Surface characterization of polyether-ether-ketone by inverse gas chromatography and the application in the improvement of thermoplastic composites interlaminar performance

-

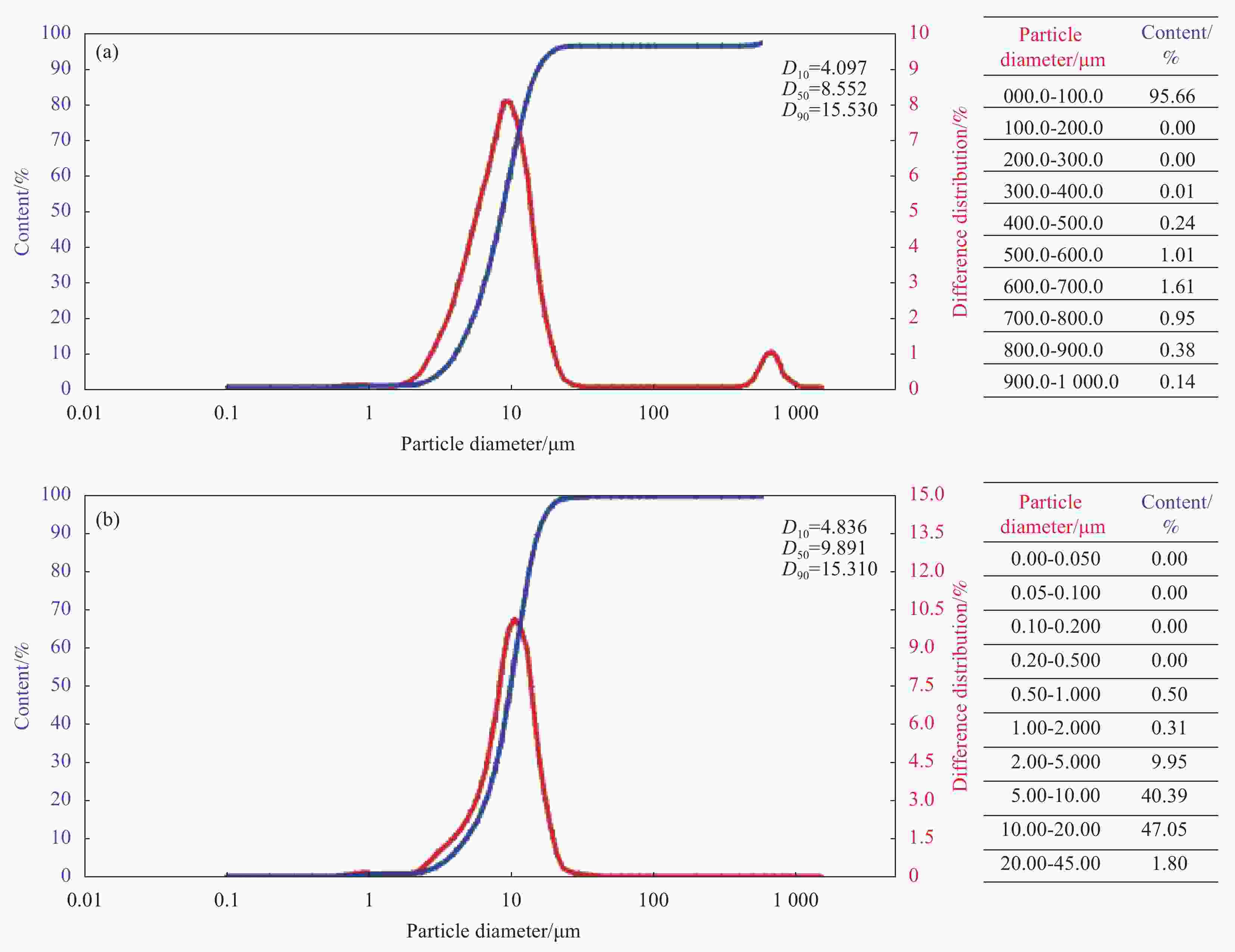

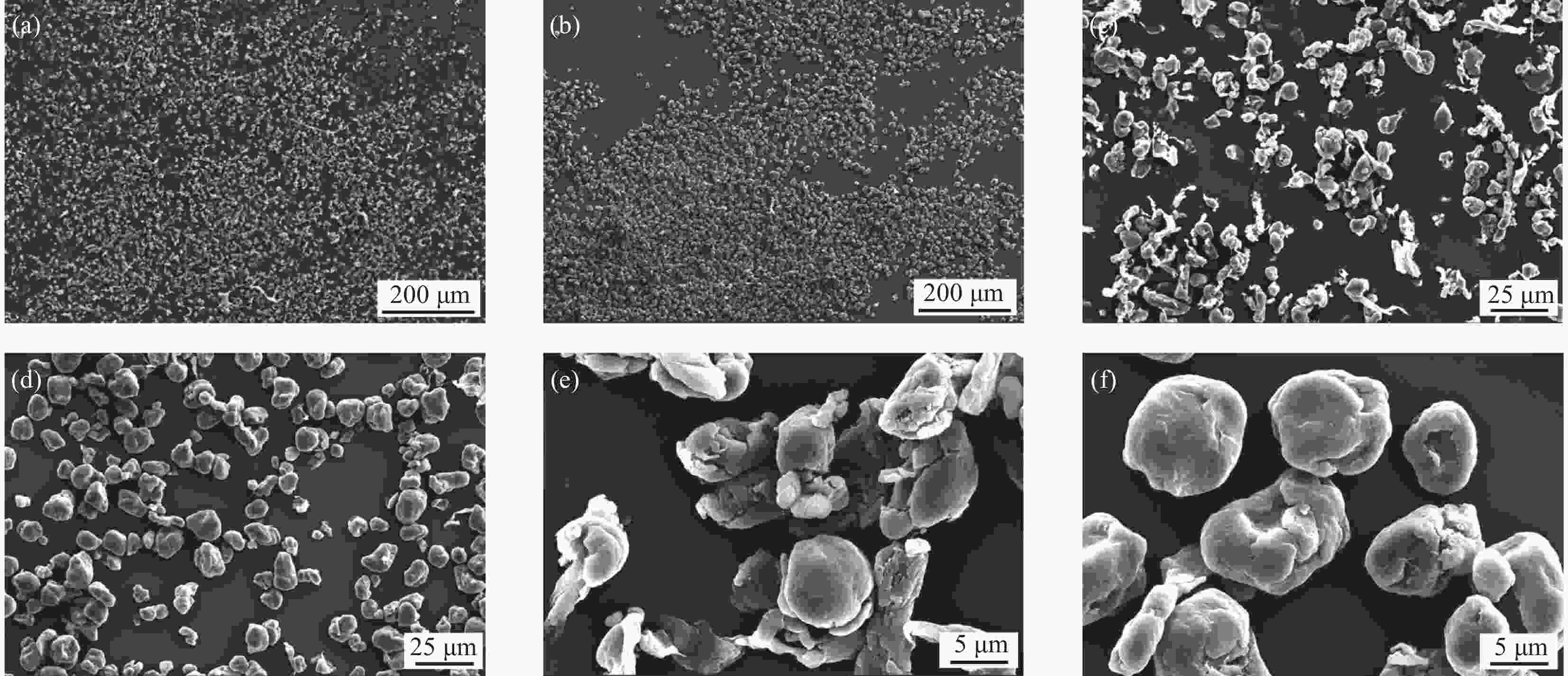

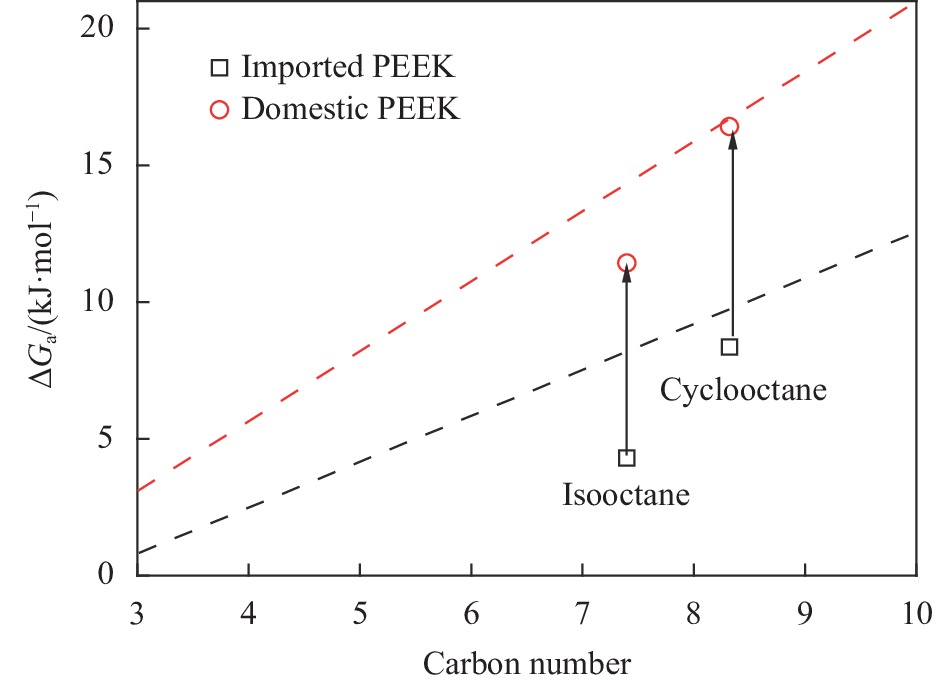

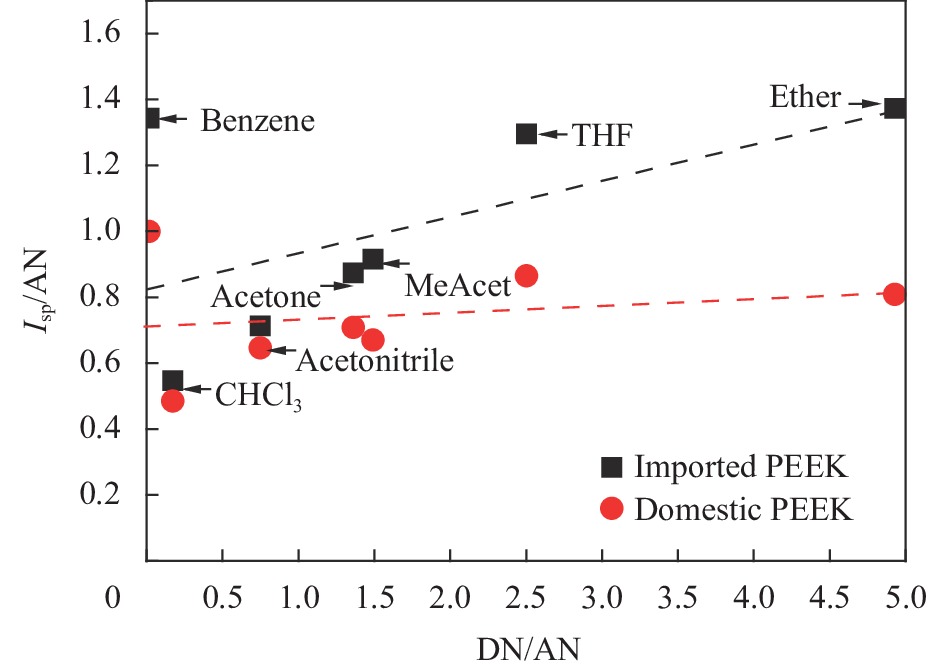

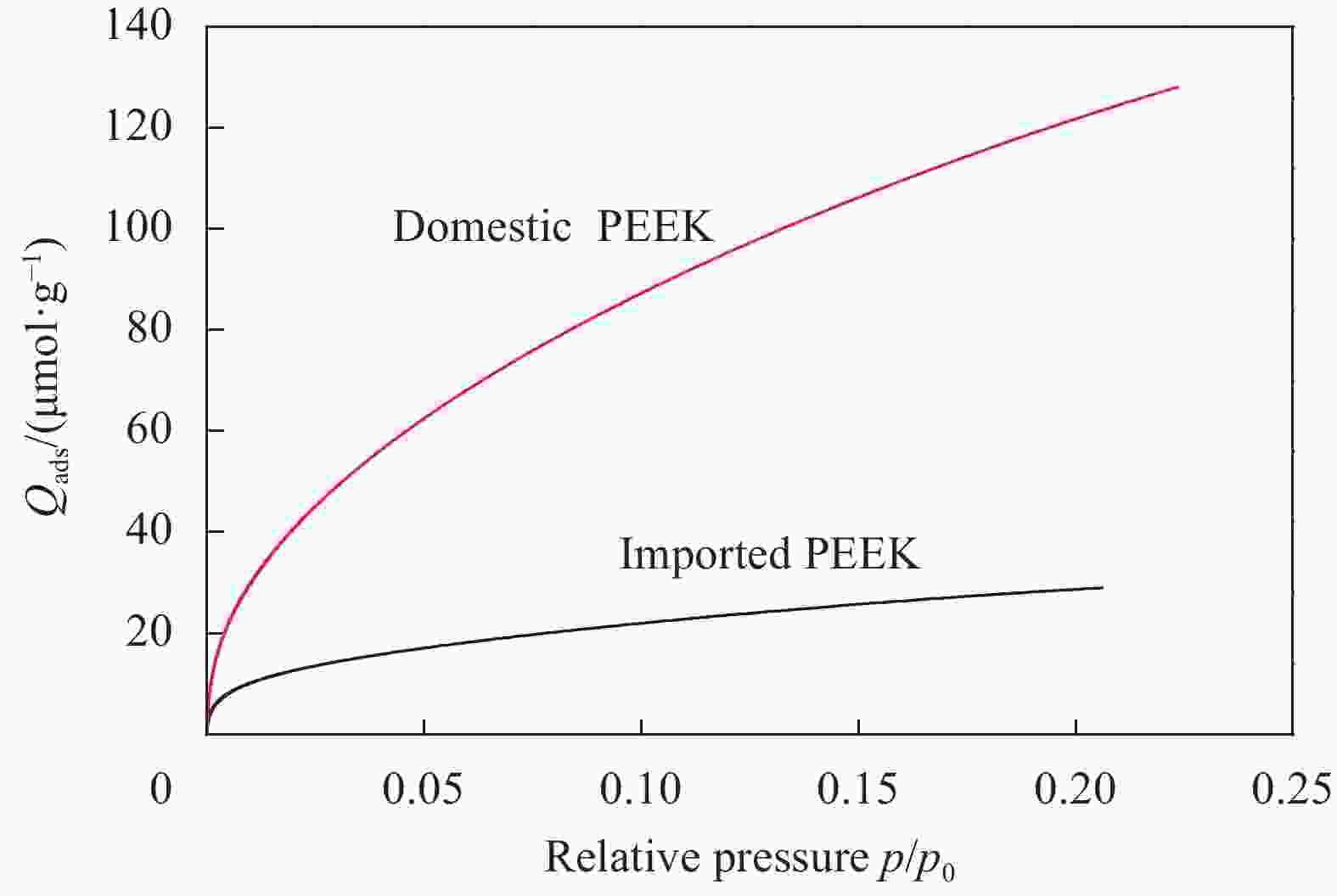

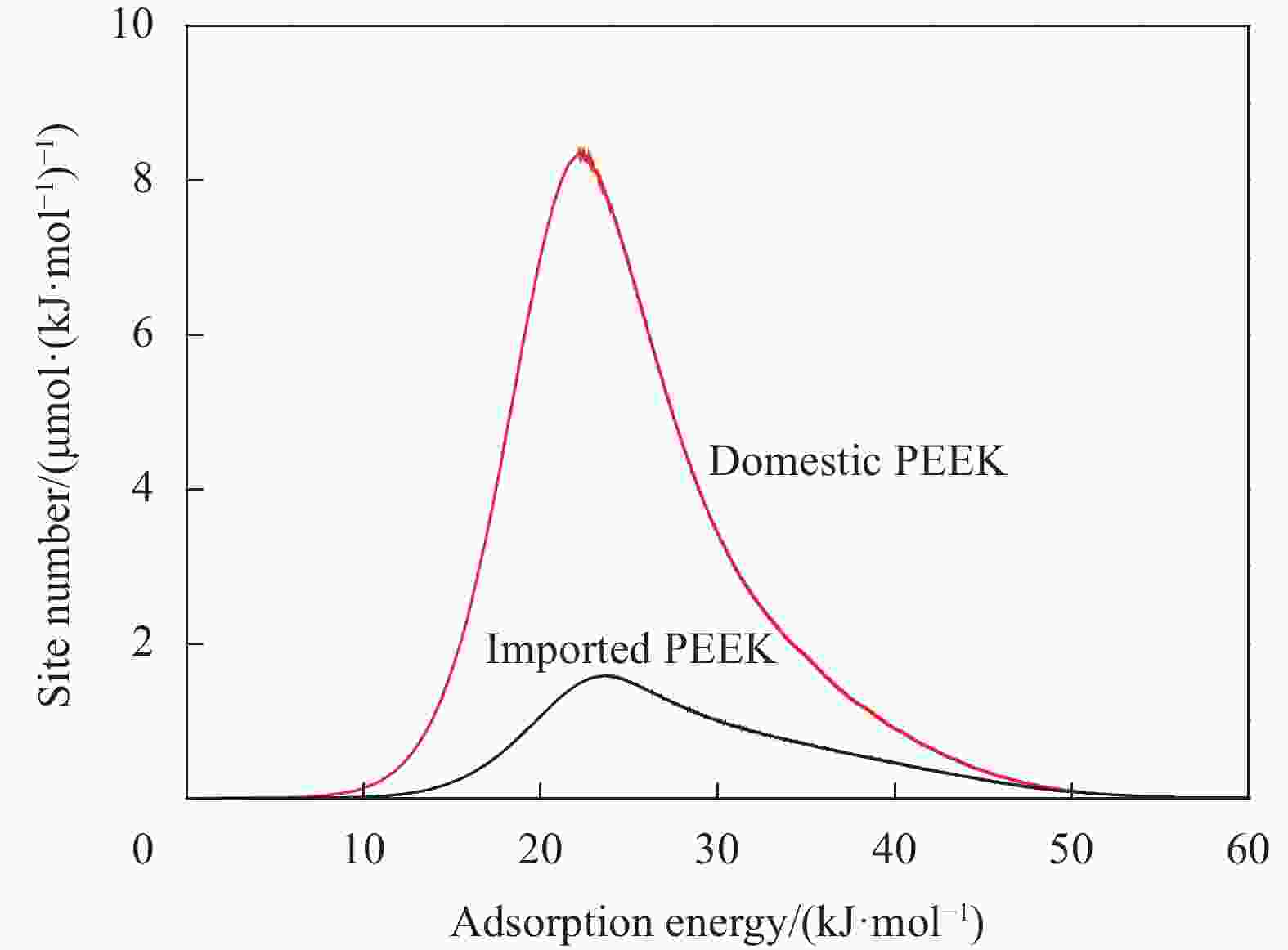

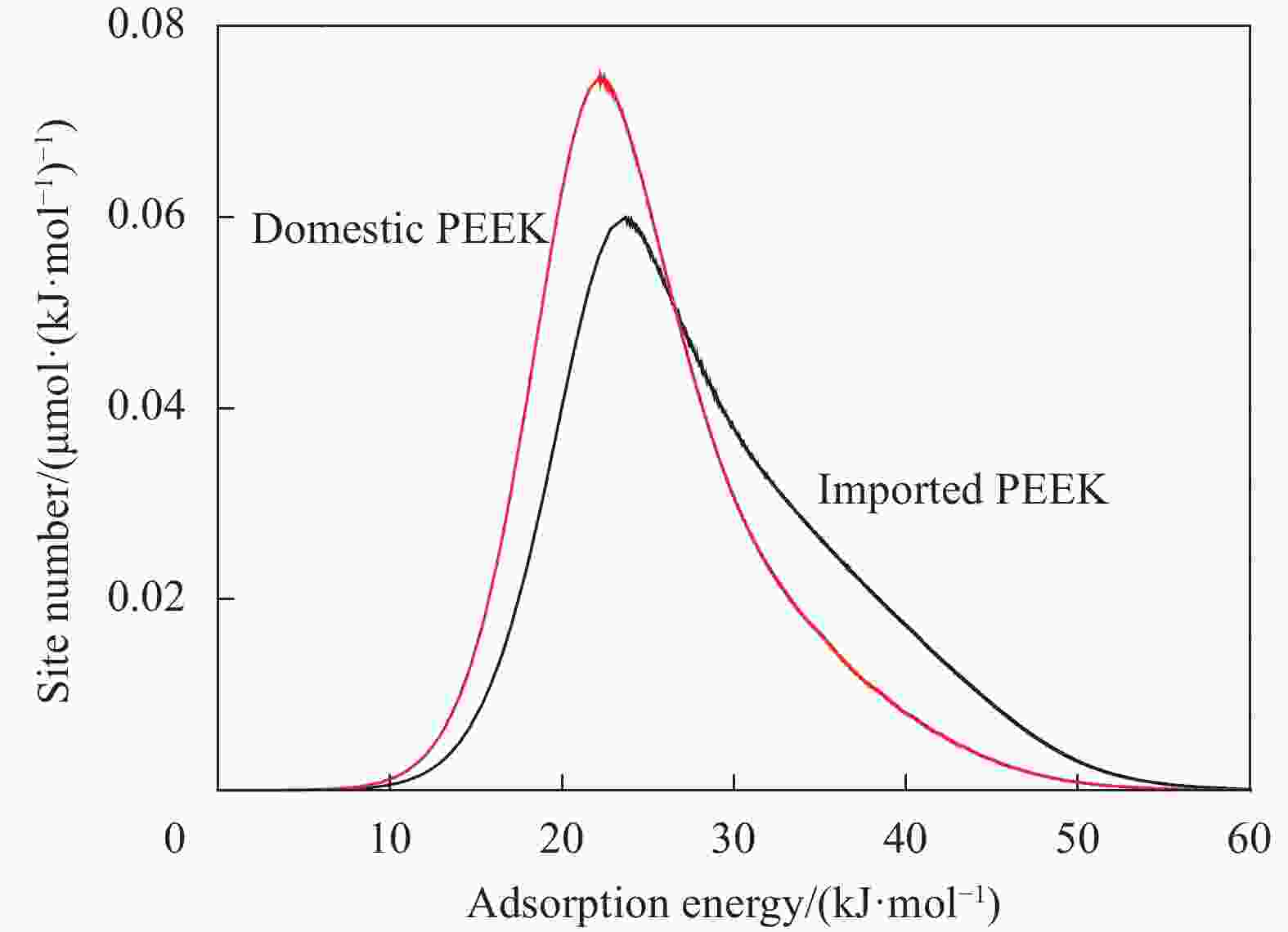

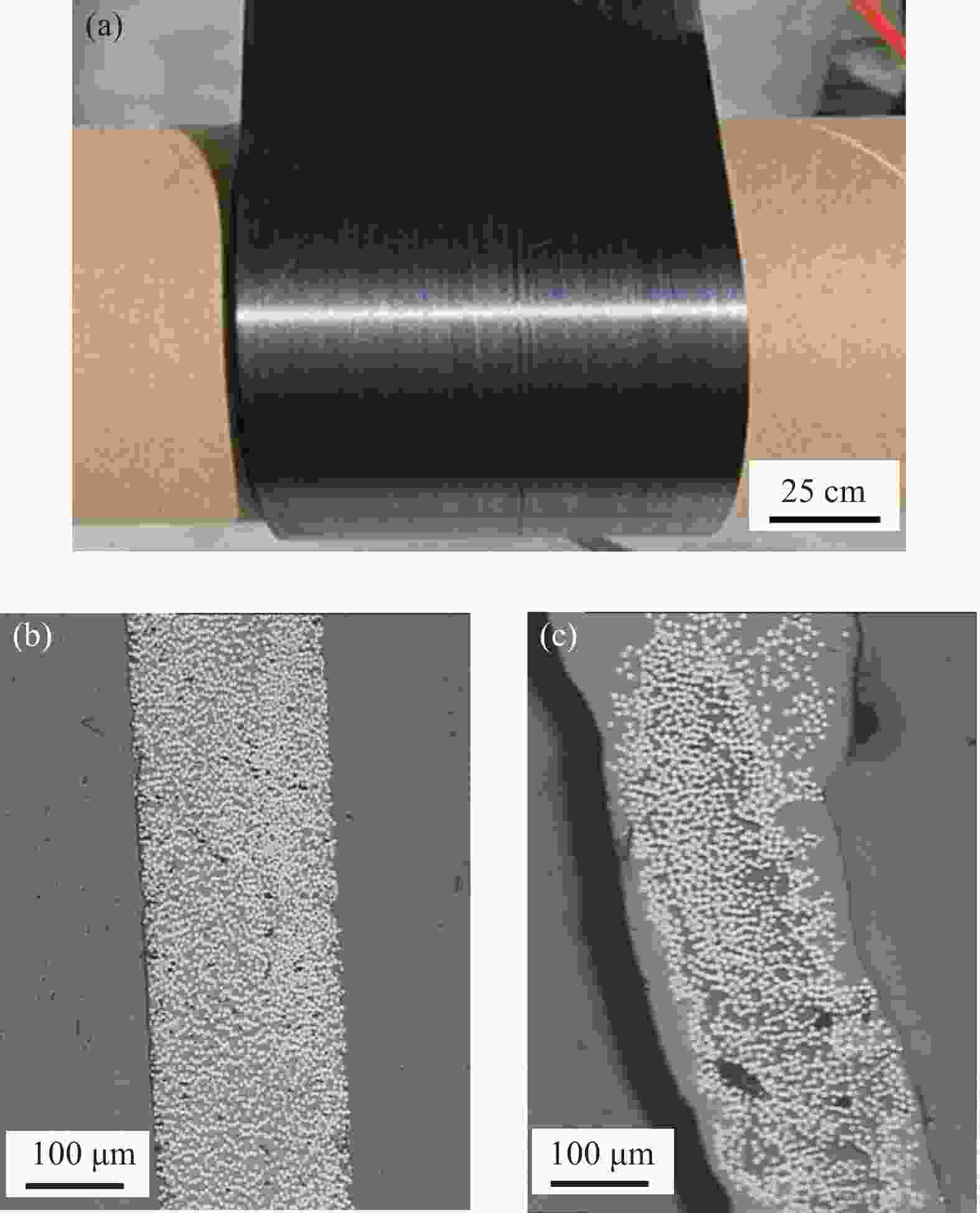

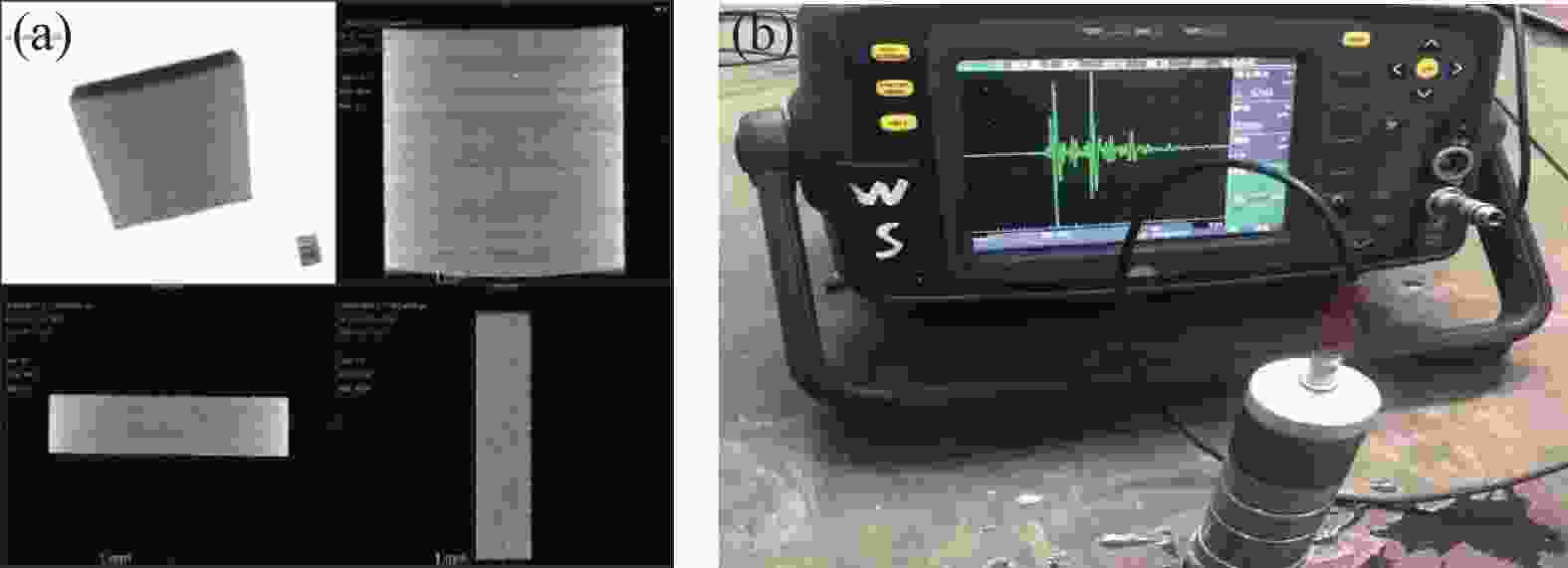

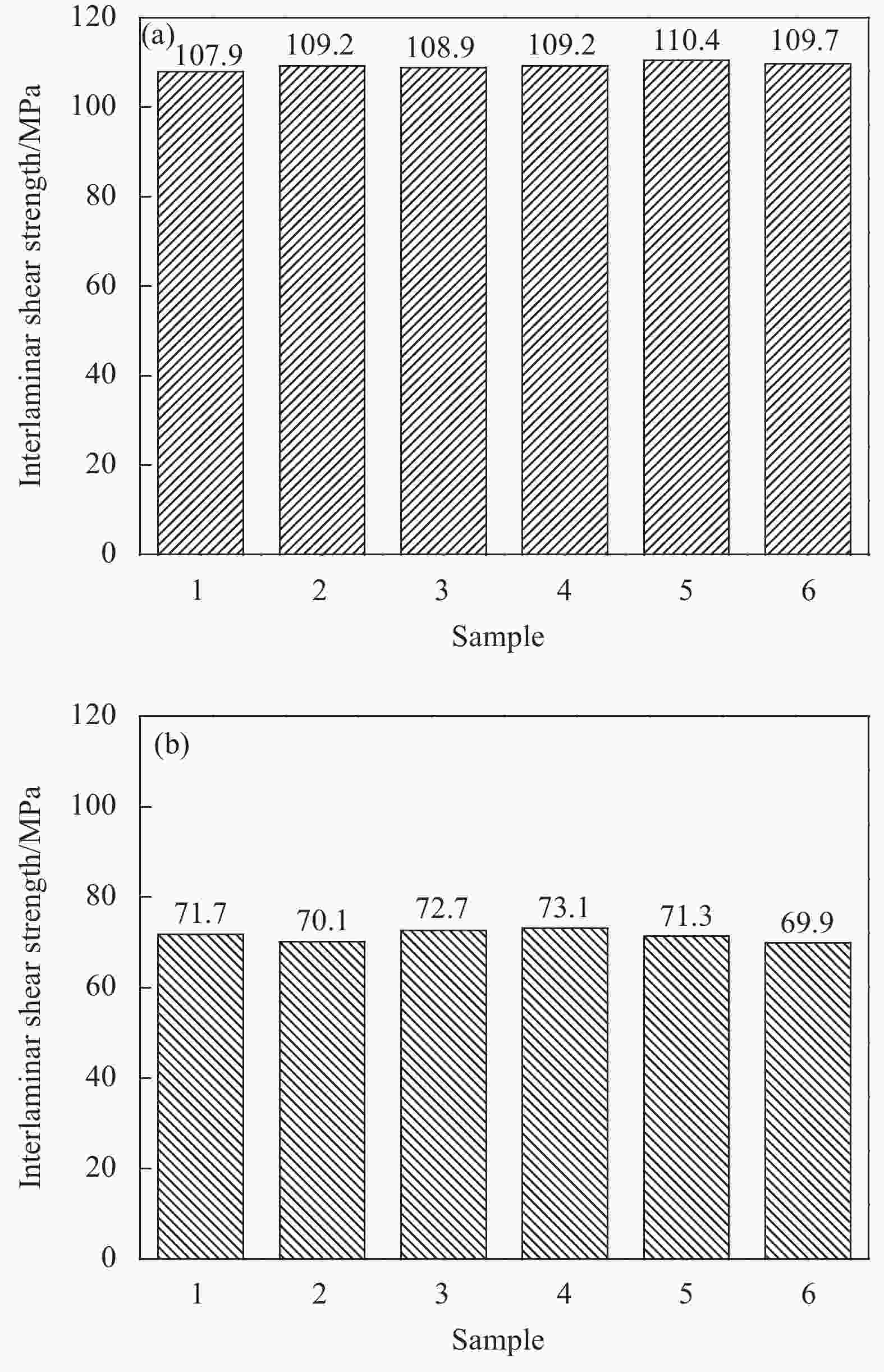

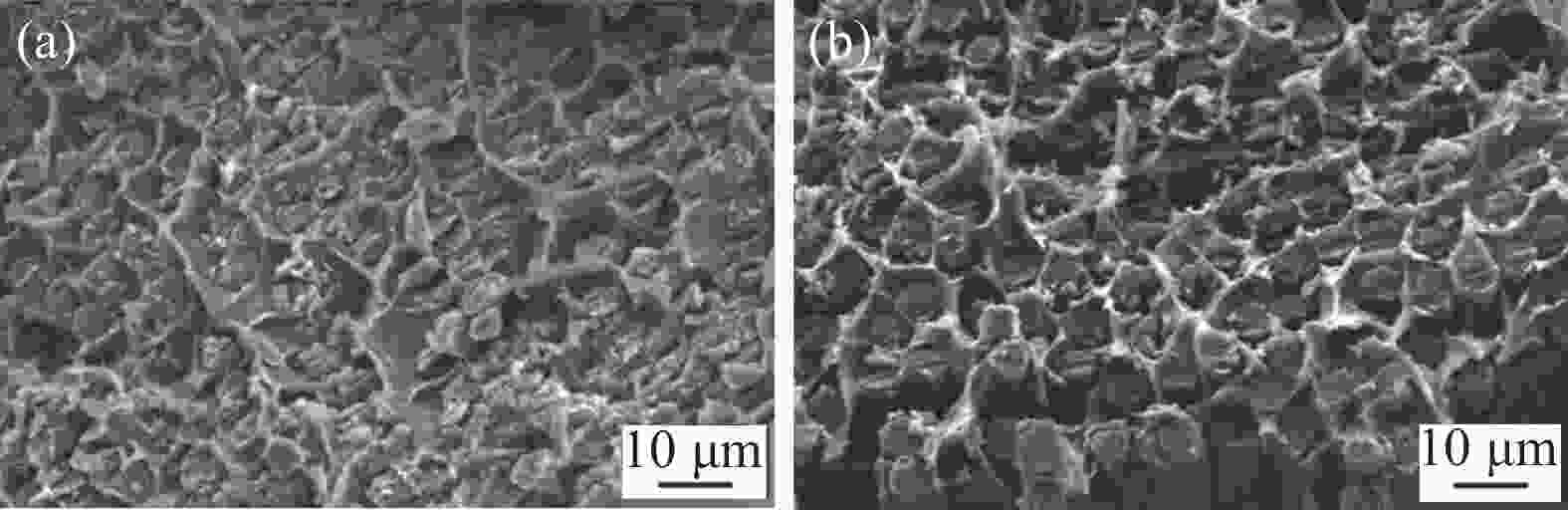

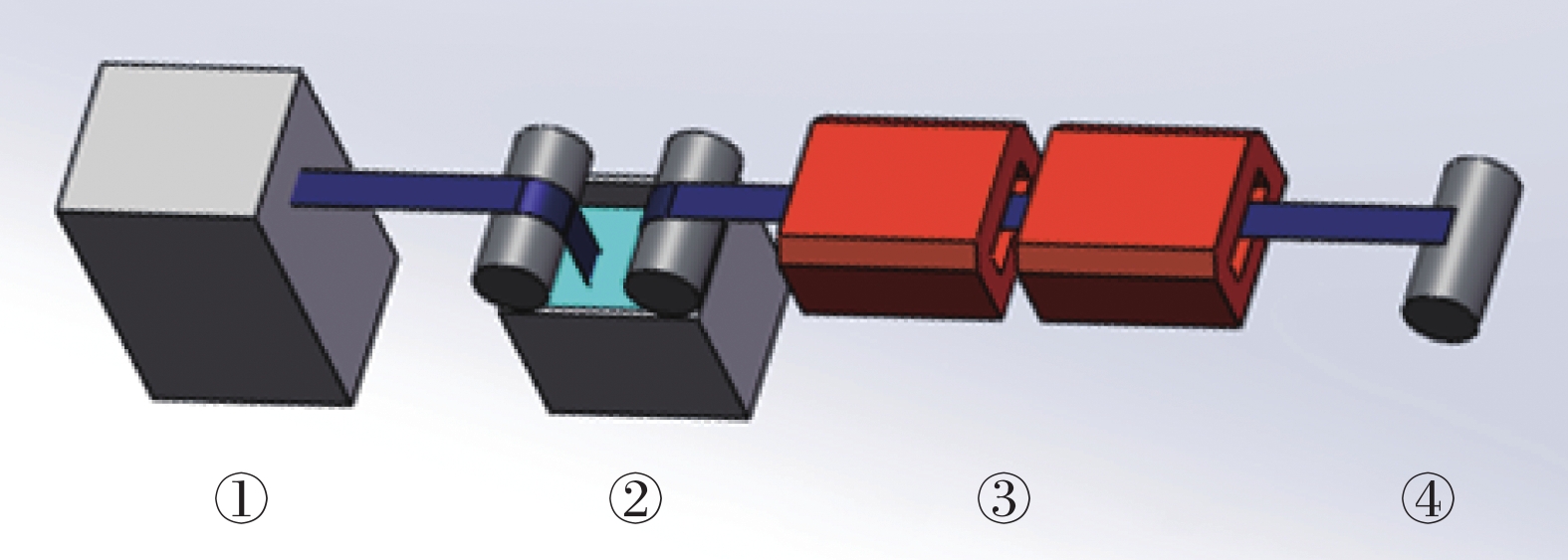

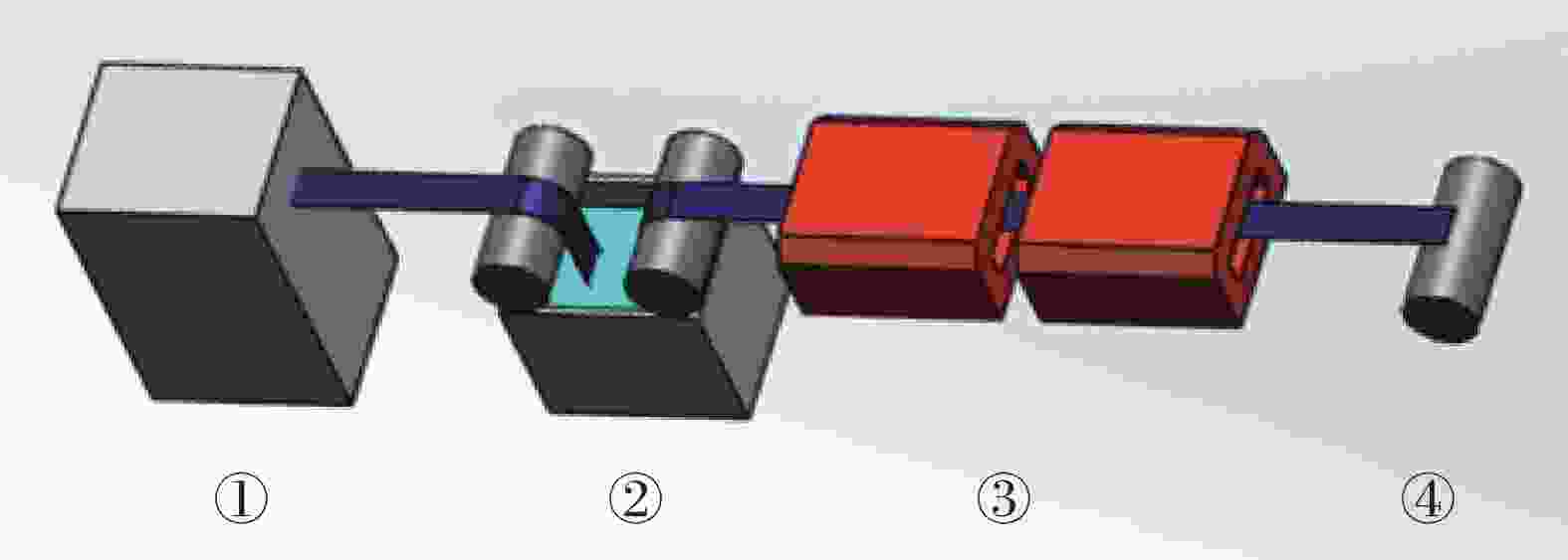

摘要: 高性能热塑性聚醚醚酮树脂基复合材料具有高韧性、耐疲劳、原材料可长期贮存、成型速度快、可重复加工和回收再利用等独特优势,在航空航天等工业领域应用广泛。粉末悬浮法通过将聚醚醚酮细粉配制成水基悬浮液实现对纤维充分浸渍,现已成为制备连续纤维增强热塑性预浸料的重要方式。本文重点开展反气相色谱法研究聚醚醚酮表面性质,并结合微观形貌、粒径分布等方面对比国内外聚醚醚酮树脂的差异。研究表明:进口聚醚醚酮树脂色散表面能(19.2 mJ/m2)明显低于同级别国产树脂(41.1 mJ/m2);极性探针分子吸附于聚醚醚酮表面的驱动力主要是酸碱作用力,表面总体表现为碱性。进口聚醚醚酮树脂相比于国产具有更高的极性,使其更容易分散在水中;而国产聚醚醚酮树脂微观形貌、表面性质则更加均匀。表面性质研究指导水基悬浮液配制,制备的连续纤维增强热塑性预浸料质量优异,孔隙率低于0.5%且纤维排布整齐,热塑性复合材料层压板层间剪切强度平均值达109 MPa,与传统热熔浸渍方法相比提升30%以上。Abstract: High performance polyether-ether-ketone (PEEK) thermoplastic composites have the advantages of good impact and fatigue resistance, unlimited ambient temperature storage life, short molding cycles, being recyclable and good reprocessing ability, which have been widely used in aerospace and other industry domains. Powder impregnation method can realize the infiltration of resin particles into fibers by water-based suspension, which has become an effective technical route for preparing continuous fiber reinforced thermoplastic prepregs. This paper focused on the surface characterization of PEEK produced in both domestic and overseas by inverse gas chromatography (IGC) as well as the comparison of microstructure and size distribution. The results show that the dispersion surface energy value of imported PEEK (19.2 mJ/m2) is obviously lower than the domestics (41.1 mJ/m2). The driving force of the adsorption between PEEK particles and polar probe molecules is acid-base interaction in nature, while the surface of PEEK particles is generally alkaline. With higher surface polarity, imported PEEK can more easily disperse into water through the dispersant. By preparing the water-based resin slurry based on the surface characterization results, the thermoplastic prepregs produced with powder impregnation method show excellent quality. The porosity of the powder impregnation prepregs is less than 0.5% and fibers are neatly arranged, with the short beam shear strength of 109 MPa, 30% higher comparing with prepregs produced by traditional hot melt impregnation method.

-

表 1 聚醚醚酮(PEEK)悬浮液配制比例表

Table 1. Compound of polyether ether ketone (PEEK) resin suspension system

Sample PEEK/kg AOT/kg H2O/kg Brand 1 10 2 200 VESTAKEEP® 2 10 6 200 PFLUON® Note: AOT—Docusate sodium. 表 2 PEEK树脂的色散表面能数据

Table 2. Dispersion surface energy data of PEEK resins

∆Ga/(kJ·mol–1) $\gamma _{\rm{s}}^{\rm{D}}/{\rm{(mJ \cdot m^{-2})}}$ R2 Imported resin 1.794±0.021 19.2±0.4 0.9997 Domestic resin 2.626±0.012 41.1±0.4 1.0000 Notes: ∆Ga—Free energy of adsorption; $\gamma _{\rm{s}}^{\rm{D}}$—Dispersive component of surface energy; R2—Coefficient of determination. 表 3 PEEK树脂的形态学指数(IM)

Table 3. Results of morphology index (IM) of PEEK resins

IM (Isooctane) IM (Cyclooctane) Imported resin 0.261±0.001 0.595±0.012 Domestic resin 0.340±0.007 0.801±0.016 表 4 PEEK树脂在极性探针下Isp数据

Table 4. Results of specific interaction Isp using polar probes of PEEK resins

Imported resin Domestic resin Acetonitrile 13.5±0.1 12.2±0.1 Chloroform 12.6±0.1 11.1±0.1 Acetone 10.9±0.1 8.9±0.1 Me-Acetate 9.8±0.2 7.2±0.2 Ether 5.4±0.2 3.2±0.2 THF 10.4±0.2 7.0±0.2 Benzene 11.1±0.2 8.2±0.2 ΣIsp 73.7±1.1 57.8±1.1 表 5 计算所得PEEK树脂的酸碱常数值

Table 5. Results of the Ka and Kb constants of PEEK resins

Ka Kb Imported resin 11.0 83.4 Domestic resin 2.6 70.1 表 6 PEEK树脂比表面积数据

Table 6. Specific surface area data of PEEK resins

Q0/(μmol·g-1) SBET/(m2·g-1) Imported resin 26.5±0.3 10.1±0.1 Domestic resin 111.9±10.4 42.4±3.9 Notes: Q0—Amount of adsorbed n-octane; SBET—specific surface area. -

[1] 邢丽英, 冯志海, 包建文, 等. 碳纤维及树脂基复合材料产业发展面临的机遇与挑战[J]. 复合材料学报, 2020, 37(11):2700-2706.XING Liying, FENG Zhihai, BAO Jianwen, et al. Facing opportunity and challenge of carbon fiber and polymer matrix composites industry development[J]. Acta Materiae Compositae Sinica,2020,37(11):2700-2706(in Chinese). [2] 蒋诗才, 包建文, 张连旺, 等. 液体成型树脂基复合材料及其工艺研究进展[J]. 航空制造技术, 2021, 64(5):70-81.JIANG Shicai, BAO Jianwen, ZHANG Lianwang, et al. Research progress of liquid molding resin matrix composites and its technology[J]. Aeronautical Manufacturing Technology,2021,64(5):70-81(in Chinese). [3] 单忠德, 范聪泽, 孙启利, 等. 纤维增强树脂基复合材料增材制造技术与装备研究[J]. 中国机械工程, 2020, 31(2):221-226.SHAN Zhongde, FAN Congze, SUN Qili, et al. Research on additive manufacturing technology and equipment for fiber reinforced resin composites[J]. China Mechanical Engineering,2020,31(2):221-226(in Chinese). [4] 周典瑞, 高亮, 霍红宇, 等. 热塑性树脂基复合材料用碳纤维上浆剂研究进展[J]. 复合材料学报, 2020, 37(8):1785-1795.ZHOU Dianrui, GAO Liang, HUO Hongyu, et al. Research progress of carbon fiber sizing agents for thermoplastic composites[J]. Acta Materiae Compositae Sinica,2020,37(8):1785-1795(in Chinese). [5] 高亮, 霍红宇, 周典瑞, 等. 基于动态共价化学树脂及复合材料的研究进展[J]. 材料工程, 2020, 48(11):68-75.GAO Liang, HUO Hongyu, ZHOU Dianrui, et al. Research progress in resin based on dynamic covalent chemistry and its composites[J]. Journal of Materials Engineering,2020,48(11):68-75(in Chinese). [6] 罗云烽, 姚佳楠. 高性能热塑性复合材料在民用航空领域中的应用[J]. 航空制造技术, 2021, 64(16):93-102.LUO Yunfeng, YAO Jianan. Applications of high performance thermoplastic composites in civil aviation[J]. Aeronautical Manufacturing Technology,2021,64(16):93-102(in Chinese). [7] 胡记强, 王兵, 张涵其, 等. 热塑性复合材料构件的制备及其在航空航天领域的应用[J]. 宇航总体技术, 2020(4):61-70.HU Jiqiang, WANG Bing, ZHANG Hanqi, et al. Fabrication of thermoplastic composite components and their application in aerospace[J]. Astronautical Systems Engineering Technology,2020(4):61-70(in Chinese). [8] 段瑛涛, 王智文, 栗娜, 等. 热塑性复合材料在汽车车身结构件上的应用开发[J]. 汽车工艺与材料, 2020(4):14-18.DUAN Yingtao, WANG Zhiwen, LI Na, et al. Application and development of thermoplastic composite materials in automotive body structure[J]. Automobile Technology & Material,2020(4):14-18(in Chinese). [9] 单毫, 陈宇, 李俊杰, 等. 红外加热缠绕成型工艺参数对CF/PEEK复合材料层间剪切性能的影响[J]. 复合材料科学与工程, 2020(1):39-46. doi: 10.3969/j.issn.1003-0999.2020.01.006SHAN Hao, CHEN Yu, LI Junjie, et al. Effect of infrared heating winding forming process paraments on interlaminar shear properties of CF/PEEK composites[J]. Composites Science and Engineering,2020(1):39-46(in Chinese). doi: 10.3969/j.issn.1003-0999.2020.01.006 [10] GALLAGHER E A, LAMORINIÈRE S, MCGARRY P. Multi-axial damage and failure of medical grade carbon fibre reinforced PEEK laminates: Experimental testing and computational modelling[J]. Journal of the Mechanical Behavior of Biomedical Materials,2018,82:154-167. doi: 10.1016/j.jmbbm.2018.03.015 [11] 李泽超, 雷鸣, 校金友, 等. 连续碳纤维增强聚醚醚酮复合材料泛温度域本构模型[J]. 复合材料学报, 2022, 39(7):3581-3589.LI Zechao, LEI Ming, XIAO Jinyou, et al. A constitutive model of continuous carbon fiber reinforced thermoplastic polyether ether ketone composites in a wide temperature range[J]. Acta Materiae Compositae Sinica,2022,39(7):3581-3589(in Chinese). [12] 陆承志, 赵乐, 杨雪勤, 等. 碳纤维增强聚醚酮酮模压复合材料结构与性能调控研究[J]. 复合材料学报, 2022, 39(8):3684-3694.LU Chengzhi, ZHAO Le, YANG Xueqin, et al. Study on structure and performance control of carbon fiber reinforced poly(ether ketone ketone) molding composites[J]. Acta Materiae Compositae Sinica,2022,39(8):3684-3694(in Chinese). [13] 刘程, 蹇锡高. 含二氮杂萘酮联苯结构热塑性聚芳醚树脂基复合材料研究进展[J]. 高分子通报, 2011(9):52-62. doi: 10.14028/j.cnki.1003-3726.2011.09.015LIU Cheng, JIAN Xigao. Recent progress in thermoplastic composites based on poly(aryl ether)s containing phthalazinone moiety[J]. Polymer Bulletin,2011(9):52-62(in Chinese). doi: 10.14028/j.cnki.1003-3726.2011.09.015 [14] 刘勇军, 尹津平, 万志鹏, 等. 可溶性含萘环结构聚醚酮酮醚酮酮的合成[J]. 高分子材料科学与工程, 2020, 36(1):27-31. doi: 10.16865/j.cnki.1000-7555.2019.0329LIU Yongjun, YIN Jinping, WAN Zhipeng, et al. Synthesis of soluble poly(aryl ether ketone ketone ether ketone ketone)s containing naphthalene ring structures[J]. Polymer Materials Science& Engineering,2020,36(1):27-31(in Chinese). doi: 10.16865/j.cnki.1000-7555.2019.0329 [15] 王运良, 陈春海. 热塑性聚酰亚胺改性聚醚醚酮树脂的力学性能研究[J]. 佳木斯大学学报: 自然科学版, 2013, 31(3):402-405.WANG Yunliang, CHEN Chunhai. Study on mechanical properties of thermoplastic polyimide modified polyether ether ketone resin[J]. Journal of Jiamusi University: Natural Science Edition,2013,31(3):402-405(in Chinese). [16] 侯相弛, 周川, 周玉敬, 等. 还原氧化石墨烯改性碳纤维/聚苯硫醚复合材料层间性能及微观形貌[J]. 复合材料学报, 2022, 39(5):2133-2140.HOU Xiangchi, ZHOU Chuan, ZHOU Yujing, et al. Interlaminar properties and micro morphology of reduced graphene oxide modified carbon fiber/polyphenylene sulfide composites[J]. Acta Materiae Compositae Sinica,2022,39(5):2133-2140(in Chinese). [17] 陆春. 碳纤维增强可溶性聚芳醚复合材料的制备、界面性能及热应力模拟[D]. 辽宁: 大连理工大学, 2007.LU Chun. CF/soluble poly(aryl ether)s composite: Preparation, inerfacial property and simulation of thermal stress[D]. Liaoning: Dalian University of Technology, 2007(in Chinese). [18] 孙洪霖. 连续碳纤维增强聚醚醚酮复合材料制备及性能研究[D]. 上海: 东华大学, 2021.SUN Honglin. Study of preparation and properties of continuous carbon fiber reinforced poly(ether ketone ketone) composite[D]. Shanghai: Donghua University, 2021(in Chinese). [19] 刘亚男, 刘晨晓, 朱明浩, 等. 模压成型CF/PEKK 与自动铺丝CF/PEEK 热塑性复合材料对比研究[J]. 航空制造技术, 2021, 64(11):50-57, 68.LIU Yanan, LIU Chenxiao, ZHU Minghao, et al. Compara-tive study between CF/PEKK thermoplastic composite by hot press molding and CF/PEEK composite using automatic fiber placement process[J]. Aeronautical Manufacturing Technology,2021,64(11):50-57, 68(in Chinese). [20] 滕凌虹, 曹伟伟, 朱波, 等. 纤维增强热塑性树脂预浸料的制备工艺及研究进展[J]. 材料工程, 2021, 49(2):42-53. doi: 10.11868/j.issn.1001-4381.2020.000358TENG Linghong, CAO Weiwei, ZHU Bo, et al. Research progress in the preparation of fiber reinforced thermoplastic resin prepreg[J]. Journal of Materials Engineering,2021,49(2):42-53(in Chinese). doi: 10.11868/j.issn.1001-4381.2020.000358 [21] 陈浩然, 李勇, 还大军, 等. T700/PEEK热塑性自动铺放预浸纱制备质量控制及性能研究[J]. 航空学报, 2018, 39(6):233-242. doi: 10.7527/S1000-6893.2017.21842CHEN Haoran, LI Yong, HUAN Dajun, et al. Quality control and mechanical properties of T700/PEEK thermoplastic prepreg for AFP[J]. Acta Aeronautica et Astronautica Sinica,2018,39(6):233-242(in Chinese). doi: 10.7527/S1000-6893.2017.21842 [22] 石峰晖, 代志双, 张宝艳. 反气相色谱法(IGC)对碳纤维表面性质的研究[C]//第十六届全国复合材料学术年会(NCCM-16). 长沙: 中国科学技术出版社, 2010: 298-304.SHI Fenghui, DAI Zhishuang, ZHANG Baoyan. Characterization of surface properties of carbon fibers by inverse gas chromatography (IGC)[C]//National Conference on Composite Materials (NCCM-16). Changsha: China Science and Technology Press, 2010: 298-304(in Chinese). [23] 石峰晖, 代志双, 张宝艳. 反气相色谱法测定环氧树脂的表面张力和溶解度参数[J]. 色谱, 2010, 28(7):697-701. doi: 10.3724/SP.J.1123.2010.00697SHI Fenghui, DAI Zhishuang, ZHANG Baoyan. Characterization of the surface tension and solubility parameter of epoxy resin by using inverse gas chromatography[J]. Chinese Journal of Chromatography,2010,28(7):697-701(in Chinese). doi: 10.3724/SP.J.1123.2010.00697 [24] 董耀武, 孙振平, 杨海静, 等. 反气相色谱在水泥颗粒表面性质研究中的应用[J]. 建筑材料学报, 2017, 20(5):667-672. doi: 10.3969/j.issn.1007-9629.2017.05.002DONG Yaowu, SUN Zhenping, YANG Haijing, et al. Application of inverse gas chromatography in analysis of cement particle surface characteristic[J]. Journal of Building Materials,2017,20(5):667-672(in Chinese). doi: 10.3969/j.issn.1007-9629.2017.05.002 [25] GUTMANN V. The donor-acceptor approach to molecular interactions[M]. New York: Springer, 1978. [26] BALARD H. Estimation of the surface energetic heterogeneity of a solid by inverse gas chromatography[J]. Langmuir,1997,13(5):1260-1269. doi: 10.1021/la951526d [27] 中国国家标准化管理委员会. 碳纤维增强塑料孔隙含量和纤维体积含量试验方法: GB/T 3365—2008[S]. 北京: 中国标准出版社, 2008.Standardization Administration of China. CFRP porosity content and fiber volume content test method: GB/T 3365—2008[S]. Beijing: Standards Press of China, 2005(in Chinese). [28] American Society of Testing Materials. Standard test method for short-beam strength of polymer matrix composite materials and their laminates: ASTM D2344-2016[S]. West Conshohocken: ASTM, 2016. [29] BRENDLÉ E, PAPIRER E. Surface properties characterization by inverse gas chromatography applications[M]. Florida: Taylor & Francis, 2006. [30] LU C R, WANG J, LU X. Wettability and interfacial properties of carbon fiber and poly(ether ether ketone) fiber hybrid composite[J]. ACS Applied Materials & Interfaces,2019,11(34):31520-31531. [31] 彭公秋, 杨进军, 曹正华, 等. T700S/QY8911复合材料界面匹配研究[J]. 航空材料学报, 2011, 31(2):43-48. doi: 10.3969/j.issn.1005-5053.2011.2.009PENG Gongqiu, YANG Jinjun, CAO Zhenghua, et al. Study on interface compatibility of T700S/QY8911 composite[J]. Journal of Aeronautical Materials,2011,31(2):43-48(in Chinese). doi: 10.3969/j.issn.1005-5053.2011.2.009 -

下载:

下载: