Enhancement of fire insulation performance for aramid non-woven fabric via chitosan/M(OH)(OCH3) (M=Co, Ni)/sodium hexametaphosphate nano-composite coating

-

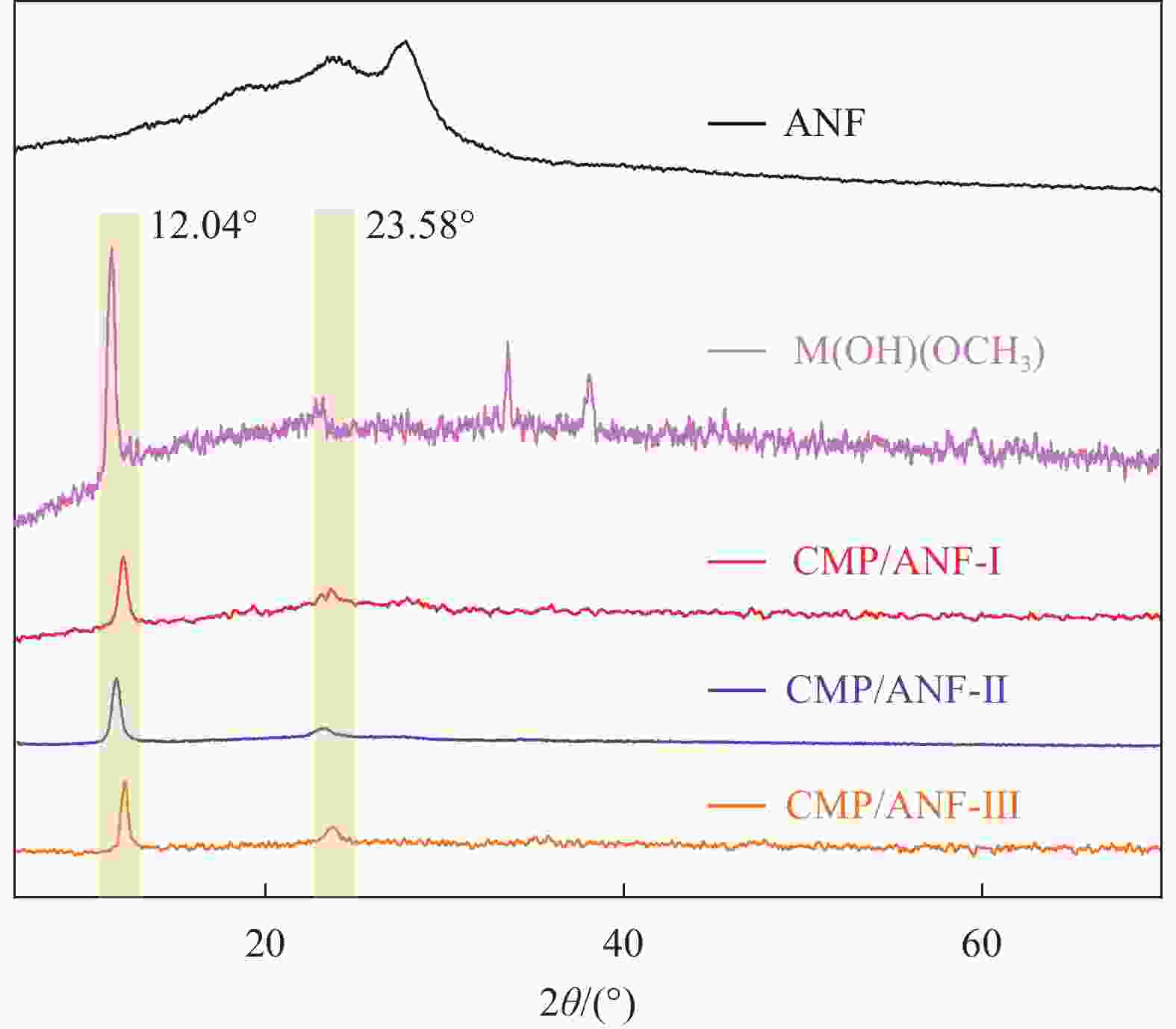

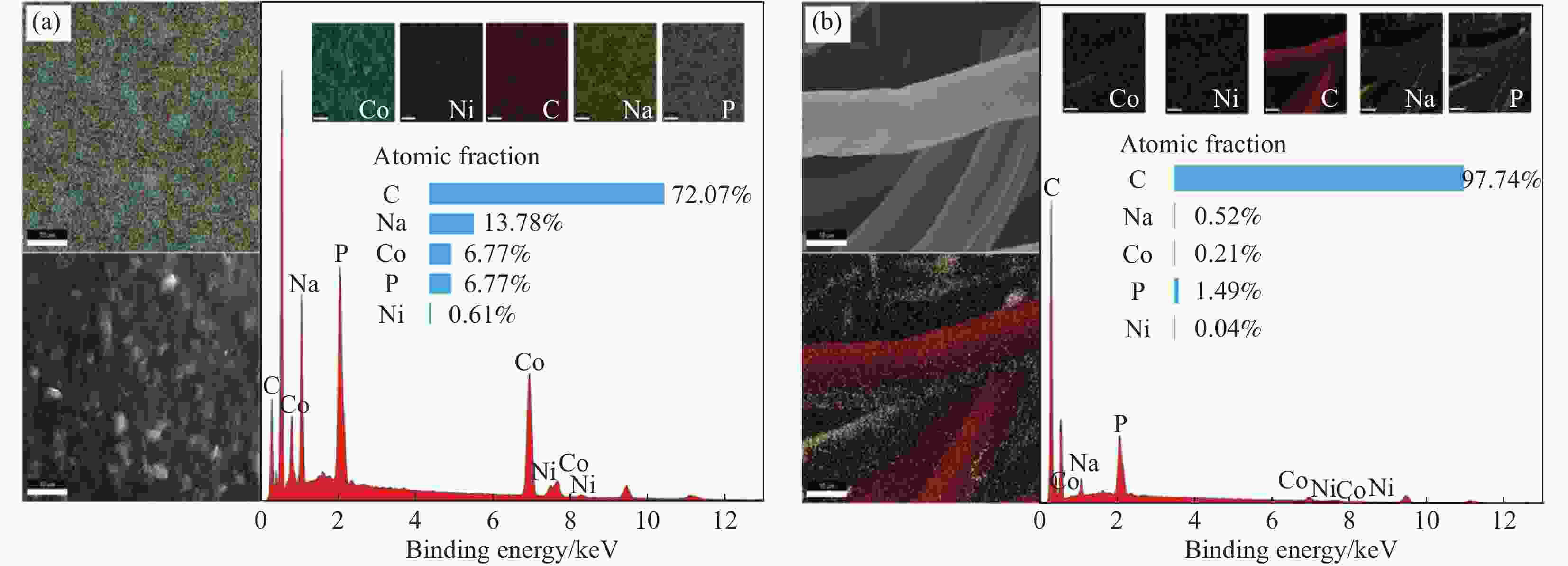

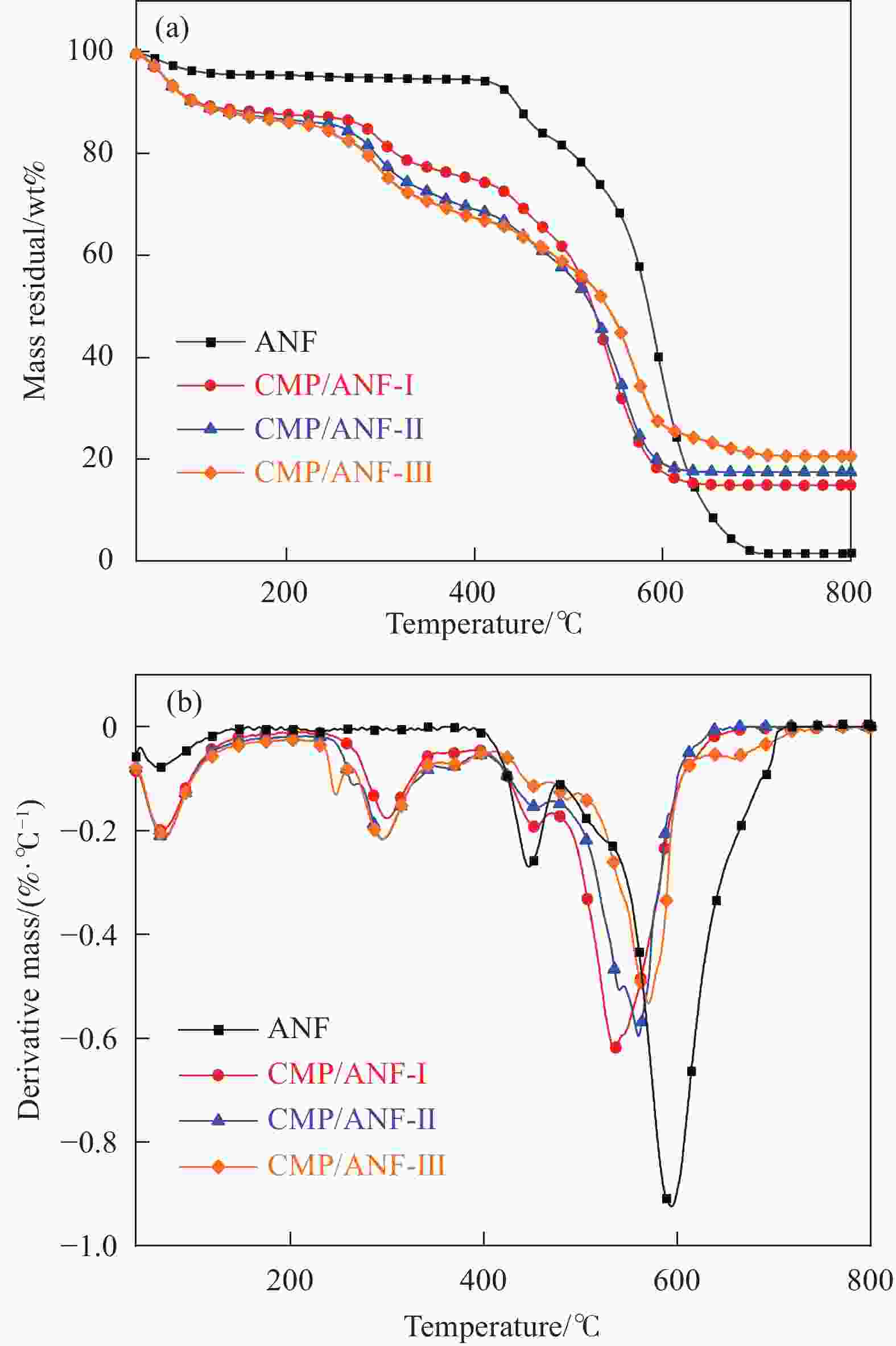

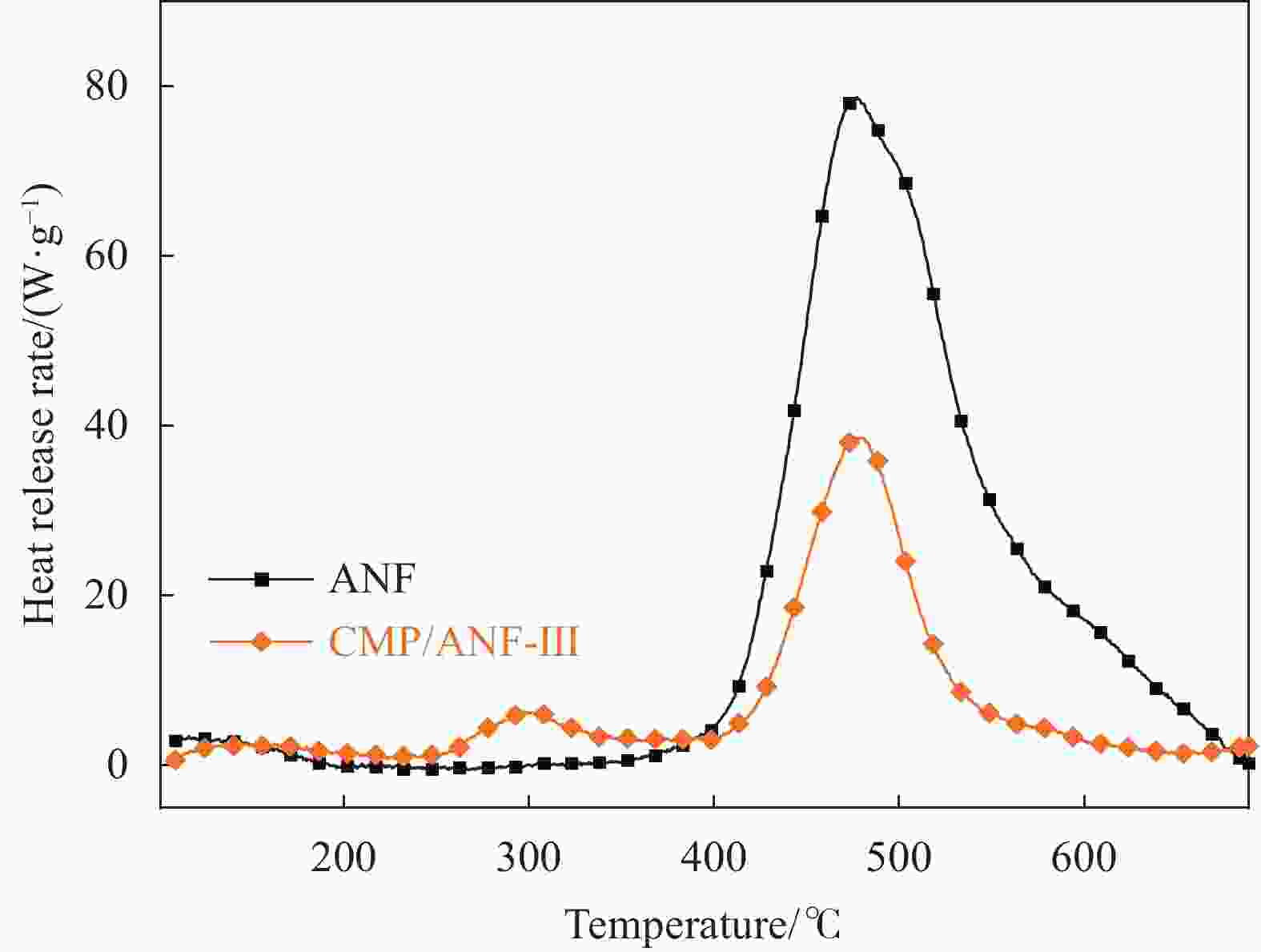

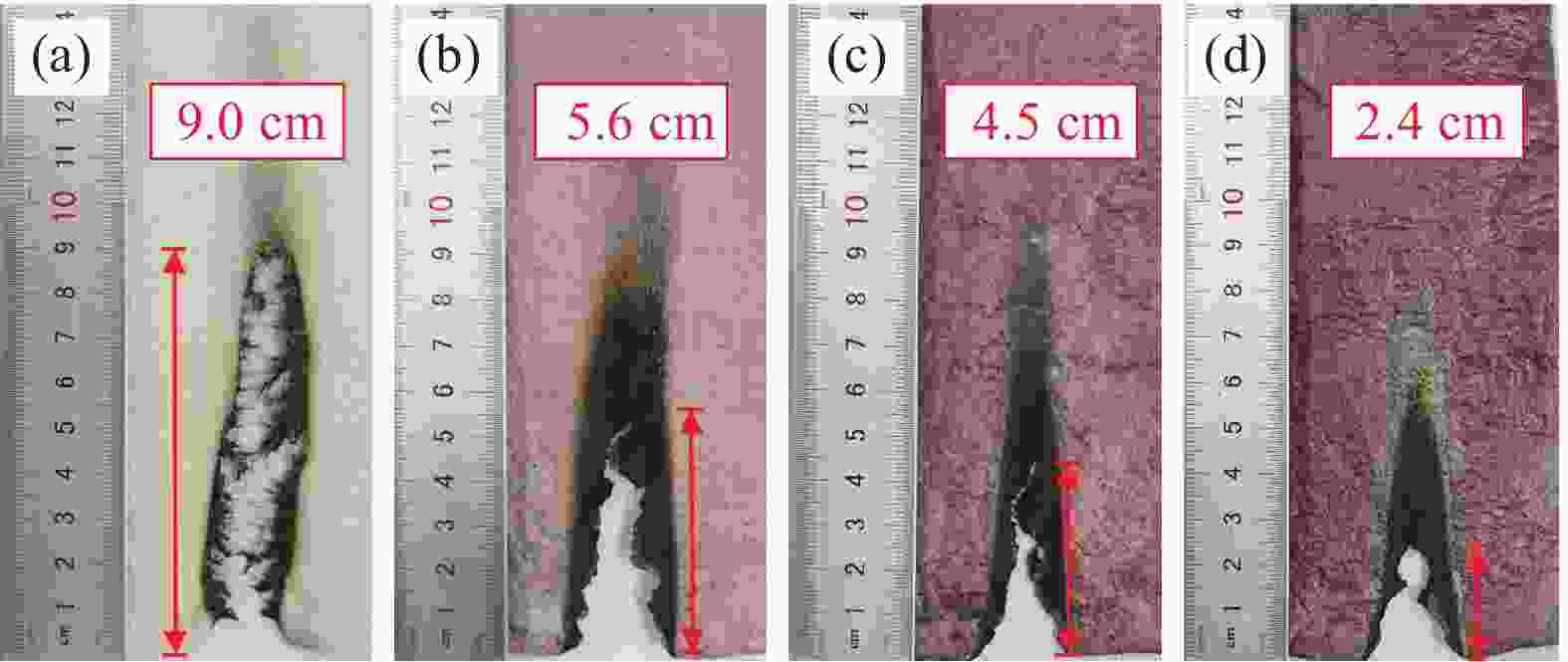

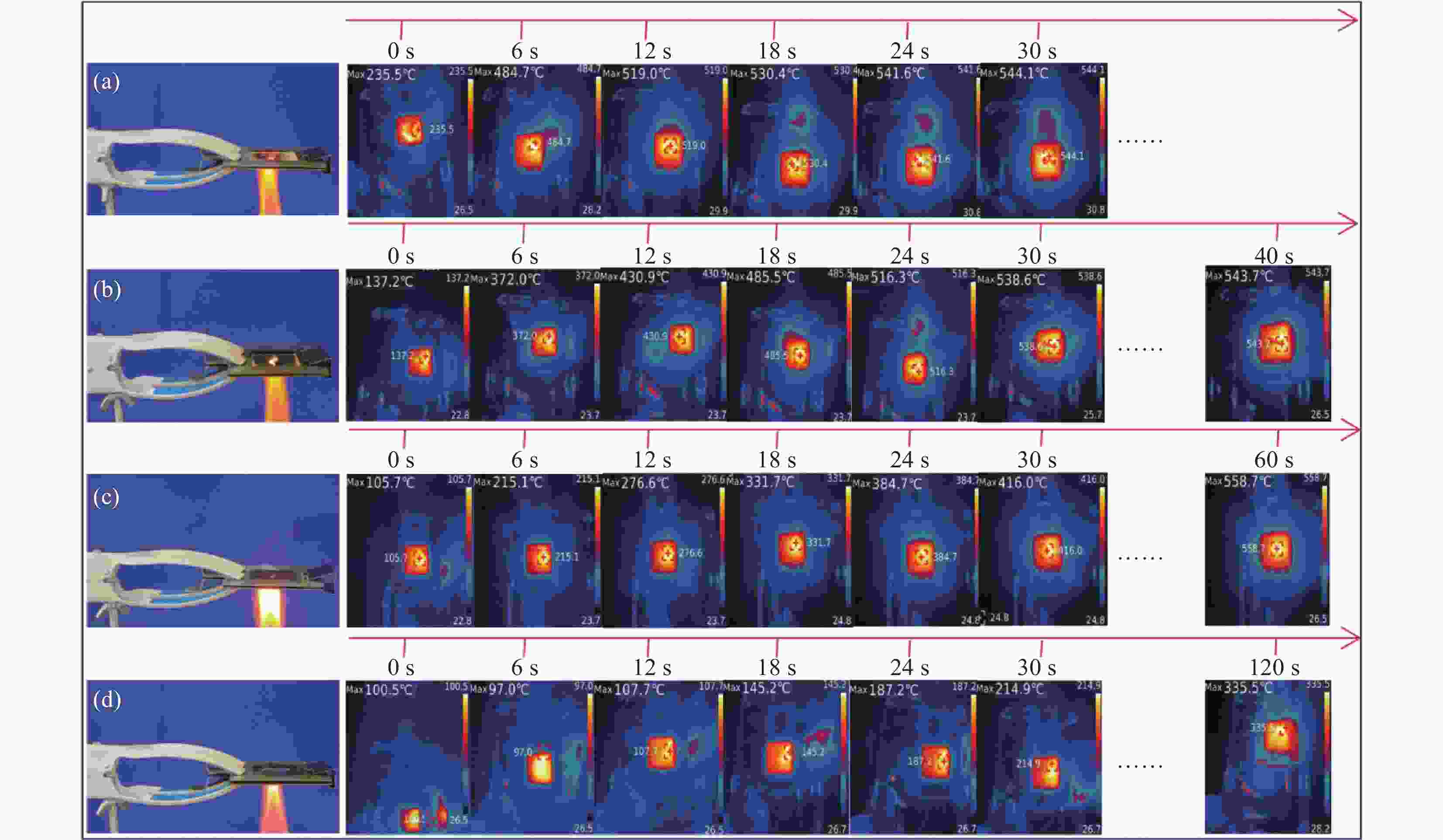

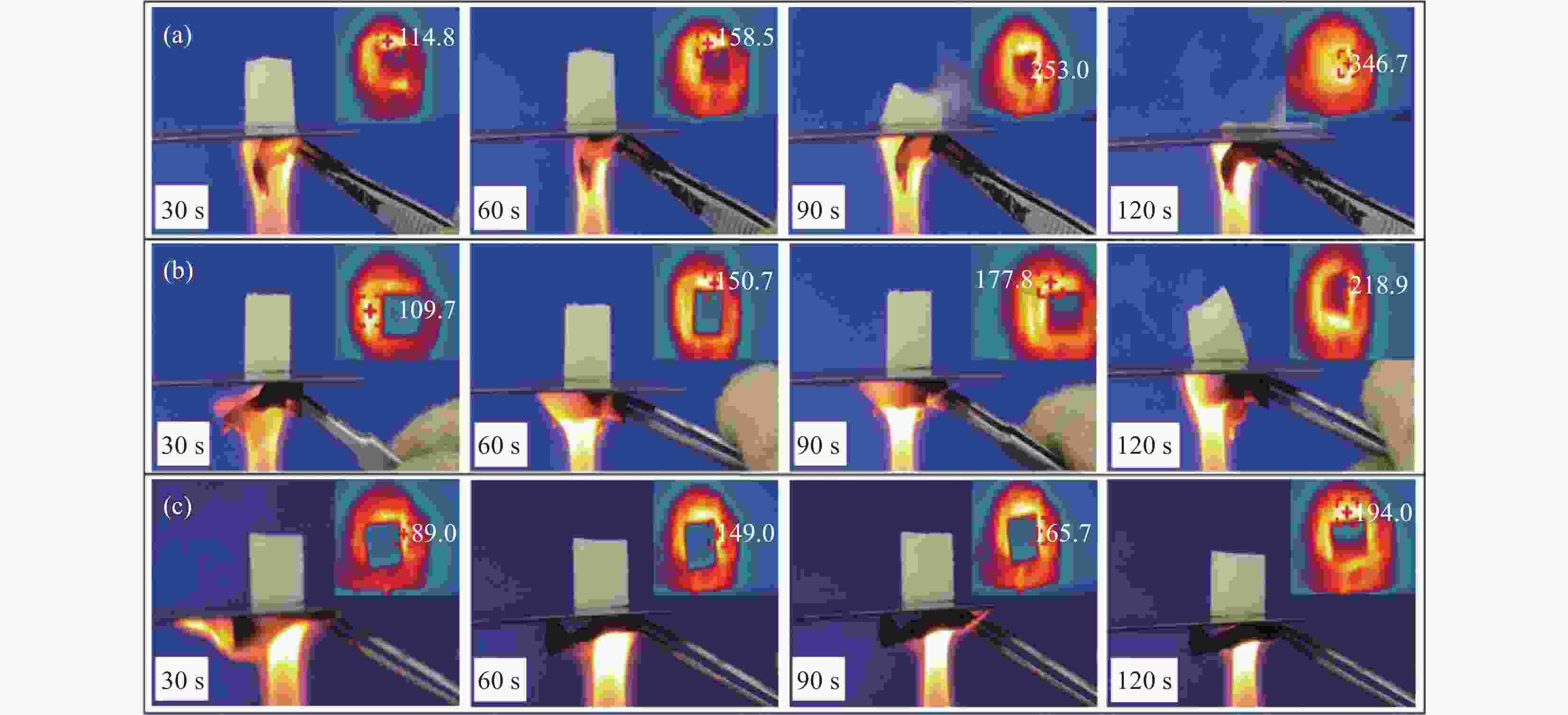

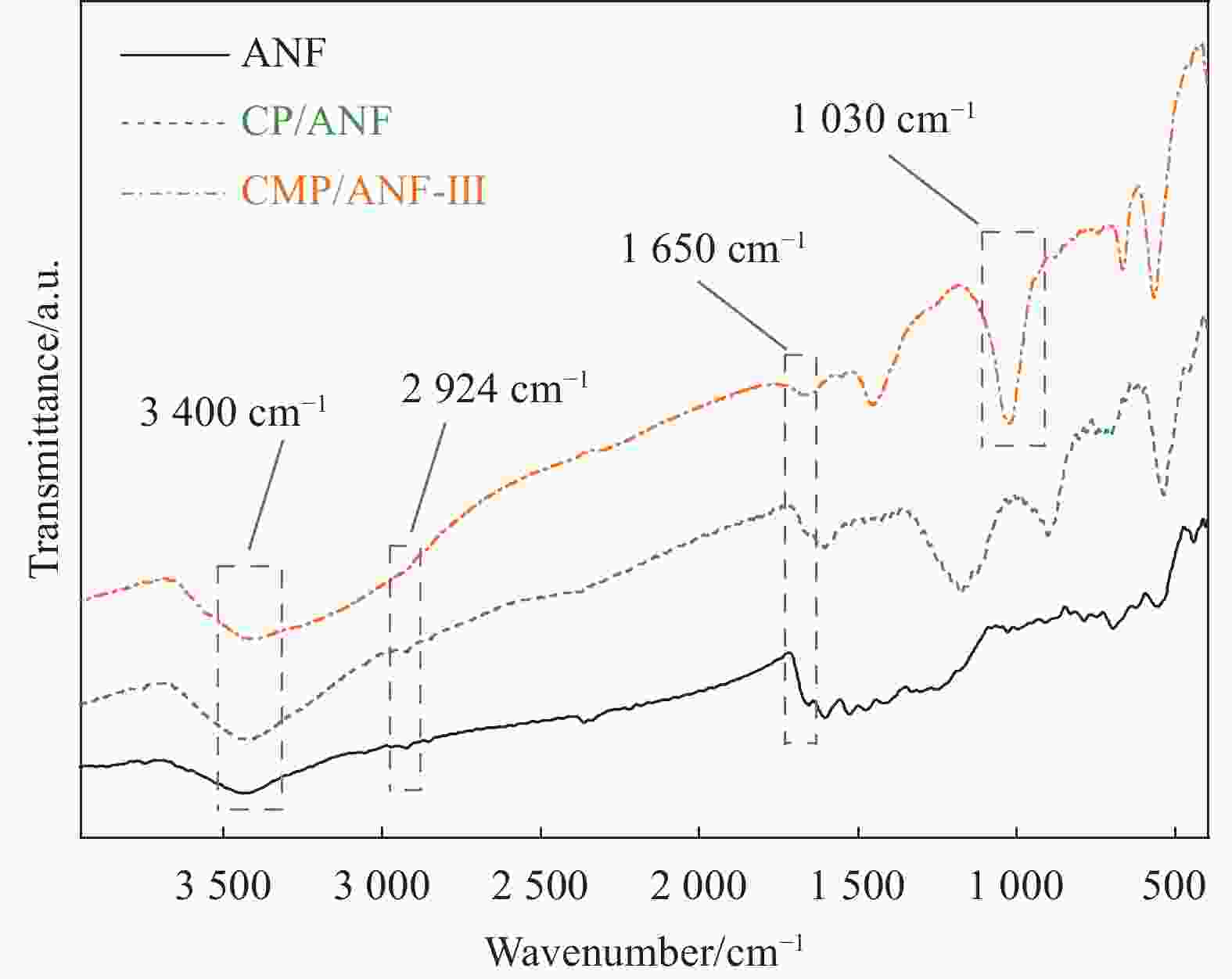

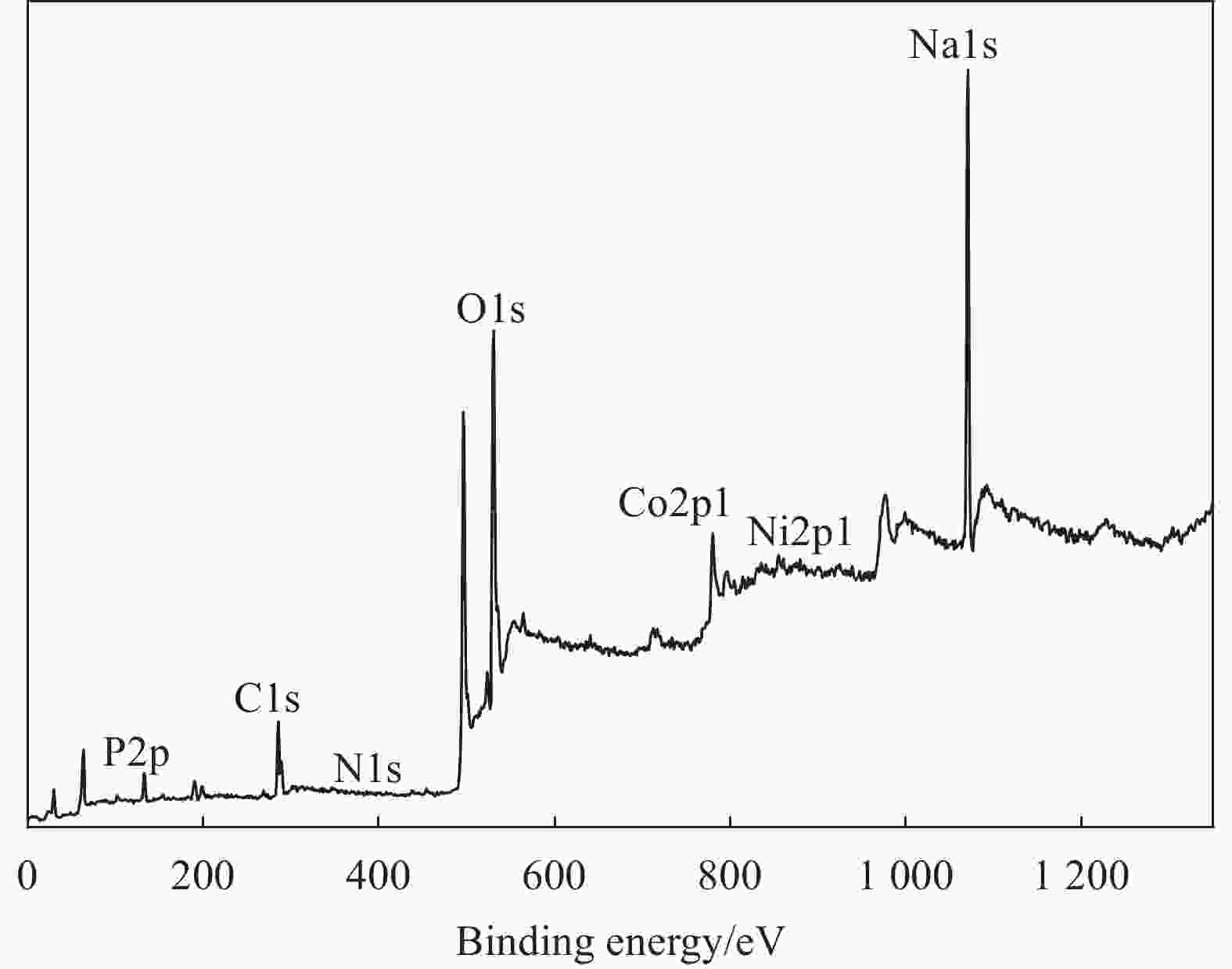

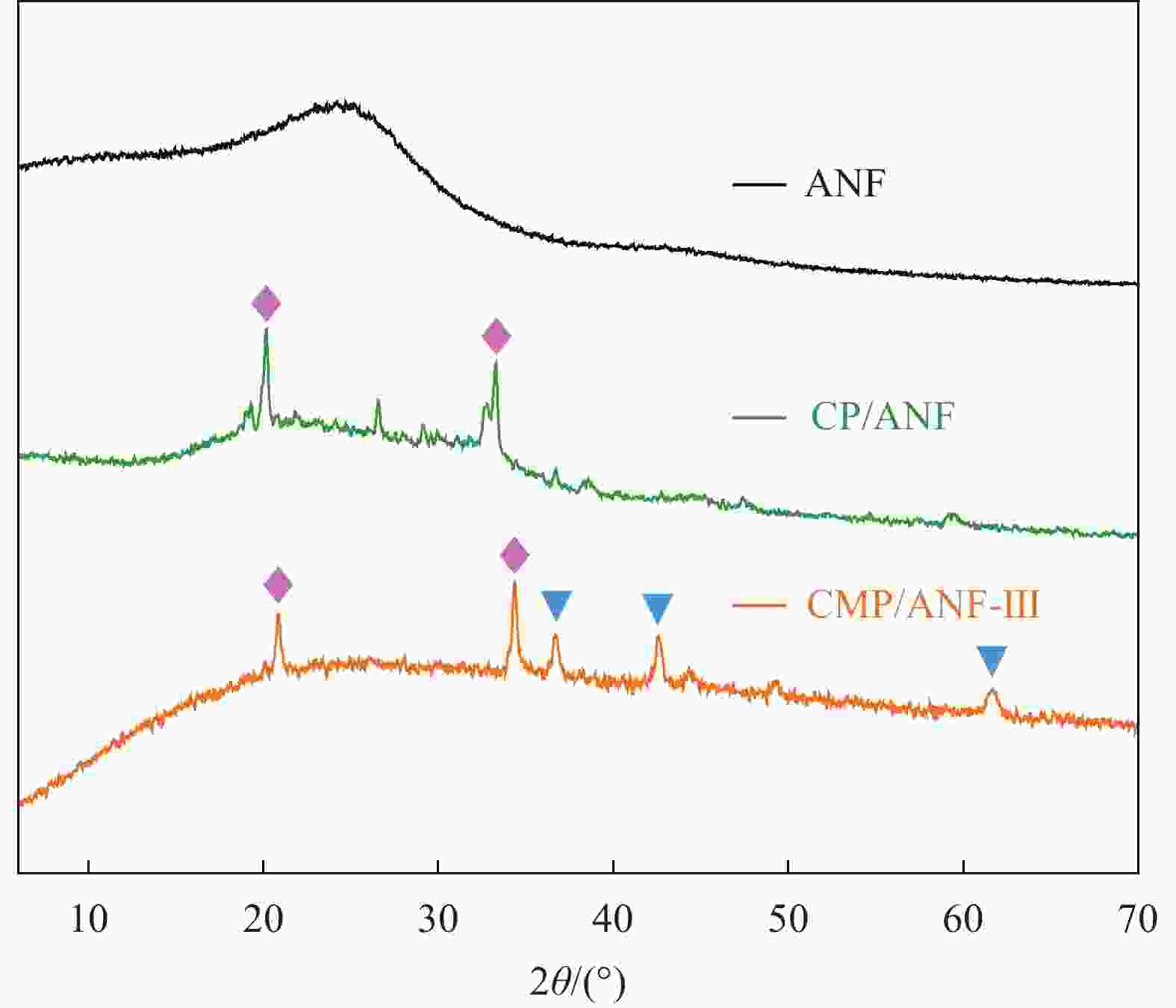

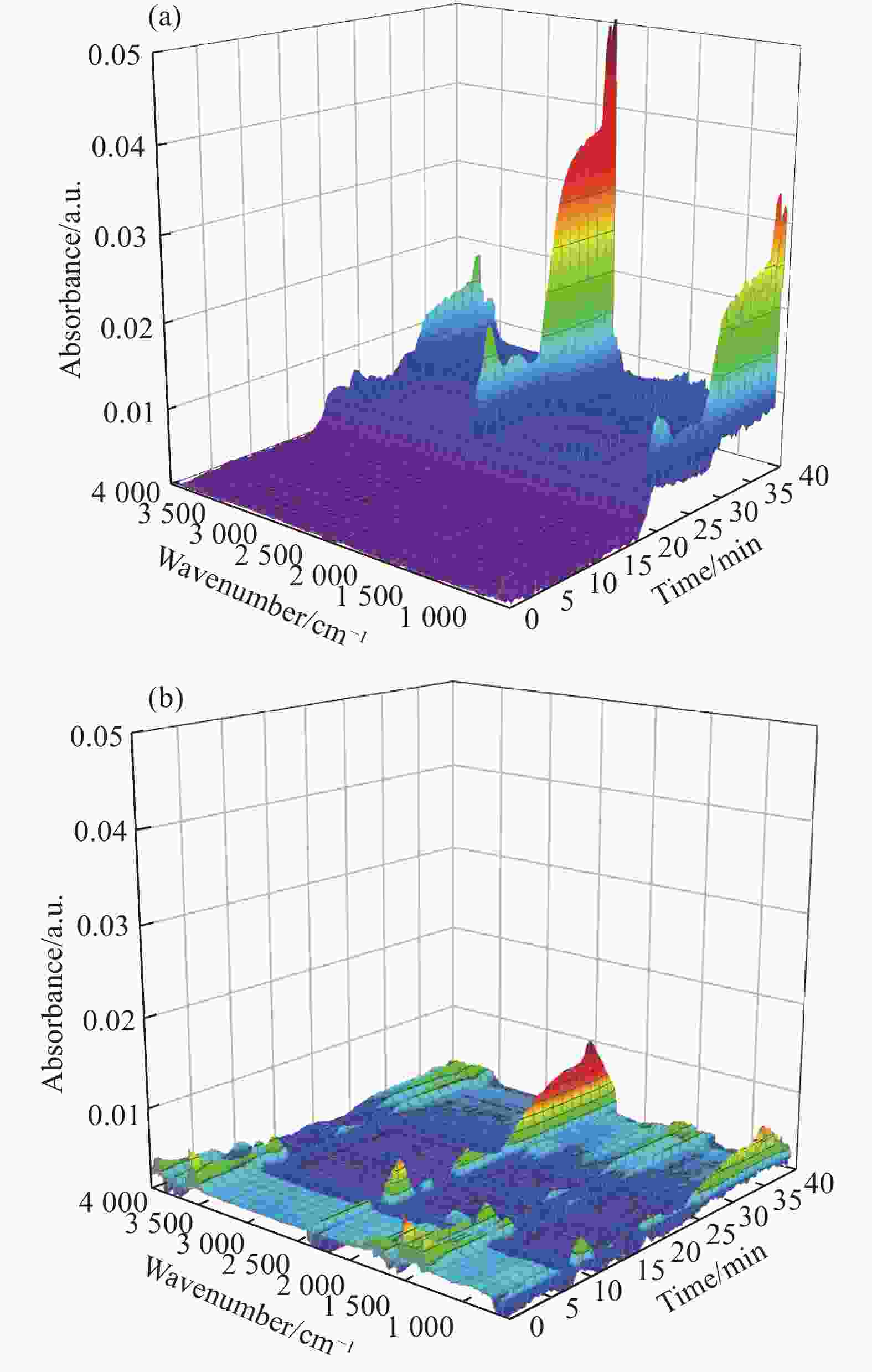

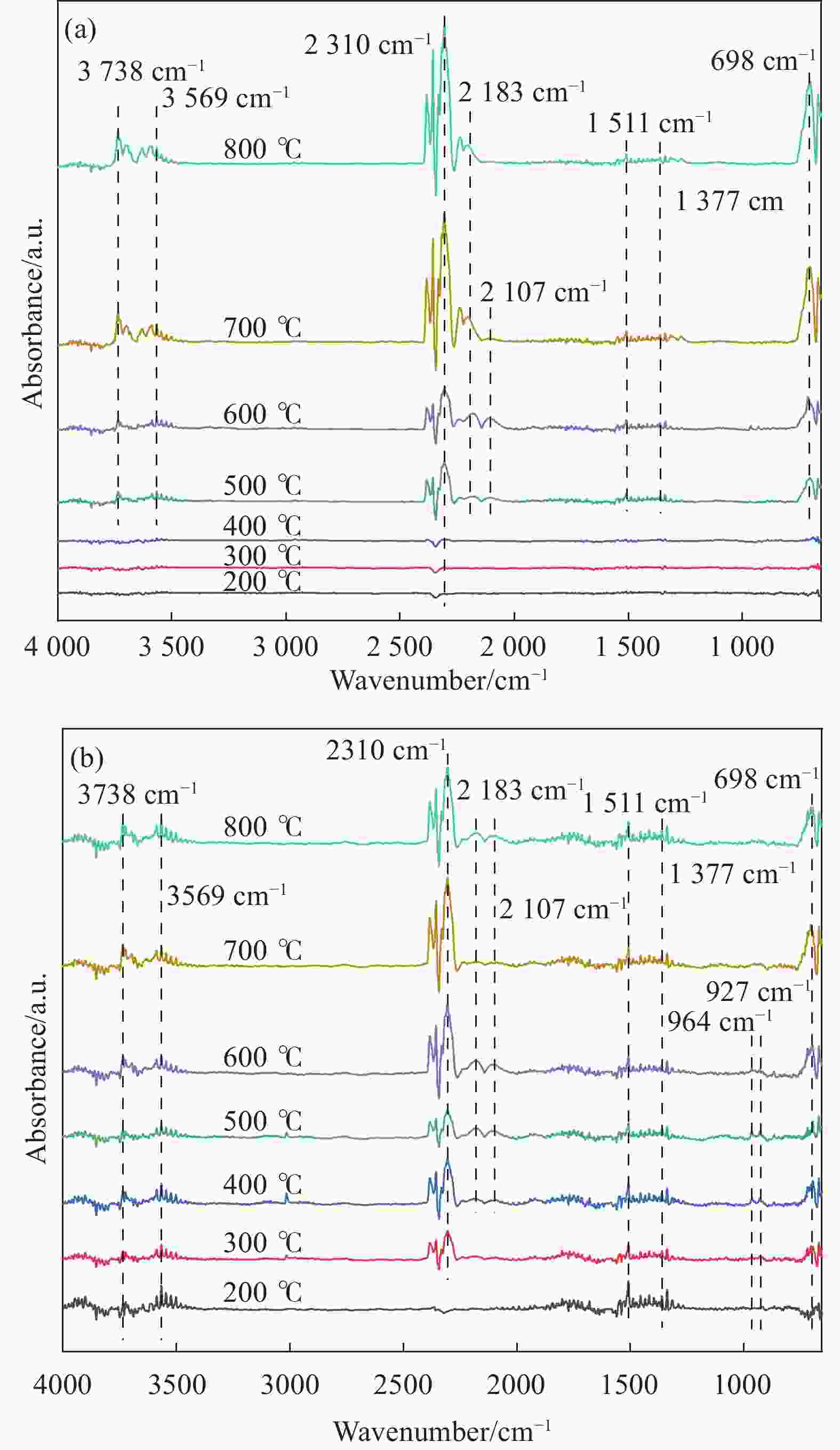

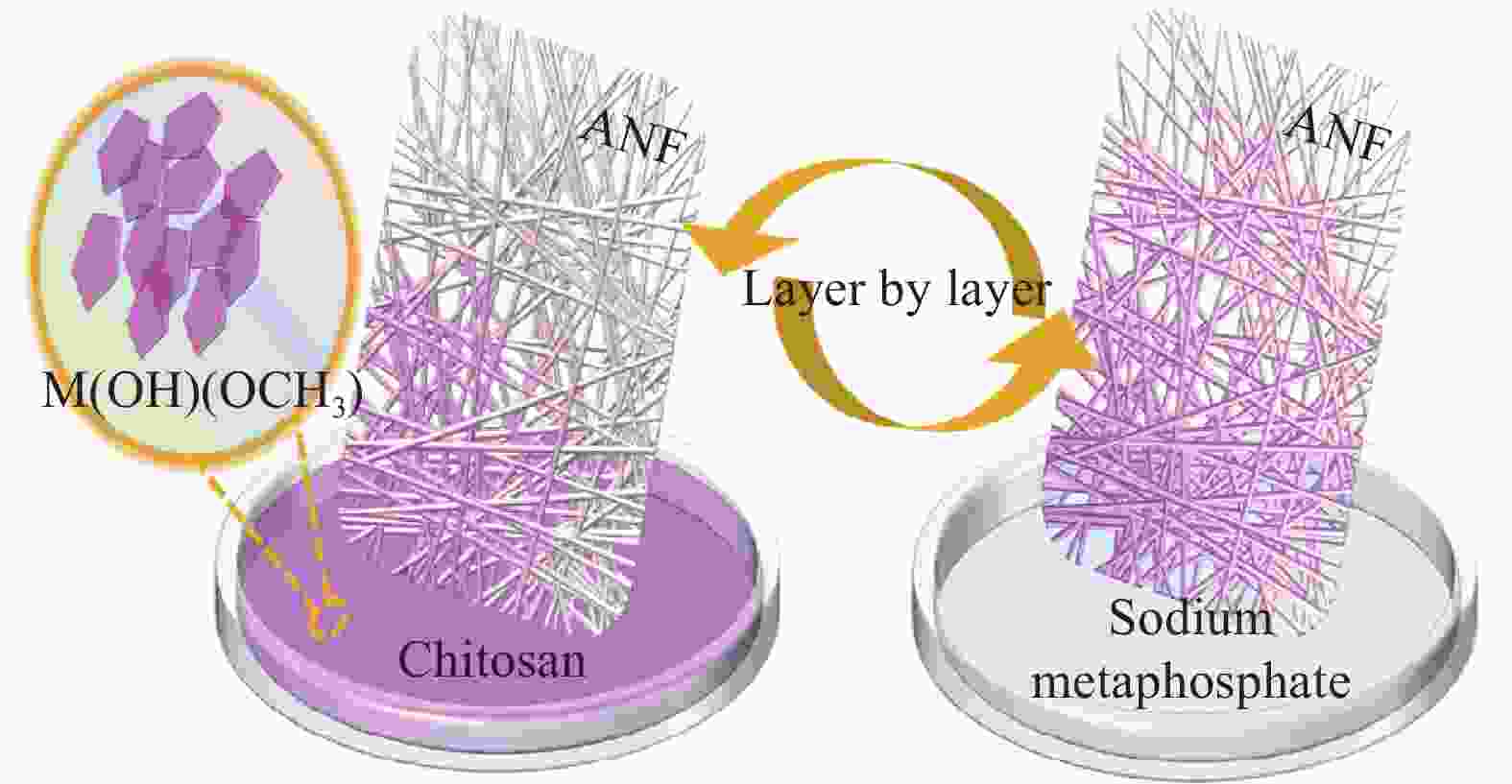

摘要: 随着火灾场景的复杂化和火灾危险性的增加,市场迫切需要高性能耐火隔热纤维以更好保护消防救援人员。本工作利用层层自组装技术,将食品级六偏磷酸钠及复合二维纳米材料M(OH)(OCH3) (M=Co, Ni)的生物质壳聚糖交替涂覆于芳纶纤维无纺布(ANF)表面,制备了新型ANF纳米复合材料。结果表明,涂覆15层样品(CMP/ANF-Ⅲ)在空气中升温至800 ℃,残炭率由1.59%(纯ANF)提高至20.55%,热稳定性显著改善。CMP/ANF-Ⅲ的热释放速率峰值(PHRR)、总热释放速率(THR)较ANF分别降低48.90%、58.57%,阻燃性能显著提高。在垂直燃烧测试中,CMP/ANF-Ⅲ的损毁长度降低至2.4 cm(纯ANF 9.0 cm)。在耐火隔热测试中,纯ANF 12 s被烧穿,而CMP/ANF-Ⅲ在120 s仍保持完整,同时背面温度大幅降低至335 ℃(纯ANF超过500 ℃)。残炭分析表明,CMP/ANF-Ⅲ燃烧后生成致密的炭层,其能有效阻挡火焰的蔓延及与基体之间的热对流,提高无纺布阻燃隔热性能。气相产物分析表明,CMP/ANF-Ⅲ较低温度下即可释放出CO2、H2O、NH3等不燃性气体,起到气相阻燃作用。本工作研制的ANF纳米复合材料为新一代高效耐火防护服装的研发提供支持。Abstract: With the complexity of fire scenarios and the increasing risk of fire, there was an urgent need for high-performance fire-resistant insulation fibers to be better developed in the market to protect firefighting and rescue personnel. In this work, we used layer-by-layer self-assembly technique to alternately coat food-grade sodium hexametaphosphate and biomass chitosan mixed with two-dimensional nanomaterials M(OH)(OCH3) (M=Co, Ni) on the surface of aramid nonwoven fabric (ANF), and prepared novel ANF composite materials. The results show that after heating from room temperature to 800 ℃ in air, the char yield of the 15BL coated sample (CMP/ANF-Ⅲ) increases from 1.59% (pure ANF) to 20.55%, significantly enhancing its thermal stability. CMP/ANF-Ⅲ exhibits lower peak heat release rate (PHRR) and total heat release (THR), which are 48.90% and 58.57% lower than ANF, demonstrating a significantly improvement in flame retardancy. In the vertical flame test, the damaged length of CMP/ANF-Ⅲ reduces to 2.4 cm (while that of the pure ANF is 9.0 cm). In the fire resistance and insulation test, pure ANF burns through in 12 s, while CMP/ANF-Ⅲ remains unharmed for 120 s, and the backside temperature greatly drops to 335 ℃ (while the pure ANF is over 500 ℃). The analysis of residual char reveals that CMP/ANF-III generates a dense char layer after combustion, effectively blocking the spread of flame and thermal convection with the matrix, thereby improving the flame retardancy and thermal insulation properties of non-woven fabric. Gas phase product analysis shows that CMP/ANF-III can release non-combustible gases such as CO2, H2O, NH3, etc. at lower temperatures, performing a gas phase flame retardant function. The ANF nanocomposite material developed in this work supports the development of a new generation of highly efficient fire-resistant and thermal protective clothing.

-

Key words:

- nanocomposite /

- coating /

- aramid fiber /

- flame retardancy /

- thermal insulation

-

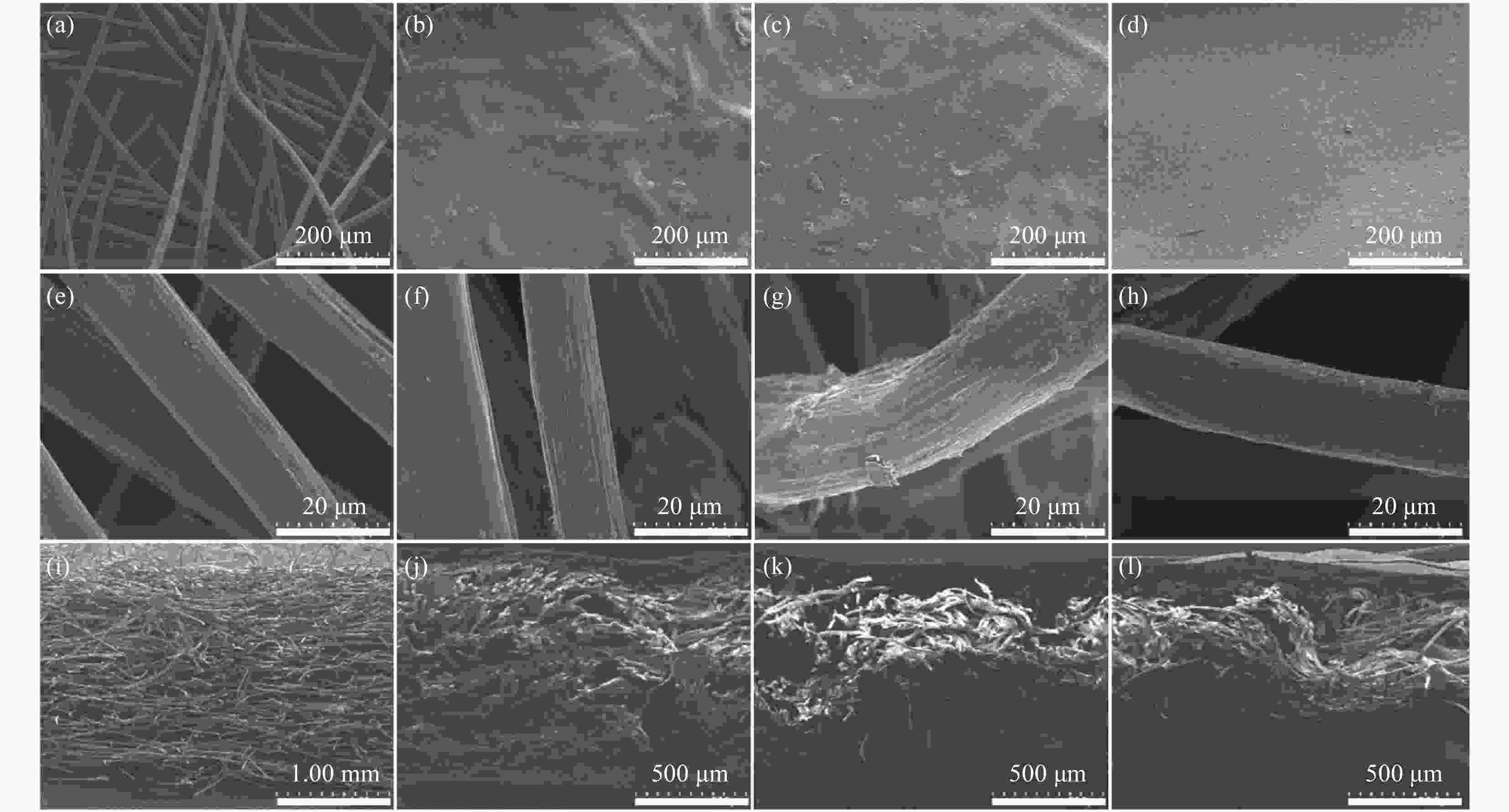

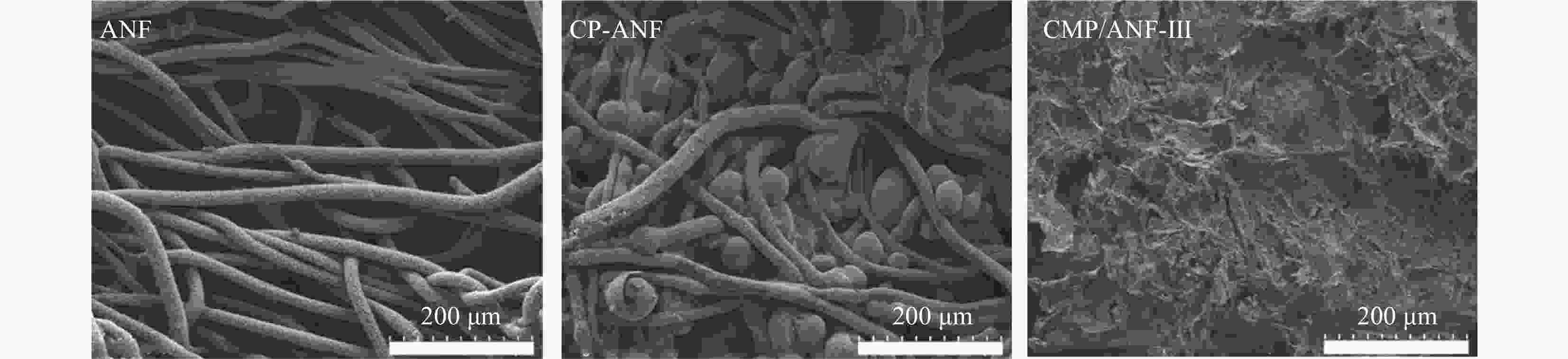

图 3 (a) ANF、(b) CMP/ANF-Ⅰ、(c) CMP/ANF-Ⅱ、(d) CMP/ANF-Ⅲ样品表面SEM照片;(e) ANF、(f) CMP/ANF-Ⅰ、(g) CMP/ANF-Ⅱ、(h) CMP/ANF-Ⅲ样品截面SEM照片;(i) ANF、(j) CMP/ANF-Ⅰ、(k) CMP/ANF-Ⅱ、(l) CMP/ANF-Ⅲ样品截面低倍数SEM照片

Figure 3. SEM images of the surface of (a) ANF, (b) CMP/ANF-Ⅰ, (c) CMP/ANF-Ⅱ, (d) CMP/ANF-Ⅲ, SEM images of the cross-section of (e) ANF, (f) CMP/ANF-Ⅰ, (g) CMP/ANF-Ⅱ, (h) CMP/ANF-Ⅲ, low magnification SEM images of the cross-section of (i) ANF、(j) CMP/ANF-Ⅰ、(k) CMP/ANF-Ⅱ、(l) CMP/ANF-Ⅲ

表 1 复合材料样品的基本参数

Table 1. Basic data of composites

Composite Thickness/

mmQuality/g Thickening

rate/%Weight gain

rate/%ANF 12.0 3.0 / / CMP/ANF-Ⅰ 13.1 5.5 9.2 84.3 CMP/ANF-Ⅱ 13.6 6.8 13.3 127.4 CMP/ANF-Ⅲ 14.0 8.1 16.7 169.9 表 2 TG和DTG结果中的重要参数

Table 2. TG and DTG results of composites

Composite T5%/

℃Tmax%/

℃Rmax/

(%·℃−1)Char residue/

wt%ANF 273 596 −0.94 1.59 CMP/ANF-Ⅰ 69 535 −0.63 14.85 CMP/ANF-Ⅱ 69 561 −0.61 17.42 CMP/ANF-Ⅲ 70 571 −0.55 20.55 Notes: T5%—temperature at 5% quality loss of composite; Tmax—temperature of the maximum quality loss of composite; Rmax—maximum mass loss rate of composite; Char residue—the residue mass of composite -

[1] XIE C J, GUO Z X, QIU T, et al. Construction of aramid engineering materials via polymerization-induced para-aramid nanofiber hydrogel[J]. Advanced Materials, 2021, 33(31): e2101280. doi: 10.1002/adma.202101280 [2] HE H L, QIN Y, LIU J R, et al. A wearable self-powered fire warning e-textile enabled by aramid nanofibers/MXene/silver nanowires aerogel fiber for fire protection used in firefighting clothing[J]. Chemical Engineering Journal, 2023, 460: 141661. doi: 10.1016/j.cej.2023.141661 [3] GARCÍA J M, GARCÍA F C, SERNA F, et al. High-performance aromatic polyamides[J]. Progress in Polymer Science, 2010, 35(5): 623-686. doi: 10.1016/j.progpolymsci.2009.09.002 [4] WANG H M, WANG H M, WANG Y L, et al. Laser writing of Janus graphene/Kevlar textile for intelligent protective clothing[J]. ACS Nano, 2020, 14(3): 3219-3226. doi: 10.1021/acsnano.9b08638 [5] FAN T, SUN Z, ZHANG Y Y, et al. Novel kevlar fabric composite for multifunctional soft body armor[J]. Composites Part B: Engineering, 2022, 242: 110106. doi: 10.1016/j.compositesb.2022.110106 [6] MATSUSHITA A F Y, NASCIMENTO J R V, LEITE J M A, et al. Incorporation of ZnO/Ag-ZnO nanoparticles into a cotton fiber by the LbL method for self-cleaning applications[J]. Journal of Molecular Liquids, 2023, 375: 121336. doi: 10.1016/j.molliq.2023.121336 [7] LI P, LIU C, XU Y J, et al. Novel and eco-friendly flame-retardant cotton fabrics with lignosulfonate and chitosan through LbL: flame retardancy, smoke suppression and flame-retardant mechanism[J]. Polymer Degradation and Stability, 2020, 181: 109302. doi: 10.1016/j.polymdegradstab.2020.109302 [8] 顾海洋, 王冬, 宗永忠, 等. 制革污泥蛋白质基生物质棉织物阻燃涂层的制备与阻燃性能[J]. 化工进展, 2023, 42(2): 641-649.GU Haiyang, WANG Dong, ZONG Yongzhong, et al. Preparation and property of tanning sludge based biomass flame retardant coating protein for cotton fabric[J]. Chemical Industry and Engineering Progress, 2023, 42(2): 641-649(in Chinese). [9] ZHOU L F, YUAN L, GUAN Q B, et al. Building unique surface structure on aramid fibers through a green layer-by-layer self-assembly technique to develop new high performance fibers with greatly improved surface activity, thermal resistance, mechanical properties and UV resistance[J]. Applied Surface Science, 2017, 411(9): 34-45. [10] WANG B B, YIN Z T, CHENG W H, et al. Flame-retardant aramid fabric with durable, self-cleaning, hydrophobic, and tunable electromagnetic interference shielding properties[J]. Composites Part A: Applied Science and Manufacturing, 2023, 166: 107392. doi: 10.1016/j.compositesa.2022.107392 [11] ZHAO Y B, ZHANG Z, SHI L Q, et al. Corrosion resistance of a self-healing multilayer film based on SiO2 and CeO2 nanoparticles layer-by-layer assembly on Mg alloys[J]. Materials Letters, 2019, 237: 14-18. doi: 10.1016/j.matlet.2018.11.069 [12] YAO J R, ZHANG L, YANG F, et al. Superhydrophobic Ti3C2TX Mxene/aramid nanofiber films for high-performance electromagnetic interference shielding in thermal environment[J]. Chemical Engineering Journal, 2022, 466(2): 136945. [13] WANG B, DUAN Y G, ZHANG J J. Titanium dioxide nanoparticles-coated aramid fiber showing enhanced interfacial strength and UV resistance properties[J]. Materials & Design, 2016, 103(2): 330-338. [14] ZHANG Y, QU R J, WANG Y, et al. Enhancement of para-aramid fibers by depositing poly-p-paraphenylene terephthalamide oligomer modified multi-walled carbon nanotubes[J]. Results in Materials, 2021, 9: 100170. doi: 10.1016/j.rinma.2021.100170 [15] CAO C, PENG J S, LIANG X M, et al. Strong, conductive aramid fiber functionalized by graphene[J]. Composites Part A: Applied Science and Manufacturing, 2021, 140: 106161. doi: 10.1016/j.compositesa.2020.106161 [16] ZHANG L W, KONG H J, QIAO M M, et al. Supercritical CO2-induced nondestructive coordination between ZnO nanoparticles and aramid fiber with highly improved interfacial-adhesion properties and UV resistance[J]. Applied Surface Science, 2020, 521: 146430. doi: 10.1016/j.apsusc.2020.146430 [17] DONG X, MA Y, FAN X G, et al. Nickel modified two-dimensional bimetallic nanosheets, M(OH)(OCH3) (M=Co, Ni), for improving fire retardancy and smoke suppression of epoxy resin[J]. Polymer, 2021, 235: 124263. doi: 10.1016/j.polymer.2021.124263 [18] WANG Y B, CEN C N, CHEN J, et al. MgO/carboxymethyl chitosan nanocomposite improves thermal stability, waterproof and antibacterial performance for food packaging[J]. Carbohydrate Polymers, 2020, 236: 116078. doi: 10.1016/j.carbpol.2020.116078 [19] ZHANG C H, YU X Q, DIAO Y J, et al. Functionalization of carboxymethyl chitosan with chlorogenic acid: preparation, characterization, and antioxidant capacity[J]. Iranian Polymer Journal, 2021, 30(1): 81-91. doi: 10.1007/s13726-020-00875-9 [20] 曾繁展, 陈宪宏, 王建锋. 连续制备柔性导热的氮化铝/芳纶纳米纤维复合薄膜[J]. 复合材料学报, 2020, 37(12): 3043-3051.ZENG Fanzhan, CHEN Xianhong, WANG Jianfeng. Continuous fabrication of flexible, thermally conductive aluminum nitride/aramid nanofiber composite films[J]. Acta Materiae Compositae Sinica, 2020, 37(12): 3043-3051(in Chinese). [21] 孙海涛, 赵婉竹, 赵兵兵, 等. 改性处理对大豆分离蛋白/壳聚糖/黑木耳多糖复合膜性质的影响[J]. 食品科学, 2022, 43(18): 76-82. doi: 10.7506/spkx1002-6630-20211028-309SUN Haitao, ZHAO Wanzhu, ZHAO Bingbing, et al. Effect of modification treatment on the properties of Soy Protein Isolate/Chitosan/Auricularia auricular Polysaccharide composite film[J]. Food Science, 2022, 43(18): 76-82(in Chinese). doi: 10.7506/spkx1002-6630-20211028-309 [22] MARTINEZ-CAMACHO A P, CORTEZ-ROCHA M O, EZQUERRA-BRAUER J M, et al. Chitosan composite films: Thermal, structural, mechanical and antifungal properties[J]. Carbohydrate Polymers, 2010, 82(2): 305-315. doi: 10.1016/j.carbpol.2010.04.069 [23] 宋顺喜, 袁宝龙, 戢德贤, 等. ANF/TiO2机械力化学复合对芳纶纳米复合纸抗紫外老化性能的影响[J]. 中国造纸, 2022, 41(11): 37-44. doi: 10.11980/j.issn.0254-508X.2022.11.005SONG Shunxi, YUAN Baolong, JI Dexian, et al. Fabrication of TiO2/ANF composite based on mechanochemical effect and its effect on the UV-resistance of aramid nanopaper[J]. China Pulp & Paper, 2022, 41(11): 37-44(in Chinese). doi: 10.11980/j.issn.0254-508X.2022.11.005 [24] 刘羽熙, 徐慧珍, 潘晨露, 等. 热塑性聚氨酯/芳纶纤维柔性复合材料蒙皮的性质研究[J]. 当代化工研究, 2023, (6): 70-72.LIU Yuxi, XU Huizhen, PAN Chenlu, et al. Study on properties of flexible thermoplastic polyurethane/aramid fiber composite envelope[J]. Modern Chemical Research, 2023, (6): 70-72(in Chinese). [25] 寇雅婕, 陈珊珊, 黄吉振, 等. 芳纶纳米纤维/壳聚糖绝缘复合薄膜力学及绝缘性能研究[J]. 中国造纸, 2023, 42(4): 48-56. doi: 10.11980/j.issn.0254-508X.2023.04.008KOU Yajie, CHEN Shanshan, HUANG Jizhen, et al. Study on the mechanics and electrical insulation properties of ANFs/CS insulating composite film[J]. China Pulp & Paper, 2023, 42(4): 48-56(in Chinese). doi: 10.11980/j.issn.0254-508X.2023.04.008 [26] 张蕤, 王坚剑, 苏天翔, 等. 天然高分子对生物聚酯 P(3, 4)HB 复合材料阻燃性能的影响[J]. 化工进展, 2015, 34(7): 1962-1966.ZHANG Rui, WANG Jianjian, SU Tianxiang, et al. Influence of different natural polymers on the flame retardant property of biodegradable P(3, 4)HB composites[J]. Chemical Industry and Engineering Progress, 2015, 34(7): 1962-1966(in Chinese). [27] FANG Y C, WU J G, CHEN Y Q, et al. Durable flame retardant and anti-dripping of PET fabric using bio-based covalent crosslinking intumescent system of chitosan and phytic acid[J]. Progress in Organic Coatings, 2023, 183: 107785. doi: 10.1016/j.porgcoat.2023.107785 [28] 高纳川, 高雪雨, 闫莉, 等. 多功能阻燃增韧剂对聚碳酸酯阻燃和力学性能的影响[J]. 复合材料学报, 2024, 41(5): 2395-2403.GAO Nachuan, GAO Xueyu, YAN Li, et al. Effect of multifunctional flame retardant tougheners on the flame retardant and mechanical properties of polycarbonates[J]. Acta Materiae Compositae Sinica, 2024, 41(5): 2395-2403(in Chinese). [29] 赵令, 张浩, 徐维成, 等. 盾粉/橡胶阻燃复合材料的制备与性能[J]. 复合材料学报, 2023, 40(9): 5085-5094.ZHAO Ling, ZHANG Hao, XU Weicheng, et al. Preparation and properties studies of shield powder/rubber flame retardant composite material[J]. Acta Materiae Compositae Sinica, 2023, 40(9): 5085-5094(in Chinese). [30] DONG X, SUN Z Y, LI D L, et al. A novel nanohybrid, Fe3O4/NHS@M(OH)(OCH3)@rGO (M= Co, Ni), with petal-shaped anisotropic interfaces imparts efficient EMW absorption, flame retardancy, and thermal management properties to epoxy resin[J]. Polymer, 2024, 301: 127069. doi: 10.1016/j.polymer.2024.127069 -

点击查看大图

点击查看大图

计量

- 文章访问数: 60

- HTML全文浏览量: 38

- 被引次数: 0

下载:

下载: