Effect of super absorbent polymers and fiber on drying shrinkage of spontaneous combustion coal gangue concrete

-

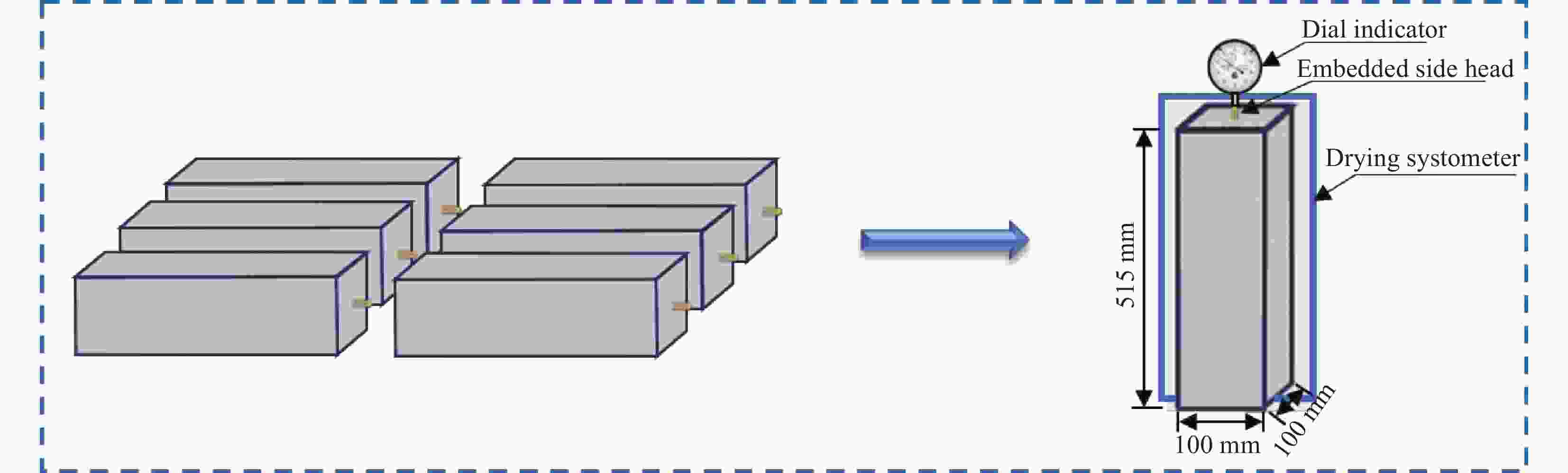

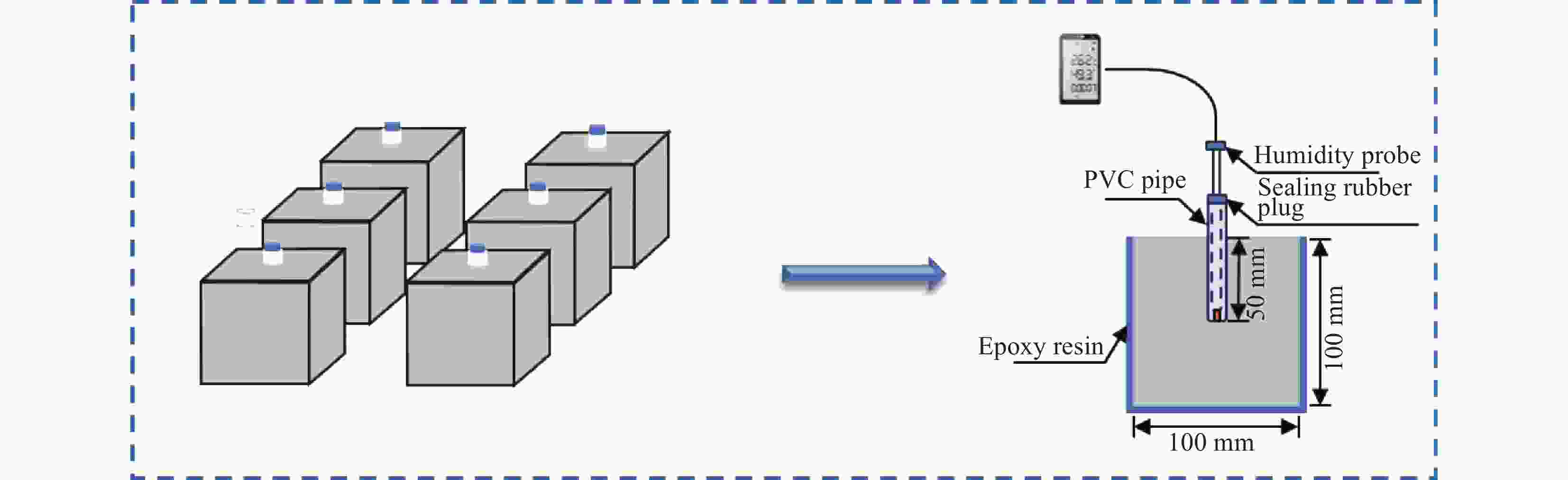

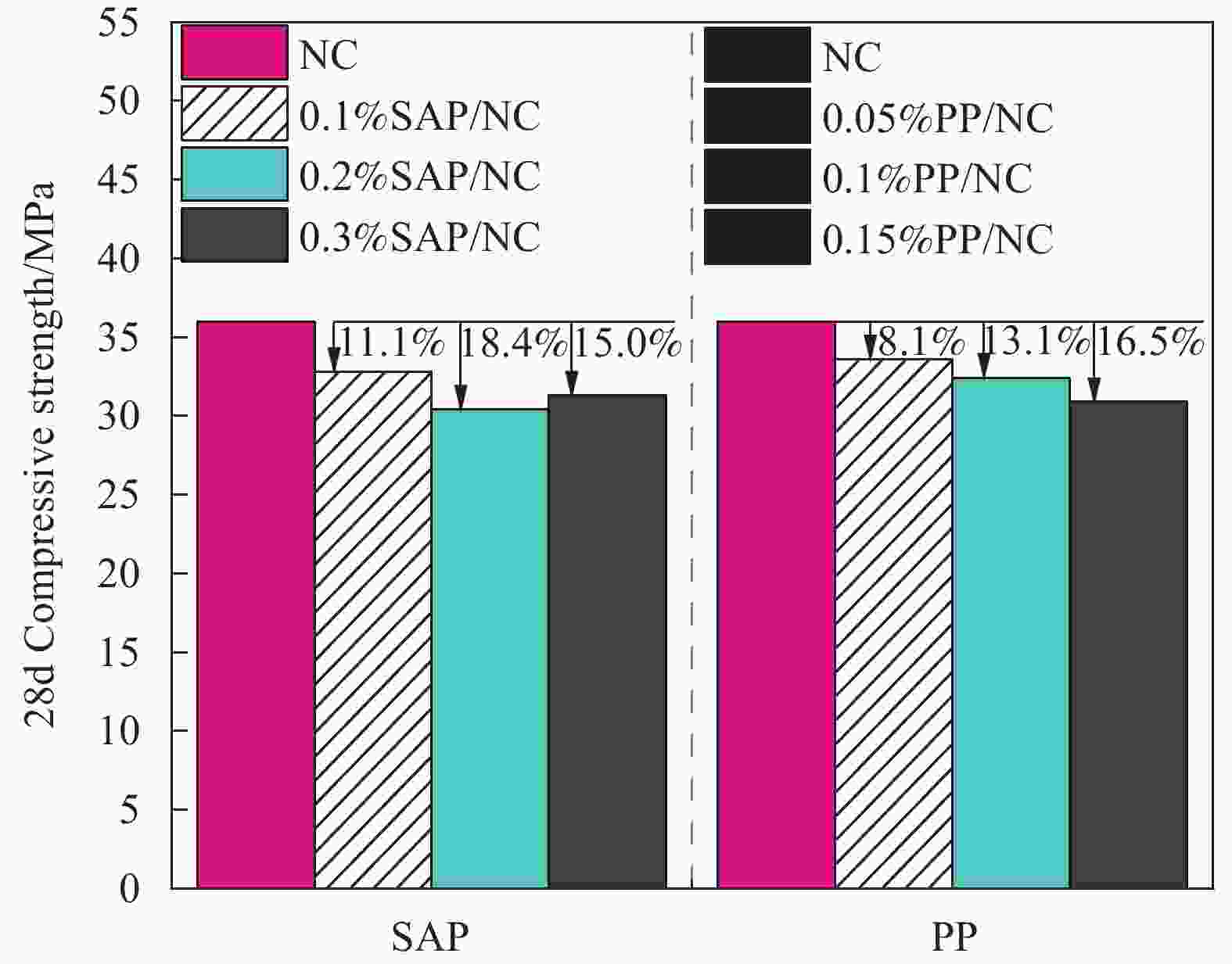

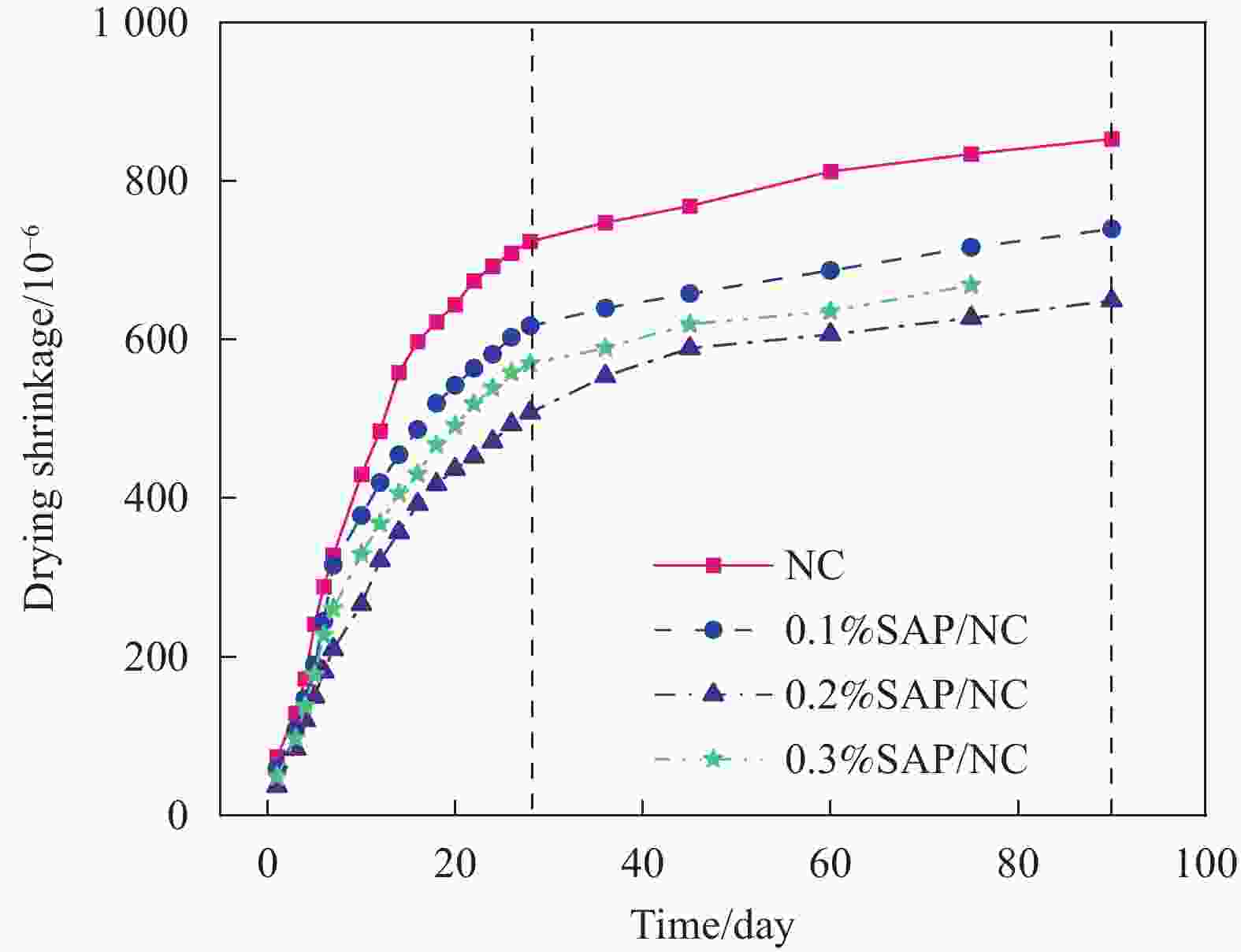

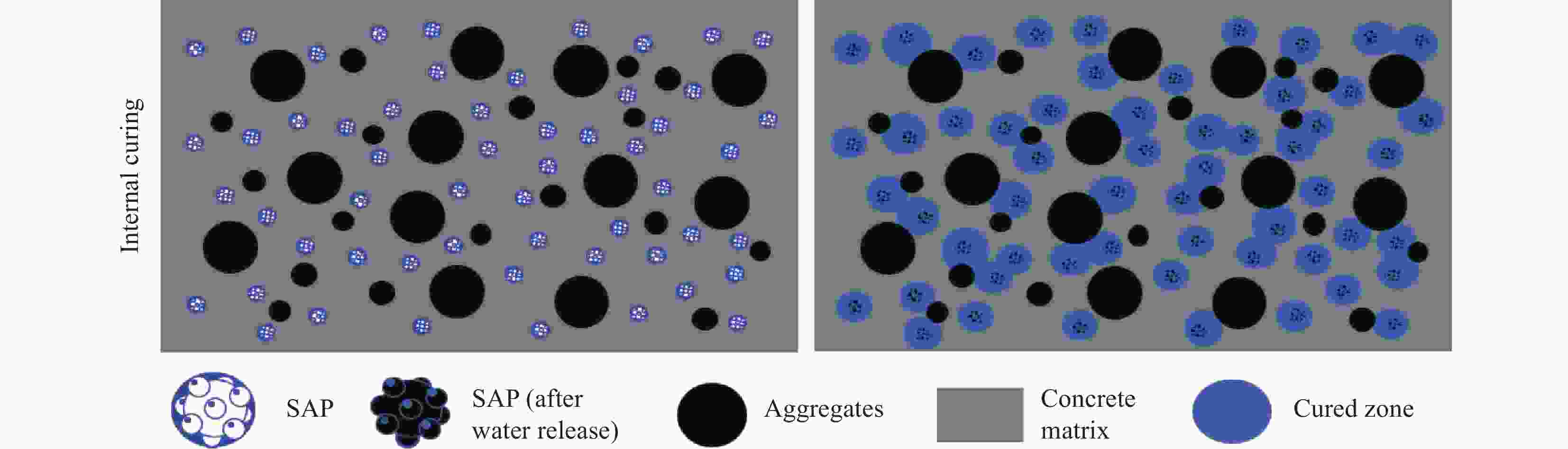

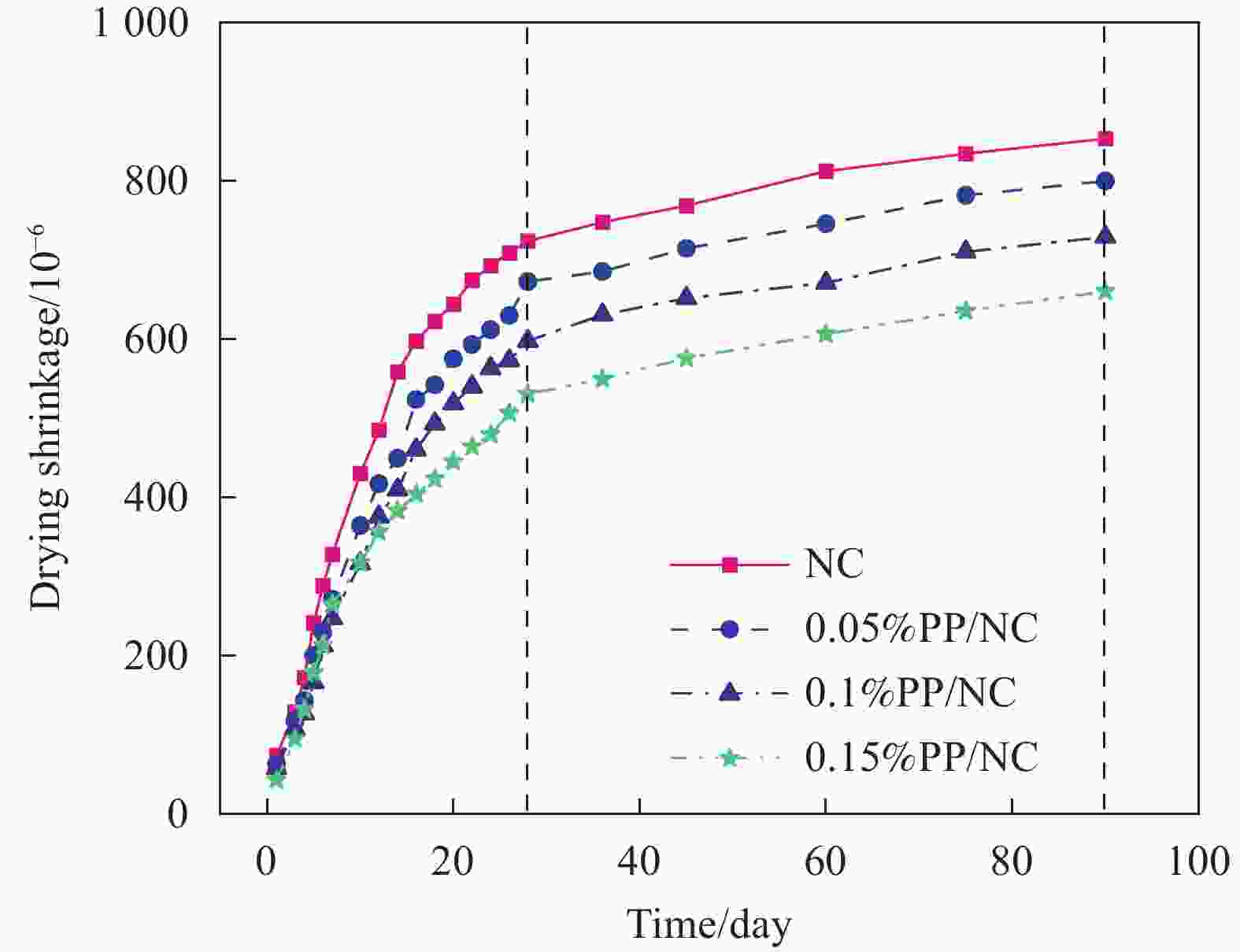

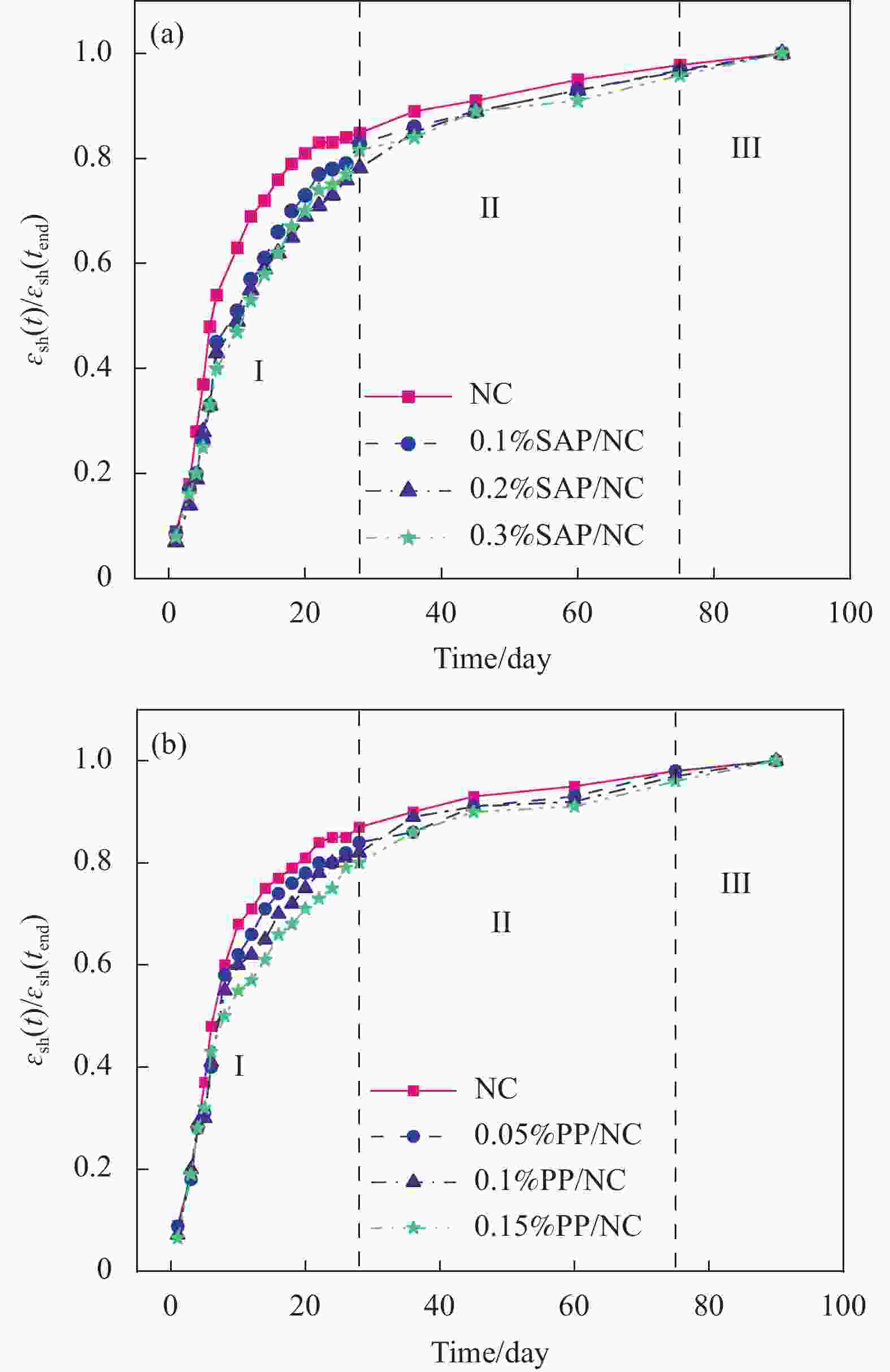

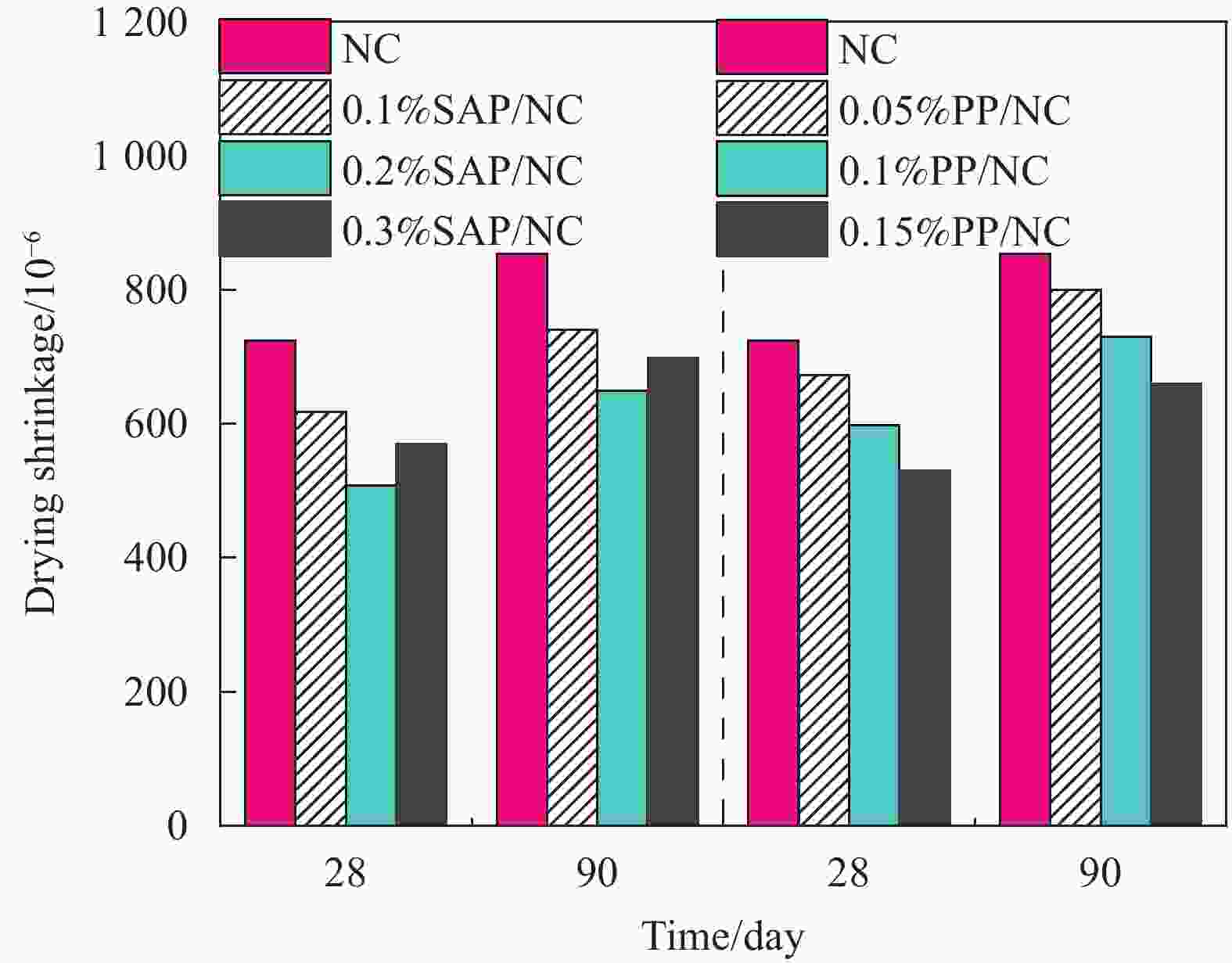

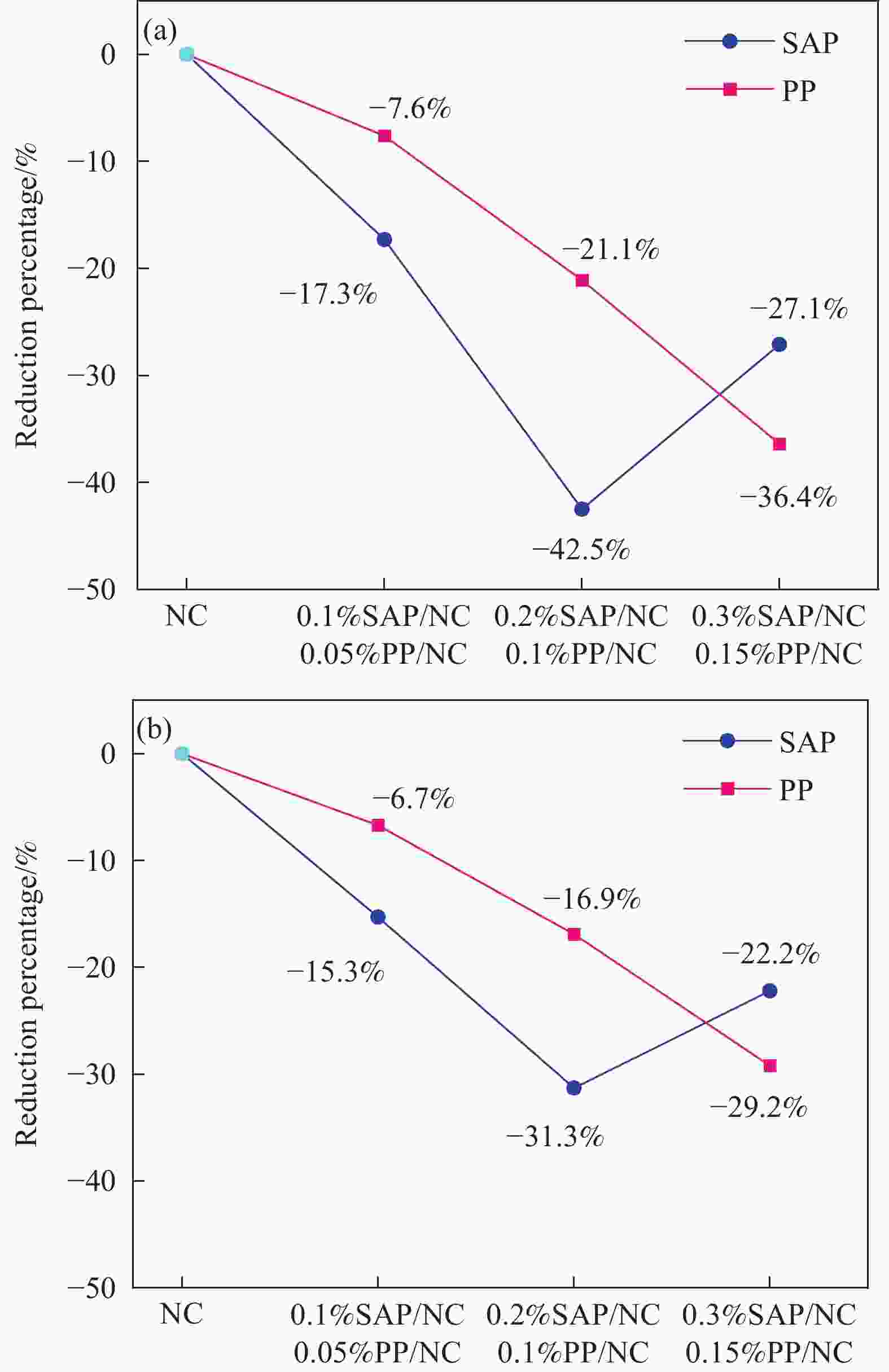

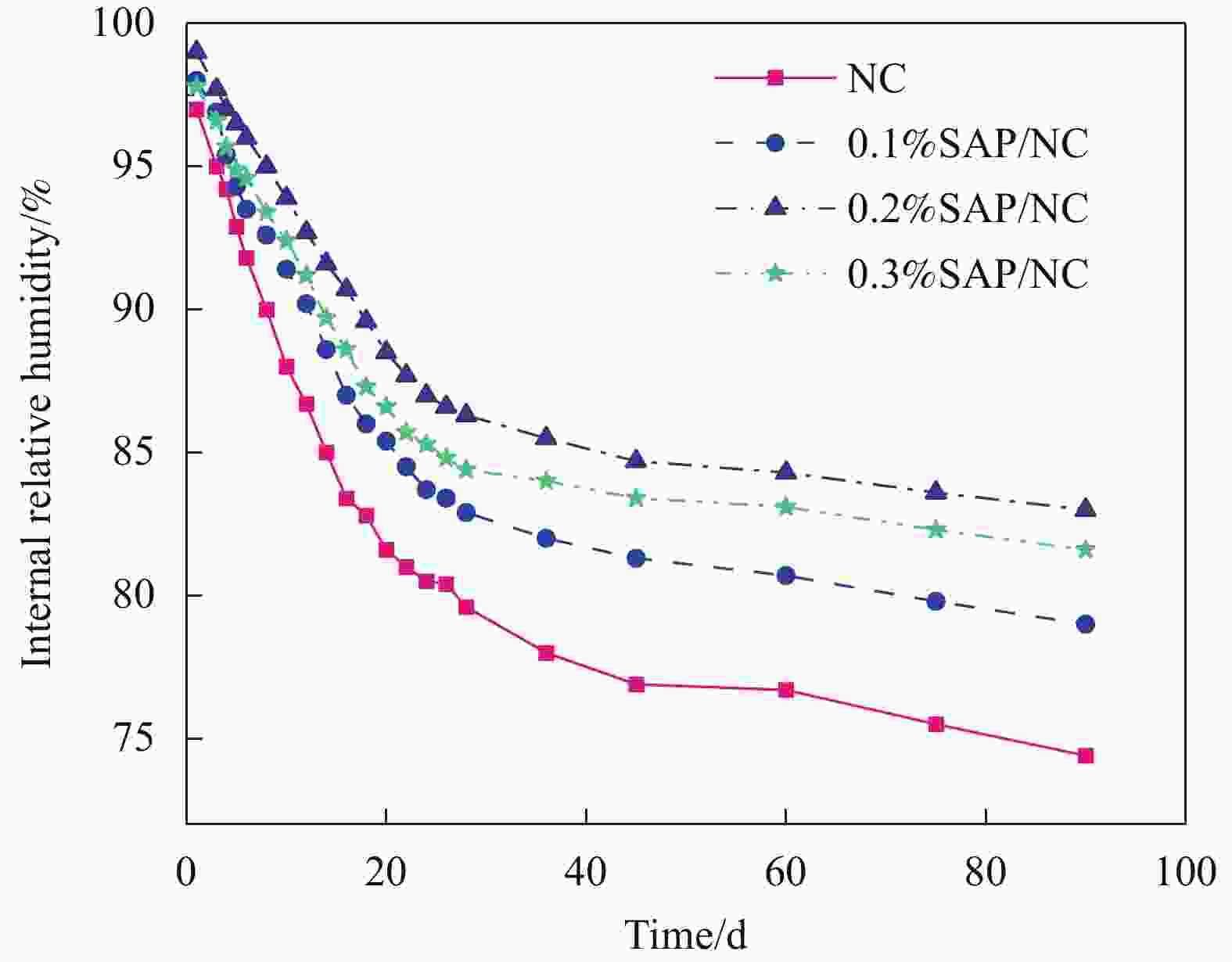

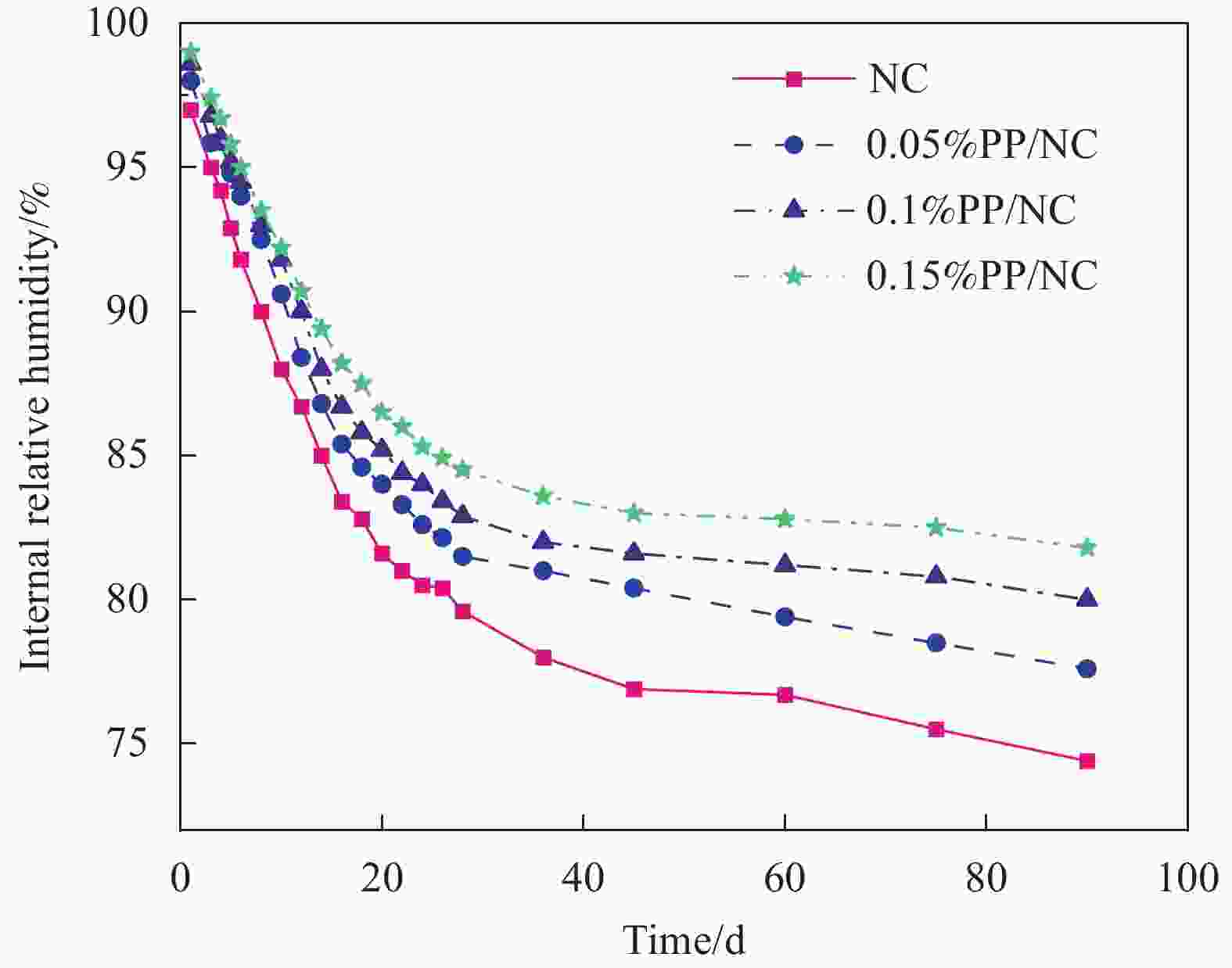

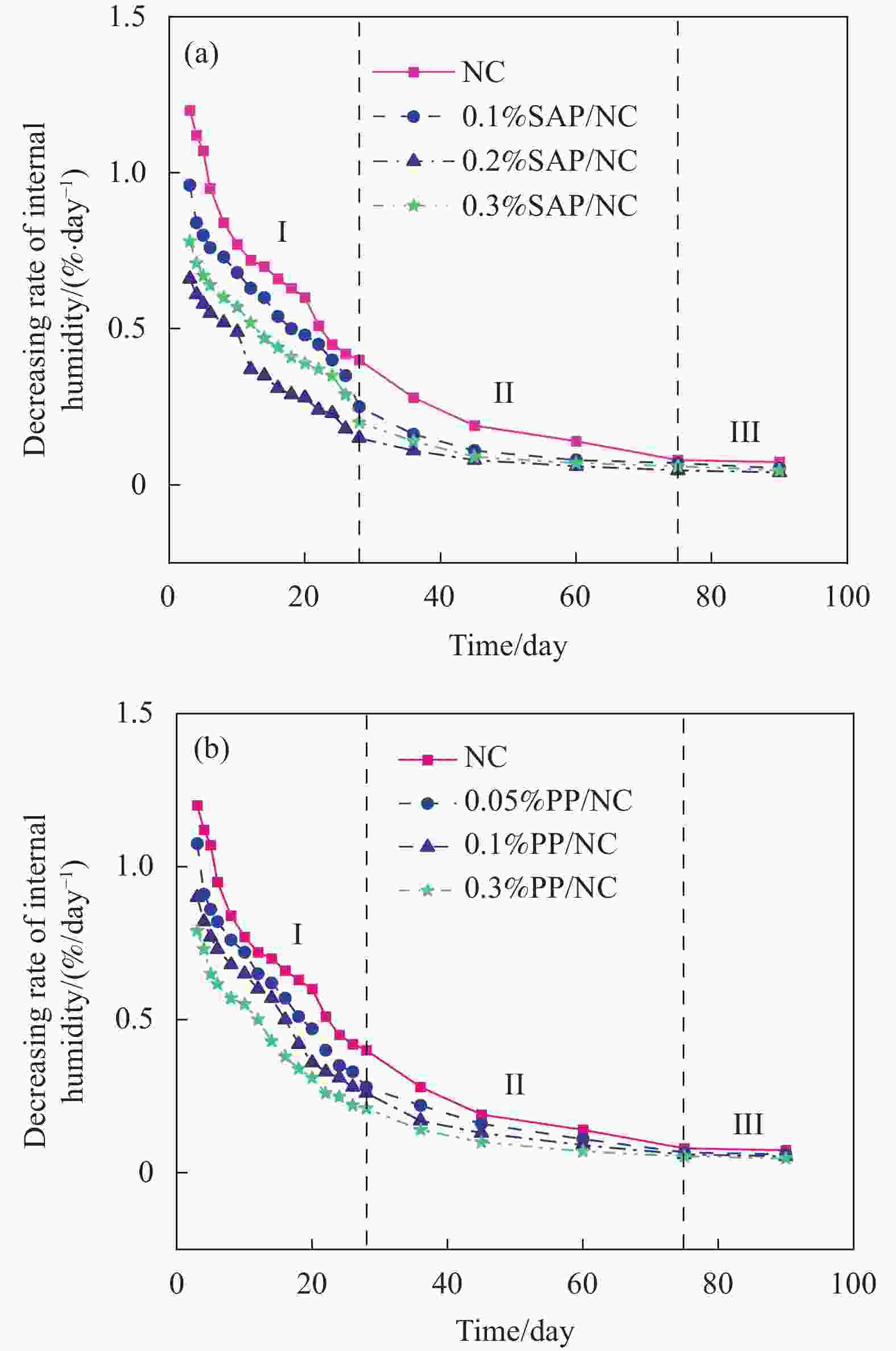

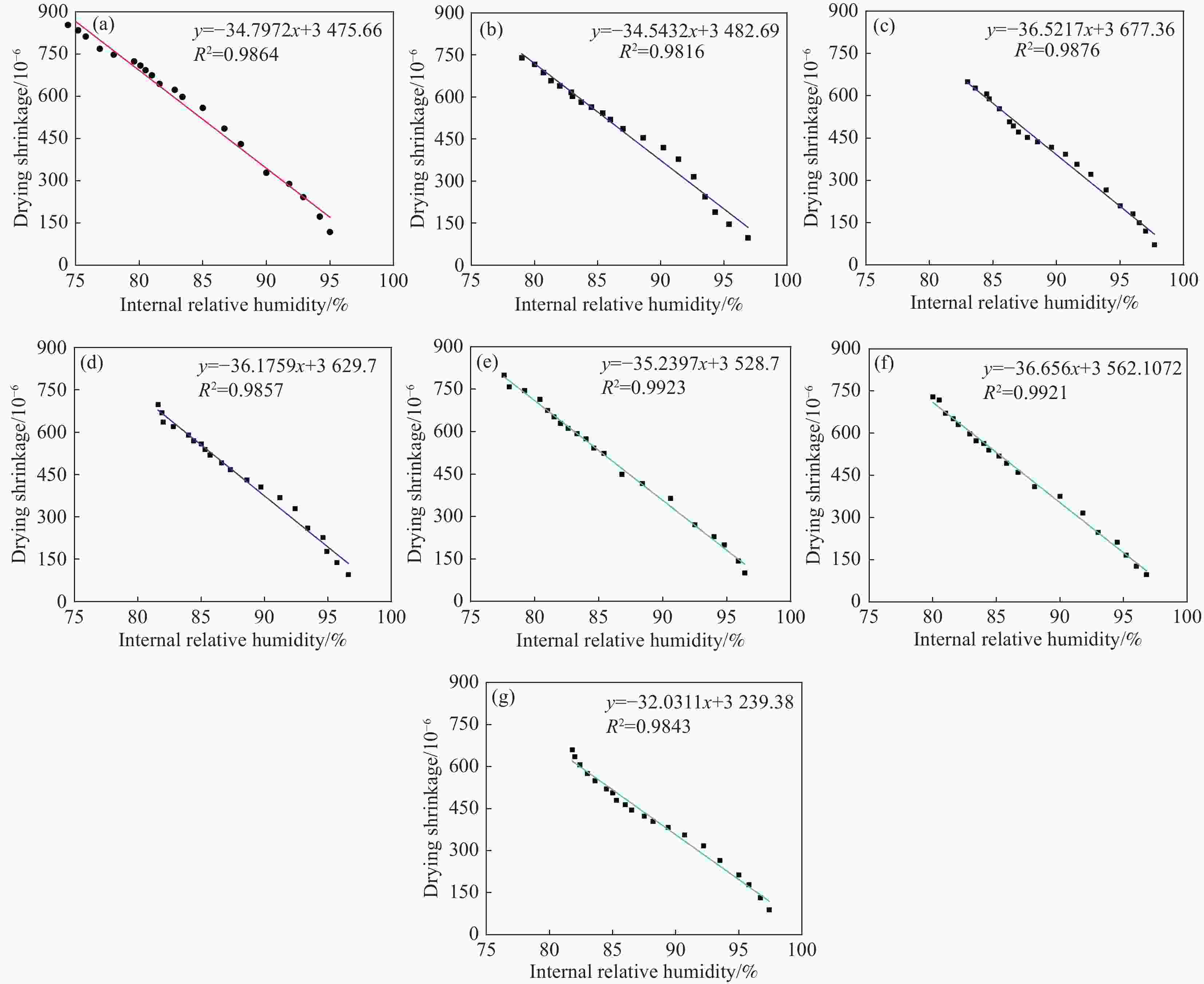

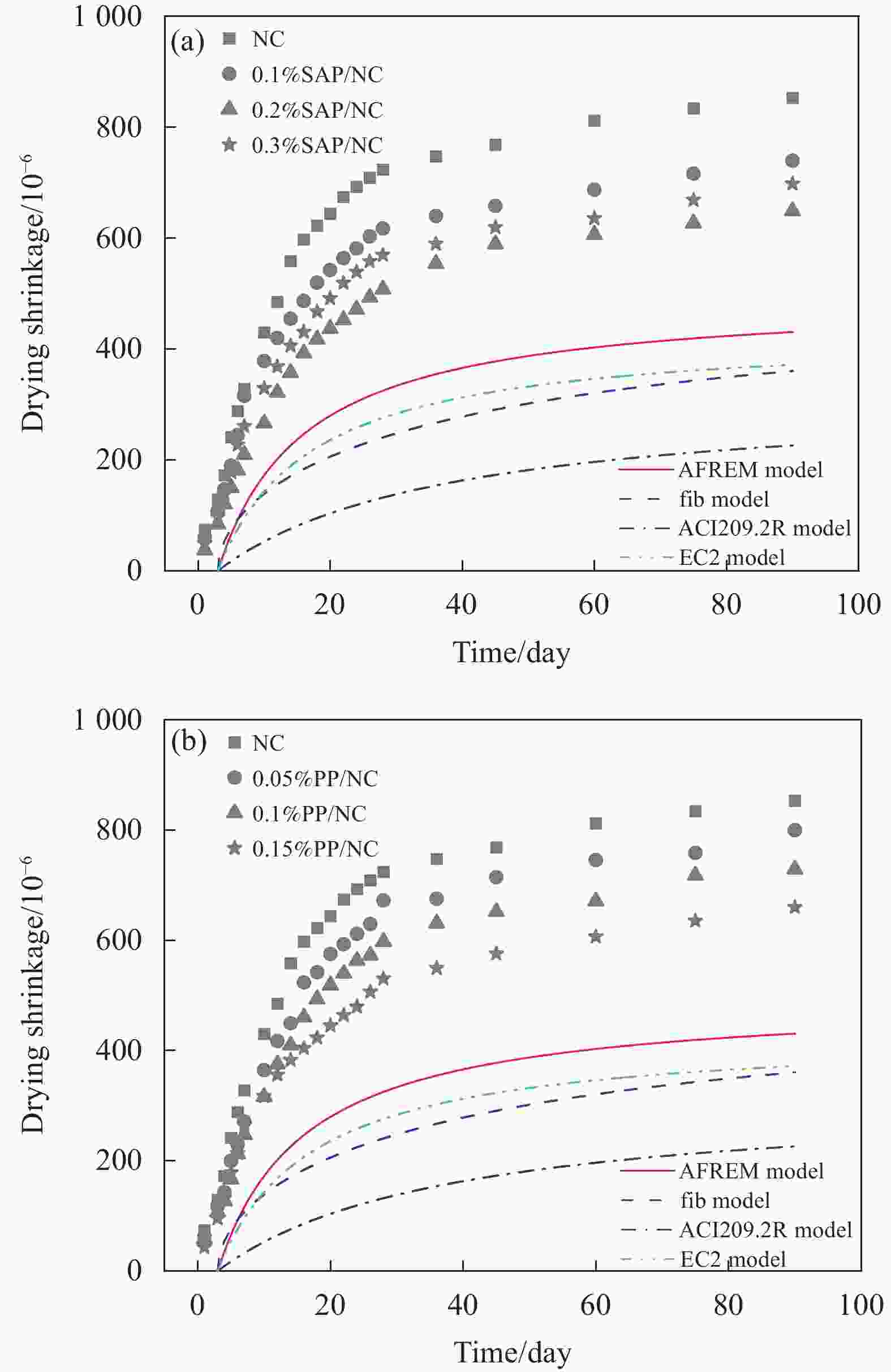

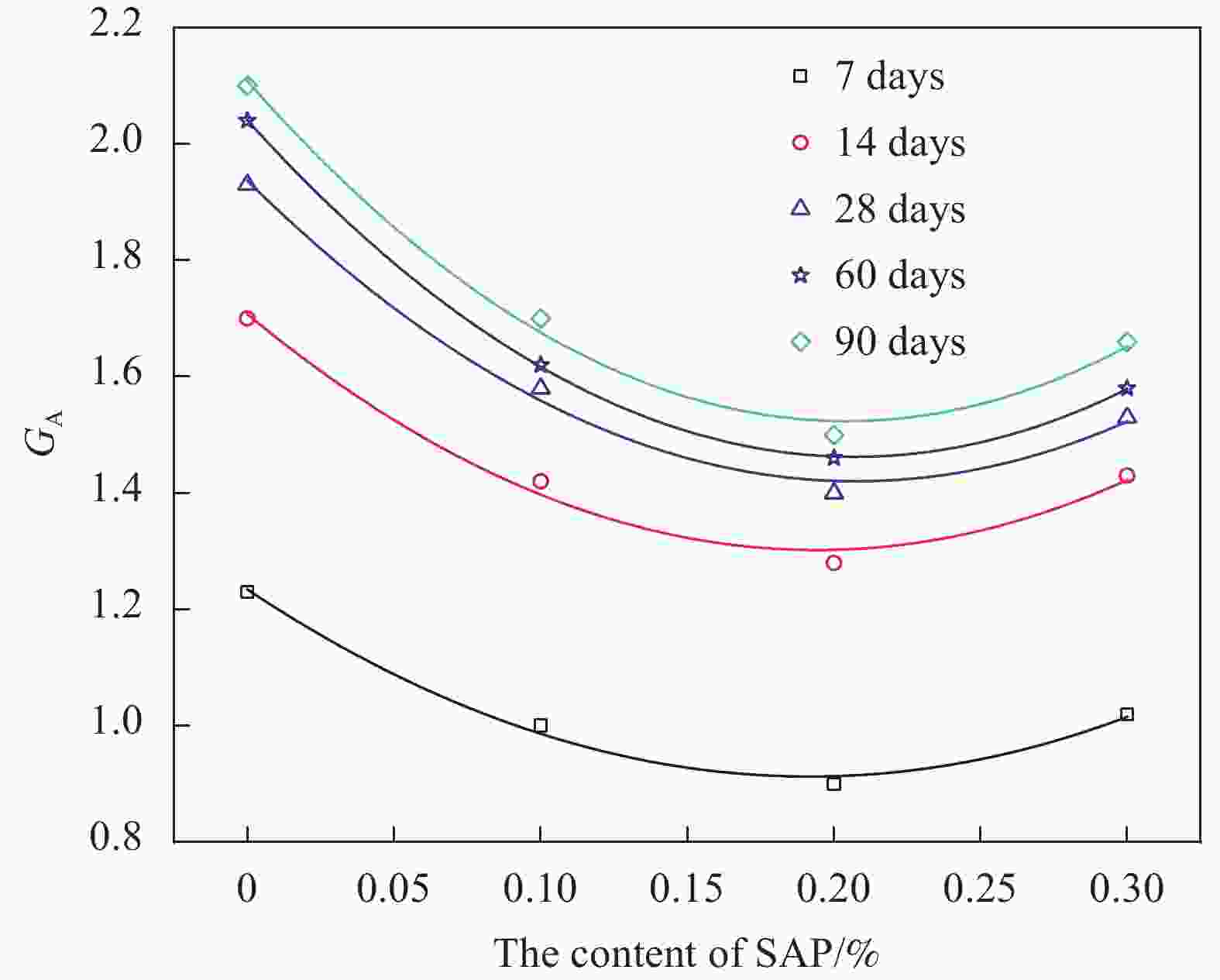

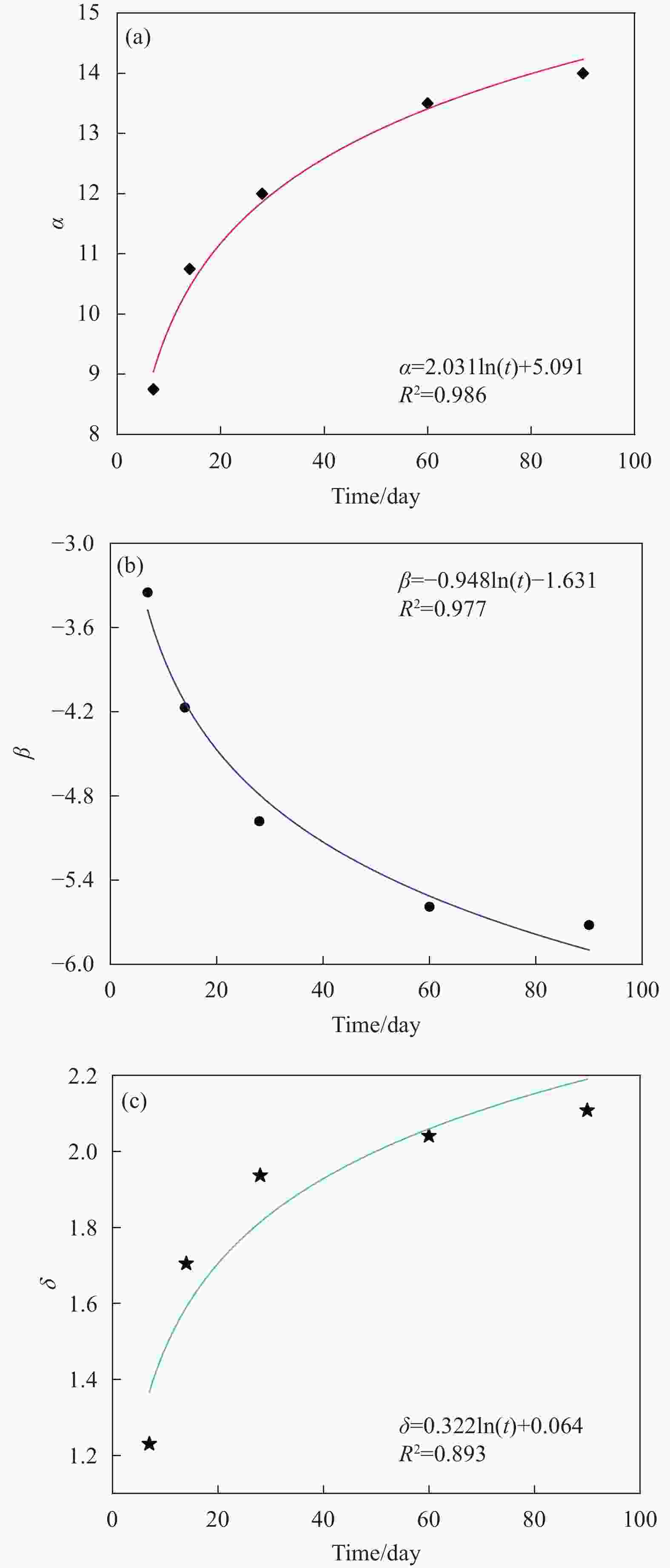

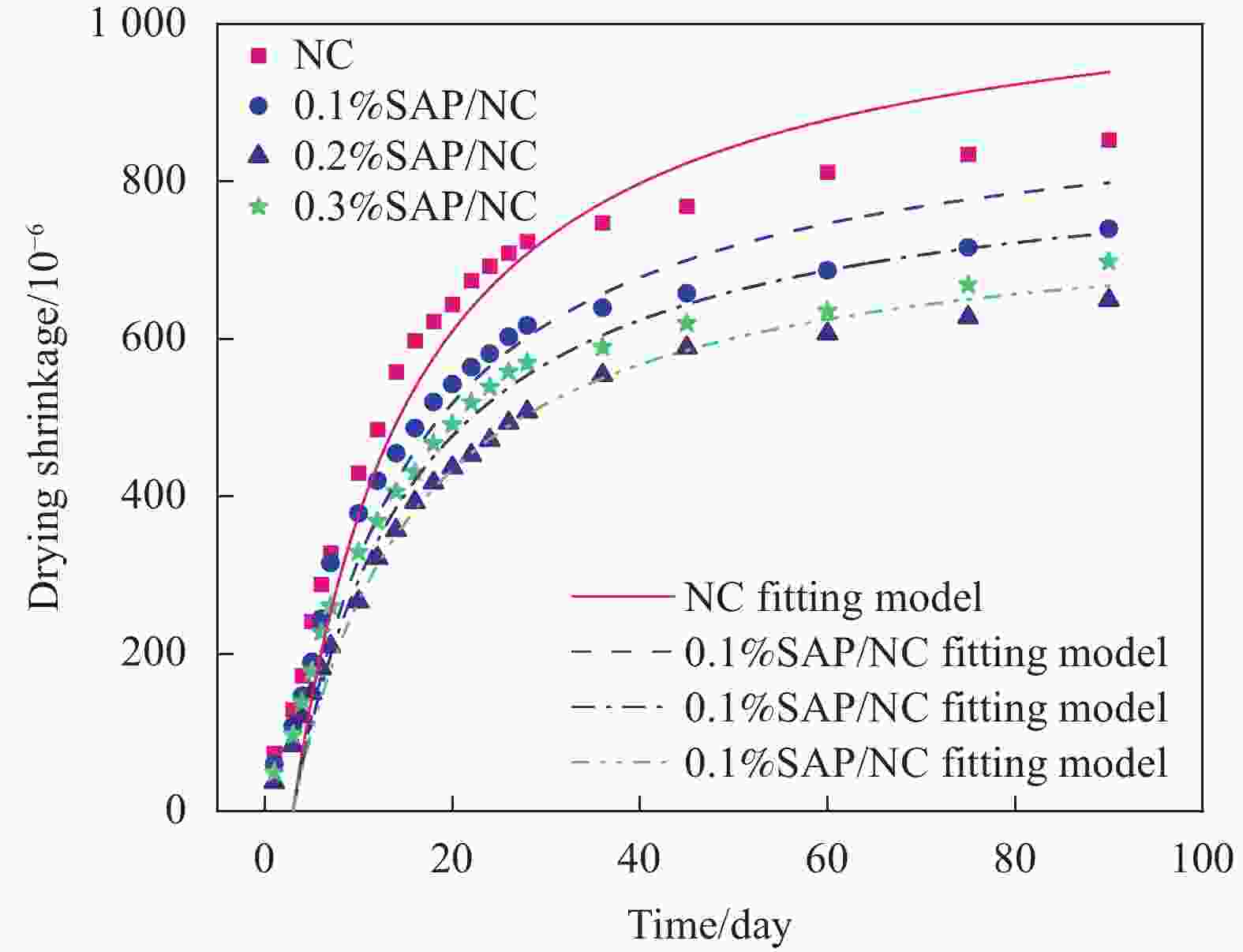

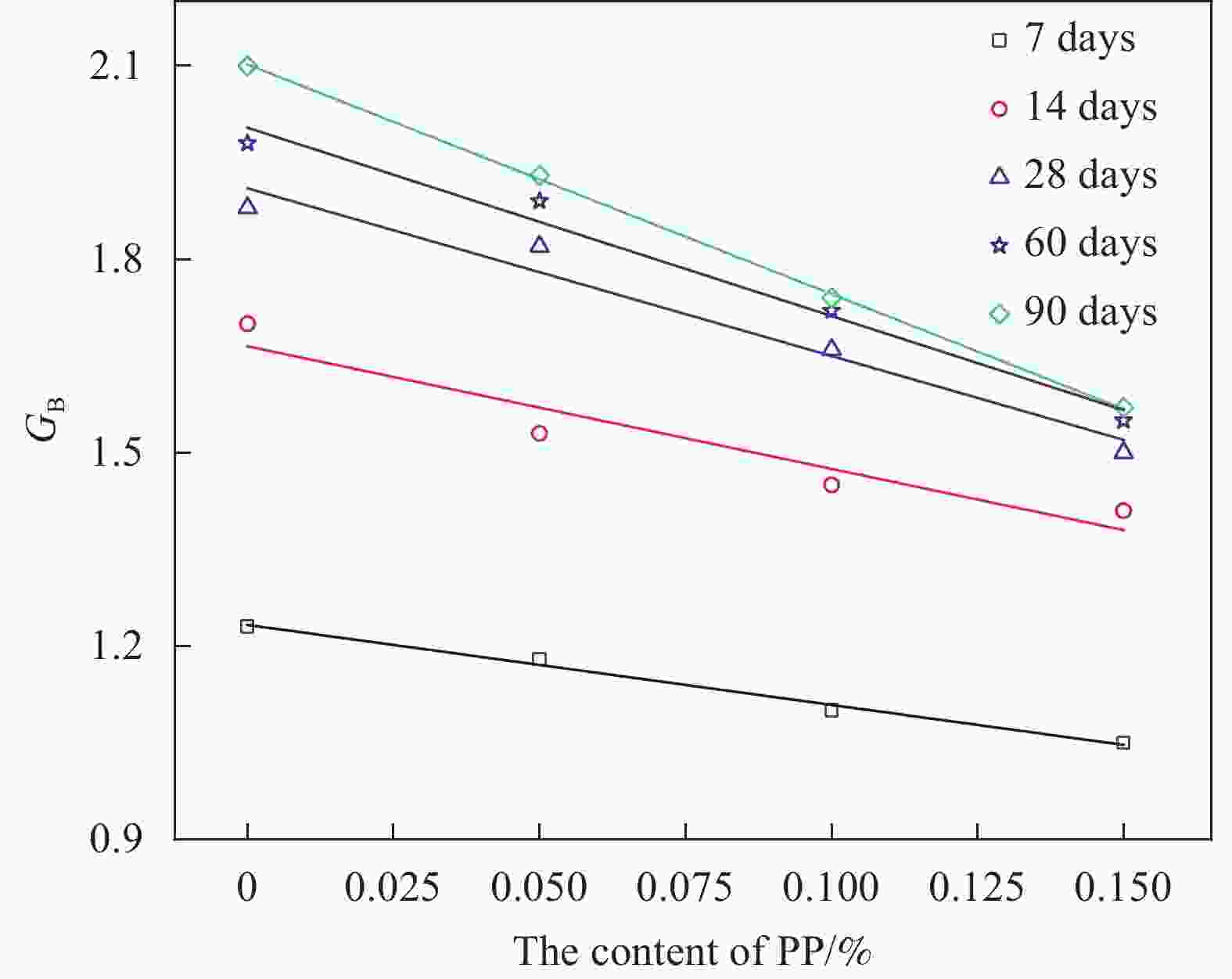

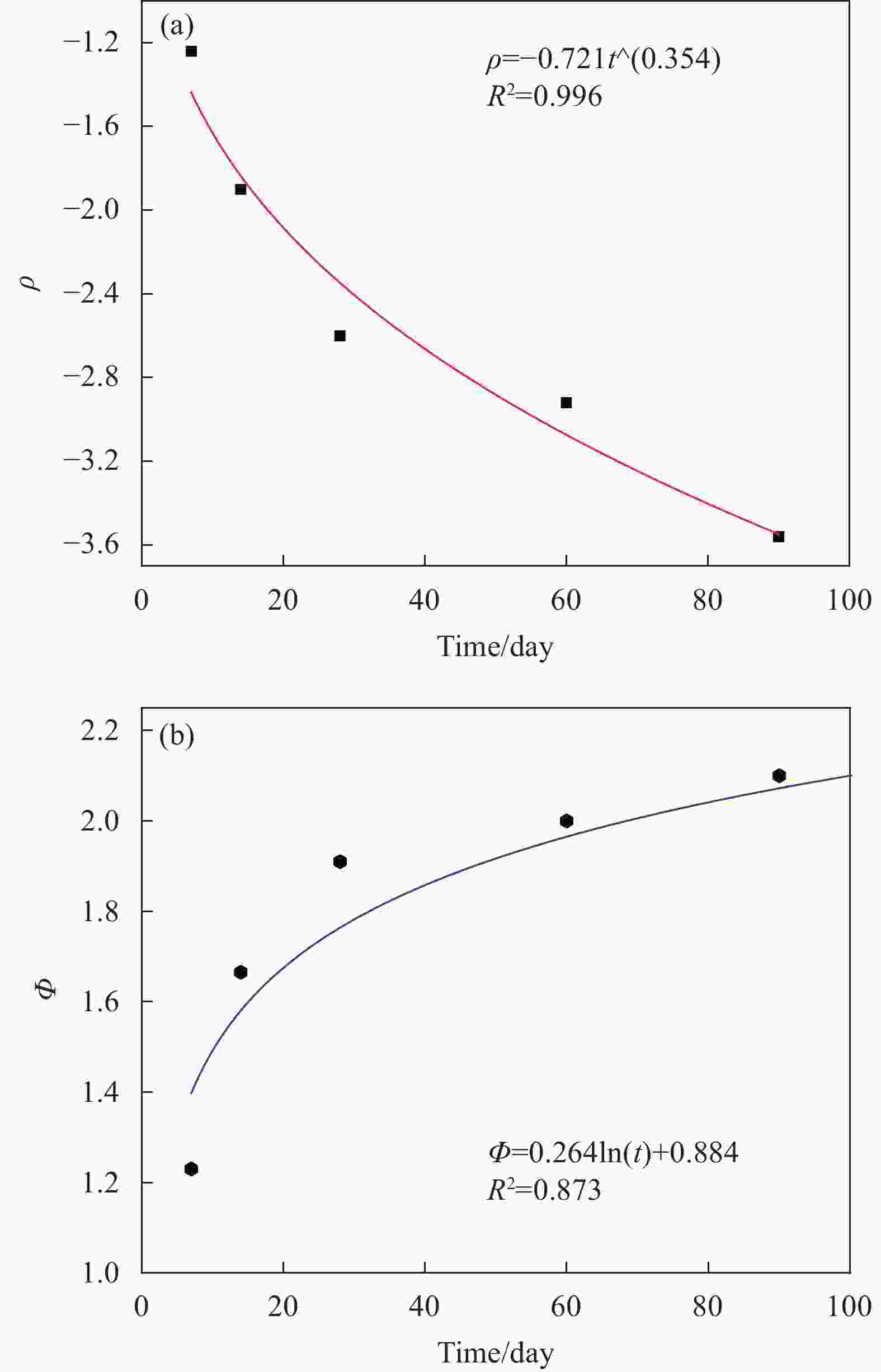

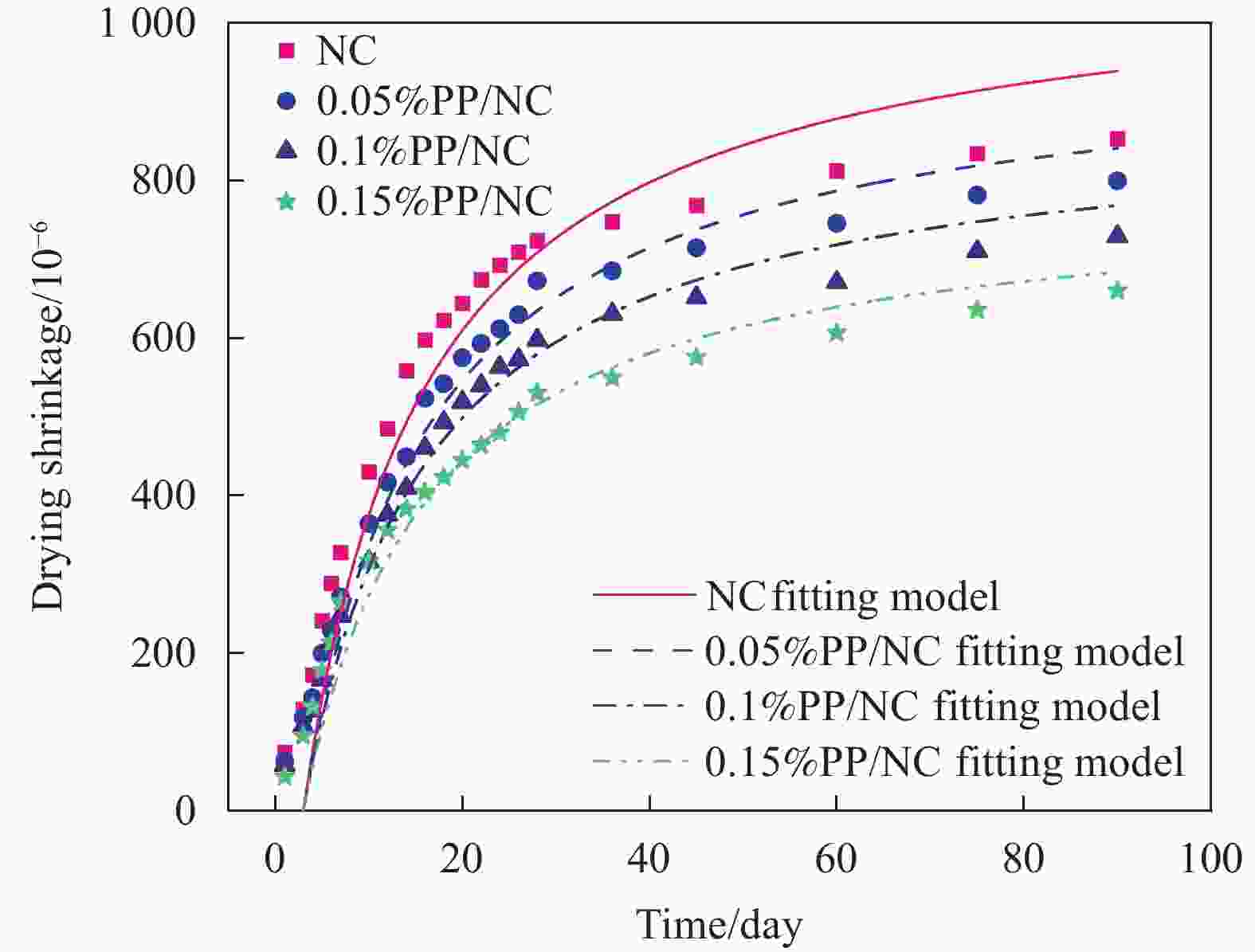

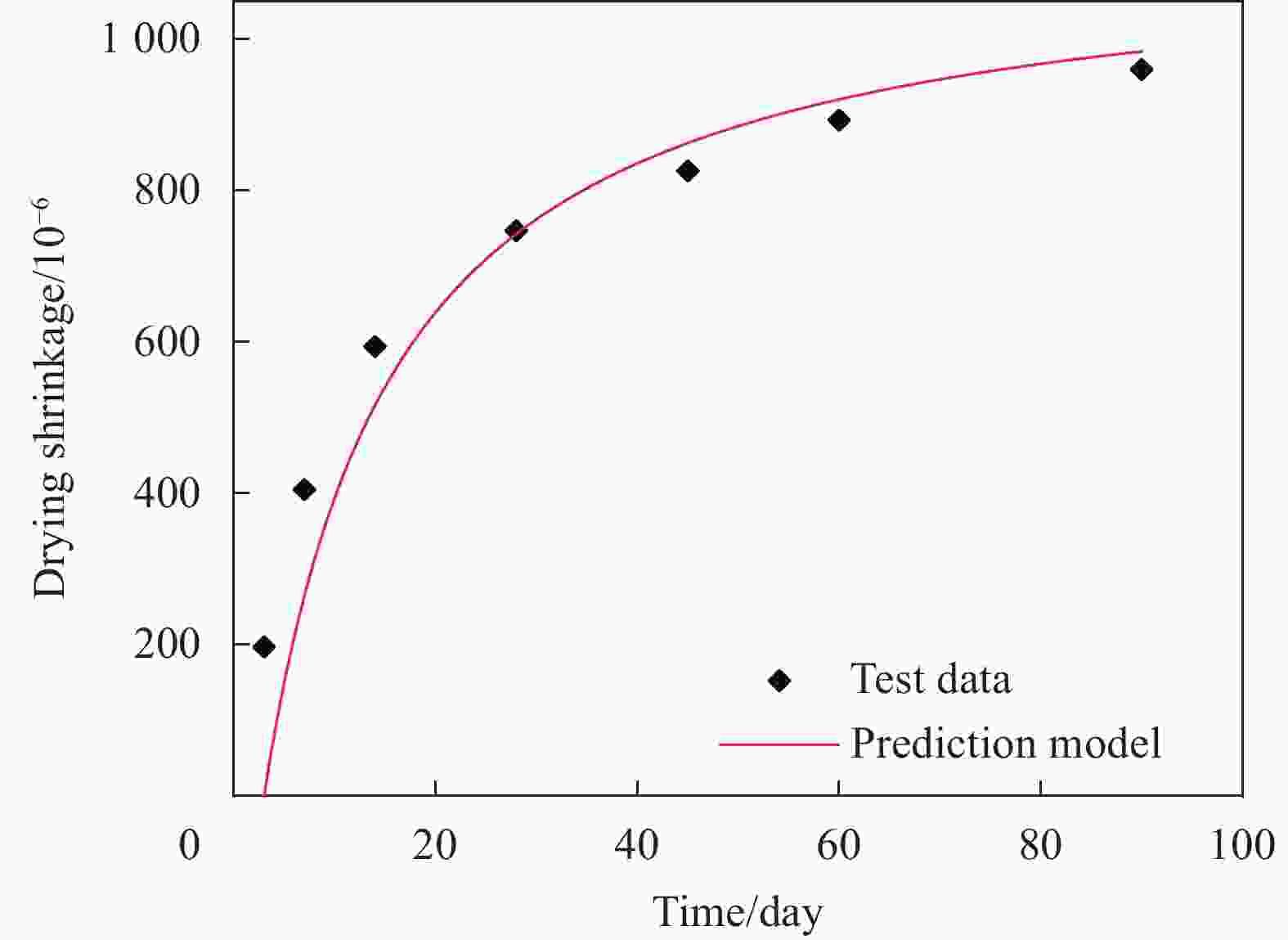

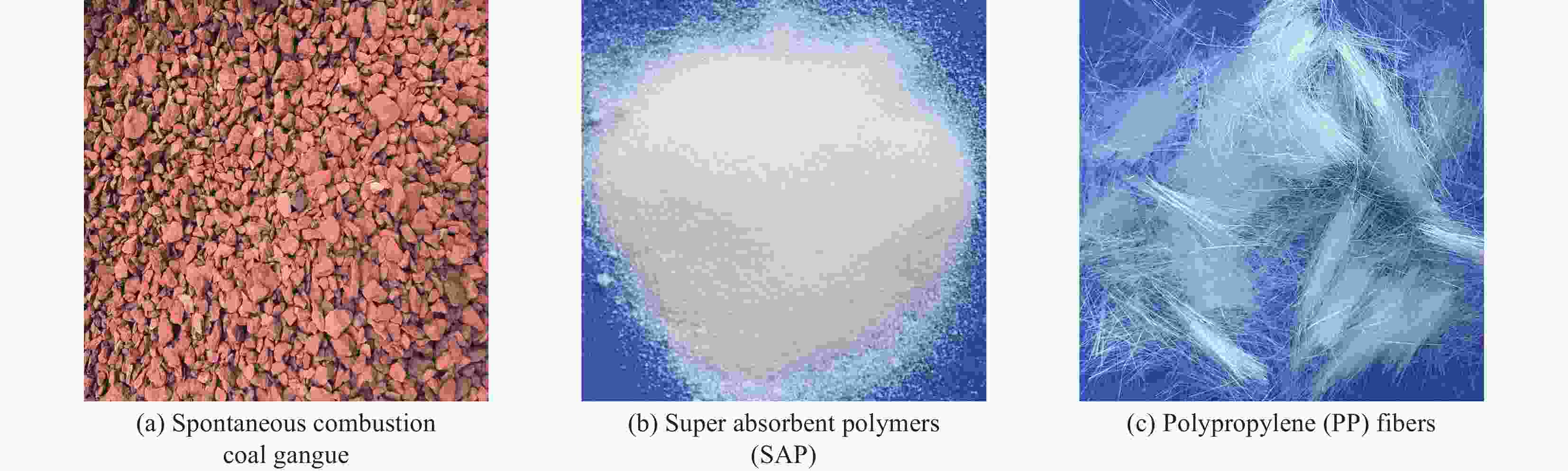

摘要: 为了探究有效降低自燃煤矸石混凝土收缩的方法,以高吸水性树脂(Super Absorbent Polymers,SAP)和聚丙烯(Polypropylene,PP)纤维掺量为变量,设计了7组自燃煤矸石混凝土试件,开展了自燃煤矸石混凝土干燥收缩试验和基体内部湿度测试试验。探究了SAP与PP纤维对基体收缩性能的影响规律,揭示了基体干燥收缩应变与内部相对湿度之间的变化规律,建立了自燃煤矸石混凝土收缩预测模型。结果表明:SAP和PP纤维的加入均能显著降低自燃煤矸石混凝土的干燥收缩,随着SAP掺量的增加,基体收缩应变先减小后增大;随着PP纤维掺量的增加,基体收缩应变逐渐减小。90d龄期时,SAP掺量为0.2%时对自燃煤矸石混凝土的减缩效果最好,与基准混凝土相比,其试件收缩应变降低了31.3%。SAP与PP纤维的加入可以抑制基体内部湿度的衰减,基体收缩应变与内部相对湿度呈线性变化;通过引入自燃煤矸石骨料影响系数对法国建筑行业规范AFREM中提出的收缩预测模型进行了修正,修正后模型的预测结果与试验结果吻合度较高,可用于自燃煤矸石骨料混凝土干燥收缩的计算。Abstract: In order to explore the effective method of reducing the shrinkage of spontaneous combustion coal gangue concrete, seven groups of samples were designed with the different dosage of super absorbent polymers (SAP)and polypropylene (PP)fibers, the drying shrinkage test and the internal humidity test were carried out. The effect of SAP and PP fibers on shrinkage performance of spontaneous combustion coal gangue concrete was investigated, the influence of SAP and PP fibers on the internal humidity of the matrix was analyzed, and the law of change between the drying shrinkage strain and the internal relative humidity of the matrix was revealed. The shrinkage prediction model of spontaneous combustion coal gangue concrete was proposed. The results show that the addition of SAP and PP fibers can significantly reduce the drying shrinkage of spontaneous combustion coal gangue concrete. The shrinkage value of the matrix first decreases and then increases with the increasing of the SAP addition; the shrinkage value of the matrix gradually decreases with the increment of PP fibers dosage. At the age of 90 days, when the volume content of SAP is 0.2%, the shrinkage reduction effect of matrix is the best, and the shrinkage strain of the sample is reduced by 31.3% compared with the plain concrete. The addition of SAP and PP fibers can inhibit the decay of the internal humidity; the shrinkage strain and the internal relative humidity of the matrix vary linearly. By introducing the influence coefficient of spontaneous combustion coal gangue aggregate, the AFREM shrinkage prediction model is modified, the predicted results are in good agreement with the experimental results, and the modified shrinkage model can be used for the calculation of dry shrinkage of spontaneous combustion coal gangue aggregate concrete.

-

图 14 基体干燥收缩应变与内部相对湿度的关系: (a) NC; (b) 0.1%SAP/NC; (c) 0.2%SAP/NC; (d) 0.3%SAP/NC; (e) 0.05%PP/NC;(f) 0.1%PP/NC; (g) 0.15%PP/NC

Figure 14. Relation between dry shrinkage strain and internal relative humidity of the matrix: (a) NC; (b) 0.1%SAP/NC; (c) 0.2%SAP/NC; (d) 0.3%SAP/NC;(e) 0.05%PP/NC; (f) 0.1%PP/NC; (g) 0.15%PP/NC

表 1 自燃煤矸石基本物理性质

Table 1. Basic physical properties of spontaneous combustion coal gangue

Type Apparent density/

(g·cm−3)Packing density/

(g·cm−3)Crush value/% Water content/% 24 hWater

absorption rate/%Spontaneous combustion coal gangue 2.63 1.04 19.4 0.44 8.64 表 2 PP纤维基本物理性质

Table 2. Basic physical properties of PP fibers

Type Density/(g·cm−3) Tensile strength/MPa Elastic modulus/GPa Length/mm PP fibers 0.91 568 4.35 19 表 3 混凝土试件组分配合比(kg/m−3)

Table 3. Mix proportions of concrete specimens (kg/m−3)

Item Cement Fly ash Water Sand Coarse aggregate Water reducer SAP PP fiber Internal conservation water NC 320 80 152 750 1040 4 0.0 0.00 0 0.1%SAP/NC 320 80 152 750 1040 4 0.4 0.00 10 0.2%SAP/NC 320 80 152 750 1040 4 0.8 0.00 20 0.3%SAP/NC 320 80 152 750 1040 4 1.2 0.00 30 0.05%PP/NC 320 80 152 750 1040 4 0.0 0.46 0 0.1%PP/NC 320 80 152 750 1040 4 0.0 0.91 0 0.15%PP/NC 320 80 152 750 1040 4 0.0 1.37 0 Notes: In the specimens of spontaneous combustion coal gangue concrete with super absorbent polymers (SAP)or polypropylene (PP)fibers, a%SAP/NC—SAP volume fraction in the matrix is a%, b%PP/NC—PP fibers volume fraction in the matrix is b%. The dosage of SAP and PP of item NC is 0. 表 4 混凝土干燥收缩模型对比分析

Table 4. Comparative analysis of drying shrinkage models of concrete

Model Drying shrinkage limit/εcd,0 Drying shrinkage development function/βds(t) Consideration factor Calculation formula Calculation formula AFREM $K\left( {{f_{{\text{cu}}}}} \right)A\left( {{f_{{\text{cu}}}},{R_{\text{H}}}} \right) \times {10^{ - 6}}$ $ \dfrac{{t - {t_{\text{s}}}}}{{{\beta _{\text{s}}}{{\left( {{{{A_{\text{c}}}} / u}} \right)}^2} + \left( {t - {t_{\text{s}}}} \right)}} $ Drying age, ambient humidity, specimen size, concrete strength, water cement ratio fib $160 + 10{\beta _{{\text{sc}}}}\left( {9 - {{{f_{{\text{cu}}}}}/ {{f_{{\text{cu0}}}}}}} \right) \times {10^{ - 6}}$ $ {\left( {\dfrac{{t - {t_{\text{s}}}}}{{350{{\left( {{h/ {{h_0}}}} \right)}^2} + \left( {t - {t_{\text{s}}}} \right)}}} \right)^{{1/ 2}}} $ Drying age, ambient humidity, cement type, strength, specimen size ACI209.2 R $ 780{{\gamma }_{\text{cp}}}{{\gamma }_{\text{ } \lambda \text{ }}}{{\gamma }_{\text{h}}}{{\gamma }_{\text{s}}}{{\gamma }_{\text{ } \psi \text{ }}}{{\gamma }_{\text{ } \alpha \text{ }}}{{\gamma }_{\text{c}}}\times {{10}^{-6}} $ $ \dfrac{{{{\left( {t - {t_{\text{s}}}} \right)}^\alpha }}}{{f + {{\left( {t - {t_{\text{s}}}} \right)}^\alpha }}} $ Drying age, curing conditions, ambient humidity, specimen size, gas content, slump, sand strain, cement dosage EC2 $ 0.85\left[ \begin{gathered} 220 + 110{\alpha _{{\text{ds1}}}} \\ \exp \left( { - {\alpha _{{\text{ds2}}}}{\raise0.7 ex\hbox{${{f_{{\text{cu}}}}}$} \mathord{\left/ {\vphantom {{{f_{{\text{cu}}}}} {{f_{{\text{cu0}}}}}}}\right.} \lower0.7 ex\hbox{${{f_{{\text{cu0}}}}}$}}} \right) \\ \end{gathered} \right]{\beta _{{\text{RH}}}} \times {10^{ - 6}} $ $\dfrac{{t - {t_{\text{s}}}}}{{\left( {t - {t_{\text{s}}}} \right) + 0.04\sqrt {{{\left( {{{2{A_{\text{c}}}} \mathord{\left/ {\vphantom {{2{A_{\text{c}}}} u}} \right. } u}} \right)}^3}} }}$ Concrete strength, cement type, environment, ambient humidity, drying age, specimen size Notes: K(fcu)−the strength of concrete related to the diffusion of internal moistureconstant; A(fcu,RH)—the shrinkage of concrete when the internal humidity decreases due to the self-drying and moisture diffusion process; βs—correlation coefficient of mineral admixtures; Ac—section area(mm2); u—section perimeter(mm); t—the considered age of the concrete (d); ts—the age of the concrete at the begineering of drying shrinkage(d); βsc—influence coefficient of cement variety; fcu—compressive strength of concrete at 28 d (MPa); fcu0—the average compressive strength of concrete(MPa); h—the effective dimensions of the cross-section(mm); h0—the constant value(mm); γcp—correction factor for maintenance conditions; γλ—correction factor for ambient relative humidity; γh—correction factor for component dimensions; γs—correction factor for collapse; γψ—correction factor for sand rate; γα—correction factor for gas content; γc—correction factor for cement content; α—a constant value depending on the shape and size of the specimen; f— a constant value about curing time(d); αds1, αds2—influence coefficients depending on the type of cement; βRH— influence coefficient depending on the relative humidity of the ambient atmosphere. -

[1] 石起振, 张耀祖, 佘宇豪. 自燃煤矸石集料混凝土体积稳定性与耐久性研究进展[J]. 新型建筑材料, 2023, 50(9): 16-21+36. doi: 10.3969/j.issn.1001-702X.2023.09.004SHI Qizhen, ZHANG Yaozu, SHE Yuhao. Research progress on volumetric stability and durability of spontaneously combusted coal gangue aggregate concrete[J]. New Building Materials, 2023, 50(9): 16-21+36(in Chinese). doi: 10.3969/j.issn.1001-702X.2023.09.004 [2] 皇民, 赵玉如, 蔺世豪, 等. 全级配煤矸石混凝土导热性能试验与分析[J]. 科学技术与工程, 2021, 21(3): 1144-1149.HUANG Min, ZHAO Yuru, LIN Shihao, et al. Test and analysis of thermal conductivity of fully graded coal gangueconcrete[J]. Science Technology and Engineering, 2021, 21(3): 1144-1149(in Chinese). [3] MA H Q, ZHU H G, WU C, et al. Effect of shrinkage reducing admixture on drying shrinkage and durability of alkali-activated coal gangue-slag material[J]. Construction and Building Materials, 2021, 270: 121372-. doi: 10.1016/j.conbuildmat.2020.121372 [4] WU K Y, LUO S R, ZHENG J L, et al. Influence of carbonation treatment on the properties of multiple interface transition zones and recycled aggregate concrete[J]. Cement and Concrete Composites, 2022, 104402. [5] 刘世, 田建华, 朱喜朋, 等. 玄武岩纤维对煤矸石陶粒混凝土抗冻性的影响[J]. 低温工程, 2024, (1): 72-80. doi: 10.3969/j.issn.1000-6516.2024.01.010LIU Shi, TIAN Jianhua, ZHU Xipeng, et al. Effect of basalt fiber on frost resistance of coal gangue ceramide concrete[J]. Cryogenic Engineering, 2024, (1): 72-80(in Chinese). doi: 10.3969/j.issn.1000-6516.2024.01.010 [6] 葛洁雅, 朱红光, 李宗徽, 等. 煤矸石粗骨料-地聚物混凝土的力学与耐久性能研究[J]. 材料导报, 2021, 35(S2): 218-223.GE Jieya, ZHU Hongguang, LI Zonghui, et al. Study on mechanical and durability of coal gangue coarse aggregate and ground polymer concrete[J]. Materials Review, 2021, 35(S2): 218-223(in Chinese). [7] 周梅, 赵华民, 王然, 等. 掺合料对自燃煤矸石砂轻混凝土抗渗和抗冻影响[J]. 硅酸盐通报, 2015, 34(1): 131-137.ZHOU Mei, ZHAO Huamin, WANG Ran, et al. Effect of admixture on impermeability and frost resistance of light concrete with spontaneous combustion coal gangue sand[J]. Bulletin of Silicate, 2015, 34(1): 131-137(in Chinese). [8] 白国良, 刘瀚卿, 王建文, 等. 基于骨料特性差异的煤矸石混凝土干燥收缩模型[J]. 土木工程学报, 2023, 56(11): 27-42.BAI Guoliang, LIU Hanqing, WANG Jianwen, et al. Drying shrinkage model of coal gangue concrete based on aggregate characteristics difference[J]. Journal of Civil Engineering, 2023, 56(11): 27-42(in Chinese). [9] 崔正龙, 郝敬力, 陈龙, 等. 自燃煤矸石混凝土强度及干燥收缩裂缝试验研究[J]. 非金属矿, 2015, 38(6): 76-78. doi: 10.3969/j.issn.1000-8098.2015.06.023CUI Zhenglong, HAO Jingli, CHEN Long, et al. Experimental study on strength and dry shrinkage crack of spontaneous combustion coal gangue concrete[J]. Non-metallic Mines, 2015, 38(6): 76-78(in Chinese). doi: 10.3969/j.issn.1000-8098.2015.06.023 [10] 李永靖, 曹爽, 邢洋, 等. 煤矸石骨料混凝土的干燥收缩性能试验研究[J]. 混凝土, 2016, (11): 95-97. doi: 10.3969/j.issn.1002-3550.2016.11.025LI Yongjing, CAO Shuang, XING Yang, et al. Experimental study on drying shrinkage performance of coal gangue aggregate concrete[J]. Concrete, 2016, (11): 95-97(in Chinese). doi: 10.3969/j.issn.1002-3550.2016.11.025 [11] 孔祥明, 张珍林. 高吸水树脂对高强混凝土早期减缩效果及机理研究[J]. 建筑材料学报, 2014, 17(4): 559-565+571. doi: 10.3969/j.issn.1007-9629.2014.04.001KONG Xiangming, ZHANG Zhenlin. Study on the effect and mechanism of high water absorbent resin on early shrinkage of high strength concrete[J]. Journal of Building Materials, 2014, 17(4): 559-565+571 (in Chinese). doi: 10.3969/j.issn.1007-9629.2014.04.001 [12] 林东野. SAP再生混凝土阻裂抗收缩性能研究[D]. 沈阳: 沈阳建筑大学, 2021.LIN Dongye. Study on crack resistance and shrinkage resistance of SAP recycled concrete [D]. Shenyang: Shenyang Jianzhu University, 2021(in Chinese). [13] 孙浩洋, 张秀芝, 陶文宏, 等. 碱激发泡沫混凝土干燥收缩影响因素及其抑制方法研究进展[J]. 复合材料学报, 2024, 41(2): 609-624.SUN Haoyang, ZHANG Xiuzhi, TAO Wenhong, et al. Research progress on influencing factors and inhibition methods of drying shrinkage of alkali-activated foam concrete[J]. Journal of Composite Materials, 2024, 41(2): 609-624(in Chinese). [14] 于本田, 陈延飞, 王焕, 等. 大掺量高吸附性石粉高强机制砂混凝土收缩开裂抑制试验[J]. 复合材料学报, 2021, 38(8): 2737-2746.YU Bentian, CHEN Yanfei, WANG Huan, et al. Shrinkage and cracking inhibition test of high-strength machine-made sand concrete with large content and high adsorption stone powder[J]. Journal of Composite Materials, 2021, 38(8): 2737-2746(in Chinese). [15] LIU K, LONG Y, CHEN L, et al. Mechanisms of autogenous shrinkage for Ultra-High Performance Concrete (UHPC) prepared with pre-wet porous fine aggregate (PFA)[J]. Journal of Building Engineering, 2022, 54: 104622. doi: 10.1016/j.jobe.2022.104622 [16] TUTKUN B, BARLAY E S, YALÇINKAYA Ç, et al. Effect of internal curing on shrinkage and cracking potential under autogenous and drying conditions[J]. Construction and Building Materials, 2023, 409: 134078. doi: 10.1016/j.conbuildmat.2023.134078 [17] 韩宇栋, 张君, 王振波. 预吸水轻骨料对高强混凝土早期收缩的影响[J]. 硅酸盐学报, 2013, 41(8): 1070-1078. doi: 10.7521/j.issn.0454-5648.2013.08.08HAN Yudong, ZHANG Jun, WANG Zhenbo. Effect of pre-absorbent lightweight aggregate on early shrinkage of high-strength concrete[J]. Chinese Journal of Ceramics, 2013, 41(8): 1070-1078(in Chinese). doi: 10.7521/j.issn.0454-5648.2013.08.08 [18] SHEN D, WEN C, ZHU P, et al. Influence of Barchip fiber on early-age autogenous shrinkage of high strength concrete[J]. Construction and Building Materials, 2020, 256: 119223. doi: 10.1016/j.conbuildmat.2020.119223 [19] INOZEMTCEV A, KOROLEV E, DUONG T Q. Lightweight concrete for 3D-printing with internal curing agent for Portland cement hydration[J]. Magazine of Civil Engineering, 2022, 109(1): 10915. [20] KUDYAKOV A I, STESHENKO A B. Shrinkage deformation of cement foam concrete[J]. IOP Conference Series: Materials Science and Engineering, 2015, 71: 012019. doi: 10.1088/1757-899X/71/1/012019 [21] MAMUN M, BINDIGANAVILE V. Sulphate resistance of fibre reinforced cement-based foams[J]. Construction and Building Materials, 2011, 25(8): 3427-3442. doi: 10.1016/j.conbuildmat.2011.03.034 [22] 詹炳根, 郭建雷, 林兴胜. 玻璃纤维增强泡沫混凝土性能试验研究[J]. 合肥工业大学学报: 自然科学版, 2009, 32(2): 226-229.ZHANBinggen, GUO Jianlei, LIN Xingsheng. Properties of foamed concrete with fiber glass reinforcement[J]. Journal of Hefei University of Technology(Natural Science), 2009, 32(2): 226-229(in Chinese). [23] YAO Y, ZHU Y, YANG Y Z. Incorporation superabsorbent polymer (SAP) particles as controlling pre-existing flaws to improve the performance of engineered cementitious composites (ECC)[J]. Construction and Building Materials, 2012, 28(1): 139-145. doi: 10.1016/j.conbuildmat.2011.08.032 [24] KIM IS, CHOI SY, CHOI Y S, et al. Effect of Internal Pores Formed by a Super absorbent polymer on durability and drying shrinkage of concrete specimens[J]. Materials, 2021, 14(18): 5199-5199. doi: 10.3390/ma14185199 [25] GONG J Q, ZENG W, ZHANG W J. Influence of shrinkage-reducing agent and polypropylene fiber on shrinkage of ceramsite concrete[J]. Construction and Building Materials, 2018, 159: 155-163. doi: 10.1016/j.conbuildmat.2017.10.064 [26] KARAHAN O, ATIS C D. The durability properties of polypropylene fiber reinforced fly ash concrete[J]. Materials and Design, 2011, 32(2): 1044-1049. doi: 10.1016/j.matdes.2010.07.011 [27] 周梅, 浦倍超, 徐秒, 等. 附加水及预湿时间对自燃煤矸石砂轻混凝土性能影响[J]. 硅酸盐通报, 2013, 32(12): 2421-2426.ZHOU Mei, PU Beichao, XU Miao, et al. Effect of additional water and pre-wetting time on performance of light concrete with coal gangue sand from spontaneous combustion[J]. Bulletin of Silicate, 2013, 32(12): 2421-2426(in Chinese). [28] 中华人民共和国住房和城乡建设部. 普通混凝土长期性能和耐久性能试验方法标准: GB/T 50082−2009[S]. 北京: 中国建筑工业出版社, 2009Ministry of Housing and Urban-Rural Development of the People's Republic of China. Standard for test methods of long-term performance and durability of ordinary concrete: GB/T 50082−2009[S]. Beijing: China State Engineering and Construction Press, 2009(in Chinese). [29] 黄嘉钰, 刘元珍, 王朝旭, 等. 保温混凝土内部湿度与干燥收缩预测模型[J]. 复合材料学报, 2022, 39(10): 4788-4800.HUANG Jiayu, LIU Yuanzhen, WANG Zhaoxu, et al. Prediction model of internal humidity and drying shrinkage of insulated concrete[J]. Journal of Composite Materials, 2022, 39(10): 4788-4800(in Chinese). [30] ZHONG P H, WYRZYKOWSKI M, TOROPOVS N, et al. Internal curing with super absorbent polymers of different chemical structures[J]. Cement and Concrete Research, 2019, 123: 105789. doi: 10.1016/j.cemconres.2019.105789 [31] 李丹丹, 惠存, 王文迪, 等. 纤维增强流动性再生混凝土强度和收缩性能试验研究[J]. 混凝土与水泥制品, 2019, (3): 5-59.LIDandan, HUI Cun, WANG Wendi, et al. Experimental study on strength and shrinkage performance of fiber reinforced flow recycled concrete[J]. Concrete and Cement Products, 2019, (3): 5-59(in Chinese). [32] 吕兴栋, 刘战鳌, 董芸. 内养护材料高吸水树脂(SAP)和陶粒对混凝土性能影响的对比研究[J]. 硅酸盐通报, 2019, 38(1): 246-252.LV Xingdong, LIU Zhanao, DONG Yun. Comparative study on the influence of internal curing material SAP and ceramite on the performance of concrete[J]. Bulletin of Silicate, 2019, 38(1): 246-252(in Chinese). [33] LIU J H, SHI C J, MA X W, et al. An overview on the effect of internal curing on shrinkage of high performance cement-based materials[J]. Construction and Building Materials, 2017, 146: 702-712. doi: 10.1016/j.conbuildmat.2017.04.154 [34] 陈德鹏, 钱春香, 高桂波, 等. 高吸水树脂对混凝土收缩开裂的改善作用及其机理[J]. 功能材料, 2007, (3): 475-478. doi: 10.3321/j.issn:1001-9731.2007.03.039CHEN Depeng, QIAN Chunxiang, GAO Guibo, et al. Effect of hyper absorbent resin on shrinkage cracking of concrete and its mechanism[J]. Functional Materials, 2007, (3): 475-478(in Chinese). doi: 10.3321/j.issn:1001-9731.2007.03.039 [35] BENTZ D P, WEISS W J. Internal curing: a 2010 state-of-the-art review[M]. Gaithersburg: US Department of Commerce, National Institute of Standards and Technology, 2011: 3. [36] 王宝. 聚丙烯粗纤维混凝土性能试验研究[D]. 哈尔滨: 哈尔滨工业大学, 2015.WANG Bao. Experimental study on performance of polypropylene crude fiber concrete [D]. Harbin: Harbin Institute of Technology, 2015(in Chinese) . [37] HSIE M, TU C, SONG P S. Mechanical properties of polypropylene hybrid fiber-reinforced concrete[J]. Materials Science and Engineering: A, 2008, 494(1-2): 153-157. doi: 10.1016/j.msea.2008.05.037 [38] 薛志超, 李林. 聚丙烯纤维对路用混凝土强度及收缩性能的影响[J]. 建筑材料学报, 2011, 14(1): 132-135. doi: 10.3969/j.issn.1007-9629.2011.01.026XUE Zhichao, LI Lin. Effect of polypropylene fiber on strength and shrinkage properties of road concrete[J]. Journal of Building Materials, 2011, 14(1): 132-135(in Chinese). doi: 10.3969/j.issn.1007-9629.2011.01.026 [39] ZHANG H, WANG Y Y, LEHUMAN D E, et al. Time-dependent drying shrinkage model for concrete with coarse ang fine recycled aggregate[J]. Cement and Concrete Composites, 2020, 105; 103426. [40] 肖黾. 减缩剂与高吸水树脂对高性能混凝土收缩性能的影响研究[D]. 湖南: 湖南大学, 2016.XIAO Mian. Study on the influence of reducing agent and high absorbent resin on shrinkage performance of high performance concrete [D]. Hunan: Hunan University, 2016(in Chinese) [41] SHEN D J, WANG M L, CHEN Ying, et al. Prediction model for relative humidity of early-age internally cured concrete with pre-wetted lightweight aggregates[J]. Construction and Building Materials, 2017, 144: 717-727. doi: 10.1016/j.conbuildmat.2017.03.088 [42] LE R, DE LARRARD F, PONS G. The AFREM code type model for creep and shrinkag of high-performance concrete[C]//Proceedings of the 4th International Symposium on Utilization of High-strength/Highperformance Concrete. Paris: Proceedings, 1996, 1: 387-396. [43] Fib model code for concrete structures 2010[S]. London: International Federation for Structural Concrete, 2013. [44] Guide for modeling and calculating shrinkage and creep in hardened concrete [S]. Farmington Hills: American Concrete Institute, 2008, 209: 76. [45] BSEN1992-1-1: 2004 Eurocode2: Design of concrete structrues -Part1-1: General rules and rules for buildings [S]. London: British Stardands Institution, 2004, 1(1): 230. [46] 肖雯雯. 考虑龄期影响的钢管高性能混凝土长期性能研究 [D]. 哈尔滨: 哈尔滨工业大学, 2008.XIAO Wenwen. Study on long-term performance of steel tubular high performance concrete considering age effect [D]. Harbin: Harbin Institute of Technology, 2008(in Chinese). [47] 张欢, 王玉银, 耿悦, 等. 考虑基体混凝土抗压强度影响的再生粗(细)骨料混凝土干燥收缩模型[J]. 建筑结构学报, 2020, 41(12): 156-164.ZHANG Huan, WANG Yuyin, GENG Yue, et al. Drying shrinkage model of reclaimed coarse (fine) aggregate concrete considering the influence of compressive strength of matrix concrete[J]. Journal of Building Structures, 2020, 41(12): 156-164(in Chinese). [48] 黄嘉钰. 骨料掺量和改性对再生保温混凝土干燥收缩性能影响的研究[D]. 太原: 太原理工大学, 2022.HUANG Jiayu. Study on effect of aggregate content and modification on dry shrinkage performance of recycled thermal insulation concrete [D]. Taiyuan: Taiyuan University of Technology, 2022(in Chinese). [49] MENG F S. Study on effects of admixture and shrinkage models on high-performance concrete[J]. Advanced Materials Research, 2011, 168: 1073-1076. [50] 杜伟良. 高延性混凝土早期收缩性能及收缩模型研究[D]. 西安: 西安建筑科技大学, 2016.DU Weiliang. Studyon early shrinkage performance and shrinkage model of high ductility concrete [D]. Xi’an: Xi’an University of Architecture and Technology, 2016(in Chinese). -

点击查看大图

点击查看大图

计量

- 文章访问数: 56

- HTML全文浏览量: 34

- 被引次数: 0

下载:

下载: