Effect of elevated temperature on failure behavior of hybrid bolted-bonded joints in composite structures

-

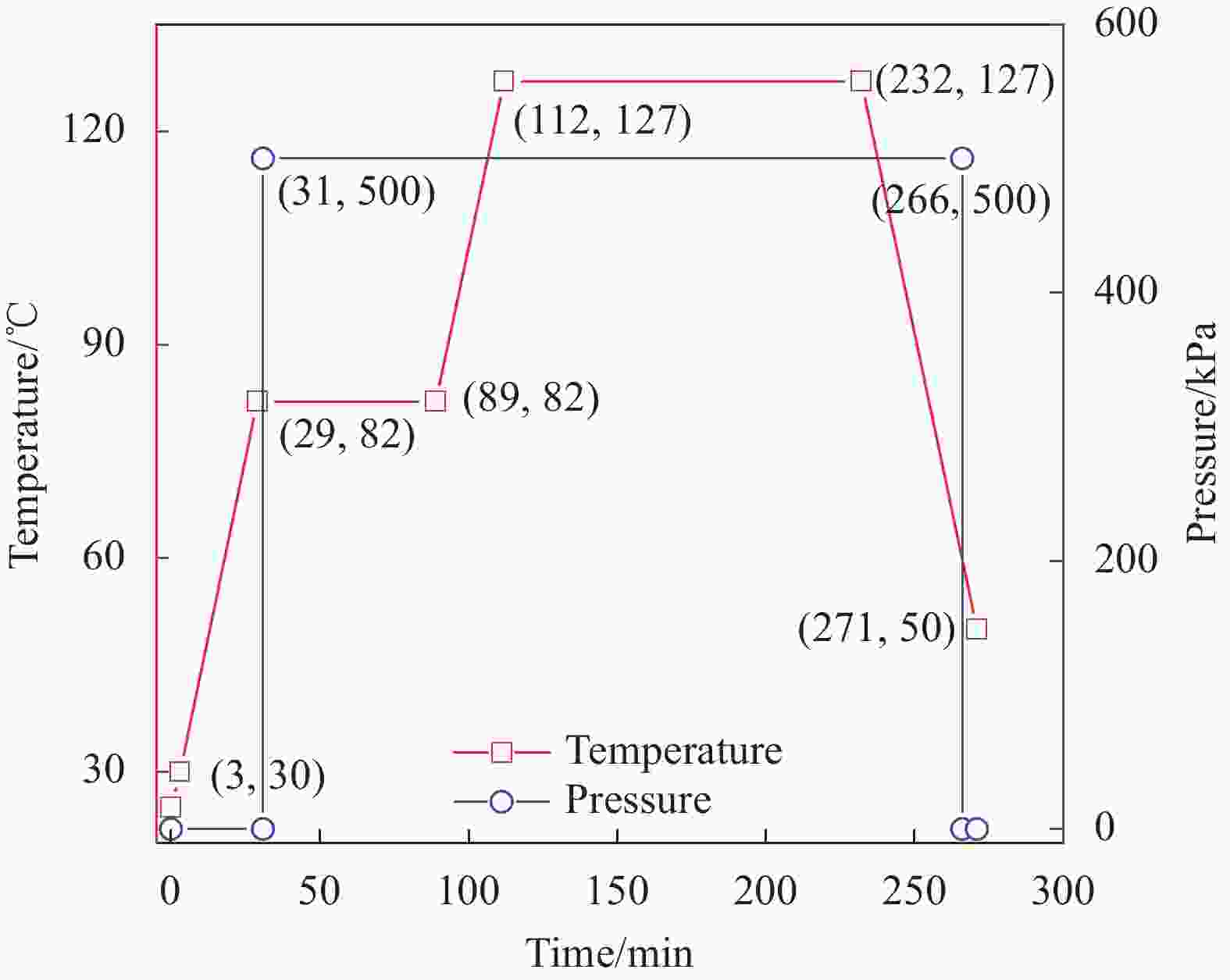

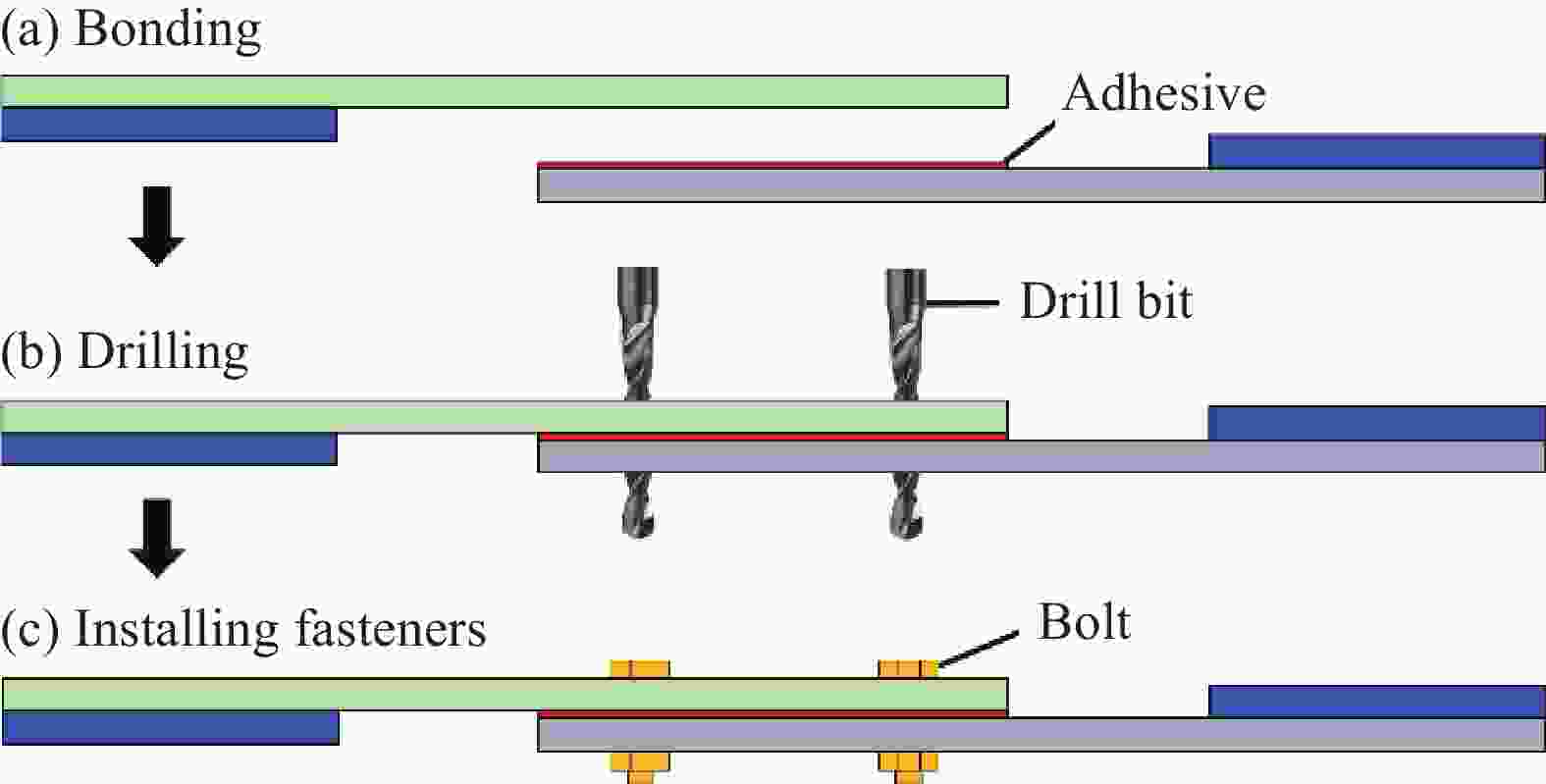

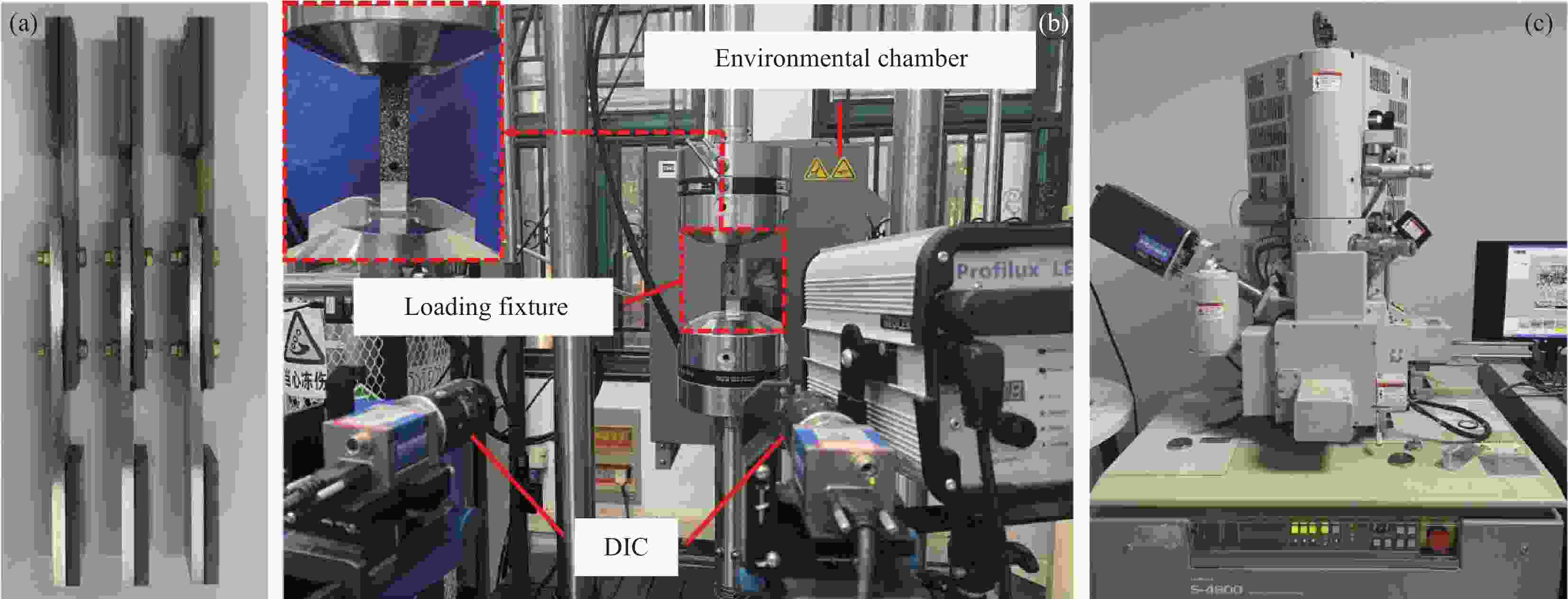

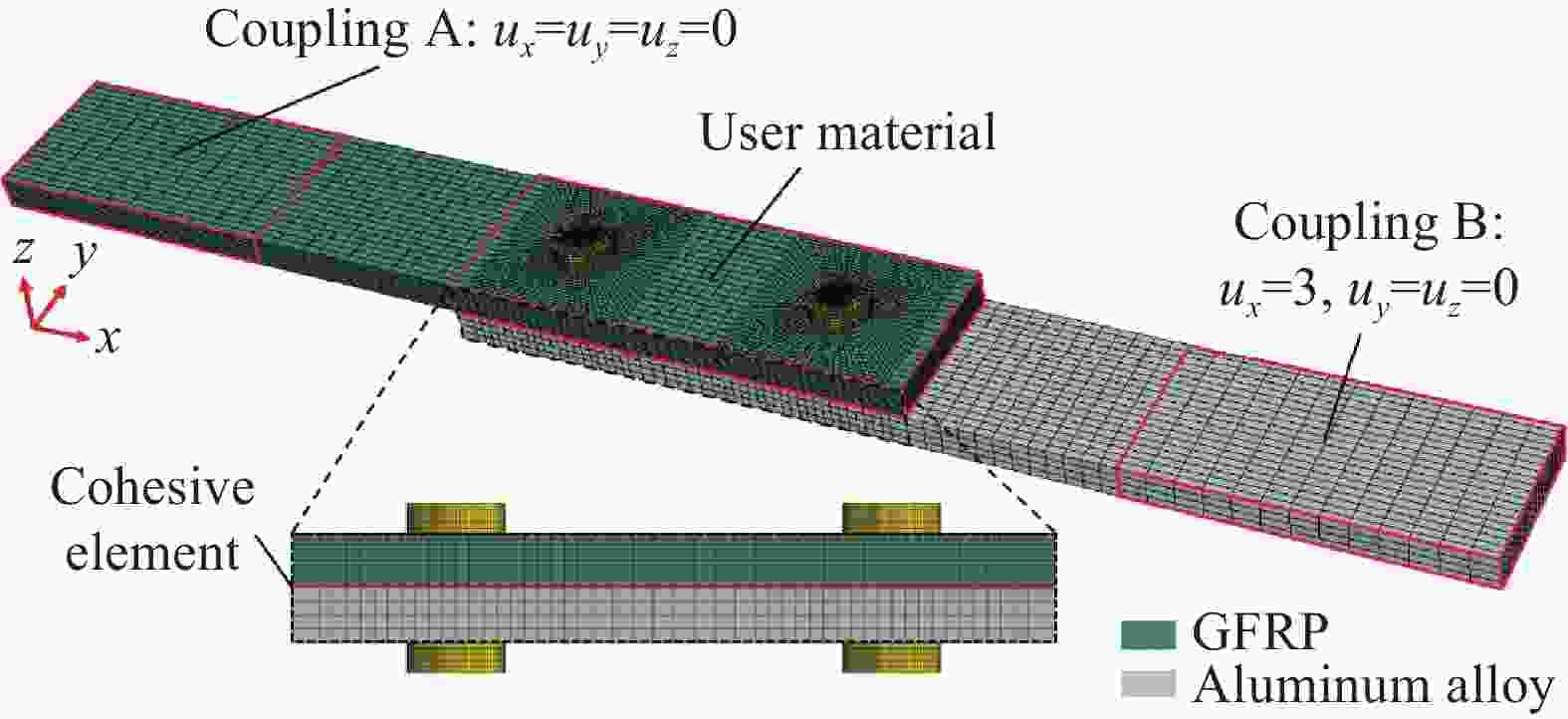

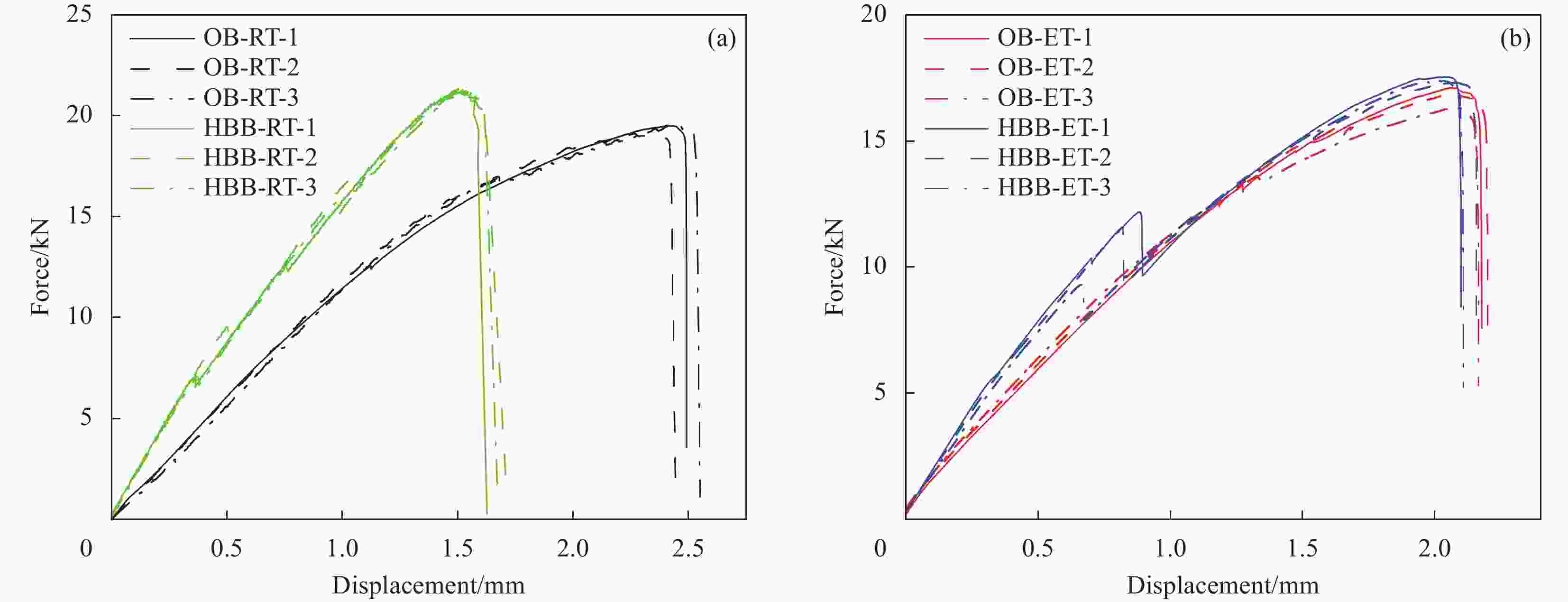

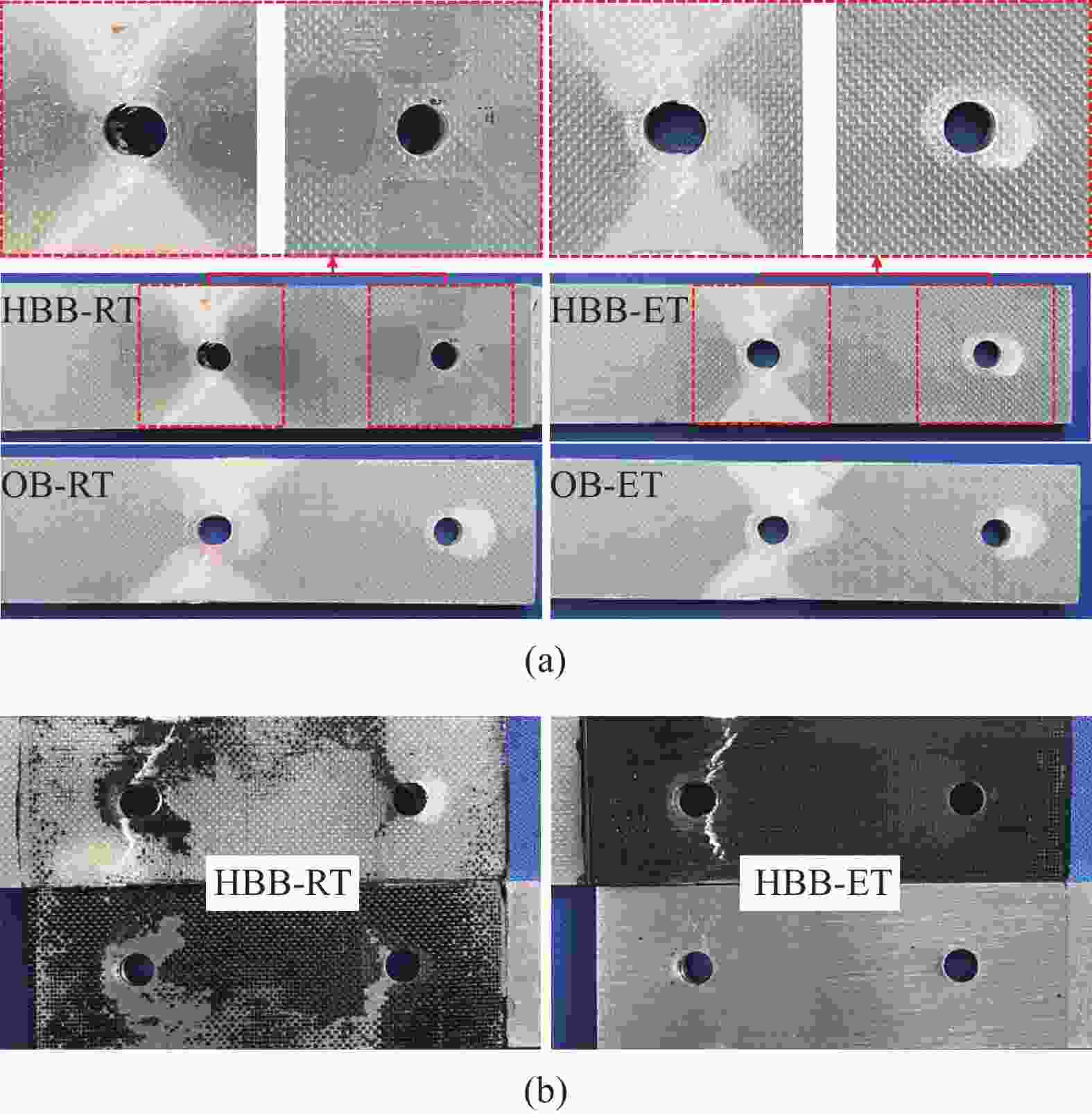

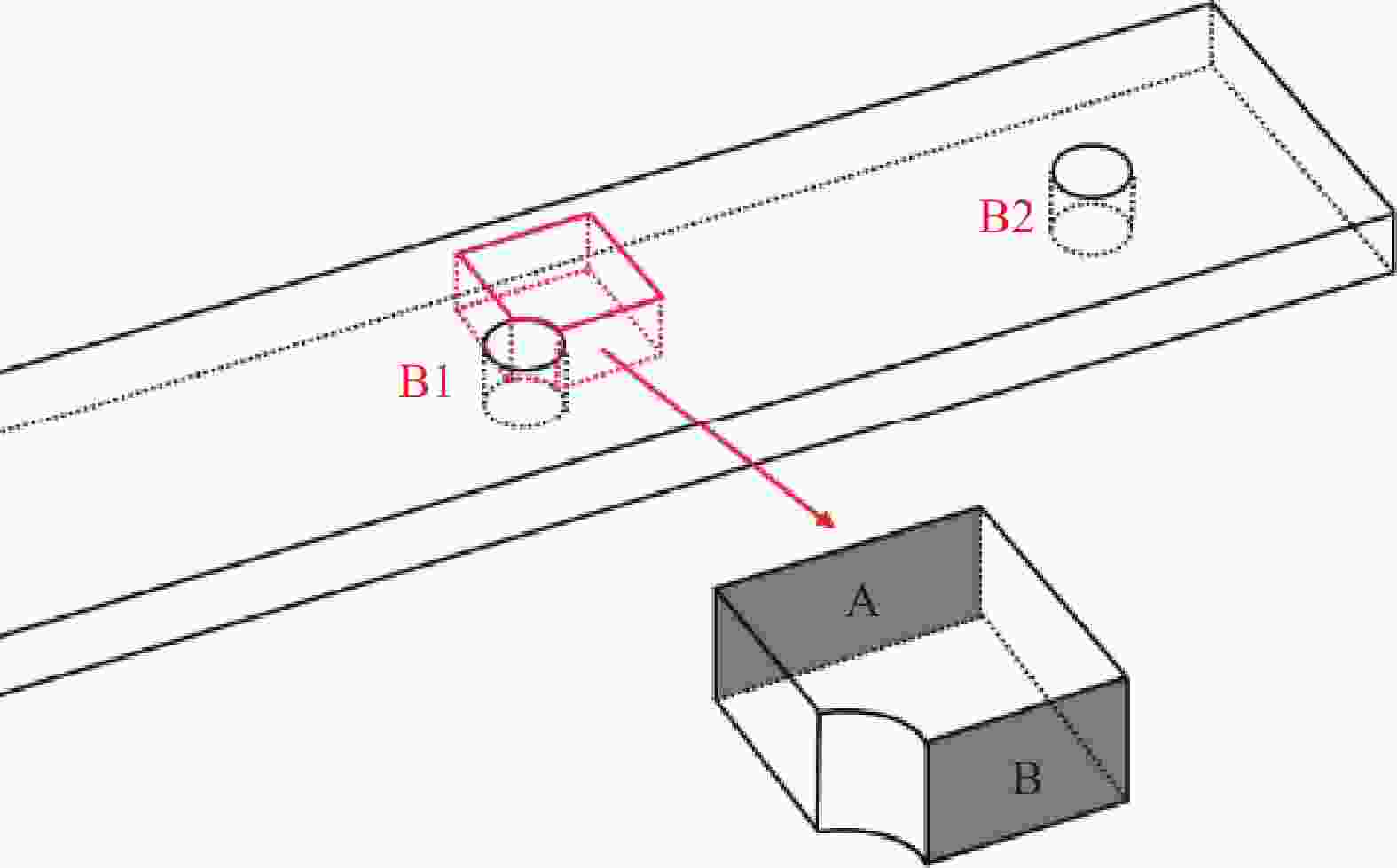

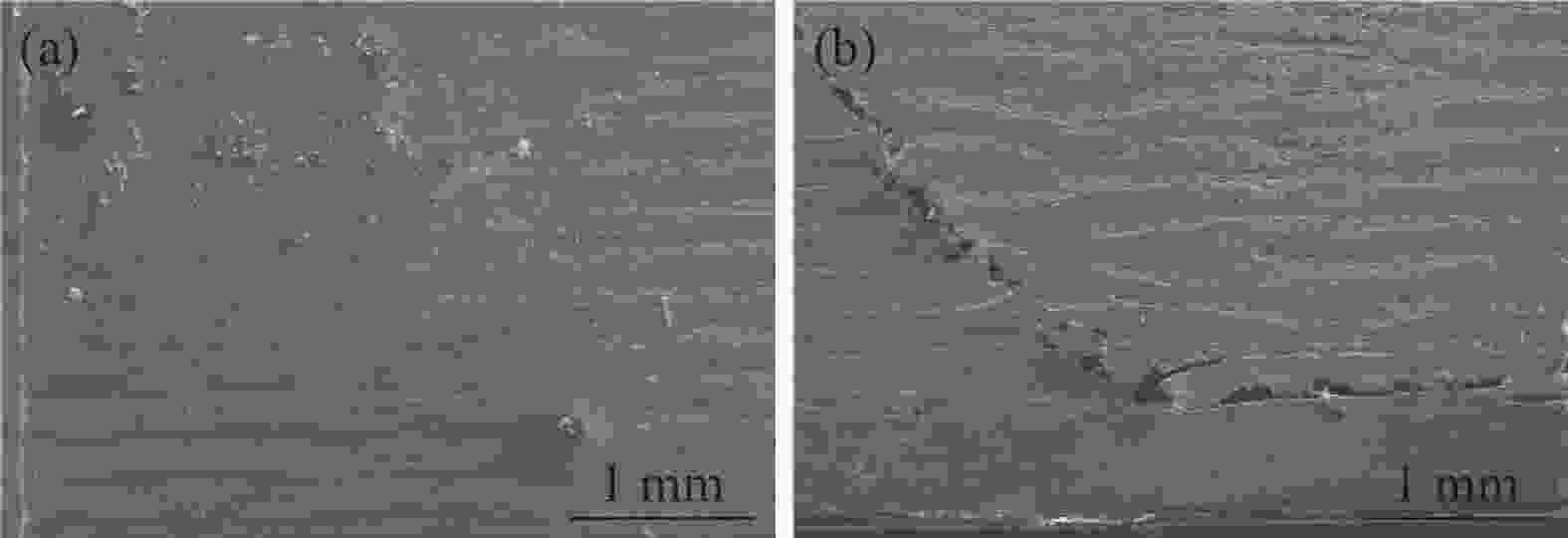

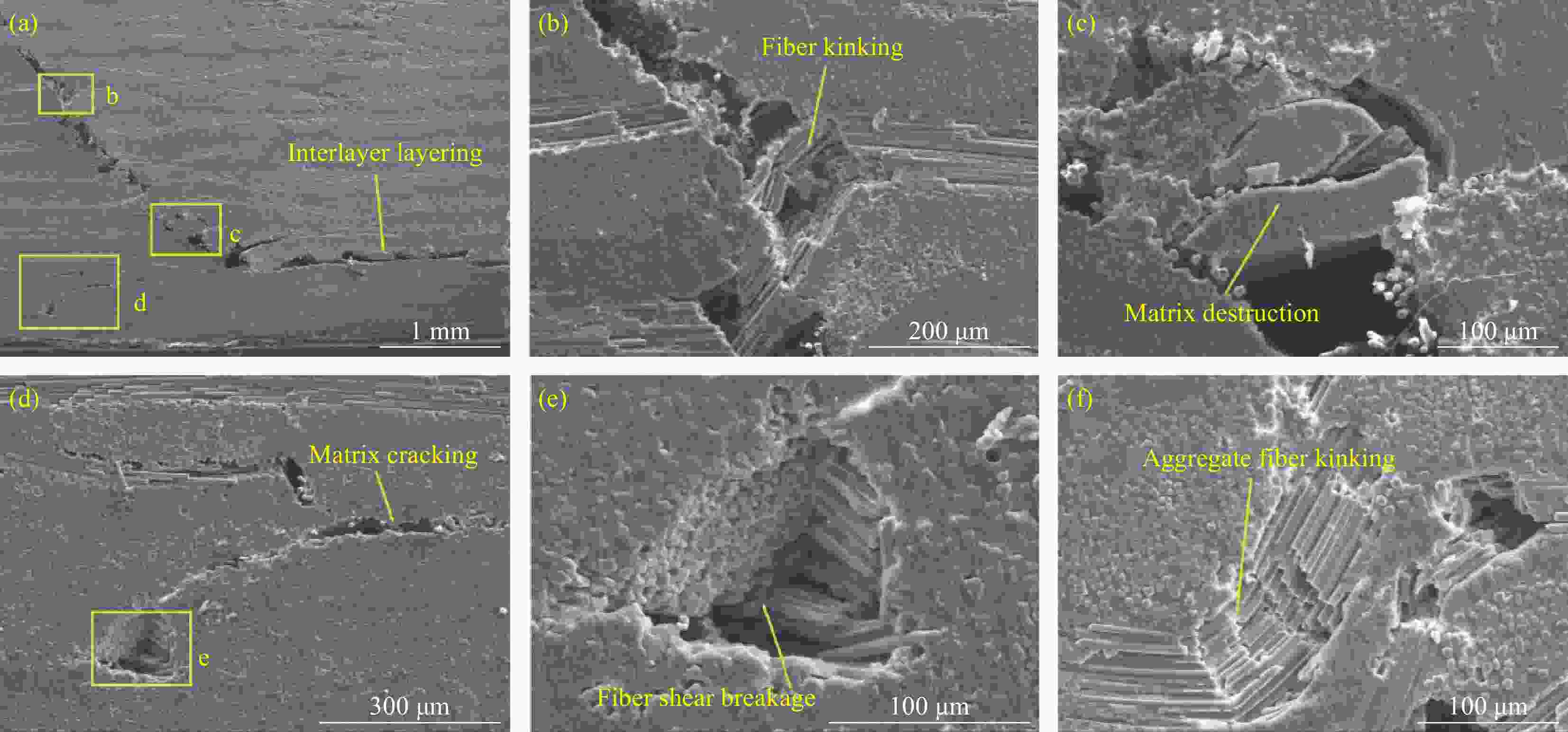

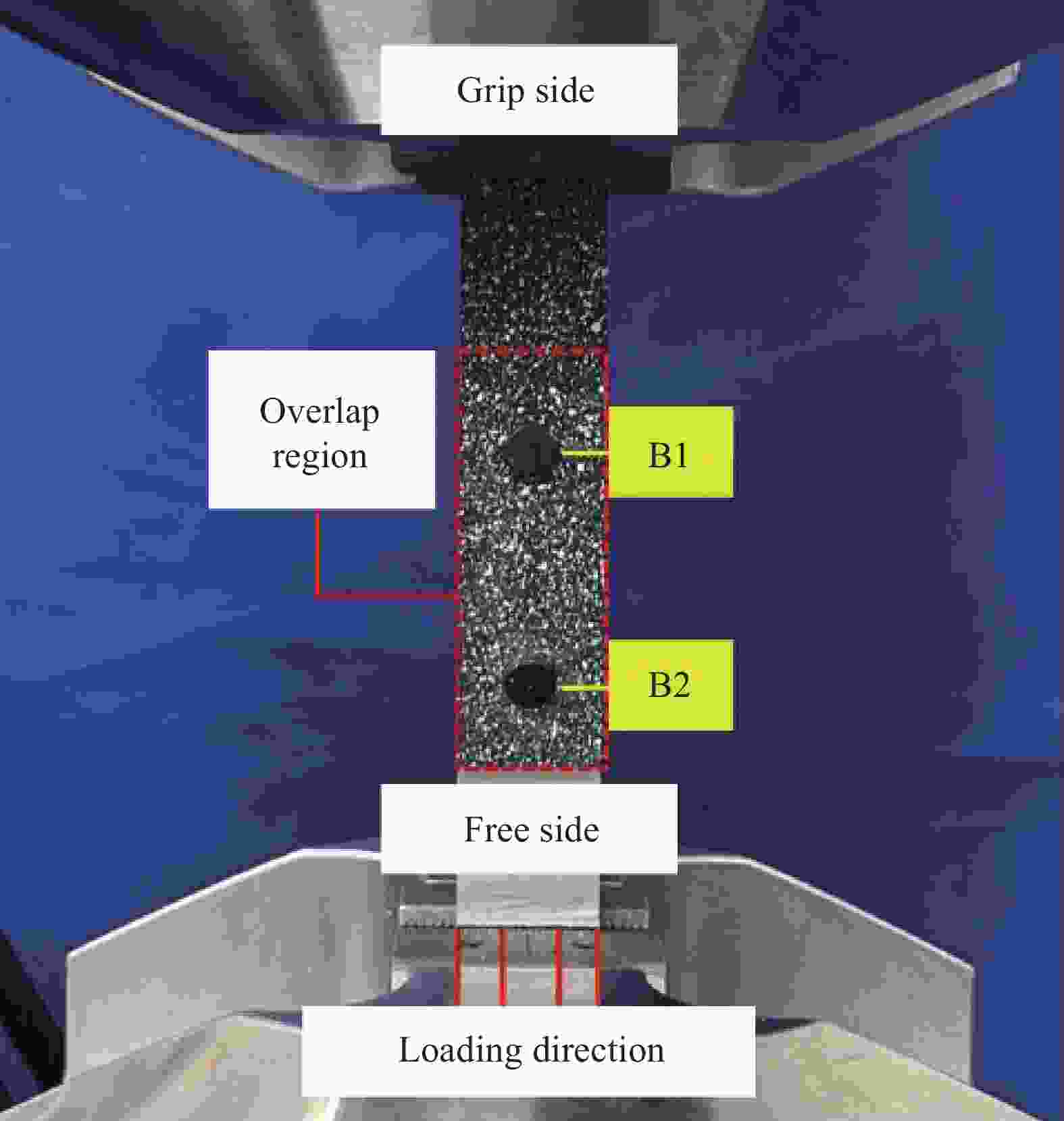

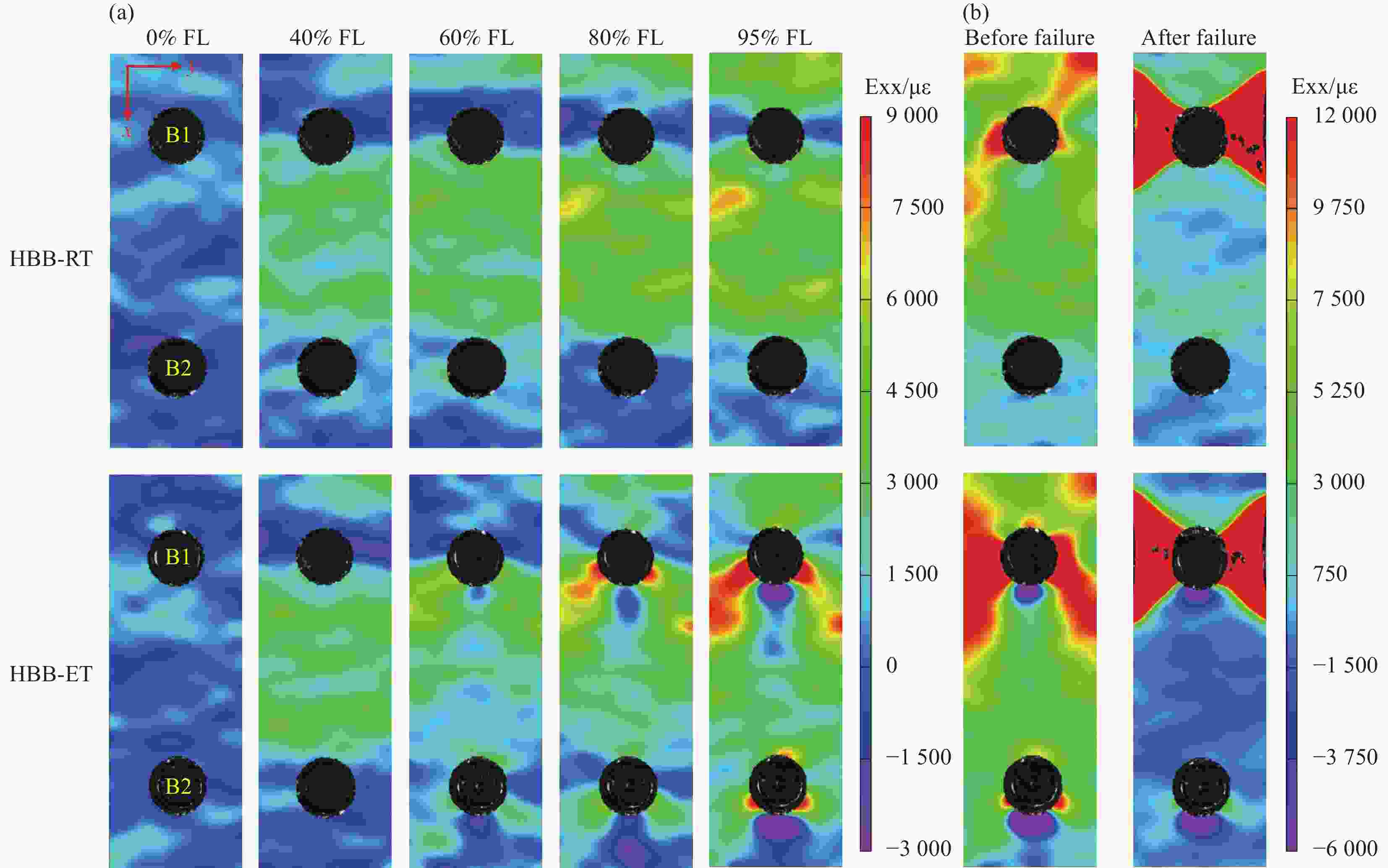

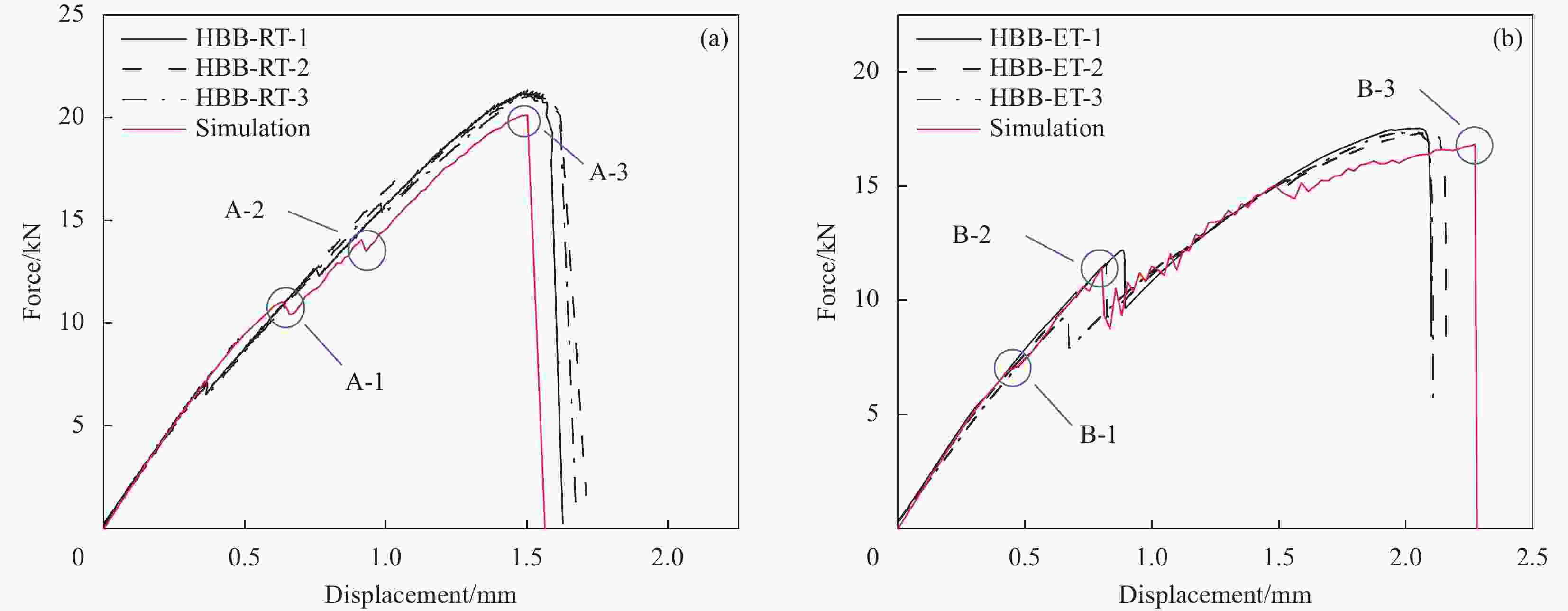

摘要: 采用试验与仿真相结合的方法,对高温环境下GFRP平纹编织层合板-铝合金双钉单搭接胶螺混合连接结构的载荷传递机制和失效模式展开探究。试验方面,开展了80℃高温环境下胶螺混合连接结构的拉伸破坏试验,并与室温胶螺混合连接、高温纯螺栓连接和室温纯螺栓连接三组工况进行对比分析;借助3D-DIC和SEM等手段对结构的宏观和微观的失效特征进行表征。数值仿真方面,构建了基于LaRC失效准则的复合材料渐进损伤失效模型,插入内聚力单元用于对胶粘剂的模拟。结果表明,胶螺混合连接在常温和高温时的极限载荷比纯螺栓连接分别提高了9.2%和4.0%,但高温环境会使胶螺混合连接试样的极限载荷值下降17.8%;胶螺混合连接在加载前期可以缓解应力集中现象,但温度载荷导致粘合剂提前失效后表面出现明显的应力集中,最终失效除了常温环境中发生的静截面拉伸破坏,还发生了由于轴承效应导致的挤压破坏,此时失效模式与纯螺栓连接一致;构建的数值仿真模型可以准确预测结构的失效模式和演化过程,对胶螺混合连接结构的载荷传递机制和失效规律进行解析。

-

关键词:

- 复合材料-铝合金混合结构 /

- 胶螺混合连接 /

- 温度-机械载荷 /

- 载荷传递机制 /

- 失效模式

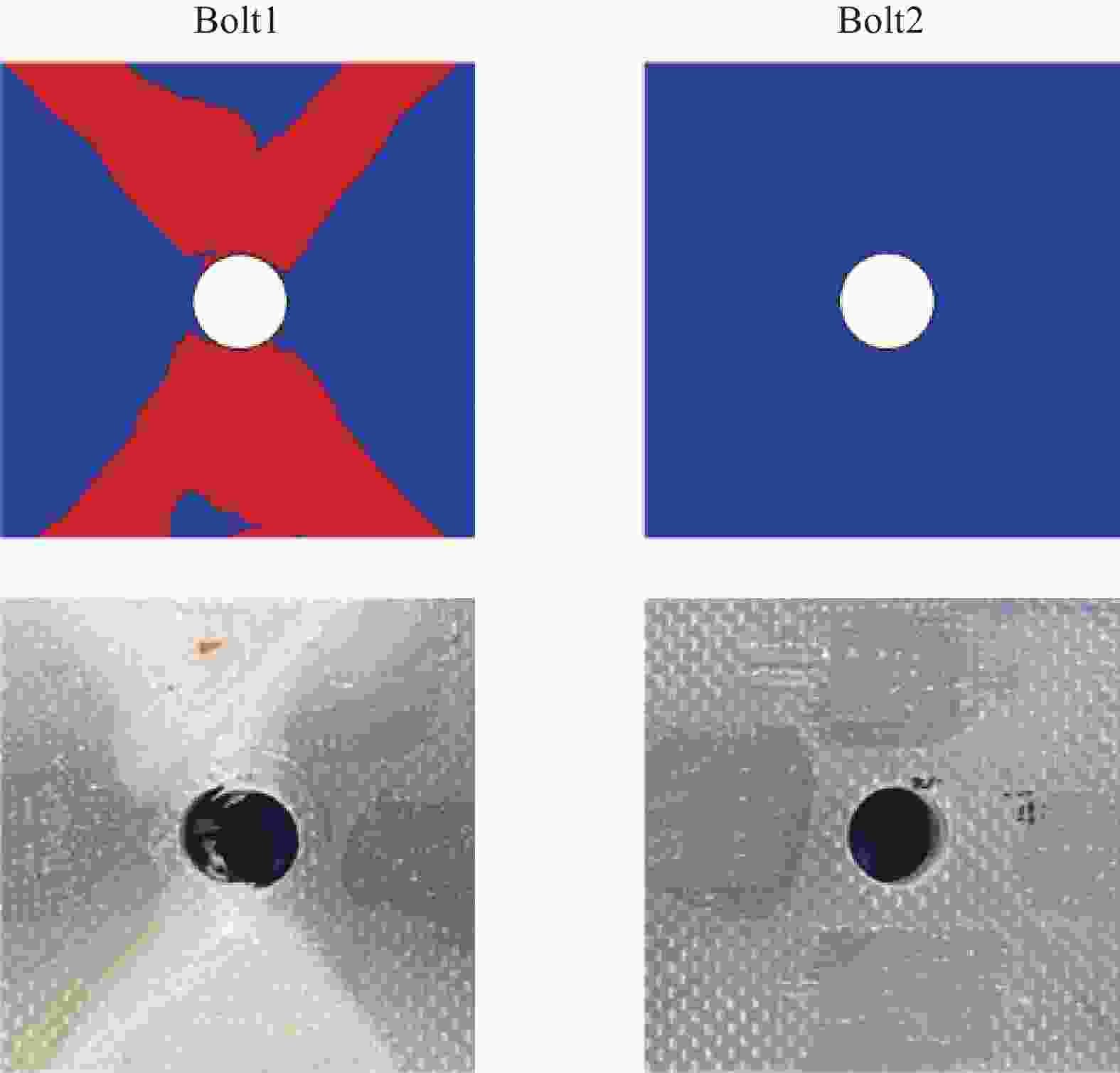

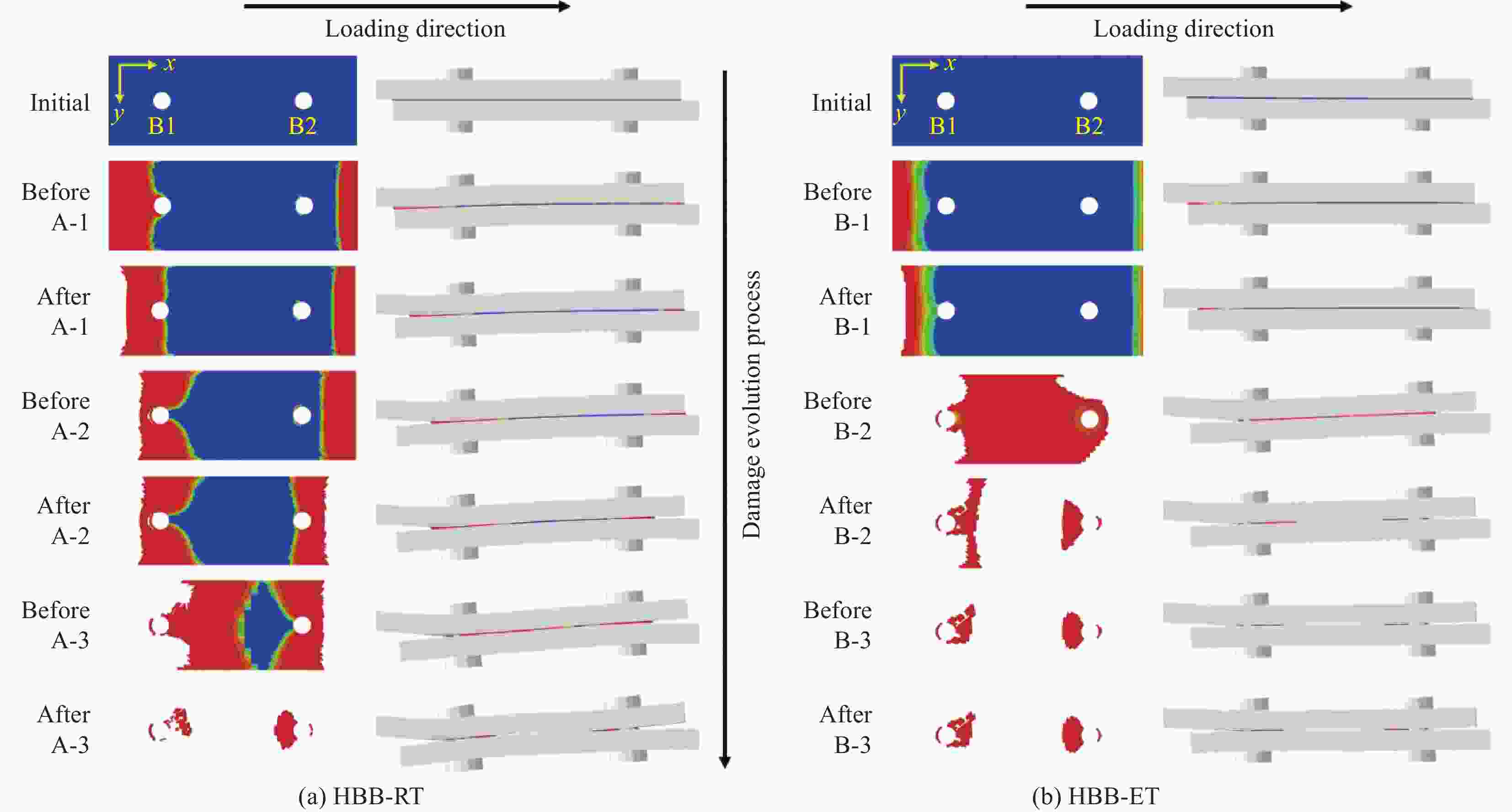

Abstract: Experiments and simulations were conducted to investigate the load transfer mechanism and failure modes of a double-bolt single-lap hybrid bolted-bonded joint between GFRP plain weave laminates and an aluminum alloy plane under high-temperature conditions. The experimental aspect involved conducting tensile failure tests on hybrid bolted-bonded joints under high-temperature conditions of 80℃, and comparing them with three other working conditions: hybrid bolted-bonded joints at room temperature, high-temperature bolted joints, and room temperature bolted joints. Failure characteristics at macroscopic and microscopic scales of the hybrid jointed structure were characterized by means of 3D-DIC and SEM. The numerical simulation involved the development of a progressive damage failure model based on the LaRC failure criterion to accurately depict the evolution of in-plane failures. Additionally, cohesive elements were incorporated between plies to effectively simulate delamination behavior. The results indicate that the hybrid bolted-bonded joint exhibits an increase in ultimate load capacity compared to a bolt-ed joint at both room temperature and elevated temperature, with enhancements of 9.2% and 4.0%, respectively. However, it is noteworthy that the ultimate load capacity of the hybrid bolted-bonded joint specimens is reduced by 17.8% in the elevated temperature environment. The hybrid bolted-bonded joint mitigates stress concentration phenomena during the early stages of loading. However, noticeable stress concentrations occur on the surface under temperature-induced loading after premature adhesive failure. The ultimate failure modes include not only the static cross-sectional tensile failure observed in ambient conditions but also compression failure induced by bearing effects. In this scenario, the failure mode aligns with that of a pure bolted connection. The developed numerical simulation model can accurately predict the failure modes and evolution process of the structure, enabling a comprehensive analysis of the load transfer mechanism and failure patterns in hybrid bolted-bonded joint structures. -

表 1 拉伸试验工况统计表

Table 1. Statistical table of tensile test conditions

No. Specimen

GroupTesting

Temperature/℃Joint

types1 HBB-ET 80 HBB 2 HBB-RT 25 HBB 3 OB-ET 80 OB 4 OB-RT 25 OB Notes: HBB-Hybrid bolted-bonded; OB-Only bolted; ET-Elevated temperature; RT-Room temperature. 表 2 铝合金2024-T4及ML30Cr-MaSiA结构钢螺栓的材料参数

Table 2. Mechanical properties of aluminum 2024-T4 and ML30Cr-MaSiA steel bolt

Property Aluminum 2024-T4 Bolt (Steel) Temperature/℃ 25 80 25 80 Density/(g·cm−3) 2.78 7.85 Young modulus/GPa 73.1 68.0 210.3 204.0 Poisson’s ratio 0.33 0.30 Yield strength/MPa 385.0 355.0 940.0 895.0 Ultimate strength/MPa 483.0 453.0 1090.0 1040.0 CTE/×10−6/℃ 20.08 9.96 Note: CTE-Coefficient of thermal expansion. 表 3 ACTECH®1203/EW301F/38平纹编织GFRP复合材料及DP-490胶粘剂的材料参数

Table 3. Mechanical properties of ACTECH®1203/EW301F/38 plain weave GFRP composite and DP-490 adhesive

Properties at 25℃ Properties at 80℃ GFRP solid

elementDensity/(g·cm−3) 1.52 Module/GPa E11=E22=24.5, E33=5.8,

G12=3.1, G13=G23=2.3E11=E22=23.2, E33=5.3,

G12=2.9, G13=G23=2.1Strength/MPa XT=YT=464.0,

XC= YC=456.0,

S=55.1XT=YT=392.0,

XC= YC=328.0,

S=37.8Poison radio v12=0.12, v13=v23=0.09 CTE/×10−6/℃ α1=α2=12.6, α3=1 Adhesive

cohesive

elementDensity/(g·cm−3) 1.52 Strength/MPa tn=14.6, ts=tt=27.5 tn=7.4, ts=tt=12.5 Fracture energy/(N·mm−1) GIC=0.325, GIIC=1.922 GIC=0.149, GIIC=0.209 Note: E−Elastic modulus; v −Poisson’s ratio; G−Shear modulus; 1−Direction of fiber; 2−Direction of matrix; 3−Thickness direction of layer; XT−Longitudinal tensile strength; XC−Longitudinal compressive strength; YT−Transverse tensile strength; YC−Transverse compressive strength; S−In-plane shear strength; tn−Normal strength of cohesive; ts, tt−Tangential strength of cohesive; GIC, GIIC −Critical value of strain energy release rate. -

[1] 蔡启阳, 赵琪. 环境温度和间隙对复合材料-金属混合结构机械连接钉载分配的影响[J]. 复合材料学报, 2021, 38(12): 4228-4238.CAI Qiyang, ZHAO Qi. Effects of temperature and clearance fit on the load distribution of composite-metal hybrid structures[J]. Acta Materiae Compositae Sinica, 2021, 38(12): 4228-4238(in Chinese). [2] LI X, TAN Z, WANG L, et al. Experimental investigations of bolted, adhesively bonded and hybrid bolted/bonded single-lap joints in composite laminates[J]. Materials Today Communications, 2020, 24: 101244. doi: 10.1016/j.mtcomm.2020.101244 [3] 曹跃杰, 魏凌峰, 张铭豪, 等. 薄层复合材料螺栓连接结构渐进失效机制试验研究[J]. 航空学报, 2021, 42(12): 311-326.CAO Yuejie, WEI Lingfeng, ZHANG Minghao, et al. Experimental study on progressive failure mechanism of thin-laminate bolted joints[J]. Acta Aeronautica et Astronautica Sinica, 2021, 42(12): 311-326(in Chinese). [4] 何柏灵, 葛东云, 莫与明, 等. T800碳纤维增强复合材料双剪单钉连接的拉伸试验及强度估算[J]. 复合材料学报, 2016, 33(7): 1540-1552.HE Bailing, GE Dongyun, MO Yuming, et al. Tensile tests and strength estimation for double-lap single-bolt joints in T800 carbon fiber reinforced composites[J]. Acta Materiae Compositae Sinica, 2016, 33(7): 1540-1552(in Chinese). [5] JIANG Z, WAN S, FANG Z, et al. Static and fatigue behaviours of a bolted GFRP/steel double lap joint[J]. Thin-Walled Structures, 2021, 158: 107170. doi: 10.1016/j.tws.2020.107170 [6] 刘志明, 许昶. 碳纤维增强环氧树脂复合材料与铝板胶螺混合连接接头失效仿真[J]. 复合材料学报, 2019, 36(10): 2308-2315.LIU Zhiming, XU Chang. Failure simulation of carbon fiber reinforced epoxy resin composite-aluminum bonded-bolted hybrid joint[J]. Acta Materiae Compositae Sinica, 2019, 36(10): 2308-2315(in Chinese). [7] 刘礼平, 段科好, 徐卓, 等. 碳纤维增强树脂基复合材料层合板胶螺混合连接失效机制[J]. 复合材料学报, 2023, 40(1): 590-600.LIU Liping, DUAN Kehao, XU Zhuo, et al. Failure mechanism of carbon fiber reinforced polymer bonded-bolted hybrid connection[J]. Acta Materiae Compositae Sinica, 2023, 40(1): 590-600(in Chinese). [8] 唐玉玲, 任煜赫, 张峻霞, 等. 胶层对复合材料多螺栓连接力学性能及钉载分配的影响[J]. 复合材料学报, 2023, 40(6): 3601-3612.TANG Yuling, REN Yuhe, ZHANG Junxia, et al. Effect of the adhesive layer on mechanical properties and load distribution in multi-bolt composite joints[J]. Acta Materiae Compositae Sinica, 2023, 40(6): 3601-3612(in Chinese). [9] TURVEY G J, SANA A. Pultruded GFRP double-lap single-bolt tension joints-Temperature effects on mean and characteristic failure stresses and knock-down factors[J]. Composite Structures, 2016, 153: 624-631. doi: 10.1016/j.compstruct.2016.06.016 [10] XUE C, YU M, YANG B, et al. Experimental and numerical study on tensile properties of bolted GFRP joints at high and low temperatures[J]. Composite Structures, 2022, 293: 115743. doi: 10.1016/j.compstruct.2022.115743 [11] SASIKUMAR A, GUERRERO J M, QUINTANAS-COROMINAS A, et al. Numerical study to understand thermo-mechanical effects on a composite-aluminium hybrid bolted joint[J]. Composite Structures, 2021, 275: 114396. doi: 10.1016/j.compstruct.2021.114396 [12] 张娇蕊, 山美娟, 黄伟, 等. 湿热环境对CFRP复合材料-铝合金螺栓连接结构静力失效的影响[J]. 复合材料学报, 2021, 38(7): 2224-2233.ZHANG Jiaorui, SHAN Meijuan, HUANG Wei, et al. Effects of hygrothermal environment on quasi-static failure of CFRP composite-aluminum alloy bolted joints[J]. Acta Materiae Compositae Sinica, 2021, 38(7): 2224-2233(in Chinese). [13] HU J, MI S, YANG Z, et al. An experimental investigation on bearing behavior and failure mechanism of bolted composite interference-fit joints under thermal effects[J]. Engineering Failure Analysis, 2022, 131: 105830. doi: 10.1016/j.engfailanal.2021.105830 [14] SHAN M, ZHANG R, GONG Y, et al. Revealing the coupled effects of hygrothermal environment and geometrical parameters on the failure of double-lap, single-bolt composite joints[J]. Journal of Materials Research and Technology, 2023, 24: 8282-8295. doi: 10.1016/j.jmrt.2023.05.071 [15] 王东, 董传瑞, 朱红民, 等. 温度对金属-复合材料混合多螺栓连接力学性能的影响[J]. 复合材料学报: 1-9[2024-03-06]. https://doi.org/10.13801/j.cnki.fhclxb.20231017.003.WANG Dong, DONG Chuanrui, ZHU Hongmin, et al. Effect of temperature on mechanical properties of metal-composite hybrid multi-bolt joint[J]. Acta Materiae Compositae Sinica, 1-9 [2024-03-06]. https://doi.org/10.13801/j.cnki.fhclxb.20231017.003 (in Chinese). [16] BUDHE S, BANEA M D, DE BARROS S, et al. An updated review of adhesively bonded joints in composite materials[J]. International Journal of Adhesion and Adhesives, 2017, 72: 30-42. doi: 10.1016/j.ijadhadh.2016.10.010 [17] BANEA M D, DE SOUSA F S M, DA SILVA L F M, et al. Effects of Temperature and Loading Rate on the Mechanical Properties of a High Temperature Epoxy Adhesive[J]. Journal of Adhesion Science and Technology, 2011, 25(18): 2461-2474. doi: 10.1163/016942411X580144 [18] BANEA M D, DA SILVA L F M, CAMPILHO R D S G. Effect of temperature on the shear strength of aluminium single lap bonded joints for high temperature applications[J]. Journal of Adhesion Science and Technology, 2014, 28(14-15): 1367-1381. doi: 10.1080/01694243.2012.697388 [19] BANEA M D, DA SILVA L F M. The effect of temperature on the mechanical properties of adhesives for the automotive industry[J]. Proceedings of the Institution of Mechanical Engineers Part L-Journal of Materials-Design and Applications, 2010, 224(L2): 51-62. [20] HIZAM R M, MENALO A C, KARUNASENA W, et al. Joint Strength of Single-Bolted Pultruded GFRP Square Hollow Sections with Mechanical Inserts under Elevated Temperatures[J]. Journal of Composites for Construction, 2020, 24(1): 04019056. doi: 10.1061/(ASCE)CC.1943-5614.0000984 [21] ZHANG H, SONG Z, ZHANG L, et al. Effects of hygrothermal ageing and temperature on the mechanical behavior of aluminum-CFRP hybrid (riveted/bonded) joints[J]. International Journal of Adhesion and Adhesives, 2023, 121: 103299. doi: 10.1016/j.ijadhadh.2022.103299 [22] ULUS H. An experimental assessment of hybrid bolted/bonded basalt fiber reinforced polymer composite joints' temperature-dependent mechanical performances by static and dynamic mechanical analyses[J]. International Journal of Adhesion and Adhesives, 2022, 114: 103120. doi: 10.1016/j.ijadhadh.2022.103120 [23] 张永杰, 孙秦. 复合材料层合板预紧螺栓连接应力分析[J]. 机械科学与技术, 2009, 28(7): 867-870. doi: 10.3321/j.issn:1003-8728.2009.07.006ZHANG Yongjie, SUN Qin. Stress Analysis of Composite Laminate Connected by Preloaded Bolt[J]. Mechanical Science and Technology for Aerospace Engineering, 2009, 28(7): 867-870(in Chinese). doi: 10.3321/j.issn:1003-8728.2009.07.006 [24] ASTM D3039/D3039M-17: Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials: [S]. West Conshohocken, PA: ASTM International, 2017. [25] ASTM D6641/D6641M-16: Standard Test Method for Compressive Properties of Polymer Matrix Composite Materials Using a Combined Loading Compression (CLC) Test Fixture: [S]. West Conshohocken, PA: ASTM International, 2016. [26] ASTM D3518/D3518M-18: Standard Test Method for In-Plane Shear Response of Polymer Matrix Composite Materials by Tensile Test of a ±45° Laminate: [S]. West Conshohocken, PA: ASTM International, 2018. [27] ASTM D5528/D5528M-13: Standard Test Method for Mode I Interlaminar Fracture Toughness of Unidirectional Fiber-Reinforced Polymer Matrix Composites: [S]. West Conshohocken, PA: ASTM International, 2013. [28] ASTM D7905/D7905M-19: Standard Test Method for Determination of the Mode II Interlaminar Fracture Toughness of Unidirectional Fiber-Reinforced Polymer Matrix Composites: [S]. West Conshohocken, PA: ASTM International, 2019. [29] PINHO S T, IANNUCCI L, ROBINSON P. Physically-based failure models and criteria for laminated fibre-reinforced composites with emphasis on fibre kinking: Part I: Development[J]. Composites Part A:Applied Science and Manufacturing, 2006, 37(1): 63-73. doi: 10.1016/j.compositesa.2005.04.016 [30] WANG X, WANG Y, JI Y, et al. Modeling Progressive Damage and Failure of Single-Lap ThinPly-Laminated Composite-Bolted Joint Using LaRC Failure Criterion[J]. Materials, 2022, 15(22): 8123. doi: 10.3390/ma15228123 [31] LIU D, CAO D, HU H, et al. Numerical study on failure behavior of open-hole composite laminates based on LaRC criterion and extended finite element method[J]. Journal of Mechanical Science and Technology, 2021, 35: 1037-1047. doi: 10.1007/s12206-021-0217-9 [32] CAO D, DUAN Q, HU H, et al. Computational investigation of both intra-laminar matrix cracking and inter-laminar delamination of curved composite components with cohesive elements[J]. Composite Structures, 2018, 192: 300-309. doi: 10.1016/j.compstruct.2018.02.072 [33] CAO D, HU H, DUAN Q, et al. Experimental and three-dimensional numerical investigation of matrix cracking and delamination interaction with edge effect of curved composite laminates[J]. Composite Structures, 2019, 225: 111154. doi: 10.1016/j.compstruct.2019.111154 -

点击查看大图

点击查看大图

计量

- 文章访问数: 117

- HTML全文浏览量: 74

- 被引次数: 0

下载:

下载: