Effects of nano-graphene oxide and ethylene-vinyl acetate rubber powder on mechanical properties and microstructure of mortar

-

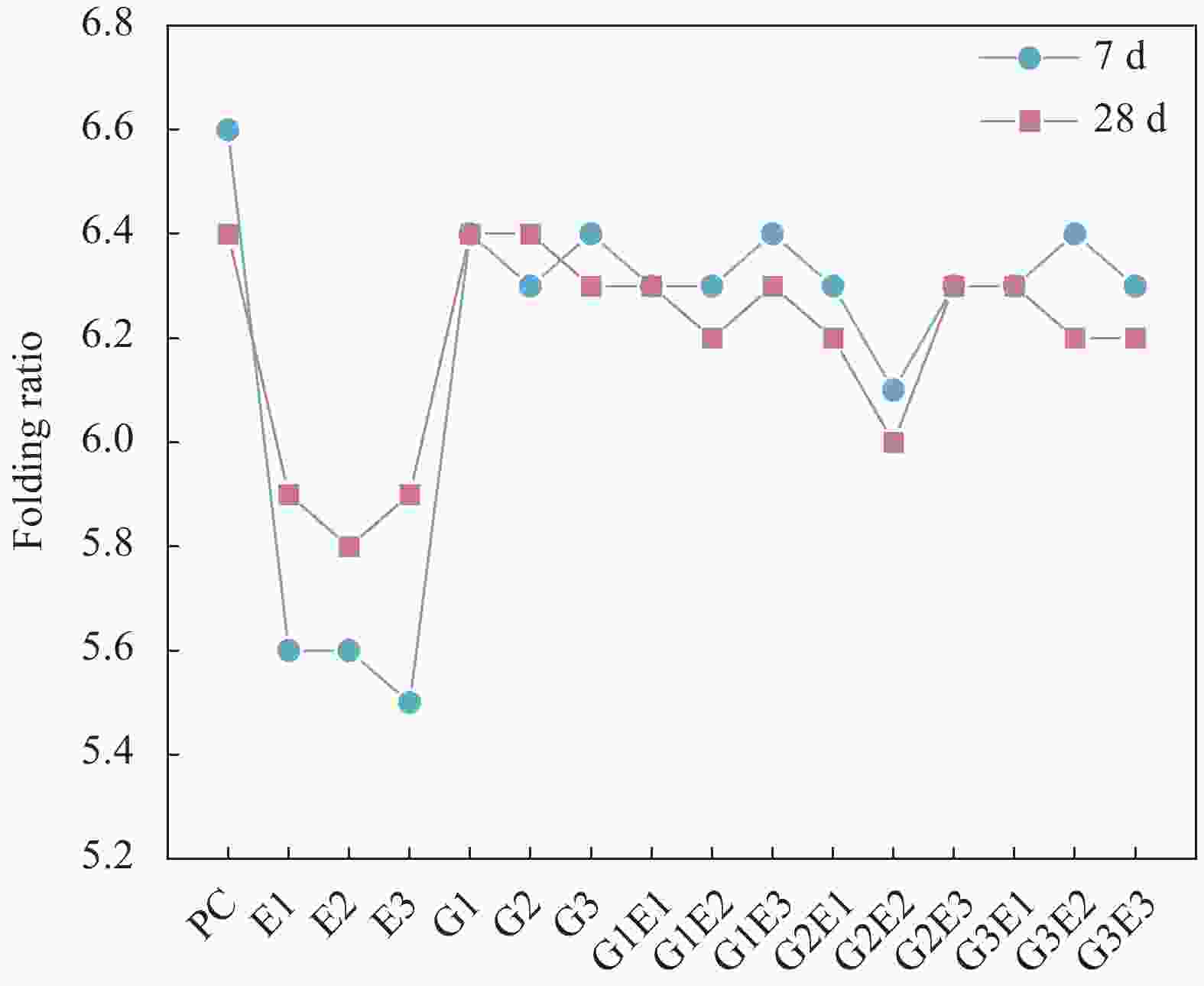

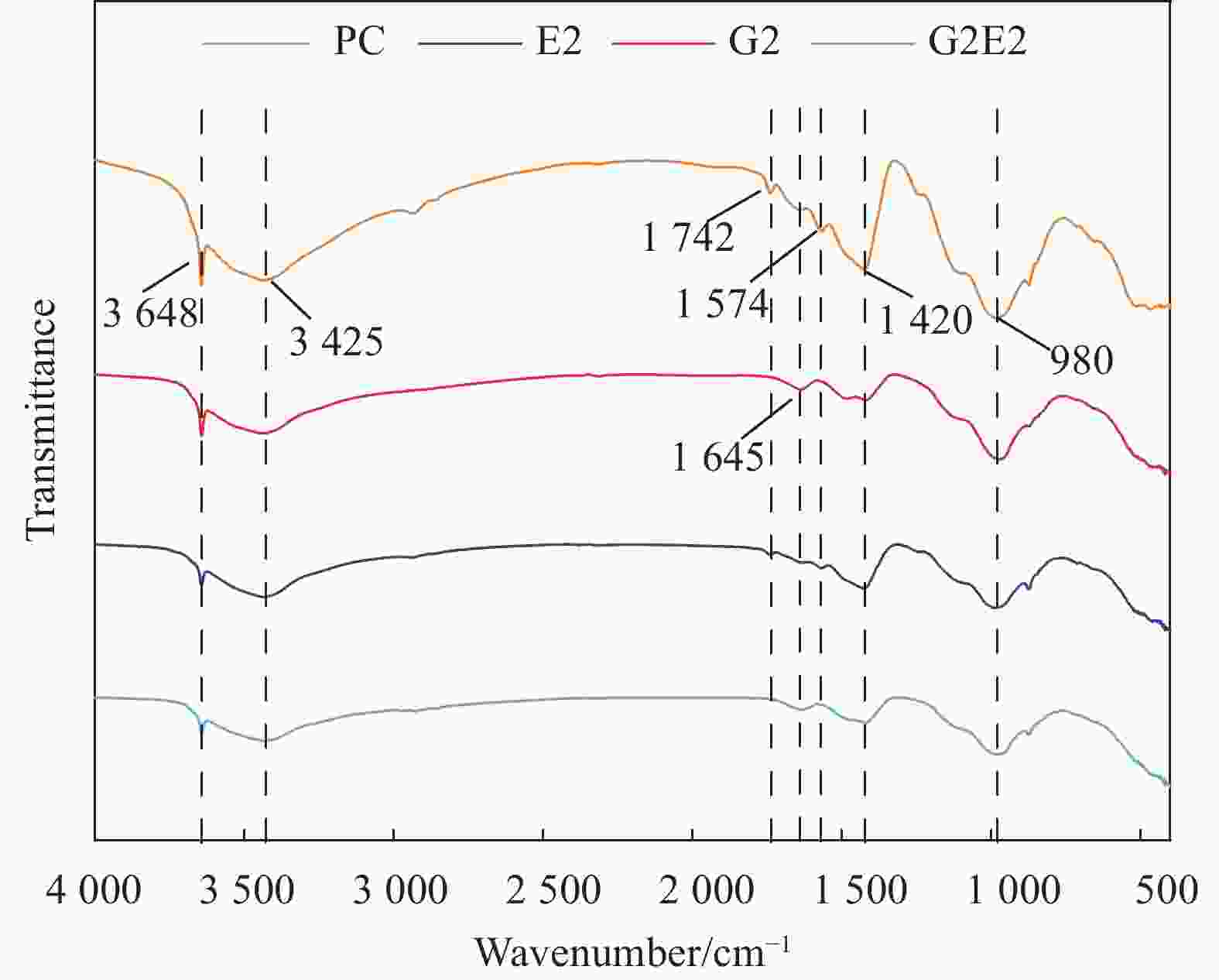

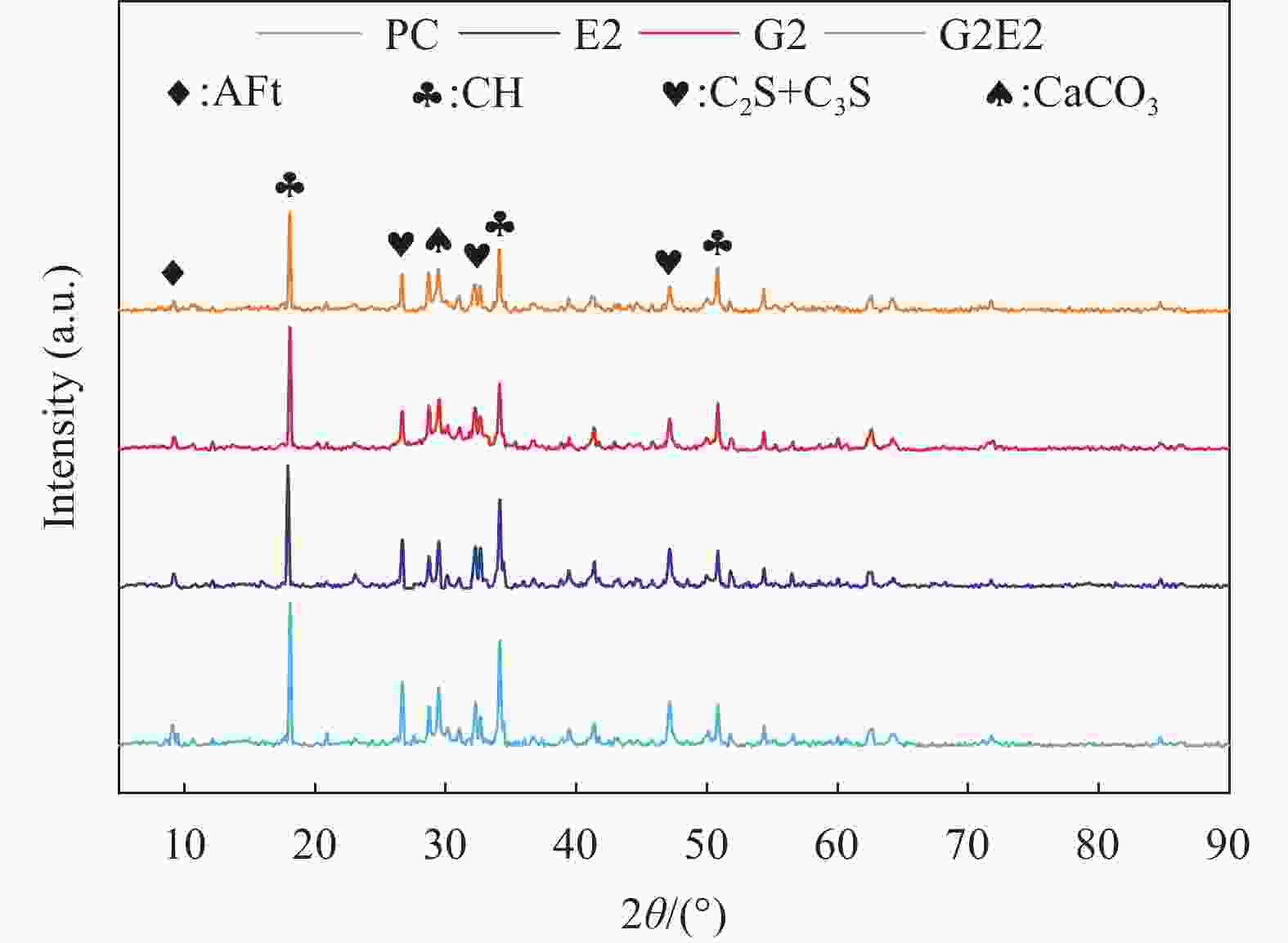

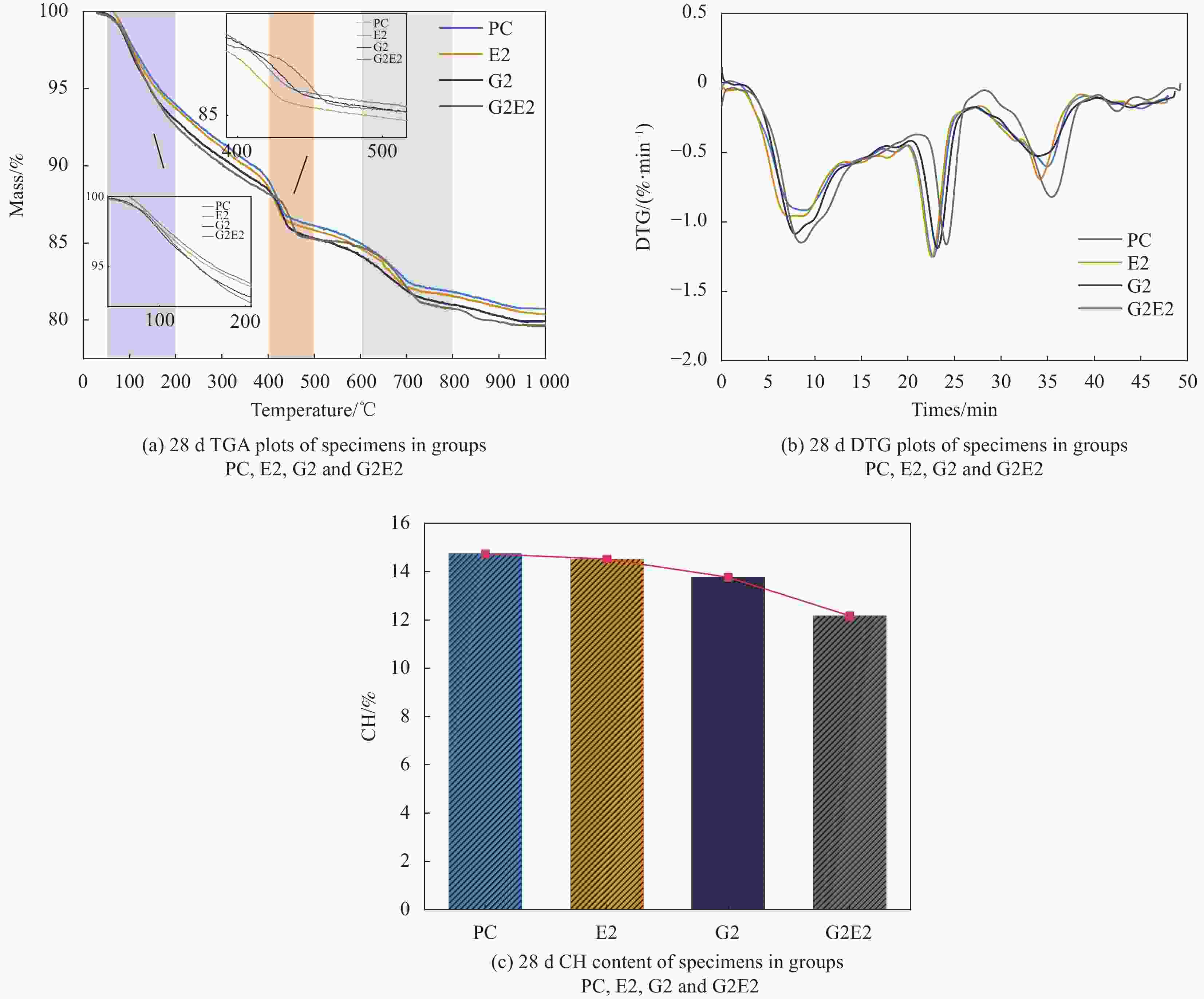

摘要: 本文采用纳米氧化石墨烯(GO)和乙烯-醋酸乙烯酯胶粉(EVA)对普通水泥砂浆进行改性,利用FTIR、XRD、TG、NMR及SEM等测试手段,在材料的化学组成、孔隙结构和微观形貌等方面揭示了GO和EVA对水泥砂浆力学性能的影响机制。结果表明:分散良好的GO降低了新拌砂浆的流动度,EVA的加入改善了这一现象;单掺0.03wt% GO的试件力学性能达到最佳,7 d龄期的抗压、抗折强度较基准组(PC)试件提高了24.1%和31%。GO和EVA复掺后,掺量分别控制在0.03wt%和4wt%时试件的28 d力学性能最优,抗压、抗折强度分别为72 MPa和12 MPa,较PC试件提高了25.9%和33.3%。微观试验结果表明:GO的成核效应加速了水泥水化进程并且可以调节花状水化晶体的产生和生长,从而细化试样孔径分布,良好的填充效应使得孔隙结构变得更加致密。EVA早期形成网状薄膜阻碍水泥水化进程,在水化后期,充分发育的网状薄膜与水泥浆体形成互穿网络结构,促进孔隙结构致密化。二者发挥协同作用,显著增强水泥砂浆力学性能。

-

关键词:

- 纳米氧化石墨烯 /

- 乙烯-醋酸乙烯酯胶粉 /

- 水泥砂浆 /

- 力学性能 /

- 孔隙结构

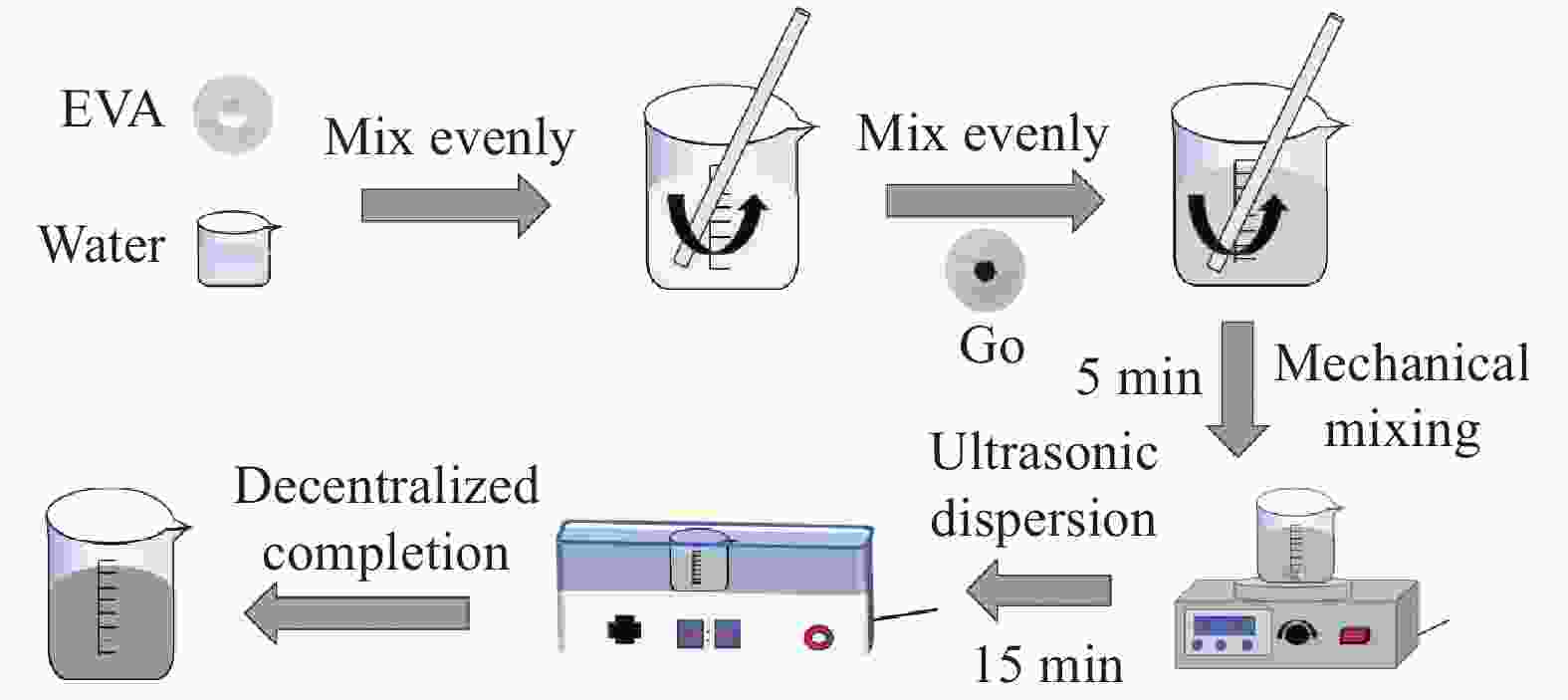

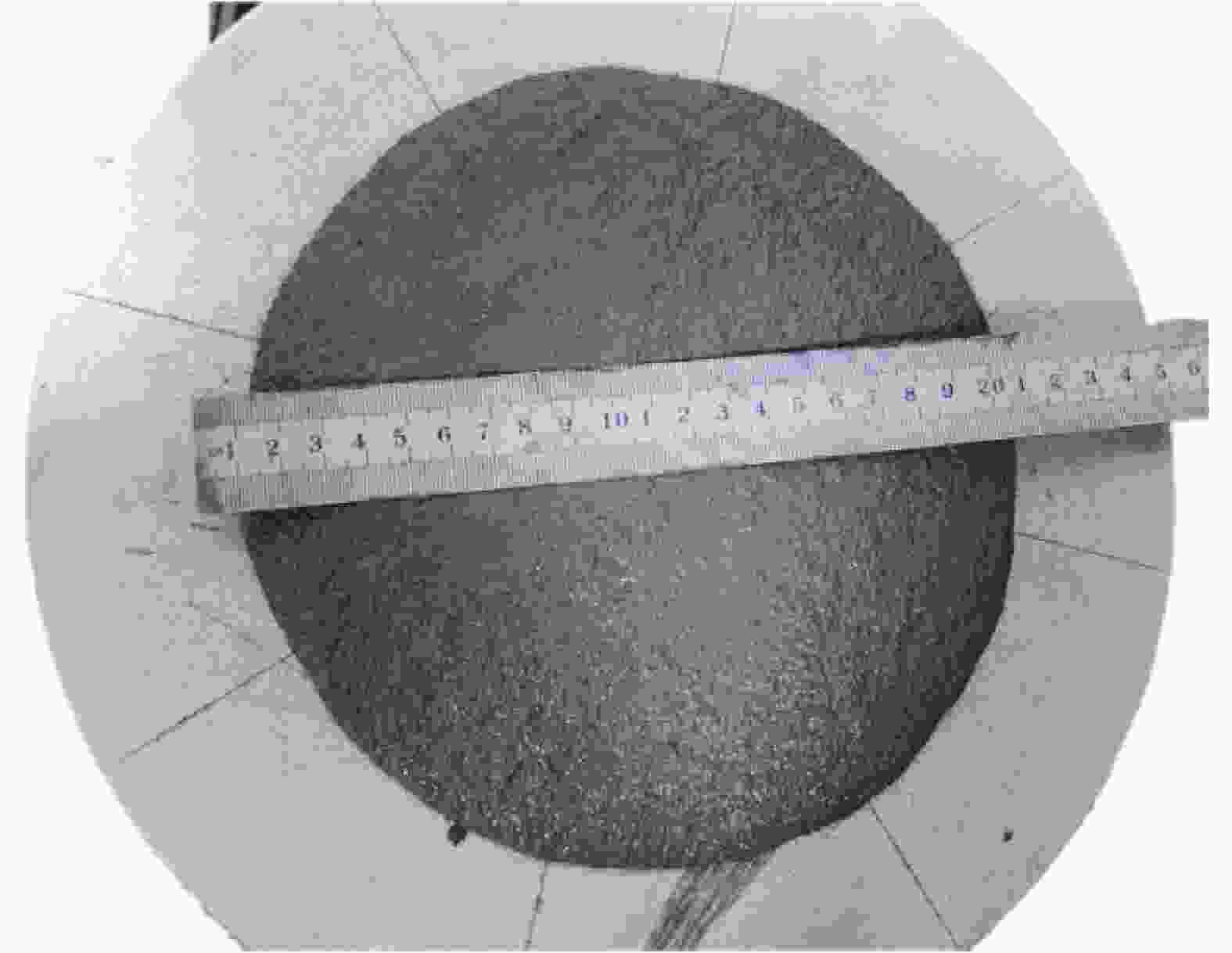

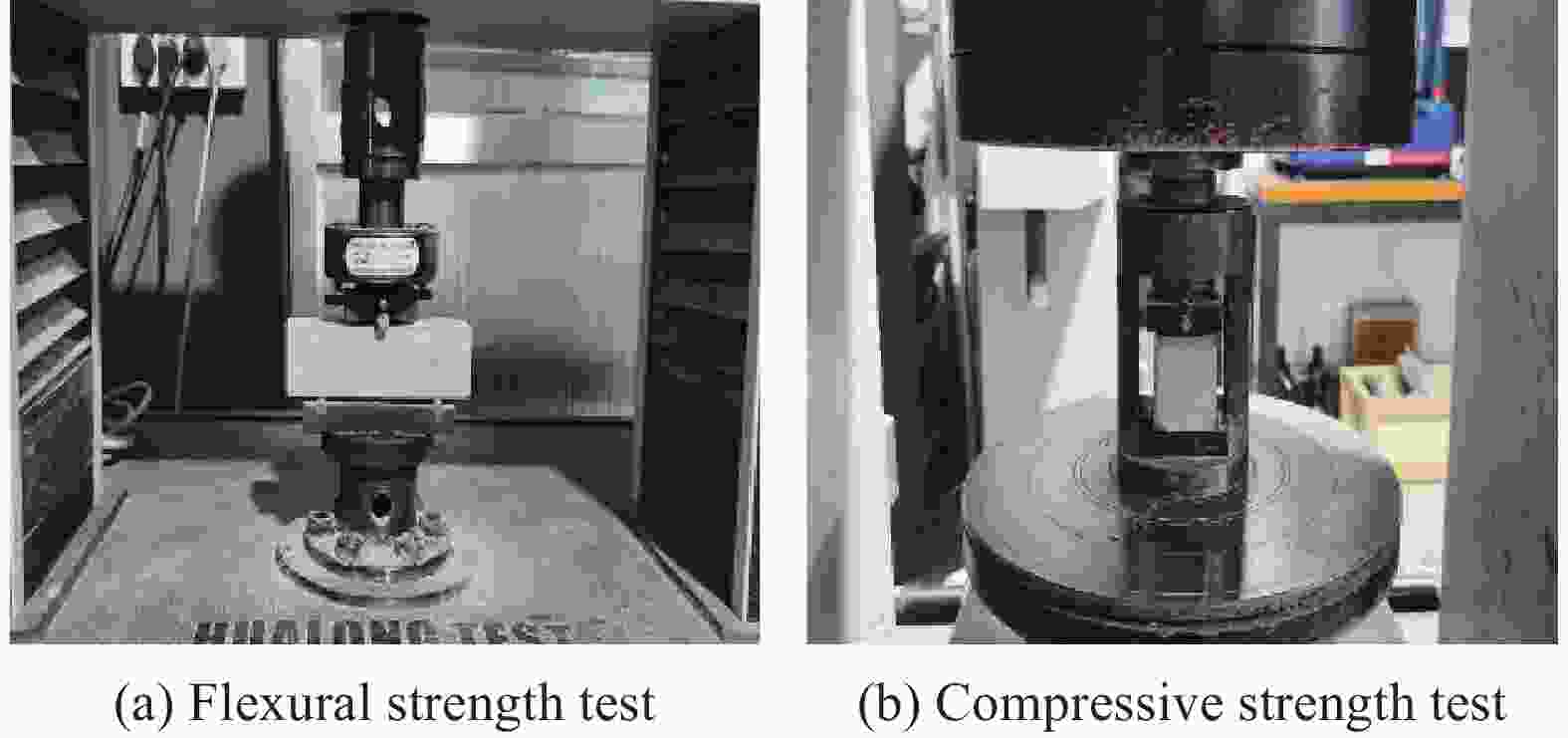

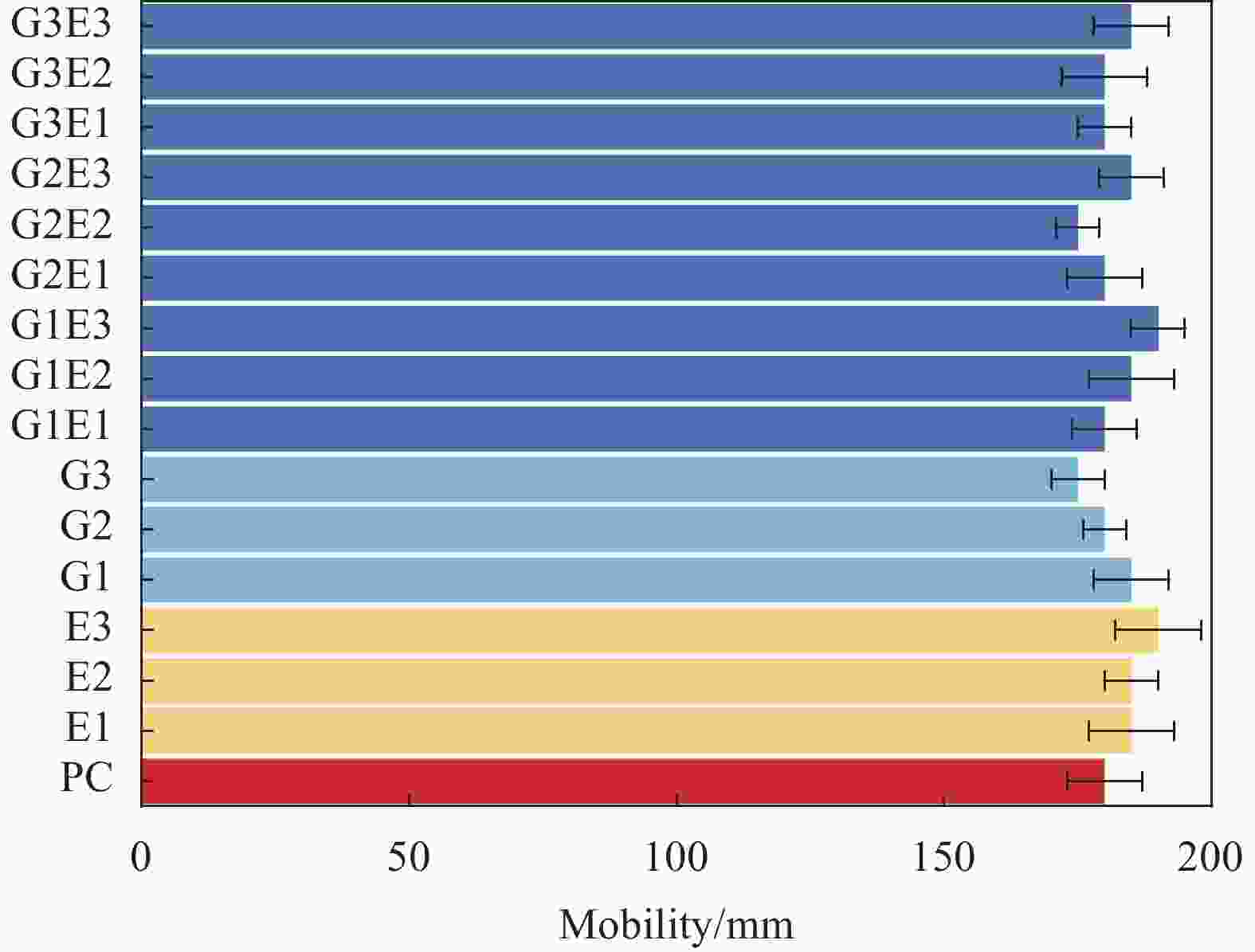

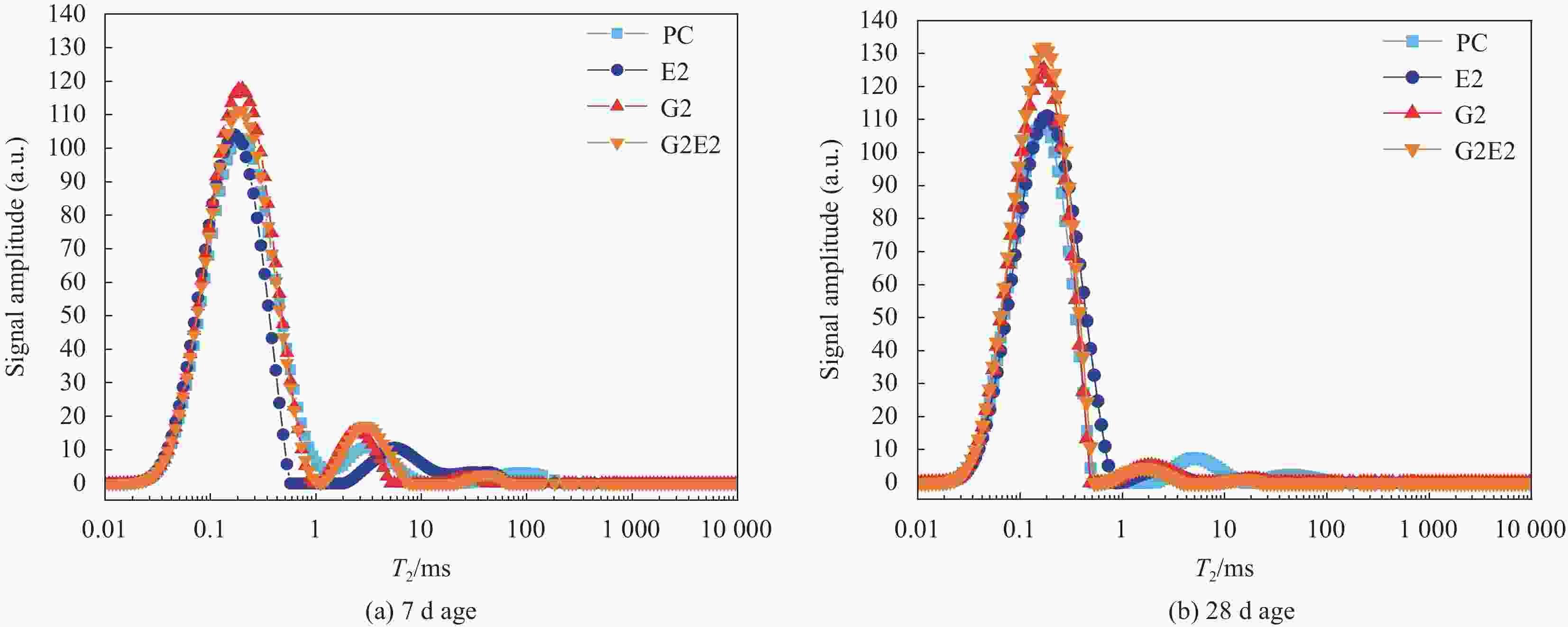

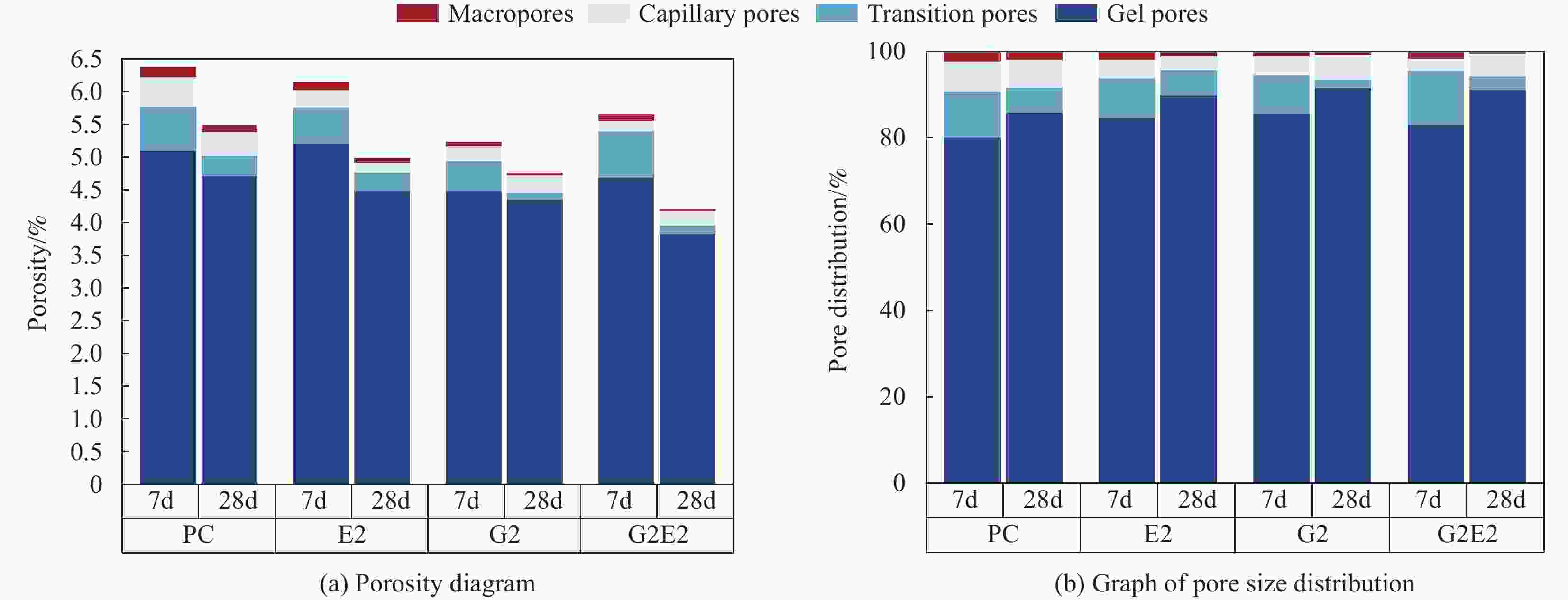

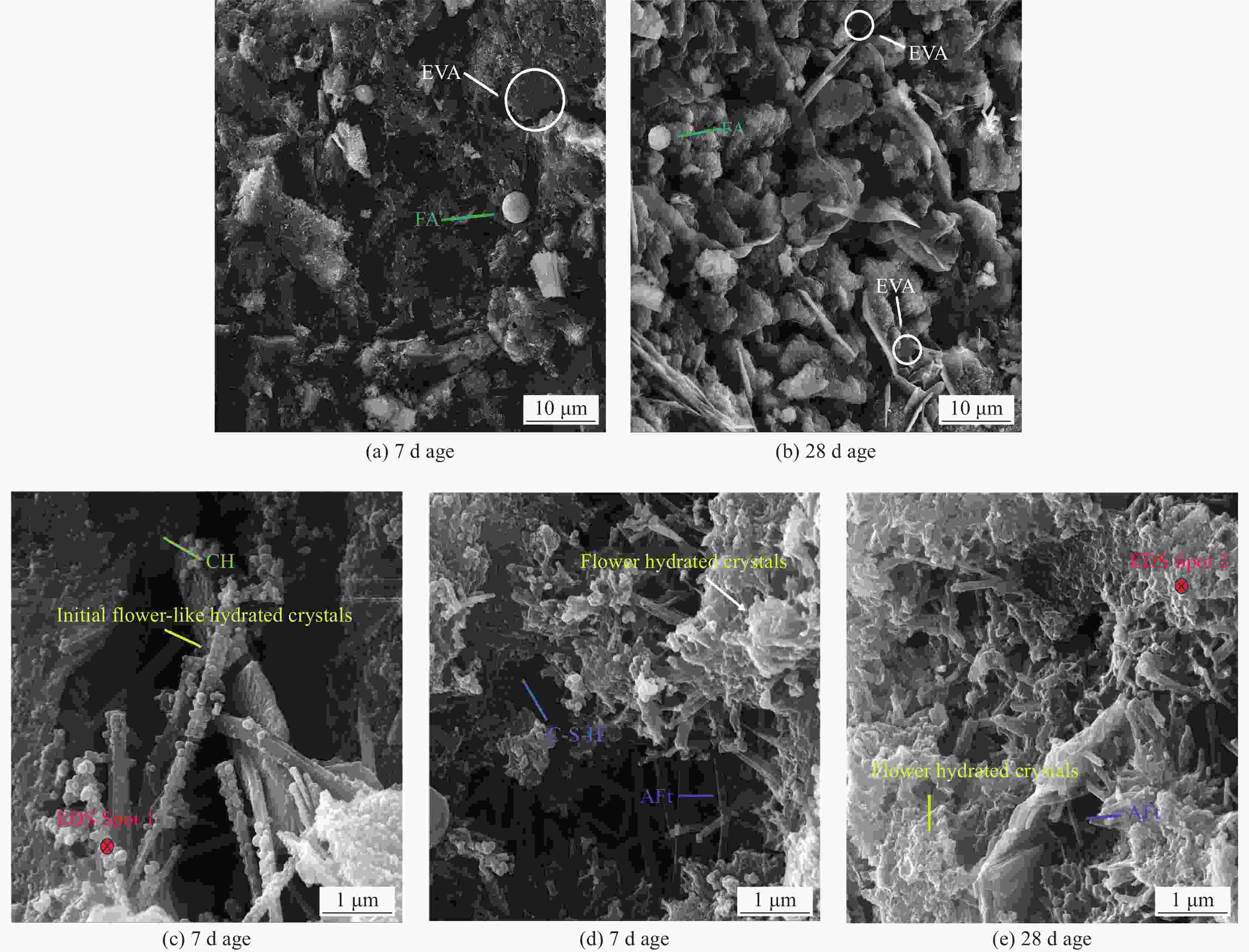

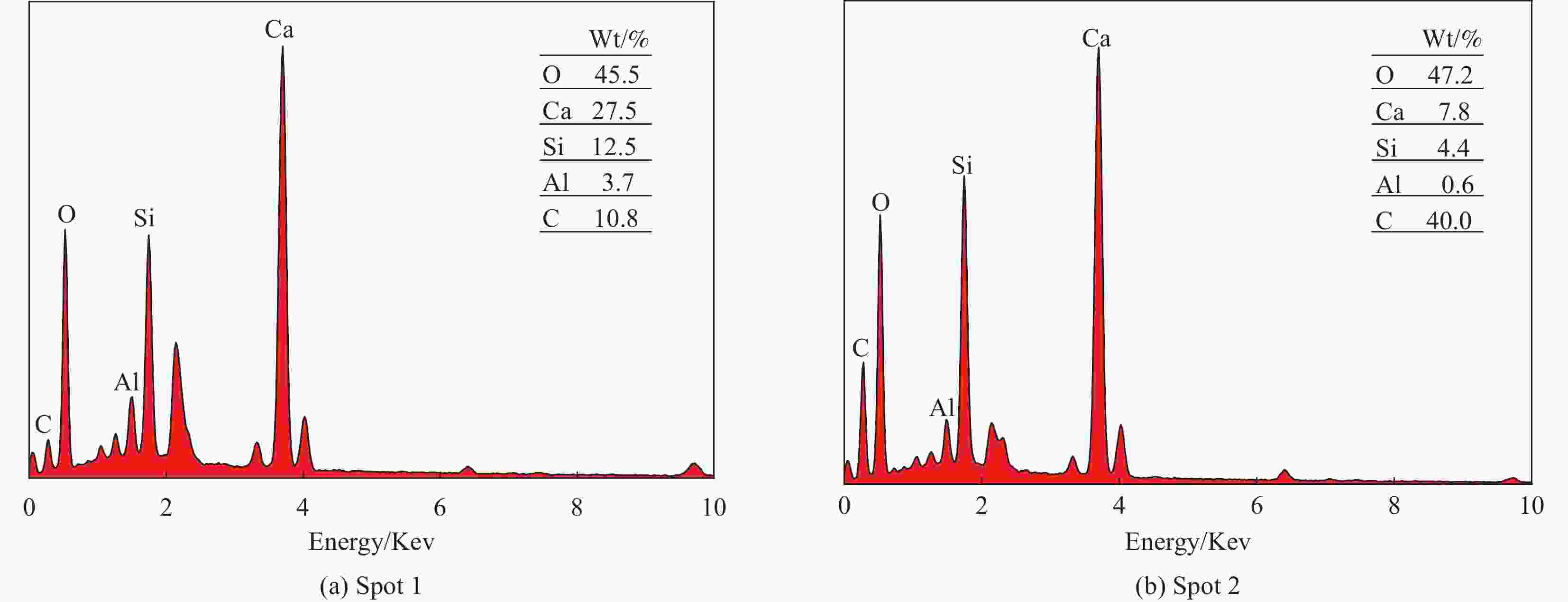

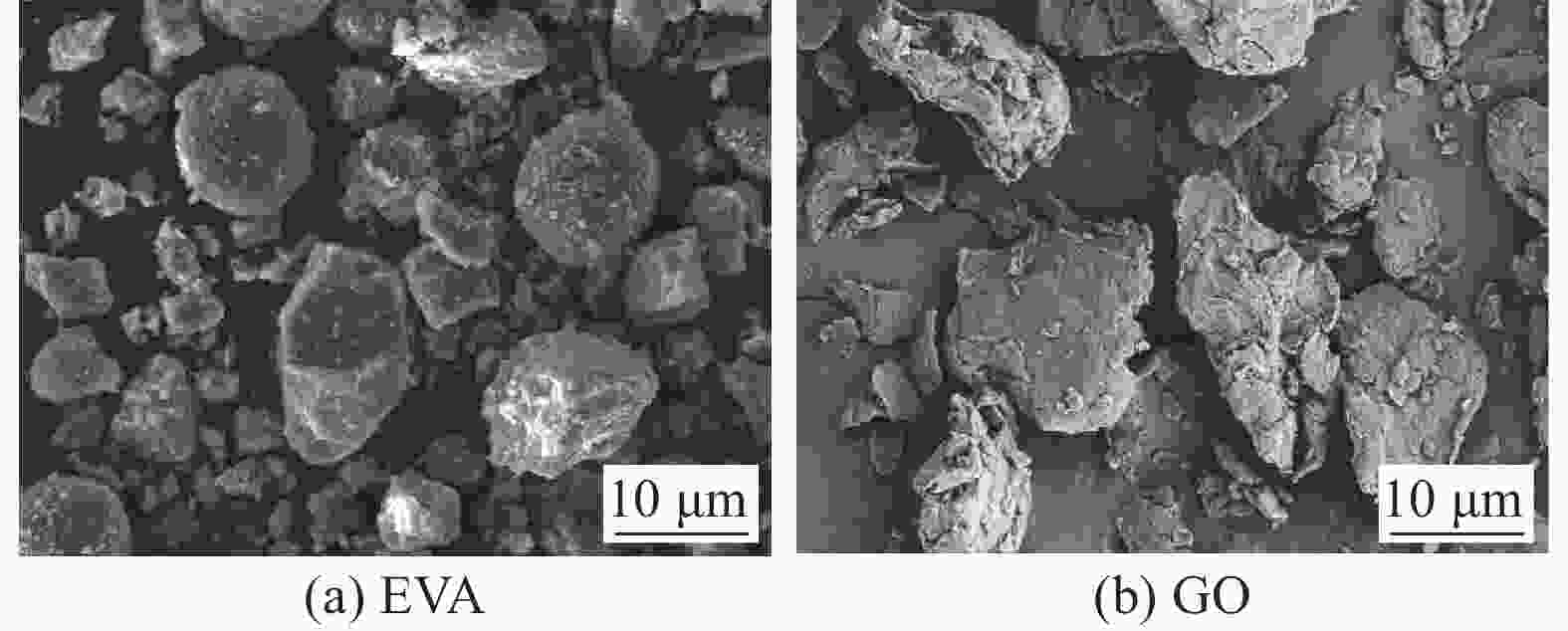

Abstract: In this study, nano-graphene oxide (GO) and ethylene-vinyl acetate rubber powder (EVA) were used to modify ordinary cement mortar, and the mechanism of the influence of GO and EVA on the mechanical properties of cement mortar was revealed in terms of the chemical composition, pore structure, and microscopic morphology of the materials by using testing methods such as FTIR, XRD, TG, NMR, and SEM. The results indicate that the well-dispersed GO reduces the fluidity of fresh mortar, and this effect could be mitigated by incorporating EVA. The mechanical properties of specimens containing 0.03wt% GO alone were found to be optimal, with a 24.1% increase in compressive strength and a 31% increase in flexural strength at 7 days compared to the benchmark group (PC). Subsequent to the composite infusion of GO and EVA, the 28-day mechanical properties of the resultant specimens exhibit peak values at a GO dosage of 0.03wt% and an EVA dosage of 4wt% weight percent, respectively. Notably, the compressive and flexural strengths recorded are 72 MPa and 12 MPa, demonstrating enhancements of 25.9% and 33.3% when compared to the properties of the PC specimens. The microscopic test outcomes demonstrate that: the nucleation effect of GO accelerates the cement hydration process and can modulate the generation and growth of flower-like hydration crystals, thus refining the pore size distribution of the specimen, and the good filling effect makes the pore structure become denser. The establishment of reticulation film in the early stage of EVA impedes the hydration process of the cement, and in the late stage of hydration, the fully developed reticulation film forms an interpenetrating network with the cement paste, facilitating the pore structure and densification. The cooperative interaction of the two significantly enhances the mechanical properties of the cement mortar. -

表 1 水泥技术指标

Table 1. Cement technical indicators

Strength grade Stability Compressive strength/MPa Flexural strength/MPa Solidification time/min 3 d 28 d 3 d 28 d Condensation Congeal 52.5 Eligible 30.2 56 6.1 8.8 151 212 表 2 EVA技术指标

Table 2. EVA technical indicators

Performances Index Solid content/% 99±1 Apparent density/(g·L−1) 540±50 Appearance White powder Stable system Polyvinyl alcohol Minimum film forming temperature/℃ 4 Main particle sizes/μm 0.5-8 表 3 GO技术指标

Table 3. GO technical indicators

Performances Index Fineness >95wt% Layer diameter 1-30 μm Appearance Brownish-black powder Storey 1-3 表 4 PC、单掺EVA、单掺GO试件

Table 4. PC, single-doped EVA, single-doped GO specimens

Number Water-to-cement ratio FA/% GO/% EVA/% Grit ratio GO: PCE Defoamer/g PC 0.35 10 0 0 1:1.5 0 0 E1 0.35 10 0 2 1:1.5 0 0.10 E2 0.35 10 0 4 1:1.5 0 0.10 E3 0.35 10 0 6 1:1.5 0 0.10 G1 0.35 10 0.01 0 1:1.5 1:2 0 G2 0.35 10 0.03 0 1:1.5 1:2 0 G3 0.35 10 0.05 0 1:1.5 1:2 0 Notes: FA represents grade II fly ash; GO represents nano-graphene oxide; EVA stands for ethylene-vinyl acetate rubber powder; PCE is powder polycarboxylic acid water reducing agent; The same below. PC is the reference group specimen; "E1", "E2", "E3"represent the content of EVA is 2%, 4% and 6%, respectively; "G1", "G2", "G3" represent the content of GO is 0.01%, 0.03% and 0.05%, respectively. 表 5 复掺GO和EVA试件

Table 5. Compound GO and EVA specimens

Number Water-to-cement ratio FA/% GO/% EVA/% Grit ratio Defoamer/g G1 E1 0.35 10 0.01 2 1:1.5 0.10 G1 E2 0.35 10 0.01 4 1:1.5 0.10 G1 E3 0.35 10 0.01 6 1:1.5 0.10 G2 E1 0.35 10 0.03 2 1:1.5 0.10 G2 E2 0.35 10 0.03 4 1:1.5 0.10 G2 E3 0.35 10 0.03 6 1:1.5 0.10 G3 E1 0.35 10 0.05 2 1:1.5 0.10 G3 E2 0.35 10 0.05 4 1:1.5 0.10 G3 E3 0.35 10 0.05 6 1:1.5 0.10 Note: "G1 E1"represents GO and EVA doping of 0.01% and 2%, respectively. 表 6 PC、E2、G2和G2 E2组试件不同龄期特征峰面积比

Table 6. Ratio of characteristic peak area at different ages of specimens in groups PC, E2, G2 and G2 E2

Age Number Total area

of peaksMain peak Sub-peak 1 Sub-peak 2 Peak area Proportion/% Peak area Proportion/% Peak area Proportion/% 7 d PC 2851.39 2622.54 91.97 178.21 6.25 50.63 1.78 7 d E2 2643.29 2395.97 90.64 197.75 7.48 49.56 1.88 7 d G2 2264.84 2112.97 93.29 140.34 6.20 11.53 0.51 7 d G2 E2 2537.79 2304.50 90.81 211.45 8.33 21.85 0.86 28 d PC 2425.77 2269.00 93.54 126.41 5.21 41.83 1.72 28 d E2 2336.80 2267.24 97.02 52.42 2.24 12.21 0.52 28 d G2 2019.19 1953.99 96.77 58.83 2.91 6.37 0.32 28 d G2 E2 1955.90 1900.81 97.18 7.33 2.42 7.76 0.40 -

[1] DEB S, MITRA N, MAJUMDER S B, et al. Improvement in tensile and flexural ductility with the addition of different types of polypropylene fibers in cementitious composites[J]. Construction and Building Materials, 2018, 180: 405-411. doi: 10.1016/j.conbuildmat.2018.05.280 [2] 杨久俊, 刘俊霞, 韩静宜, 等. 大流动度超高强钢纤维混凝土力学性能研究[J]. 建筑材料学报, 2010, 13(1): 1-6. doi: 10.3969/j.issn.1007-9629.2010.01.001YANG Jiujun, LIU Junxia, HAN Jingyi, et al. Studies on Mechanical Property of High Fluidity Steel Fiber Reinforced Ultra-high Strength Concrete[J]. Journal Of Building Materials, 2010, 13(1): 1-6(in Chinese). doi: 10.3969/j.issn.1007-9629.2010.01.001 [3] PANDITHARADHYA B J, MULANGI R H, RAVI SHANKAR A U. Mechanical and durability studies on fly ash based fibre reinforced concrete[J/OL]. Materials Today: Proceedings, 2023. https://doi.org/10.1016/j.matpr.2023.06.280 [4] ŠOUKAL F, BOCIAN L, NOVOTNÝ R, et al. The Effects of Silica Fume and Superplasticizer Type on the Properties and Microstructure of Reactive Powder Concrete[J]. Materials, 2023, 16(20): 6670. doi: 10.3390/ma16206670 [5] WANG R, WANG P M. Action of redispersible vinyl acetate and versatate copolymer powder in cement mortar[J]. Construction and Building Materials, 2011, 25(11): 4210-4214. doi: 10.1016/j.conbuildmat.2011.04.060 [6] LI H, XUE Z, LIANG H, et al. Influence of defoaming agents on mechanical performances and pore characteristics of Portland cement paste/mortar in presence of EVA dispersible powder[J]. Journal of Building Engineering, 2021, 41: 102780. doi: 10.1016/j.jobe.2021.102780 [7] Betioli A M, Hoppe Filho J, Cincotto M A, et al. Chemical interaction between EVA and Portland cement hydration at early-age[J]. Construction and Building Materials, 2009, 23(11): 3332-3336. doi: 10.1016/j.conbuildmat.2009.06.033 [8] Bomediano K S, Gomes C E M, Fontanini P S P. Propriedades da argamassa modificada com polímeros redispersíveis de etileno-acetato de vinila (EVA)[J]. Ambiente Construído, 2020, 20: 419-429. [9] Cai Y, Wang P M, Zhong S Y. Influence of coagulation of polymer dispersion on the properties of polymer-modified mortar[J]. Advanced Materials Research, 2015, 1129: 162-168. doi: 10.4028/www.scientific.net/AMR.1129.162 [10] LI H, GU L, DONG B, et al. Improvements in setting behavior and strengths of cement paste/mortar with EVA redispersible powder using C-S-Hs-PCE[J]. Construction and Building Materials, 2020, 262: 120097. doi: 10.1016/j.conbuildmat.2020.120097 [11] 李刊, 魏智强, 乔宏霞等. 纳米SiO2改性聚合物水泥基材料性能试验研究[J]. 湖南大学学报(自然科学版), 2021, 48(11): 150-159.Li Kan, WEI Zhiqiang, QIAO Hongxia, et al. Experimental Study on Property of Polymer Cement Based Composite Modified by Nano-SiO2[J]. Journal of Hunan University(Natural Sciences), 2021, 48(11): 150-159(in Chinese). [12] ENTZ D P. Activation energies of high-volume fly ash ternary blends: Hydration and setting[J]. Cement and Concrete Composites, 2014, 53: 214-223. doi: 10.1016/j.cemconcomp.2014.06.018 [13] SATO T, BEAUDOIN J J. Effect of nano-CaCO3 on hydration of cement containing supplementary cementitious materials[J]. Advances in Cement Research, 2011, 23(1): 33-43. doi: 10.1680/adcr.9.00016 [14] YANG H, MONASTERIO M, CUI H, et al. Experimental study of the effects of graphene oxide on microstructure and properties of cement paste composite[J]. Composites Part A: Applied Science and Manufacturing, 2017, 102: 263-272. doi: 10.1016/j.compositesa.2017.07.022 [15] HOU D. Reactive molecular dynamics and experimental study of graphene-cement composites: Structure, dynamics and reinforcement mechanisms[J]. Carbon, 2017, 115: 188-208. doi: 10.1016/j.carbon.2017.01.013 [16] LI Z, YOUNG R J, WANG R, et al. The role of functional groups on graphene oxide in epoxy nanocomposites[J]. Polymer, 2013, 54(21): 5821-5829. doi: 10.1016/j.polymer.2013.08.026 [17] CHUAH S, PAN Z, SANJAYAN J G, et al. Nano reinforced cement and concrete composites and new perspective from graphene oxide[J]. Construction and Building Materials, 2014, 73: 113-124. doi: 10.1016/j.conbuildmat.2014.09.040 [18] YU L, BAI S, GUAN X. Effect of graphene oxide on microstructure and micromechanical property of ultra-high performance concrete[J]. Cement and Concrete Composites, 2023, 138: 104964. doi: 10.1016/j.cemconcomp.2023.104964 [19] Wang Q, Wang J, Lv C, et al. Rheological behavior of fresh cement pastes with a graphene oxide additive[J]. New Carbon Materials, 2016, 31(6): 574-584. [20] Liu C, Huang X, Wu Y Y, et al. The effect of graphene oxide on the mechanical properties, impermeability and corrosion resistance of cement mortar containing mineral admixtures[J]. Construction and Building Materials, 2021, 288: 123059. doi: 10.1016/j.conbuildmat.2021.123059 [21] LV S, MA Y, QIU C, et al. Effect of graphene oxide nanosheets of microstructure and mechanical properties of cement composites[J]. Construction and Building Materials, 2013, 49: 121-127. doi: 10.1016/j.conbuildmat.2013.08.022 [22] NASEEM Z, SHAMSAEI E, SAGOE-CRENTSIL K, et al. Antifoaming effect of graphene oxide nanosheets in polymer-modified cement composites for enhanced microstructure and mechanical performance[J]. Cement and Concrete Research, 2022, 158: 106843. doi: 10.1016/j.cemconres.2022.106843 [23] NASEEM Z, SHAMSAEI E, SAGOE-CRENTSIL K, et al. Microstructural and polymer film interaction mechanisms: Insights of GO-reinforced polymer-modified cement composites[J]. Journal of Building Engineering, 2023, 80: 107962. [24] GHOLAMPOUR A, KIAMAHALLEH M V, TRAN D N H, et al. Revealing the dependence of the physiochemical and mechanical properties of cement composites on graphene oxide concentration[J]. RSC Advances, 2017, 7(87): 55148-55156. doi: 10.1039/C7RA10066C [25] Zhao L, Guo X, Song L, et al. An intensive review on the role of graphene oxide in cement-based materials[J]. Construction and Building Materials, 2020, 241: 117939. doi: 10.1016/j.conbuildmat.2019.117939 [26] Alex A G, Kedir A, Tewele T G. Review on effects of graphene oxide on mechanical and microstructure of cement-based materials[J]. Construction and Building Materials, 2022, 360: 129609. doi: 10.1016/j.conbuildmat.2022.129609 [27] Zhang X, Du M, Fang H, et al. Polymer-modified cement mortars: Their enhanced properties, applications, prospects, and challenges[J]. Construction and Building Materials, 2021, 299: 124290. doi: 10.1016/j.conbuildmat.2021.124290 [28] VALLURUPALLI K, MENG W, LIU J, et al. Effect of graphene oxide on rheology, hydration and strength development of cement paste[J]. Construction and Building Materials, 2020, 265: 120311. doi: 10.1016/j.conbuildmat.2020.120311 [29] 国家能源局. 聚合物改性水泥砂浆试验规程: DL/T 5126-2021[S]. 北京 中国电力出版社, 2021National Energy Administration. Test code for ploymer modified cement mortar: DL/T 5126-2001 [S]. Beijing: China Electric Power Press, 2021. (in Chinese) [30] 中国国家标准化管理委员会. 水泥胶砂流动度测定方法: GB/T 2419-2005[S]. 北京: 中国标准出版社, 2005.Standardization Administration of the People’s Republic of China. Test method for fludity of cement mortar: GB/T 2419-2005[S]. Beijing: China Standards Press, 2005. (in Chinese) [31] 中国国家标准化管理委员会. 水泥胶砂强度检验方法(ISO法): GB/T 17671-2021[S]. 北京: 中国标准出版社, 2021.Standardization Administration of the People’s Republic of China. Test method of cement mortar strength(ISO method): GB/T 2419-2005[S]. Beijing: China Standards Press, 2021. (in Chinese) [32] 黄观送, 苏丽, 薛翠真, 等. 基于核磁共振技术的玄武岩-聚丙烯混杂纤维增强混凝土孔隙特征分析[J/OL]. 复合材料学报, 1-17[2024-06-19]. https://doi-org-s.lut.yitlink.com:443/10.13801/j.cnki.fhclxb.20240520.002.HUANG Guansong, SU Li, XUE Cuizhen, et al. Analysis on pore characteristics of hybrid basalt-polypropylene fiber-reinforced concrete based on nuclear magnetic resonance technology. [J/OL]. Acta Materiae Compositae Sinica, 1-17[2024-06-19]. https://doi-org-s.lut.yitlink.com:443/10.13801/j.cnki.fhclxb.20240520.002. (in Chinese) [33] 朱翔琛, 张云升, 刘志勇, 等. 基于核磁共振技术的硫酸盐冻融下机制骨料混凝土孔结构演变规律研究[J/OL]. 复合材料学报, 1-14[2024-06-19]. https://doi-org-s.lut.yitlink.com:443/10.13801/j.cnki.fhclxb.20231218.006.in Chinese) ZHU Xiangchen, ZHANG Yunsheng, LIU Zhiyong, et al. Study on the evolution of pore structure of manufactured aggregate concrete under sulfate freeze-thaw based on nuclear magnetic resonance technology. [J/OL]. Acta Materiae Compositae Sinica, 1-14[2024-06-19]. https://doi.org/10.13801/j.cnki.fhclxb. 20231218.006. (in Chinese) [34] SHANG Y, ZHANG D, YANG C, et al. Effect of graphene oxide on the rheological properties of cement pastes[J]. Construction and Building Materials, 2015, 96: 20-28. doi: 10.1016/j.conbuildmat.2015.07.181 [35] LIU J, ZHAO L, CHI L, et al. Effect of multilayer graphene oxide on the hydration and early mechanical strength of cement mortar in low temperature[J]. Construction and Building Materials, 2023, 364: 129997. doi: 10.1016/j.conbuildmat.2022.129997 [36] WU Y, SUN Q, KONG L, et al. Properties and microstructure of polymer emulsions modified fibers reinforced cementitious composites[J]. Journal of Wuhan University of Technology-Mater. Sci. Ed., 2014, 29(4): 795-802. [37] 刘春燕. 氧化石墨烯水泥基材料性能及其应用研究 [D]. 西安: 西安建筑科技大学, 2017.LIU Chunyan. Research on properties and engineering applications of cement-based materials enhanced by graphene oxide [D]. Xian: Xi'an University of Architecture and Technology, 2017(in Chinese) [38] LV S, HU H, ZHANG J, et al. Structure, performances, and formation mechanism of cement composites with large-scale regular microstructure by distributing uniformly few-layered graphene oxide in cement matrix[J]. Structural Concrete, 2019, 20(1): 471-482. [39] ZHAO L, GUO X, GE C, et al. Investigation of the effectiveness of PC@GO on the reinforcement for cement composites[J]. Construction and Building Materials, 2016, 113: 470-478. doi: 10.1016/j.conbuildmat.2016.03.090 [40] PENG H, GE Y, CAI C S, et al. Mechanical properties and microstructure of graphene oxide cement-based composites[J]. Construction and Building Materials, 2019, 194: 102-109. doi: 10.1016/j.conbuildmat.2018.10.234 [41] LEE S J, JEONG S H, KIM D U, et al. Effects of graphene oxide on pore structure and mechanical properties of cementitious composites[J]. Composite Structures, 2020, 234: 111709. doi: 10.1016/j.compstruct.2019.111709 [42] 陈潇, 张浩宇, 霍神焕等. 壳聚糖改性地聚合物的力学及吸附性能[J]. 复合材料学报, 2019, 36(12): 2959-2967.CHEN Xiao, ZHANGHaoyu, HUO Shenhuan, et al. Mechanical and adsorption of geopolymer by chitosan[J]. Acta Materiae Compositae Sinica, 2019, 36(12): 2959-2967(in Chinese). [43] LIANG G, NI D, LI H, et al. Synergistic effect of EVA, TEA and C-S-Hs-PCE on the hydration process and mechanical properties of Portland cement paste at early age[J]. Construction and Building Materials, 2021, 272: 121891. doi: 10.1016/j.conbuildmat.2020.121891 [44] HULAGABALI M M, VESMAWALA G R, PATIL Y D. Synthesis, characterization, and application of graphene oxide and reduced graphene oxide and its influence on rheology, microstructure, and mechanical strength of cement paste[J]. Journal of Building Engineering, 2023, 71: 106586. doi: 10.1016/j.jobe.2023.106586 [45] MOKHTAR M M, ABO-EL-ENEIN S A, HASSAAN M Y, et al. Mechanical performance, pore structure and micro-structural characteristics of graphene oxide nano platelets reinforced cement[J]. Construction and Building Materials, 2017, 138: 333-339. doi: 10.1016/j.conbuildmat.2017.02.021 [46] INDUKURI C S R, NERELLA R, MADDURU S R C. Workability, microstructure, strength properties and durability properties of graphene oxide reinforced cement paste[J]. Australian Journal of Civil Engineering, 2020, 18(1): 73-81. doi: 10.1080/14488353.2020.1721952 [47] SHOUKRY H, KOTKATA M F, ABO-EL-ENEIN S A, et al. Thermo-physical properties of nanostructured lightweight fiber reinforced cementitious composites[J]. Construction and Building Materials, 2016, 102: 167-174. doi: 10.1016/j.conbuildmat.2015.10.188 [48] 李少飞, 魏智强, 乔宏霞, 等. 纳米氧化石墨烯与聚合物改性水泥基复合材料性能研究进展[J/OL]. 材料导报, 1-22 [2024-06-19]. http://kns.cnki.net.lut.yitlink.com:80/kcms/detail/50.1078.tb.20240614.1838.004.html.LI Shaofei, WEI Zhiqiang, QIAO Hongxia, et al. Research progress on properties of polymer cement-based composites modified by nano-graphene oxide [J/OL]. Materials Reports. 1-22[2024-06-19]. http://kns.cnki.net.lut.yitlink.com:80/kcms/detail/50.1078.tb.20240614.1838.004.html. (in Chinese) [49] 李刊, 魏智强, 乔宏霞, 等. 纳米SiO2改性聚合物水泥基复合材料早期微观结构及性能[J]. 复合材料学报, 2020, 37(09): 2272-2284.LI Kan , WEI Zhiqiang, QIAO Hongxia, Microstructure and properties of polymer cement-based composites modified by nano SiO2 in early age.[J]. Acta Materiae Compositae Sinica, 2020, 37(09): 2272-2284. (in Chinese) [50] CHINTALAPUDI K, RAO PANNEM R M. Strength properties of graphene oxide cement composites[J]. Materials Today: Proceedings, 2021, 45: 3971-3975. doi: 10.1016/j.matpr.2020.08.369 [51] SHARMA S, KOTHIYAL N C. Comparative effects of pristine and ball-milled graphene oxide on physico-chemical characteristics of cement mortar nanocomposites[J]. Construction and Building Materials, 2016, 115: 256-268. doi: 10.1016/j.conbuildmat.2016.04.019 -

点击查看大图

点击查看大图

计量

- 文章访问数: 59

- HTML全文浏览量: 25

- 被引次数: 0

下载:

下载: