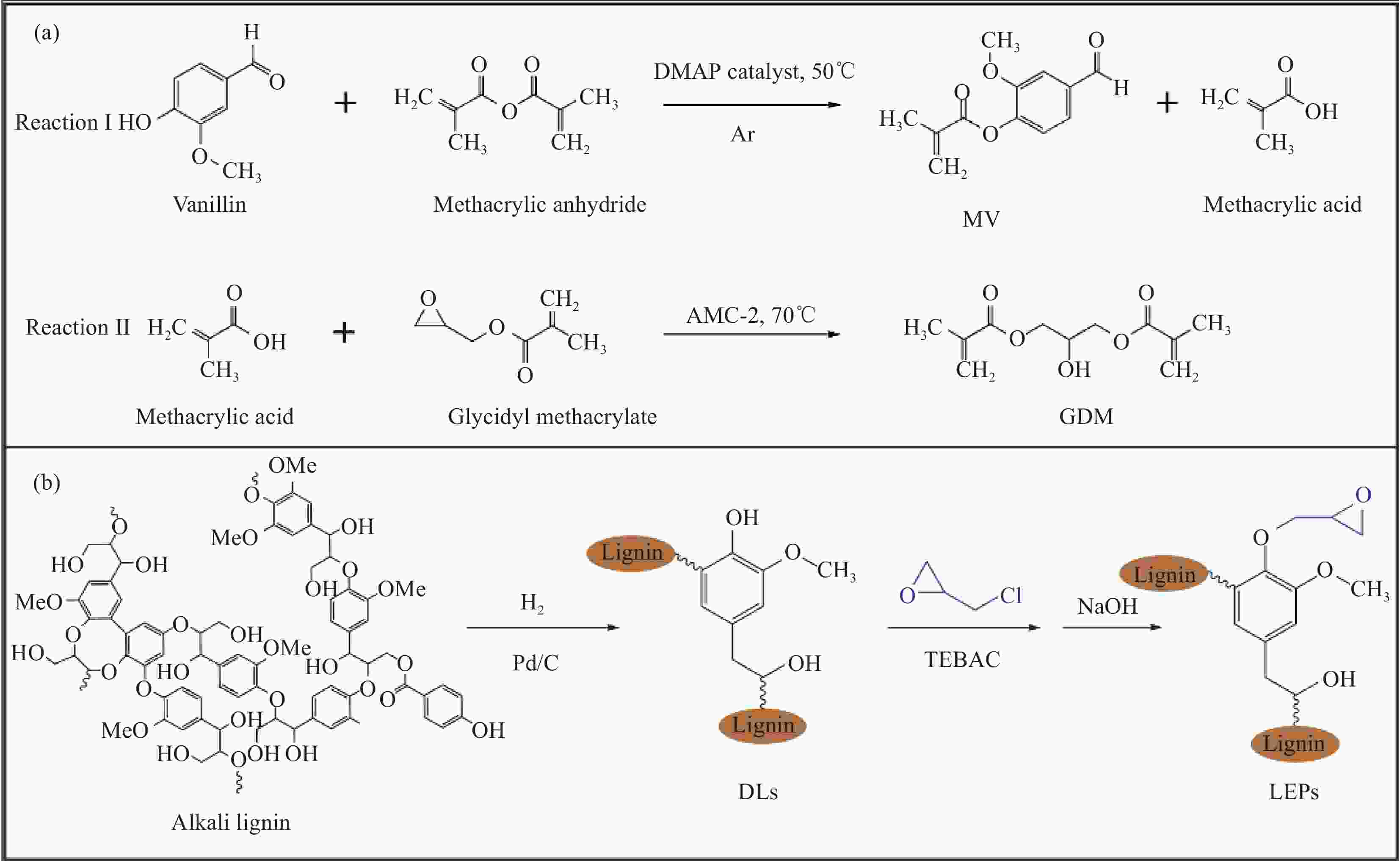

Researches and applications of lignin and its derivatives in 3D printing photosensitive resins

-

摘要: 随着社会消费需求向绿色、可持续发展方向不断转型及国家“双碳”战略目标的提出,深入开发低碳环保型3D打印材料(如生物质基3D打印光敏树脂)是十分必要的。木质素作为仅次于纤维素的第二大可再生绿色生物质资源,在3D打印材料中具有广阔的应用前景。本文综述了木质素及其衍生物用作生物质基3D打印光敏树脂材料的最新应用研究,包括木质素基光敏预聚物、木质素基活性稀释剂、木质素基光引发剂及木质素作为添加剂在3D打印光敏树脂材料中的应用机制及性能影响。最后对木质素基3D打印光敏树脂的未来挑战和工业化前景进行了分析与展望。Abstract: It is eagerly necessary to further develop the low-carbon and environmentally friendly 3D printing feedstocks, such as biomass-based three-dimensional (3D) printing photosensitive resin polymers, considering the continuous transformation of social consumption demands to green and sustainable development direction and the proposal of the national “double carbon” strategic goal. Lignin, as the second renewable and green biopolymer after cellulose, has exhibited its great application prospects in 3D printing feedstocks. The aim of this paper is to provide a critical review on the most cutting-edge researches of lignin and its derivatives as biomaterial feedstocks of 3D printing photosensitive resins, including the applications mechanism and performance effects of lignin-based photosensitive oligomers, lignin-derived reactive diluents, lignin-derived photo-initiators, as well as the lignin-based additives. Finally, the challenges and industrial prospects of lignin-based photosensitive resins as 3D printing feedstocks are analyzed and prospected.

-

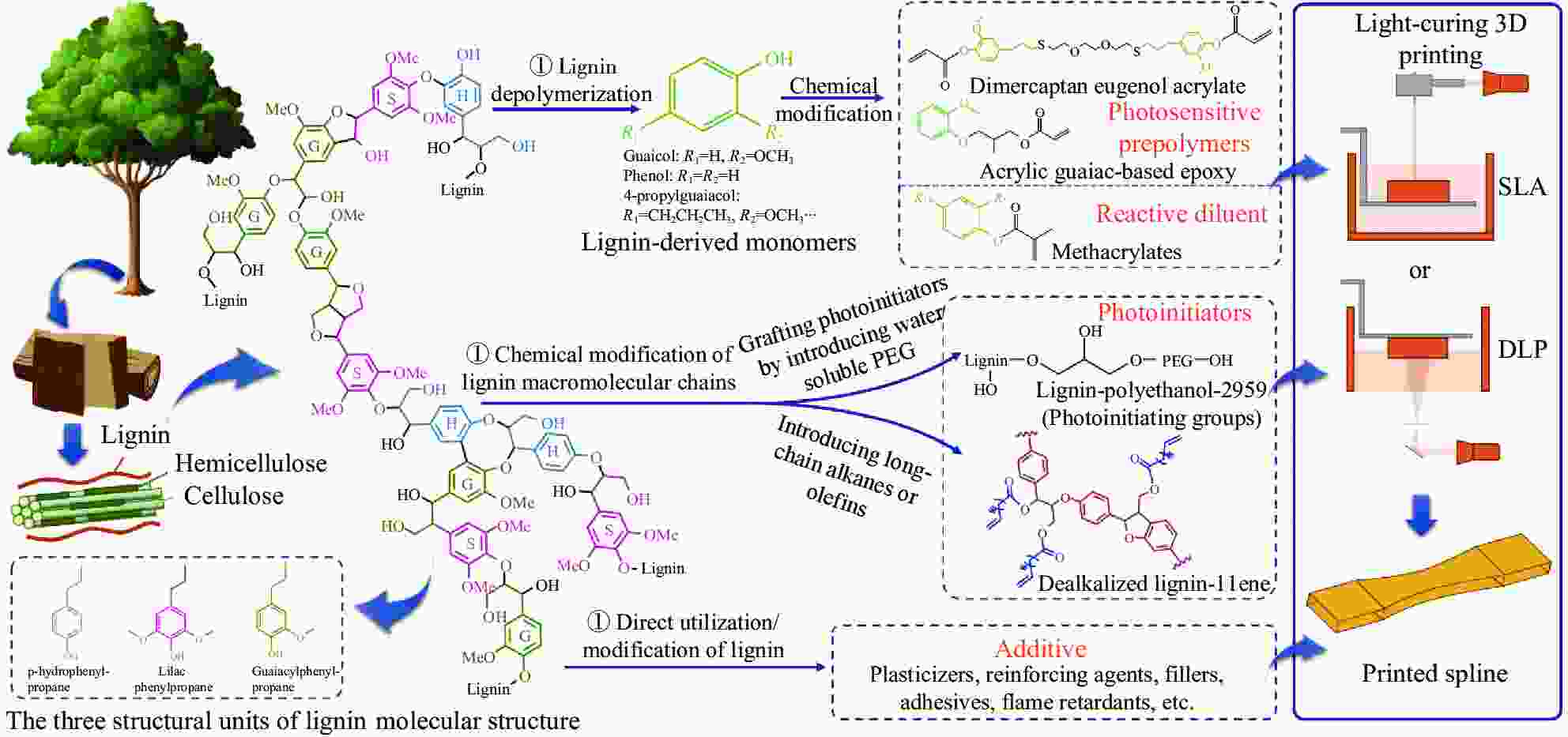

图 1 (a) 甲基丙烯酸香兰素(MV)光敏预聚物(反应I)和交联剂甘油二甲基丙烯酸酯甘油(GDM)(反应II)的制备过程(AMC-2是50%三价有机铬络合物和50%邻苯二甲酸酯混合物)[60];(b) 木质素基环氧树脂(LEPs)的合成工艺[46]

Figure 1. (a) Preparation process of methacrylated vanillin (MV) photosensitive prepolymer (Reaction I) and glycerol dimethacrylate glycerol (GDM) as cross-linkers (Reaction II) (AMC-2 is a mixture of 50% trivalent organic chromium complexes and 50% phthalate esters)[60]; (b) Synthesis process of lignin based epoxy resins (LEPs)[46]

DMAP—4-dimethylaminopyridine; DLs—Depolymerized lignins; TEBAC—Trimethylbenzenemethanaminium chloride

图 2 (a) 甲基丙烯酸酐与木质素模型化合物(苯酚、愈创木酚和4-丙基愈创木酚)反应制备木质素基丙烯酸类活性稀释剂[62];(b) 25℃下甲基丙烯酸丁香酚(MAESO-ME)体系和MAESO65-苯乙烯35树脂的黏度与剪切速率的关系;(c) MAESO-ME热固性体系的不溶物质量百分比[63]

Figure 2. (a) Reaction of a lignin model compound (phenol, guaiacol and 4-propylguaiacol) with methacrylic anhydride to produce a lignin based acrylic active diluent[62]; (b) Viscosity as a function of shear rate for the MAESO-ME resin system and MAESO65-styrene35 resin at 25℃; (c) Insoluble mass percent for the MAESO-ME thermoset system[63]

MG—Metharylated guaiacol; PM—Phenyl methacrylate; M4PG—4-propyl-2-methoxyphenyl methacrylate

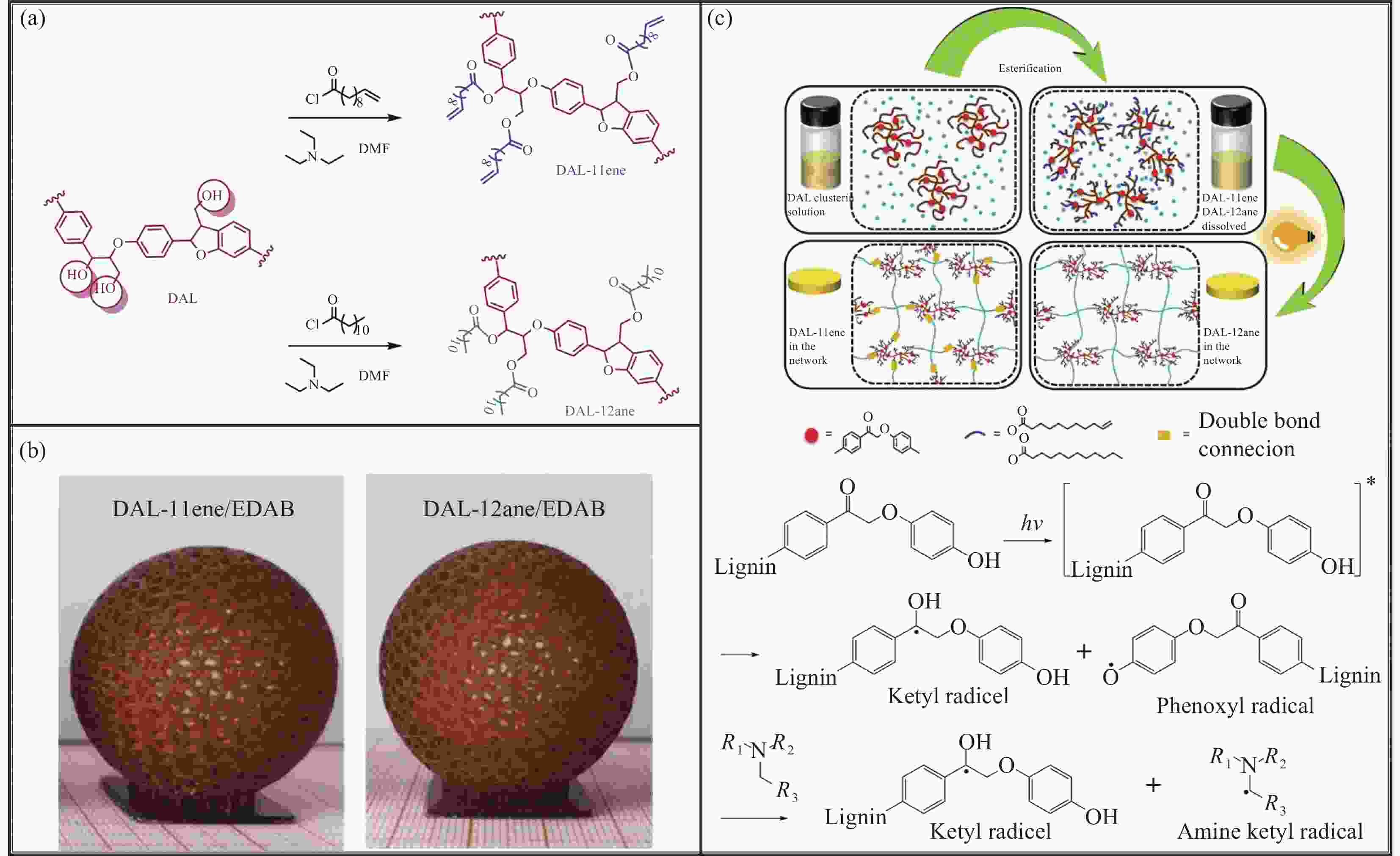

图 3 (a) 经十一酰氯酯化的脱碱木质素 (DAL-11 烯烃) 和经十二烷酰氯酯化的脱碱木质素 (DAL-12 烷烃) 的合成路线;(b) 以1,6-己二醇二丙烯酸酯 (HDDA) 为单体,以DAL-11 烯烃/4-(二甲氨基) 苯甲酸乙酯 (EDAB) 或DAL-12 烷烃/EDAB 为光引发剂,采用数字光处理(DLP) 3D 打印技术制备的空心球;(c) 使用DAL衍生物作为光引发剂(PI)的聚合物片剂的制造过程和DAL 在光照下产生自由基的示意图[70]

Figure 3. (a) Synthetic route of dealkalized lignin esterified by undecanoyl chloride (DAL-11ene) and dealkalized lignin esterified by dodecanoyl chloride (DAL-12ane); (b) Hollow spheres fabricated by digital light processing (DLP) 3D printed using 1, 6-hexanediol diacrylate (HDDA) as monomer and DAL-11ene/ethyl 4-(dimethylamino)benzoate (EDAB) or DAL-12ane/EDAB as photo-initiator; (c) Schematic illustration for fabrication of polymer tablets using DAL derivatives as photo-initiators and the generation of free radicals in DAL induced by UV light[70]

DMF—N,N-dimethylformamide

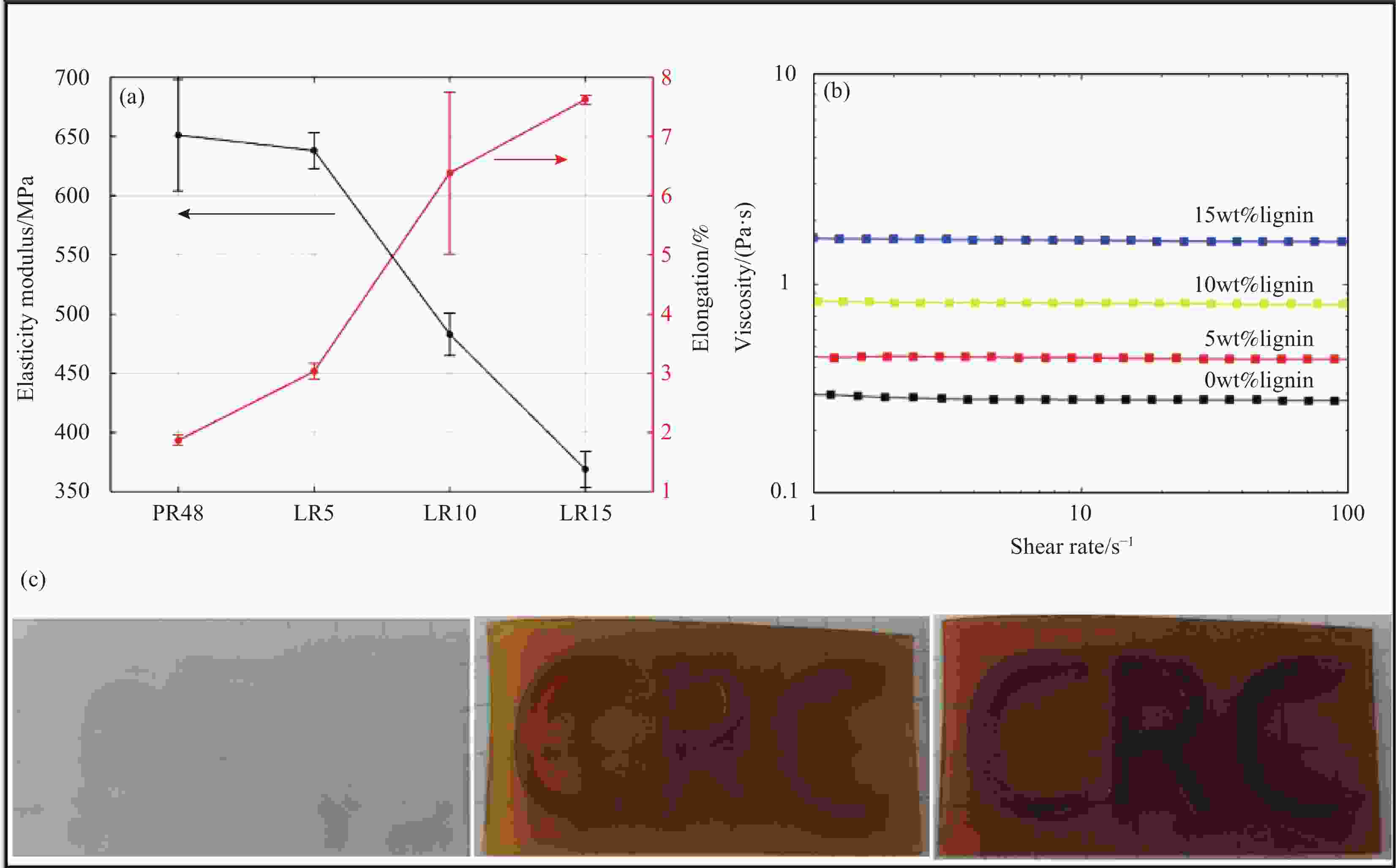

图 4 (a) 改性木质素含量对固化木质素树脂的弹性模量和延展性影响;(b) 含有不同酰化木质素(木质素-M)含量的光固化丙烯酸酯树脂的黏度与剪切速率的曲线图 (与市售PR48 (极性树脂第48号) 树脂相比,黏度随木质素含量的增加而增加);(c) 含有不同量木质素-M (从左至右0wt%、5wt% 和10wt%) 的照片显示了木素的引入对3D 打印质量的影响[2]

Figure 4. (a) Effects of modified lignin content on the elastic modulus and ductility of cured lignin resin; (b) Plot of viscosity versus shear rate of photocurable acrylate resins containing various acylated lignin (lignin-M) contents (Viscosity increases with lignin content compared to the commercial PR48 (Polar resin number 48) resin); (c) Photographs of various resins with 0wt% (commercial resin, left), 5wt% (middle), and 10wt% (right) lignin towards 3D print quality[2]

图 5 (a) 木质素基3D光敏树脂的光固化示意图;(b) 用木质素基甲基丙烯酸酯树脂制备的3D打印样品;(c) 不同含量木质素对3D打印样品硬度的影响(比例尺为1 cm);(d) 木质素含量分别为0.2wt%(I、III)和0wt%(II、IV)的3D打印材料进行UV固化后的表面(I、II)和横截面(III、IV)的SEM图像;(e) 不同木质素比例光固化树脂的3D打印样品的抗拉强度结果对比[73];(f) 有机溶剂分散的木质素和石墨烯纳米片(GNP)作为光固化聚氨酯(PU)的填料用于3D打印油墨的示意图[74];(g) 太阳麻/环氧树脂复合材料在不同木质素含量下的拉伸强度(i)、拉伸模量(ii)、弯曲强度(iii)、弯曲模量(iv)[75]

Figure 5. (a) Photocuring schematic of lignin based 3D photosensitive resin; (b) 3D printed sample prepared from lignin based methacrylate resin; (c) Effects of various lignin contents on the stiffness of 3D printed samples (Scale bars of 1 cm); (d) SEM images of the surfaces (I, II) and cross sections (fracture surface) (III, IV) of UV cured 3D printing feedstocks with (0.2wt%, I and III) and without (0wt%, II and IV) lignin addition; (e) Comparisons of tensile strength of UV cured 3D printed samples with different lignin ratios[73]; (f) Schematic of organosolv dispersed lignin-graphene nanoplatelets (GNP) as fillers of photo-curable polyurethane (PU) for 3D printing inks[74]; (g) Tensile strength (i), tensile modulus (ii), flexural strength (iii), and flexural modulus (iv) of Sun hemp/epoxy composites at different lignin contents[75]

Vf—Volume fraction of the fiber

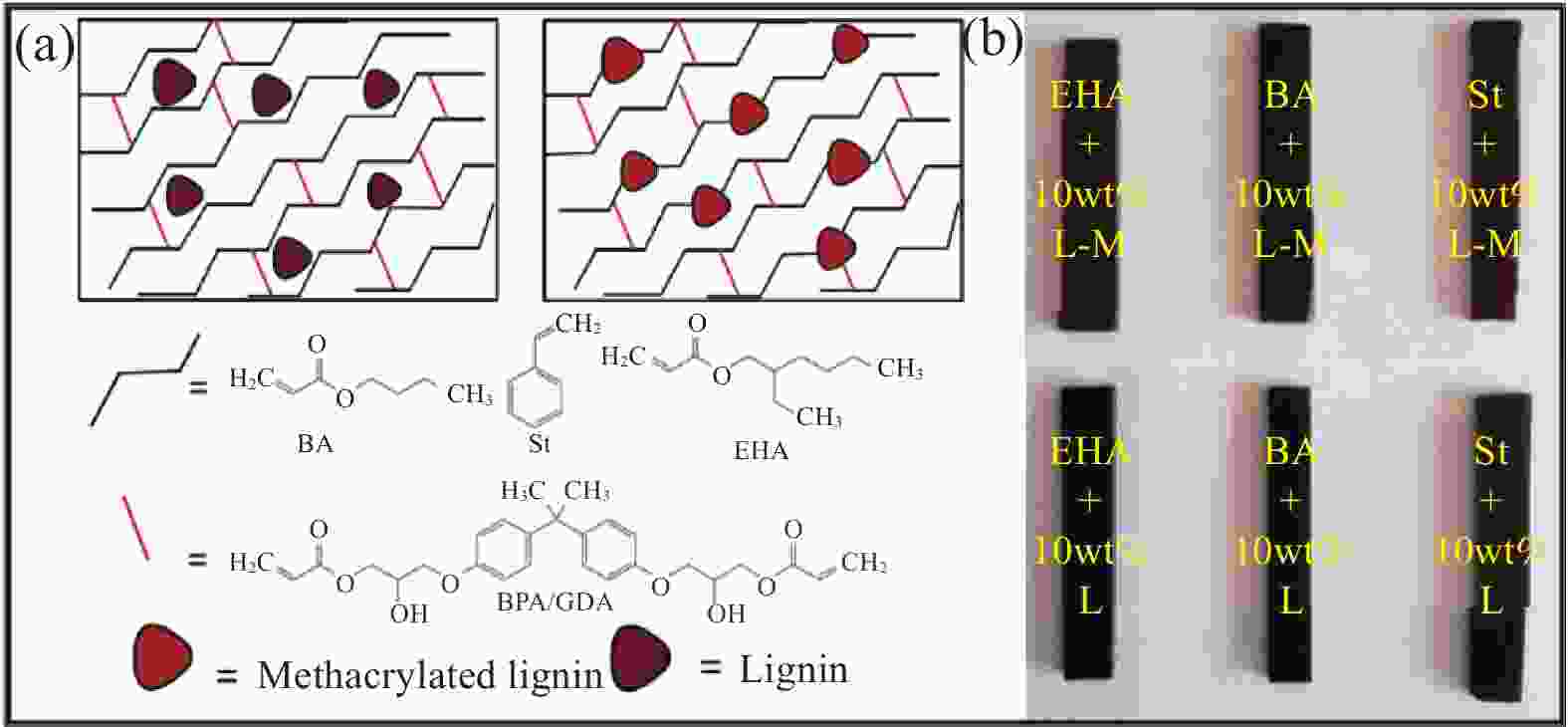

图 6 (a) 以双酚 A 甘油酯 (甘油/苯酚) 二丙烯酸酯 (BPA/GDA) 为主要单体,以丙烯酸丁酯 (BA)、丙烯酸 2-乙基己酯 (EHA) 或苯乙烯 (St)为活性稀释剂制备木质素基复合材料示意图;(b) 通过UV固化工艺制备含木质素基聚合物的生物复合材料[39]

Figure 6. (a) Preparation schematic of lignin based composite with bisphenol A glycerolate (1 glycerol/phenol) diacrylate (BPA/GDA) as the main monomer, with butyl acrylate (BA), 2-ethylhexyl acrylate (EHA) or styrene (St) as the active diluents; (b) Lignin-containing polymer biocomposites obtained by a UV curing process[39]

L-M—Lignin modified with methacryloyl chloride; L—Unmodified lignin

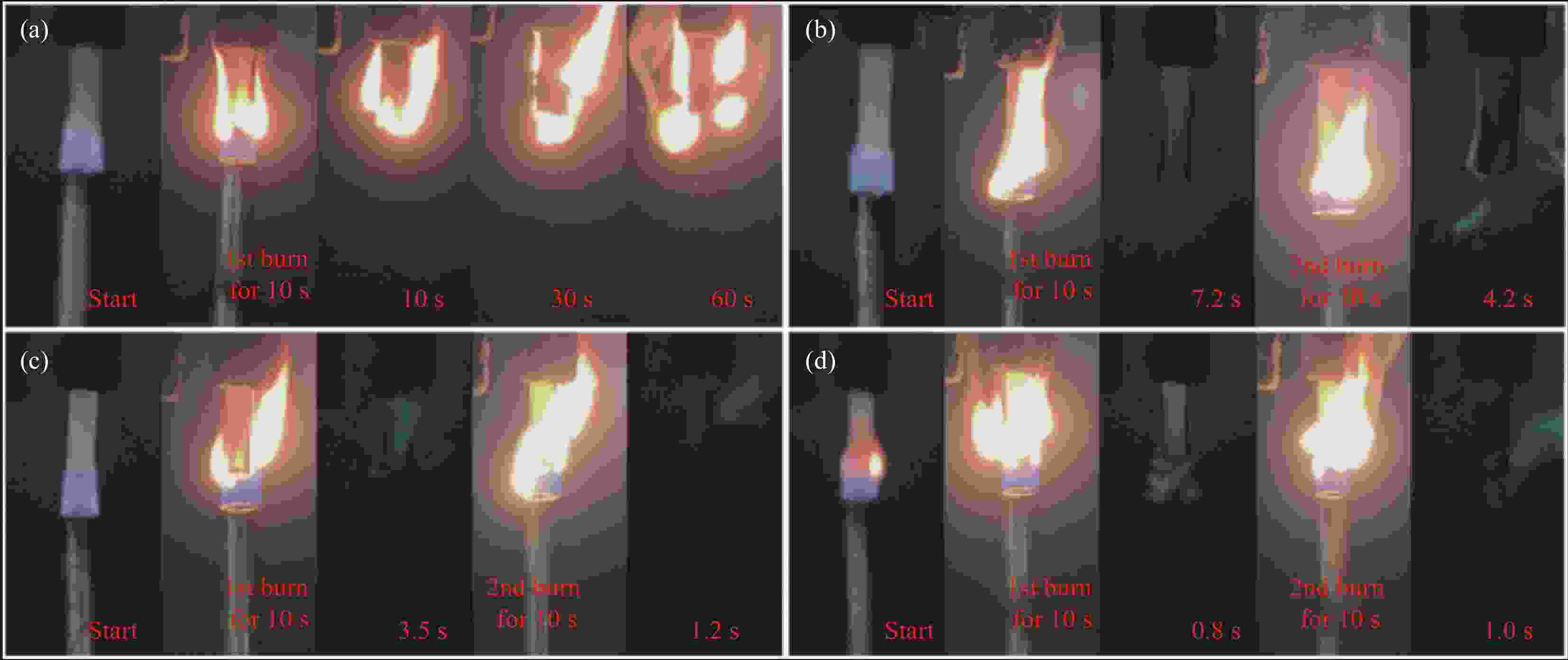

图 7 UL-94 测试用双酚 A 二缩水甘油醚 (DGEBA)/4,4-二氨基二苯甲烷 (DDM) (a)、B1 D9 (含有9,10-二氢-9-氧-10-磷酸-纳米-10-氧化物单元的生物基环氧单体 (DGEBDB)与 DGEBA 的质量比为1∶9,如下相似)/DDM (b)、B2 D8/DDM (c) 和B3 D7/DDM (d) 样品的数码照片[79]

Figure 7. Digital photographs for UL-94 test of different systems: (a) Diglycidyl ether of bisphenol A (DGEBA)/4,4-diaminodiphenylmethane (DDM); (b) B1 D9 (The mass ratio between the bio-based epoxy monomer containing 9, 10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide units (DGEBDB) and DGEBA was 1∶9, similar below)/DDM; (c) B2 D8/DDM; (d) B3 D7/DDM[79]

Category Function Content/wt% Photosensitive prepolymer Acrylate monomer, epoxy monomer, thiol-ene Act as the main material and determine the basic physical and

chemical properties of light-cured products50-90 Reactive diluent Free radical type, cationic type Adjust viscosity and participate in curing reactions 20-60 Photoinitiators Free radical photoinitiator,

cationic photoinitiatorAbsorb UV and initiate rapid polymerization of

photosensitive resin system0-10 Additives Defoamer Inhibit or eliminate air bubbles in the photosensitive system Polymerization inhibitor Improve the storage stability of photosensitive resin and extend

the service lifePigment Enrich the appearance and adjust the light curing speed

during 3D printing0-30 Filler Affects rheology and physical properties Dispersant Disperse the pigment filler uniformly in the system -

[1] PRAVEENA B A, LOKESH N, BURADI A, et al. A comprehensive review of emerging additive manufacturing (3D printing technology): Methods, materials, applications, challenges, trends and future potential[J]. Materials Today: Proceedings,2022,52(3):1309-1313. [2] SUTTON J, RAJAN K, HARPER D, et al. Lignin-containing photoactive resins for 3D printing by stereolithography[J]. ACS Applied Materials & Interfaces,2018,10(42):36456-36463. [3] TRUBY R L, LEWIS J A. Printing soft matter in three dimensions[J]. Nature,2016,540(7633):371-378. doi: 10.1038/nature21003 [4] HOLMBERG A L, NGUYEN N A, KARAVOLIAS M G, et al. Softwood lignin-based methacrylate polymers with tunable thermal and viscoelastic properties[J]. Macromolecules,2016,49(4):1286-1295. doi: 10.1021/acs.macromol.5b02316 [5] LIGON S, LISKA R, STAMPFL J, et al. Polymers for 3D printing and customized additive manufacturing[J]. Chemical Reviews,2017,117(15):10212-10290. doi: 10.1021/acs.chemrev.7b00074 [6] BASSETT A W, HONNIG A E, BREYTA C M, et al. Vanillin-based resin for additive manufacturing[J]. ACS Sustainable Chemistry and Engineering,2020,8(14):5626-5635. doi: 10.1021/acssuschemeng.0c00159 [7] MUELLER B. Additive manufacturing technologies-rapid prototyping to direct digital manufacturing[J]. Assembly Automation, 2012, 32(2): 59-77. [8] VAN DE PAS D J, TORR K M. Biobased epoxy resins from deconstructed native softwood lignin[J]. Biomacromolecules,2017,18(8):2640-2648. doi: 10.1021/acs.biomac.7b00767 [9] RINALDI R, JASTRZEBSKI R, CLOUGH M T, et al. Paving the way for lignin valorisation: Recent advances in bioengineering, biorefining and catalysis[J]. Angewandte Chemie International Edition,2016,55(29):8164-8215. doi: 10.1002/anie.201510351 [10] KAKUCHI R, TSUJI R, FUKASAWA K, et al. Polymers of lignin-sourced components as a facile chemical integrant for the passerini three-component reaction[J]. Polymer Journal,2021,53(4):523-531. doi: 10.1038/s41428-020-00448-w [11] HOLMBERG A L, RENO K H, NGUYEN N A, et al. Syringyl methacrylate, a hardwood lignin-based monomer for high-Tg polymeric materials[J]. ACS Macro Letters,2016,5(5):574-578. doi: 10.1021/acsmacrolett.6b00270 [12] LIU H, CHUNG H. Visible-light induced thiol-ene reaction on natural lignin[J]. ACS Sustainable Chemistry & Engineering,2017,5(10):9160-9168. doi: 10.1021/acssuschemeng.7b02065 [13] XU Y, YUAN L, WANG Z, et al. Lignin and soy oil-derived polymeric biocomposites by “grafting from” RAFT polymerization[J]. Green Chemistry,2016,18(18):4974-4981. doi: 10.1039/C6GC00859C [14] KOCH G. Raw material for pulp[M]. American: WILEY-VCH Verlag GmbH & Co., KGaA, 2006: 21-68. [15] RAJAN K, MANN J, ENGLISH E, et al. Sustainable hydrogels based on lignin-methacrylate copolymers with enhanced water retention and tunable material properties[J]. Biomacromolecules,2018,19(7):2665-2672. doi: 10.1021/acs.biomac.8b00282 [16] AHBABI K, ALRASHDI M, AHMED W K. The capabilities of 3D printing technology in the production of battery energy storage system[C]//6th International Conference on Renewable Energy: Generation and Applications (ICREGA). Al Ain: IEEE, 2021: 211-216. [17] LI H, ZHANG Y, TAI Y, et al. Flexible transparent electromagnetic interference shielding films with silver mesh fabricated using electric-field-driven microscale 3D printing[J]. Optics & Laser Technology,2022,148(28):107717-107725. [18] American Society for Materials and Testing. Standard terminology for additive manufacturing—Coordinate systems and test methodologies: ISO/ASTM 52921—2013[S]. West Conchhocken: ASTM, 2013. [19] GIBSON I, ROSEN D, STUCKER B. Additive manufacturing technologies[M]. US: Springer, 2015: 1-474. [20] ROCHA V G, SAIZ E, TIRICHENKO I S, et al. Direct ink writing advances in multi-material structures for a sustainable future[J]. Journal of Materials Chemistry A,2020,8(31):15646-15657. doi: 10.1039/D0TA04181E [21] MURPHY S V, ATALA A. 3D bioprinting of tissues and organs[J]. Nature Biotechnology,2014,32(8):773-785. doi: 10.1038/nbt.2958 [22] GROSS B C, ERKAL J L, LOCKWOOD S Y, et al. Evaluation of 3D printing and its potential impact on biotechnology and the chemical sciences[J]. Analytical Chemistry,2014,86(7):3240-3253. doi: 10.1021/ac403397r [23] MARKSTEDT K, MANTAS A, TOURNIER I, et al. 3D bioprinting human chondrocytes with nanocellulose-alginate bioink for cartilage tissue engineering applications[J]. Biomacromolecules,2015,16(5):1489-1496. doi: 10.1021/acs.biomac.5b00188 [24] HOCHLEITNER G, JÜNGST T, BROWN T D, et al. Additive manufacturing of scaffolds with sub-micron filaments via melt electrospinning writing[J]. Biofabrication,2015,7(3):035002. doi: 10.1088/1758-5090/7/3/035002 [25] WIMPENNY D I, BRYDEN B, PASHBY I R. Rapid laminated tooling[J]. Journal of Materials Processing Technology,2003,138(1-3):214-218. doi: 10.1016/S0924-0136(03)00074-8 [26] TIM H, DON C, MATHIEU V, et al. 3D printing cellulose hydrogels using laser induced thermal gelation[J]. Journal of Manufacturing & Materials Processing,2018,2(3):42-60. [27] YANG J, AN X, LIU L, et al. Cellulose, hemicellulose, lignin, and their derivatives as multi-components of bio-based feedstocks for 3D printing[J]. Carbohydrate Polymers,2020,250(92):116881. [28] HALLEY P J, GEORGE G A. Chemorheology of polymers: From fundamental principles to reactive processing[M]. Cambridge: Cambridge University Press, 2009: 1-443. [29] ROGERS D P. Lignin-derived thermosetting vinyl ester resins for high performance applications[D]. Southern New Jersey: Rowan University, 2015. [30] BAUER F, FLYUNT R, CZIHAL K, et al. UV curing of nanoparticle reinforced acrylates[J]. Nuclear Instruments and Methods in Physics Research Section B: Beam Interactions with Materials and Atoms,2007,265(1):87-91. [31] BAGHERI A, JIN J. Photopolymerization in 3D printing[J]. ACS Applied Polymer Materials,2019,1(4):593-611. doi: 10.1021/acsapm.8b00165 [32] OFFICE U. Environmental protection agency: National emissions standards for hazardous air pollutants: Reinforced plastic composites production[J]. Federal Register,2003,68:19375-19443. [33] TUCK C O, PÉREZ E, HORVÁTH I T, et al. Valorization of biomass: Deriving more value from waste[J]. Science,2012,337(6095):695-699. doi: 10.1126/science.1218930 [34] GRAICHEN F H M, GRIGSBY W J, HILL S J, et al. Yes, we can make money out of lignin and other bio-based resources[J]. Industrial Crops and Products,2017,106:74-85. doi: 10.1016/j.indcrop.2016.10.036 [35] ZHAO W, SIMMONS B, SINGH S, et al. From lignin association to nano-/micro-particle preparation: Extracting higher value of lignin[J]. Green Chemistry,2016,18(21):5693-5700. doi: 10.1039/C6GC01813K [36] TANASE-OPEDAL M, VÍCTOR E E, RODRÍGUEZ A, et al. Lignin: A biopolymer from forestry biomass for biocomposites and 3D printing[J]. Materials,2019,12(18):3006. doi: 10.3390/ma12183006 [37] BOERIU C G, BRAVO D, GOSSELINK R, et al. Characterisation of structure-dependent functional properties of lignin with infrared spectroscopy[J]. Industrial Crops and Products,2004,20(2):205-218. doi: 10.1016/j.indcrop.2004.04.022 [38] SHAO Y, CHAUSSY D, GROSSEAU P, et al. Use of microfibrillated cellulose/lignosulfonate blends as carbon precursors: Impact of hydrogel rheology on 3D printing[J]. Industrial & Engineering Chemistry Research,2015,54(43):10575-10582. [39] GOLISZEK M, PODKOŚCIELNA B, KLEPKA T, et al. Preparation, thermal, and mechanical characterization of UV-cured polymer biocomposites with lignin[J]. Polymers,2020,12(5):1159. doi: 10.3390/polym12051159 [40] LAURICHESSE S, AVÉROUS L. Chemical modification of lignins: Towards biobased polymers[J]. Progress in Polymer Science,2014,39(7):1266-1290. doi: 10.1016/j.progpolymsci.2013.11.004 [41] WANG K, FENG X, SUN R. Molecular characteristics of kraft-aq pulping lignin fractionated by sequential organic solvent extraction[J]. International Journal of Molecular Sciences,2010,11(8):2988-3001. doi: 10.3390/ijms11082988 [42] SUTTON J. Evaluation of lignin-containing photopolymers for use in additive manufacturing[D]. Knoxville: University of Tennessee, 2019. [43] YU Q, BAHI A, KO F. Influence of poly(ethylene oxide) (PEO) percent and lignin type on the properties of lignin/PEO blend filament[J]. Macromolecular Materials and Engineering,2015,300(10):1023-1032. doi: 10.1002/mame.201500045 [44] YANG J, LIU L, AN X, et al. Facile preparation of lignosulfonate induced silver nanoparticles for high efficient removal of organic contaminants in wastewater[J]. Industrial Crops and Products,2021,169(13):113644. [45] ETIN N S, ZMEN N. Use of organosolv lignin in phenol-formaldehyde resins for particleboard production: II. Particleboard production and properties[J]. International Journal of Adhesion and Adhesives,2002,22(6):481-486. doi: 10.1016/S0143-7496(02)00059-3 [46] LIU G, JIN C, HUO S, et al. Preparation and properties of novel bio-based epoxy resin thermosets from lignin oligomers and cardanol[J]. International Journal of Biological Macromolecules,2021,193:1400-1408. doi: 10.1016/j.ijbiomac.2021.10.203 [47] ZHOU N N, THILAKARATHNA W P D W, HE Q S, et al. A review: Depolymerization of lignin to generate high-value bio-products: Opportunities, challenges, and prospects[J]. Frontiers in Energy Research,2022,9:1-18. [48] 赵杰, 李伶, 沈涛, 等. 光固化3D打印中光敏树脂的研究进展[J]. 山东陶瓷, 2021, 44(5):15-19. doi: 10.3969/j.issn.1005-0639.2021.05.004ZHAO Jie, LI Ling, SHEN Tao, et al. Research progress of UV curable ceramic photosensitive resin for 3D printing[J]. Shandong Ceramics,2021,44(5):15-19(in Chinese). doi: 10.3969/j.issn.1005-0639.2021.05.004 [49] 李振, 张云波, 张鑫鑫, 等. 光敏树脂和光固化3D打印技术的发展及应用[J]. 理化检验-物理分册, 2016, 52(10):686-689, 712.LI Zhen, ZHANG Yunbo, ZHANG Xinxin, et al. Development and application of photosensitive resin and photo-curing 3D printing technology[J]. Physical Testing and Chemical Analysis (Part A: Physical Testing),2016,52(10):686-689, 712(in Chinese). [50] SASAKI I, KUSHI K, INUKAI K I. Liquid photosensitive resin composition containing carboxylated epoxy acrylates or methacrylates: US, 4789620[P]. 1988-12-06. [51] 刘岚, 陈用烈. 一种新型的光固化活性稀释剂—乙烯基醚[J]. 高分子通报, 1997(4):242-245.LIU Lan, CHEN Yonglie. Vinyl ether—A new type of reactive diluents for photocuring[J]. Chinese Polymer Bulletin,1997(4):242-245(in Chinese). [52] 王世崇, 朱雨薇, 吴瑶, 等. 光固化3D打印技术及光敏树脂的开发与应用[J]. 功能高分子学报, 2022, 35(1):19-35.WANG Shichong, ZHU Yuwei, WU Yao, et al. Development and applications of UV-curing 3D printing and photosensitive resin[J]. Journal of Functional Polymers,2022,35(1):19-35(in Chinese). [53] YAGCI Y, JOCKUSCH S, TURRO N. Photoinitiated polymerization: Advances, challenges, and opportunities[J]. Macromolecules,2010,43(15):6245-6260. doi: 10.1021/ma1007545 [54] 胡楠, 胡明明, 李志鑫, 等. 消泡剂的研究进展与展望[J]. 盐科学与化工, 2021, 50(3):10-16. doi: 10.3969/j.issn.2096-3408.2021.03.003HU Nan, HU Mingming, LI Zhixin, et al. Research progress and prospect of defoamer[J]. Journal of Salt Science and Chemical Industry,2021,50(3):10-16(in Chinese). doi: 10.3969/j.issn.2096-3408.2021.03.003 [55] 蒙嘉华, 彭小琴, 姚荣茂, 等. 络合剂和阻聚剂对双组分丙烯酸酯胶性能影响的研究[J]. 化学与粘合, 2021, 43(2):118-120, 142. doi: 10.3969/j.issn.1001-0017.2021.02.010MENG Jiahua, PENG Xiaoqin, YAO Rongmao, et al. Study on the effects of complexing agent and polymerization inhibitor on the properties of two-component acrylate adhesive[J]. Chemistry and Adhesion,2021,43(2):118-120, 142(in Chinese). doi: 10.3969/j.issn.1001-0017.2021.02.010 [56] 吴丽珍, 邓昌云, 傅兵, 等. 3D打印用光敏树脂的制备及改性研究进展[J]. 塑料科技, 2017, 45(7):112-119.WU Lizhen, DENG Changyun, FU Bing, et al. Progress on preparation and modification of photosensitive resin used in 3D printing[J]. Plastics Science and Technology,2017,45(7):112-119(in Chinese). [57] 何岷洪, 宋坤, 莫宏斌, 等. 3D打印光敏树脂的研究进展[J]. 功能高分子学报, 2015, 28(1):102-108.HE Minhong, SONG Kun, MO Hongbin, et al. Progress on photosensitive resins for 3D printing[J]. Journal of Functional Polymers,2015,28(1):102-108(in Chinese). [58] PODGÓRSKI M, BECKA E, CLAUDINO M, et al. Ester-free thiol-ene dental restoratives—Part A: Resin development[J]. Dental Materials,2015,31(11):1255-1262. doi: 10.1016/j.dental.2015.08.148 [59] 丁云雨. 3D打印用光敏树脂的制备及膨胀单体改性光敏树脂[D]. 青岛: 青岛科技大学, 2016.DING Yunyu. Preparation of photosensitive resin for 3D printing and modified photosensitive resin with expansion monomer[D]. Qingdao: Qingdao University of Science and Technology, 2016(in Chinese). [60] STANZIONE III J F, SADLER J M, LA SCALA J J, et al. Vanillin-based resin for use in composite applications[J]. Green Chemistry,2012,14(8):2346-2352. doi: 10.1039/c2gc35672d [61] DING R, DU Y, GONCALVES R B, et al. Sustainable near UV-curable acrylates based on natural phenolics for stereolithography 3D printing[J]. Polymer Chemistry,2019,10(9):1067-1077. doi: 10.1039/C8PY01652F [62] BASSETT A W, ROGERS D P, SADLER J M, et al. The effect of impurities in reactive diluents prepared from lignin model compounds on the properties of vinyl ester resins[J]. Journal of Applied Polymer Science,2016,133(45):43817. doi: 10.1002/app.43817 [63] ZHANG Y, LI Y, WANG L, et al. Synthesis and characterization of methacrylated eugenol as a sustainable reactive diluent for a maleinated acrylated epoxidized soybean oil resin[J]. ACS Sustainable Chemistry & Engineering,2017,5(10):8876-8883. [64] STANZIONE J F, SADLER J M, LA SCALA J J, et al. Lignin model compounds as bio-based reactive diluents for liquid molding resins[J]. ChemSusChem, 2012, 5(7): 1291-1297. [65] JAGTAP A R, MORE A. Developments in reactive diluents: A review[J]. Polymer Bulletin,2021,44:1-42. [66] YU A Z, SERUM E M, RENNER A C, et al. Renewable reactive diluents as practical styrene replacements in biobased vinyl ester thermosets[J]. ACS Sustainable Chemistry & Engineering,2018,6(10):12586-12592. [67] LIU Y, HUANG X, HAN K, et al. High-performance lignin-based water-soluble macromolecular photoinitiator for the fabrication of hybrid hydrogel[J]. ACS Sustainable Che-mistry & Engineering,2019,7(4):4004-4011. [68] LANZALUNGA O, BIETTI M. Photo- and radiation chemical induced degradation of lignin model compounds[J]. Journal of Photochemistry and Photobiology B: Biology,2000,56(2):85-108. [69] FENG X, YANG Z, CHMELY S, et al. Lignin-coated cellulose nanocrystal filled methacrylate composites prepared via 3D stereolithography printing: Mechanical reinforcement and thermal stabilization[J]. Carbohydrate Polymers,2017,169:272-281. doi: 10.1016/j.carbpol.2017.04.001 [70] ZHANG X, KECK S, QI Y, et al. Study on modified dealkaline lignin as visible light macromolecular photoinitiator for 3D printing[J]. ACS Sustainable Chemistry & Engineering,2020,8(29):10969-10970. [71] QI Y, ZHANG X, HUANG X, et al. High-efficient lignin-based polymerizable macromolecular photoinitiator with UV-blocking property for visible light polymerization[J]. International Journal of Biological Macromolecules,2022,204:234-244. doi: 10.1016/j.ijbiomac.2022.01.199 [72] SAMMONS R, HARPER D, LABBÉ N, et al. Characterization of organosolv lignins using thermal and FT-IR spectroscopic analysis[J]. Bioresources,2013,8(2):2752-2767. [73] ZHANG S, LI M, HAO N, et al. Stereolithography 3D printing of lignin-reinforced composites with enhanced mechanical properties[J]. ACS Omega,2019,4(23):20197-20204. doi: 10.1021/acsomega.9b02455 [74] IBRAHIM F, MOHAN D, SAJAB M S, et al. Evaluation of the compatibility of organosolv lignin-graphene nanoplatelets with photo-curable polyurethane in stereolithography 3D printing[J]. Polymers,2019,11(10):1544. doi: 10.3390/polym11101544 [75] BHONGADE P A L, BORKAR D S P. Use of lignin as a compatibiliser in sunn hemp fibre reinforced epoxy composites[J]. International Journal of Advanced Engineering Research and Science,2016,3(10):36-39. doi: 10.22161/ijaers/3.10.8 [76] SUN J, WANG C, YEO J, et al. Lignin epoxy composites: Preparation, morphology, and mechanical properties[J]. Macromolecular Materials and Engineering,2016,301(3):328-336. doi: 10.1002/mame.201500310 [77] FACHE M, DARROMAN E, BESSE V. Vanillin, a promising biobased building-block for monomer synthesis[J]. Green Chemistry,2014,16(4):1987-1998. doi: 10.1039/C3GC42613K [78] NIKAFSHAR S, ZABIHI O, HAMIDI S, et al. A renewable bio-based epoxy resin with improved mechanical performance that can compete with DGEBA[J]. RSC Advances,2017,7(14):8694-8701. doi: 10.1039/C6RA27283E [79] LIU J, DAI J, WANG S, et al. Facile synthesis of bio-based reactive flame retardant from vanillin and guaiacol for epoxy resin[J]. Composites Part B: Engineering,2020,190:107926. doi: 10.1016/j.compositesb.2020.107926 [80] WANG S, MA S, XU C, et al. Vanillin-derived high-performance flame retardant epoxy resins: facile synthesis and properties[J]. Macromolecules,2017,50(5):1892-1901. doi: 10.1021/acs.macromol.7b00097 [81] RALPH J, LUNDQUIST K, BRUNOW G, et al. Lignins: Natural polymers from oxidative coupling of 4-hydroxyphenyl- propanoids[J]. Phytochemistry Reviews,2004,3(1):29-60. [82] ASMADI M, KAWAMOTO H, SAKA S. Gas- and solid/liquid-phase reactions during pyrolysis of softwood and hardwood lignins[J]. Journal of Analytical and Applied Pyrolysis,2011,92(2):417-425. doi: 10.1016/j.jaap.2011.08.003 [83] BURANOV A U, MAZZA G. Lignin in straw of herbaceous crops[J]. Industrial Crops and Products,2008,28(3):237-259. doi: 10.1016/j.indcrop.2008.03.008 [84] RAGAUSKAS A J, BECKHAM G T, BIDDY M J, et al. Lignin valorization: Improving lignin processing in the biorefinery[J]. Science,2014,344(6185):1246843. doi: 10.1126/science.1246843 [85] 李航. 有机溶剂木质素的结构和热解特性研究[D]. 北京: 华北电力大学, 2021.LI Hang. Research on structure and pyrolytic characteristics of organosolv lignin[D]. Beijing: North China Electric Power University, 2021(in Chinese). [86] YAO L, LU Y C, HU H Q, et al. Structural characterization of lignin and its degradation products with spectroscopic methods[J]. Journal of Spectroscopy,2017,2017:1-15. doi: 10.1155/2017/8951658 -

下载:

下载: