Performance of interlayer toughened carbon fiber/epoxy composites of low areal density PA66 fiber veil

-

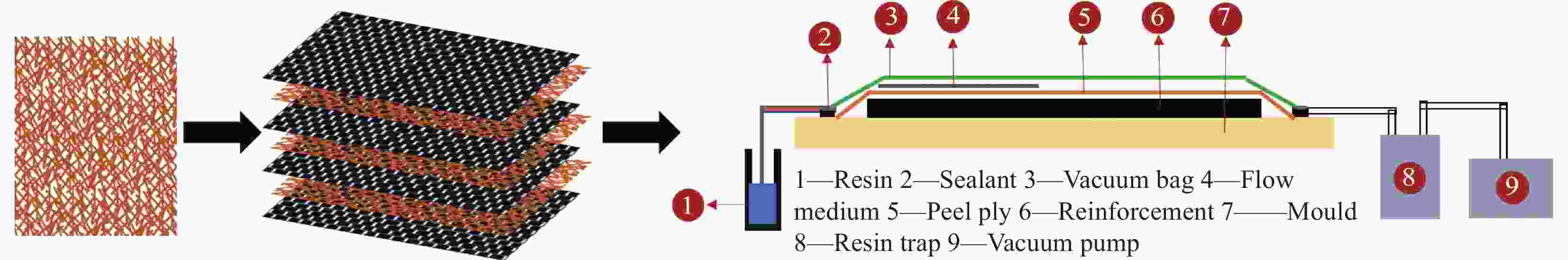

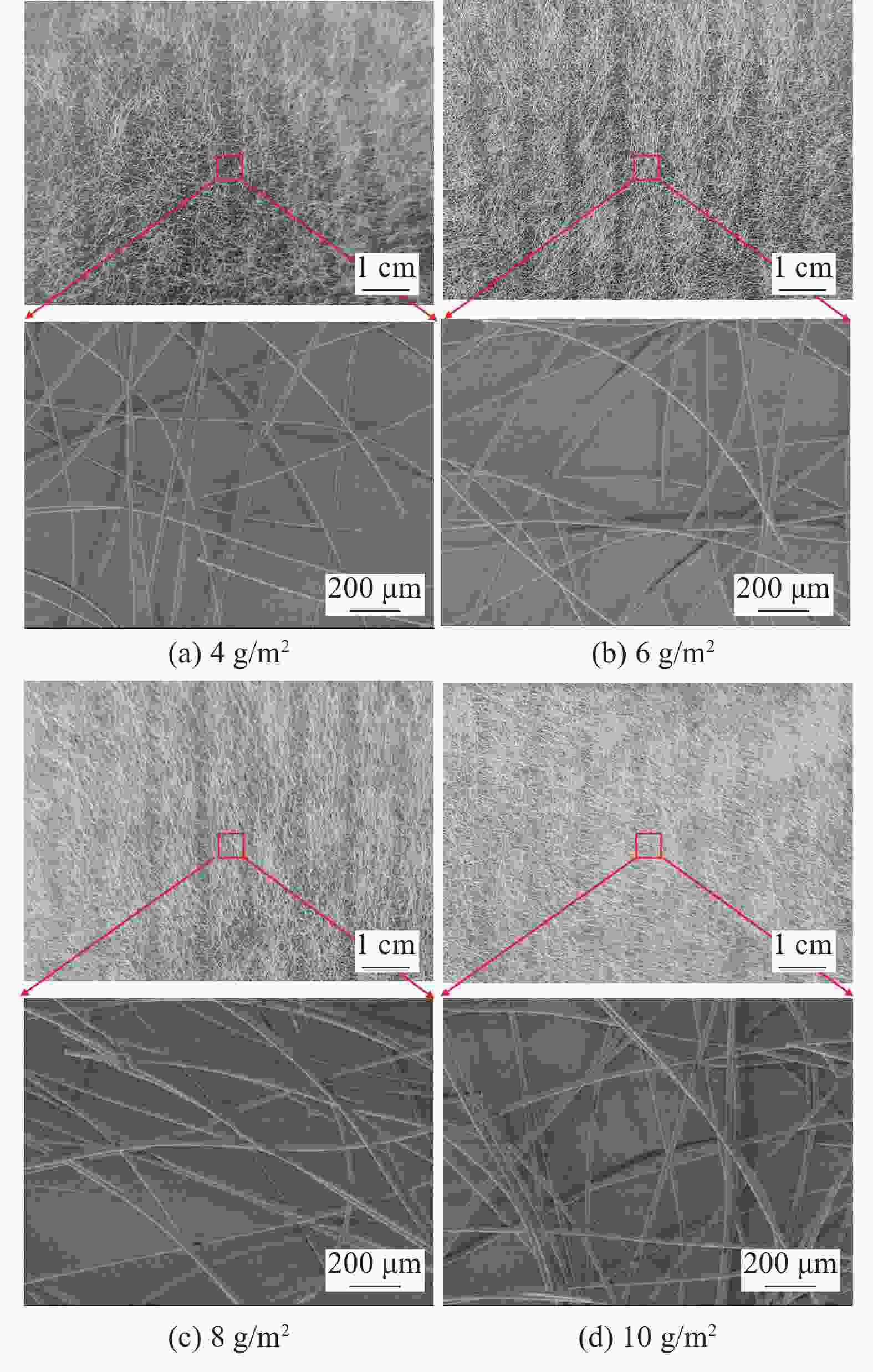

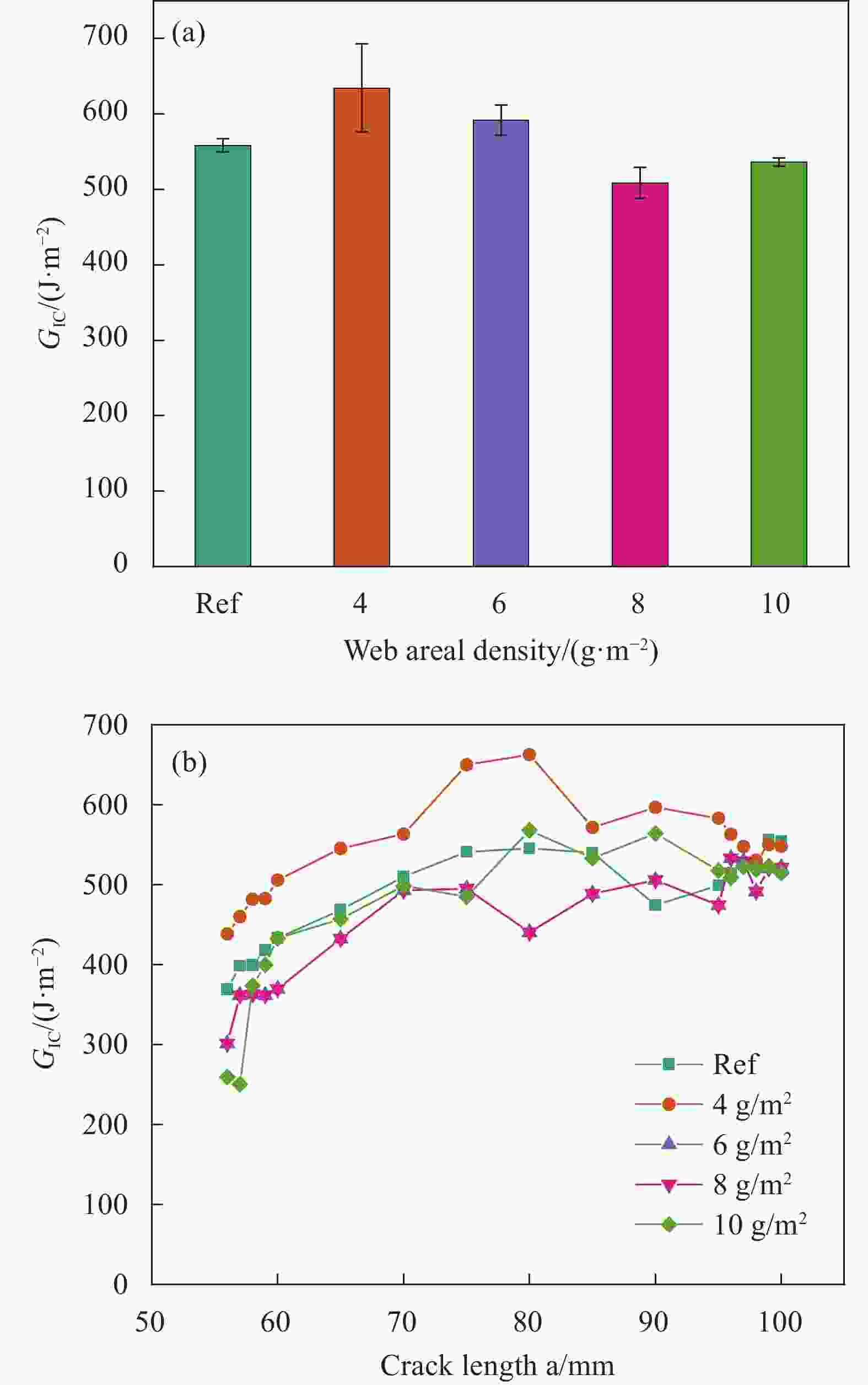

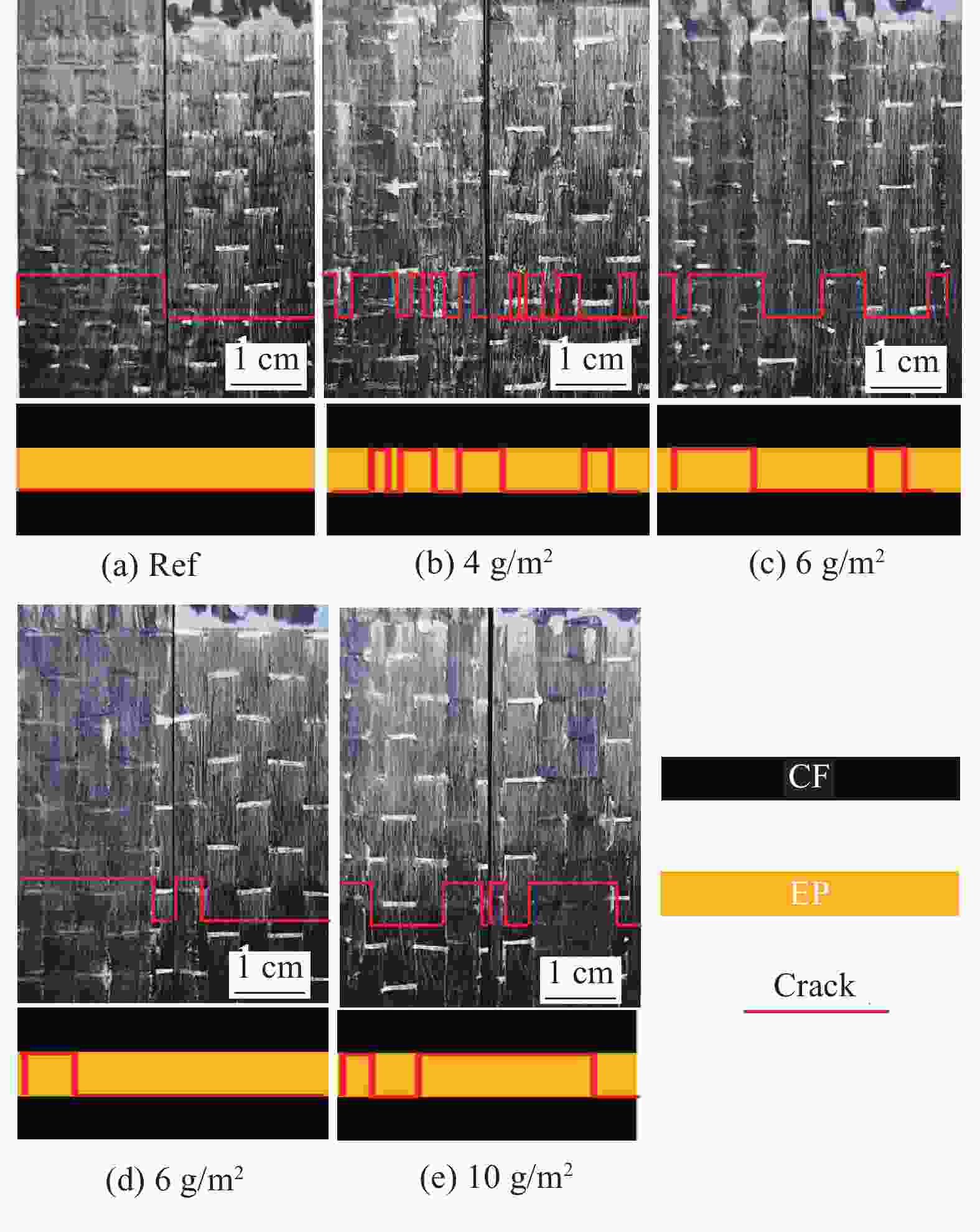

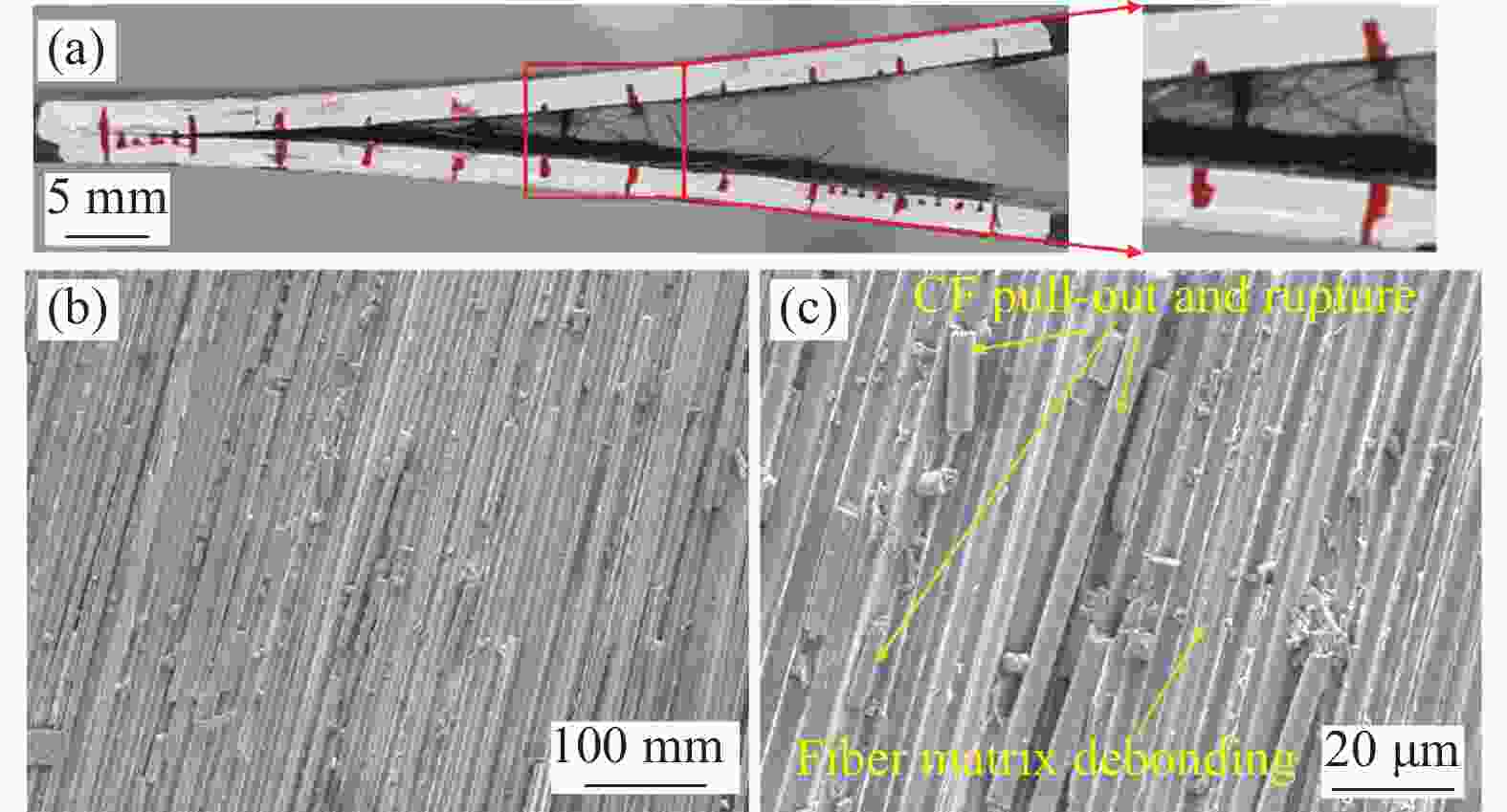

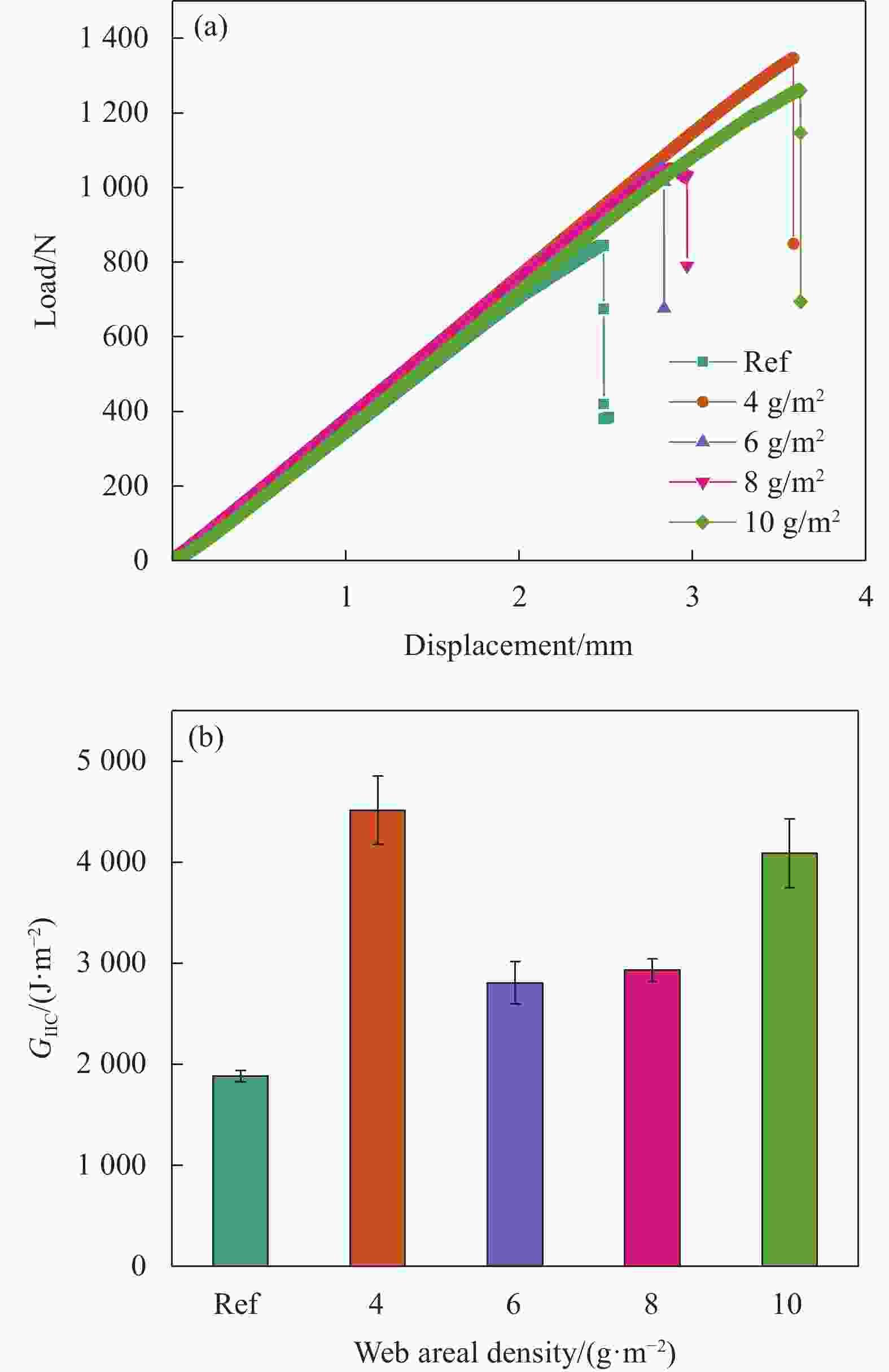

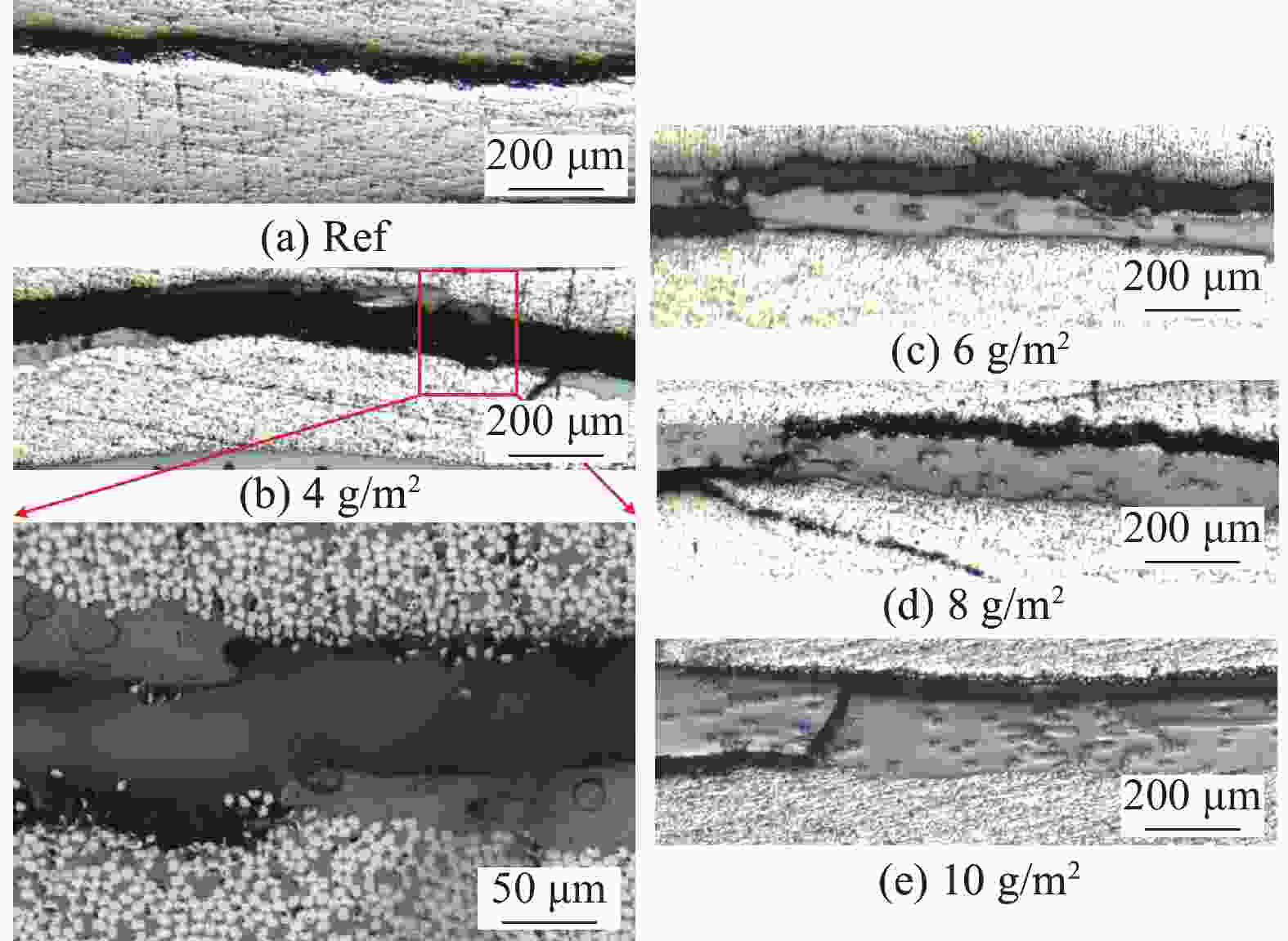

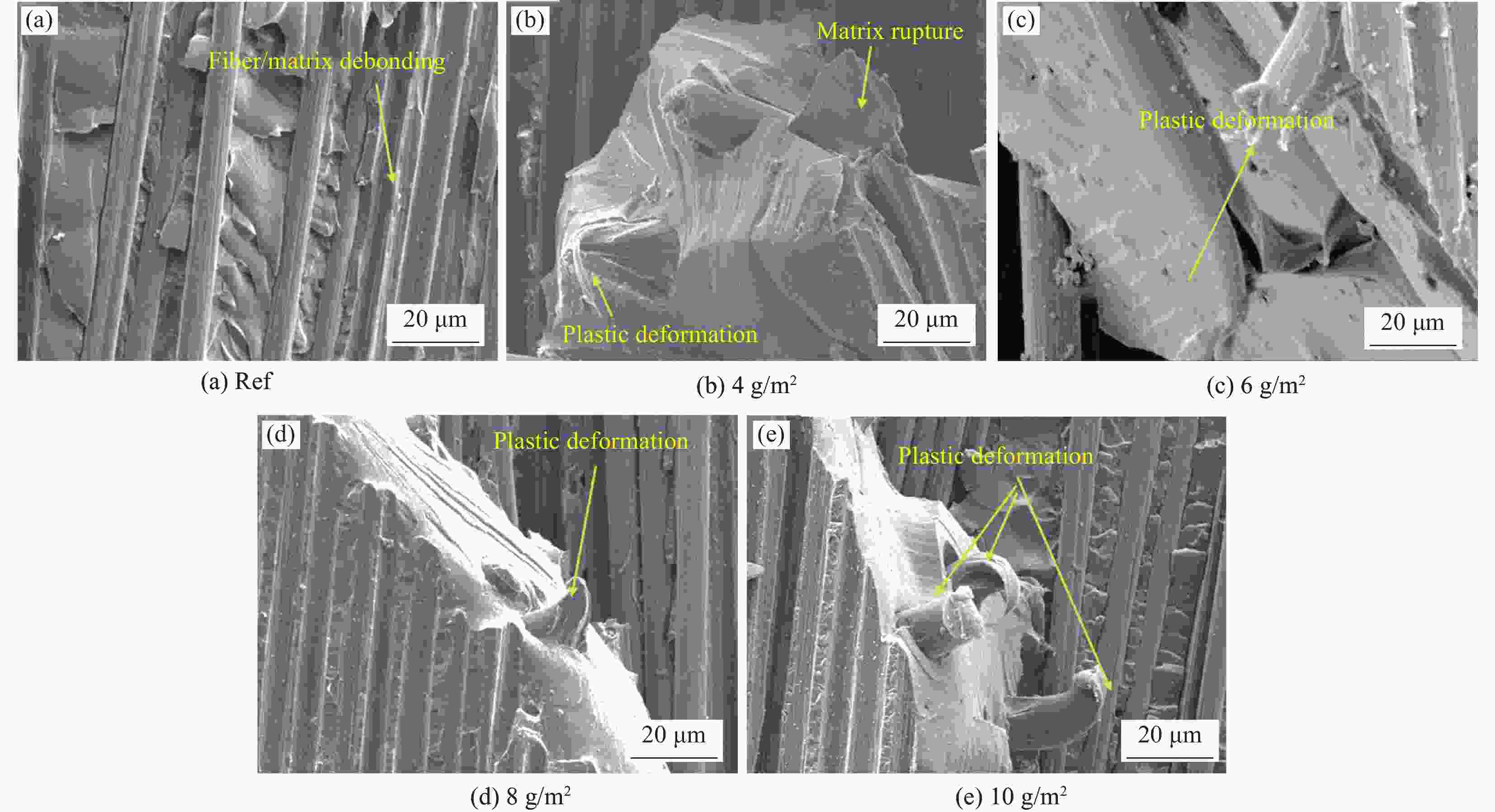

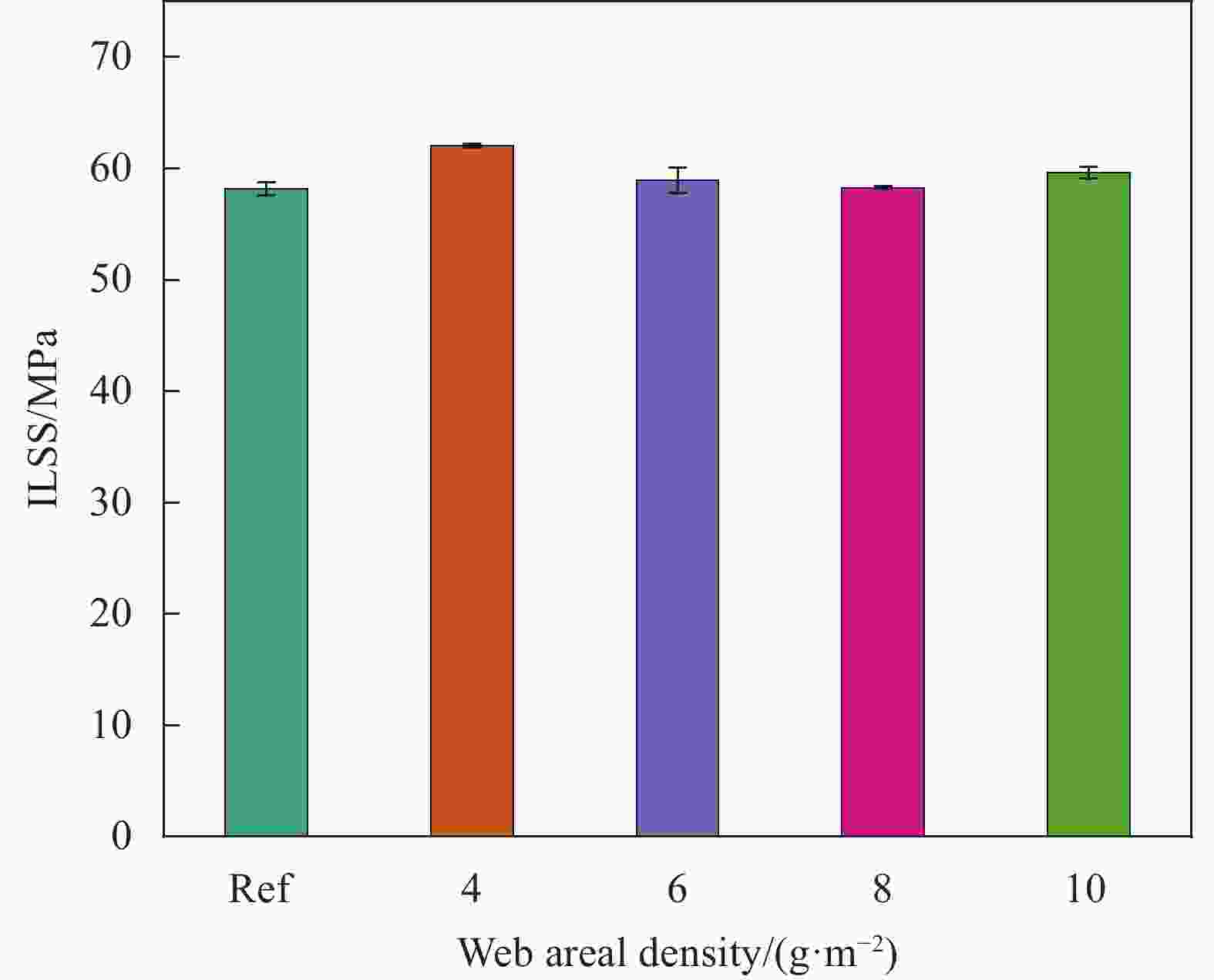

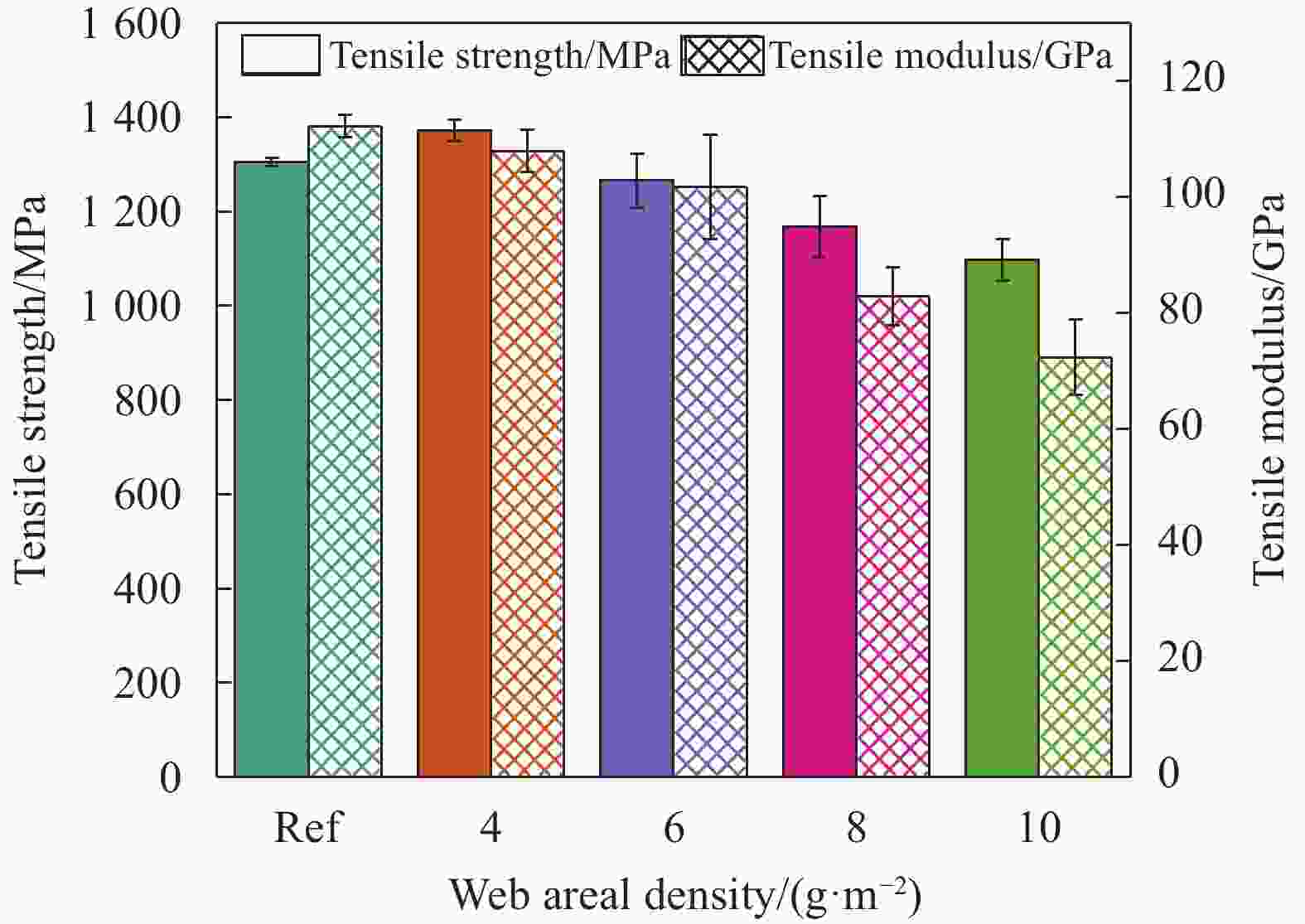

摘要: 为改善碳纤维/环氧(CF/EP)复合材料的层间断裂韧性,通过湿法成网技术制备出四种不同面密度的聚酰胺66纤维网纱(PA66V),随后将增韧网纱插入碳纤维单向布层间,借助真空辅助树脂灌注(VARI)工艺固化成型制备得到CF/EP复合材料。文中测试了增韧前后CF/EP复合材料的I型层间断裂韧性(GIC)和II型层间断裂韧性(GIIC),结合断面SEM照片揭示了PA66V引入后CF/EP复合材料的增韧机制,并研究了网纱的引入对CF/EP复合材料其它力学性能的影响。结果表明,面密度为4 g/m2 PA66V的加入将CF/EP复合材料的GIC和GIIC分别提升了13.6%和139.8%,其增韧机制主要包括PA66纤维的桥接拔出、塑性变形以及引发裂纹偏转等;此时,CF/EP复合材料的层间剪切强度和拉伸强度也分别提高了6.5%和5.2%。Abstract: In order to improve the interlaminar fracture toughness of carbon fiber/epoxy (CF/EP) composites , four polyamide 66 fiber veils (PA66V) with different areal densities were prepared by wet-laid method, and then the toughened fiber veils was inserted into the carbon fiber unidirectional cloth layer, and the CF/EP composite material was prepared by curing and molding by vacuum assisted resin infusion (VARI) process. In this paper, the interlaminar fracture toughness of mode I (GIC) and mode II (GIIC) of CF/EP composites before and after toughening was tested, and the toughening mechanism of CF/EP composites after the introduction of PA66V was revealed by SEM photos of the cross-section, and the effect of the introduction of veils on other mechanical properties of CF/EP composites was studied. The results show that the addition of PA66V with an areal density of 4 g/m2 increases the GIC and GIIC of CF/EP composites by 13.6% and 139.8%, respectively, and its toughening mechanisms mainly include bridging and pulling, plastic deformation and crack deflection of PA66 fibers. At this time, the interlaminar shear strength and tensile strength of CF/EP composites are also increased by 6.5% and 5.2%, respectively.

-

Key words:

- composite /

- interlaminar toughening /

- carbon fiber /

- polyamide 66 /

- fiber veil

-

表 1 拉伸测试样品的纤维体积分数和平均厚度

Table 1. Fiber volume fraction and average thickness of the tensile test samples

Laminate for tensile The average thickness/mm Fiber volume fraction/% Ref 0.81 54.63 4 g/m2 0.90 49.47 6 g/m2 0.97 45.87 8 g/m2 1.02 43.46 10 g/m2 1.12 39.64 -

[1] RAJAK D K, PAGAR D D, MENEZES P L, et al. Fiber-Reinforced Polymer Composites: Manufacturing, Properties, and Applications[J]. Polymers, 2019, 11(10): 1667. doi: 10.3390/polym11101667 [2] DAS T K, GHOSH P, DAS N C. Preparation, development, outcomes, and application versatility of carbon fiber-based polymer composites: a review[J]. Advanced Composites and Hybrid Materials, 2019, 2(2): 214-233. doi: 10.1007/s42114-018-0072-z [3] LIBONATI F, VELLWOCK A E, IELMINI F, et al. Bone-inspired enhanced fracture toughness of de novo fiber reinforced composites[J]. Scientific Reports, 2019, 9(1): 3142. doi: 10.1038/s41598-019-39030-7 [4] HUANG Y, QIU Y, WEI Y. Composite interlaminar fracture toughness imparted by electrospun PPO veils and interleaf particles: A mechanistical comparison[J]. Composite Structures, 2023, 312: 116865. doi: 10.1016/j.compstruct.2023.116865 [5] 李朝阳, 薛怿, 阳泽濠, 等. 聚醚砜多孔纤维网纱层间增韧碳纤维/环氧复合材料的性能[J]. 材料研究学报, 2024, 38(1): 33-42.LI Zhaoyang, XUE Yi, YANG Zehao, et al. Performance of Interlayer Toughened Carbon Fiber/Epoxy Composites of Polyethersulfone Porous Fiber Veil[J]. Chinese Journal of Materials Research, 2024, 38(1): 33-42(in Chinese). [6] 孙厚礼, 孙琳, 王晓波, 等. 碳纤维三维编织-铺层混合结构复合材料管的轴向压缩性能[J]. 复合材料学报, 2024, 41:SUN H L, SUN L, WANG X B, et al. Axial compressive property of 3D braided-unidirectional hybrid tubes[J]. Acta Materiae Compositae Sinica, 2024, 41: (in Chinese). [7] 姚佳伟, 冯瑞瑄, 牛一凡, 等. 纳米碳材料/热塑性树脂层间增韧热固性树脂基复合材料研究进展[J]. 复合材料学报, 2022, 39(2): 528-543.YAO Jiawei, FENG Ruixuan, NIU Yifan, et al. Research progress of the interleaved thermoset composites by carbon nanomaterials/thermoplastic resin[J]. Acta Materiae Compositae Sinica, 2022, 39(2): 528-543(in Chinese). [8] XUE Y, LI Z, LUO J, et al. Simultaneous toughening and strengthening of CF/EP composites through bi-component thermoplastics with hybrid phases between composite layers[J]. Composites Part B:Engineering, 2024, 274: 111286. doi: 10.1016/j.compositesb.2024.111286 [9] OU Y, FU A, WU L, et al. Enhanced interlaminar fracture toughness of unidirectional CFRP laminates with tailored microstructural heterogeneity of toughening layer[J]. Composites Part A:Applied Science and Manufacturing, 2024, 176: 107872. doi: 10.1016/j.compositesa.2023.107872 [10] YU B, WANG W, ZHOU G, et al. Rapid and scalable synthesis of novel carboxylated aramid nanofibers for simultaneously improving the strength and toughness of carbon fiber/epoxy laminates[J]. Composites Science and Technology, 2024, 245: 110320. doi: 10.1016/j.compscitech.2023.110320 [11] CHEN Q, WU F, JIANG Z, et al. Improved interlaminar fracture toughness of carbon fiber/epoxy composites by a combination of extrinsic and intrinsic multiscale toughening mechanisms[J]. Composites Part B:Engineering, 2023, 252: 110503. doi: 10.1016/j.compositesb.2023.110503 [12] MACCAFERRI E, MAZZOCCHETTI L, BENELLI T, et al. Self-Assembled NBR/Nomex Nanofibers as Lightweight Rubbery Nonwovens for Hindering Delamination in Epoxy CFRPs[J]. ACS Applied Materials & Interfaces, 2022, 14(1): 1885-1899. [13] CUGNONI J, AMACHER R, KOHLER S, et al. Towards aerospace grade thin-ply composites: Effect of ply thickness, fibre, matrix and interlayer toughening on strength and damage tolerance[J]. Composites Science and Technology, 2018, 168: 467-477. doi: 10.1016/j.compscitech.2018.08.037 [14] CHENG C, ZHANG C, ZHOU J, et al. Improving the interlaminar toughness of the carbon fiber/epoxy composites via interleaved with polyethersulfone porous films[J]. Composites Science and Technology, 2019, 183: 107827. doi: 10.1016/j.compscitech.2019.107827 [15] MARINO S G, KOŠŤáKOVá E K, CZéL G. Development of pseudo-ductile interlayer hybrid composites of standard thickness plies by interleaving polyamide 6 nanofibrous layers[J]. Composites Science and Technology, 2023, 234: 109924. doi: 10.1016/j.compscitech.2023.109924 [16] 张代军, 包建文, 钟翔屿, 等. 聚醚砜超细纤维无纺布层间增韧碳纤维环氧复合材料制备与表征[J]. 复合材料学报, 2022, 39(8): 3767-3775.ZHANG Daijun, BAO Jianwen, ZHONG Xiangyu, et al. Preparation and properties of carbon fiber reinforced epoxy resin composites interlaminate-toughened by polyethersulfone ultrafine-fiber non-woven fabric[J]. Acta Materiae Compositae Sinica, 2022, 39(8): 3767-3775(in Chinese). [17] VAN DER HEIJDEN S, DAELEMANS L, MEIREMAN T, et al. Interlaminar toughening of resin transfer molded laminates by electrospun polycaprolactone structures: Effect of the interleave morphology[J]. Composites Science and Technology, 2016, 136: 10-17. doi: 10.1016/j.compscitech.2016.09.024 [18] SAGHAFI H, FOTOUHI M, MINAK G. Improvement of the Impact Properties of Composite Laminates by Means of Nano-Modification of the Matrix—A Review[J]. Applied Sciences, 2018, 8(12): 2406. doi: 10.3390/app8122406 [19] SALIMI-MOFRAD H, RAHBAR RANJI A, SAGHAFI H. Effect of electrospun PA66 nanofibrous mat thickness on mode-II fracture toughness using acoustic emission (AE) with data clustering technique[J]. Theoretical and Applied Fracture Mechanics, 2023, 124: 103788. doi: 10.1016/j.tafmec.2023.103788 [20] BECKERMANN, GARETH W, PICKERING, et al. Mode I and Mode II interlaminar fracture toughness of composite laminates interleaved with electrospun nanofibre veils[J]. Composites, Part A Applied science and manufacturing, 2015, 72: 11-21 doi: 10.1016/j.compositesa.2015.01.028 [21] BECKERMANN G W. Nanofiber interleaving veils for improving the performance of composite laminates[J]. Reinforced Plastics, 2017, 61(5): 289-293. doi: 10.1016/j.repl.2017.03.006 [22] BEYLERGIL B, TANOĞLU M, AKTAŞ E. Effect of polyamide-6, 6 (PA 66) nonwoven veils on the mechanical performance of carbon fiber/epoxy composites[J]. Composite Structures, 2018, 194: 21-35. doi: 10.1016/j.compstruct.2018.03.097 [23] CHENG C, CHEN Z, HUANG Z, et al. Simultaneously improving mode I and mode II fracture toughness of the carbon fiber/epoxy composite laminates via interleaved with uniformly aligned PES fiber webs[J]. Composites Part A:Applied Science and Manufacturing, 2020, 129: 105696. doi: 10.1016/j.compositesa.2019.105696 [24] ASTM. Standard test method for mode I interlaminar fracture toughness of unidirectional fiber-reinforced polymer matrix composites: D5528/D5528 M-21[S]. West Conshohocken: ASTM International, 2021 [25] ASTM. Standard test method for determination of the mode Ⅱ interlaminar fracture toughness of unidirectional fiber-reinforced polymer matrix composites: D7905/D7905 M-19[S]. West Conshohocken: ASTM International, 2019. [26] ASTM. Standard test method for short-beam strength of polymer matrix composite materials and their laminates: ASTM D2344/D2344 M−16[S]. West Conshohocken: ASTM International, 2016. [27] ASTM. Standard test method for tensile properties of polymer matrix composite materials: D3039/D3039 M-14[S] West Conshohocken: ASTM International, 2014. [28] 吴龙强, 欧云福, 茅东升, 等. 取向碳纳米管纤维纱插层碳纤维/环氧树脂复合材料的层间性能及增韧机制[J]. 复合材料学报, 2023, 40(10): 5611-5620.WU Longqiang, OU Yunfu, MAO Dongsheng, et al. Interlaminar properties and toughening mechanisms of aligned carbon nanotube fiber veil interleaved carbon fiber/epoxy composites[J]. Acta Materiae Compositae Sinica, 2023, 40(10): 5611-5620(in Chinese). [29] DAELEMANS L, VAN DER HEIJDEN S, DE BAERE I, et al. Nanofibre bridging as a toughening mechanism in carbon/epoxy composite laminates interleaved with electrospun polyamide nanofibrous veils[J]. Composites Science and Technology, 2015, 117: 244-256. doi: 10.1016/j.compscitech.2015.06.021 [30] OU Y, GONZáLEZ C, VILATELA J J. Interlaminar toughening in structural carbon fiber/epoxy composites interleaved with carbon nanotube veils[J]. Composites Part A:Applied Science and Manufacturing, 2019, 124: 105477. doi: 10.1016/j.compositesa.2019.105477 [31] XU F, YANG B, FENG L, et al. Improved Interlaminar Fracture Toughness and Electrical Conductivity of CFRPs with Non-Woven Carbon Tissue Interleaves Composed of Fibers with Different Lengths[J]. Polymers, 2020, 12(4): 803. doi: 10.3390/polym12040803 -

点击查看大图

点击查看大图

计量

- 文章访问数: 119

- HTML全文浏览量: 78

- 被引次数: 0

下载:

下载: