctional superhydrophobic coatings fabricated from basalt scales on a fluorocarbon coating base[J]. Journal of Materials Science & Technology, 2021, 84: 86-96. [18] 张晨, 朱占勃, 赵景茂. 两种水性聚氨酯涂层在3种加速老化试验中的性能对比[J]. 表面技术, 2021, 50(10): 330-336.ZHANG Chen, ZHU Zhanbo, ZHAO Jingmao, et al. Property comparison of two water-based polyurethane coatings in three accelerated aging experiments[J]. Surface Technology, 2021, 50(10): 330-336(in Chinese). [19] LI G, YANG B, GUO C, et al. Time dependence and service life prediction of chloride resistance of concrete coatings[J]. Construction and Building Materials, 2015, 83: 19-25. doi: 10.1016/j.conbuildmat.2015.03.003 [20] 朱永华, 姚敬华, 林仲玉, 等. 用人工加速老化法比较聚氨酯面漆和丙烯酸磁漆的性能[J]. 材料保护, 2005, (5): 57-59+79. doi: 10.3969/j.issn.1001-1560.2005.05.017ZHU Yonghua, YAO Jinghua, LIN Zhongyu, et al. Artificial accelerated aging (UV) method for performance comparison of organic coatings[J]. Material Protection, 2005, (5): 57-59+79(in Chinese). doi: 10.3969/j.issn.1001-1560.2005.05.017 [21] TONG J, XIE S, MIAO J T, et al. Preparation of UV-cured polyurethane-urea acrylate coatings with high hardness and toughness[J]. Progress in Organic Coatings, 2024, 186: 107969. doi: 10.1016/j.porgcoat.2023.107969 [22] 许斌, 刘强, 钱建才, 等. 含氟聚氨酯防护涂层体系在模拟海洋环境下的防护性能[J]. 表面技术, 2022, 51(9): 243-250+270.XU Bin, LIU Qiang, QIAN Jiancai, et al. Protective performance of fluoropolyurethane coating system in simulated marine environment[J]. Surface Technology, 2022, 51(9): 243-250+270(in Chinese). [23] 张洪彬, 师超, 郑南飞, 等. 丙烯酸聚氨酯涂层在高湿热海洋大气环境中的老化行为[J]. 材料保护, 2020, 53(5): 10-14.ZHANG Hongbin, SHI Chao, ZHENG Nanfei, et al. Aging behaviors of acrylic polyurethane coatings in marine atmosphere environment with high temperature and humidity[J]. Material Protection, 2020, 53(5): 10-14(in Chinese). [24] 马纪源, 郭辉, 张馨月, 等. 实海浸泡条件下聚氨酯涂层的失效行为[J]. 表面技术, 2023, 52(1): 178-186.MA Jiyuan, GUO Hui, ZHANG Xinyue, et al. Failure behavior of polyurethane coating immersed in real seawater[J]. Surface Technology, 2023, 52(1): 178-186(in Chinese). [25] GB/T 13096-2008. 拉挤玻璃纤维增强塑料杆力学性能实验方法[S]. 北京: 中国国家标准化管理委员会, 2008.GB/T 13096-2008. Test method for mechanical properties of pultruded glass fiber reinforced plastic rods [S]. Beijing: Standardization Administration of the People’s Republic of China, 2008. (in Chinese) [26] 许艾沿, 杜运兴, 潘柳景泰, 等. 海水海砂混凝土中混杂碳-玄武岩纤维筋拉伸性能退化机制及寿命预测[J]. 复合材料学报, 2024, 41: 1-11.XU Aiyan, DU Yunxing, PAN Liujingtai, et al. Degradation mechanism of tensile properties and life prediction of hybrid carbon/basalt fiber reinforced polymer bars in seawater sea-sand concrete[J]. Acta Materiae Compositae Sinica, 2024, 41: 1-11(in Chinese). [27] 陈宇豪, 刘福伟, 陈吉, 等. 酚醛环氧/环氧树脂复合涂层不同紫外线吸收剂含量时的抗老化性能[J]. 材料保护, 2015, 48(9): 41-44+8.CHEN Yuhao, LIU Fuwei, CHEN Ji, et al. Aging resistance of phenolic epoxy/epoxy composite coating with different UV absorber content[J]. Materials Protection, 2015, 48(9): 41-44+8(in Chinese). [28] 吕平, 李华灵, 黄微波. 有机防护涂层老化研究进展[J]. 材料导报, 2011, 25(7): 83-85.LYU Ping, LI Hualing, HUANG Weibo. New Progress of the research on organic protective coatings[J]. Materials Reports, 2011, 25(7): 83-85(in Chinese). [29] WU Y, QIAO S, WU J, et al. Fluorosilane emulsifying chlortrifluoroethylene ternary copolymerization design towards strong adhesion, anti-corrosion, fluorescent waterborne fluorocarbon coatings for tinplate substrate[J]. Applied Surface Science, 2024, 663: 160196. doi: 10.1016/j.apsusc.2024.160196 [30] MOHAMMAD S A, SHINGDILWAR S, BANERJEE S, et al. Macromolecular engineering approach for the preparation of new architectures from fluorinated olefins and their applications[J]. Progress in Polymer Science, 2020, 106: 101255. doi: 10.1016/j.progpolymsci.2020.101255 [31] 肖鑫, 秦灏. 常温固化氟碳涂料的研究进展[J]. 湖南工程学院学报(自然科学版), 2003, (1): 81-83.XIAO Xin, QIN Hao. Research progress on room temperature cured fluorocarbon coatings[J]. Journal of Hunan Institute of Engineering, 2003, (1): 81-83(in Chinese). [32] 张洪敏. 疏水/抗冲刷氟碳涂层的研究[D]. 南京: 南京航空航天大学, 2015.ZHANG Hongmin, Study on hydrophobic and anti-erosion behaviors of fluorocarbon coating[D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2015. (in Chinese) [33] 修林鹏. 真实海水环境下海水海砂混凝土内的FRP筋耐久性[D]. 大连: 大连理工大学, 2022.XIU Linpeng. The Durability of FRP bars covered with seawater and sea sand concrete in a real marine environment[D]. Dalian: Dalian University of Technology, 2022. (in Chinese) [34] 谭思蓉. 实验室加速模拟海洋浸泡环境下BFRP筋耐久性研究[D]. 广州: 广东工业大学, 2019.TAN Sirong. Study on the durability of BFRP bars by using an accelerating simulated marine immersion environment[D]. Guangzhou: Guangdong University of Technology, 2019. (in Chinese) [35] 林静. 喷涂聚脲防护涂层耐腐蚀性能及长期自然曝晒老化性能研究[D]. 青岛: 青岛理工大学, 2018.LIN Jing. Study on corrosion resistance and long term natural sun exposure of spray polyurea protective coating[D]. Qingdao: Qingdao University of Technology, 2018. (in Chinese) [36] 刘付胜聪, 肖汉宁, 李玉平, 等. 纳米TiO2和紫外线吸收剂对丙烯酸酯涂层抗光氧化性能的影响[J]. 功能材料, 2004, (4): 495-497+500. doi: 10.3321/j.issn:1001-9731.2004.04.033LIU Fushengcong, XIAO Hanning, LI Yuping, et al. The Effect of nano TiO2 and UV absorbers on the photooxidation resistance of acrylate coatings[J]. Functional Materials, 2004, (4): 495-497+500(in Chinese). doi: 10.3321/j.issn:1001-9731.2004.04.033 [37] 刘攀. 桥梁钢结构防腐涂层的老化失效机制和寿命预测研究[D]. 西安: 长安大学, 2009.LIU Pan. Study on the aging failure mechanism and life prediction of steel bridge’s anti-corrosion coating [D]. Xi’an: Chang’an University, 2009. (in Chinese) [38] LU L, MA Z, LIU Q, et al. Pollutant-accelerated aging behaviors of fluorocarbon coating in tropical marine atmosphere[J]. Progress in Organic Coatings, 2020, 139: 105447(in Chinese). doi: 10.1016/j.porgcoat.2019.105447 [39] 井晓菲. 海洋环境下混凝土结构用聚氨酯(脲)涂层性能研究[D]. 青岛: 青岛理工大学, 2019.JING Xiaofei. Study on properties of polyurethane(urea) coating for concrete structures in marine environment[D]. Qingdao: Qingdao University of Technology, 2019. (in Chinese) [40] 于雪艳, 陈正涛, 李旭朝, 等. 常温固化氟碳涂料耐老化性能研究[J]. 涂料工业, 2014, 44(2): 21-27. doi: 10.3969/j.issn.0253-4312.2014.02.005YU Xueyan, CHEN Zhengtao, LI Xuzhao, et al. Study on weather resistant performance of fluorocarbon coatings cured at room temperature[J]. Paint and Coatings Industry, 2014, 44(2): 21-27(in Chinese). doi: 10.3969/j.issn.0253-4312.2014.02.005 -

点击查看大图

点击查看大图

计量

- 文章访问数: 80

- HTML全文浏览量: 39

- 被引次数: 0

下载:

下载: