Fabrication and properties of lignin-reinforced self-healing polyurea elastomer

-

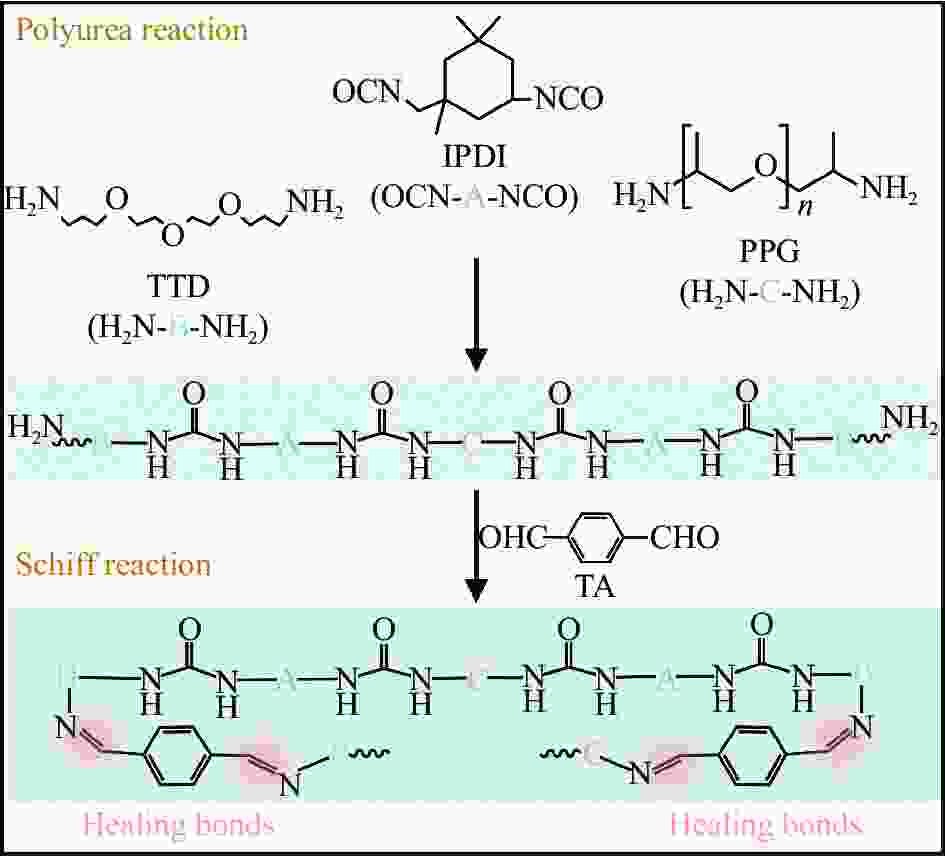

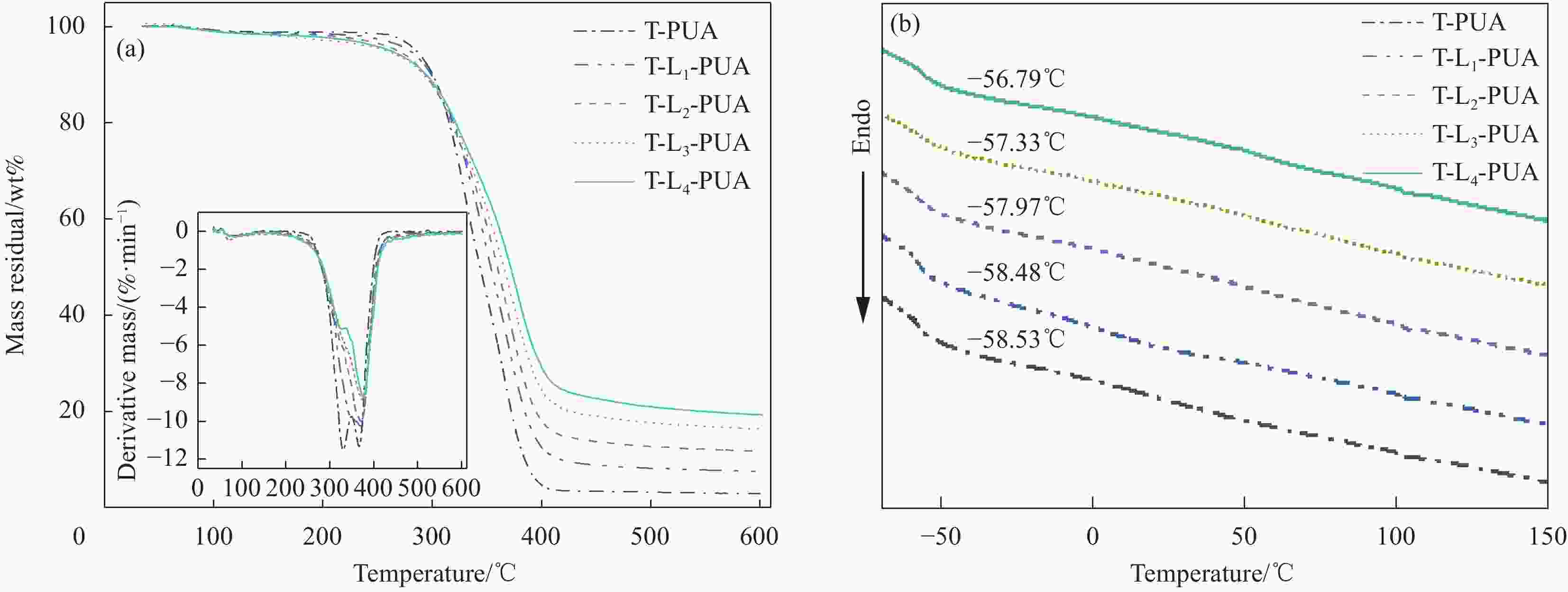

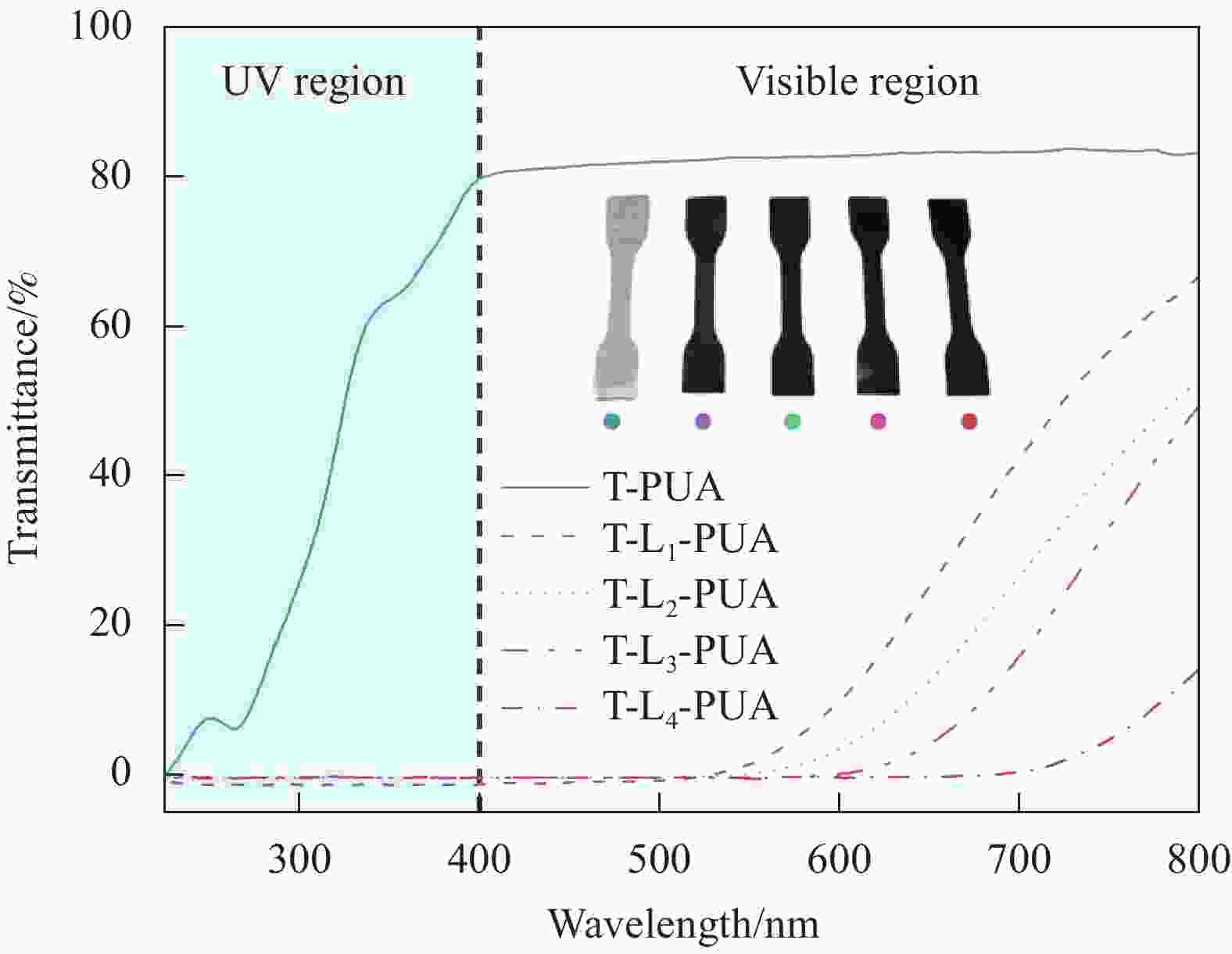

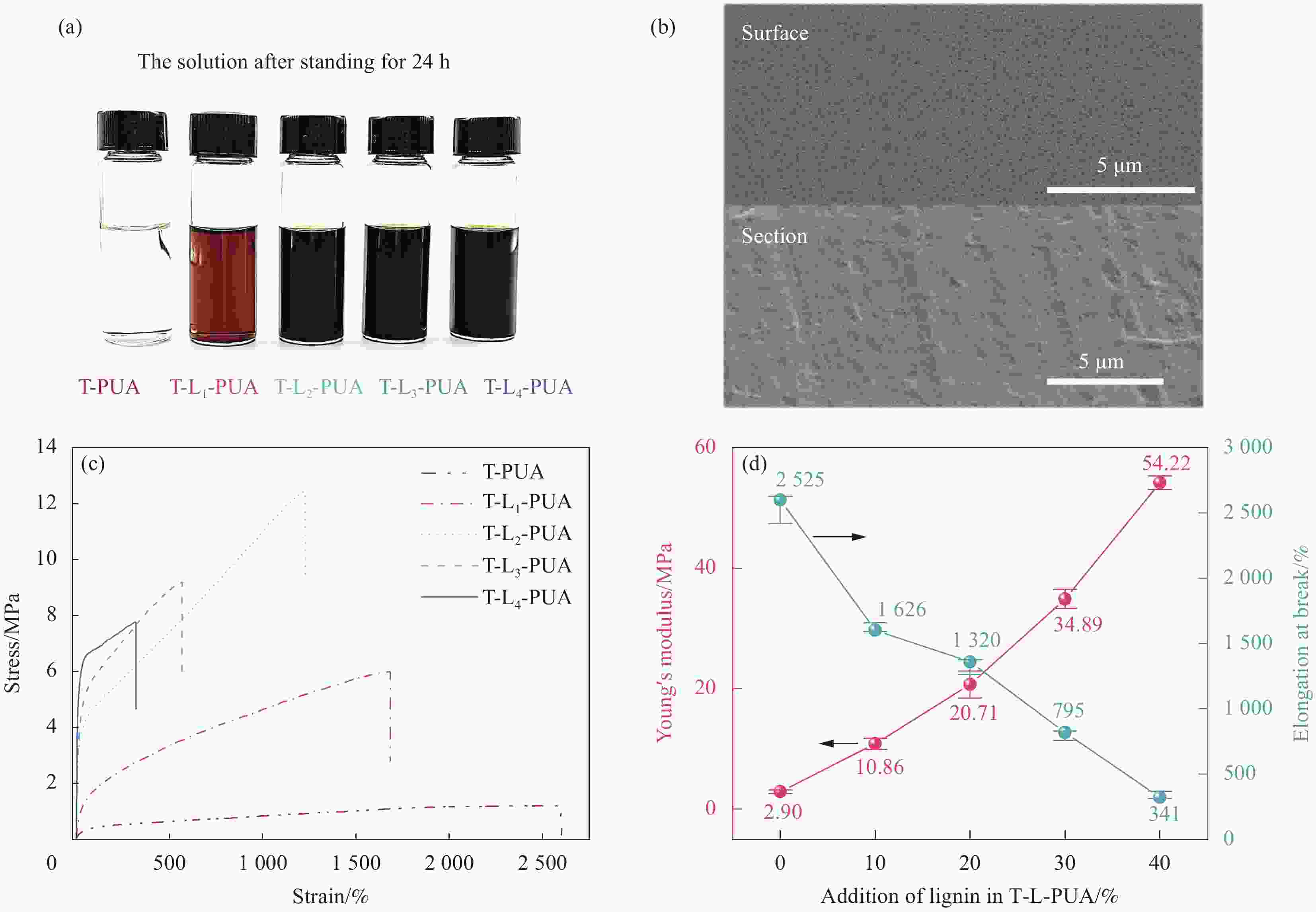

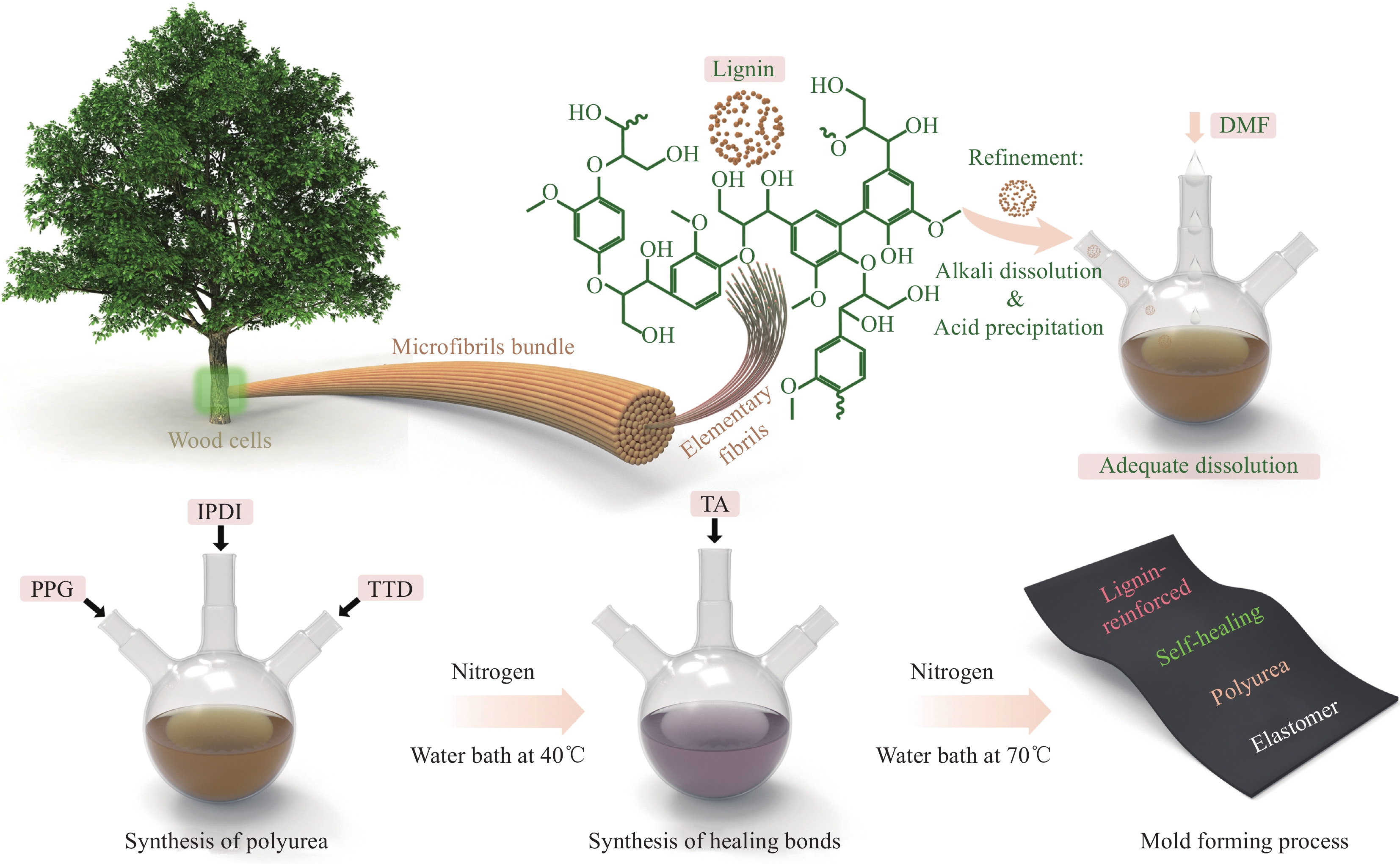

摘要: 制备具有良好力学性能和室温下高效自修复性的高分子材料一直是一项艰难挑战。本文采用天然芳香基木质素作为增强相,通过两步法(聚脲反应及席夫碱反应)制备了一种木质素增强的自修复聚脲弹性体(T-L-PUA)。探讨了木质素添加量对T-L-PUA的热性能、紫外线(UV)阻隔性能及力学性能的影响并分析了其基于动态可逆亚胺键(C=N)的自修复特性及可回收性。结果表明:T-L-PUA的热稳定性随木质素比例增加有明显提升,其中残碳量较未加木质素样品(T-PUA)最多提升了16.6%。T-L-PUA在UV区(280~400 nm)的低透过率有助其实现UV阻隔功能。与T-PUA的平均透过率(41.6%)相比,所有T-L-PUA的平均透过率均在0.2%左右。木质素添加量为20%时力学性能最佳,相应T-L-PUA拉伸强度为12.44 MPa,较纯自修复聚脲弹性体提升了937%。T-L-PUA具有良好的自修复性,室温下修复48 h,T-L-PUA的拉伸强度及断裂伸长率的恢复效率分别在91%和92%以上。此外,T-L-PUA还可以通过热压回收和溶剂回收,重塑后力学性能基本保持不变。Abstract: The preparation of polymeric materials with good mechanical properties and efficient self-healing properties at room temperature has been a difficult challenge. Herein, a lignin-reinforced self-healing polyurea elastomer (T-L-PUA) was prepared by a two-step process (polyurea reaction and Schiff base reaction) using natural aromatic-based lignin as the reinforcing phase. The effects of lignin addition on the thermal, UV-blocking and mechanical properties of T-L-PUA were investigated and the self-healing property and recyclability based on dynamic reversible imine bonding (C=N) of T-L-PUA were analyzed. The results show that the thermal stability of T-L-PUA is significantly enhanced with the increase of lignin ratio, where the maximum increase of residual carbon is 16.6% compared with the sample without lignin. The low transmittance of T-L-PUA in the UV region (280-400 nm) helps to realize the UV-blocking function. Compared with the average transmittance of self-healing polyurea composite elastomer (T-PUA) (41.6%), the average transmittance of all T-L-PUAs is around 0.2%. The best mechanical property appears at 20% of lignin addition, and the corresponding tensile strength of T-L-PUA is 12.44 MPa, which is 937% higher than that of pure polyurea elastomer. T-L-PUA exhibits good self-healing properties. When T-L-PUA is repaired at room temperature for 48 h, the recovery efficiencies of tensile strength and elongation at break is above 91% and 92%, respectively. In addition, the T-L-PUA can also be recovered by the hot-pressing and solvent dissolution processes, and the mechanical properties remain largely unchanged after remolding.

-

Key words:

- lignin /

- polyurea elastomer /

- self-healing property /

- imine bond /

- composites

-

图 6 (a) T-PUA及T-L-PUA溶液的照片;(b) T-L2-PUA表面及截面的SEM图像;T-PUA及不同木质素含量T-L-PUA的拉伸应力-应变曲线(c)和杨氏模量及断裂伸长率(d)

Figure 6. (a) Pictures of the solutions of T-PUA and T-L-PUA; (b) SEM images of T-L2-PUA surface and section; Stress-strain curves (c), Young's modulus and elongation at break (d) of T-PUA and T-L-PUA with different lignin contents

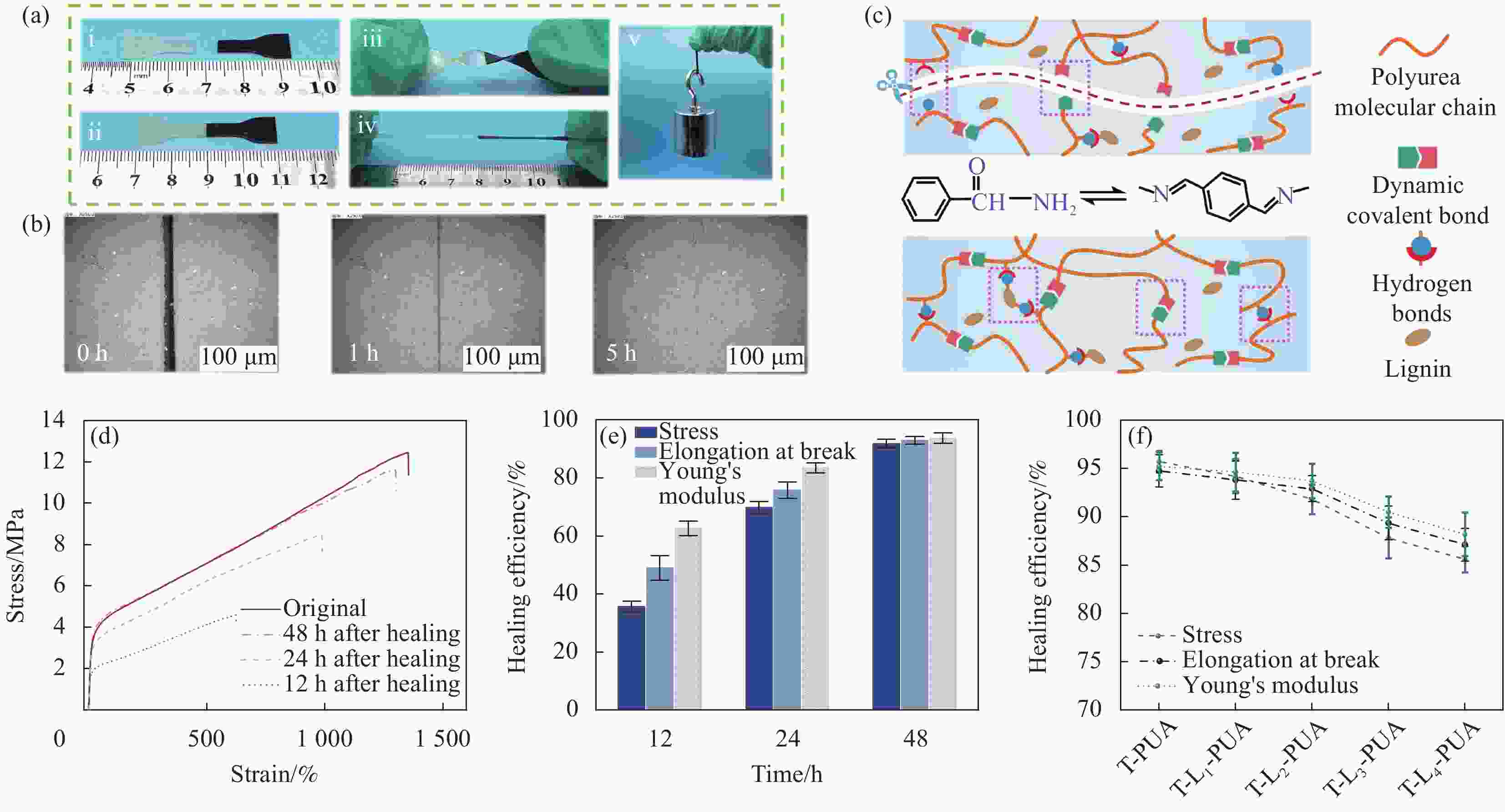

图 7 (a) T-L2-PUA自修复试验过程的照片;(b) 修复0 h、1 h、5 h的T-L2-PUA表面超景深光学图像;(c) T-L-PUA的自修复机制示意图;修复12 h、24 h、48 h的T-L2-PUA拉伸应力-应变曲线(d)及恢复效率(e);(f) 不同木质素含量T-L-PUA修复48 h后的恢复效率

Figure 7. (a) Pictures of the self-healing test process of T-L-PUA; (b) Super depth-of-field optical images of surface of T-L2-PUA repaired for 0 h, 1 h and 5 h; (c) Schematic diagram of the self-healing mechanism of T-L-PUA; Tensile stress-strain curves (d) and recovery efficiencies (e) of T-L2-PUA repaired for 12 h, 24 h and 48 h; (f) Recovery efficiency of T-L-PUA with different lignin contents after 48 h healing

图 8 (a) T-L2-PUA热压回收前后的照片;(b) 热压循环回收后的T-L2-PUA的拉伸应力-应变曲线;(c) T-L2-PUA溶剂回收工艺;(d) 溶剂循环回收后的T-L2-PUA的拉伸应力-应变曲线

Figure 8. (a) Photographs of T-L2-PUA before and after hot-press recycling; (b) Tensile stress-strain curves of T-L2-PUA after hot-pressing cycle recovery; (c) Solvent recovery process of T-L2-PUA; (d) Tensile stress-strain curves of T-L2-PUA after solvent cycle recovery

表 1 T-L-PUA的样品命名

Table 1. Sample naming of T-L-PUA

Sample Mass ratio lignin∶(IPDI, PPG, TTD) T-L1-PUA 0.1∶1 T-L2-PUA 0.2∶1 T-L3-PUA 0.3∶1 T-L4-PUA 0.4∶1 表 2 T-PUA及不同木质素含量T-L-PUA的热性能结果

Table 2. Thermal properties of T-PUA and T-L-PUA with different lignin contents

Sample T5%/℃ T50%/℃ Tmax/℃ Rmax/(%·min−1) Ch/% T-PUA 285.5 343.8 366.4 11.300 2.800 T-L1-PUA 279.8 353.7 369.1 10.200 7.420 T-L2-PUA 268.9 359.7 372.1 10.000 11.630 T-L3-PUA 262.2 364.2 373.6 8.850 16.770 T-L4-PUA 261.6 369.5 376.0 8.710 19.430 Notes: T5% and T50%—Temperature corresponding to mass loss of 5% and 50%; Tmax—Temperature at the maximum rate of mass loss; Rmax—Maximum mass loss rate; Ch—Residual mass fraction. -

[1] SANTANA J S, CARDOSO E S, TRIBONI E R, et al. Polyureas versatile polymers for new academic and technological applications[J]. Polymers,2021,13(24):4393. doi: 10.3390/polym13244393 [2] ZHANG R, HUANG W B, LYU P, et al. Polyurea for blast and impact protection: A review[J]. Polymers,2022,14(13):2670. doi: 10.3390/polym14132670 [3] SHOJAEI B, NAJAFI M, YAZDANBAKHSH A, et al. A review on the applications of polyurea in the construction industry[J]. Polymers for Advanced Technologies,2021,32(8):2797-2812. doi: 10.1002/pat.5277 [4] WANG Z H, SCHERES L, XIA H S, et al. Developments and challenges in self-healing antifouling materials[J]. Advanced Functional Materials,2020,30(26):1908098. doi: 10.1002/adfm.201908098 [5] LI Z L, YU R, GUO B L. Shape-memory and self-healing polymers based on dynamic covalent bonds and dynamic noncovalent interactions: Synthesis, mechanism, and application[J]. ACS Applied Bio Materials,2021,4(8):5926-5943. doi: 10.1021/acsabm.1c00606 [6] 周威明, 丁春香, 潘明珠. 基于动态共价交联网络自修复涂层的研究进展[J]. 复合材料学报, 2023, 40(3):1381-1394. doi: 10.13801/j.cnki.fhclxb.20220424.002ZHOU Weiming, DING Chunxiang, PAN Mingzhu. Research progress of self-healing coatings based on dynamic covalent crosslinking[J]. Acta Materiae Compositae Sinica,2023,40(3):1381-1394(in Chinese). doi: 10.13801/j.cnki.fhclxb.20220424.002 [7] LI T, XIE Z, XU J, et al. Design of a self-healing cross-linked polyurea with dynamic cross-links based on disulfide bonds and hydrogen bonding[J]. European Polymer Journal,2018,107:249-257. doi: 10.1016/j.eurpolymj.2018.08.005 [8] BAO C Y, JIANG Y J, ZHANG H Y, et al. Room-temperature self-healing and recyclable tough polymer composites using nitrogen-coordinated boroxines[J]. Advanced Functional Materials,2018,28(23):1800560. doi: 10.1002/adfm.201800560 [9] WEI Z, WANG Y, FU X, et al. Recyclable and reprocessable thermosetting polyurea with high performance based on Diels-Alder dynamic covalent crosslinking[J]. Macromolecular Research,2021,29(8):562-568. doi: 10.1007/s13233-021-9064-x [10] LI Y H, LI W J, SUN A L, et al. A self-reinforcing and self-healing elastomer with high strength, unprecedented toughness and room-temperature reparability[J]. Materials Horizons,2021,8(1):267-275. doi: 10.1039/D0MH01447H [11] LI C H, ZUO J L. Self-healing polymers based on coordination bonds[J]. Advanced Materials,2020,32(27):1903762. [12] BURATTINI S, COLQUHOUN H M, FOX J D, et al. A self-repairing, supramolecular polymer system: Healability as a consequence of donor-acceptor π-π stacking interactions[J]. Chemical Communications,2009(44):6717-6719. doi: 10.1039/b910648k [13] GAN M J, NIU Y Q, QU X J, et al. Lignin to value-added chemicals and advanced materials: Extraction, degradation, and functionalization[J]. Green Chemistry,2022,24(20):7705-7750. doi: 10.1039/D2GC00092J [14] BALAKSHIN M Y, CAPANEMA E A, SULAEVA I, et al. New opportunities in the valorization of technical lignins[J]. ChemSusChem,2021,14(4):1016-1036. doi: 10.1002/cssc.202002553 [15] SUN R C. Lignin source and structural characterization[J]. ChemSusChem,2020,13(17):4385-4393. doi: 10.1002/cssc.202001324 [16] ZHANG X, LIU W F, LIU W Q, et al. High performance PVA/lignin nanocomposite films with excellent water vapor barrier and UV-shielding properties[J]. International Journal of Biological Macromolecules,2020,142:551-558. doi: 10.1016/j.ijbiomac.2019.09.129 [17] LI H, SUN J T, WANG C, et al. High modulus, strength, and toughness polyurethane elastomer based on unmodified lignin[J]. ACS Sustainable Chemistry & Engineering,2017,5(9):7942-7949. [18] 中国国家标准化管理委员会. 硫化橡胶或热塑性橡胶拉伸应力应变性能的测定: GB/T 528—2009[S]. 北京: 中国标准出版社, 2009.Standardization Administration of the People's Republic of China. Rubber, vulcanized or thermoplastic—Determination of tensile stress-strain properties: GB/T 528—2009[S]. Beijing: China Standards Press, 2009(in Chinese). [19] WU P X, CHENG H Y, WANG Y, et al. New kind of thermoplastic polyurea elastomers synthesized from CO2 and with self-healing properties[J]. ACS Sustainable Chemistry & Engineering,2020,8(33):12677-12685. [20] SHI Z, KANG J, ZHANG L. Water-enabled room-temperature self-healing and recyclable polyurea materials with super-strong strength, toughness, and large stretchability[J]. ACS Applied Materials & Interfaces,2020,12(20):23484-23493. [21] CHEN T, FANG L, LI X, et al. Self-healing polymer coatings of polyurea-urethane/epoxy blends with reversible and dynamic bonds[J]. Progress in Organic Coatings,2020,147:105876. doi: 10.1016/j.porgcoat.2020.105876 [22] ZHANG S, QIN B, XU J F, et al. Multi-recyclable shape memory supramolecular polyurea with long cycle life and superior stability[J]. ACS Materials Letters,2021,3(4):331-336. doi: 10.1021/acsmaterialslett.1c00053 [23] 王娜, 李炳奇, 谢贵堂, 等. PPG/PTMG基单组分聚脲的制备及性能研究[J]. 化工新型材料, 2020, 48(10):143-145, 150. doi: 10.19817/j.cnki.issn1006-3536.20200805.098WANG Na, LI Bingqi, XIE Guitang, et al. Preparation and properties of PPG/PTMG based one-component polyurea[J]. New Chemical Materials,2020,48(10):143-145, 150(in Chinese). doi: 10.19817/j.cnki.issn1006-3536.20200805.098 [24] 程家骥, 王旭, 王浩东. 聚脲材料包覆可膨胀石墨微胶囊阻燃天然橡胶[J]. 复合材料学报, 2021, 38(1):232-238. doi: 10.13801/j.cnki.fhclxb.20200513.002CHENG Jiaji, WANG Xu, WANG Haodong. Expandable graphite microencapsulated with polyurea shell flame retardant natural rubber[J]. Acta Materiae Compositae Sinica,2021,38(1):232-238(in Chinese). doi: 10.13801/j.cnki.fhclxb.20200513.002 [25] 胡秀英, 毛冲冲, 贺畅, 等. 聚席夫碱/碳纳米管复合材料的制备及储锂性能[J]. 材料工程, 2021, 49(12):139-146. doi: 10.11868/j.issn.1001-4381.2021.000275HU Xiuying, MAO Chongchong, HE Chang, et al. Preparation and lithium storage properties of poly (Schiff base)/carbon nanotubes composites[J]. Journal of Materials Engineering,2021,49(12):139-146(in Chinese). doi: 10.11868/j.issn.1001-4381.2021.000275 [26] 郭蒙, 孙晓日, 张运臣, 等. 3-醛基水杨酸及其Schiff碱的合成与表征[J]. 潍坊学院学报, 2011, 11(2):83-86, 133. doi: 10.3969/j.issn.1671-4288.2011.02.021GUO Meng, SUN Xiaori, ZHANG Yunchen, et al. Synthesis and characterization of 3-formylsalicylic acid and its Schiff base[J]. Journal of Weifang University,2011,11(2):83-86, 133(in Chinese). doi: 10.3969/j.issn.1671-4288.2011.02.021 [27] 孙自才, 魏峥, 魏可镁. 高密度自由醛基聚合物粉体材料的制备与应用[J]. 高等学校化学学报, 2008, 29(11):2218-2222. doi: 10.3321/j.issn:0251-0790.2008.11.020SUN Zicai, WEI Zheng, WEI Kemei. Preparation and application of the polymer powder with high density of free aldehyde linkers[J]. Chemical Journal of Chinese Universities,2008,29(11):2218-2222(in Chinese). doi: 10.3321/j.issn:0251-0790.2008.11.020 [28] HUANG S Q, SU S Y, GAN H B, et al. Facile fabrication and characterization of highly stretchable lignin-based hydroxyethyl cellulose self-healing hydrogel[J]. Carbohydrate Polymers,2019,223:115080. doi: 10.1016/j.carbpol.2019.115080 [29] 来雅赟, 尚欣宇, 邸明伟, 等. 木质素基聚酯型聚氨酯胶黏剂的制备及表征[J]. 化学与黏合, 2018, 40(6):397-400.LAI Yayun, SHANG Xinyu, DI Mingwei, et al. Preparation and characterization of lignin based polyester polyurethane adhesive[J]. Chemistry and Adhesion,2018,40(6):397-400(in Chinese). [30] 李锋, 李逸青, 毛海立, 等. 低共熔溶剂分离油茶果壳木质素及其抗氧化活性和热解特性分析[J]. 食品工业科技, 2022, 43(24):261-267. doi: 10.13386/j.issn1002-0306.2022040112LI Feng, LI Yiqing, MAO Haili, et al. Antioxidant activity and pyrolysis properties of lignin extracted from Camellia oleifera shell by deep eutectic solvents(DES)[J]. Science and Technology of Food Industry,2022,43(24):261-267(in Chinese). doi: 10.13386/j.issn1002-0306.2022040112 [31] 况培培, 张一静, 陈莹, 等. 木质素复合氧化石墨烯导电水凝胶制备及性能[J]. 林业工程学报, 2022, 7(4):93-99.KUANG Peipei, ZHANG Yijing, CHEN Ying, et al. Preparation and properties of conductive hydrogels derived from lignin-graphene oxide composite[J]. Journal of Forestry Engineering,2022,7(4):93-99(in Chinese). [32] ZHANG T, CAI W, CHU F K, et al. Hydroxyapatite/polyurea nanocomposite: Preparation and multiple performance enhancements[J]. Composites Part A: Applied Science and Manufacturing,2020,128:105681. doi: 10.1016/j.compositesa.2019.105681 [33] ZHAO W, LIANG Z H, FENG Z H, et al. New kind of lignin/polyhydroxyurethane composite: Green synthesis, smart properties, promising applications, and good reprocessability and recyclability[J]. ACS Applied Materials & Interfaces,2021,13(24):28938-28948. [34] JIA Z, LU C X, ZHOU P C, et al. Preparation and characterization of high boiling solvent lignin-based polyurethane film with lignin as the only hydroxyl group provider[J]. RSC Advances,2015,5(66):53949-53955. doi: 10.1039/C5RA09477A [35] SILVA T F D, MENEZES F, MONTAGNA L S, et al. Effect of lignin as accelerator of the biodegradation process of poly(lactic acid)/lignin composites[J]. Materials Science and Engineering: B,2019,251:114441. doi: 10.1016/j.mseb.2019.114441 [36] SUN D, LV Z W, RAO J, et al. Effects of hydrothermal pretreatment on the dissolution and structural evolution of hemicelluloses and lignin: A review[J]. Carbohydrate Polymers,2022,281:119050. doi: 10.1016/j.carbpol.2021.119050 [37] SUN N, DI M W, LIU Y. Lignin-containing polyurethane elastomers with enhanced mechanical properties via hydrogen bond interactions[J]. International Journal of Biological Macromolecules,2021,184:1-8. doi: 10.1016/j.ijbiomac.2021.06.038 [38] POSOKNISTAKUL P, TANGKRAKUL C, CHAOSUANPHAE P, et al. Fabrication and characterization of lignin particles and their ultraviolet protection ability in PVA composite film[J]. ACS Omega,2020,5(33):20976-20982. doi: 10.1021/acsomega.0c02443 [39] LUO T, WANG C, JI X X, et al. Innovative production of lignin nanoparticles using deep eutectic solvents for multifunctional nanocomposites[J]. International Journal of Biological Macromolecules,2021,183:781-789. doi: 10.1016/j.ijbiomac.2021.05.005 [40] GOUVEIA J R, DE SOUSA JUNIOR R R, RIBEIRO A O, et al. Effect of soft segment molecular weight and NCO:OH ratio on thermomechanical properties of lignin-based thermoplastic polyurethane adhesive[J]. European Polymer Journal,2020,131:109690. doi: 10.1016/j.eurpolymj.2020.109690 [41] LI X J, JIANG C M, ZHAO F N, et al. Fully stretchable triboelectric nanogenerator for energy harvesting and self-powered sensing[J]. Nano Energy,2019,61:78-85. doi: 10.1016/j.nanoen.2019.04.025 [42] ZHANG Y, LIAO J J, FANG X C, et al. Renewable high-performance polyurethane bioplastics derived from lignin–poly(ε-caprolactone)[J]. ACS Sustainable Chemistry & Engineering,2017,5(5):4276-4284. [43] SHANG Z H, DING D L, WANG X, et al. High thermal conductivity of self-healing polydimethylsiloxane elastomer composites by the orientation of boron nitride nano sheets[J]. Polymers for Advanced Technologies,2021,32(12):4745-4754. doi: 10.1002/pat.5467 [44] MO P J, HU Z Y, MO Z J, et al. Fast self-healing and self-cleaning anticorrosion coating based on dynamic reversible imine and multiple hydrogen bonds[J]. ACS Applied Polymer Materials,2022,4(7):4709-4718. doi: 10.1021/acsapm.2c00294 [45] SUN N, WANG Z F, MA X, et al. Preparation and characterization of lignin-containing self-healing polyurethane elastomers with hydrogen and disulfide bonds[J]. Industrial Crops and Products,2021,174:114178. doi: 10.1016/j.indcrop.2021.114178 [46] MIN J B, ZHOU Z X, WANG H N, et al. Room temperature self-healing and recyclable conductive composites for flexible electronic devices based on imine reversible covalent bond[J]. Journal of Alloys and Compounds,2022,894:162433. doi: 10.1016/j.jallcom.2021.162433 -

下载:

下载: