Preparation and properties of maleic acid modified lignin reinforced nanocellulose composite film

-

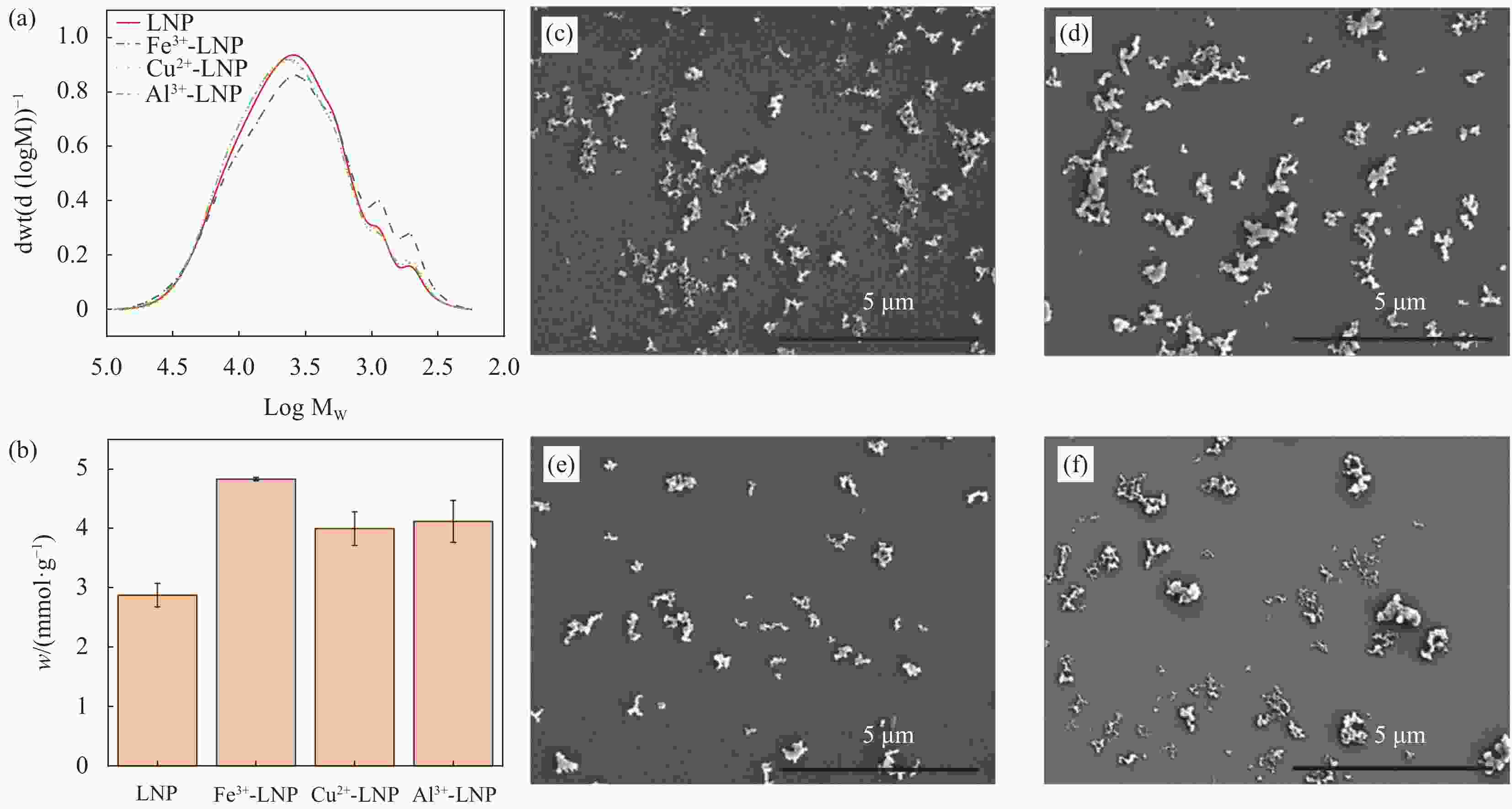

摘要: 以小麦秸秆为原料,采用金属氯化物催化马来酸分离提取木质素纳米颗粒(LNP)。随着金属氯化物的添加,制备得到粒径小、羧基含量高(4.83 mmol/g)、分散性好、含有不同金属离子的LNP。然后将LNP作为增强剂添加到纳米纤维素(CNF)中,采用真空过滤法制备得到复合薄膜材料。对纯CNF膜和复合膜的表面形貌、光学性能、表面色度值和力学性能进行比较分析,结果表明LNP添加量为3wt%时,复合膜具有超过95%的UVA屏蔽率和超过99%的UVB屏蔽率。同时,LNP的加入显著提高了复合膜的拉伸强度(最高达到188.5 MPa),采用AFM测得CNF和不同LNP之间的相互作用力(276~ 406 nN)均高于CNF之间的相互作用力(202 nN),与复合膜的拉伸强度提高相一致。综上所述,本研究在CNF膜中引入含金属离子的LNP,在复合膜中构建了具有金属离子交联和氢键结合相互作用的超强网络,为木质素增强纤维素基薄膜材料的开发提供新思路。Abstract: Lignin nanoparticles (LNP) was isolated from wheat straw using metal chloride-catalyzed maleic acid pretreatment in this study. With the addition of metal chlorides, LNP with small particle size, high carboxyl content (4.83 mmol/g), good dispersion and containing different metal ions were prepared. Subsequently, LNP was added as reinforcing agents to CNF, and the composite films were successfully prepared by vacuum filtration method. The surface morphology, optical property, surface chromaticity value and mechanical property of pure CNF and composite films are compared and analyzed. The results show that the composite films could achieve more than 95% UVA shielding ratio and 99% UVB shielding ratio when LNP content is only 3wt%. Meanwhile, the addition of LNP significantly increase the tensile strength of composite film (up to 188.5 MPa). The interaction forces between CNF and different LNPs (276~ 406 nN) are all higher than those between CNFs (202 nN) as measured using AFM, which is consistent with the improvement in tensile strength of the composite films. In summary, LNP containing metal ions are introduced into CNF films to construct super-strong network with metal ion cross-linking and hydrogen bonding interactions, which provides a new idea for the development of lignin-reinforced cellulose-based film materials.

-

表 1 LNP的平均粒径及平均分子量

Table 1. The average particle size and average molecular weight of LNP

Sample Average particle size (nm) Mn Mw Mw/Mn LNP 457.40± 3.61 2489 6215 2.50 Fe3+-LNP 599.87± 5.03 2075 6079 2.93 Cu2+-LNP 450.10± 2.14 2464 6292 2.55 Al3+-LNP 454.03± 3.42 2510 6451 2.57 Notes: Mn- Number-average molecular weight; Mw- Weight-average molecular weight; Mw/Mn- Polydispersity index. -

[1] HO B T, ROBERTS T K, LUCAS S. An overview on biodegradation of polystyrene and modified polystyrene: the microbial approach[J]. Critical Reviews in Biotechnology, 2017, 38(2): 308-320. [2] MOHANAN N, MONTAZER Z, SHARMA P K, et al. Microbial and enzymatic degradation of synthetic plastics[J]. Frontiers in Microbiology, 2020, 11: 580709. doi: 10.3389/fmicb.2020.580709 [3] HORODYTSKA O, VALDéS F J, FULLANA A. Plastic flexible films waste management - A state of art review[J]. Waste Management, 2018, 77: 413-425. doi: 10.1016/j.wasman.2018.04.023 [4] FILICIOTTO L, ROTHENBERG G. Biodegradable plastics: standards, policies, and impacts[J]. ChemSusChem, 2020, 14(1): 56-72. [5] CHEN M J, ZHANG X Q, LIU C F, et al. Approach to renewable lignocellulosic biomass film directly from bagasse[J]. ACS Sustainable Chemistry & Engineering, 2014, 2(5): 1164-1168. [6] 姜海晶, 晶态纳米纤维素基复合膜光学性质的研究[D]. 长春: 吉林大学, 2019.JIANG H J. The optical property of cellulose nanocrystal-based composite films[D]. Changchun: Jilin University, 2019 (in Chinese). [7] 马小婷, 徐雁. 纳米纤维素: 多层次跨尺度无机功能体系的构筑平台[J]. 高分子学报, 2020, 51(8): 833-863. doi: 10.11777/j.issn1000-3304.2020.20073MA X T, XU Y. Nanocellulose: a sustainable platform for functional materials organization[J]. Acta Polymerica Sinica, 2020, 51(8): 833-863 (in Chinese). doi: 10.11777/j.issn1000-3304.2020.20073 [8] ZHANG Y Z, WEI Y, QIAN Y Y, et al. Lignocellulose enabled highly transparent nanopaper with tunable ultraviolet-blocking performance and superior durability[J]. ACS Sustainable Chemistry & Engineering, 2020, 8(46): 17033-17041. [9] AMINI E, HAFEZ I, TAJVIDI M, et al. Cellulose and lignocellulose nanofibril suspensions and films: A comparison[J]. Carbohydrate Polymers, 2020, 250: 117011. doi: 10.1016/j.carbpol.2020.117011 [10] BIAN H Y, CHEN L D, DONG M L, et al. Natural lignocellulosic nanofibril film with excellent ultraviolet blocking performance and robust environment resistance[J]. International Journal of Biological Macromolecules, 2021, 166: 1578-1585. doi: 10.1016/j.ijbiomac.2020.11.037 [11] JIANG Y, LIU X Y, YANG Q, et al. Effects of residual lignin on composition, structure and properties of mechanically defibrillated cellulose fibrils and films[J]. Cellulose, 2019, 26(3): 1577-1593. doi: 10.1007/s10570-018-02229-4 [12] BIAN H Y, SHU X, SU W H, et al. Biodegradable, flexible and ultraviolet blocking nanocellulose composite film incorporated with lignin nanoparticles[J]. International Journal of Molecular Sciences, 2022, 23(23): 14863. doi: 10.3390/ijms232314863 [13] ÖSTERBERG M, SIPPONEN M H, MATTOS B D, et al. Spherical lignin particles: a review on their sustainability and applications[J]. Green Chemistry, 2020, 22(9): 2712-2733. doi: 10.1039/D0GC00096E [14] YU S X, WANG M L, XIE Y M, et al. Lignin self-assembly and auto-adhesion for hydrophobic cellulose/lignin composite film fabrication[J]. International Journal of Biological Macromolecules, 2023, 233: 123598. doi: 10.1016/j.ijbiomac.2023.123598 [15] FAROOQ M, ZOU T, RIVIERE G, et al. Strong, ductile, and waterproof cellulose nanofibril composite films with colloidal Lignin particles[J]. Biomacromolecules, 2019, 20(2): 693-704. doi: 10.1021/acs.biomac.8b01364 [16] OU J F, HU S N, YAO L, et al. Simultaneous strengthening and toughening lignin/cellulose nanofibril composite films: Effects from flexible hydrogen bonds[J]. Chemical Engineering Journal, 2023, 453: 139770. doi: 10.1016/j.cej.2022.139770 [17] BUDNYAK T M, AMINZADEH S, PYLYPCHUK I V, et al. Peculiarities of synthesis and properties of lignin(-)silica nanocomposites prepared by sol-gel method[J]. Nanomaterials (Basel), 2018, 8(11): 950. doi: 10.3390/nano8110950 [18] MYINT A A, LEE H W, SEO B, et al. One pot synthesis of environmentally friendly lignin nanoparticles with compressed liquid carbon dioxide as an antisolvent[J]. Green Chemistry, 2016, 18(7): 2129-2146. doi: 10.1039/C5GC02398J [19] SUN J, DUTTA T, PARTHASARATHI R, et al. Rapid room temperature solubilization and depolymerization of polymeric lignin at high loading[J]. Green Chemistry, 2016, 18(22): 6012-6020. doi: 10.1039/C6GC02258H [20] WU Chen, YANG Y M, SUN K Q, et al. Lignin decolorization in organic solvents and their application in natural sunscreen[J]. International Journal of Biological Macromolecules, 2023, 237: 124081. doi: 10.1016/j.ijbiomac.2023.124081 [21] MA Q L, CHEN L H, WANG R B, et al. Direct production of lignin nanoparticles (LNPs) from wood using p-toluenesulfonic acid in an aqueous system at 80°C: characterization of LNP morphology, size, and surface charge[J]. Holzforschung, 2018, 72(11): 933-942. doi: 10.1515/hf-2018-0033 [22] ZHANG Y, NAEBE M. Lignin: A review on structure, properties, and applications as a light-colored UV absorber[J]. ACS Sustainable Chemistry & Engineering, 2021, 9(4): 1427-1442. [23] SU C, HIRTH K, LIU Z L, et al. Acid hydrotropic fractionation of switchgrass at atmospheric pressure using maleic acid in comparison with p-TsOH: Advantages of lignin esterification[J]. Industrial Crops and Products, 2021, 159: 113017. doi: 10.1016/j.indcrop.2020.113017 [24] CAI C, HIRTH K, GLEISNER R, et al. Maleic acid as a dicarboxylic acid hydrotrope for sustainable fractionation of wood at atmospheric pressure and ≤100℃: mode and utility of lignin esterification[J]. Green Chemistry, 2020, 22(5): 1605-1617. doi: 10.1039/C9GC04267A [25] 王瑞琦. 木质素氧化、酯化改性及在聚氨酯材料中的应用研究[D]. 长春: 吉林大学, 2019.WANG Ruiqi. Study on the oxidation and esterfication of lignin and its application[D]. Changchun: Jilin University, 2019 (in Chinese). [26] CHEN L H, DOU J Z, MA Q L, et al. Rapid and near-complete dissolution of wood lignin at ≤80℃ by a recyclable acid hydrotrope[J]. Science Advances, 2017, 3(9): e1701735. doi: 10.1126/sciadv.1701735 [27] SALENTINIG S, SCHUBERT M. Softwood lignin self-assembly for nanomaterial design[J]. Biomacromolecules, 2017, 18(8): 2649-2653. doi: 10.1021/acs.biomac.7b00822 [28] 张梦丽, 陈港, 魏渊, 等. 木质素-纳米纤维素复合薄膜的制备及其紫外光屏蔽性能[J]. 复合材料学报, 2022, 39(03): 1239-1248.ZHANG M L, CHEN G, WEI Y, et al. Preparation and UV-blocking performance of lignin-cellulose nanofiber composite film[J]. Acta Materiae Compositae Sinica, 2022, 39(03): 1239-12489 (in Chinese). [29] SIRVIö J A, ISMAIL M Y, ZHANG K, et al. Transparent lignin-containing wood nanofiber films with UV-blocking, oxygen barrier, and anti-microbial properties[J]. Journal of Materials Chemistry A, 2020, 8(16): 7935-7946. doi: 10.1039/C9TA13182E [30] CHEN C, SUN W J, WANG L, et al. Transparent multifunctional cellulose nanocrystal films prepared using trivalent metal ion exchange for food packaging[J]. ACS Sustainable Chemistry & Engineering, 2022, 10(29): 9419-9430. [31] 姜波, 金永灿. 基于木质素分子结构特性的功能材料研究进展[J]. 复合材料学报, 2022, 39(7): 3059-3083.JIANG B, JIN Y C. Research progress of lignin functional materials based on its structural properties[J]. Acta Materiae Compositae Sinica, 2022, 39(7): 3059-3083 (in Chinese). [32] WANG J Y, DENG Y H, QIAN Y, et al. Reduction of lignin color via one-step UV irradiation[J]. Green Chemistry, 2015, 18(3): 695-699. [33] HU S X, GU J, JIANG F, et al. Holistic rice straw nanocellulose and hemicelluloses/lignin composite films[J]. ACS Sustainable Chemistry & Engineering, 2016, 4(3): 728-737. [34] MA L, ZHU Y, HUANG Y, et al. Strong water-resistant, UV-blocking cellulose/glucomannan/lignin composite films inspired by natural LCC bonds[J]. Carbohydrate Polymer, 2022, 281: 119083. doi: 10.1016/j.carbpol.2021.119083 [35] ROJO E, PERESIN M S, SAMPSON W W, et al. Comprehensive elucidation of the effect of residual lignin on the physical, barrier, mechanical and surface properties of nanocellulose films[J]. Green Chemistry, 2015, 17(3): 1853-1866. doi: 10.1039/C4GC02398F [36] MICIC M, BENITEZ I, RUANO M, et al. Probing the lignin nanomechanical properties and lignin-lignin interactions using the atomic force microscopy[J]. Chemical Physics Letters, 2001, 347(1-3): 41-45. doi: 10.1016/S0009-2614(01)01022-3 [37] QIN C R, CLARKE K, LI K C. Interactive forces between lignin and cellulase as determined by atomic force microscopy[J]. Biotechnology for biofuels, 2014, 7: 65. doi: 10.1186/1754-6834-7-65 [38] ZHU C T, MONTI S, MATHEW A P. Evaluation of nanocellulose interaction with water pollutants using nanocellulose colloidal probes and molecular dynamic simulations[J]. Carbohydrate Polymers, 2020, 229: 115510. doi: 10.1016/j.carbpol.2019.115510 [39] TAN X, LI K. Adhesion forces between ligno-cellulose surfaces by atomic force microscopy[J]. Journal of pulp and Paper Science, 2008, 34(2): 77-85. [40] NOTLEY S M, NORGREN M. Measurement of interaction forces between lignin and cellulose as a function of aqueous electrolyte solution conditions[J]. Langmuir, 2006, 22(26): 11199-11204. doi: 10.1021/la0618566 -

点击查看大图

点击查看大图

计量

- 文章访问数: 78

- HTML全文浏览量: 75

- 被引次数: 0

下载:

下载: