Effects of stress state and strain rate on the in-plane mechanical behavior of plain woven CFRP

-

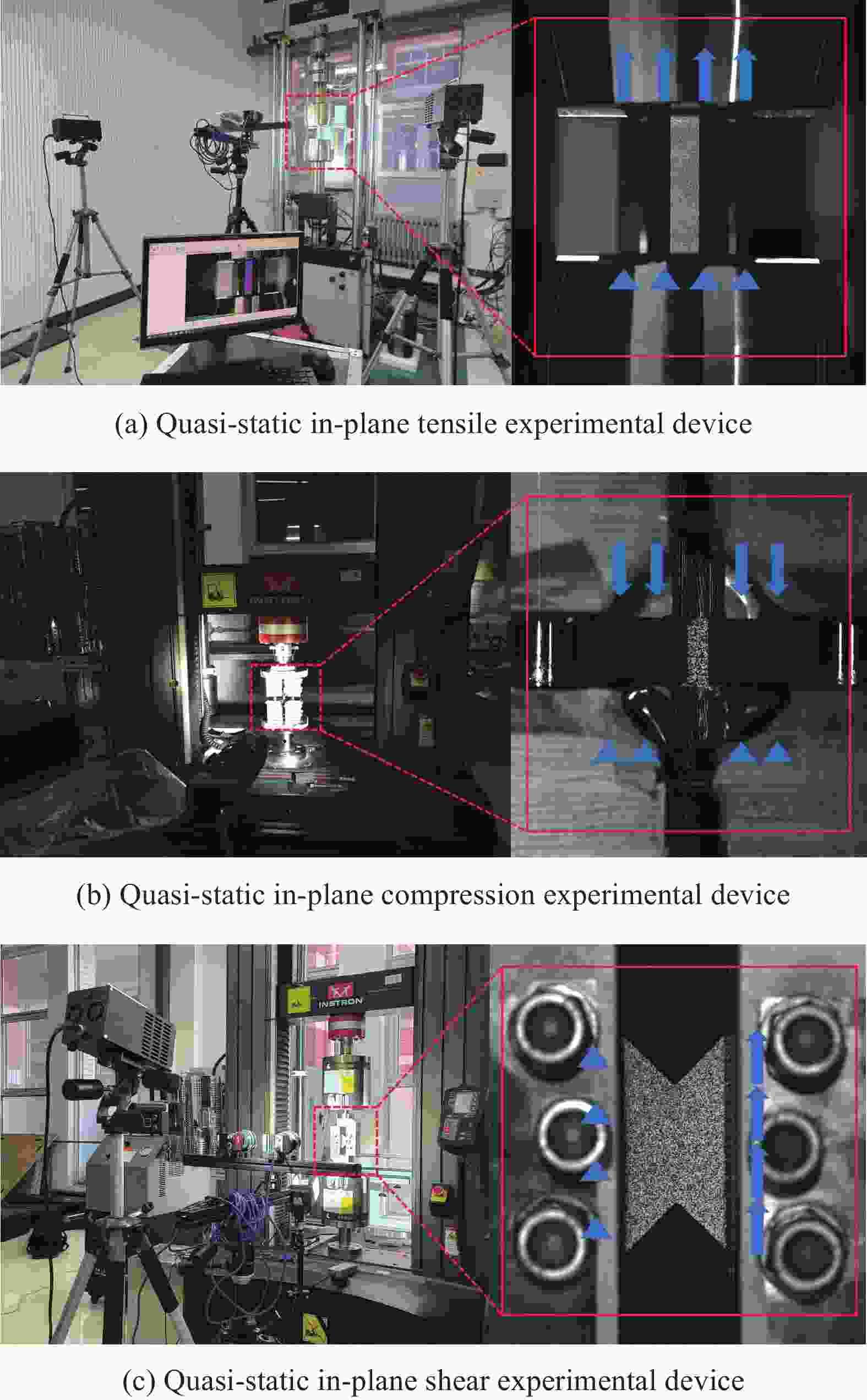

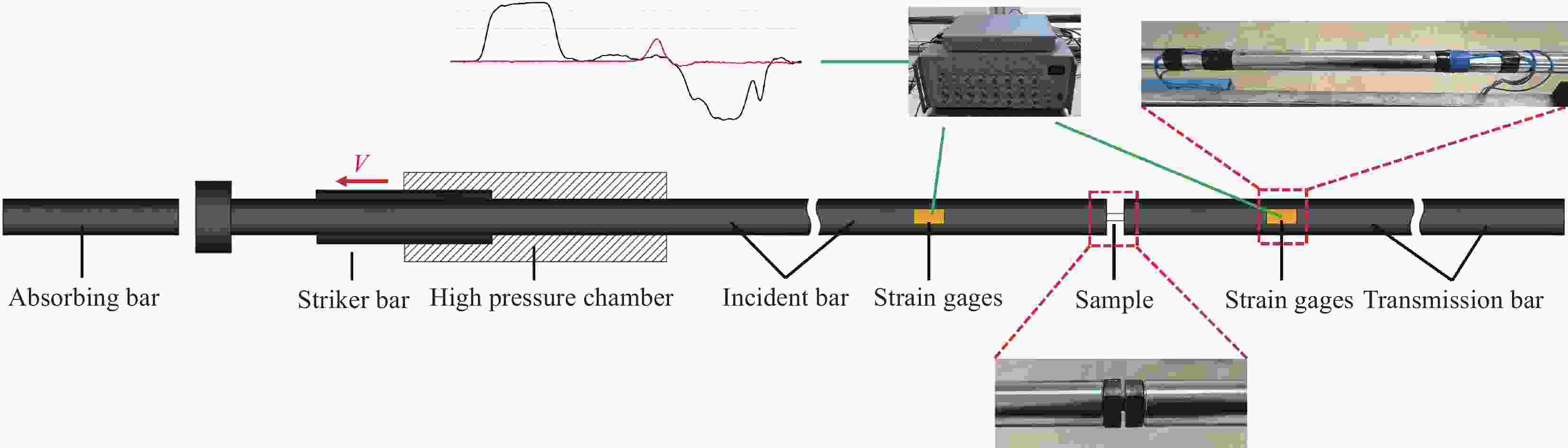

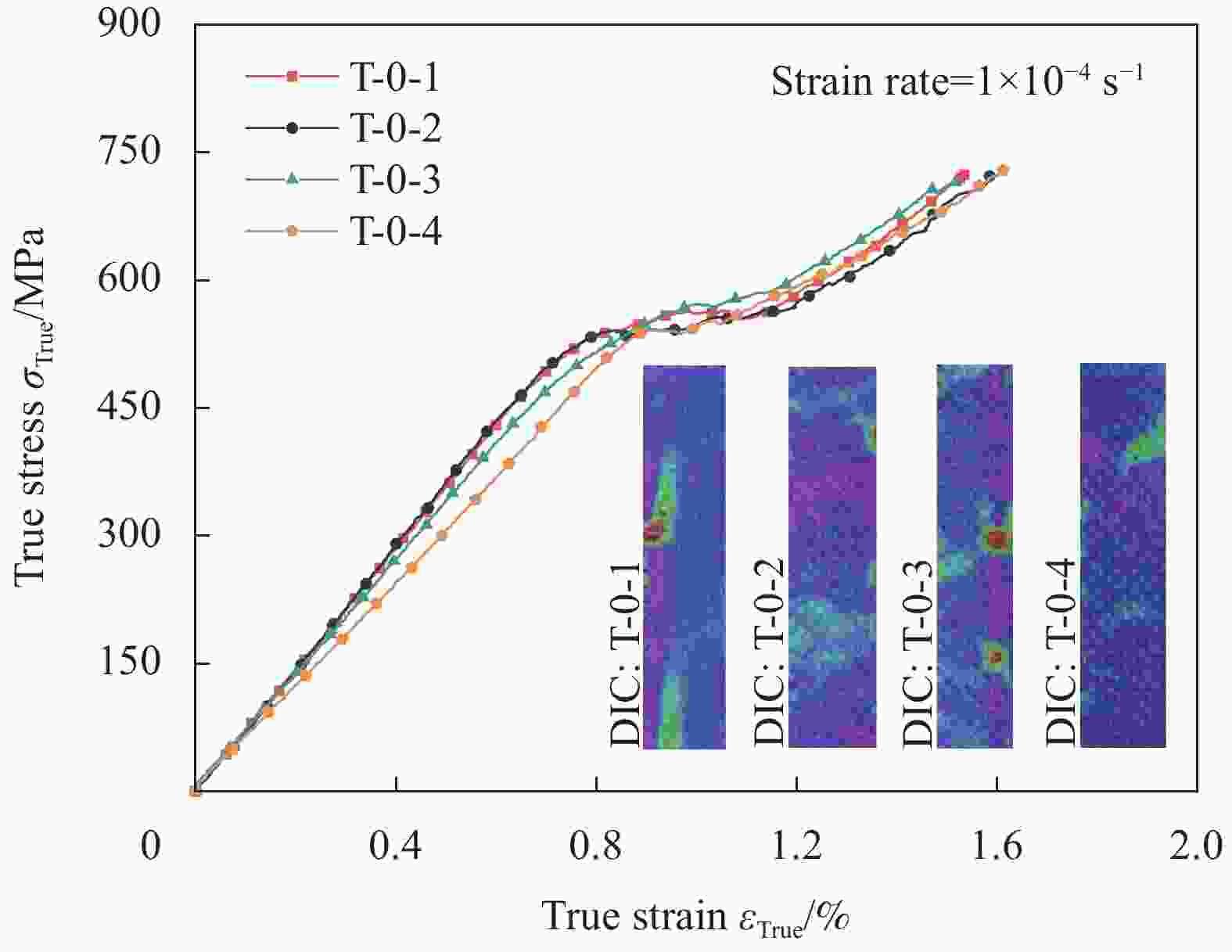

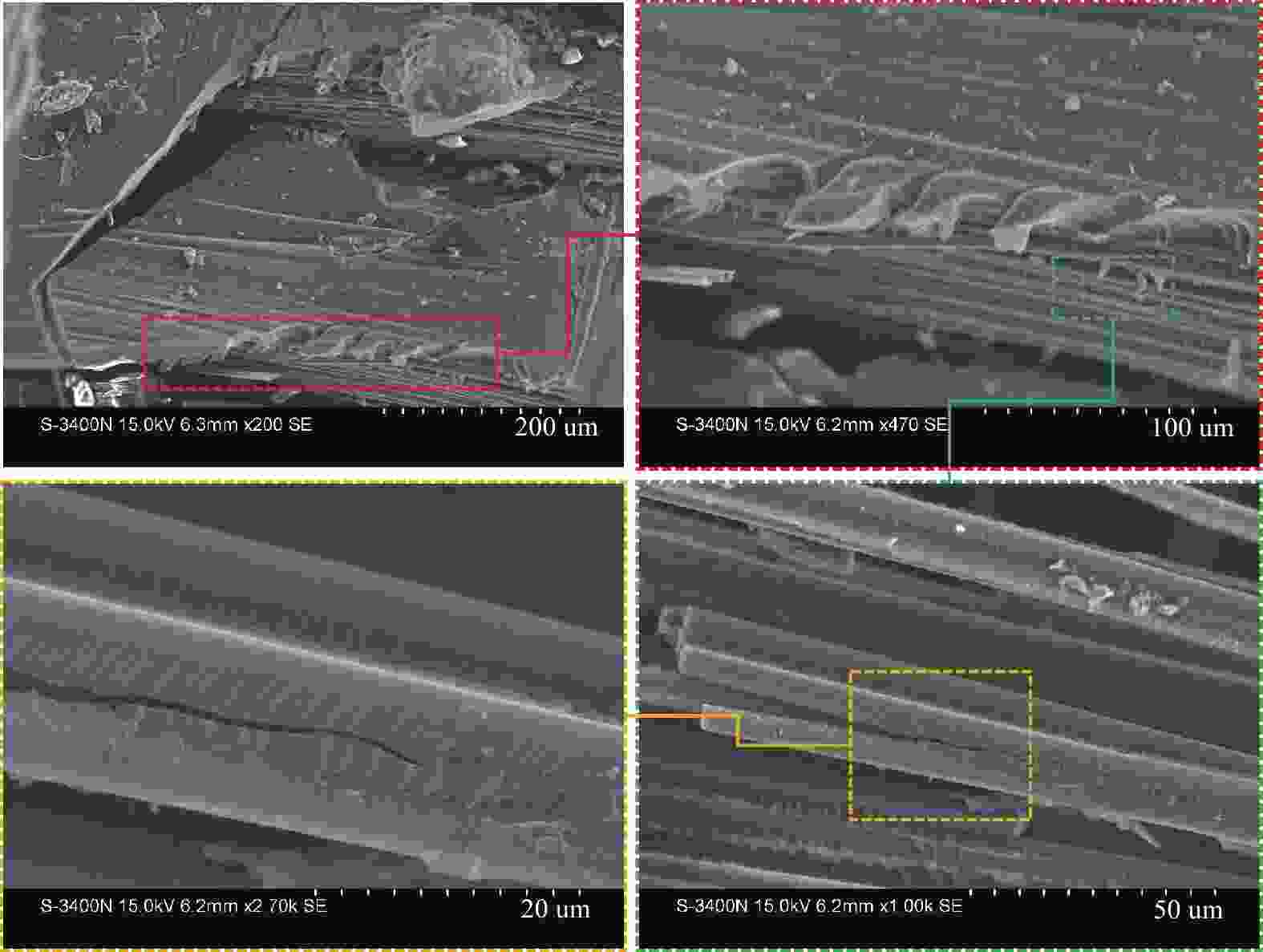

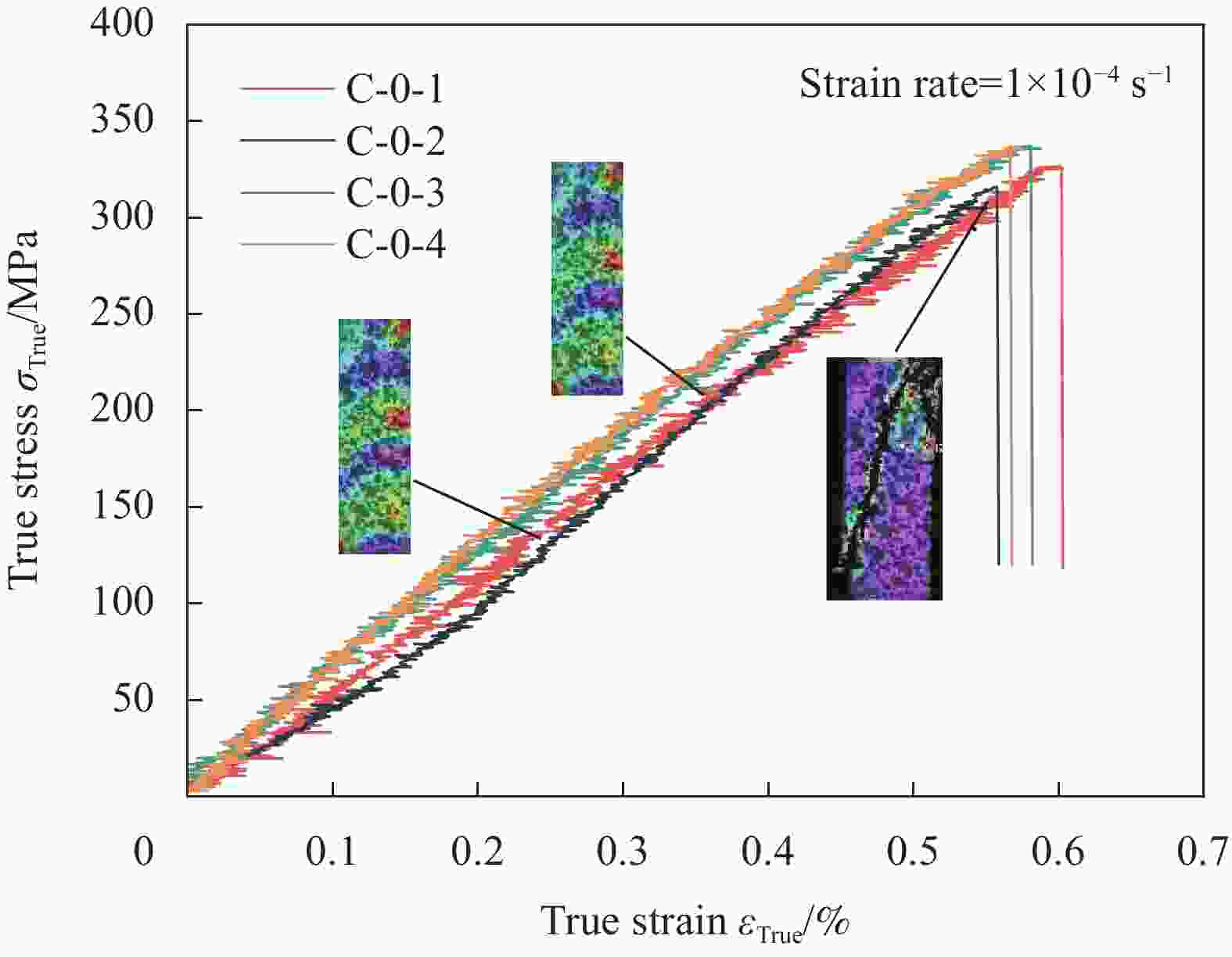

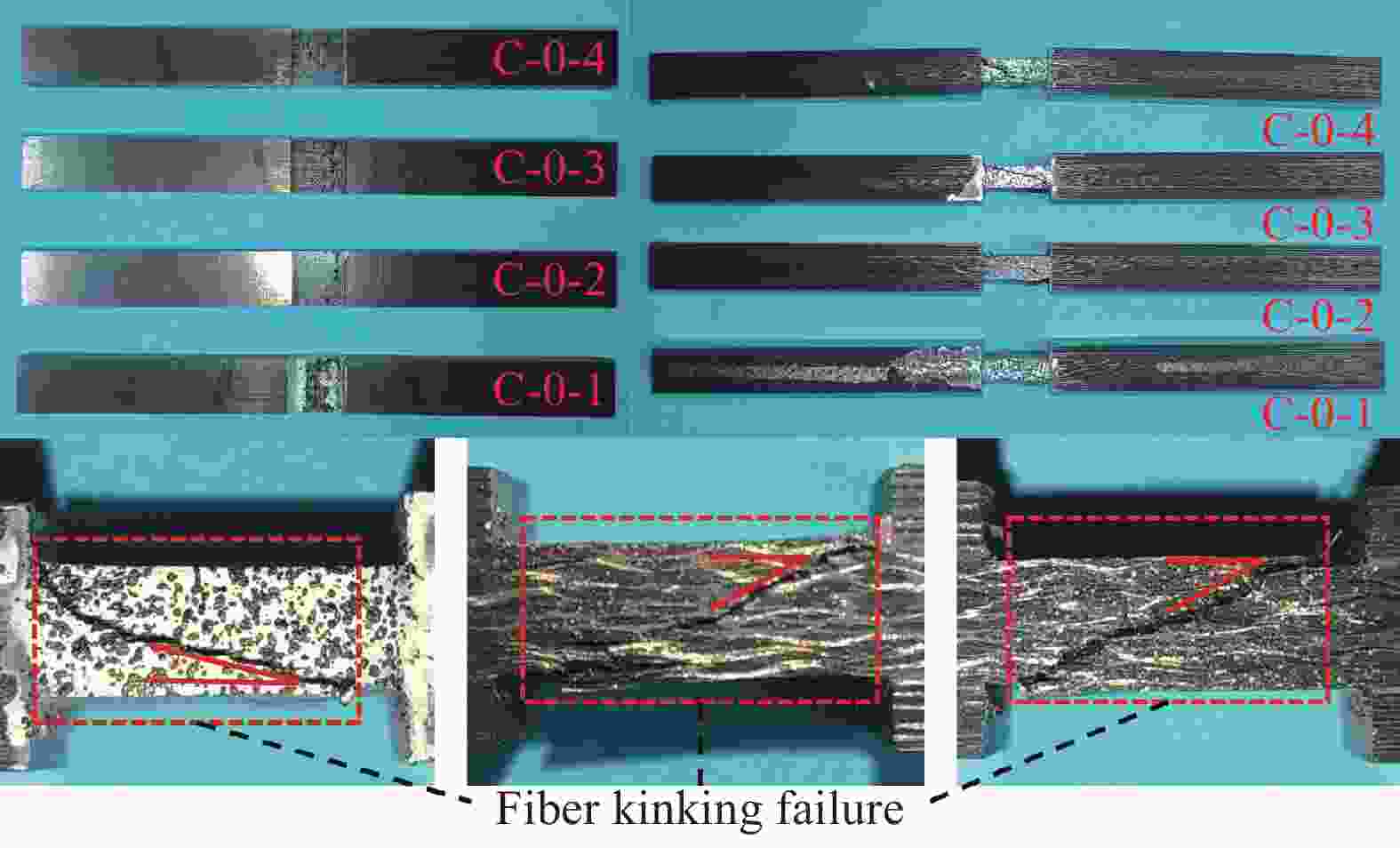

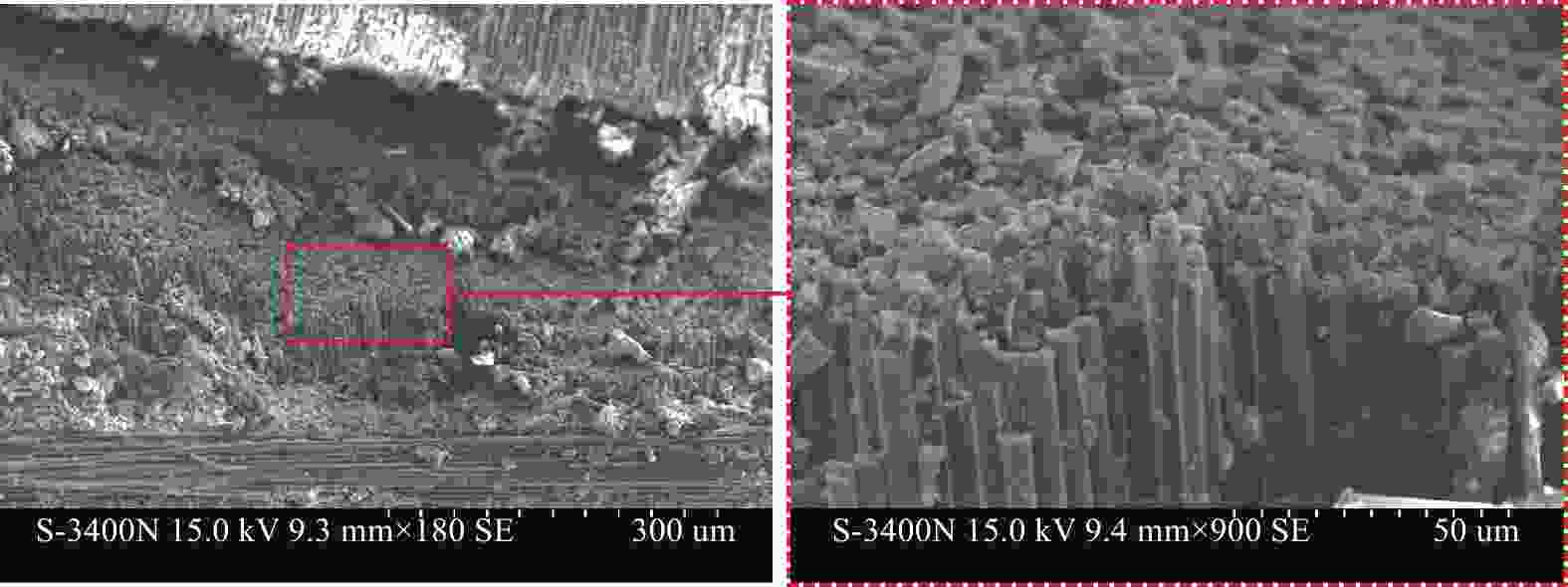

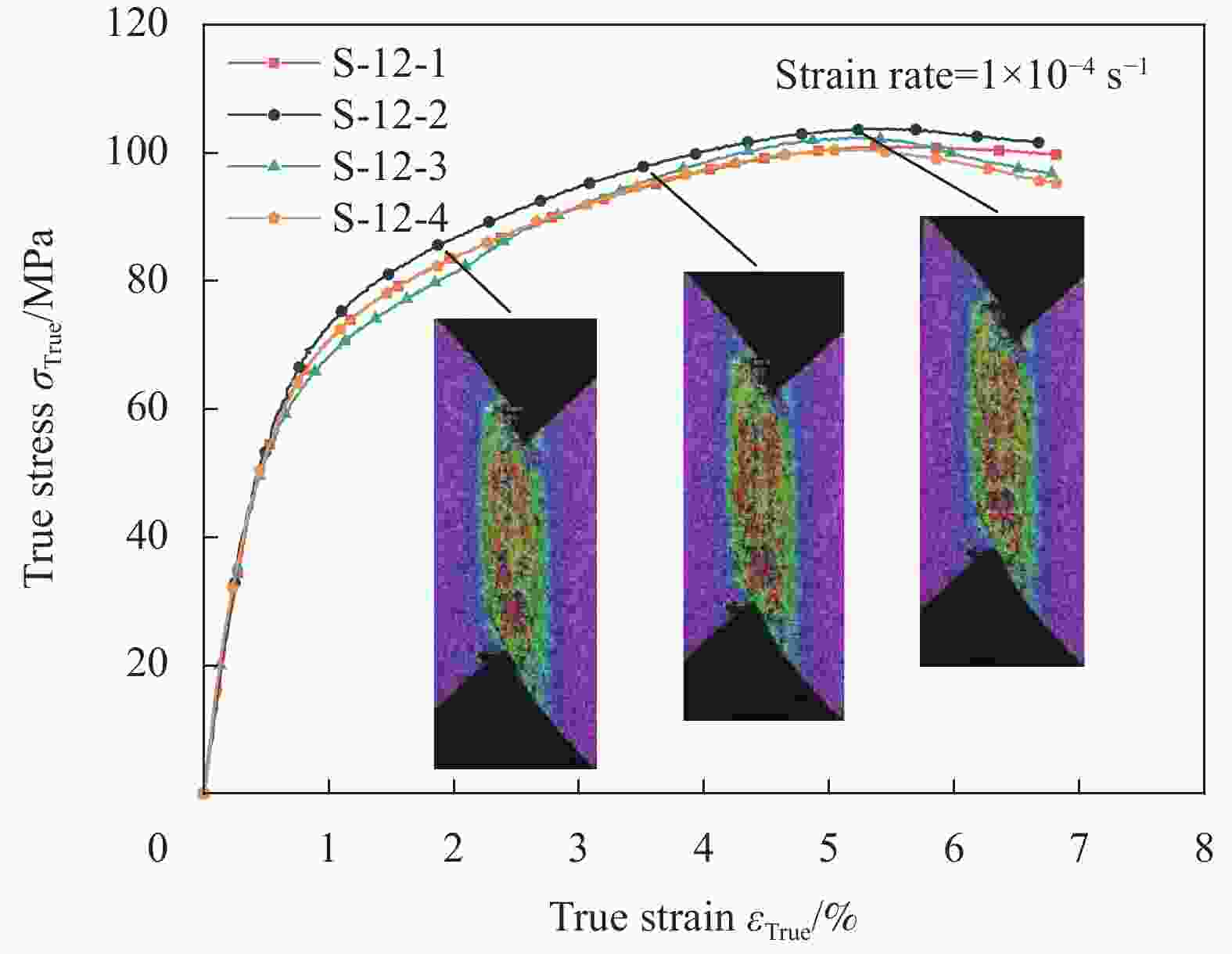

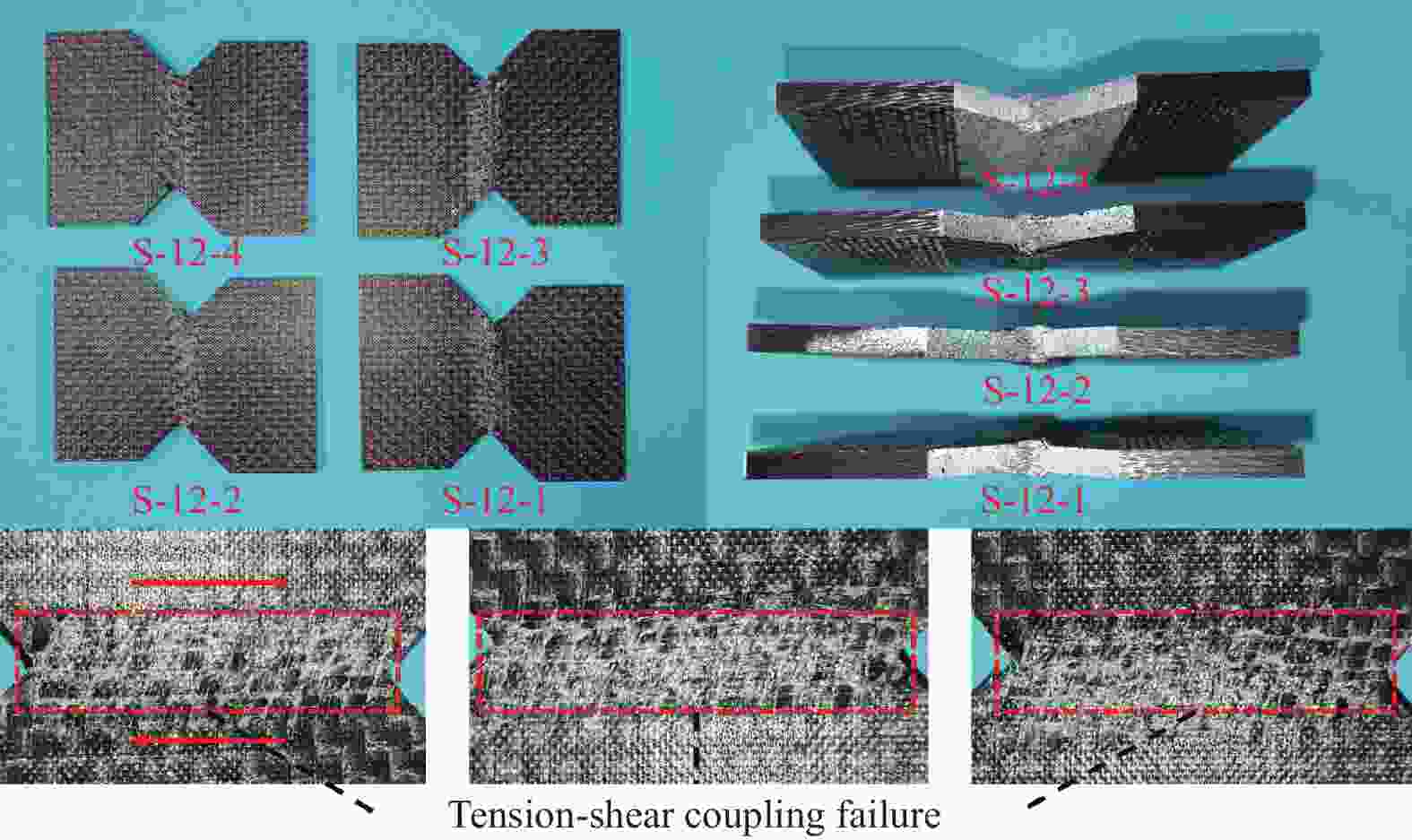

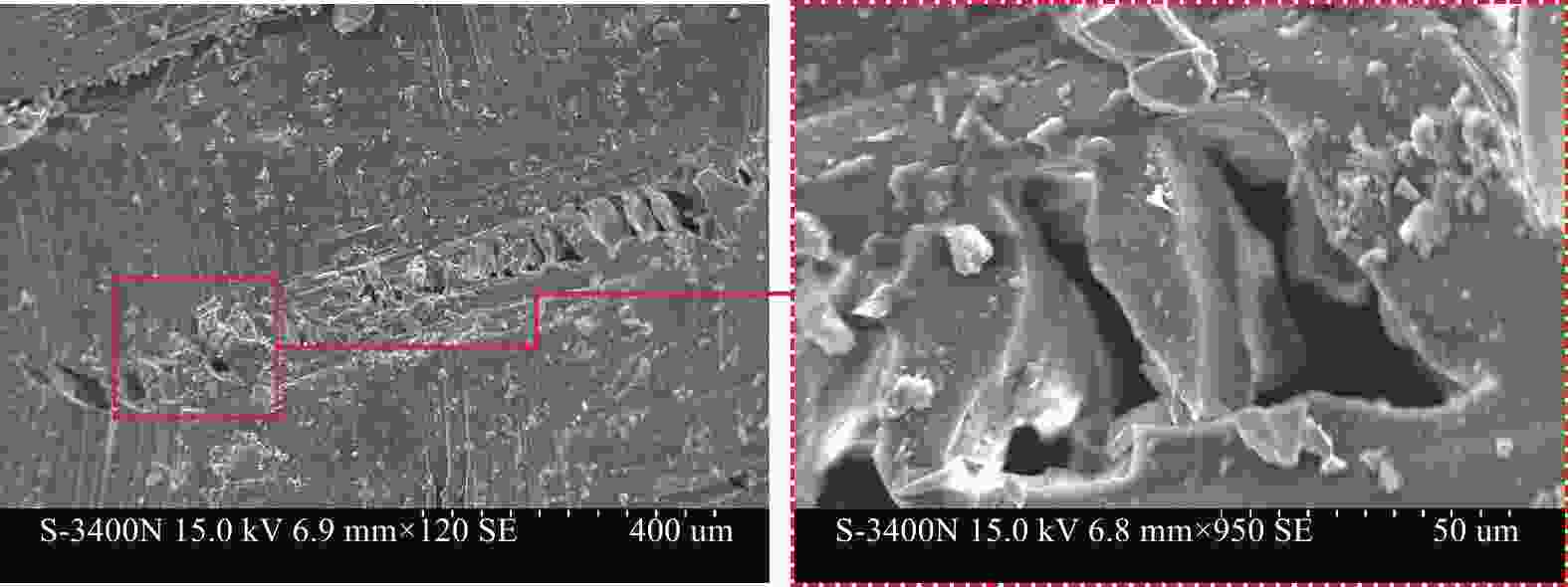

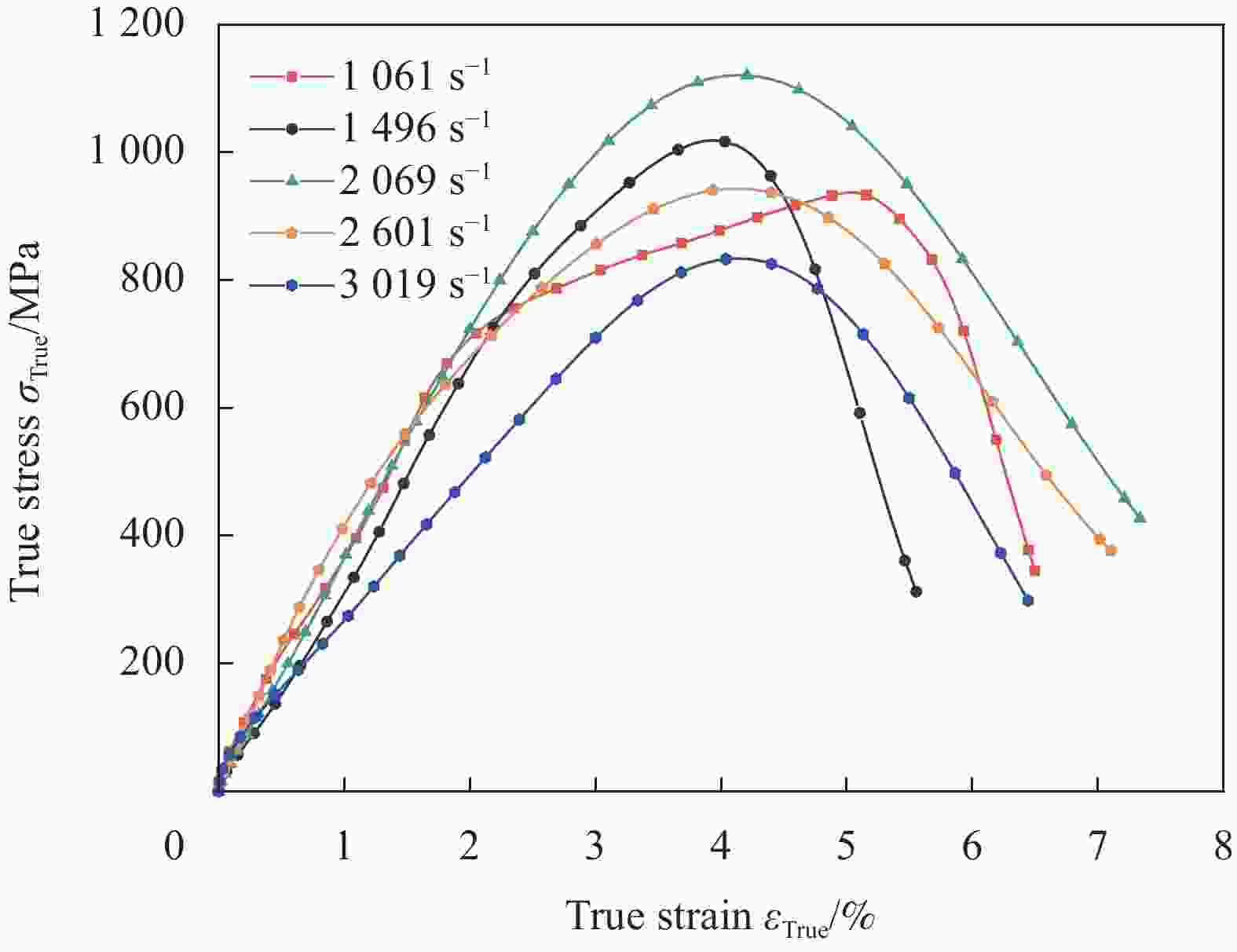

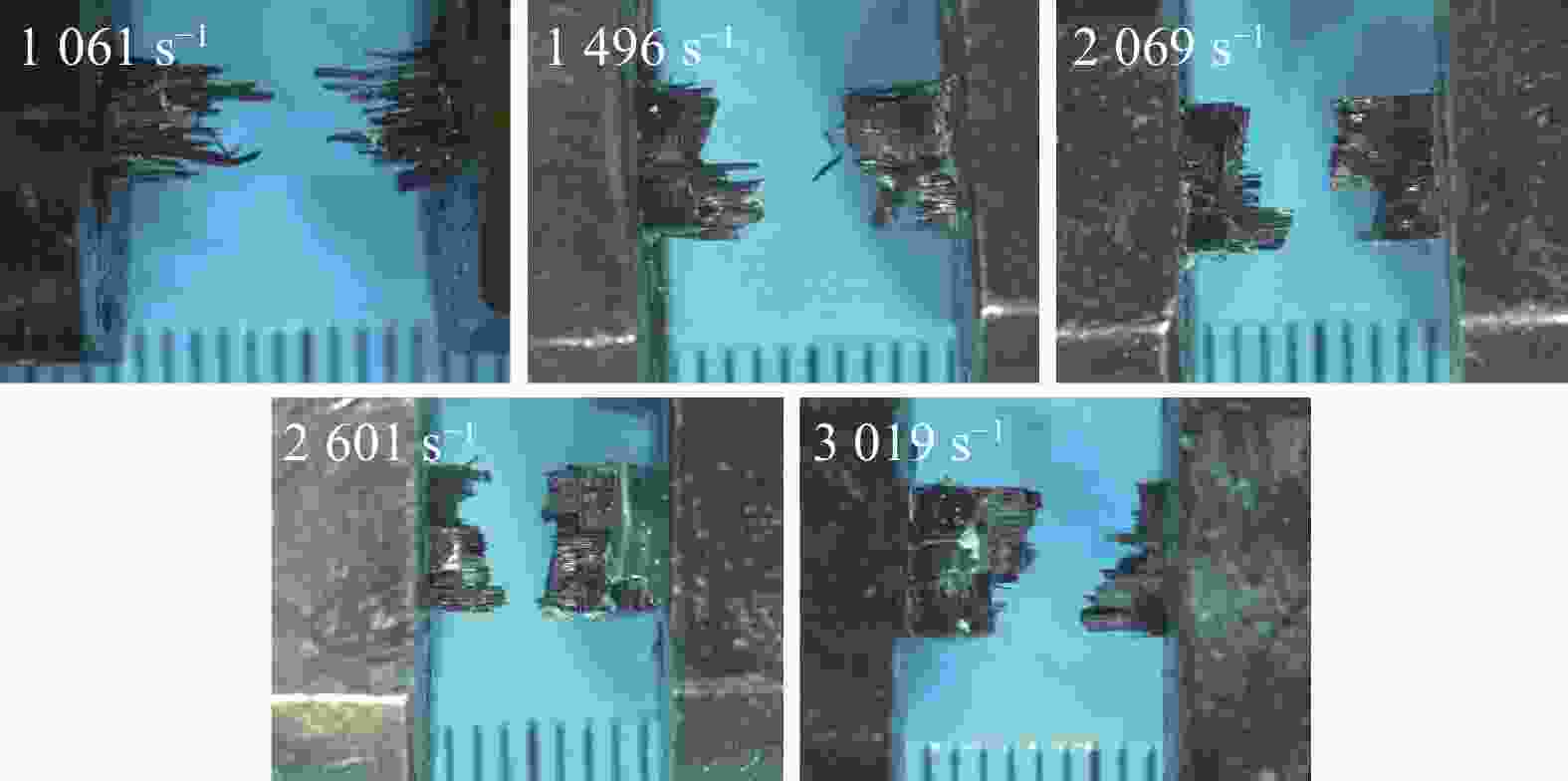

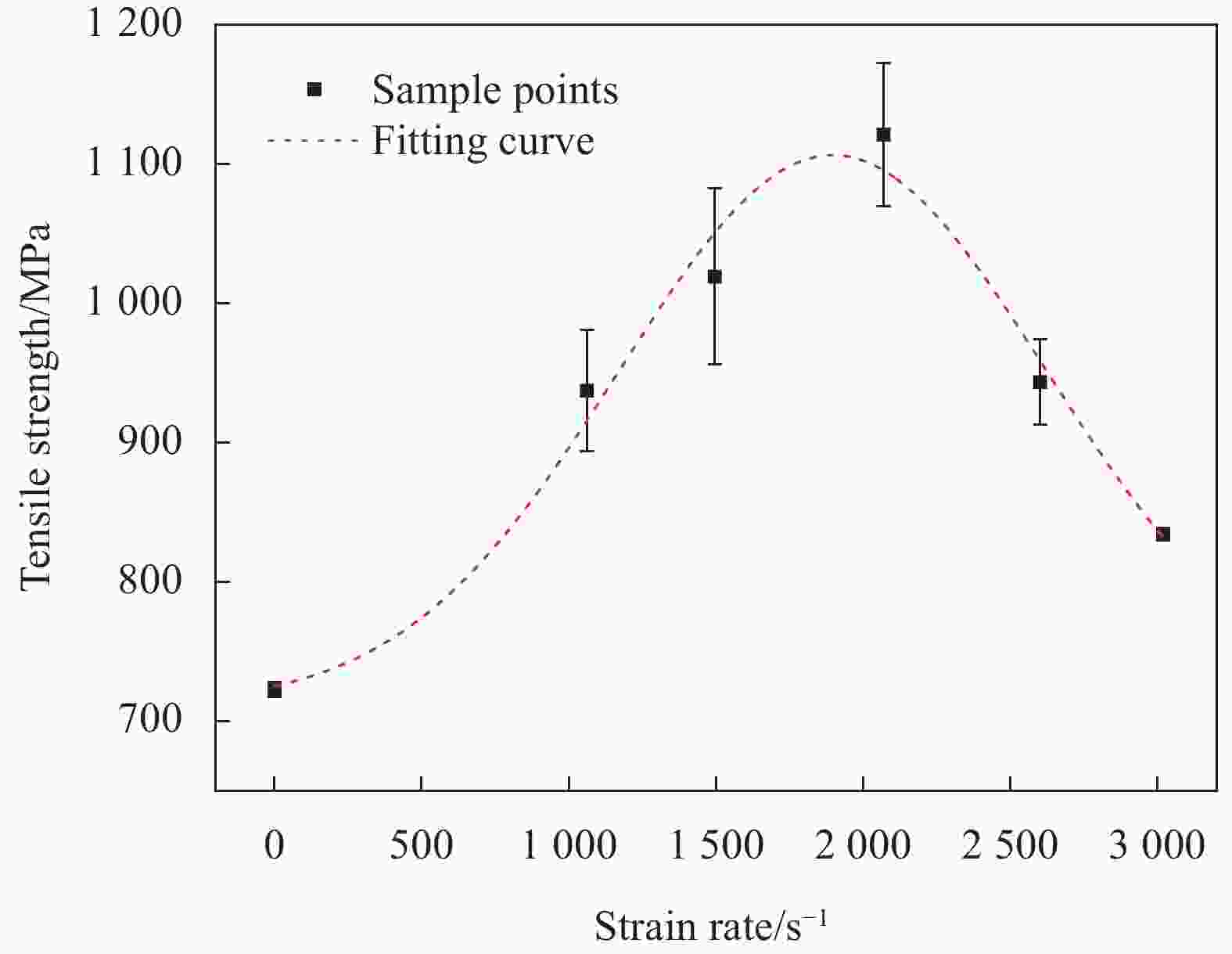

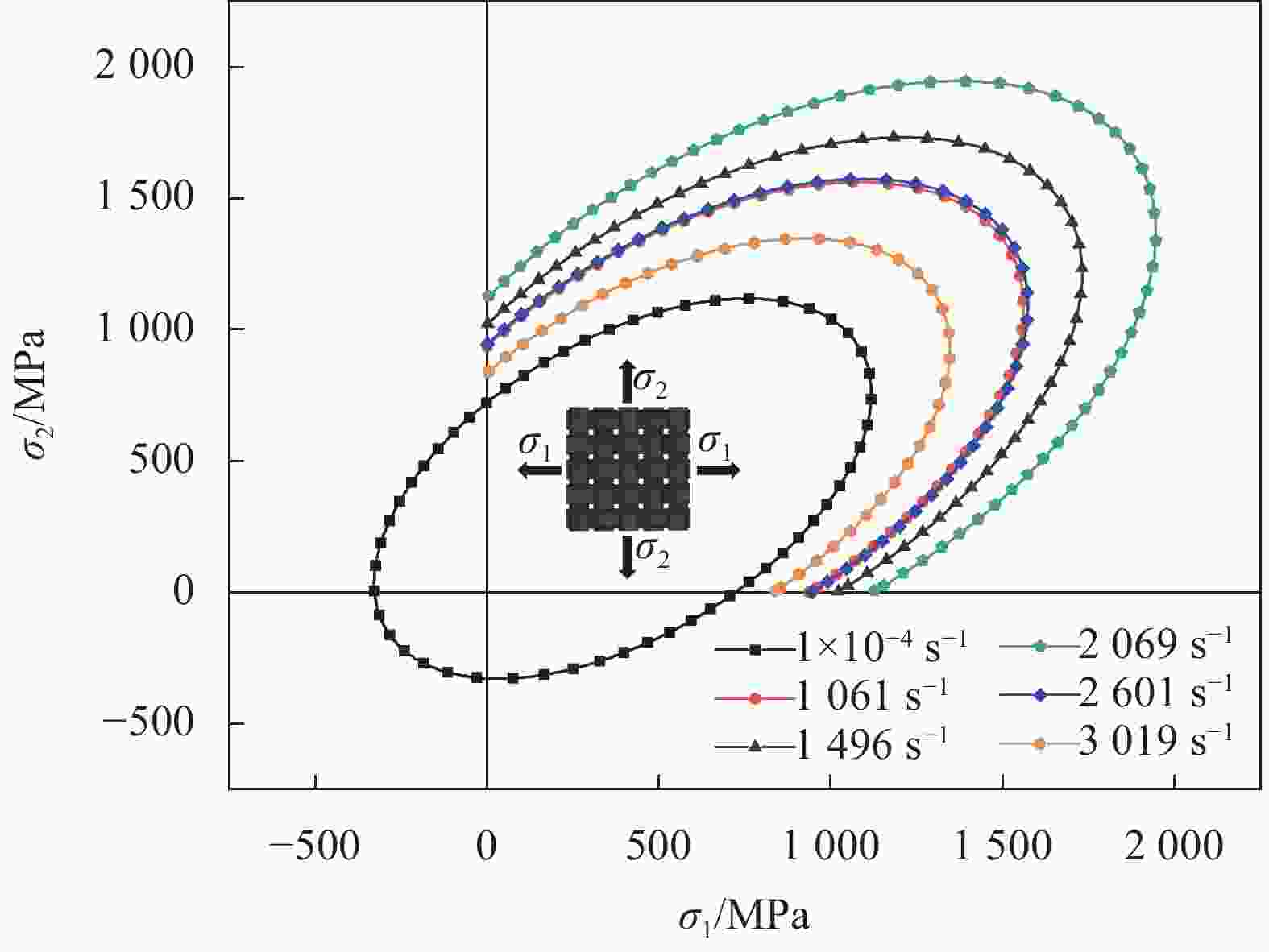

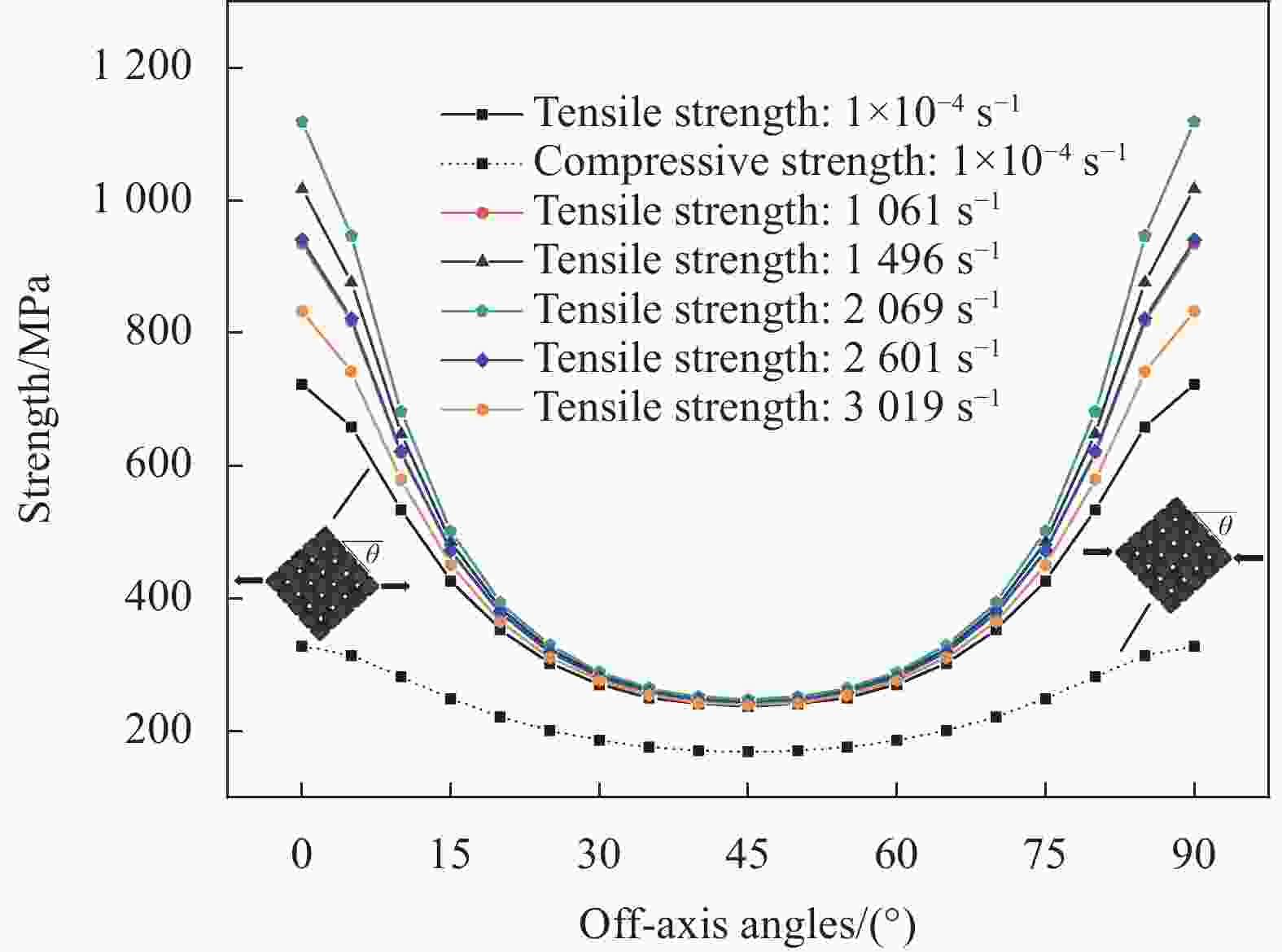

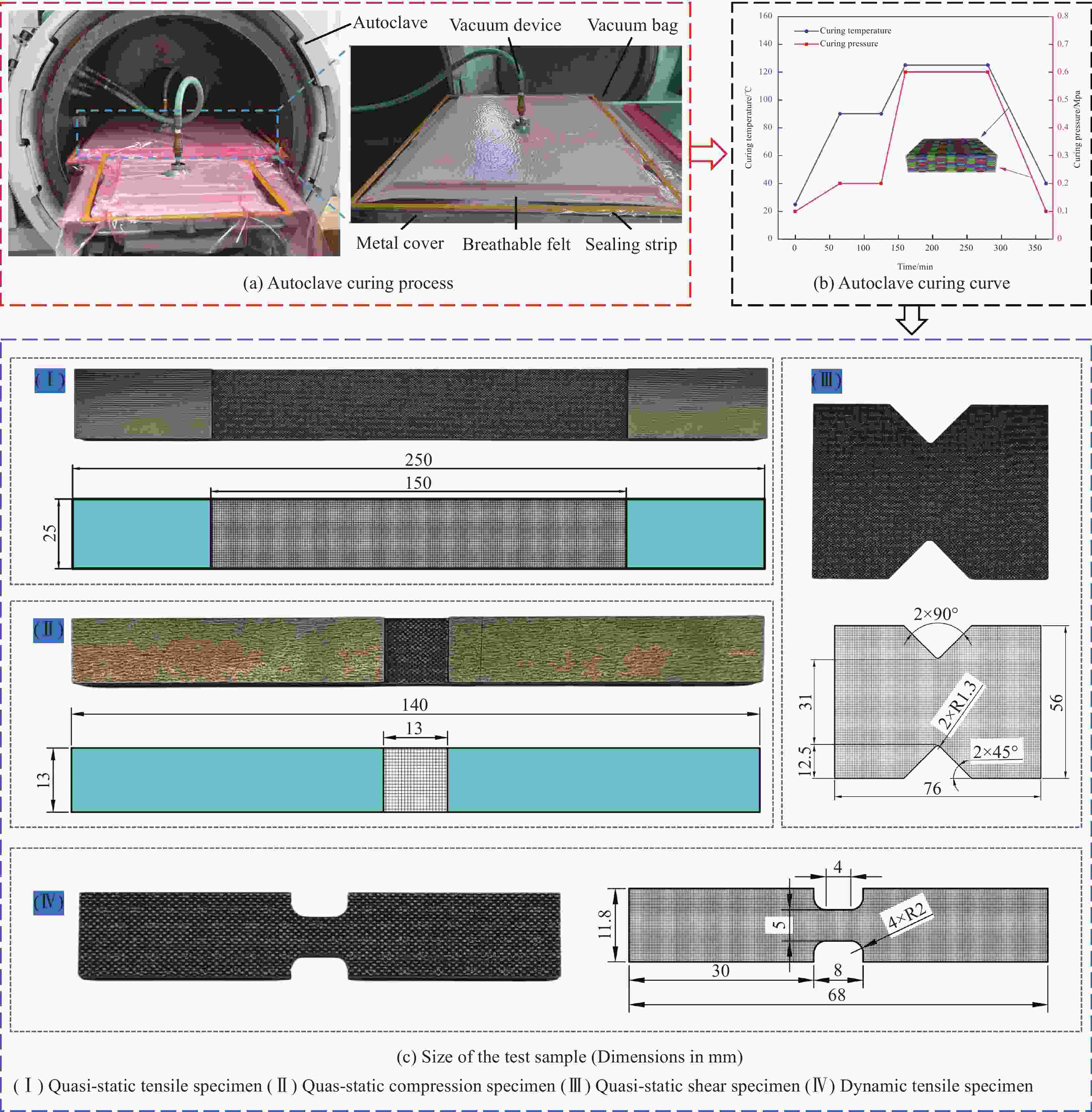

摘要: 平纹编织碳纤维增强聚合物基复合材料(Plain Weave Carbon Fiber Reinforced Polymer,PWCFRP)因其均匀的面内力学性能而被广泛应用于航空、航天、车辆等工程领域,但其力学性能的表征和失效机制的揭示一直是应用中的难点。为探究应力状态与应变率对PWCFRP面内力学行为的影响,进行了准静态拉伸、压缩、剪切实验和动态拉伸实验,分析了材料的力学性能与损伤机制,并基于Tsai-Wu失效准则定量分析了材料在多轴应力状态、不同应变率、不同离轴角下的失效包络。结果表明:准静态载荷下PWCFRP表现出显著的拉压不对称性,拉伸强度相较压缩强度提高了120.46%;拉伸和剪切载荷下PWCFRP的力学行为具有非线性。拉伸状态下材料的失效主要为纤维束的拉伸断裂,断裂位置呈现一定随机性;压缩状态下材料的失效主要是由局部高剪切应力引起的纤维束扭结断裂导致的,断裂角度约呈37°;剪切状态下材料的失效模式主要为树脂的拉剪耦合失效。动态拉伸载荷下PWCFRP的拉伸强度随着应变率的提高先增大后减小,2000 s−1应变率时强度值最高。多轴应力状态下,PWCFRP的拉伸强度和应变率效应显著程度均与离轴角度(0°~45°)呈负相关趋势。Abstract: Plain Weave Carbon Fiber Reinforced Polymer (PWCFRP) is widely used in engineering fields such as aviation, aerospace, and vehicles due to its uniform in-plane mechanical properties. However, its mechanical properties and failure mechanisms have always been difficulties in application. In order to explore the effects of stress state and strain rate on the in-plane mechanical behavior of PWCFRP, we conducted quasi-static tension, compression, shear experiments and dynamic tension experiments to analyze the mechanical properties and damage mechanism of the material, and based on the Tsai-Wu failure criterion, the failure envelope of the material under multi-axial stress state, different strain rates and different off-axis angles was quantitatively analyzed. The results show that under quasi-static load, PWCFRP shows significant tension-compression asymmetry, and the tensile strength is increased by 120.46% compared to the compressive strength; under tensile and shear loads, the mechanical behavior of PWCFRP is nonlinear. The failure of the material in the tensile state is mainly caused by the tensile fracture of the fiber bundles, and the fracture location shows a certain randomness; the material failure in the compressed state is mainly caused by the kink fracture of the fiber bundles caused by local high shear stress, and the fracture angle is approximately 37°; the failure mode of the material in the shear state is mainly the tensile-shear coupling failure of the resin. Under dynamic tensile load, the tensile strength of PWCFRP first increases and then decreases with the increase of strain rate, with the highest strength value at the strain rate of 2000 s−1. Under the multi-axial stress state, the tensile strength and the significance of the strain rate effect of PWCFRP show a negative correlation trend with the off-axis angle (0°-45°).

-

Key words:

- plain woven carbon fiber /

- stress state /

- strain rate effect /

- mechanical behavior /

- failure envelope

-

表 1 准静态力学实验设计

Table 1. Experimental design of quasi-static mechanics

Sample number Displacement rate/(mm·min−1) Strain rate/s−1 T-0-1 ~ T-0-5 0.9 1×10−4 C-0-1 ~ C-0-5 0.08 S-12-1 ~ S-12-5 0.18 Notes:T represents tensile test; C represents compression test; S represents shear plane; 0 represents the warp direction of the yarn; 12 represents the in-plane shear plane; 1~5 represents the test number value. -

[1] KARABOGA F, GOLEC F, YUNUS D E, et al. Mechanical response of carbon fiber reinforced epoxy composite parts joined with varying bonding techniques for aerospace applications[J]. Composite Structures, 2024, 331: 117920. doi: 10.1016/j.compstruct.2024.117920 [2] Hiremath N, Young S, Ghossein H, et al. Low cost textile-grade carbon-fiber epoxy composites for automotive and wind energy applications[J]. Composites Part B: Engineering, 2020, 198: 108156. doi: 10.1016/j.compositesb.2020.108156 [3] 陆文成, 武一丁, 余毅磊, 等. 不同厚度比的SiC陶瓷-纤维增强树脂基复合材料装甲的损伤失效及其抗弹性能[J/OL]. 复合材料学报, 1-132024-08-18]. https: //doi. org/10.13801/j. cnki. fhclxb. 20240508.003. LU Wencheng, WU Yiding, YU Yilei, et al. Damage failure and ballistic performance of SiC ceramic-fiber reinforced resin-based composite armor with different thickness ratios[J/OL]. Acta Materiae Compositae Sinica, 1-13[2024-08-18]. https://doi.org/10.13801/j.cnki.fhclxb.20240508.003(in Chinese). [4] YANG T, Hu L, XIONG X, et al. A comparison of fabric structures for carbon fiber reinforced composite: Laminated and orthogonal woven structures[J]. Polymer Composites, 2021, 42(10): 5300-5309. doi: 10.1002/pc.26223 [5] WANG Z, XIE H, LUO Q, et al. Optimizaition for formability of plain woven carbon fiber fabrics[J]. International Journal of Mechanical Sciences, 2021, 197: 106318. doi: 10.1016/j.ijmecsci.2021.106318 [6] 吕睿, 任毅如. C型CFRP薄壁结构轴向吸能特性及其触发机制[J]. 复合材料学报, 2023, 40(10): 5947-5956.LV Rui, REN Yiru. Axial energy absorption characteristics and trigger mechanism of C-channel CFRP thin-walled structures[J]. Acta Materiae Compositae Sinica, 2023, 40(10): 5947-5956(in Chinese). [7] GONABADI H, OILA A, YADAV A, et al. Structural performance of composite tidal turbine blades[J]. Composite Structures, 2021, 278: 114679. doi: 10.1016/j.compstruct.2021.114679 [8] YANG J, YANG X, ZHU H, et al. The effect of off-axis angles on the mesoscale deformation response and failure behavior of an orthotropic textile carbon-epoxy composite[J]. Composite Structures, 2018, 206: 952-959. doi: 10.1016/j.compstruct.2018.08.010 [9] XIAO J, WU Z, PAN Z, et al. Analysis of in-plane compression failure mechanism in carbon fiber braided composite with different off-axial angles[J]. Journal of Composite Materials, 2022, 56(13): 2029-2046. doi: 10.1177/00219983221077485 [10] QIAN Y, BAO Q, LI Z, et al. Numerical investigation on the mechanical behaviors of 2D woven composites under complex in-plane stress states[J]. Composite Structures, 2023, 315: 117008. doi: 10.1016/j.compstruct.2023.117008 [11] 朱俊, 桂林, 李果, 等. 基于结构参数的平纹机织复合材料等效弹性性能预测[J]. 复合材料学报, 2023, 40(2): 804-813.ZHU Jun, GUI Lin, LI Guo, et al. Prediction of the effective elastic properties for plain woven fabric composite based on the structural parameters[J]. Acta Materiae Compositae Sinica, 2023, 40(2): 804-813(in Chinese). [12] ZHANG X, SHI Y, LI Z. Experimental study on the tensile behavior of unidirectional and plain weave CFRP laminates under different strain rates[J]. Composites Part B: Engineering, 2019, 164: 524-536. doi: 10.1016/j.compositesb.2019.01.067 [13] JIN W, ZHANG Y, JIANG L, et al. A dynamic constitutive model and simulation of braided CFRP under high-speed tensile loading[J]. Materials, 2022, 15(18): 6389. doi: 10.3390/ma15186389 [14] KUMAR M, NAIK N. Prediction of mechanical behavior of composites under high strain rate tensile loading[J]. Mechanics Research Communications, 2018, 90: 1-7. doi: 10.1016/j.mechrescom.2018.04.001 [15] LU J, ZHU P, JI Q, et al. Experimental study of in-plane mechanical properties of carbon fibre woven composite at different strain rates[J]. Polymers and Polymer Composites, 2017, 25(4): 289-298. doi: 10.1177/096739111702500406 [16] LI X, YAN Y, GUO L, et al. Effect of strain rate on the mechanical properties of carbon/epoxy composites under quasi-static and dynamic loadings[J]. Polymer Testing, 2016, 52: 254-264. doi: 10.1016/j.polymertesting.2016.05.002 [17] 王正浩, 赵桂平, 马君峰, 等. 碳/环氧树脂复合材料应变率效应的实验研究[J]. 复合材料学报, 2007, (2): 113119. doi: 10.3321/j.issn:1000-3851.2007.02.020WANG Zhenghao, ZHAO Guiping, MA Junfeng, et al. Experimental study on strain rate effect of carbon/epoxy resin composites[J]. Acta Materiae Compositae Sinica, 2007, (2): 113119(in Chinese). doi: 10.3321/j.issn:1000-3851.2007.02.020 [18] 朱德举, 欧云福. 标距和应变率对Kevlar49单束拉伸力学性能的影响[J]. 复合材料学报, 2016, 33(2): 225-233.ZHU Deju, OU Yunfu. Effects of gauge length and strain rate on tensile mechanical properties of Kevlar49 single yarn[J]. Acta Materiae Compositae Sinica, 2016, 33(2): 225-233(in Chinese). [19] 阮班超, 史同亚, 王永刚. E玻璃纤维增强环氧树脂基复合材料轴向拉伸力学性能的应变率效应[J]. 复合材料学报, 2018, 35(10): 2715-2722.RUAN Banchao, SHI Tongya, WANG Yonggang. Influence of strain rate on tensile mechanical behavior of Eglass fiber reinforced epoxy resin composites[J]. Acta Materiae Compositae Sinica, 2018, 35(10): 2715-2722(in Chinese). [20] 辛振, 沈超明. 计及温度与应变率效应的超高分子量聚乙烯纤维束的拉伸力学性能[J]. 高分子材料科学与工程, 2024, 40(3): 118-124.XIN Zhen, SHEN Chaoming. Tensile mechanical properties of ultra-high molecular weight polyethylene fiber bundles taking into account the effects of temperature and strain rate[J]. Polymer Materials Science and Engineering, 2024, 40(3): 118-124(in Chinese). [21] 蔡宣明, 潘成龙, 郭安肖, 等. 高速冲击加载下碳纤维复合材料层合结构抗侵彻特性及响应机理[J]. 振动与冲击, 2024, 43(12): 88-96+165.CAI Xuanming, Pan Chenglong, Guo Anxiao, et al. Penetration resistance and response mechanism of carbon fiber composite laminated structures under high-speed impact loading[J]. Journal of Vibration and Shock, 2019, 43(12): 88-96+165(in Chinese). [22] Gargano A, Das R, Mouritz A P. Finite element modelling of the explosive blast response of carbon fibre-polymer laminates[J]. Composites Part B: Engineering, 2019, 177: 107412. doi: 10.1016/j.compositesb.2019.107412 [23] 蔡登安. 纤维增强复合材料的力学行为与多轴疲劳性能研究[D]. 南京航空航天大学, 2018.CAI Dengan. Study on Mechanical Behavior and Multi-axial fatigue Properties of fiber reinforced composites [D]. Nanjing University of Aeronautics and Astronautics, 2018(in Chinese). [24] CHAMIS C. Failure criteria for filamentary composites[C]. Composite materials: Testing and design, ASTM STP 460, American Society for Testing and Materials, 1969, 336-351. [25] HOFFMAN O. The brittle strength of orthotropic materials[J]. Journal of Composite Materials, 1967, 1(2): 200-206. doi: 10.1177/002199836700100210 [26] TSAI S, WU E. A general theory of strength for anisotropic materials[J]. Journal of Composite Materials, 1971, 5(1): 58-80. doi: 10.1177/002199837100500106 [27] JENKIN C. Report on materials used in the construction of aircraft and aircraft engines[R]. HM Stationery Office, London, 1920: 95-131. [28] HASHIN Z, ROTEM A. A fatigue failure criterion for fiber reinforced materials[J]. Journal of Composite Materials, 1973, 7(4): 448-464. doi: 10.1177/002199837300700404 [29] CHANG F, CHANG K. A progressive damage model for laminated composites containing stress concentrations[J]. Journal of Composite Materials, 1987, 21(9): 834-855. doi: 10.1177/002199838702100904 [30] TANG Z, ZHANG B. Prediction of biaxial failure envelopes for composite laminates based on Generalized Method of Cells[J]. Composites Part B: Engineering, 2012, 43(3): 914-925. doi: 10.1016/j.compositesb.2012.01.003 [31] DINIZ C, CUNHA S, GOMES G, et al. Optimization of the layers of composite materials from neural networks with Tsai-Wu failure criterion[J]. Journal of Failure Analysis and Prevention, 2019, 19: 709-715. doi: 10.1007/s11668-019-00650-w [32] ARRUDA M. Orthotropic damage model for composite structures using the 3D Tsai-Wu failure criterion[J]. Mechanics of Advanced Materials and Structures, 2023: 1-17. [33] ASTM Standards. Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials: D3039-17[S]. West Conshohocken, PA: ASTM International, 2017. [34] ASTM Standards. Standard Test Method for Compressive Properties of Polymer Matrix Composite Materials Using a Combined Loading Compression (CLC) Test Fixture: D6641-23[S]. West Conshohocken, PA: ASTM International, 2023. [35] ASTM Standards. Standard Test Method for Shear Properties of Composite Materials by V-Notched Rail Shear Method: D7078-20[S]. West Conshohocken, PA: ASTM International, 2020. [36] 孙晓旺. 高效率、高精度耦合算法及对材料冲击响应特性应用的研究[D]. 中国科学技术大学, 2017.SUN Xiaowang. A Study on Coupled Arithmetic of High Efficiency and High Precision and its Application on Material Impact Response[D]. University of Science and Technology of China, 2017(in Chinese). [37] 黄鲛, 陈婧旖, 罗磊, 等. 基于数字图像技术的C/SiC复合材料拉伸行为与失效机制[J]. 复合材料学报, 2022, 39(5): 2387-2397.HUANG Jiao, CHEN Jingyi, LUO Lei, et al. Tensile behavior and failure mechanism of C/SiC composite based on digital image technology[J]. Acta Materiae Compositae Sinica, 2022, 39(5): 2387-2397(in Chinese). [38] JIA S, WANG F, ZHOU J, et al. Study on the mechanical performances of carbon fiber/epoxy composite material subjected to dynamical compression and high temperature loads[J]. Composite Structures, 2020, 258: 113421. [39] 胡燕琪. 高速冲击下三维机织复合材料宏细观建模方法研究[D]. 浙江大学, 2021.HU Yanqi. Study on Macro-meso Modeling Method of 3D Woven Composites under High Speed Impact[D]. Zhejiang University, 2021(in Chinese). [40] PINHO S, DAVILA C, CAMANHO P, et al. Failure models and criteria for FRP under in-plane or three-dimensional stress states including shear non-linearity [R]. National Aeronautics and Space Administration, NASA/TM-2005-213530, 2005. [41] 杨光猛, 万小朋, 侯赤. 纤维束波动效应对平纹编织复合材料损伤行为的影响[J]. 复合材料学报, 2020, 37(1): 132-139.YANG Guangmeng, WAN Xiaopeng, HOU Chi. Damage behavior of plain woven composites considering undulation effect of fiber bundles[J]. Acta Materiae Compositae Sinica, 2020, 37(1): 132-139(in Chinese). [42] 朱德举, 张晓彤, 张怀安. 动态拉伸载荷下应变率和温度对Kevlar 49芳纶纤维布增强环氧树脂复合材料力学性能的影响[J]. 复合材料学报, 2016, 33(3): 459-468.ZHU Deju, ZHANG Xiaotong, ZHANG Huaian. Effect of strain rate and temperature on mechanical properties of epoxy resin composites reinforced by Kevlar 49 aramid fiber cloth under dynamic tensile load[J]. Acta Materiae Compositae Sinica, 2016, 33(3): 459-468(in Chinese). [43] 王正浩, 赵桂平, 马君峰, 等. 碳/环氧树脂复合材料应变率效应的实验研究[J]. 复合材料学报, 2007, (2): 113-119. doi: 10.3321/j.issn:1000-3851.2007.02.020WANG Zhenghao, ZHAO Guiping, MA Junfeng, et al. Experimental study on strain rate effect of carbon/epoxy resin composites[J]. Acta Materiae Compositae Sinica, 2007, (2): 113-119(in Chinese). doi: 10.3321/j.issn:1000-3851.2007.02.020 [44] SUN X, XU Q, ZHU L. An effective Gaussian fitting approach for image contrast enhancement[J]. IEEE Access, 2019, 7: 31946-31958. doi: 10.1109/ACCESS.2019.2900717 [45] 孙晓旺, 张进成, 彭兵, 等. 军用车辆底部爆炸冲击下载员下肢保护装置设计与优化[J]. 兵工学报, 2021, 42(12): 2555-2564. doi: 10.3969/j.issn.1000-1093.2021.12.003SUN Xiaowang, ZHANG Jincheng, PENG Bing, et al. Design and optimization of occupant lower limb protection device against explosion shock below military vehicle[J]. Journal of Ordnance Engineering, 2021, 42(12): 2555-2564(in Chinese). doi: 10.3969/j.issn.1000-1093.2021.12.003 [46] JONES R. Mechanics of composite materials [M]. Washington, DC: Scripta Book Company, 1975. -

点击查看大图

点击查看大图

计量

- 文章访问数: 55

- HTML全文浏览量: 31

- 被引次数: 0

下载:

下载: