Effect of ultra-low temperature on flexural properties of steel fiber reinforced rubber concrete

-

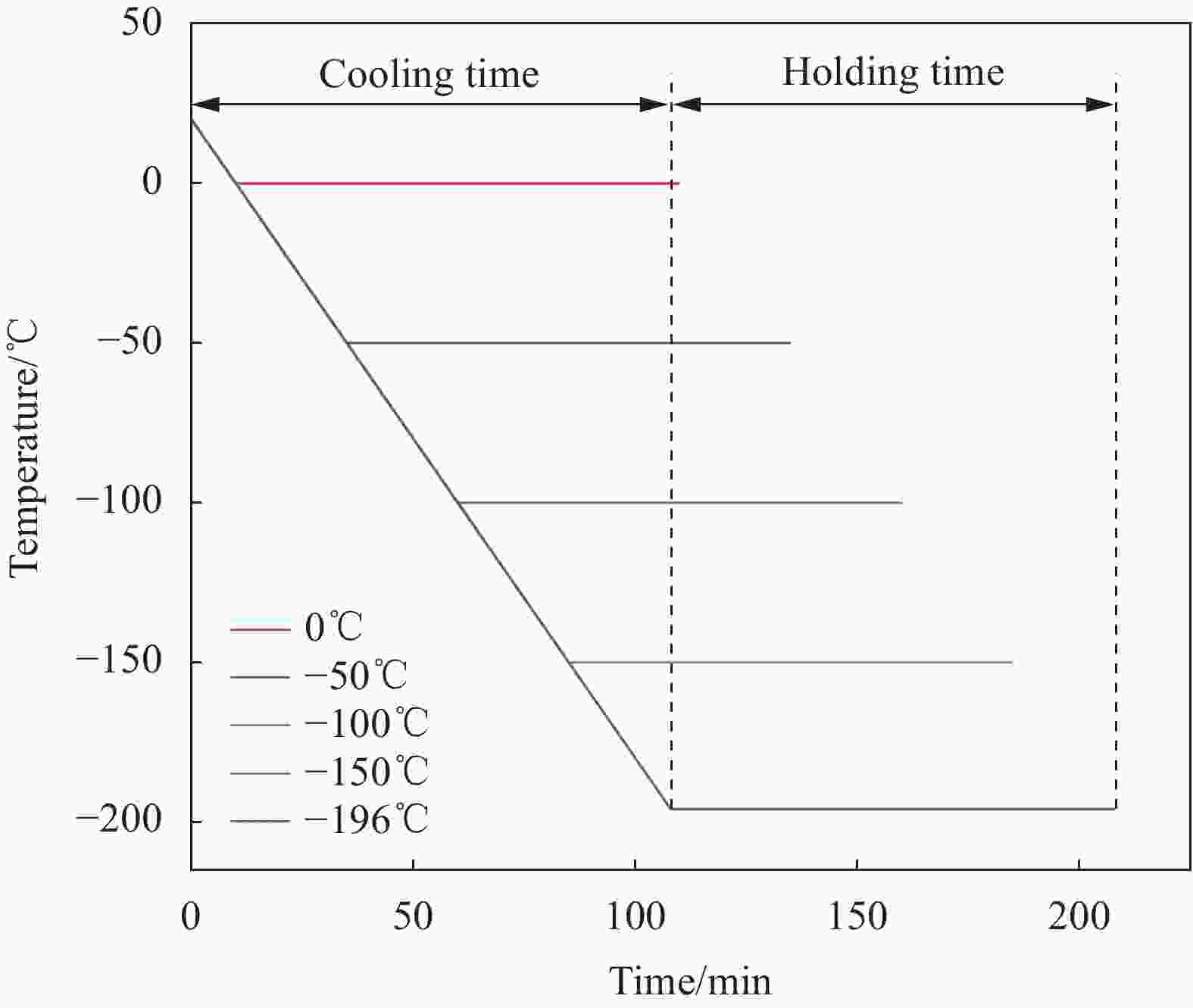

摘要: 采用钢纤维和再生橡胶颗粒制备混凝土可以实现固废资源化利用并保证其良好的力学性能。本文针对超低温(低至−196℃)极端工况下钢纤维增强橡胶混凝土(SFRRC)抗弯性能演变开展研究,设计了7组不同配比的钢纤维增强橡胶混凝土梁式试件,经过低温深冷处理后进行四点弯曲试验,分析了超低温作用对钢纤维橡胶混凝土弯曲性能的影响,结果表明:常温下随着钢纤维和橡胶体积掺量的增加,SFRRC抗弯强度均会明显提升。随着温度的降低,钢纤维增强橡胶混凝土的弯拉强度有明显提升,当温度降低至−196℃时,其抗弯强度最大可提升151.6%;同时SFRRC在超低温环境下韧性会随着温度的降低而下降。研究成果为钢纤维橡胶混凝土的性能优化设计和在超低温工程中的应用提供支持。Abstract: The use of steel fibers and recycled rubber aggregate to prepare concrete can achieve the utilization of solid waste resources and ensure its good mechanical properties. In this paper, the flexural performance evolution of steel fiber reinforced rubber concrete (SFRRC) under the extreme conditions of ultra-low temperature (up to −196℃) was investigated, and seven groups of beam specimens with different ratios of steel fiber reinforced rubber concrete were designed to carry out four-point bending tests after low-temperature deep-cooling treatment to analyze the effect of ultra-low temperature on the flexural properties of SFRRC. It is demonstrated that with the increase of steel fiber and rubber volume admixture, the flexural strength of SFRRC is significantly increased at room temperature. As the temperature decreases, the bending and tensile strength of steel fiber reinforced rubber concrete is significantly improved, and when the temperature decreases to −196℃, its bending strength can be improved by 151.6%. Meanwhile the SFRRC toughness decreases in the ultra-low temperature environments. The research results provide support for the optimal design of steel fiber reinforced rubber concrete and its application in ultra-low temperature engineering.

-

Key words:

- ultra-low temperature /

- steel fiber /

- rubberized concrete /

- bending performance /

- toughness

-

表 1 镀铜微丝钢纤维性能指标

Table 1. Performance index of copper plated microfilament steel fiber

Type Density/(g·cm−3) Diameter/mm Length/mm Elastic modulus/GPa Tensile strength/MPa Copper plated micro wire steel fiber 7.8 0.25 13 200 ≥2850 表 2 橡胶颗粒性能指标

Table 2. Performance index of rubber particles

Type Mesh Apparent density /(kg·m-3) Bulk density/(kg·m-3) Average particle size /μm Rubber particles 80 1180 299 175 表 3 钢纤维橡胶混凝土配合比及试件分组

Table 3. Mix proportion of steel fiber rubber concrete and the grouping of test pieces

Specimen Volume fraction of

steel fiber/vol%Volume fraction of

rubber particle/vol%Steel fiber/

(kg·m−3)Rubber particle/

(kg·m−3)Fly ash/

(kg·m−3)Cement/

(kg·m−3)Sand/

(kg·m−3)Water/

(kg·m−3)NC 0 0 0 0 533.33 120 133.3 248 20%RC 0 20 0 0.24 0.5%SF-20%RC 0.5 20 0.16 0.24 1%SF-10%RC 1.0 10 0.31 0.12 1%SF-20%RC 1.0 20 0.31 0.24 1%SF-30%RC 1.0 30 0.31 0.36 1.5%SF-20%R 1.5 20 0.47 0.24 表 4 SFRRC平均弯拉强度试验值(MPa)

Table 4. Average flexural strength test value of SFRRC specimens (MPa)

Specimen 20℃ 0℃ −50℃ −100℃ −150℃ −196℃ NC 2.70 3.31 6.14 5.73 2.77 0.35 20%RC 2.24 1.95 4.91 10.39 5.82 5.13 0.5%SF-20%RC 2.28 4.84 10.39 14.02 11.87 12.76 1%SF-10%RC 2.96 2.46 6.35 4.98 7.22 6.38 1%SF-20%RC 4.36 4.57 8.00 10.98 8.67 10.18 1%SF -30%RC 4.51 4.87 8.35 14.95 9.76 9.13 1.5%SF -20%RC 7.06 3.68 8.81 18.91 14.82 17.43 -

[1] Xu XQ, Zhang ZG, Hu YG, et al. Bearing Strength of Crumb Rubber Concrete under Partial Area Loading[J]. MATERIALS, 2020, 13(11): 2446. doi: 10.3390/ma13112446 [2] 王晓初, 江必有, 聂晓梅. 中国废旧轮胎循环利用前景与建议[J]. 橡塑技术与装备, 2022, 48(8): 5-8.WANG Xiaochu, JIANG Biyou, NIE Xiaomei. Prospects and suggestions for recycling of waste tires in China[J]. China Rubber/Plastics Technology and Equipment, 2022, 48(8): 5-8 (in Chinese). [3] Liu F, Zheng WH, Li LJ, et al. Mechanical and fatigue performance of rubber concrete[J]. CONSTRUCTION AND BUILDING MATERIALS, 2013, 47: 711-9. doi: 10.1016/j.conbuildmat.2013.05.055 [4] 汪振双, 苏昊林. 冻融条件下再生橡胶混凝土损伤演变与强度相关性研究[J]. 硅酸盐通报, 2016, 35(12): 4286-91.WANG Zhenshuang, SU Hhaolin. Correlation between Recycled Rubber Concrete Strength and Damage Evolution in Freeze Thaw Cycles[J]. BULLETIN OF THE CHINESE CERAMIC SOCIETY, 2016, 35(12): 4286-91 (in Chinese). [5] Savas BZ, Ahmad S, Fedroff D. Freeze-thaw durability of concrete with ground waste tire rubber[J]. Transportation Research Record, 1996, 1574(1): 80-8. [6] Fedroff D, Ahmad S, Savas BZ. Mechanical Properties of Concrete with Ground Waste Tire Rubber[J]. Transportation Research Record, 1996, 1532(1): 66-72. doi: 10.1177/0361198196153200110 [7] 徐金花, 冯夏庭, 陈四利. 橡胶集料对混凝土抗冻性的影响[J]. 东北大学学报(自然科学版), 2012, 33(6): 895-8.XU Jinhua, FENG Xiating, CHEN Sili. Effects of Rubber Aggregate on the Frost Resistance of Concrete[J]. Journal of Northeastern University (Natural Science), 2012, 33(6): 895-8 (in Chinese). [8] 李旭东, 朱江, 张东升. 掺钢纤维的橡胶混凝土力学性能试验研究[C]//天津大学. 第十二届全国现代结构工程学术研讨会暨第二届全国索结构技术交流会论文集. 工业建筑杂志社, 2012: 5.LI Xudong, ZHU Jiang, ZHANG Dongsheng. Experimental study on mechanical properties of steel fiber reinforced rubber concrete[C]// Tianjin University. Proceedings of the 12th National Symposium on Modern Structural Engineering and the 2nd National Technical Exchange Meeting on Cable Structures. Industrial Building Magazine, 2012. 5 (in Chinese). [9] 朱江, 张东升, 李旭东. 钢纤维改性橡胶混凝土的研究应用与展望[C]//天津大学. 第十三届全国现代结构工程学术研讨会论文集. 工业建筑杂志社, 2013: 8.ZHU Jiang, ZHANG Dongsheng, LI Xudong. Application and Prospect of Steel Fiber Modified Rubber Concrete [C] // Tianjin University. Proceedings of the 13th National Symposium on Modern Structural Engineering. Industrial Building Magazine, China 2013. 8 (in Chinese). [10] 高丹盈, 朱海堂, 汤寄予. 纤维高强混凝土抗剪性能的试验研究[J]. 建筑结构学报, 2004, 6: 88-92+8.GAO Danying, ZHU Haitang, TANG Jiyu. Experimental study on behavior of fiber reinforced high-strength concrete under shear[J]. Journal of Building Structures, 2004, 6: 88-92+8 (in Chinese). [11] 梁兴文, 胡翱翔, 于婧, 等. 钢纤维对超高性能混凝土抗弯力学性能的影响[J]. 复合材料学报, 2018, 35(3): 722-31.LIANG Xingwen, HU Aoxiang, YU Jing, et al. Effect of steel fibers on the flexural response of ultra-high performance concrete[J]. Acta Materiae Compositae Sinica, 2018, 35(3): 722-31 (in Chinese). [12] 蒋正武, 李雄英, 张楠. 超低温下高强砂浆强度发展[J]. 硅酸盐学报, 2011, 39(4): 703-7.JIANG Zhengwu, LI Xiongying, ZHANG Nan. Strength development of high strength mortar at very low temperature[J]. Journal of the Chinese Ceramic Society, 2011, 39(4): 703-7 (in Chinese). [13] Xue G, Liu J-x, Cao M-l. A Study of the Impact Resistance of Rubber Concrete at Low Temperatures (-30°C)[J]. Advances in Civil Engineering, 2019, 1: 1-14. doi: 10.35534/ace.0101001c [14] Yu Y, Jin Z, Zhu H, et al. Effect of rubber particles on impact resistance of concrete at a temperature of -20℃[J]. Archives of Civil and Mechanical Engineering, 2021, 21(3): 107. doi: 10.1007/s43452-021-00257-9 [15] Changming B, Dongxu Z, Lei L, et al. Research progress on rubber concrete properties: a review[J]. Journal of Rubber Research, 2022, 25(2): 105-25. doi: 10.1007/s42464-022-00161-8 [16] Dahmani L, Khenane A, Kaci S. Behavior of the reinforced concrete at cryogenic temperatures[J]. Cryogenics, 2007, 47(9): 517-25. [17] Kim M-J, Yoo D-Y, Kim S, et al. Effects of fiber geometry and cryogenic condition on mechanical properties of ultra-high-performance fiber-reinforced concrete[J]. Cement and Concrete Research, 2018, 107: 30-40. doi: 10.1016/j.cemconres.2018.02.003 [18] Kim M-J, Yoo D-Y. Analysis on enhanced pullout resistance of steel fibers in ultra-high performance concrete under cryogenic condition[J]. Construction and Building Materials, 2020, 251: 118953. doi: 10.1016/j.conbuildmat.2020.118953 [19] 艾金华, 何倍, 张翼, 等. 超低温作用下UHPC受弯力学行为及其本构关系[J]. 建筑材料学报, 2024, 27(1): 23-9.AI Jinhua, HE Bei, ZHANG Yi, et al. Flexural Behaviour and Constitutive Correlation of UHPC at Cryogenic Temperatures[J]. JOURNAL OF BUILDING MATERIALS, 2024, 27(1): 23-9 (in Chinese). [20] Xie J, Li X, Wu H. Experimental study on the axial-compression performance of concrete at cryogenic temperatures[J]. Construction and Building Materials, 2014, 72: 380-8. doi: 10.1016/j.conbuildmat.2014.09.033 [21] 苏骏, 钱维民. 超低温作用对超高韧性水泥基复合材料抗弯性能的影响[J]. 复合材料学报, 2022, 39(6): 2844-54.SU Jun, QIAN Weimin. Effect of ultra-low temperature on flexural behavior of ultra-high toughness cementitious composites[J]. Acta Materiae Compositae Sinica, 2022, 39(6): 2844-54 (in Chinese). [22] 中国工程建设协会标准. 纤维混凝土试验方法标准: CECS 13−2010[S] 北京: 中国计划出版社, 2010.China Association for Engineering Construction Standardization. Fiber reinforced concrete test method standard: CECS 13−2010[S]. Beijing: Planning Press, 2010(in Chinese). [23] 时旭东, 居易, 郑建华, 等. 混凝土低温受压强度试验研究[J]. 建筑结构学报, 2014, 44(5): 29-33.SHI Xudong, JU Yi, ZHENG Jianhua, et al. Experimental study on compressive strength of concrete exposed to cryogenic temperature[J]. Building Structure, 2014, 44(5): 29-33 (in Chinese). [24] Rostásy FS, Wiedemann G. Stress-strain-behaviour of concrete at extremely low temperature[J]. Cement and Concrete Research, 1980, 10(4): 565-72. doi: 10.1016/0008-8846(80)90100-3 [25] 胡金泉, 裴万胜, 王冲, 等. 超低温混凝土力学性能与抗冻融耐久性研究进展[J]. 冰川冻土, 2024, 46(1): 111-25.HU Jinquan, PEI Wansheng, WANG Chong, et al. Progress in mechanical properties and frost durability of ultra-low temperature concrete[J]. Journal of Glaciology and Geocryology, 2024, 46(1): 111-125 (in Chinese). [26] 苏骏, 黄福, 王淞波, 等. 低温作用下改性骨料-钢纤维再生混凝土弯曲性能试验[J]. 复合材料学报, 2024, 41(2): 884-97.SU Ju, HUANG Fu, WANG Songbo, et al. Experimental study on bending properties of modified aggregate-steel fibre recycled concrete under low temperature[J]. Acta Materiae Compositae Sinica, 2024, 41(2): 884-97 (in Chinese). [27] Liu J, Cheng L, Zhou D. Study on the flexural performance and brittle fracture characteristics of steel fiber-reinforced concrete exposed to cryogenic temperatures[J]. Construction and Building Materials, 2024, 432: 136604. doi: 10.1016/j.conbuildmat.2024.136604 [28] Montejo Luis A, Sloan John E, Kowalsky Mervyn J, et al. Cyclic Response of Reinforced Concrete Members at Low Temperatures[J]. Journal of Cold Regions Engineering, 2008, 22(3): 79-102. doi: 10.1061/(ASCE)0887-381X(2008)22:3(79) [29] 李丽娟, 陈智泽, 谢伟锋, 等. 橡胶改性高强混凝土基本性能的试验研究[J]. 混凝土, 2007, 5: 60-3.LI Lijuan, CHEN Zhize, XIE Weifeng, et al. Experimental study of the performance of high strength concrete modified by recycled rubber powder[J]. Concrete, 2007, 5: 60-3 (in Chinese). [30] Liu R, Li H, Jiang Q, et al. Experimental investigation on flexural properties of directional steel fiber reinforced rubberized concrete[J]. Structures, 2020, 27: 1660-9. doi: 10.1016/j.istruc.2020.08.007 [31] 高丹盈, 赵亮平, 冯虎, 等. 钢纤维混凝土弯曲韧性及其评价方法[J]. 建筑材料学报, 2014, 17(5): 783-9. doi: 10.3969/j.issn.1007-9629.2014.05.006GAO Danying, ZHAO Liangping, FENG Hu, et al. Flexural Toughness and It's Evaluation Method of Steel Fiber Reinforced Concrete[J]. Journal of building materials, 2014, 17(5): 783-9 (in Chinese). doi: 10.3969/j.issn.1007-9629.2014.05.006 [32] SKAPSKI A, BILLUPS R, A R. Capillary cone method for determination of surface tension of solids.[J]. Journal of Chemical Physics, 1957, 26(5): 1350-1. [33] 过镇海. 混凝土的强度和本构关系[M]. 北京: 中国建筑工业出版社, 2004: 33-39.GUO Zhenhai. Strength and constitutive relation of concrete[M]. Beijing: China Building Industry Press, 2004: 33-39 (in Chinese). [34] Wu Z, Shi C, He W, et al. Effects of steel fiber content and shape on mechanical properties of ultra high performance concrete[J]. Construction and Building Materials, 2016, 103: 8-14. doi: 10.1016/j.conbuildmat.2015.11.028 [35] 赵秋红, 董硕, 朱涵. 钢纤维-橡胶/混凝土单轴受压全曲线试验及本构模型[J]. 复合材料学报, 2021, 38(7): 2359-69.ZHAO Qiuhong, DONG Shuo, ZHU Han. Experiment on stress-strain behavior and constitutive model of steel fiber-rubber/concrete subjected to uniaxial compression[J]. Acta Materiae Compositae Sinica, 2021, 38(7): 2359-69 (in Chinese). -

点击查看大图

点击查看大图

计量

- 文章访问数: 53

- HTML全文浏览量: 31

- 被引次数: 0

下载:

下载: