Microstructure evolution and carbon footprint evaluation of ground activated recycled powder / multi-component composite cementitious materials

-

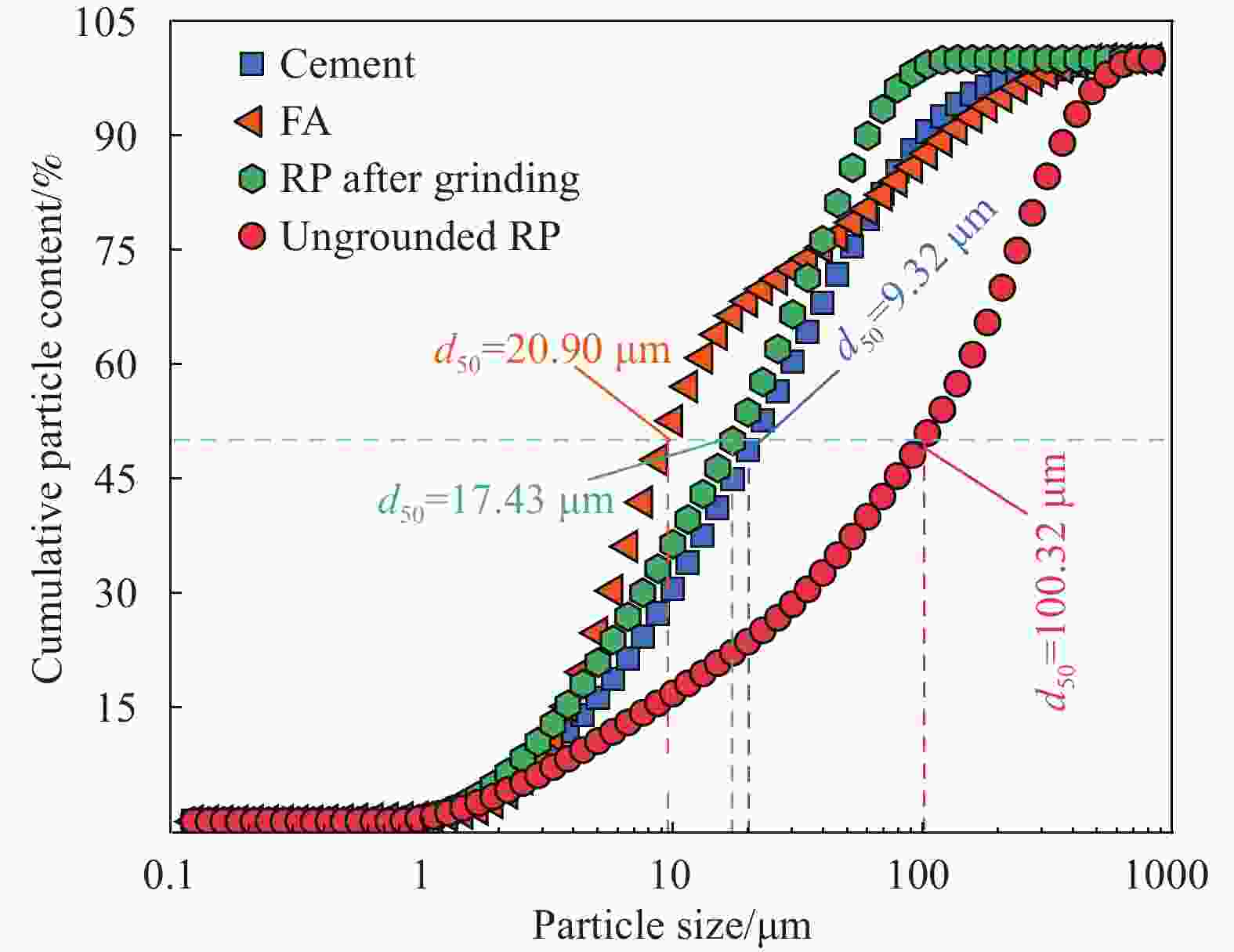

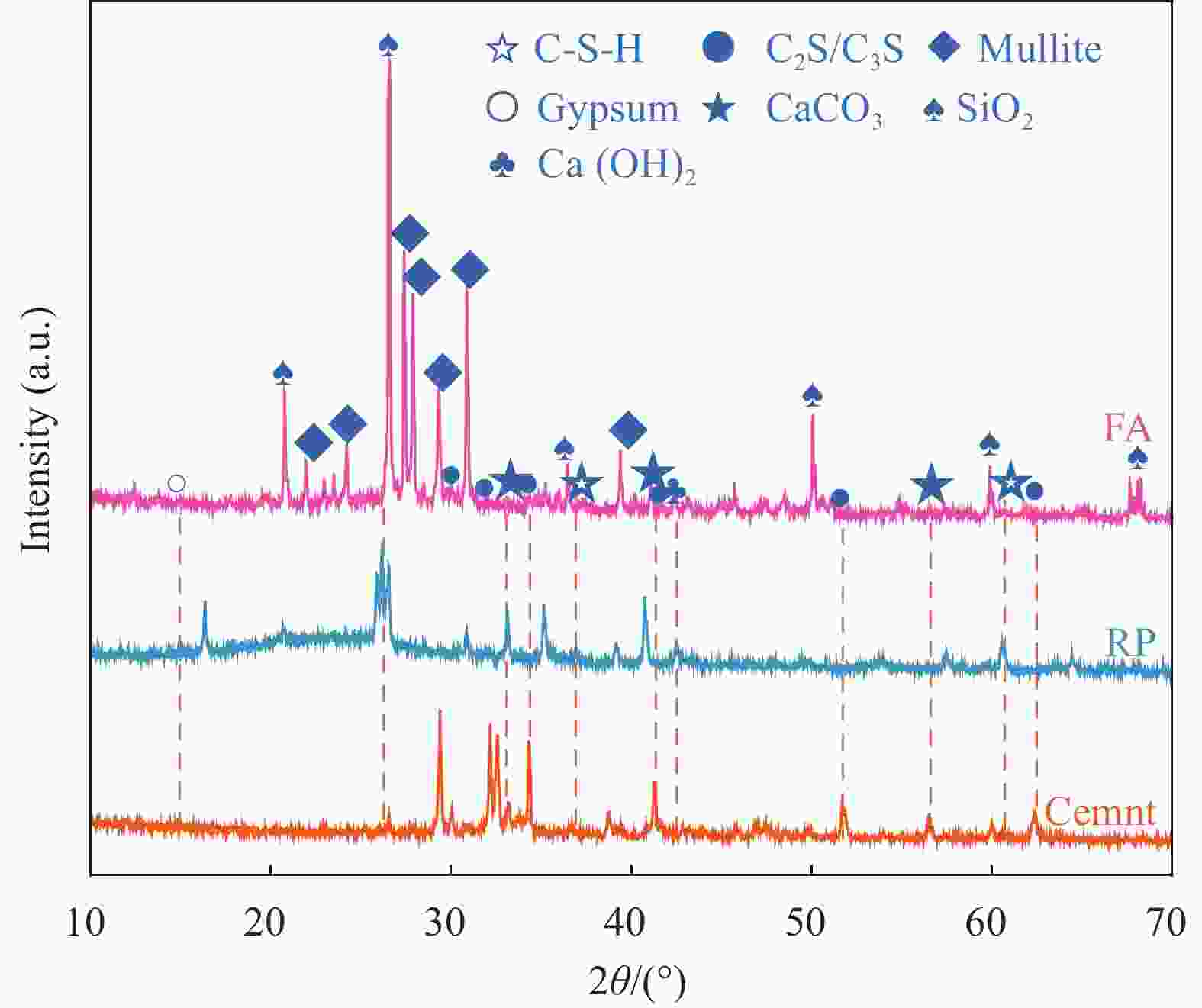

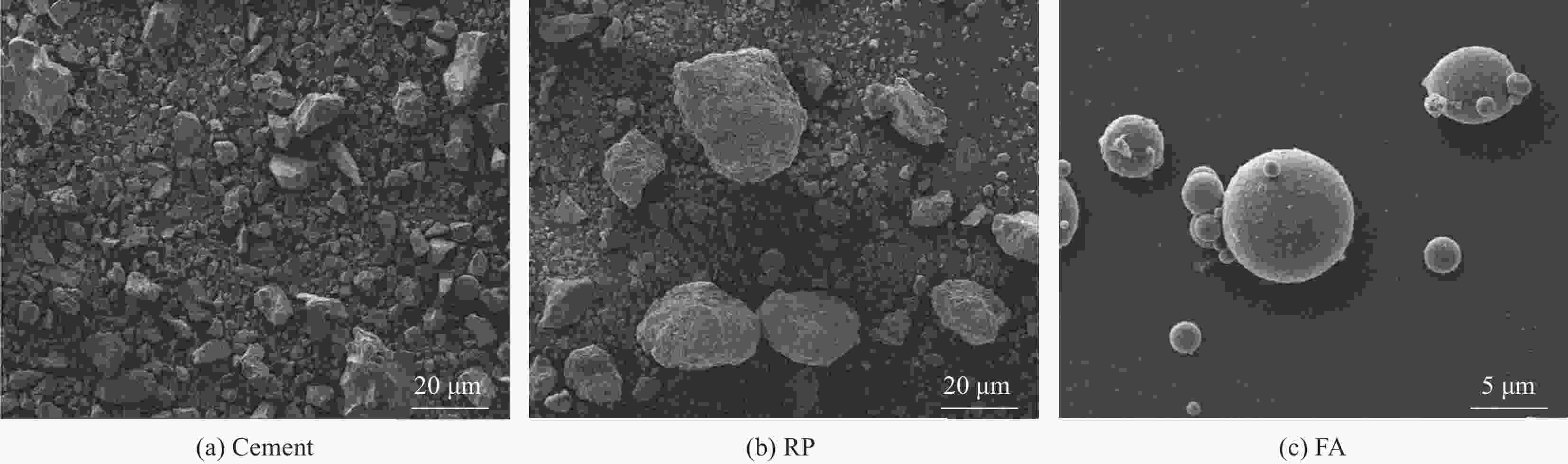

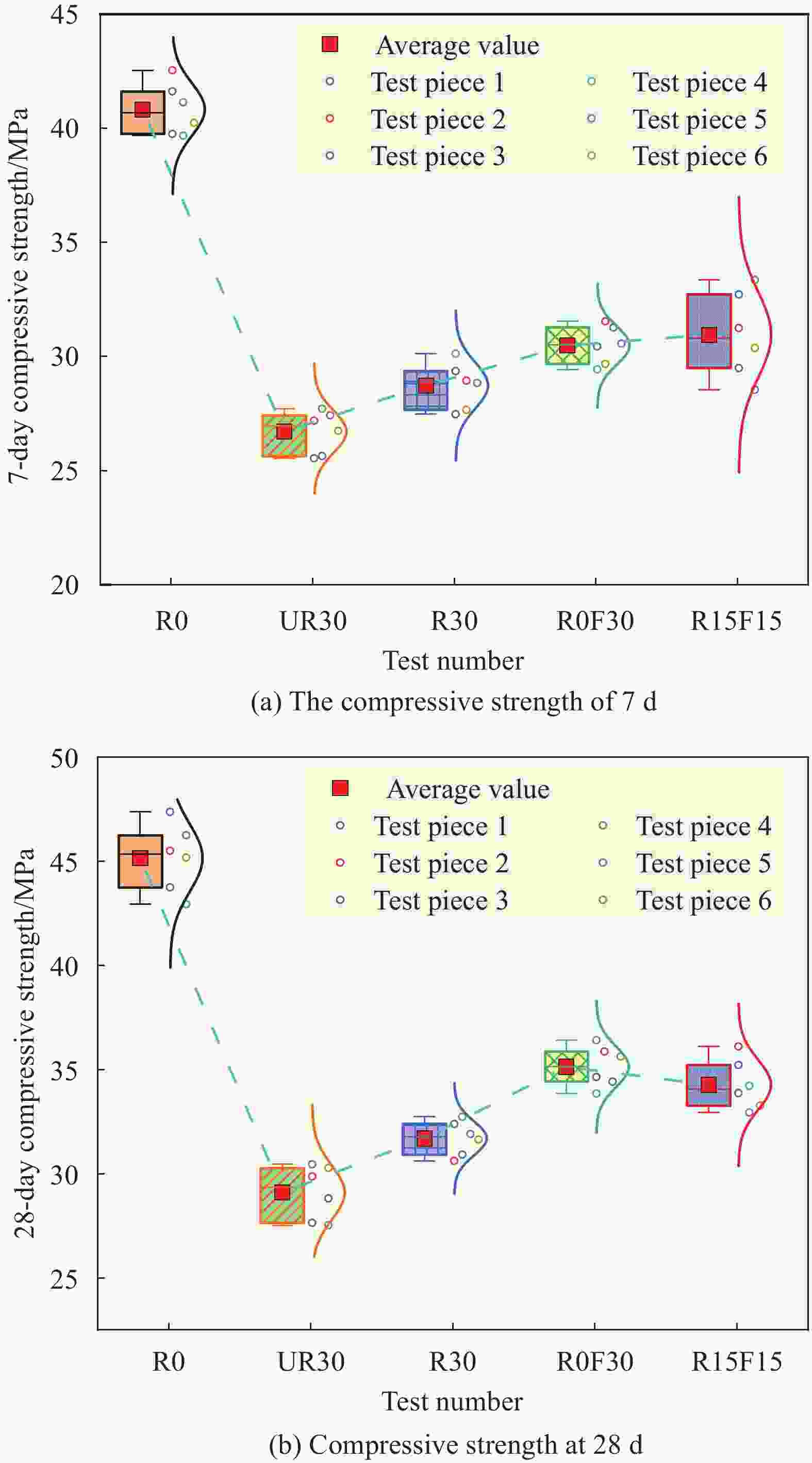

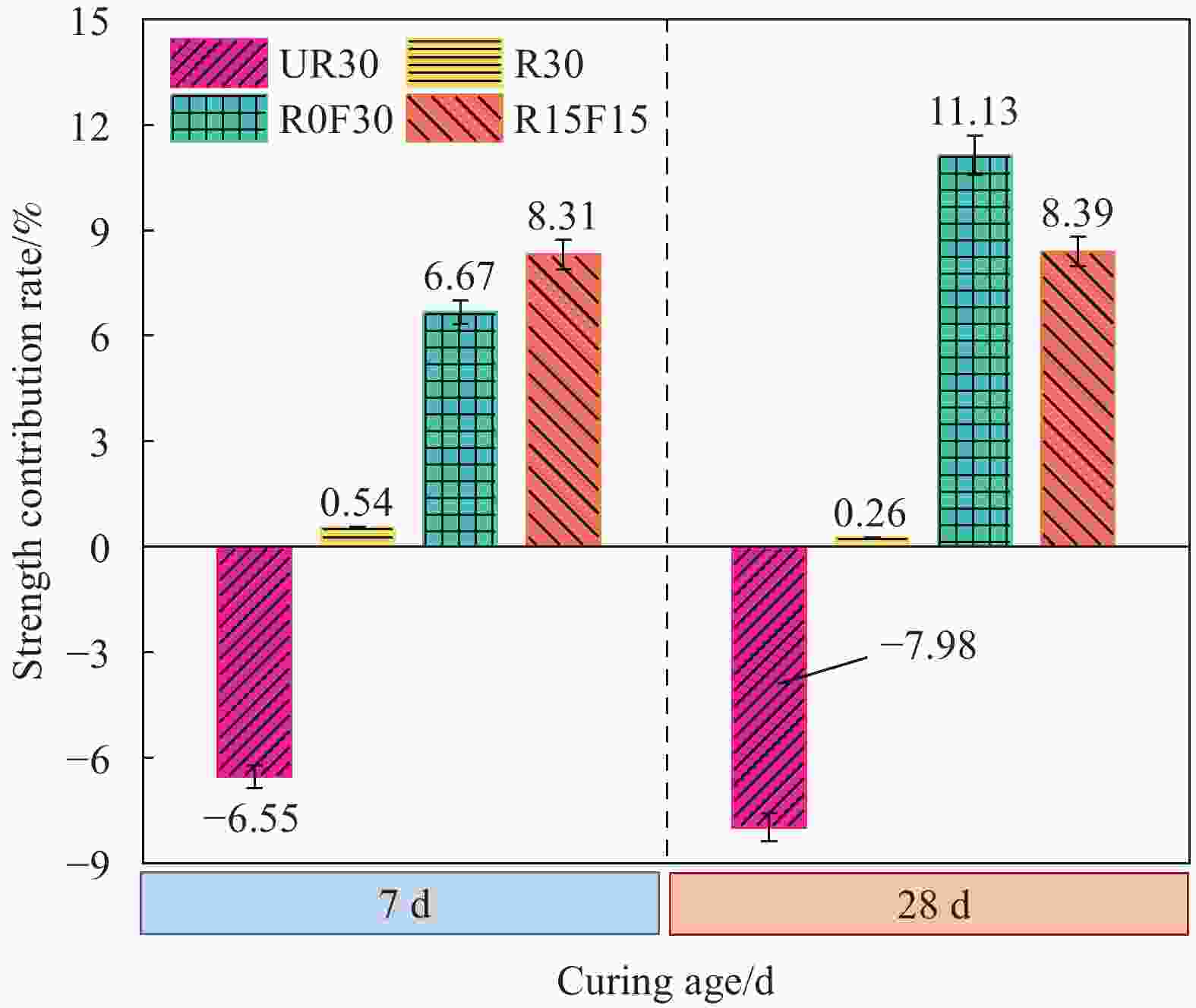

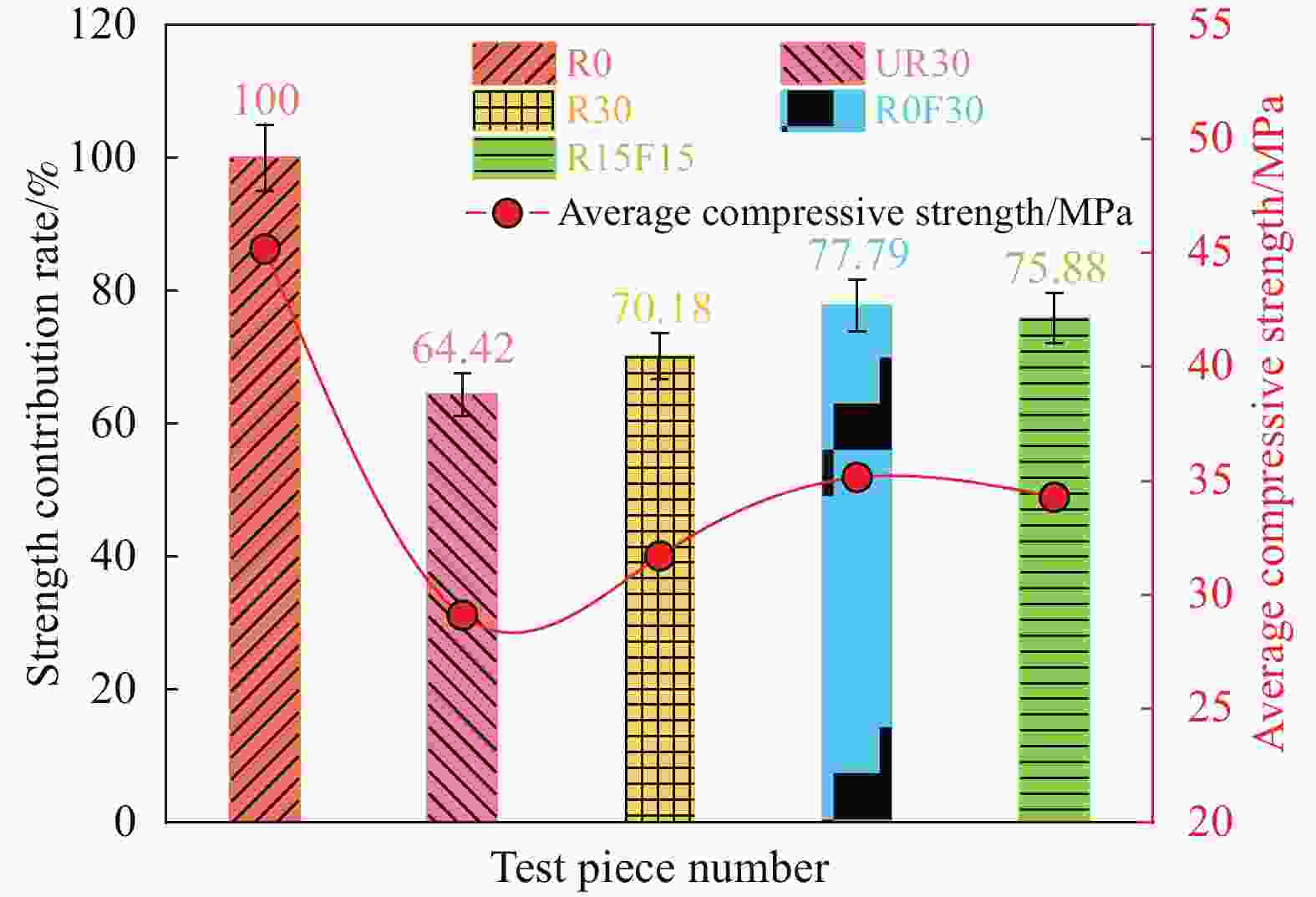

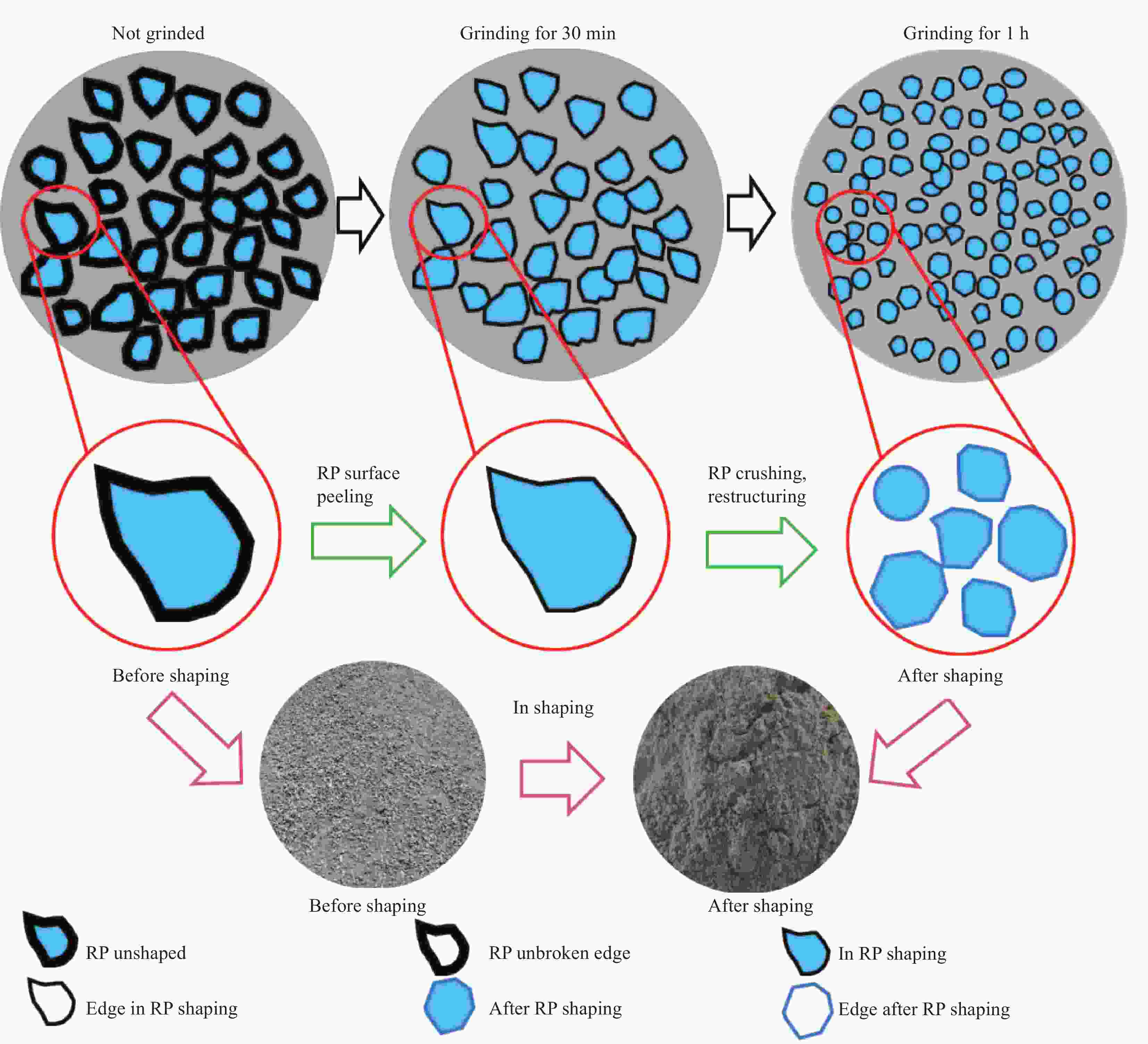

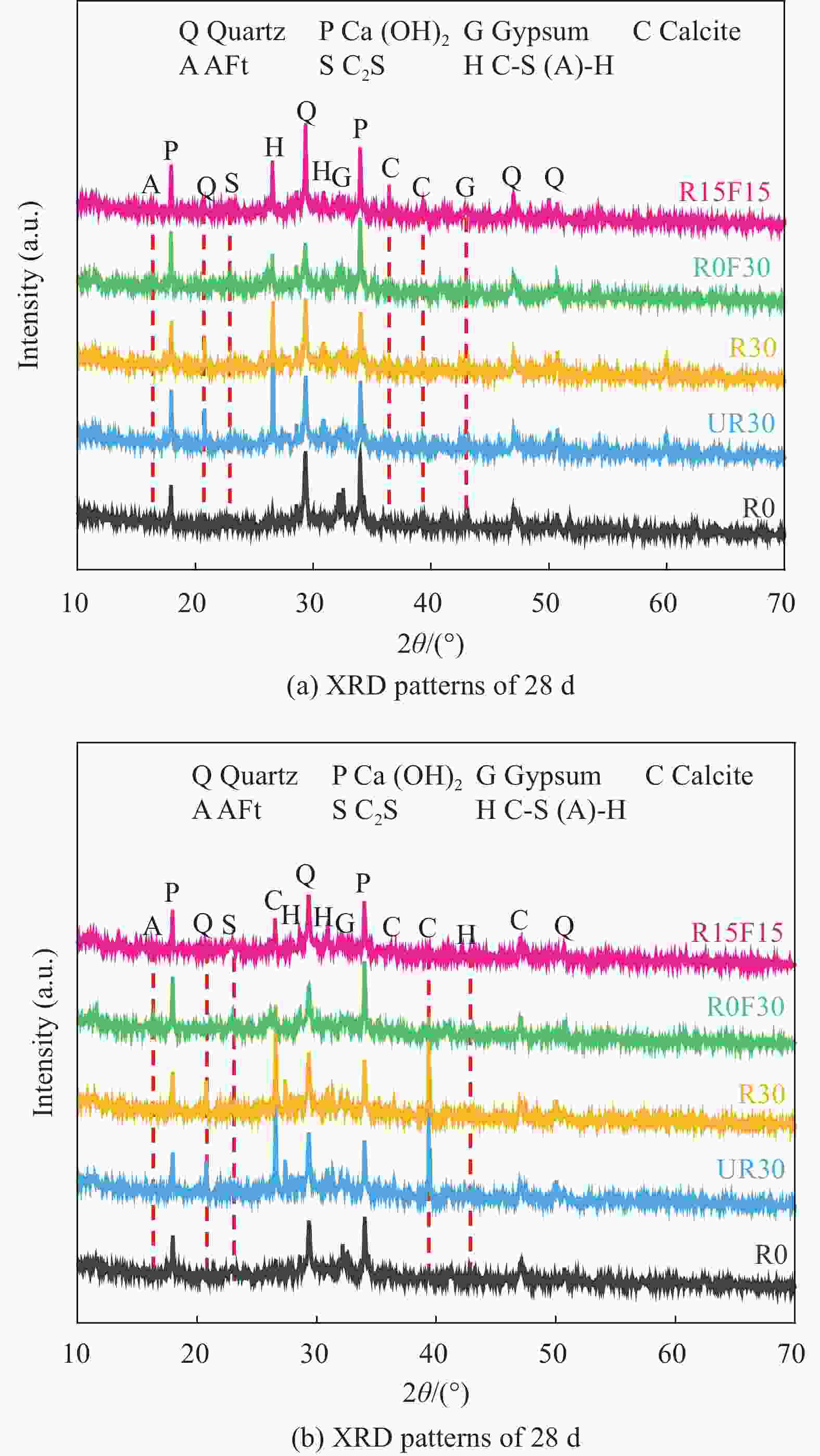

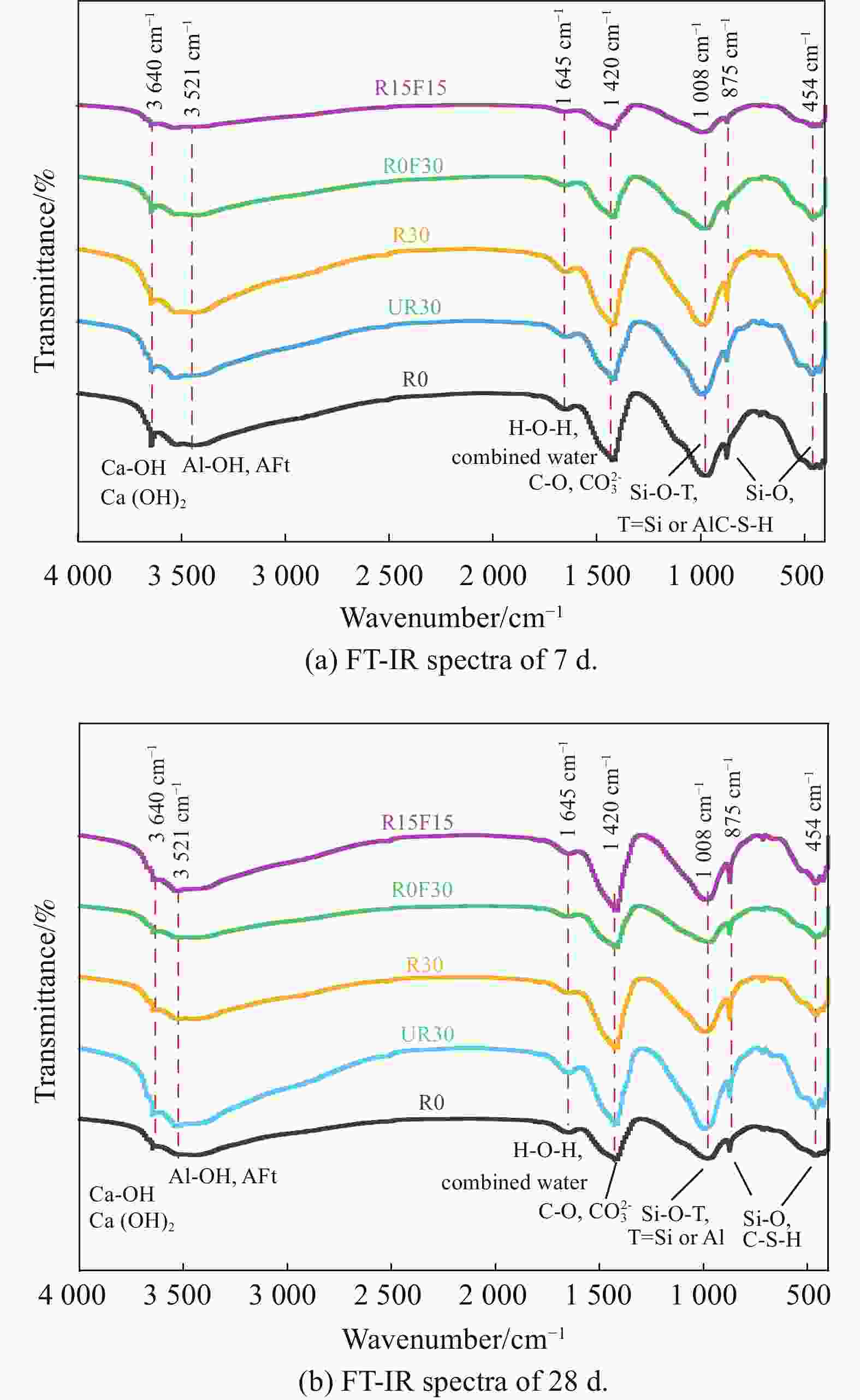

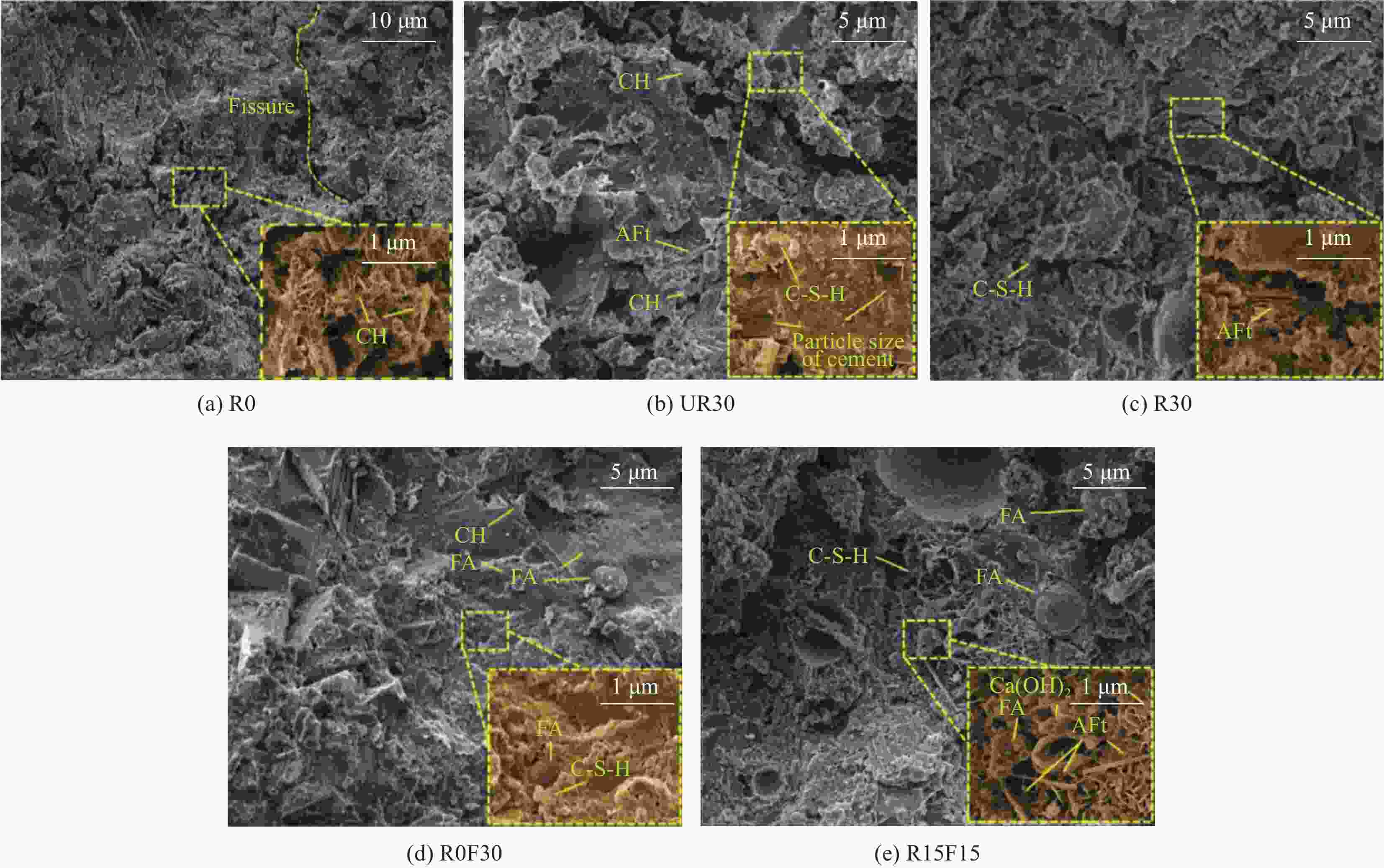

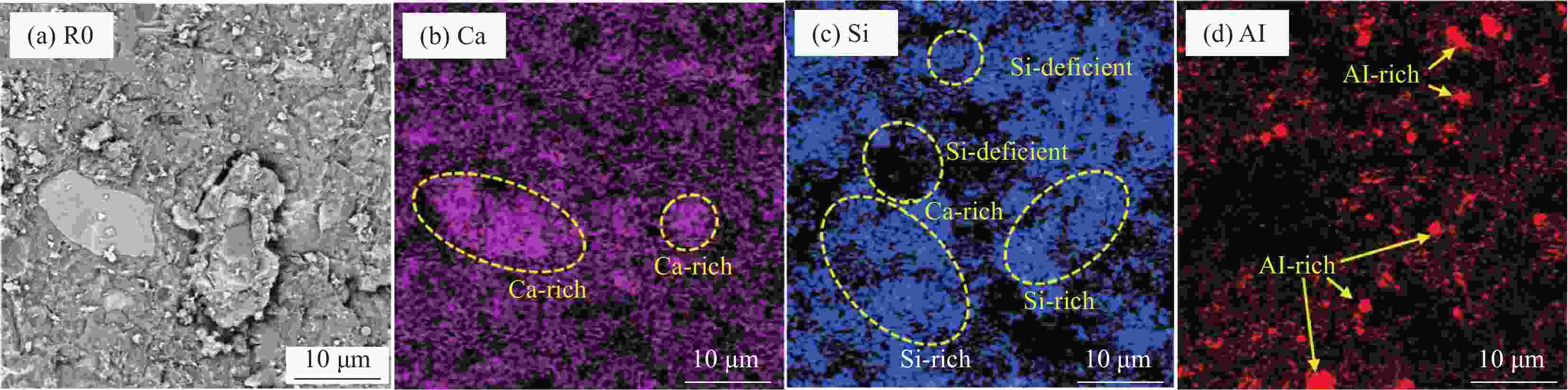

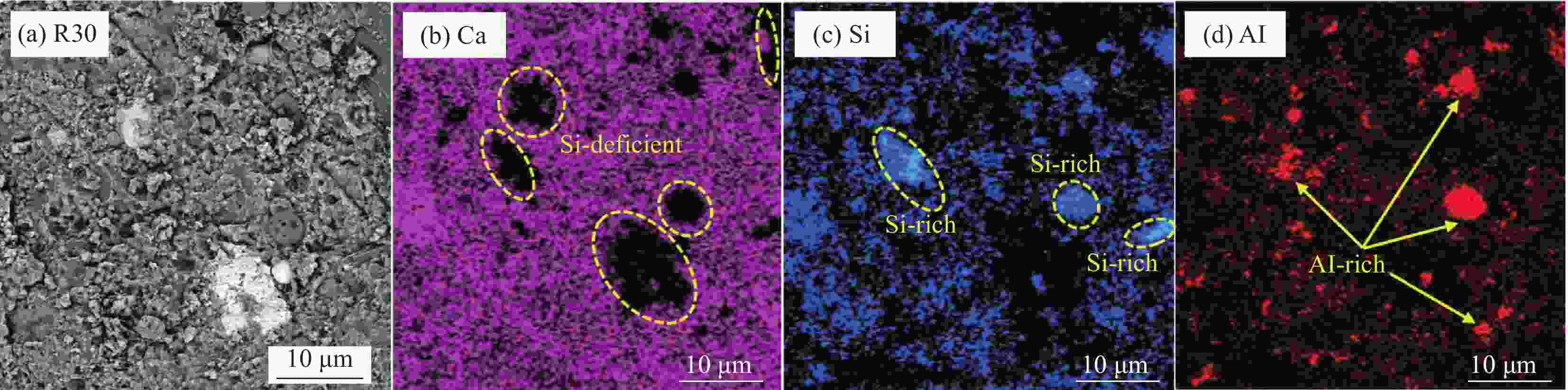

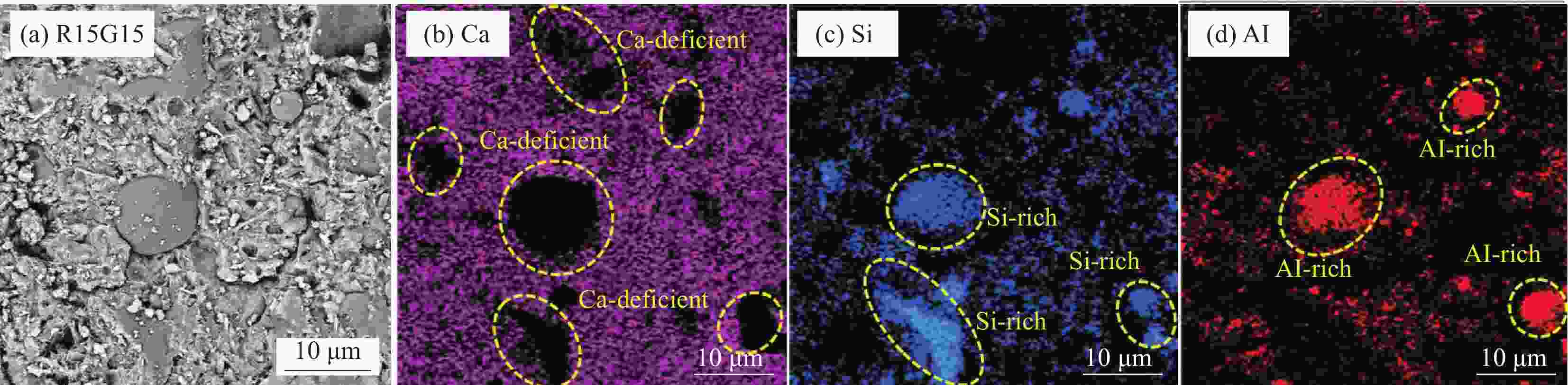

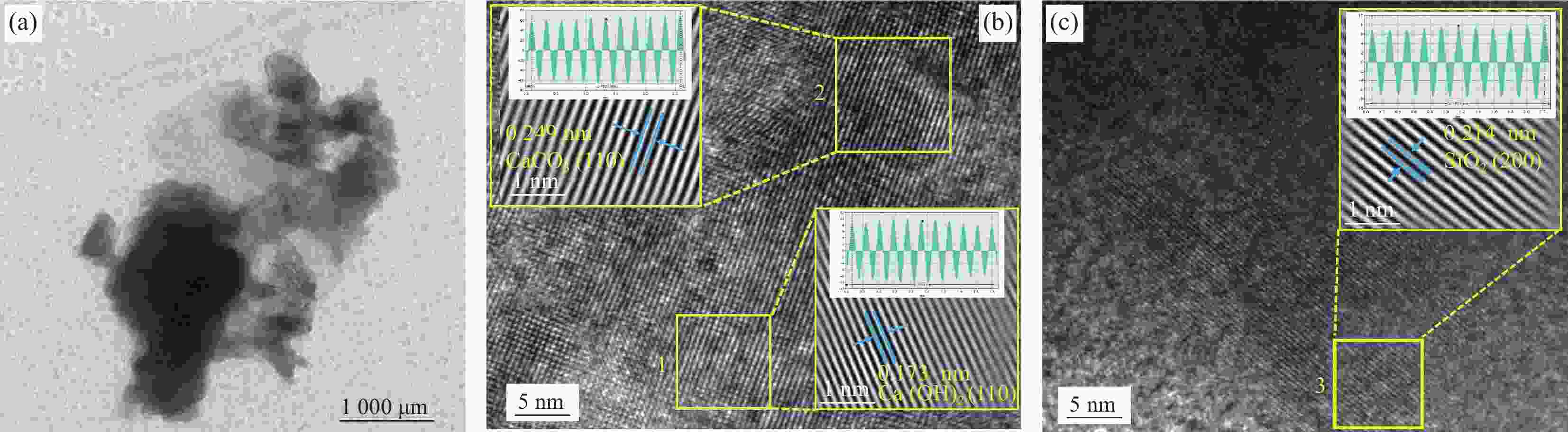

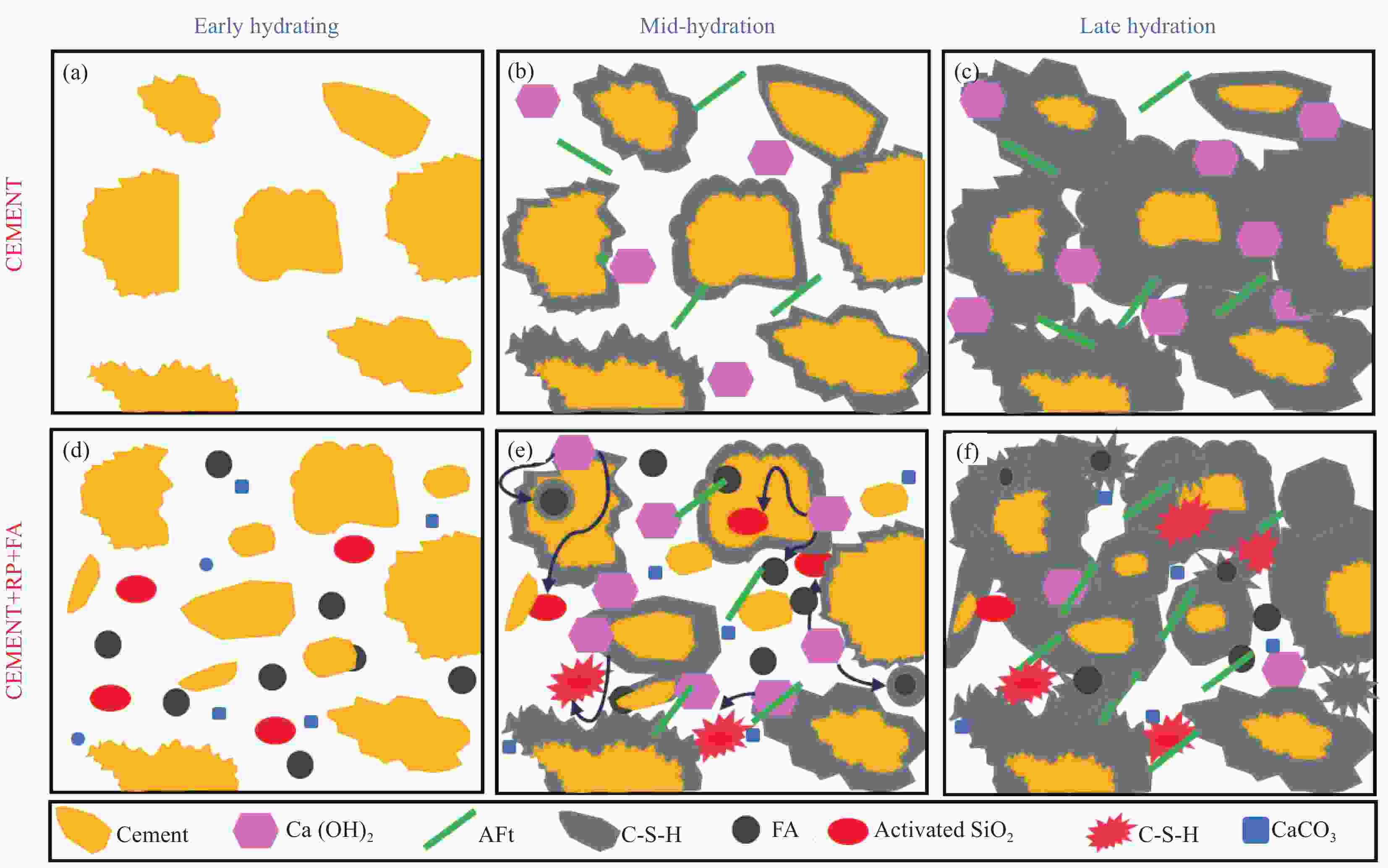

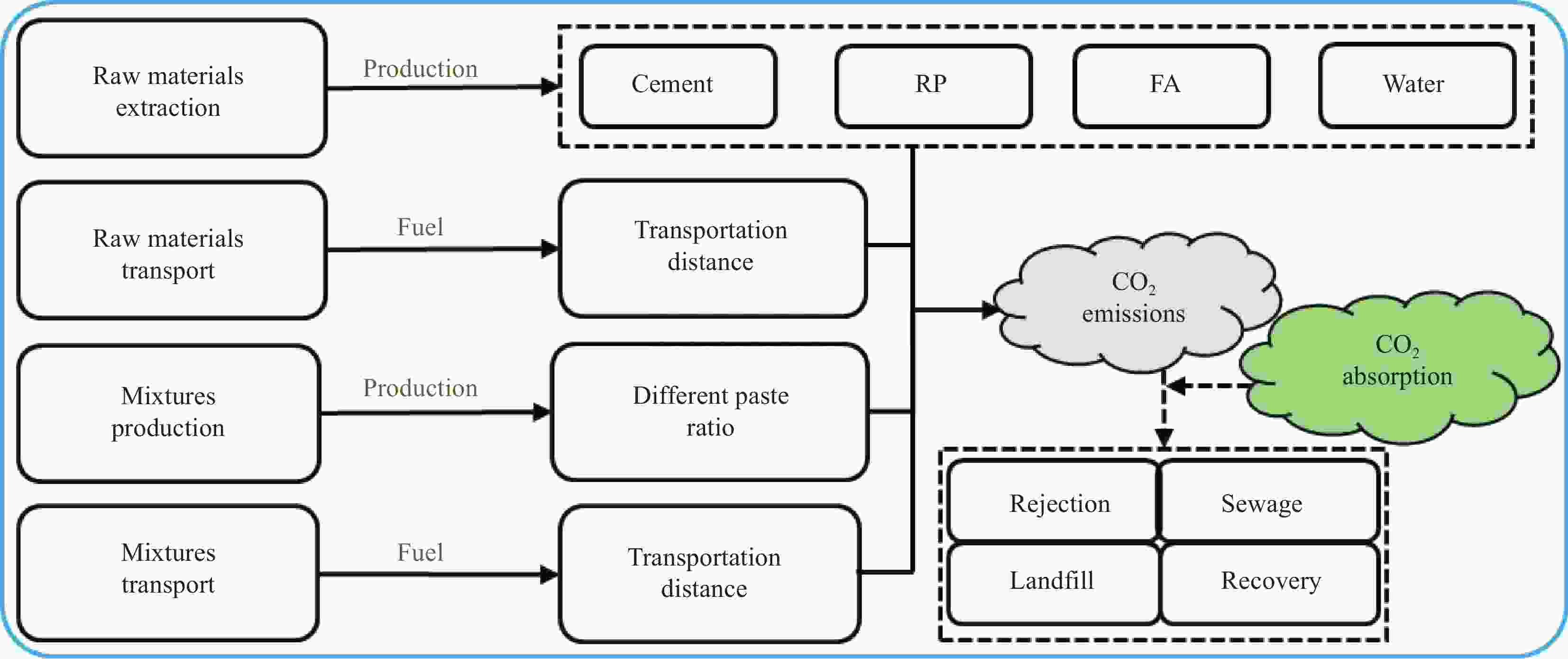

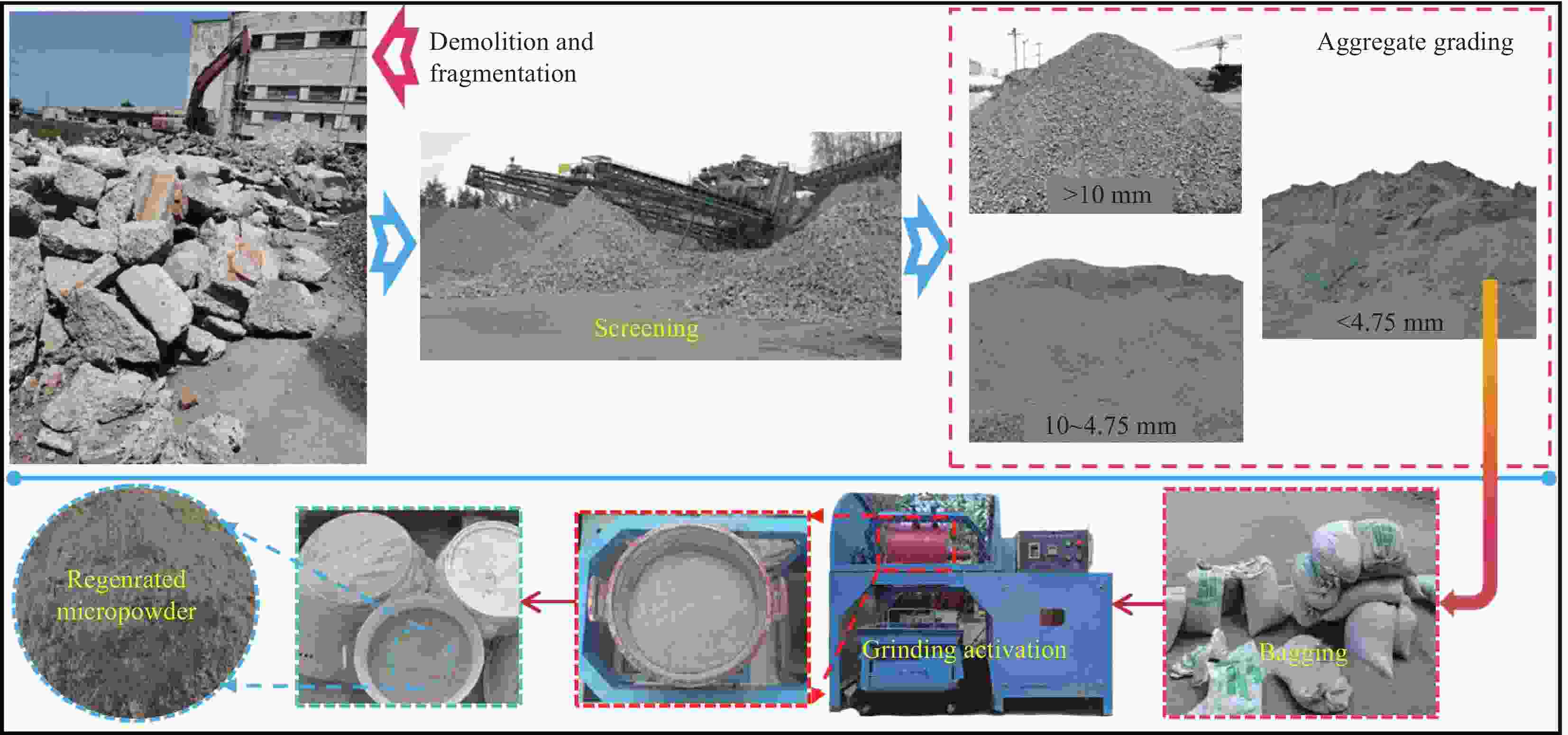

摘要: 为大规模应用再生微粉(RP)替代普通硅酸盐水泥(OPC)作为辅助胶凝材料(SCM)。本研究旨在构建RP/多元复合胶凝材料(MCCM),通过抗压强度试验和XRD、FT-IR、SEM、BSE-EDS、TEM等微观测试手段,对RP/MCCM的强度发展、相组织演化和微观结构等进行了研究,并以生命周期评价(LCA)方法对RP/MCCM碳减排效益进行分析。研究发现:研磨活化后,RP掺量为30% (R30)时,28 d抗压强度在未活化的基础上提高7.6%。RP掺入后Al—OH增强,C—O和$\text{CO}_{3}^{2-} $键峰变窄,S元素分布均匀,有利于钙矾石(AFt)和CaCO3相的生成。CaCO3、Ca(OH)2、SiO2纳米结构在RP和粉煤灰(FA)分别复掺15%时(R15F15),其三元体系中紧密的结合在一起,未出现明显的断层,从而改善了其结构致密性和强度。此外,碳排放分析发现,RP掺入降低了原材料提取和运输过程碳排放,实现了减排目标。Abstract: In order to replace ordinary Portland cement (OPC) as an supplementary cementitious material (SCM) for large-scale application of recycled powder (RP). The purpose of this study is to construct RP/multi-component composite cementitious material (MCCM). The strength development, phase structure evolution and microstructure of RP/MCCM were studied by compressive strength test and microscopic test methods such as XRD, FT-IR, SEM, BSE-EDS and TEM. The life cycle assessment (LCA) method was used to analyze the carbon emission reduction benefits of RP/MCCM. It indicates that after grinding activation, the 28 d compressive strength increased by 7.6% on the basis of unactivated value when the RP content was 30% (R30). After RP incorporation, the Al—OH is enhanced, the C—O and $\text{CO}_{3}^{2-} $bond peaks are narrowed, and the S element is evenly distributed, which is beneficial to the formation of ettringite (AFt) and CaCO3 phases. The CaCO3, Ca(OH)2 and SiO2 nanostructures are tightly bonded together in the ternary system without obvious faults appear when RP and fly ash (FA) are mixed with 15% (R15F15) respectively. Hence, the compactness and strength of the structure are improved. Moreover, the results of carbon emission analysis show that the incorporation of RP can reduce carbon emissions during raw material extraction and transportation, and achieve emission reduction targets.

-

表 1 化学成分检测

Table 1. chemical composition

Chemical composition/wt% SiO2 Al2O3 Fe2O3 CaO MgO SO3 K2O NaO2 TiO2 Cement 20.13 9.53 3.65 60.08 1.69 2.57 1.20 0.18 0.95 RP 46.792 11.99 5.649 25.602 3.071 1.34 2.23 1.11 1.12 FA 46.39 34.28 7.23 3.60 2.08 2.00 1.03 0.68 2.48 表 2 水泥净浆配合比设计

Table 2. Mix proportion design of cement paste

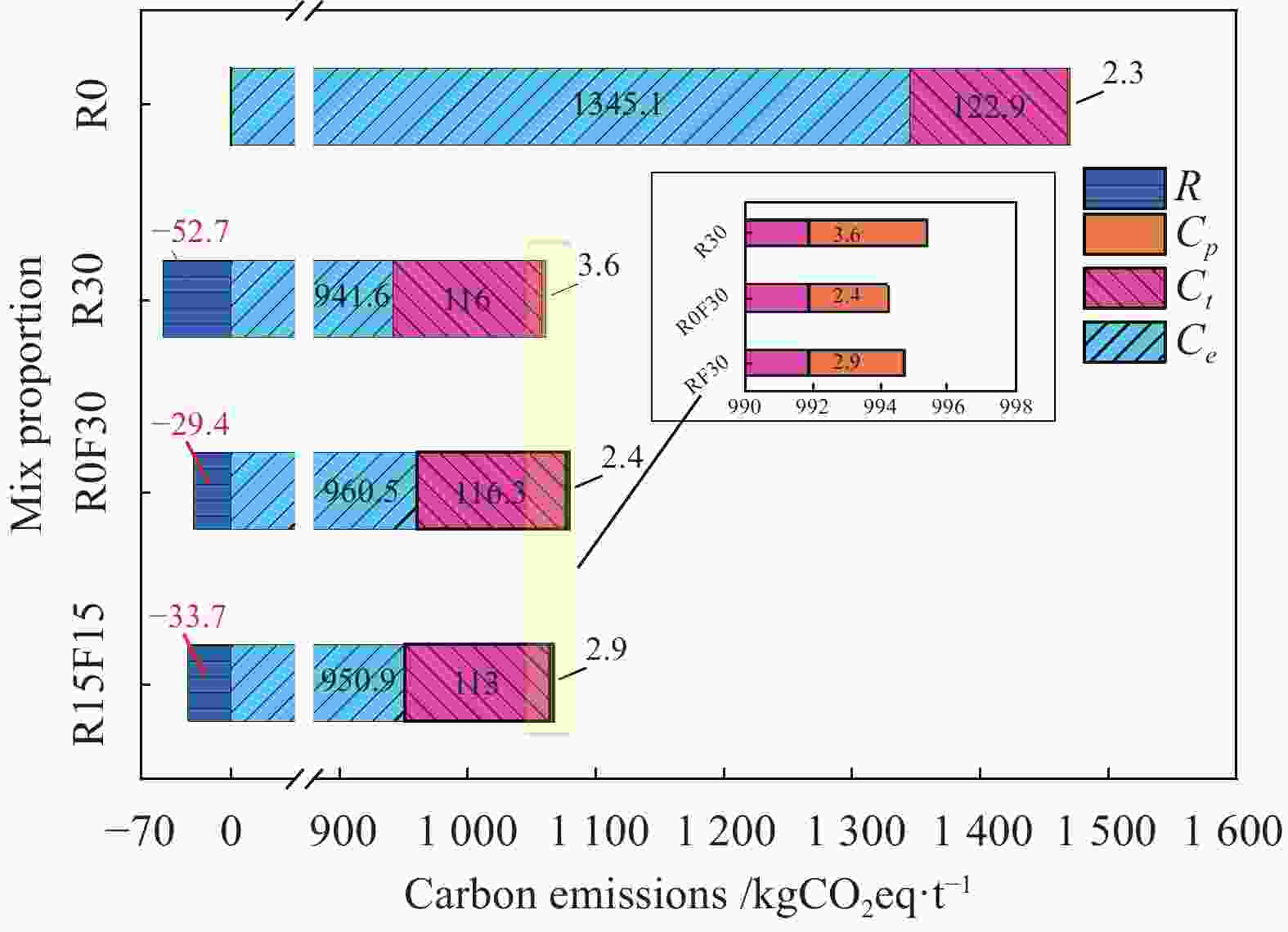

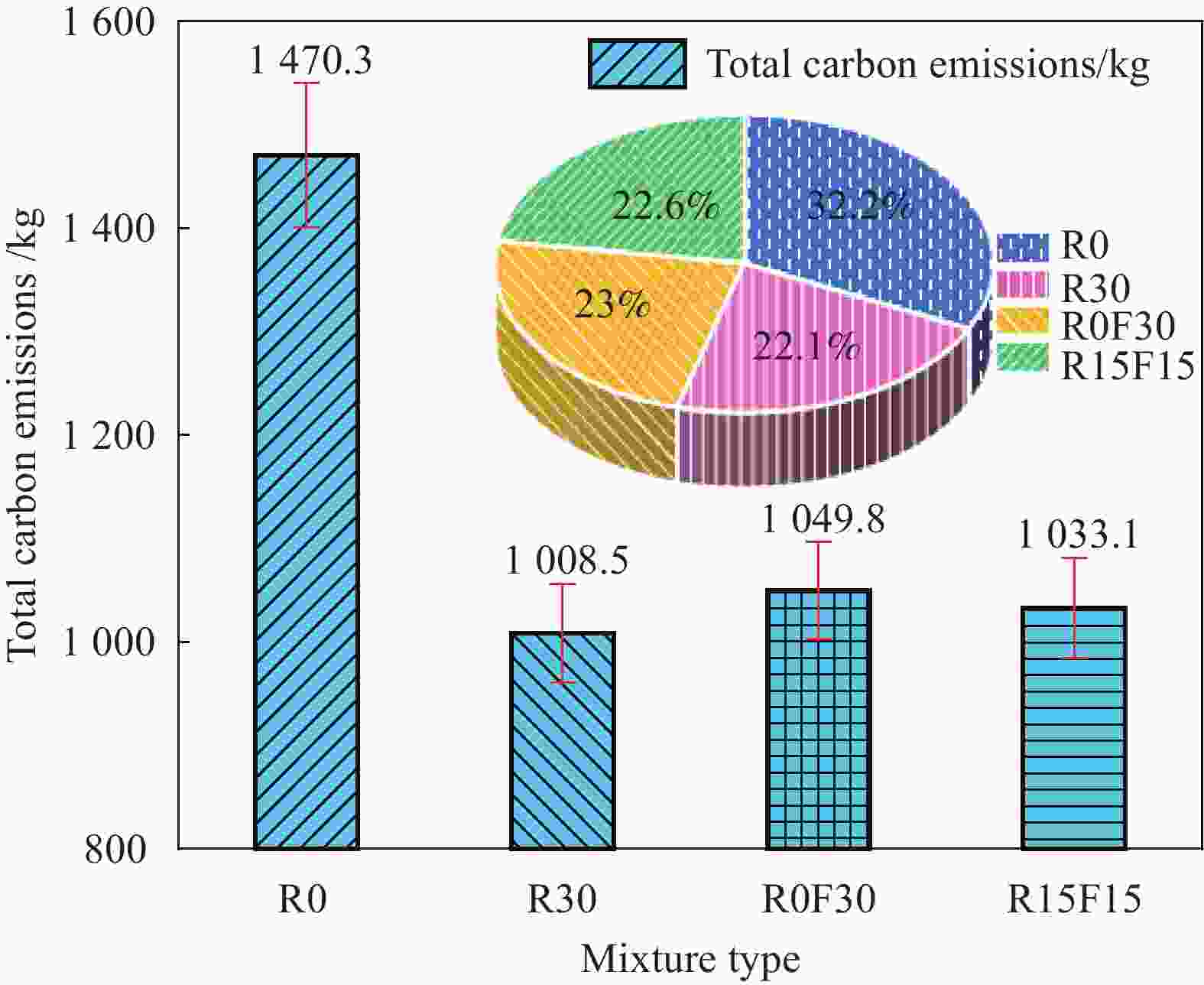

Number Unit/g w/b Cement URP RP FA Water R0 450 0 0 0 135 0.3 UR30 315 135 0 0 135 0.3 R30 315 0 135 0 135 0.3 R0F30 315 0 0 135 135 0.3 R15F15 315 0 67.5 67.5 135 0.3 Note: URP is Ungrounded recycled powder; R0 is cement paste, R15 is 15% of the recycled powder blending ratio after grinding, and F15 is 15% of the fly ash blending ratio. 表 3 原料提取阶段碳排放量计算结果

Table 3. Calculation results of carbon emission in the raw material extraction stage

Mixture type Materials The mass of 1 m3 mixture/t The mass of each

material in 1/(m3·t−1)Raw material production CEF/(kgCO2eq·t−1) Raw material CE/kg Raw materials

for CE Ce/kgR0 Cement 2.1 1.83 735 1345.1 1345.1 Water 0.29 0.15 0.04 R30 Cement 2.1 1.28 785 941.5 941.6 RP 0.54 0 0 Water 0.29 0.15 0.1 R0F30 Cement 2.1 1.28 735 941.5 960.5 FA 0.55 34.5 18.94 Water 0.29 0.15 0.1 R15F15 Cement 2.1 1.28 735 941.5 950.9 RP 0.27 0 0 FA 0.19 34.5 9.3 Water 0.29 0.15 0.1 Notes: Carbon Emission Factor(CEF); Carbon Emissions(CE) 表 4 原料和混合物运输阶段的碳排放的计算结果

Table 4. Calculation results of carbon emissions during the transportation stage of raw materials and mixture

Mixture

typeMaterials

The mass of 1 m3

mixture /tThe mass of each material in 1/(m3·t−1) Transport CEF/

(kgCO2eq·t−1)Raw material transportation distance/km Transport CE/kg Raw material transportationCE Ct1/kg Net slurry transportation distance /km Mixed material transportationCE Ct2/kg R0 Cement 2.10 1.83 1.1 30 72.5 72.5 20.00 50.4 Water 0.29 30 0.00 R30 Cement 2.10 1.28 1.1 30 46.1 65.56 20.00 50.4 RP 0.54 30 19.4 Water 0.29 30 0.00 R0F30 Cement 2.10 1.28 1.1 30 46.1 65.88 20.00 50.4 FA 0.55 30 19.4 Water 0.29 30 0.00 R15F15 Cement 2.10 1.28 1.1 30 46.50 62.75 20.00 50.4 RP 0.27 30 9.72 FA 0.19 30 6.91 Water 0.29 30 0.00 表 5 混合物生产阶段碳排放量的计算结果

Table 5. Calculation results of carbon emissions during the mixture production stage

Mixture

typeMaterials The mass

of 1 m3

mixture /tThe mass of

each material

in 1/(m3·t−1)In the production

process CEF/

(kgCO2eq·t−1)Produce

CE/kgAfter processing

CEF/(kgCO2eq·t−1)After

processing

CE/kgThe mixture

produces the

CE Cp/kgR0 Cement 2.1 1.83 1.1 2.89 / / 2.3 Water 0.29 R30 Cement 2.1 1.28 1.1 2.88 2.32 1.26 3.6 RP 0.54 Water 0.29 R0F30 Cement 2.1 1.28 1.1 3.01 / / 2.4 FA 0.55 Water 0.29 R15F15 Cement 2.1 1.28 1.1 2.77 2.32 0.63 2.9 RP 0.27 FA 0.19 Water 0.29 表 6 建筑固废(CSW)处理碳排放量计算

Table 6. Calculation of carbon emissions from construction solid waste (CSW) treatment

Mixture

typeCSW

MaterialsThe mass

of 1 m3

mixture /tThe mass of

each material

in 1/(m3·t−1)Transport

CEF/

(kgCO2eq·t−1)CSW

transport

distance/kmCSW

transport

CE /kgCSW-

processed

CEF/

(kgCO2eq·t−1)Sewage

treatment

sCE/kgAvoid CSW

landfilling

CEF/(kgCO2eq·t−1)CSW

landfill

CE/kgReductive

CE R/kgR30 Cement 2.1 1.83 −1.1 0 −47.5 −7.1 4.1 −2.1 −1.13 −52.7 RP 0.29 80 Water 1.28 0 R0F30 Cement 2.1 0.54 −1.1 0 −22.5 −7.1 3.9 −2.1 −1.15 −29.4 FA 0.29 40 Water 1.28 0 R15F15 Cement 2.1 0.55 −1.1 0 −22.2 −7.1 3.3 −2.1 −0.97 −33.7 RP 0.29 80 FA 1.28 40 Water 0.27 0 -

[1] 侯文静, 何彩庆, 陈文清. 农业固废基水凝胶用于水体中重金属吸附的研究进展[J]. 复合材料学报, 2024, 1-15.HOU Wenjing, HE Caiqing, CHEN Wenqing. Adsorption of heavy metals by agricultural solid waste based hydrogel: A review[J]. Acta Materiae Compositae Sinica, 2024, 1-15 (in Chinese). [2] 刘树龙, 王贻明, 吴爱祥, 等. 赤泥复合充填材料浸出行为及固化机制[J]. 复合材料学报, 2023, 40(12): 6729-6739.LIU Shulong, WANG Yiming, WU Aixiang, et al. Leaching behavior and curing mechanism of red mud composite filling material[J]. Acta Materiae Compositae Sinica, 2023, 40(12): 6729-6739 (in Chinese). [3] 刘超, 林鑫, 刘化威, 等. 风积沙与再生复合微粉对超高性能混凝土力学性能的影响[J]. 复合材料学报, 2022, 39(11): 5415-5422.LIU Chao, LIN Xin, LIU Huawei et al. Effect of wind sand and recycled composite powder on mechanical properties of ultra-high performance concrete[J]. Acta Materiae Compositae Sinica, 2022, 39(11): 5415-5422 (in Chinese). [4] ZHANG H, GAO S, LI H, et al. Triaxial test analysis and discrete element simulation of CFBC[J]. Construction and Building Materials, 2023, 409: 133754. doi: 10.1016/j.conbuildmat.2023.133754 [5] LIN Y, ALENGARAM U J, IBRAHIM Z, et al. Performance appraisal of high volume of sustainable unprocessed eco-minerals, ground and unground eco-processed pozzolan as cement replacement materials in mortar[J]. Construction and Building Materials, 2024, 411: 134344. doi: 10.1016/j.conbuildmat.2023.134344 [6] BOGAS J A, REAL S, CRUZ R, et al. Mechanical performance and shrinkage of compressed earth blocks stabilised with thermoactivated recycled cement[J]. Journal of Building Engineering, 2023, 79: 107892. doi: 10.1016/j.jobe.2023.107892 [7] LEE J, LOTHENBACH B, MOON J. Performance improvement of Portland-limestone cement by mechanochemical activation[J]. Cement and Concrete Research, 2024, 176: 107411. doi: 10.1016/j.cemconres.2023.107411 [8] ALZAZA A, OHENOJA K, DABBEBI R, et al. Enhancing the hardened properties of blended cement paste cured at 0° C by using alkali-treated ground granulated blast furnace slag[J]. Cement and Concrete Composites, 2022, 134: 104757. doi: 10.1016/j.cemconcomp.2022.104757 [9] SHEN P, ZHANG Y, JIANG Y, et al. Phase assemblance evolution during wet carbonation of recycled concrete fines[J]. Cement and Concrete Research, 2022, 154: 106733. doi: 10.1016/j.cemconres.2022.106733 [10] YAO Y, LIU C, LIU H, et al. Deterioration mechanism understanding of recycled powder concrete under coupled sulfate attack and freeze–thaw cycles[J]. Construction and Building Materials, 2023, 388: 131718. doi: 10.1016/j.conbuildmat.2023.131718 [11] HOU S, DUAN Z, YE T, et al. Mechanical properties and pore structure of 3D printed mortar with recycled powder[J]. Construction and Building Materials, 2023, 394: 132068. doi: 10.1016/j.conbuildmat.2023.132068 [12] 苏骏, 黄福, 王淞波, 等. 低温作用下改性骨料-钢纤维再生混凝土弯曲性能试验[J]. 复合材料学报, 2024, 41(2): 884-897.SU Jun, HUANG Fu, WANG Songbo, et al. Test on the bending performance of modified aggregate-steel fiber regenerated concrete under low temperature action[J]. Acta Materiae Compositae Sinica, 2024, 41(2): 884-897 (in Chinese). [13] LIANG T, HUO M, YU L, et al. Life cycle assessment-based decision-making for thermal remediation of contaminated soil in a regional perspective[J]. Journal of Cleaner Production, 2023, 392: 136260. doi: 10.1016/j.jclepro.2023.136260 [14] 苏骏, 钟子龙, 蔡雅琼, 等. 基于地聚物骨料的高延性纤维增强水泥基复合材料力学性能与拉伸本构模型[J]. 复合材料学报, 2024, 1-18Su Jun, Zhong Zilong, Cai Yaqiong, et al. Mechanical properties and tensile constitutive model of highly flexible fiber-reinforced cement-based composite based on ground polymer aggregate[J]. Acta Materiae Compositae Sinica, 2024, 1-18 (in Chinese). [15] 水泥胶砂强度检验方法(ISO 法): GB/T 17671—2021[S]. 北京: 中国标准出版社, 2021.Test method for strength of cement cement (ISO method): GB/T 17671-2021[S]. Beijing: China Standards Press, 2021 (in Chinese). [16] DU J, ZHANG T, CHEN P, et al. Phase separation of recycled concrete powder during grinding and consequent influences on its hydration behaviors in cement paste[J]. Cement and Concrete Composites, 2023, 142: 105203. doi: 10.1016/j.cemconcomp.2023.105203 [17] 刘泽军, 赵柳, 李艳等. 不同长径比聚乙烯醇(PVA)/高延性纤维增强水泥基复合材料(ECC)动态压缩性能[J]. 复合材料学报, 2023, 40(12): 6859-6870.LIU Zejun, ZHAO Liu, LI Yan, et al. Dynamic compression properties of polyvinyl alcohol (PVA) /reinforced reinforced composite (ECC)[J]. Acta Materiae Compositae Sinica, 2023, 40(12): 6859-6870 (in Chinese). [18] HERRING A, KING P L, SAADATFAR M, et al. 3D microstructure controls on mineral carbonation[J]. Journal of CO2 Utilization, 2021, 47: 101494. doi: 10.1016/j.jcou.2021.101494 [19] 许建疆, 郭军林, 甘丹等. 粉煤灰微珠-沙漠砂陶粒混凝土力学性能试验[J]. 复合材料学报, 2024, 41(1): 348-360.XU Jianjiang, GUO Junlin, GAN Dan, et al. Mechanical properties test of fly ash beads-desert sand ceramrit concrete[J]. Acta Materiae Compositae Sinica, 2024, 41(1): 348-360 (in Chinese). [20] ABDELLATIEF M, ABD ELRAHMAN M, ELGENDY G, et al. Response surface methodology-based modelling and optimization of sustainable UHPC containing ultrafine fly ash and metakaolin[J]. Construction and Building Materials, 2023, 388: 131696. doi: 10.1016/j.conbuildmat.2023.131696 [21] JING Y, JIANG Y, CHEN B, et al. Influence of steel slag powder on the characteristics of magnesium phosphate cement[J]. Journal of Building Engineering, 2023, 77: 107454. doi: 10.1016/j.jobe.2023.107454 [22] PALACIOS M, SANZ-Pont D, MOHAMED A K, et al. Heating cement to slow down its hydration: the unexpected role of PCE interpolymer bridge formation[J]. Cement and Concrete Research, 2022, 156: 106765. doi: 10.1016/j.cemconres.2022.106765 [23] SHELOTE K M, BALA A, GUPTA S. An overview of mechanical, permeability, and thermal properties of silica fume concrete using bibliographic survey and building information modelling[J]. Construction and Building Materials, 2023, 385: 131489. doi: 10.1016/j.conbuildmat.2023.131489 [24] LI H, KANG X, LI S, et al. Characterization and mechanism study of sulfate saline soil solidification in seasonal frozen regions using ternary solid waste-cement synergy[J]. Construction and Building Materials, 2024, 427: 136263. doi: 10.1016/j.conbuildmat.2024.136263 [25] GUO X, LI Y, SHI H, et al. Carbon reduction in cement industry-An indigenized questionnaire on environmental impacts and key parameters of life cycle assessment (LCA) in China[J]. Journal of Cleaner Production, 2023, 426: 139022. doi: 10.1016/j.jclepro.2023.139022 [26] 朱红兵, 付正昊, 王烨, 等. 界面剂对全轻陶粒混凝土与普通混凝土粘结界面力学性能的影响[J]. 复合材料学报, 2024, 1-17ZHU Hongbing, FU Zhenghao, WANG Ye, et al. Effects of interfacial agents on mechanical properties of interface between fully light ceramsite concrete and ordinary concrete[J]. Acta Materiae Compositae Sinica, 2024, 1-17 (in Chinese). [27] ZHANG X, LI H, WANG H, et al. Properties of RCA stabilized with alkali-activated steel slag based materials in pavement base: Laboratory tests, field application and carbon emissions[J]. Construction and Building Materials, 2024, 411: 134547. doi: 10.1016/j.conbuildmat.2023.134547 [28] YAN P, MA Z, LI H, et al. Laboratory tests, field application and carbon footprint assessment of cement-stabilized pure coal solid wastes as pavement base materials[J]. Construction and Building Materials, 2023, 366: 130265. doi: 10.1016/j.conbuildmat.2022.130265 [29] 朱翔琛, 张云升, 刘志勇, 等. 基于核磁共振技术的硫酸盐冻融下机制骨料混凝土孔结构演变规律研究[J]. 复合材料学报, 2024, 1-14.ZHU Xiangchen, ZHANG Yunsheng, LIU Zhiyong, et al. Study on the evolution of aggregate concrete hole under sulfate freeze-thaw based on nuclear magnetic resonance technology[J]. Acta Materiae Compositae Sinica, 2024, 1-14 (in Chinese). -

点击查看大图

点击查看大图

计量

- 文章访问数: 94

- HTML全文浏览量: 47

- 被引次数: 0

下载:

下载: