Study on bamboo fiber and sodium alginate enhancing the degradability of polylactic acid

-

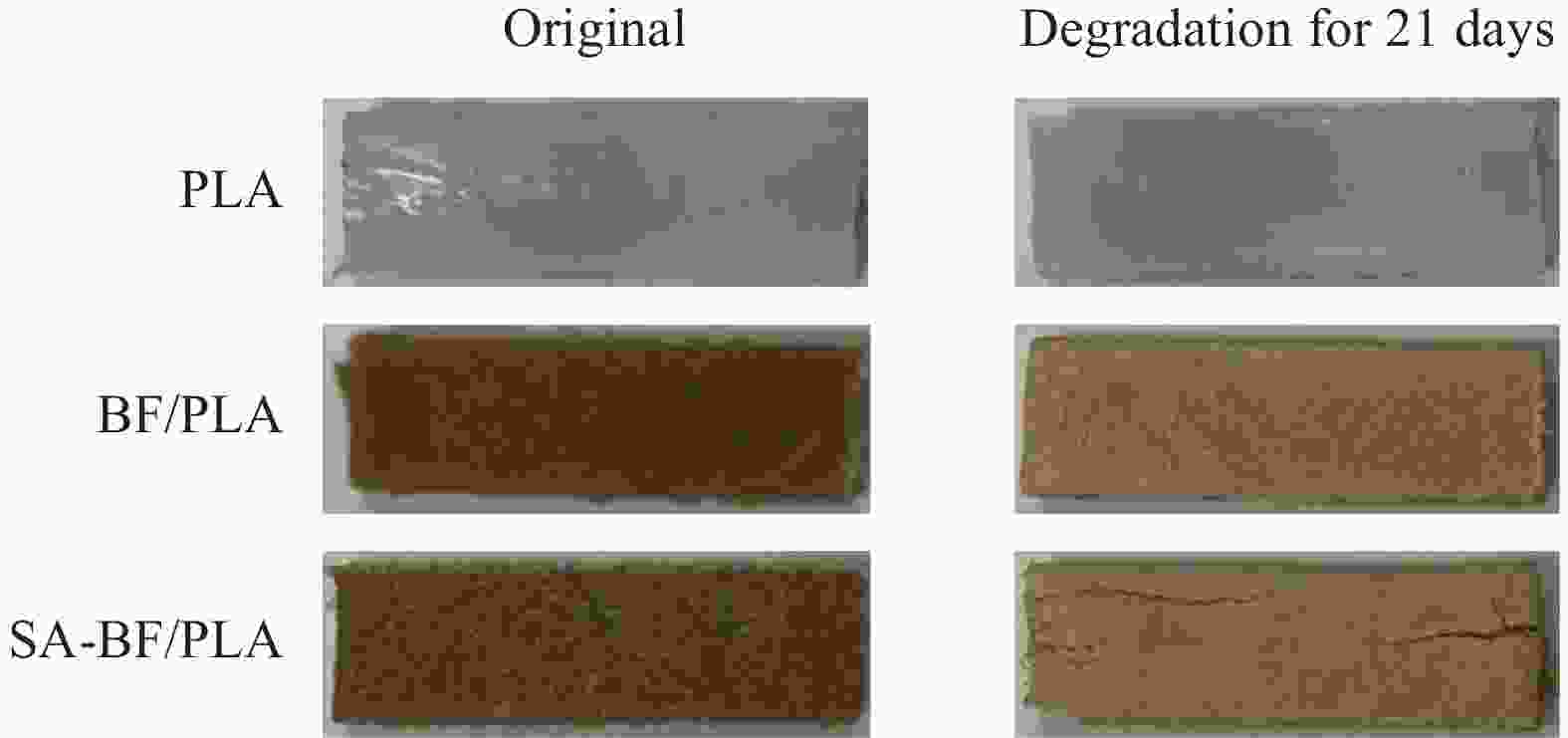

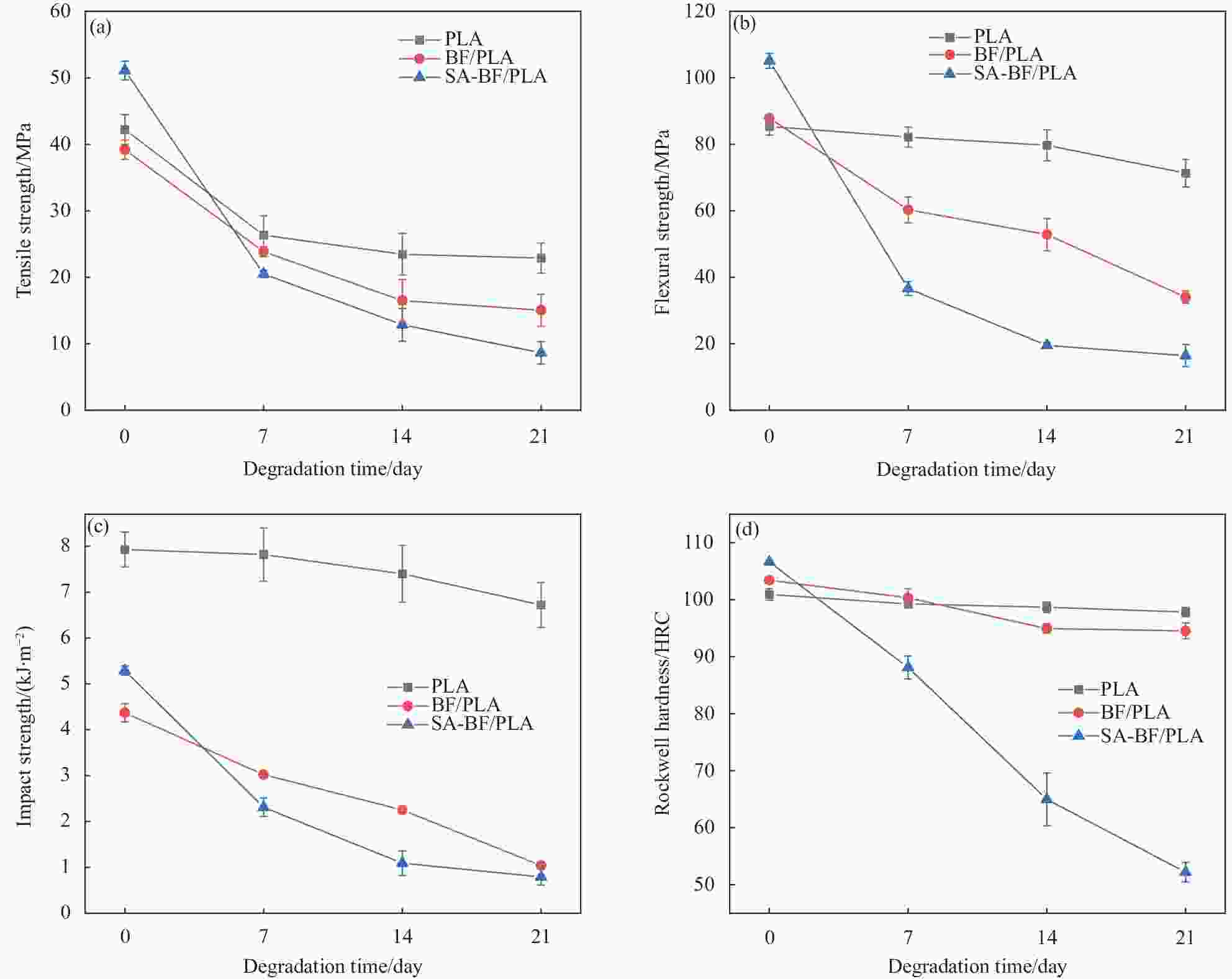

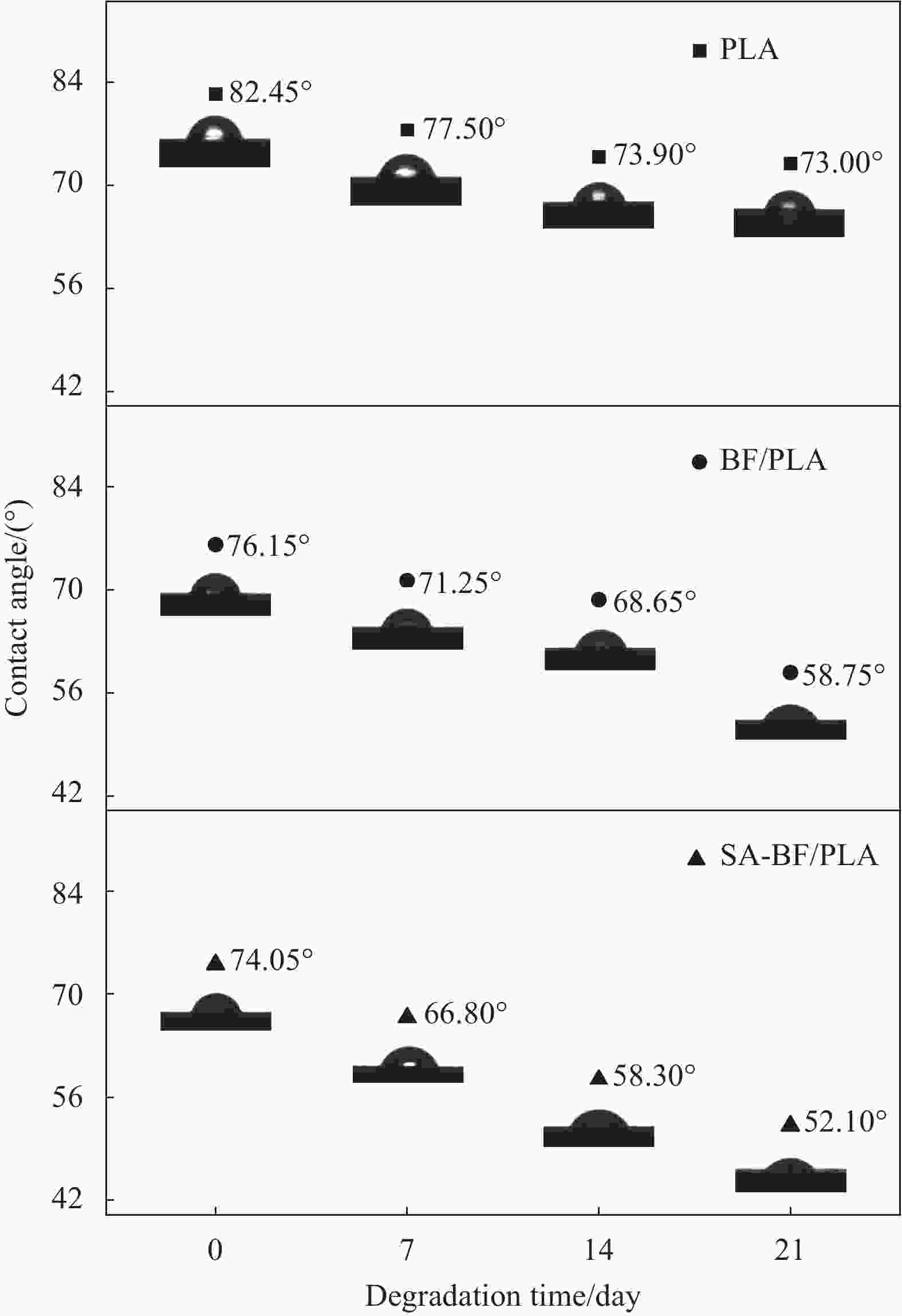

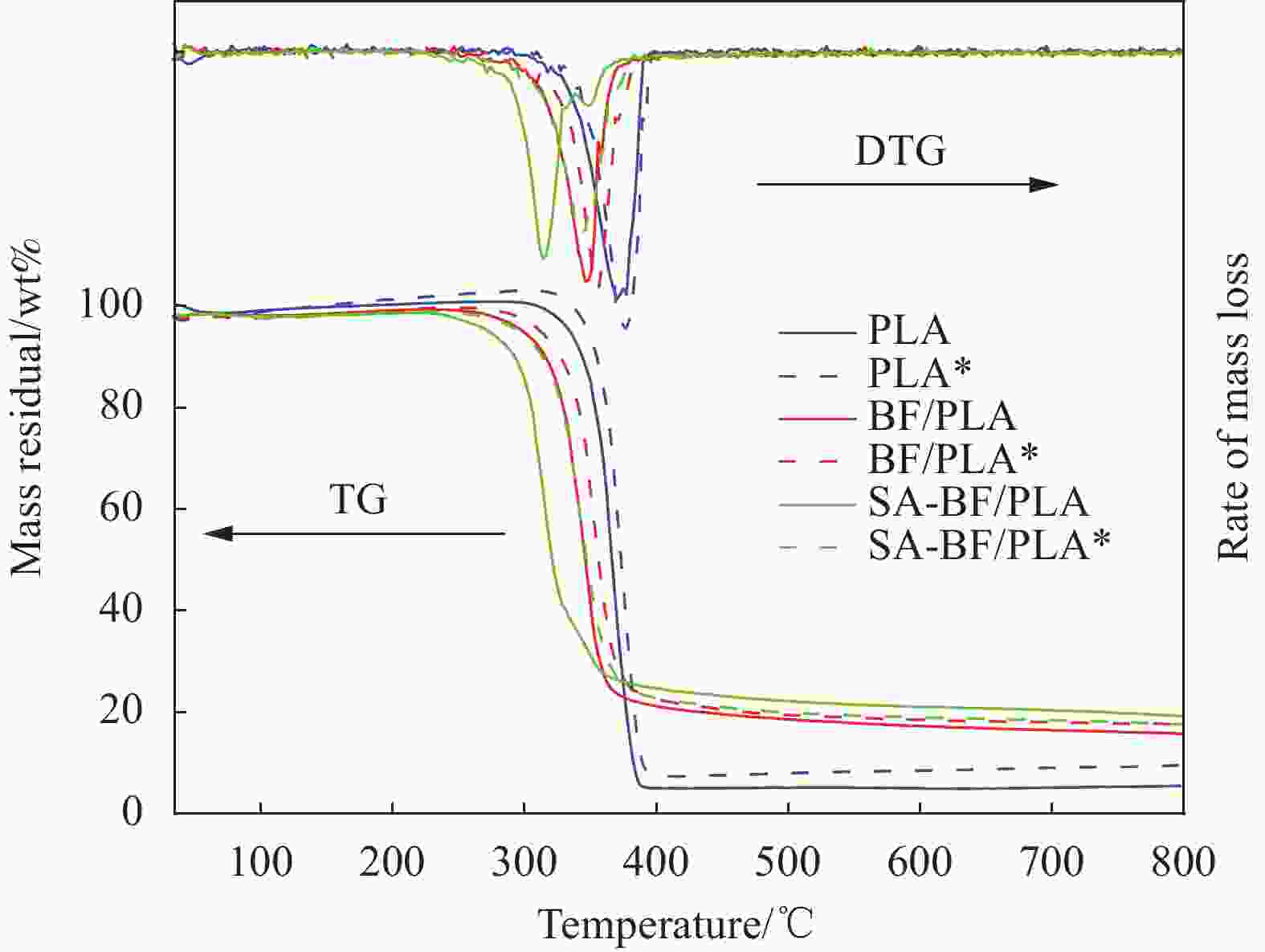

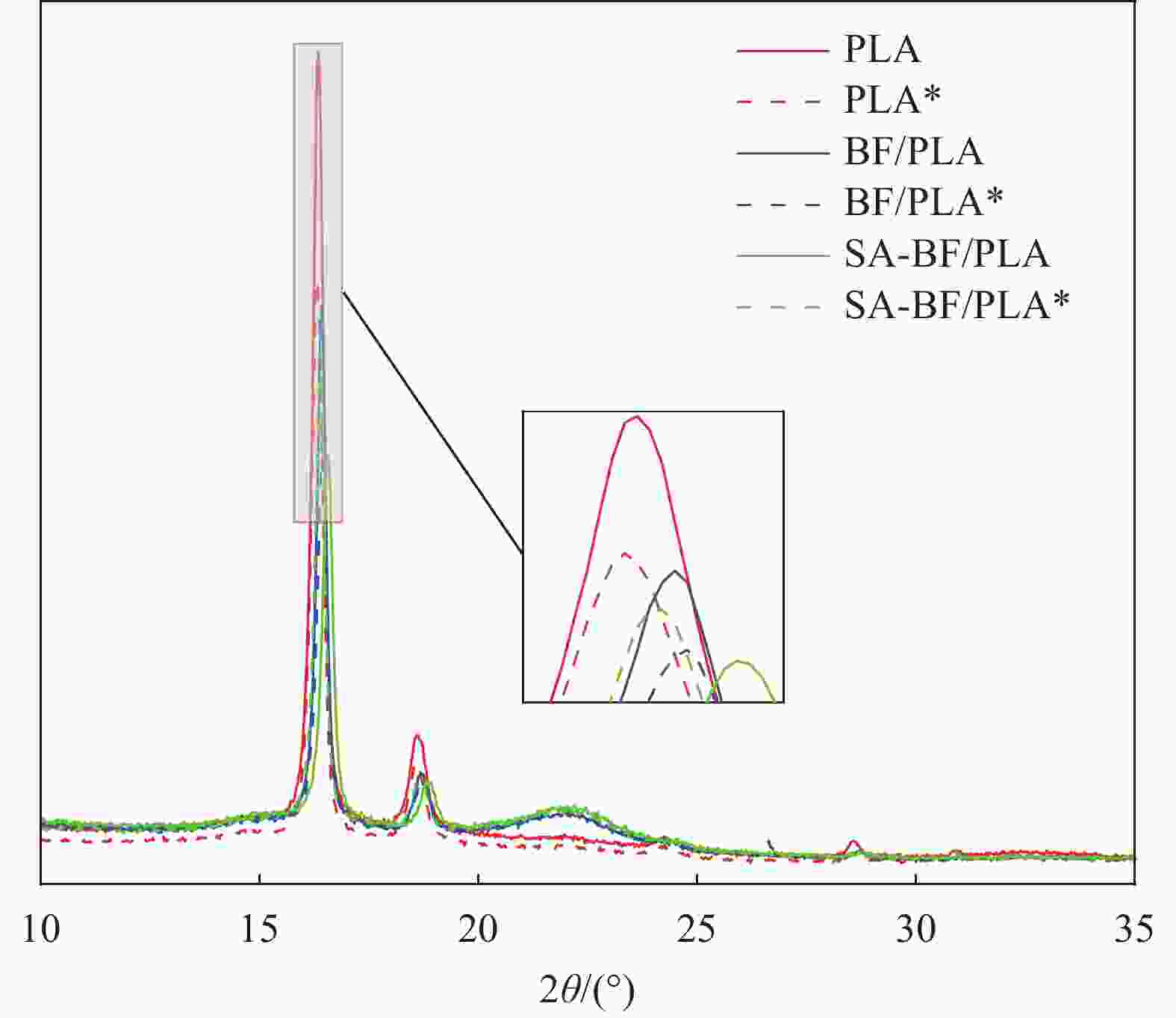

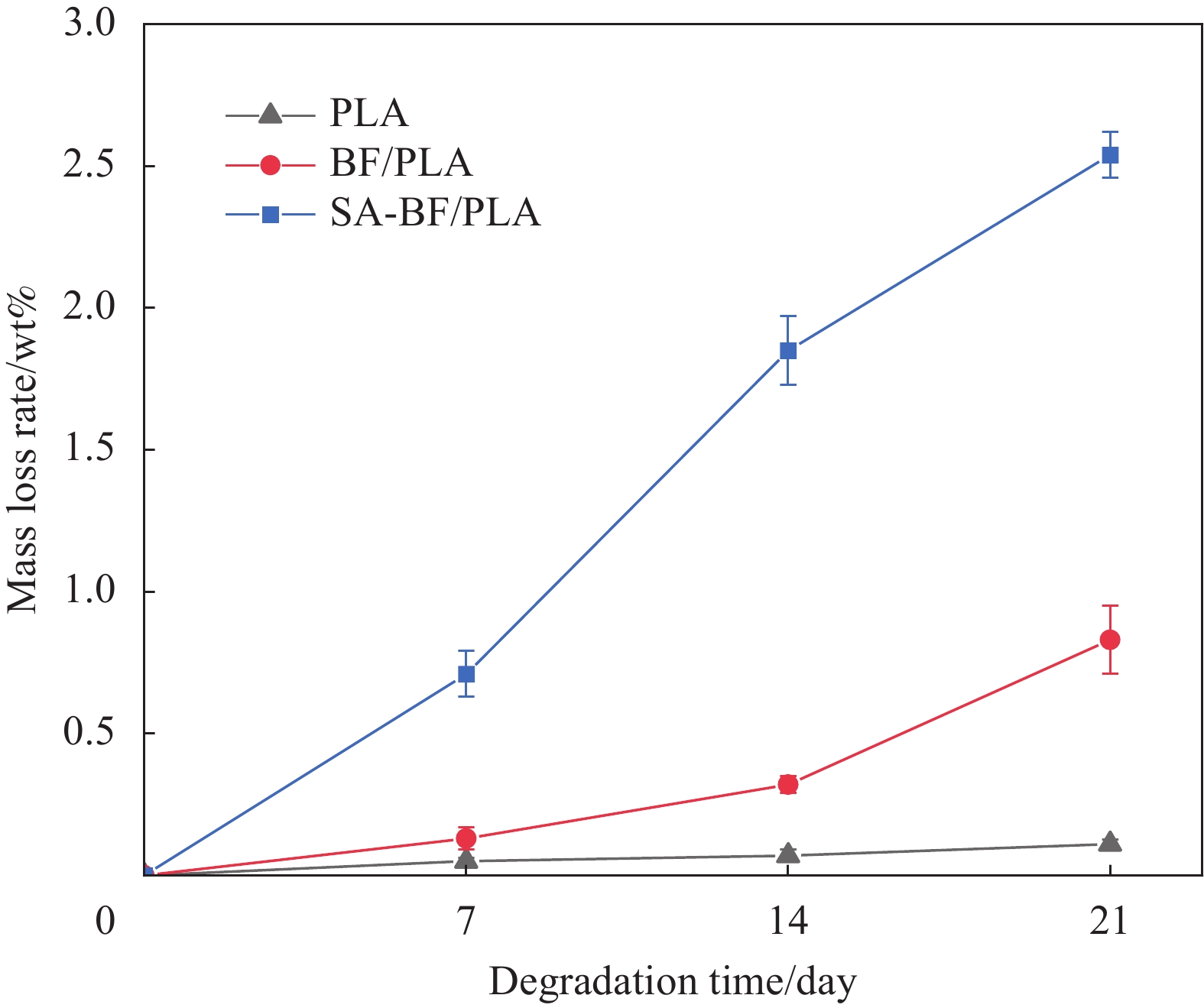

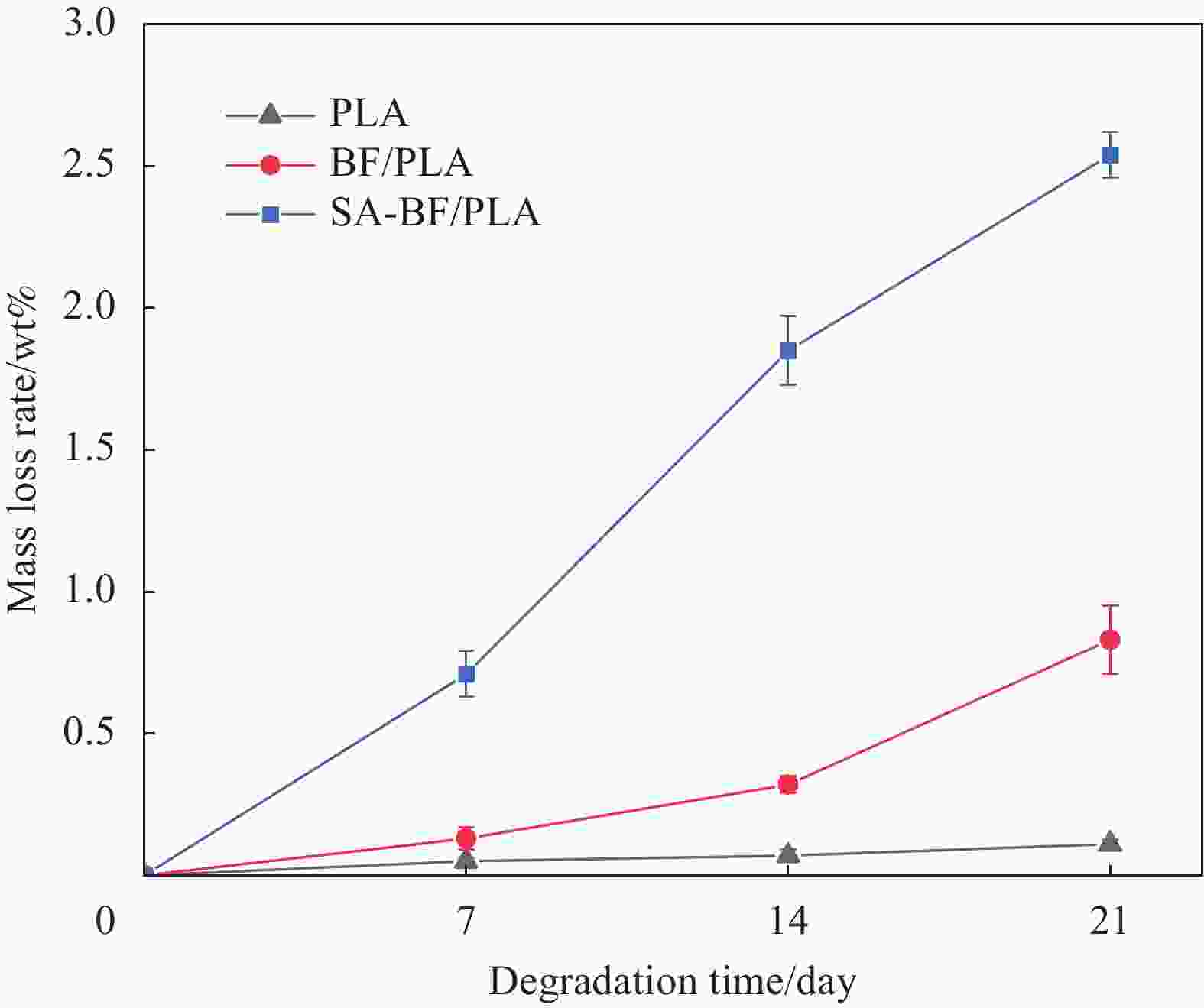

摘要: 为提高聚乳酸(PLA)的降解性,将竹纤维(BF)和海藻酸钠(SA)与PLA共混制备复合材料,并进行土壤降解试验以探究其降解性能,检测降解后复合材料的质量损失率、表面微观结构、官能团变化、热性能和结晶度等指标。结果表明:SA和BF均可提升PLA复合材料降解的质量损失率。降解21天后,BF/PLA和SA-BF/PLA复合材料的质量损失率分别为0.83%和2.54%,相较于纯PLA的0.11%分别提高了7.55和23.09倍。降解后,SA-BF/PLA复合材料的表面出现大量的裂痕与凹陷,这增大了复合材料与土壤中的接触面积,进而加速了复合材料的降解。纯PLA在降解过程中质量损失率很低,但降解后其羰基含量明显上升,表明土壤降解会导致部分PLA长链高分子断裂为小分子。相比于纯PLA,BF/PLA和SA-BF/PLA复合材料的结晶度大幅度降低,表明SA和BF可降低PLA复合材料的结晶度,提高其降解性。由此可见,SA和BF可提升PLA复合材料的降解性能。此研究结果将为高降解性PLA复合材料的制备提供理论参考。Abstract: In order to improve the degradability of polylactic acid (PLA), bamboo fiber (BF) and sodium alginate (SA) were blended with PLA to prepare composite materials. And then the PLA composites were buried in soil for degradation test. The mass loss, morphological properties, FTIR, thermal properties and crystallinity of the PLA composites were measured after degradation. The results shown that both SA and BF can improve the mass loss of PLA composites during degradation. After 21 days of degradation, the mass loss rates of BF/PLA and SA-BF/PLA composites were 0.83% and 2.54%, which were 7.55 and 23.09 times higher than that of pure PLA (0.11%), respectively. A large number of cracks and depressions appeared on the surface of SA-BF/PLA composites after degradation, which increased the contact area between the PLA composites and the soil, and thus accelerated the degradation of the PLA composites. The mass loss rate of PLA materials was very low after degradation, but the carbanyl group of PLA materials increased significantly, this indicated that soil degradation could lead to the fracture of some PLA long-chain polymers into small molecules. Compared with pure PLA, the crystallinity of BF/PLA and SA-BF/PLA composites was significantly reduced, this meant that SA and BF could reduce the crystallinity of the PLA composites and enhance their degradability. The results indicated that SA and BF can improve the degradability of PLA composites. The results would provide theoretical reference for the preparation of highly degradable PLA composites.

-

Key words:

- polylactic acid /

- bamboo fiber /

- sodium alginate /

- soil degradation /

- degradability

-

表 1 土壤降解前后不同PLA复合材料的热重分析数据

Table 1. Thermogravimetric analysis data of different PLA composites before/after soil degradation

Treatments Initial temperature/℃ Peak temperature/℃ Final temperature/℃ Residue at 800℃/% PLA 349.5 377.3 384.0 5.51 PLA* 354.7 376.7 387.5 9.58 BF/PLA 331.8 345.8 358.4 15.79 BF/PLA* 346.6 356.3 368.4 17.64 SA-BF/PLA 304.3 313.6 331.4 19.19 SA-BF/PLA* 334.8 343.3 361.0 17.58 -

[1] LIM L T, AURAS R, RUBINO M. Processing technologies for poly (lactic acid)[J]. Progress in Polymer Science,2008,33(8):820-852. doi: 10.1016/j.progpolymsci.2008.05.004 [2] 黄子翔, 刘一帆, 王越, 等. 可降解聚乳酸复合膜的制备与性能表征[J]. 塑料, 2021, 50(1):117-122.HUANG Zixiang, LIU Yifan, WANG Yue, et al. Preparation and performance characterization of biodegradable poly(lactic acid) composite membrane[J]. Plastics,2021,50(1):117-122(in Chinese). [3] NASER A Z, DEIAB I, DARRAS B M. Poly(lactic acid) (PLA) and polyhydroxyalkanoates (PHAs), green alternatives to petroleum-based plastics: A review[J]. RSC Advances,2021,11(28):17151-17196. doi: 10.1039/D1RA02390J [4] NIKOLAIVITS E, PANTELIC B, AZEEM M, et al. Progressing plastics circularity: A review of mechano-biocatalytic approaches for waste plastic (Re) valorization[J]. Frontiers in Bioengineering and Biotechnology,2021,9:1-31. doi: 10.12970/2311-1755.2021.09.01 [5] 白聪艳, 张宏, 魏小红. 微生物对聚乙烯塑料的降解性能研究[J]. 山东化工, 2022, 51(2):42-44. doi: 10.3969/j.issn.1008-021X.2022.02.013BAI Congyan, ZHANG Hong, WEI Xiaohong. Study of microbial degradation performance of polyethylene plastics baiconyan[J]. Shangdong Chemical Industry,2022,51(2):42-44(in Chinese). doi: 10.3969/j.issn.1008-021X.2022.02.013 [6] ARMENTANO I, BITINIS N, FORTUNATI E, et al. Multifunctional nanostructured PLA materials for packaging and tissue engineering[J]. Progress in Polymer Science,2013,38(10-11):1720-1747. doi: 10.1016/j.progpolymsci.2013.05.010 [7] RAMESHKUMAR S, SHAIJU P, O'CONNOR K E, et al. Bio-based and biodegradable polymers-State-of-the-art, challenges and emerging trends[J]. Current Opinion in Green and Sustainable Chemistry,2020,21:75-81. doi: 10.1016/j.cogsc.2019.12.005 [8] YANG N, SUN Z X, FENG L S, et al. Plastic film mulching for water-efficient agricultural applications and degradable films materials development research[J]. Materials and Manufacturing Processes,2015,30(2):143-154. doi: 10.1080/10426914.2014.930958 [9] 陈倩, 曾威, 石伊康, 等. 接枝细菌纤维素改性聚乳酸复合材料的制备与性能[J]. 复合材料学报, 2023, 40(3):1430-1437.CHEN Qian, ZENG Wei, SHI Yikang, et al. Preparation and properties of polylactic acid composite modified by bacterial cellulose[J]. Acta Materiae Compositae Sinica,2023,40(3):1430-1437(in Chinese). [10] SUN C, WEI S Y, TAN H Y, et al. Progress in upcycling polylactic acid waste as an alternative carbon source: A review[J]. Chemical Engineering Journal,2022,446:1-21. [11] 沈一丁, 赖小娟, 王磊. 聚乳酸/乙基纤维素复合膜的制备及其性能[J]. 复合材料学报, 2007, 24(3):40-44. doi: 10.3321/j.issn:1000-3851.2007.03.008SHEN Y D, LAI X J, WANG L. Preparation and properties of poly(lactic acid)/ethyl cellulose composite films[J]. Acta Materiae Compositae Sinica,2007,24(3):40-44(in Chinese). doi: 10.3321/j.issn:1000-3851.2007.03.008 [12] SUN J Y, SHEN J J, CHEN S K, et al. Nanofiller reinforced biodegradable PLA/PHA composites: Current status and future trends[J]. Polymers,2018,10(5):1-22. [13] JEON B, HAN J W, LEE K S, et al. Improvement of the mechanical properties of biodegradable polymers using a microcellular foaming process and natural by-products[J]. Polymer-Plastics Technology and Engineering,2012,51(4):401-406. doi: 10.1080/03602559.2011.639835 [14] PATTANASUTTICHONLAKUL W, SOMBATSOMPOP N, PRAPAGDEE B. Accelerating biodegradation of PLA using microbial consortium from dairy wastewater sludge combined with PLA-degrading bacterium[J]. International Biodeterioration & Biodegradation,2018,132:74-83. [15] YAACOB N D, ISMAIL H, TING S S. Soil burial of polylactic acid/paddy straw powder biocomposite[J]. Bioresources,2016,11(1):1255-1269. [16] 崔晓霞, 曲萍, 陈品, 等. 可生物降解聚乳酸/纳米纤维素复合材料的亲水性和降解性[J]. 化工新型材料, 2010, 38(S1):107-109, 139. doi: 10.3969/j.issn.1006-3536.2010.z1.028CUI Xiaoxia, QU Ping, CHEN Pin, et al. Study on the degradation of cellulose nanowhiskers/poly(lactic acid) composites[J]. New Chemical Materials,2010,38(S1):107-109, 139(in Chinese). doi: 10.3969/j.issn.1006-3536.2010.z1.028 [17] 中国国家标准化管理委员会. 塑料 拉伸性能的测定: GB/T 1040.1—2018[S]. 北京: 中国标准出版社, 2018.Standardization Administration of the People’s Republic of China. Plastics—Determination of tensile properties: GB/T 1040.1—2018[S]. Beijing: China Standards Press, 2018(in Chinese). [18] 中国国家标准化管理委员会. 塑料 弯曲性能的测定: GB/T 9341—2008[S]. 北京: 中国标准出版社, 2008.Standardization Administration of the People’s Republic of China. Plastics—Determination of flexural properties: GB/T 9341—2008[S]. Beijing: China Standards Press, 2008(in Chinese). [19] 中国国家标准化管理委员会. 塑料 简支梁冲击性能的测定: GB/T 1043.1—2008[S]. 北京: 中国标准出版社, 2008.Standardization Administration of the People’s Republic of China. Plastics—Determination of charpy impact properties: GB/T 1043.1—2008[S]. Beijing: China Standards Press, 2008(in Chinese). [20] 中国国家标准化管理委员会. 塑料 硬度测定: GB/T 3398.2—2008[S]. 北京: 中国标准出版社, 2008.Standardization Administration of the People’s Republic of China. Plastics—Determination of hardness: GB/T 3398.2—2008[S]. Beijing: China Standards Press, 2008(in Chinese). [21] KONG X, JIN D C, JIN S L, et al. Responses of bacterial community to dibutyl phthalate pollution in a soil-vegetable ecosystem[J]. Journal of Hazardous Materials,2018,353:142-150. doi: 10.1016/j.jhazmat.2018.04.015 [22] LUO Y Y, ZHANG Y Y, XU Y B, et al. Distribution characteristics and mechanism of microplastics mediated by soil physicochemical properties[J]. Science of the Total Envi-ronment,2020,726:1-7. [23] 樊鑫炎, 黄俊雅, 杨炎晓, 等. 多功能CeO2/纤维素纳米纤维复合超疏水涂层的制备与性能[J]. 复合材料学报, 2023, 40(5): 3002-3017.FAN X Y, HUANG J Y, YANG Y X, et al. Fabrication and properties of multifunctional CeO2/cellulose nanofibers composite superhydrophobic coating[J]. Acta Materiae Compositae Sinica, 2023, 40(5): 3002-3017. [24] FAKHRI L A, GHANBARZADEH B, DEHGHANNYA J, et al. Photo-catalytic and biotic degradation of polystyrene packaging film: Effect of zinc oxide photocatalyst nanoparticles and nanoclay[J]. Chemosphere,2021,283:130972. [25] 倪爱清, 张厉丰, 冀运东, 等. E玻璃纤维/乙烯基酯复合材料的氙灯老化性能研究[J]. 复合材料学报, 2013, 30(S1):33-39. doi: 10.13801/j.cnki.fhclxb.2013.s1.022NI A Q, ZHANG L F, JI Y D, et al. The study of artificial xenon arc lamp ageing on E-glass/vinyl ester composites[J]. Acta Materiae Compositae Sinica,2013,30(S1):33-39(in Chinese). doi: 10.13801/j.cnki.fhclxb.2013.s1.022 [26] VALAPA R B, PUGAZHENTHI G, KATIYAR V. Hydrolytic degradation behaviour of sucrose palmitate reinforced poly(lactic acid) nanocomposites[J]. International Jour-nal of Biological Macromolecules,2016,89:70-80. doi: 10.1016/j.ijbiomac.2016.04.040 [27] 常萧楠, 何春霞, 付菁菁, 等. 竹炭和壳聚糖对聚氯乙烯基木塑复合材料界面性能的影响[J]. 复合材料学报, 2016, 33(9):2022-2029. doi: 10.13801/j.cnki.fhclxb.20151109.002CHANG X N, HE C X, FU J J, et al. Effects of bamboo charcoal and chitosan on interfacial property of polyvinyl chloride based wood-plastic composites[J]. Acta Materiae Compositae Sinica,2016,33(9):2022-2029(in Chinese). doi: 10.13801/j.cnki.fhclxb.20151109.002 [28] JIA H, ZHANG M, WENG Y X, et al. Degradation of polylactic acid/polybutylene adipate-co-terephthalate by coculture of Pseudomonas mendocina and Actinomucor elegans[J]. Journal of Hazardous Materials,2021,403:123679. [29] 祁睿格, 何春霞, 晋强. 麦秸/聚氯乙烯复合材料新疆户外老化性能[J]. 复合材料学报, 2019, 37(7):1539-1546. doi: 10.13801/j.cnki.fhclxb.20191113.003QI R G, HE C X, JIN Q. Outdoor exposure aging performance of wheat straw/polyvinyl chloride composites in Xinjiang[J]. Acta Materiae Compositae Sinica,2019,37(7):1539-1546(in Chinese). doi: 10.13801/j.cnki.fhclxb.20191113.003 [30] XIA L, LU S R, ZHONG B, et al. Effect of boron doping on waterproof and dielectric properties of polyborosiloxane coating on SiO2 f/SiO2 composites[J]. Chinese Journal of Aeronautics,2019,32(8):2017-2027. doi: 10.1016/j.cja.2018.11.008 [31] CHAI X C, HE C X, LIU Y T, et al. Degradation of wheat straw/polylactic acid composites by Aspergillus niger[J]. Polymer Composites,2022,43(3):1823-1831. doi: 10.1002/pc.26500 [32] CAI H, DAVE V, GROSS R A, et al. Effects of physical aging, crystallinity, and orientation on the enzymatic degradation of poly(lactic acid)[J]. Journal of Polymer Science Part B-Polymer Physics,1996,34(16):2701-2708. doi: 10.1002/(SICI)1099-0488(19961130)34:16<2701::AID-POLB2>3.0.CO;2-S [33] ZHANG X Q, ESPIRITU M, BILYK A, et al. Morphological behaviour of poly(lactic acid) during hydrolytic degradation[J]. Polymer Degradation and Stability,2008,93(10):1964-1970. doi: 10.1016/j.polymdegradstab.2008.06.007 [34] LV S S, GU J Y, GAO J, et al. Effect of annealing on the thermal properties of poly(lactic acid)/starch blends[J]. International Journal of Biological Macromolecules,2015,74:397-303. doi: 10.1016/j.ijbiomac.2014.12.023 -

下载:

下载: