Experimental and numerical study on buckling behaviour of steel-carbon fiber reinforced polymer hybrid cylindrical shells

-

摘要: 为开展金属-碳纤维增强树脂复合材料(CFRP)复合型柱壳屈曲特性试验及数值研究,制作2组金属-CFRP复合型柱壳及金属柱壳,并对其几何误差检测,试验研究了金属-CFRP复合型柱壳屈曲特性。其次,基于真实几何缺陷,开展了复合型和金属柱壳线性屈曲及非线性屈曲分析,数值与试验具有良好一致性。最后,讨论了CFRP铺层角度、层数对复合型柱壳非线性屈曲载荷影响。结果表明:复合型及金属柱壳试验载荷误差分别为8.29%和6.77%,试验重复性良好;CFRP层可使金属柱壳获得70%的极限载荷增益,并可减弱金属层破坏强度;随着铺设层数增加,复合型柱壳受外压下的铺设角度相应减小,最佳铺设角度为65°~85°,且该范围内,铺设层数影响较小,相同铺设层数下载荷值最大相差7.56%,最小相差为0.57%。

-

关键词:

- 复合材料 /

- 柱壳 /

- 金属-碳纤维增强树脂复合材料(CFRP)复合型结构 /

- 静水压力 /

- 屈曲特性

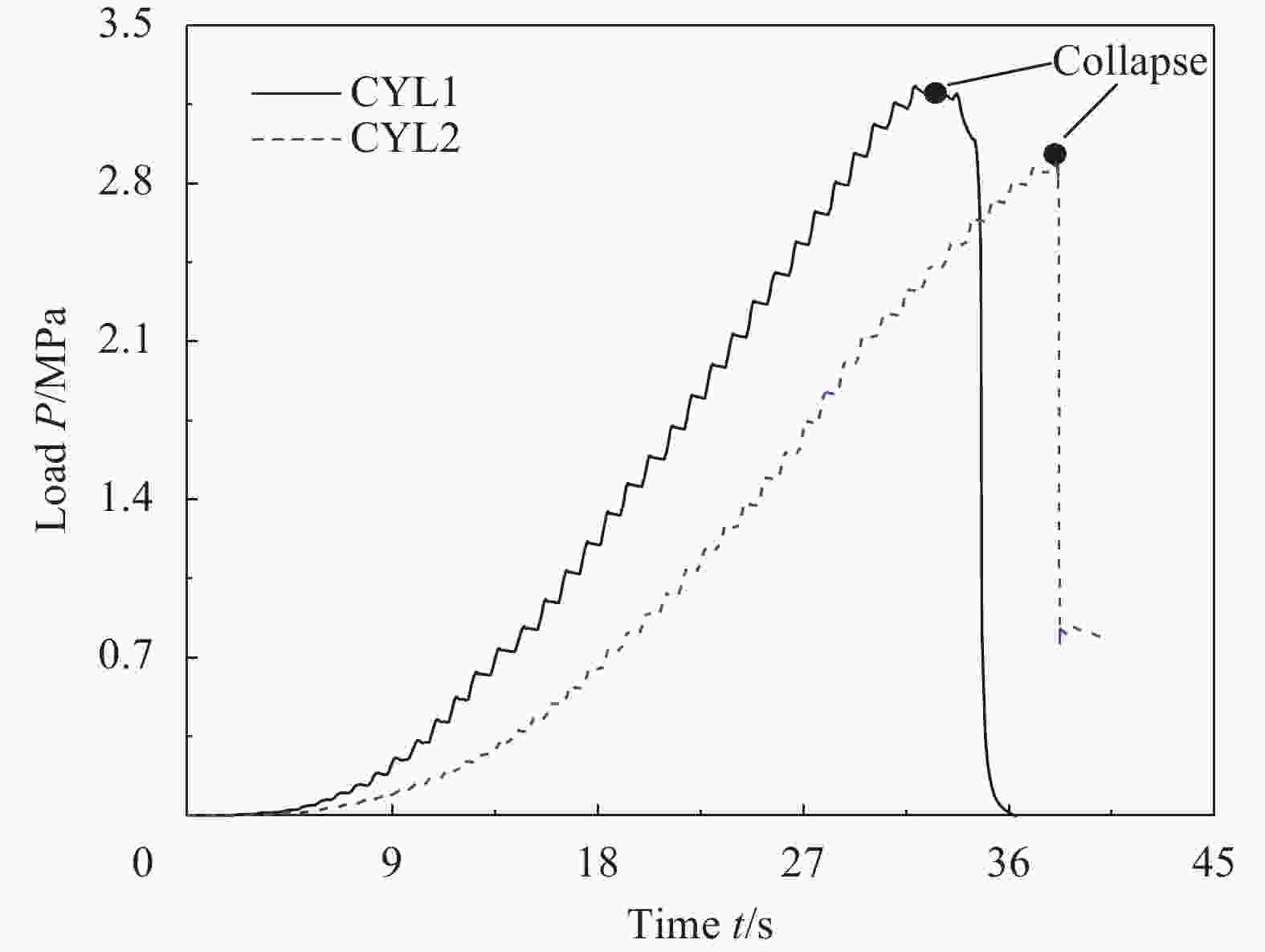

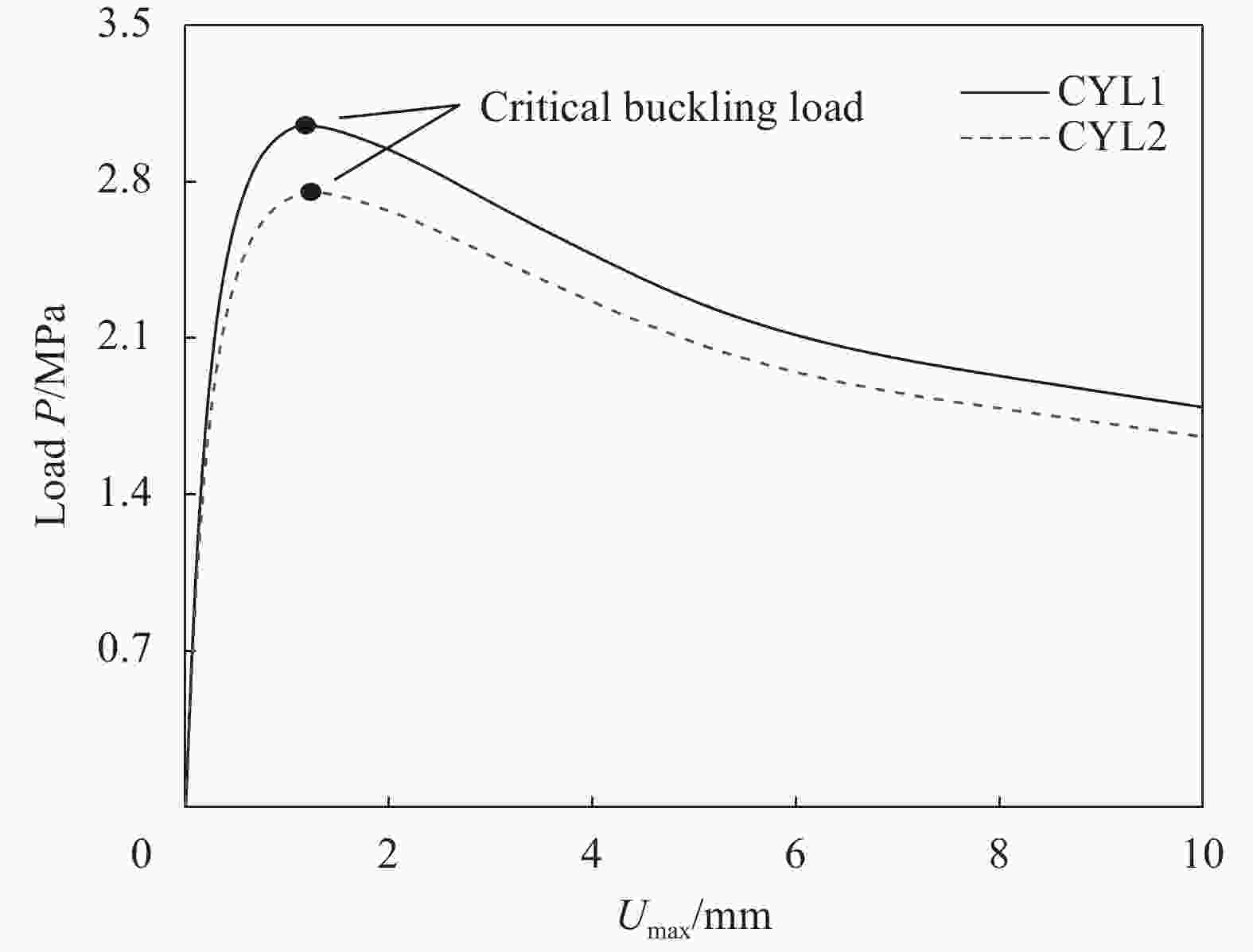

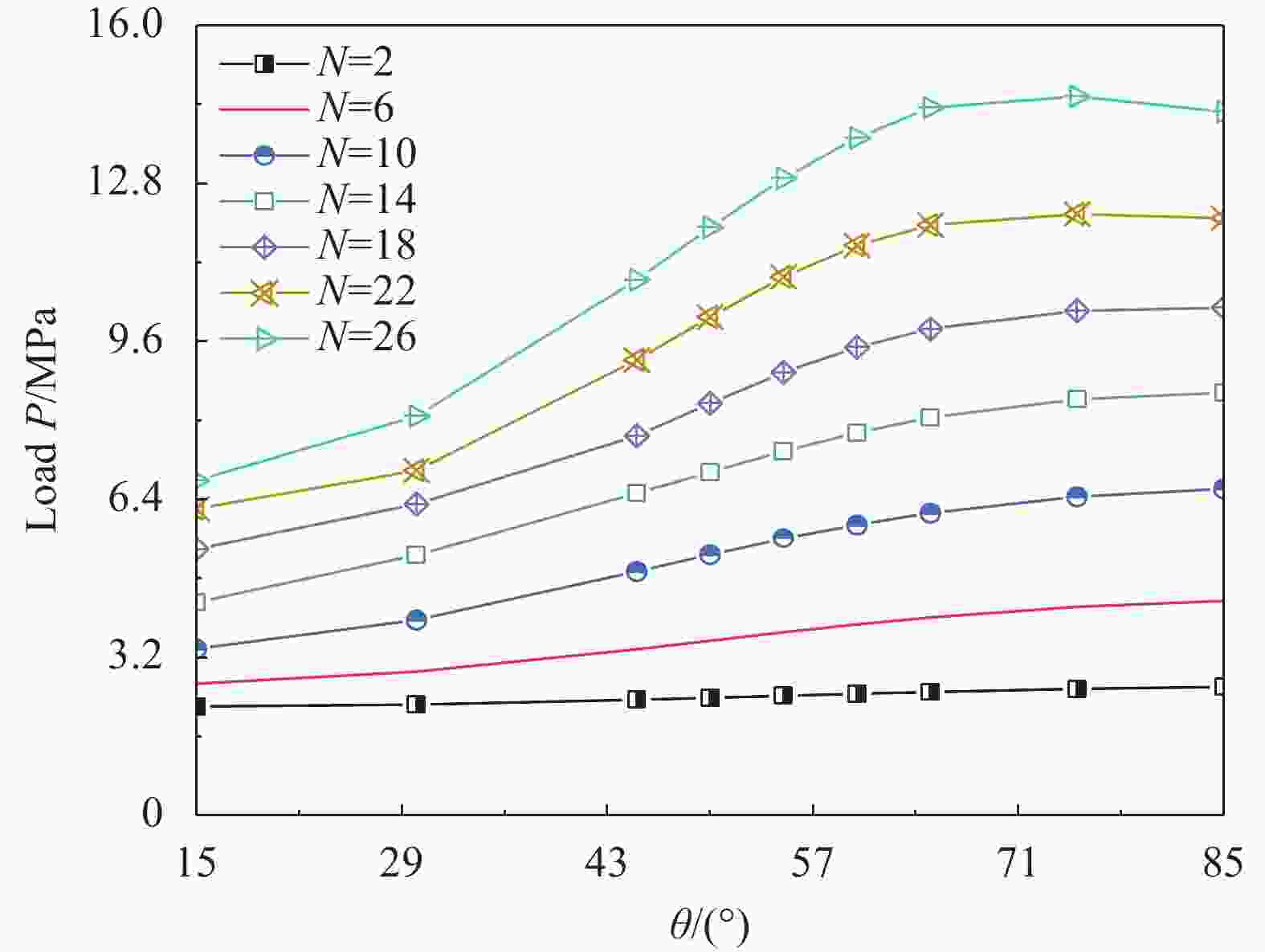

Abstract: The current study is an experimental and numerical investigation of the buckling of steel-carbon fiber reinforced polymer (CFRP) hybrid cylinders. Two groups of steel-CFRP hybrid and steel-only cylinders were manufactured. Geometric measurements and hydrostatic experiments were performed to determine the geometric and buckling properties of the cylinders. Linear eigenvalue and nonlinear analyses were performed to examine the buckling properties of the samples. The finite element model of each sample was established in accordance with the sample’s real geometric shape. The experimental and numerical data agree favorably. Furthermore, the effect of wrapped angle and layers in the hybrid cylinders on the cylinders’ critical buckling load was investigated. The results indicate that the experimental results obtained for the four cylinders are repeatable. The maximum difference between the experimental collapse loads is 8.29% and 6.77% for the hybrid and steel-only cylinders, respectively. The stiffness provided by CFRP approximately is 1.7 times the loading capacity of the steel-only cylinders. The damage of steel layer of hybrid cylinders is smaller than steel-only cylinders. As the wrapped layers increase, the wrapped angle of CFRP layers of hybrid decreases. The optimal range of wrapped angle is 65°-85°. Wrapped layers have less effect on critical buckling load of hybrid cylinders with the wrapped angle of 65°-85°. The maximum and minimum difference errors are 7.56% and 0.57%, respectively. -

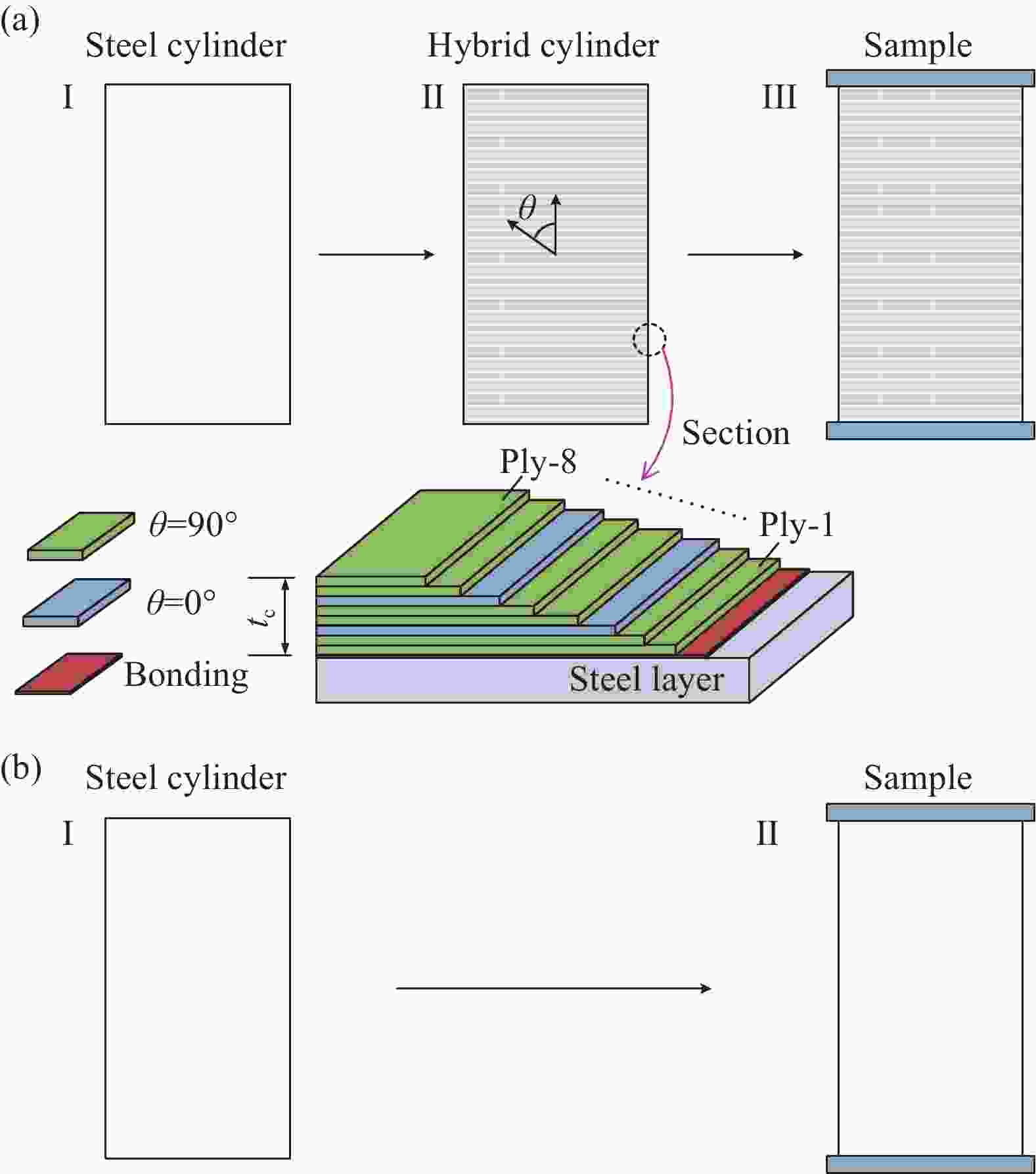

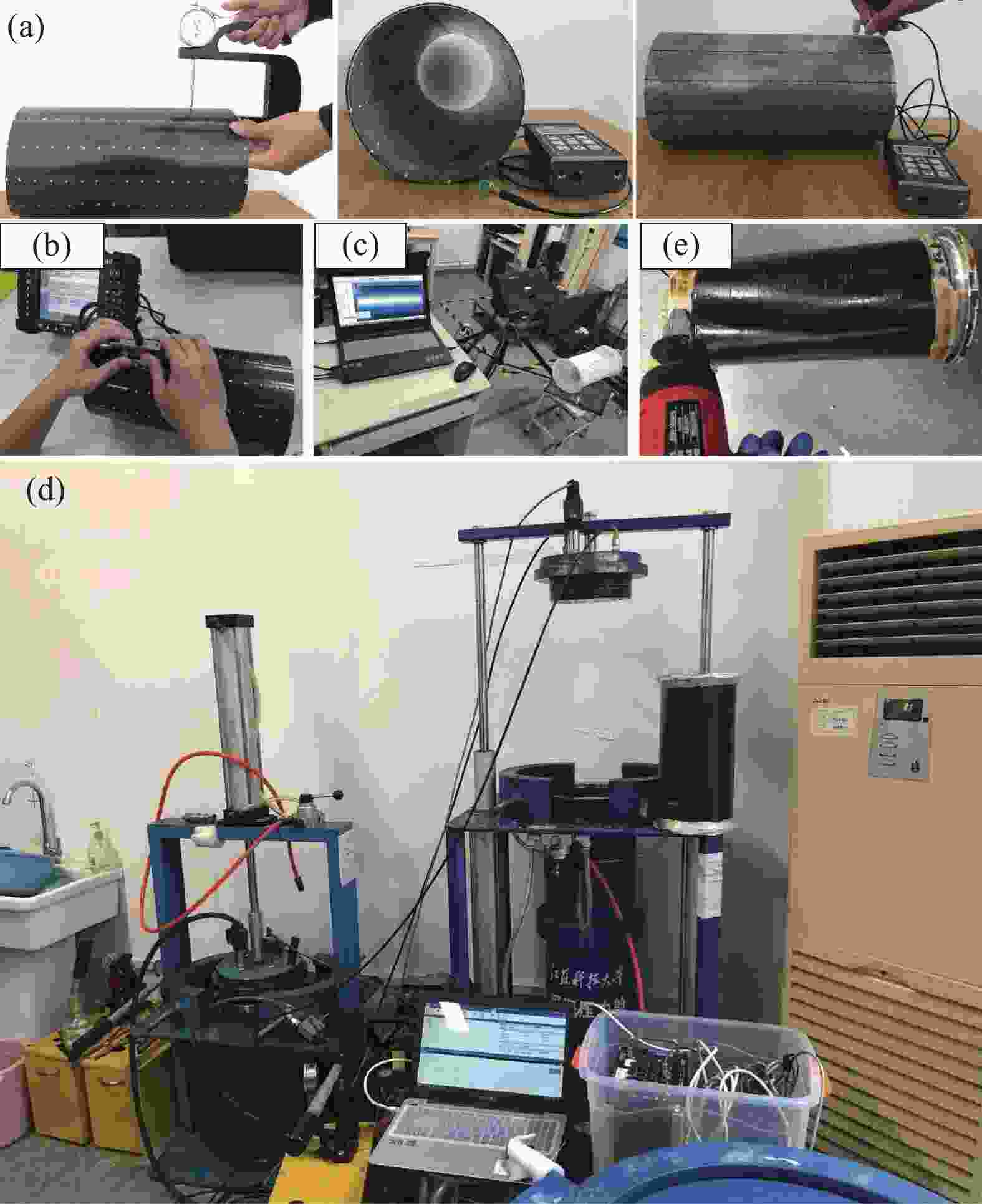

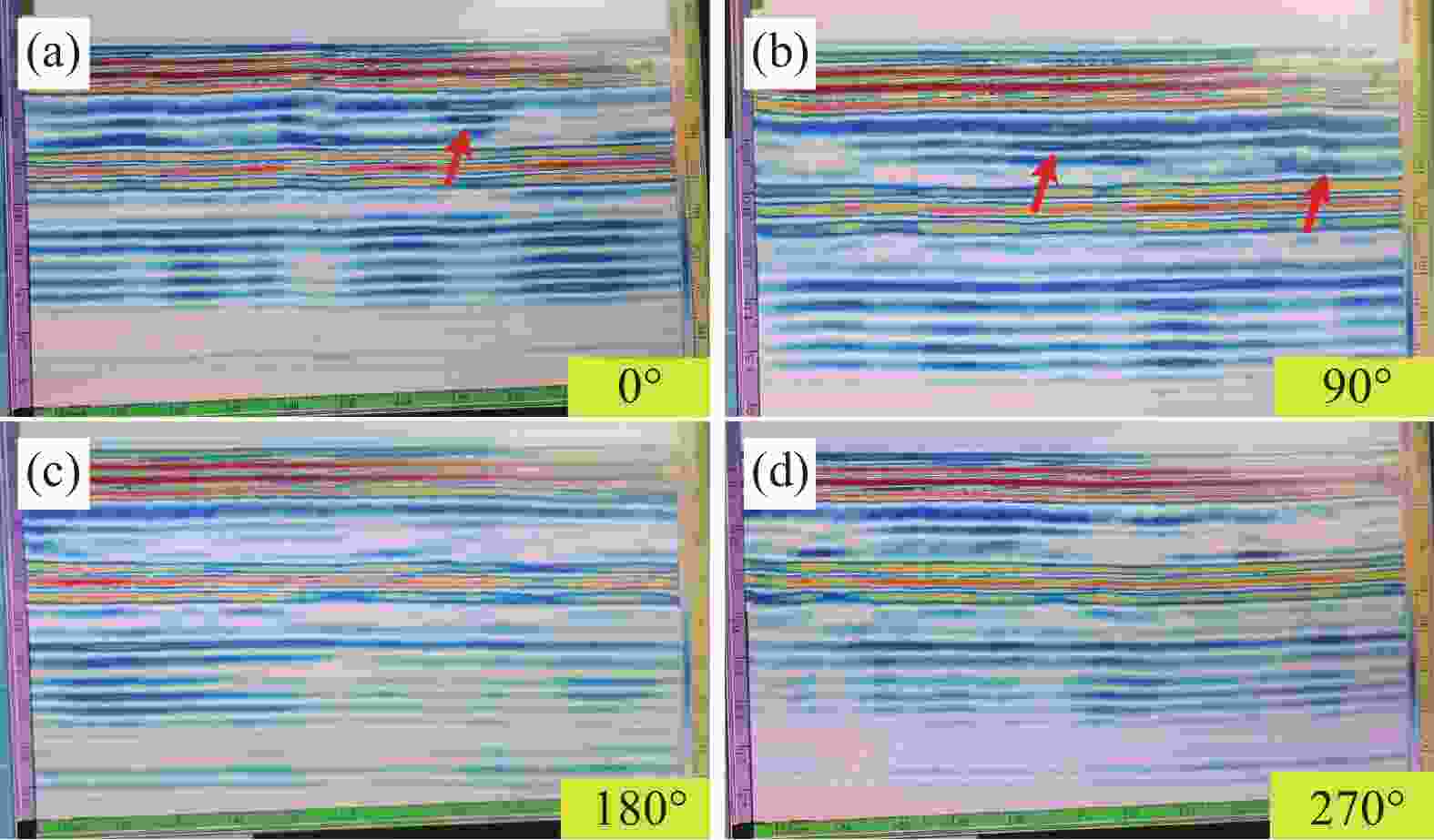

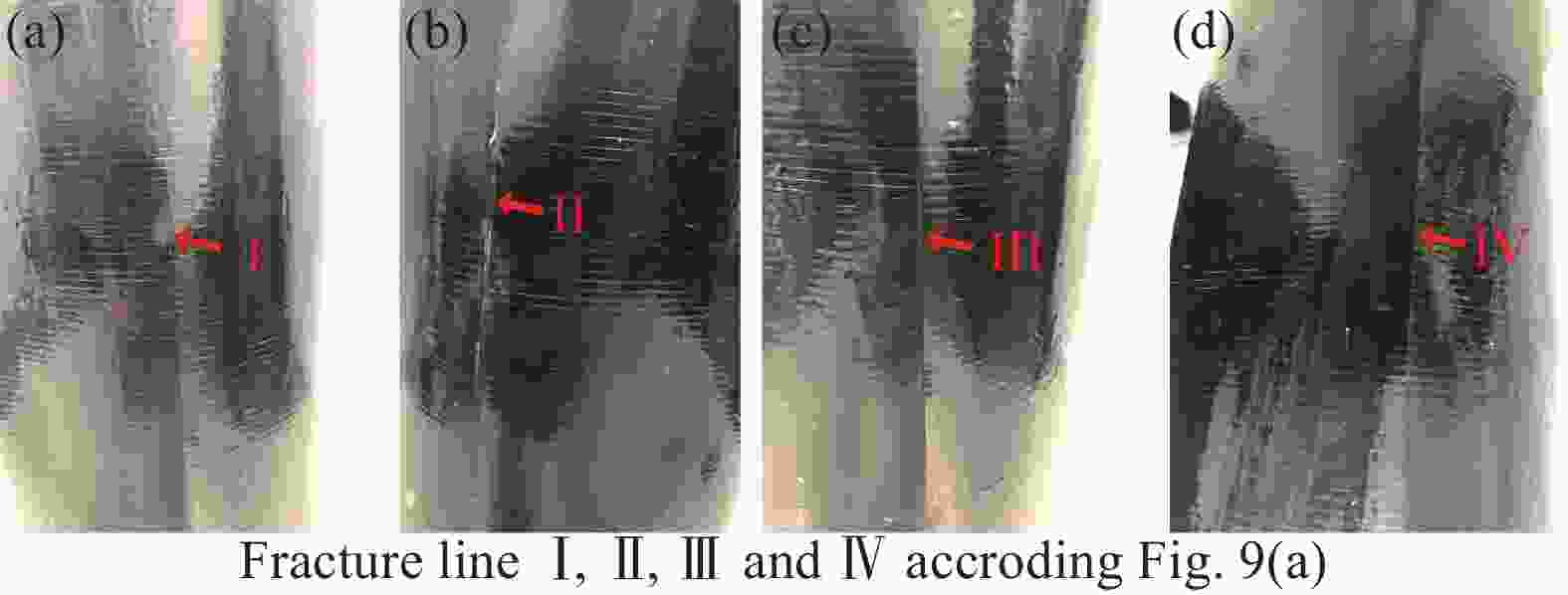

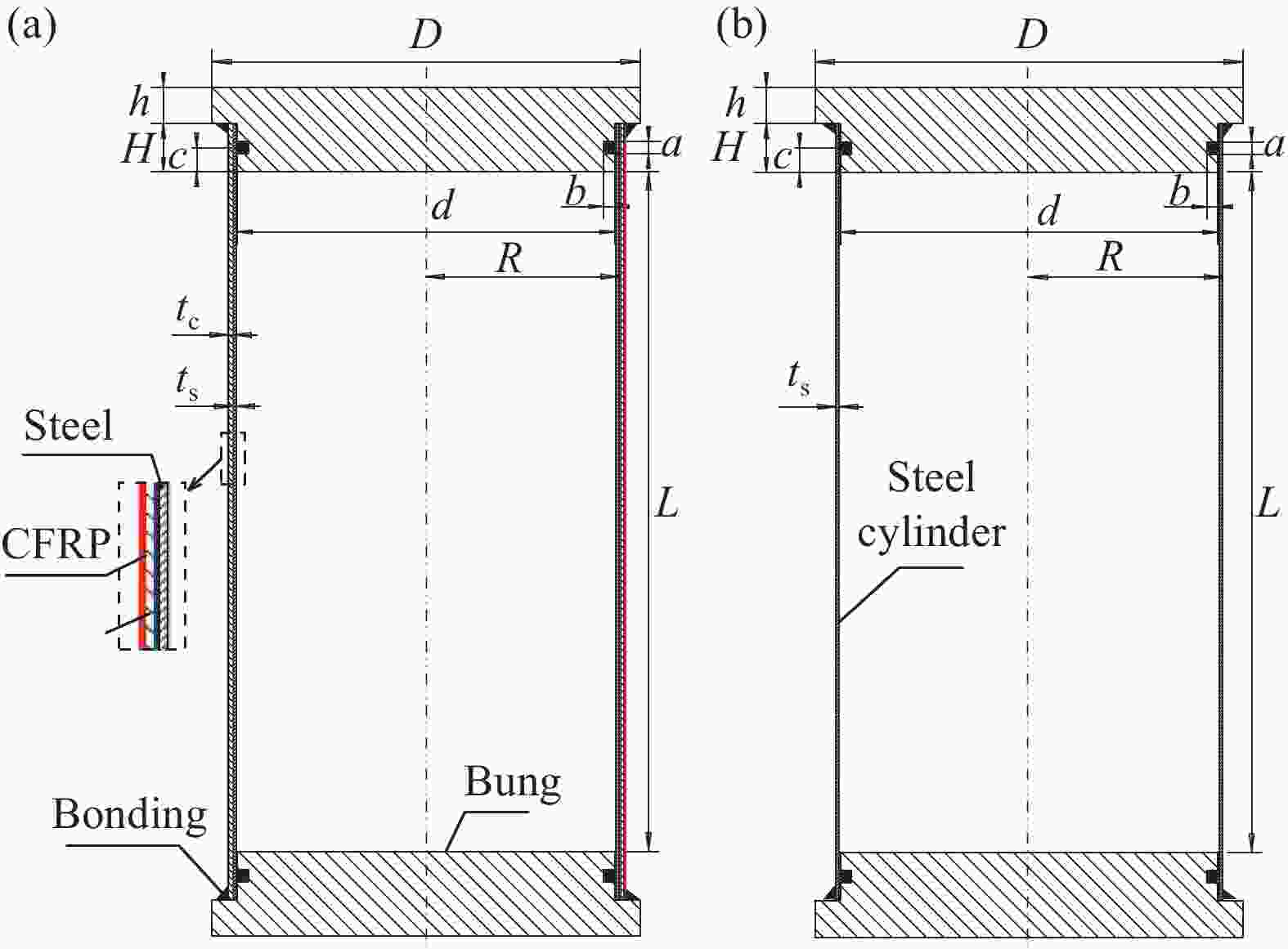

图 1 试样结构图:(a) 金属-碳纤维增强树脂复合材料(CFRP)复合型柱壳;(b) 金属柱壳

Figure 1. Schematics of the cylinders closed with heavy flanges: (a) Steel-carbon fiber reinforced polymer (CFRP) hybrid cylinder; (b) Steel cylinder

D—Outer diameter of bung; d—Inner diameter of bung; tc—Thickness of composite layer; ts—Thickness of steel layer; L—Length of cylinder; R—Inner radius of cylinder; b—Depth of sealing groove; a—Width of sealing groove; H—Thickness of inner plug for bung; h—Thickness of outer disk for bung; c—Distance between the sealing groove center and inner disk

表 1 试样几何参数

Table 1. Geometric parameters of specimens

Sample L/mm R/mm ts-nominal/mm tc-nominal/mm D/mm a/mm b/mm c/mm h/mm H/mm CYL1 280 79.5 1.5 1.2 180 5 2.74 10 10 20 CYL2 280 79.5 1.5 1.2 180 5 2.74 10 10 20 CYP1 280 79.5 1.5 — 180 5 2.74 10 10 20 CYP2 280 79.5 1.5 — 180 5 2.74 10 10 20 Notes: ts-nominal—Nominal thickness of steel layer; tc-nominal—Nominal thickness of composite layer;CYL—Steel-composite hybrid cylinder; CYP—Steel cylinder. 表 2 CFRP复合材料的性能

Table 2. Material properties of CFRP composites

Parameter Value Parameter Value XT 1400.09 E11 115 XC 580.06 E22 7.70 YT 44.36 G12 3.72 YC 133.03 G13 3.72 S12 45.04 ν12 0.33 S13 45.04 Notes: XT, XC—Tensile and compressive strength in fiber direction; E11, E22—Tensile and transverse Young’s modulus; ν12—Poisson's ratio; YT—Transverse tensile strength; YC—Transverse compressive strength; G12, G13—Shear modulus; S12, S13—Shear strength. 表 3 金属-CFRP复合型柱壳和金属柱壳试样壁厚及试验载荷

Table 3. Wall thickness and the tested collapse strength of specimens for steel-CFRP hybrid cylinder and steel cylinders

Sample ttotal-min (ts-min)/mm ttotal-max (ts-max)/mm ttotal-av (ts-av)/mm St. dev. (ts-St.dev.) Ptest/MPa CYL1 2.369 (1.248) 3.052 (1.408) 2.579 (1.314) 0.0836 (0.0171) 3.232 CYL2 2.242 (1.284) 2.860 (1.350) 2.576 (1.305) 0.0509 (0.0244) 2.964 CYP1 1.272 (–) 1.378 (–) 1.309 (–) 0.0192 (–) 1.915 CYP2 1.244 (–) 1.372 (–) 1.308 (–) 0.0186 (–) 1.785 Notes: ttotal—Total thickness of cylinder; Ptest—Tested collapse strength; ts-av—Metal wall thickness; min—Minimum; max—Maximum; av—Average; St.dev.—Standard deviation. 表 4 金属-CFRP复合型柱壳和金属柱壳试样重力与名义浮力

Table 4. Comparison of the buoyancy and gravity of specimens for steel-CFRP hybrid cylinder and steel cylinders

Sample CYL1 CYL2 CYP1 CYP2 Buoyancy F/N 69.11 69.11 67.22 67.22 Gravity G/N 118.12 119.89 109.45 110.21 Notes: FCYL=(3.14×(79.5+1.2)×(79.5+1.2)×320+3.14×90×90×10×2)×9.8=69.11 N; FCYP=(3.14×79.5×79.5×320+3.14×90×90×10×2)×9.8=67.22 N. 表 5 复合型柱壳和金属柱壳试样网格数、线性屈曲及非线性临界屈曲载荷

Table 5. Finite element number, linear eigenvalue and critical buckling load of fabricated CYS and CYH determined through numerical analysis

Sample S4 R SC8 R Plinear/MPa Pnon/MPa CYL1 8550 5900 3.521 (1.089) 3.024 (0.936) CYL2 8550 5900 3.352 (1.131) 2.751 (0.928) CYP1 8350 — 2.170 (1.133) 1.946 (1.016) CYP2 8350 — 2.108 (1.181) 1.845 (1.034) Notes: Plinear—Linear buckling load; Pnon—Critical buckling load; Ratio of the calculated values to test values is indicated in parentheses. 表 6 铺设角度θ及层数N对复合型柱壳非线性临界屈曲载荷影响

Table 6. Effect of wrapped angle θ and layers N on critical buckling load of hybrid cylinder

Angle θ/° Layers N Load P/MPa Angle θ/° Layers N Load P/MPa Angle θ/° Layers N Load P/MPa ±15 2 2.218 ±50 2 2.394 ±65 2 2.512 6 2.678 6 3.551 6 4.021 10 3.387 10 5.294 10 6.135 14 4.329 14 6.964 14 8.067 18 5.407 18 8.355 18 9.863 22 6.221 22 10.099 22 11.962 26 6.790 26 11.912 26 14.335 ±30 2 2.259 ±55 2 2.435 ±75 2 2.577 6 2.925 6 3.720 6 4.239 10 3.970 10 5.613 10 6.467 14 5.282 14 7.384 14 8.436 18 6.318 18 8.978 18 10.227 22 6.997 22 10.911 22 12.184 26 8.096 26 12.906 26 14.565 ±45 2 2.354 ±60 2 2.474 ±85 2 2.617 6 3.379 6 3.879 6 4.354 10 4.951 10 5.896 10 6.622 14 6.534 14 7.760 14 8.570 18 7.697 18 9.489 18 10.286 22 9.229 22 11.552 22 12.097 26 10.854 26 13.729 26 14.252 -

[1] MAGNUCKI K, JASION P, RODAK M. Strength and buckling of an untypical dished head of a cylindrical pressure vessel[J]. International Journal of Pressure Vessels and Piping,2018,161:17-21. [2] MAGNUCKI K, LEWINSKI J, CICHY R. Strength and buckling problems of dished heads of pressure vessels-contemporary look[J]. Journal of Pressure Vessel Technology, Transactions of the ASME,2018,140(4):1-14. [3] BLACHUT J. Buckling of cylinders with imperfect length[C]//Proceedings of the ASME 2013 Pressure Vessels and Piping Conference. Paris, 2013: 1-9. [4] BŁACHUT J. Experimental perspective on the buckling of pressure vessel components[J]. Applied Mechanics Reviews,2014,66(1):30-33. [5] BLACHUT J, MAGNUCKI K. Strength, stability, and optimization of pressure vessels: Review of selected problems[J]. Applied Mechanics Reviews, 2008, 61(1-6): 0608011–06080133. [6] KHAMLICHI A, BEZZAZI M, LIMAM A. Buckling of elastic cylindrical shells considering the effect of localized axisymmetric imperfections[J]. Thin-Walled Structures,2004,42(7):1035-1047. doi: 10.1016/j.tws.2004.03.008 [7] FATEMI S M, SHOWKATI H, MAALI M. Experiments on imperfect cylindrical shells under uniform external pressure[J]. Thin-Walled Structures,2013,65:14-25. doi: 10.1016/j.tws.2013.01.004 [8] IFAYEFUNMI O, FADZULLAH S H S M. Buckling behaviour of imperfect axially compressed cylinder with an axial crack[J]. International Journal of Automotive and Mechanical Engineering,2017,14(1):3837-3848. doi: 10.15282/ijame.14.1.2017.3.0313 [9] BŁACHUT J. Buckling of axially compressed cylinders with imperfect length[J]. Computers and Structures, 2010, 88(5-6): 365–374. [10] ROSS C T F. Pressure vessels[M]. Philadelphia: Woodhead Publishing Limited, 2011. [11] CHO S R, DO Q T, SHIN H K. Residual strength of damaged ring-stiffened cylinders subjected to external hydrostatic pressure[J]. Marine Structures,2017,56:186-205. doi: 10.1016/j.marstruc.2017.08.005 [12] CHO S R, MUTTAQIE T, DO Q T, et al. Experimental investigations on the failure modes of ring-stiffened cylinders under external hydrostatic pressure[J]. International Journal of Naval Architecture and Ocean Engineering,2018,10(6):711-729. doi: 10.1016/j.ijnaoe.2017.12.002 [13] SHIOMITSU D, YANAGIHARA D. Elastic local shell and stiffener-tripping buckling strength of ring-stiffened cylindrical shells under external pressure[J]. Thin-Walled Structures,2020,148:106622. [14] WANG X, LI P, WANG R. Study on hydro-forming technology of manufacturing bimetallic CRA-lined pipe[J]. International Journal of Machine Tools and Manufacture, 2005, 45(4-5): 373-378. [15] WANG Y, YANG L, BAI B, et al. Evaluation of limit deformation behavior in hydro-bulging of the double-layer sheet metal using diffuse and localized instability theories[J]. International Journal of Mechanical Sciences,2019,150:145-153. doi: 10.1016/j.ijmecsci.2018.10.027 [16] CARVELLI V, PANZERI N, POGGI C. Buckling strength of GFRP under-water vehicles[J]. Composites Part B: Engi-neering,2001,32(2):89-101. doi: 10.1016/S1359-8368(00)00063-9 [17] ÖZBEK Ö. Axial and lateral buckling analysis of kevlar/epoxy fiber-reinforced composite laminates incorporating silica nanoparticles[J]. Polymer Composites,2021,42(3):1109-1122. doi: 10.1002/pc.25886 [18] DAVIES P, CHOQUEUSE D, BIGOURDAN B, et al. Compo-site cylinders for deep sea applications: An overview[J]. Journal of Pressure Vessel Technology, Transactions of the ASME,2016,138(6):1-8. [19] WEI R, PAN G, JIANG J, et al. An efficient approach for stacking sequence optimization of symmetrical laminated composite cylindrical shells based on a genetic algorithm[J]. Thin-Walled Structures,2019,142:160-170. [20] KARBHARI V M, SEIBLE F. Fiber reinforced composites-advanced materials for the renewal of civil infrastructure[J]. Applied Composite Materials,2000,7(2):95-124. [21] TOUTANJI H, DEMPSEY S. Stress modeling of pipelines strengthened with advanced composites materials[J]. Thin-Walled Structures,2001,39(2):153-165. doi: 10.1016/S0263-8231(00)00049-5 [22] DRAIDI Z, BUI T T, LIMAM A, et al. Buckling behavior of metallic cylindrical shell structures strengthened with CFRP composite[J]. Advances in Civil Engineering,2018(6):423163. [23] ZHANG Y, LIU Z, XIN J, et al. The attenuation mechanism of CFRP repaired corroded marine pipelines based on experiments and FEM[J]. Thin-Walled Structures,2021,169:108469. [24] KR SINGH D, VILLAMAYOR A, HAZRA A. Numerical and experimental analysis of loctite adhesive composite wrapping on EN 10028 steel pipe[J]. Materials Today: Proceedings,2020,44:4158-4165. [25] VUKELIC G, VIZENTIN G, BAKHTIARI R. Failure analysis of a steel pressure vessel with a composite wrap repair proposal[J]. International Journal of Pressure Vessels and Piping,2021,193:104476. [26] FAWZIA S, AL-MAHAIDI R, ZHAO X L, et al. Strengthening of circular hollow steel tubular sections using high modulus CFRP sheets[J]. Construction and Building Materials,2007,21(4):839-845. doi: 10.1016/j.conbuildmat.2006.06.014 [27] TENG J G, HU Y M. Behaviour of FRP-jacketed circular steel tubes and cylindrical shells under axial compression[J]. Construction and Building Materials,2007,21(4):827-838. doi: 10.1016/j.conbuildmat.2006.06.016 [28] VAKILI M, SHOWKATI H. Experimental and numerical investigation of elephant foot buckling and retrofitting of cylindrical shells by FRP[J]. Journal of Composites for Construction,2016,20(4):04015087. doi: 10.1061/(ASCE)CC.1943-5614.0000640 [29] CHOQUEUSE D, BIGOURDAN B, DEUFF A, et al. Hydrostatic compression behaviour of steel-composite hybrid tubes[C]//ICCM International Conferences on Composite Materials. Edinburgh, 2009: 1-10. [30] ZHANG J, ZHU Z, WANG F, et al. Buckling behaviour of double-layer and single-layer stainless steel cylinders under external pressure[J]. Thin-Walled Structures,2021,161:107485. doi: 10.1016/j.tws.2021.107485 [31] ZHANG J, ZHANG M, CUI W, et al. Elastic-plastic buckling of deep sea spherical pressure hulls[J]. Marine Structures,2018,57:38-51. doi: 10.1016/j.marstruc.2017.09.007 [32] CARROLL M, ELLYIN F, KUJAWSKI D, et al. The rate-dependent behaviour of ±55° filament-wound glass-fibre/epoxy tubes under biaxial loading[J]. Composites Science and Technology,1995,55(4):391-403. doi: 10.1016/0266-3538(95)00119-0 [33] LIU W, SODEN P D, KADDOUR A S. Design of end plugs and specimen reinforcement for testing ±55° glass/epoxy composite tubes under biaxial compression[J]. Computers and Structures, 2005, 83(12-13): 976-988. -

下载:

下载: