Mechanical and temperature control properties of energy storage mortar based on bio-coating/phase change microcapsules

-

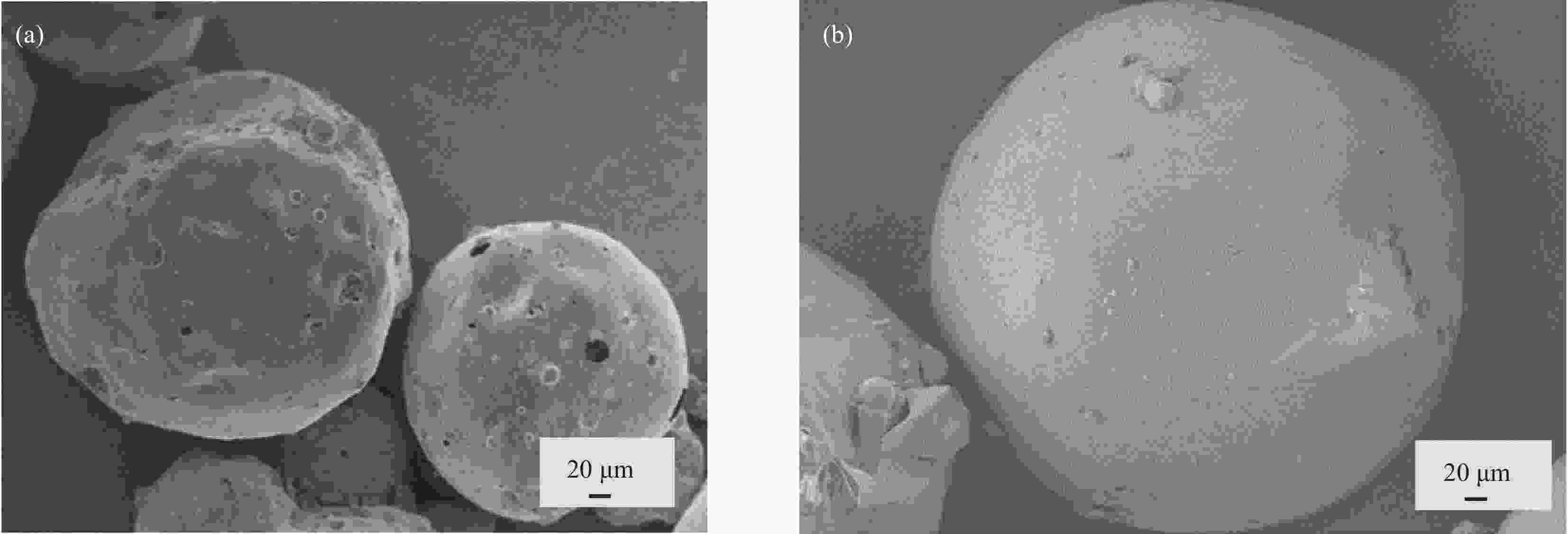

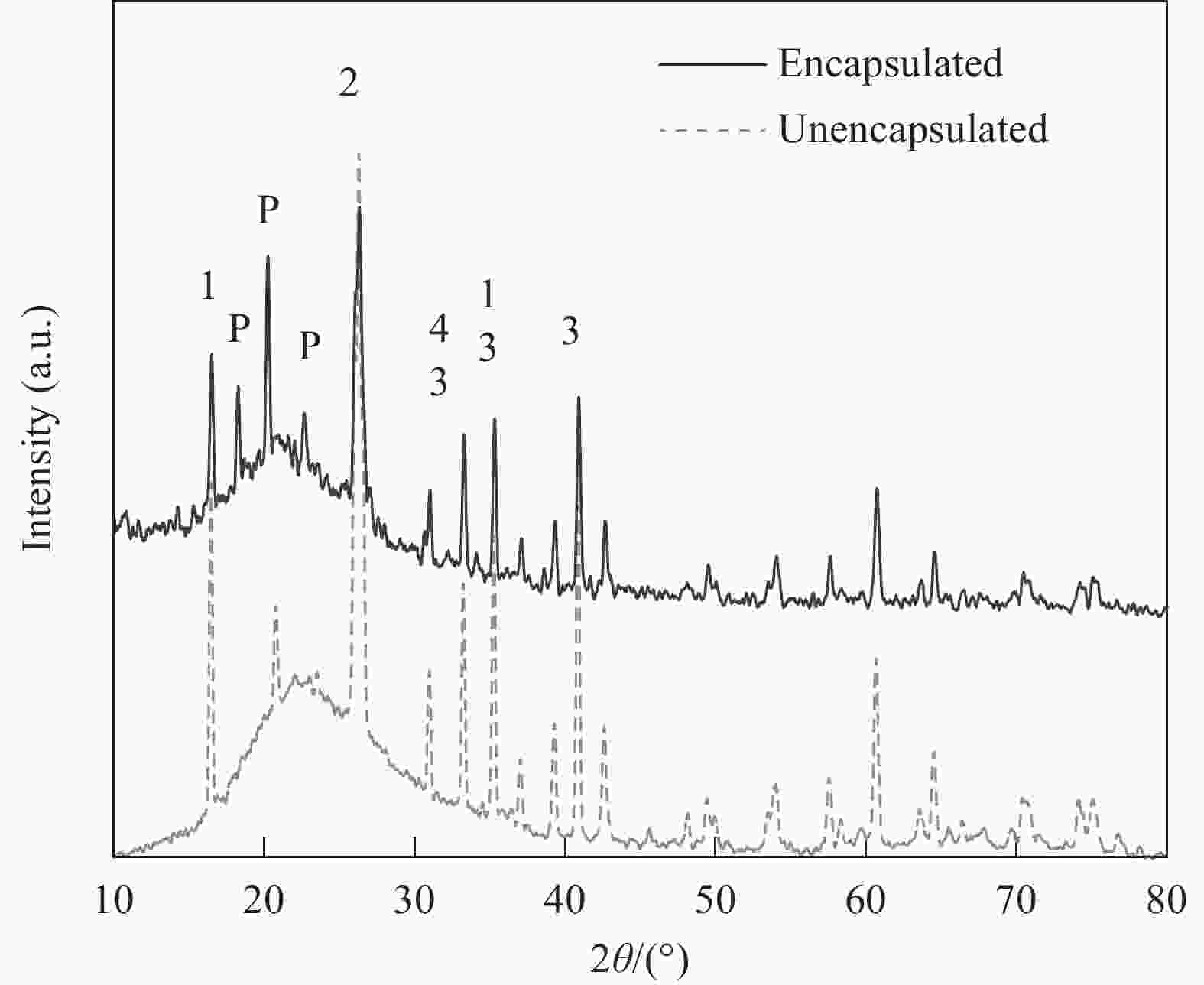

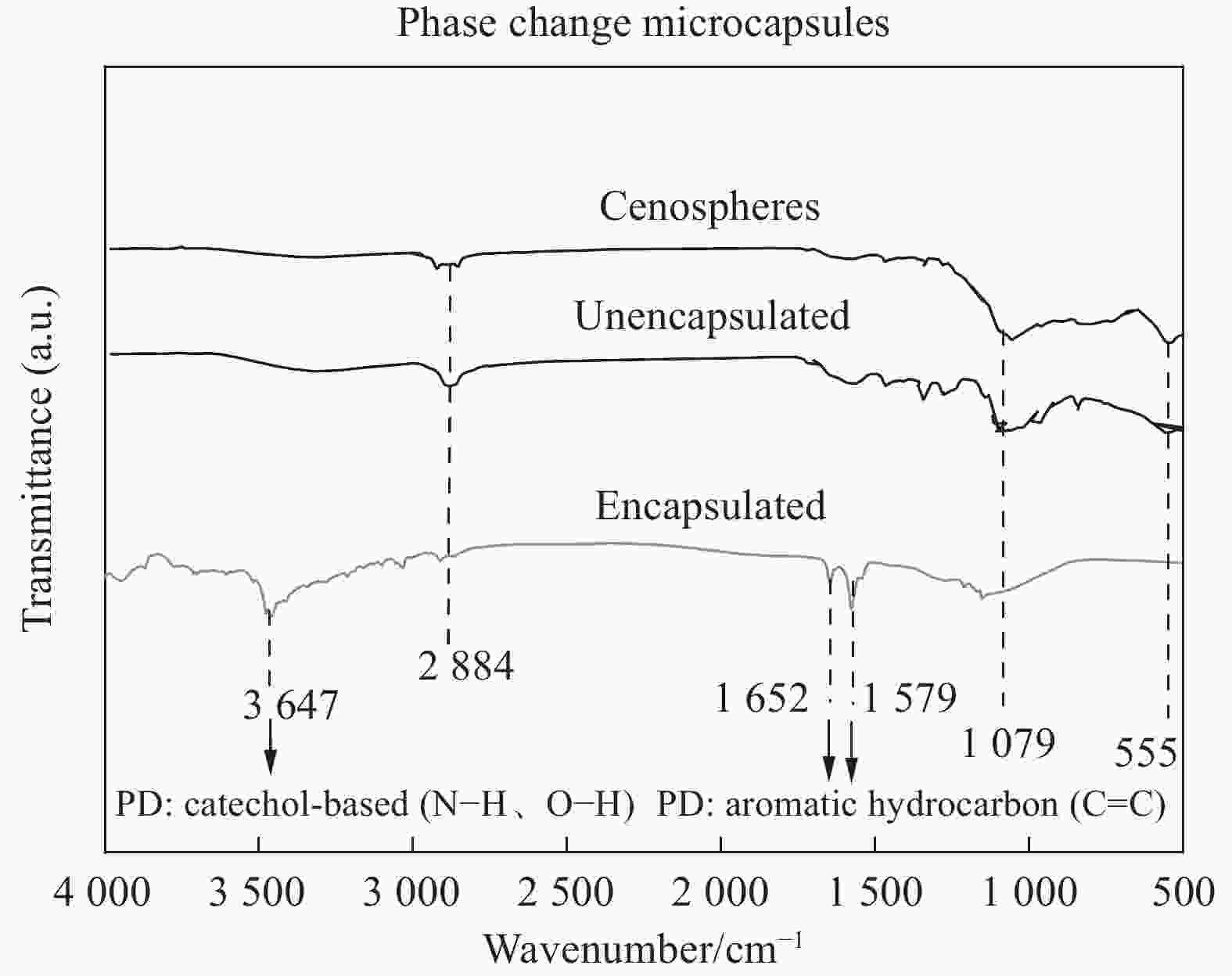

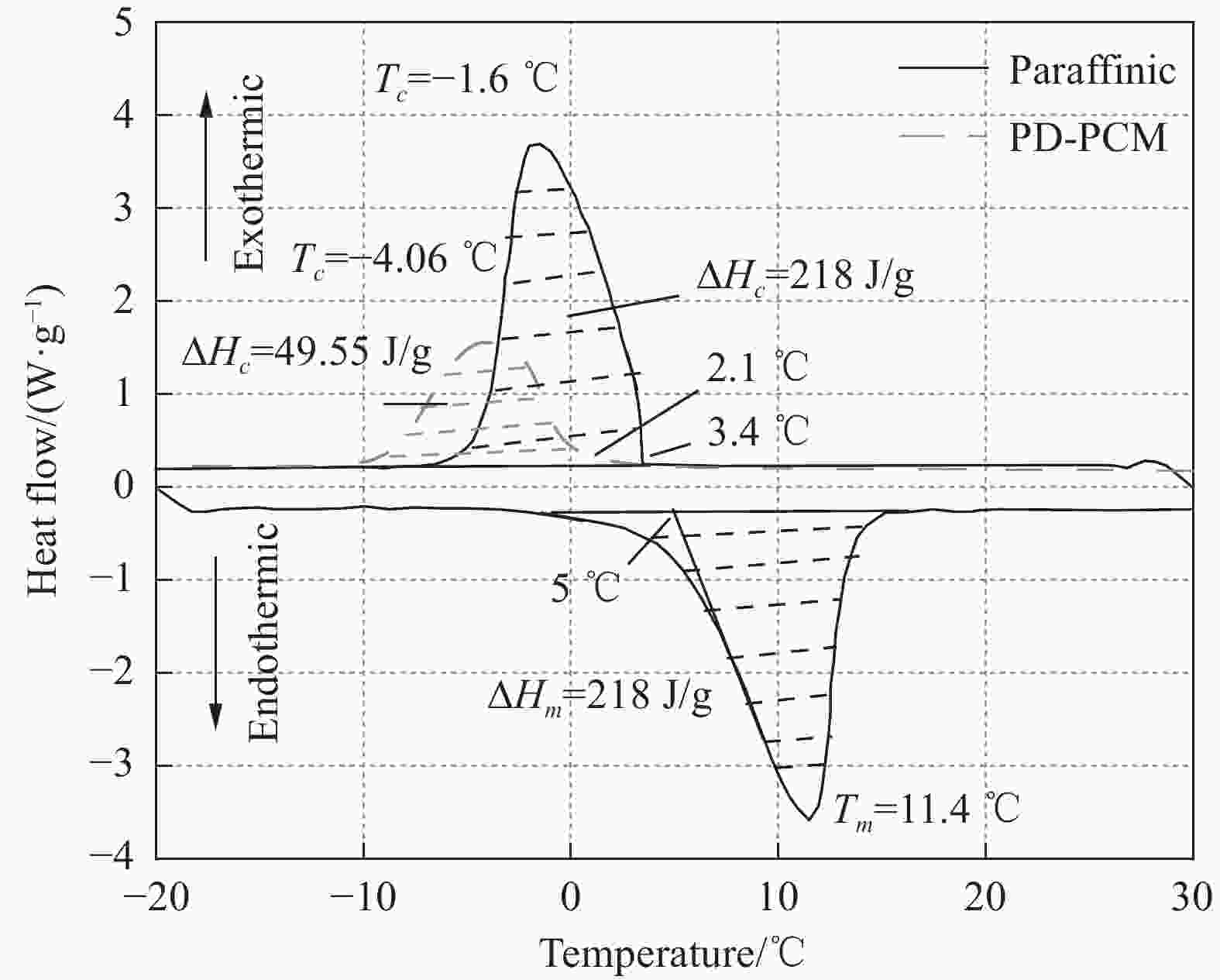

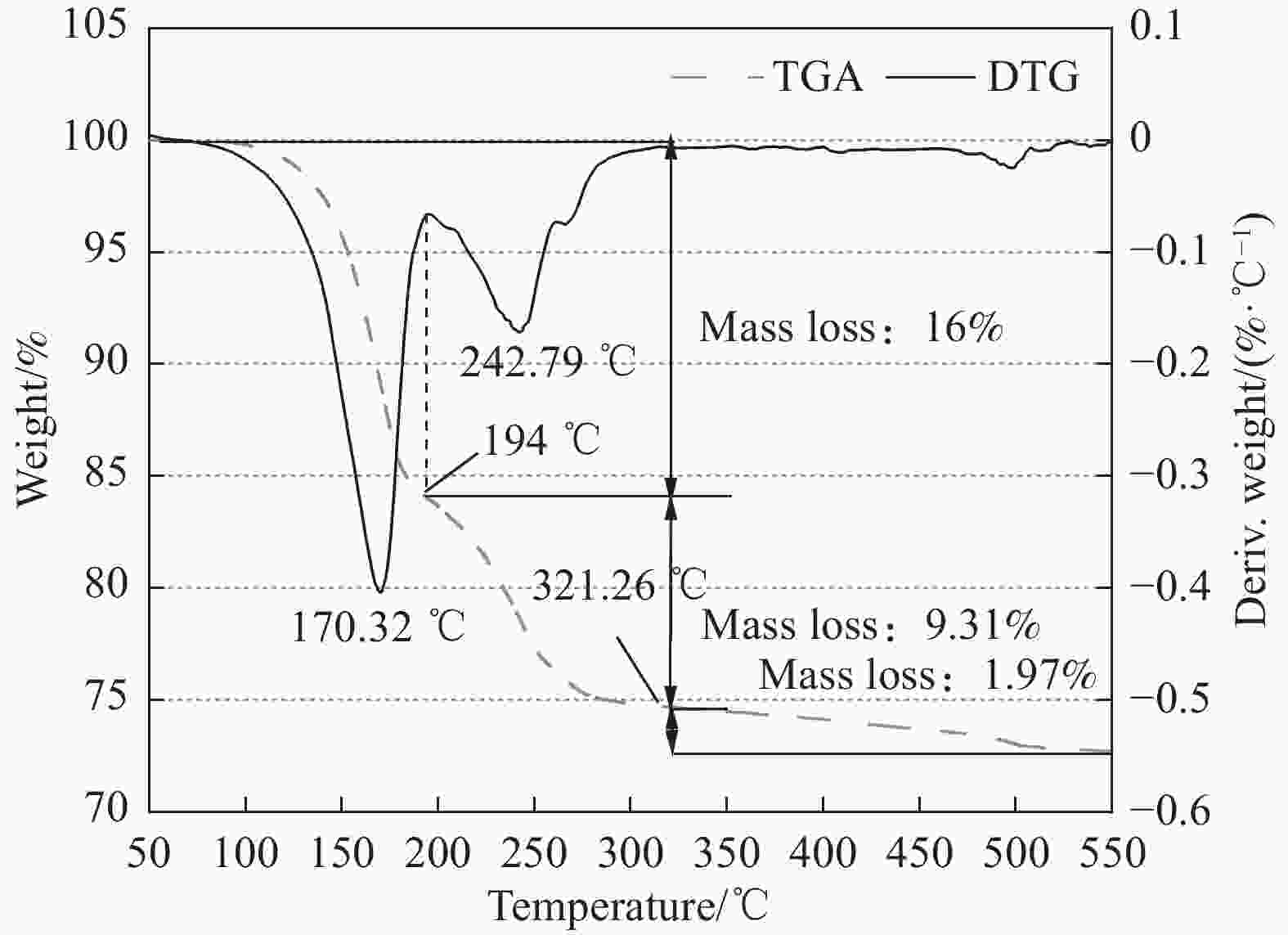

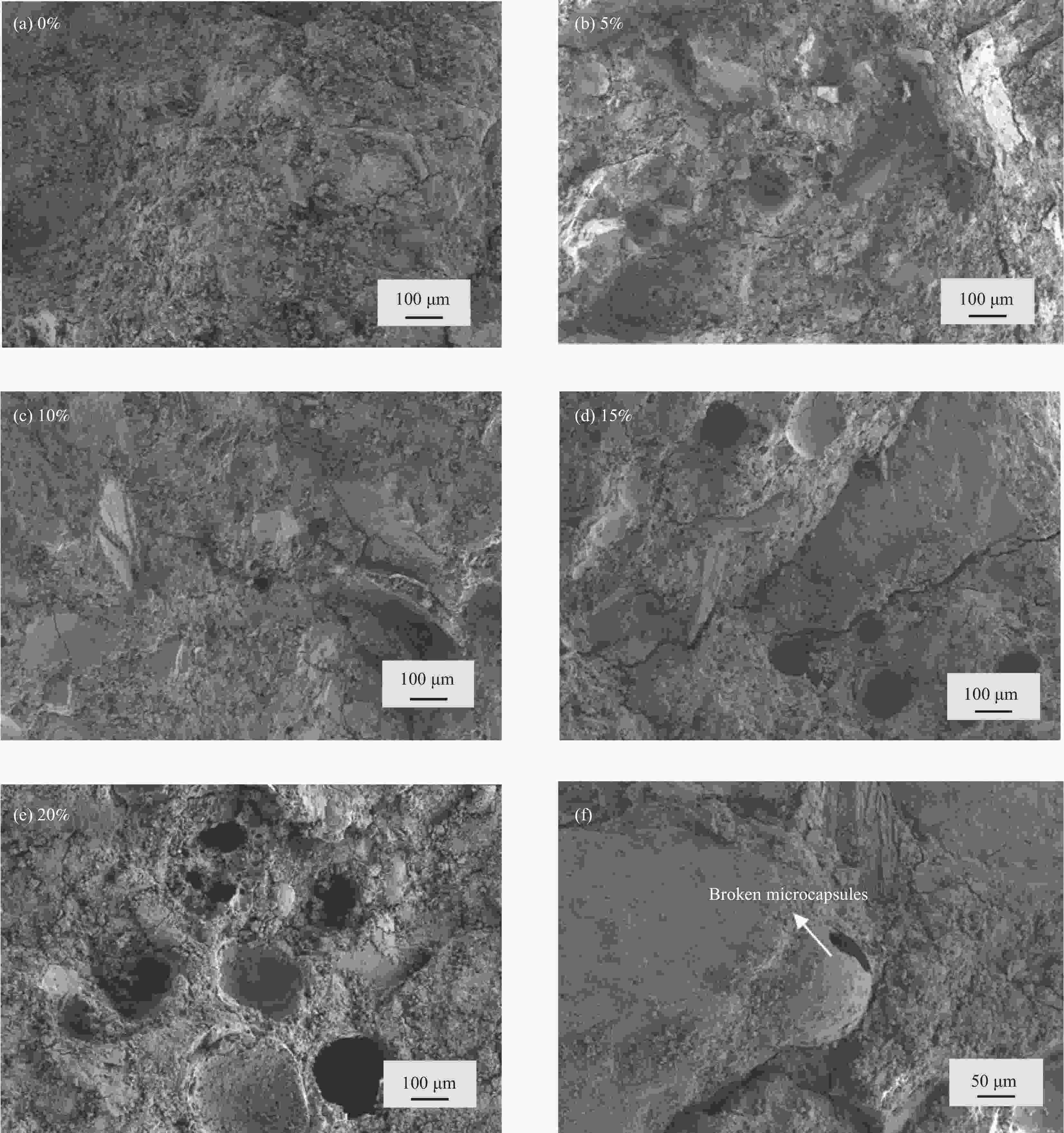

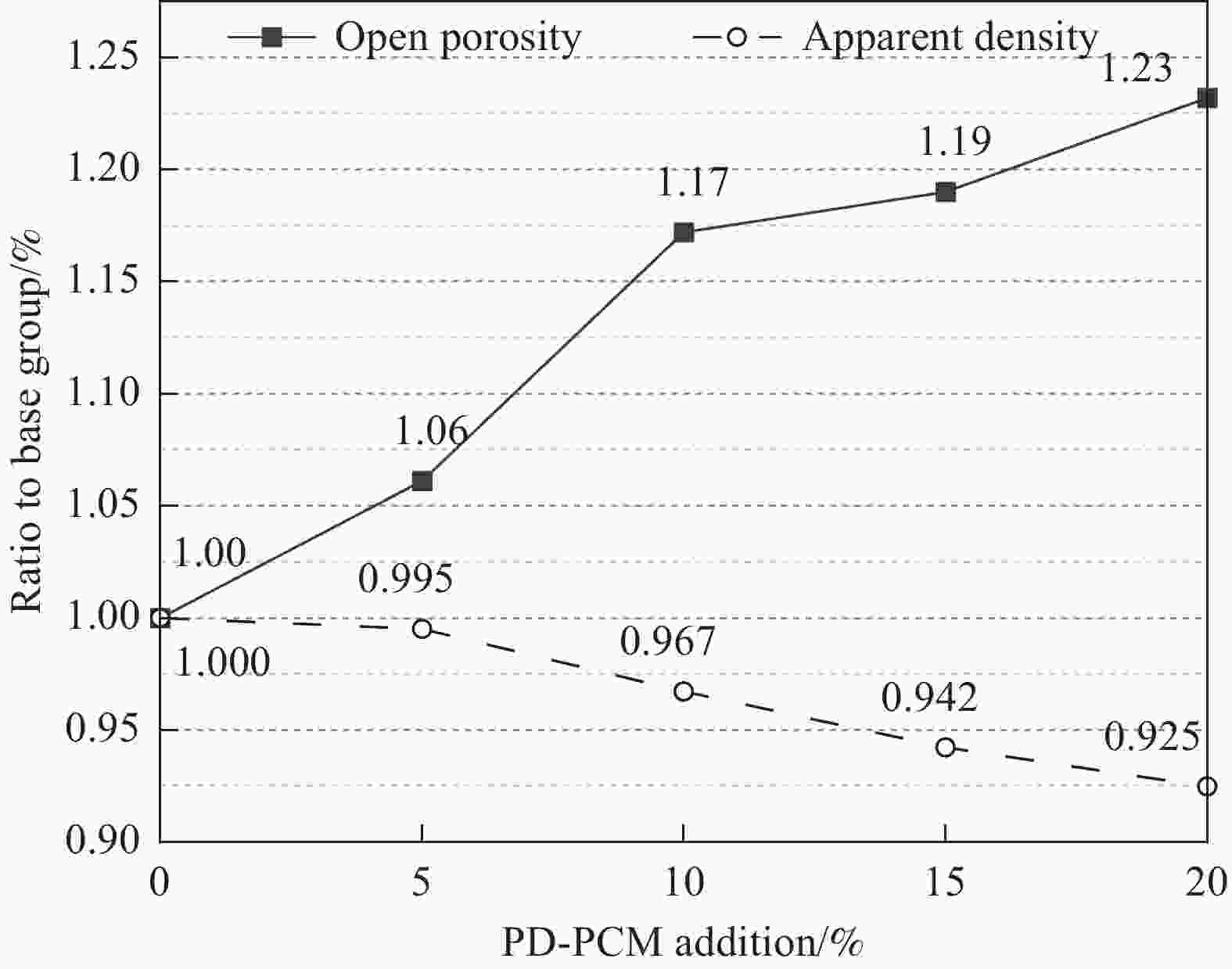

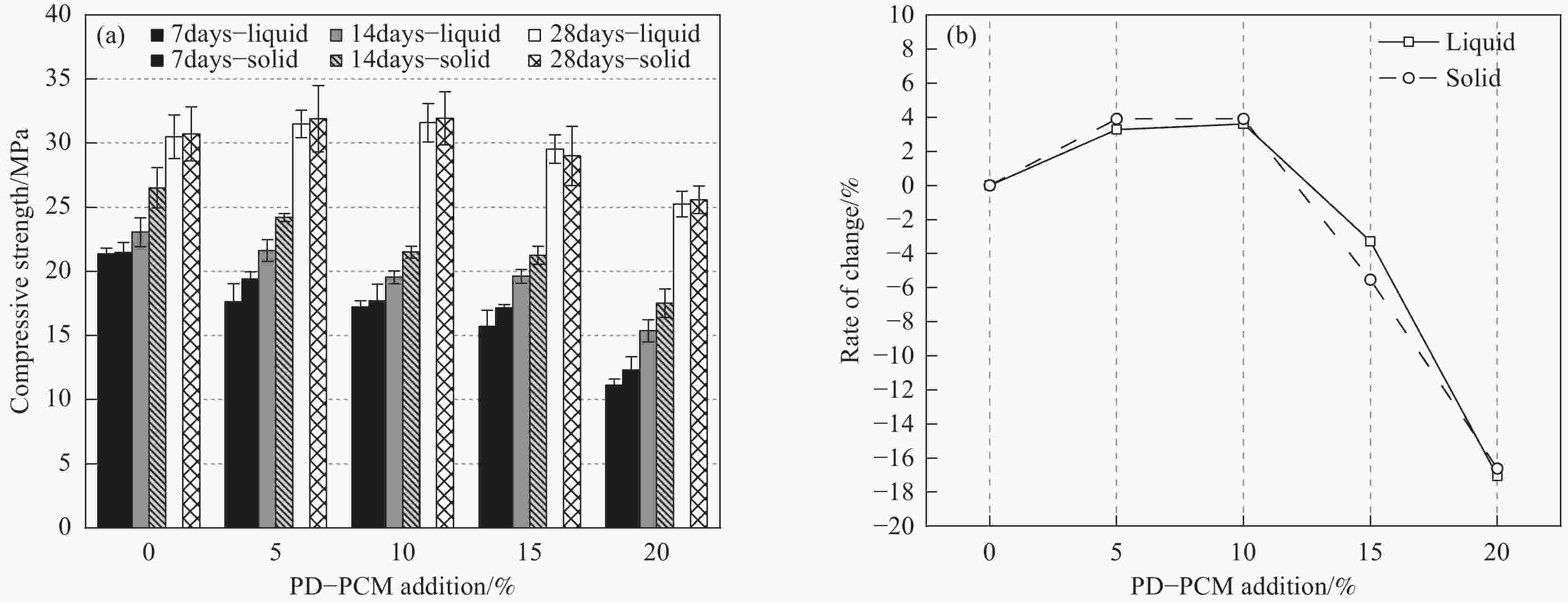

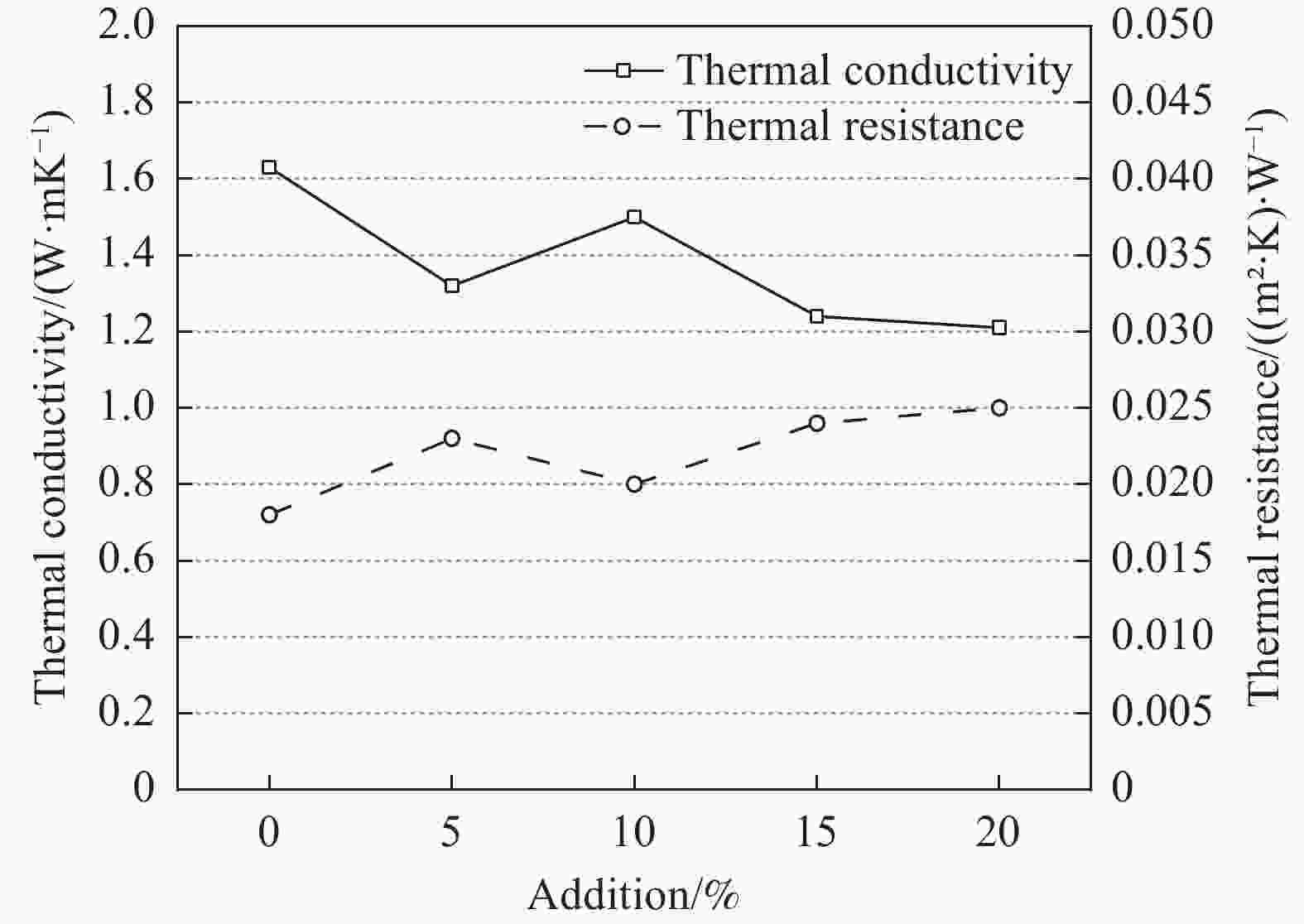

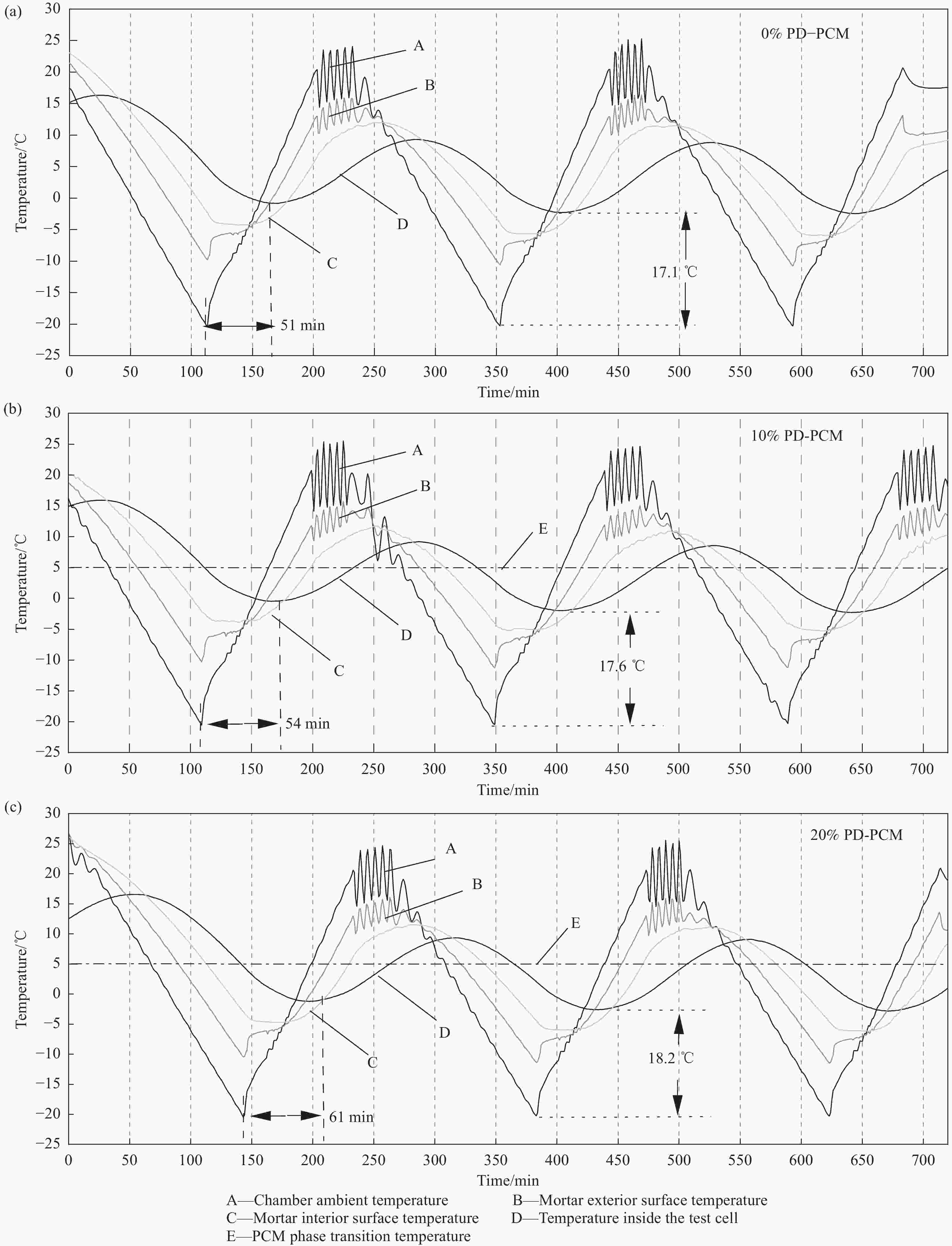

摘要: 为研究生物涂层/相变微胶囊对水泥砂浆力学及温控性能的影响,将表面覆有聚多巴胺涂层的相变微胶囊(PD-PCM)引入水泥砂浆中制成储能砂浆。研究了不同PD-PCM掺量(5% ~ 20%)储能砂浆的微观结构、力学性能、热工性能和冬季低温环境下的温控性能。结果表明:储能砂浆的孔隙率随着PD-PCM掺量的增加而增大,20%掺量孔隙率增加23.2%;添加PD-PCM有效减缓了传统相变储能砂浆抗压强度的大幅下降,其5%和10%掺量较基准砂浆分别提高3.6%及3.8%,20%掺量仅下降16.8%;PD-PCM的添加改善了砂浆的热工性能,其导热系数随着PD-PCM掺量的增加而降低,热阻随着PD-PCM掺量的增加而提高,20%掺量导热系数降低25.8%,热阻提高38.9%;通过绝热箱实验可知,当PD-PCM掺量为20%时,其箱内谷值温度与时滞分别较基准水泥砂浆增加1.1℃和10 min。相变储能砂浆在满足力学性能要求的同时,又具有良好的热工性能和储能调温能力,在建筑调温等领域具有广阔的应用前景。Abstract: In order to study the effect of bio-coating/phase change microcapsules on the mechanical and temperature control properties of cement mortar, phase change microcapsules (PD-PCM) coated with polydopamine on the surface were introduced into cement mortar to make energy storage mortar. The microstructure, mechanical properties, thermal properties and temperature control properties of energy storage mortars with different PD-PCM dosages (5%-20%) were investigated under the low-temperature environment in winter. The results show that: the porosity of energy storage mortar increases with the increase of PD-PCM dosage, and the porosity of 20% dosage increases by 23.2%; the addition of PD-PCM effectively slows down the significant decrease of compressive strength of traditional phase change energy storage mortar, and its 5% and 10% dosage increase by 3.6% and 3.8% respectively compared with the baseline mortar, and the 20% dosage decreases by 16.8%; the addition of PD-PCM improves the thermal performance of the mortar, and the thermal performance of the mortar is improved by 20% dosage, and the thermal performance of the mortar is reduced by 20%. The addition of PD-PCM improves the thermal performance of mortar, its thermal conductivity decreases with the increase of PD-PCM dosage, and the thermal resistance increases with the increase of PD-PCM dosage, the thermal conductivity decreases by 25.8% with 20% dosage, and the thermal resistance improves by 38.9%; through the experiment of adiabatic box, it can be seen that when the dosage of PD-PCM is 20%, the valley temperature and time lag of its box increase by 1.1℃ and 10 min, compared with that of the standard cement mortar, respectively. The phase change energy storage mortar has good thermal performance and energy storage and temperature regulation capability while meeting the requirements of mechanical properties, which has a broad application prospect in the field of building temperature regulation.

-

表 1 砂浆配合比(kg/m3)

Sample number Cement Water Medium sand Phase change microcapsule SJM25 -P0 450 300 1350.0 0 SJM25 -P5 450 300 1282.5 26.6 SJM25 -P10 450 300 1215 53.3 SJM25 -P15 450 300 1147.5 79.9 SJM25 -P20 450 300 1080 106.5 Notes: SJM25-P0 is the benchmark mortar specimen without adding phase change microcapsules, No. SJM25-P5 is the mortar specimen prepared by replacing 5% of the volume of phase change microcapsules, and so on. 表 2 各组砂浆试样最终用水量与固体成分重量之比以及测试的砂浆稠度

Table 2. Ratio of final water consumption to weight of solid components and consistency of mortar tested for each group of mortar specimens

Mortar

compositionWater to

solids ratioConsistency at

fresh state /mm0% 0.166 162 5% 0.171 165 10% 0.180 167 15% 0.191 166 20% 0.202 170 表 3 100 g PD-PCM经历多次升-降温循环后其质量损失结果

Table 3. Results of mass loss of 100 g of PD-PCM after undergoing several ascending-descending temperature cycles

100 g Number of cycles G1 G2 G3 60 120 200 60 120 200 60 120 200 Mass/g 99.54 99.5 99.44 99.55 99.49 99.45 99.55 99.5 99.45 Mass loss rate 0.46% 0.50% 0.56% 0.45% 0.51% 0.55% 0.45% 0.50% 0.55% Notes: G1 is the first set of experiments, and the other numbers follow suit. 表 4 基准水泥砂浆与储能砂浆试样进行真空饱和度测试所测得的物理性能(变异系数)

Table 4. Physical properties measured by vacuum saturation testing of reference cement mortar and energy storage mortar specimens (Coefficient of variation)

Property No. of tests Mortar composition 0% 5% 10% 15% 20% Bulk density ρ/(kg·m−3) 3 2.13

(0.53%)2.12

(0.22%)2.06

(0.21%)2.01

(0.44%)1.97

(0.12%)Open porosity p/% 3 16.65

(5.24%)17.67

(1.37%)19.51

(1.29%)19.81

(2.00%)20.51

(0.96%)表 5 各组砂浆的导热系数与热阻(变异系数)

Table 5. Thermal conductivity and thermal resistance of each group of mortar (coefficient of variation)

Property No. of

testsMortar composition 0% 5% 10% 15% 20% Thermal

conductivity-

λ/(W·(m·K)−1)3 1.63

(1%)1.32

(2%)1.5

(2%)1.24

(1%)1.21

(2%)Thermal

resistance-

R/((m2∙K)·W−1)3 0.018

(2%)0.023

(2%)0.020

(1%)0.024

(1%)0.025

(2%) -

[1] 清华大学建筑节能研究中心. 中国建筑节能年度发展研究报告2023-城市能源系统专题[M]. 北京: 中国建筑工业出版社, 2023.Tsinghua University building Energy Conservation research Center. Annual development research report of building energy efficiency in China-2023-special topics of urban energy system[M]. Beijing: China Architecture & Building Press, 2023. (in Chinese) [2] ZHU N, LI S S, HU P F, et al. Numerical investigations on performance of phase change material Trombe wall in building[J]. Energy, 2019, 187: 116057. doi: 10.1016/j.energy.2019.116057 [3] D'ALESSANDRO A, PISELLO A L, FABIANI C, et al. Multifunctional smart concretes with novel phase change materials: Mechanical and thermo-energy investigation[J]. Applied Energy, 2018, 212: 1448-1461. doi: 10.1016/j.apenergy.2018.01.014 [4] 苏建民. 十二水磷酸氢二钠定形复合相变材料[D]. 广州: 华南理工大学, 2020.SU Jianming. Disodium hydrogen phosphate dodecahydrate shape stable composite phase change material[D]. Guangzhou: South China University of Technology, 2020. (in Chinese) [5] SAEED R M, SCHLEGEL J P, CASTANO C, et al. Preparation and thermal performance of methyl palmitate and lauric acid eutectic mixture as phase change material (PCM)[J]. Journal of Energy Storage, 2017, 13: 418-424. doi: 10.1016/j.est.2017.08.005 [6] 卢素梅, 孟庆林, 张磊, 等. 围护结构内表面辐射率对室内热舒适影响的实验研究[J]. 建筑节能, 2019, 47(9): 98-104.LU Sumei, MENG Qinglin, ZHANG Lei, et al. Effect of the inner wall surface radiation rate on the indoor thermal comfort[J]. Building Energy Efficiency, 2019, 47(9): 98-104(in Chinese). [7] 张家玮, 黄玮, 黄大建, 等. 基于微孔漂珠的相变微胶囊制备及其对砂浆力学和热性能影响[J]. 复合材料学报, 2023, 40(8): 4703-4719.ZHANG Jiawei, HUANG Wei, HUANG Dajian, et al. Preparation of phase change microcapsules based on microporous cenospheres and their effects on mechanical and thermal properties of mortar[J]. Journal of Composite Materials, 2023, 40(8): 4703-4719(in Chinese). [8] 徐春明, 杨朝合, 林世雄. 石油炼制工程(第四版). 北京安定门外安华里2区1号. 石油工业出版社. 2010: 155Xu Chunming, Yang Chaohe, Lin Shixiong. Petroleum refining engineering (4th ed. ). No. 1, Anhua Lane 2, Andingmenwai, Beijing, China. Petroleum Industry Press. 2010: 155. (in Chinese) [9] 李进. 穿孔漂珠相变胶囊封装涂层的制备、表征及性能研究[D]. 安徽理工大学, 2021.Li Jin. Preparation, characterization and performance study of phase change capsule encapsulation coating with perforated bleached beads[D]. Anhui University of Technology, 2021. (in Chinese) [10] 于文艳, 孟琦, 童浩然. 微胶囊相变材料对砂浆热性能和力学性能的影响[J]. 建筑材料学报, 2023, 26(2): 215-220.YU Wenyan, MENG Qi, TONG Haoran. Effect of mi croencapsulated phase change materials on me-chanical and thermal properties of mortar[J]. Journal of Building Materials, 2023, 26(2): 215-220(in Chinese). [11] 陆江, 瞿铭良, 田帅奇. 相变微胶囊/加气混凝土复合材料的热工性能[J]. 建筑材料学报, 2020, 23(2): 341-346+363.LU Jiang, QU Mingliang, TIAN Shuaiqi. Thermal properties of phase change microcapsules/aerated concrete composites[J]. Journal of Building Materials, 2020, 23(2): 341-346+363(in Chinese). [12] Hunger M, Entrop A G, Mandilaras I, et al. The behavior of self-compacting concrete containing micro-encapsulated Phase Charge Materials[J]. Cement and Concrete Composites, 2009, 31(10): 731-743. doi: 10.1016/j.cemconcomp.2009.08.002 [13] 缪文娟. 基于微纳米SiO2相变微胶囊的水泥基储热材料设计及性能调控[D]. 武汉理工大学, 2020.MIAO Wenjuan. Design and performance regulation of cement-based thermal storage materials based on micro- and nano- SiO2 phase change microcapsules [D]. Wuhan University of Technology, 2020. (in Chinese) [14] 朱颖, 赵金兴, 曲晶瑩, 等. 新型相变水泥砂浆热力学性能研究[J]. 隧道建设(中英文), 2022, 42(9): 1570-1577.ZHU Ying, ZHAO Jinxing, QU Jingying, et al. Research on thermomechanical properties of new phase change cement mortar[J]. Tunnel Construction, 2022, 42(9): 1570-1577(in Chinese). [15] 边亚东, 王盟盟, 吕亚军, 等. 相变储能砂浆的制备和力学性能试验研究[J]. 混凝土与水泥制品, 2021, (1): 26-29.BIAN Yadong, Wang Mengmeng, Lv Yajun, et al. Experimental study on the preparation and mechanical properties of phase change energy storage mortar[J]. Concrete and Cement Products, 2021, (1): 26-29(in Chinese). [16] 中华人民共和国国家质量技术监督检验检疫总局. 建筑用砂: GB/T 14684-2011[S]. 北京: 中国标准出版社, 2011.General Administration of Quality Supervision, Inspec tion and Quarantine of the People's Republic of China. Sand for construction: GB/T 17671−2021[S]. Beijing: Standards Press of China, 2011. (in Chinese) [17] 中华人民共和国住房和城乡建设部. 建筑砂浆基本性能试验方法标准: JGJ/T 70-2009[S]. 北京: 中国建筑工业出版社, 2009.Ministry of Housing and Urban-Rural Development of the People's Republic of China. Standard of test method for basic properties of construction mortar: JGJ/T 70-2009[S]. Beijing: China Architecture & Building Press, 2009. (in Chinese) [18] 中华人民共和国国家质量技术监督检验检疫总局. 水泥胶砂流动度测定方法: GB_T 2419-2005[S]. 北京: 中国标准出版社, 2005.General Administration of Quality Supervision, Inspec tion and Quarantine of the People's Republic of China. Method for determining the flowability of cementitious sand: GB_T 2419-2005[S]. Beijing: China Standard Press, 2005. (in Chinese) [19] 中华人民共和国国家质量技术监督检验检疫总局. 致密定形耐火制品体积密度、显气孔率和真气孔率试验方法: GB/T 2997-2015 [S]. 北京: 中国标准出版社, 2017.General Administration of Quality Supervision, Inspec tion and Quarantine of the People's Republic of China. Test methods for bulk density, apparent porosity and true porosity of dense shaped refractory products: GB/T 2997-2015 [S]. Beijing: China Standard Press, 2017. (in Chinese) [20] ILLAMPAS R, RIGOPOULOS I, IOANNOU I. Influence of microencapsulated Phase Change Materials (PCMs) on the properties of polymer modified cementitious repair mortar[J]. Journal of Building Engineering, 2021, 40: 102328. doi: 10.1016/j.jobe.2021.102328 [21] RAMAKRISHNAN S, WANG X, SANJAYAN J, et al. Thermal energy storage enhancement of lightweight cement mortars with the application of phase change materials[J]. Procedia engineering, 2017, 180: 1170-1177. doi: 10.1016/j.proeng.2017.04.277 [22] NEPOMUCENO M C, SILVA P D. Experimental evaluation of cement mortars with phase change material incorporated via lightweight expanded clay aggregate[J]. Construction and Building Materials, 2014, 63: 89-96. doi: 10.1016/j.conbuildmat.2014.04.027 [23] 史巍, 侯景鹏. 石蜡相变储能砂浆应用性能研究[J]. 新型建筑材料, 2012, 39(8): 19-21.SHI Wei, HOU Jingpeng. Study on the application per formance of paraffin phase change energy storage mortar[J]. New Building Materials, 2012, 39(8): 19-21(in Chinese). [24] CAO V D, PILEHVAR S, SALAS-BRINGAS C, et al. Thermal performance and numerical simulation of geopolymer concrete containing different types of thermoregulating materials for passive building applications[J]. Energy and Buildings, 2018, 173: 678-688. doi: 10.1016/j.enbuild.2018.06.011 [25] KHERADMAND M, ABDOLLAHNEJAD Z, PACHECO-TORGAL F. Alkali-activated cement-based binder mortars containing phase change materials (PCMs): Mechanical properties and cost analysis[J]. European Journal of Environmental and Civil Engineering, 2020, 24(8): 1068-1090. doi: 10.1080/19648189.2018.1446362 [26] 张剑, 晏华, 陈淑莲, 等. 低熔点石蜡微胶囊掺量对相变蓄热砂浆性能的影响[J]. 新型建筑材料, 2012, 39(3): 13-16.ZHANG Jian, YAN Hua, CHEN Shulian, et al. Influence of low melting point paraffin microcapsules on the performance of phase change thermal storage mortar[J]. New Building Materials, 2012, 39(3): 13-16(in Chinese). [27] HALDER S, WANG J, FANG Y, et al. Cenosphere-based PCM microcapsules with bio-inspired coating for thermal energy storage in cementitious materials[J]. Materials Chemistry and Physics, 2022, 291: 126745. doi: 10.1016/j.matchemphys.2022.126745 [28] 于戈. 正癸酸/膨胀珍珠岩复合相变水泥板导热系数研究[J]. 新型建筑材料, 2017, 44(12): 8-11.YU Ge. Study on thermal conductivity of n-decanoic acid/expanded perlite composite phase change cement board[J]. New Building Materials, 2017, 44(12): 8-11(in Chinese). [29] 尹冠生, 张锦涛, 史明辉, 等. 相变蓄热泡沫混凝土热性能[J]. 复合材料学报, 2023, 40(7): 4246-4259.YIN Guansheng, ZHANG Jintang, SHI Minghui, et al. Thermal properties of phase change thermal storage foam concrete[J]. Journal of Composite Materials, 2023, 40(7): 4246-4259(in Chinese). [30] 文颖, 汤胜, 孙赛玲, 等. 相变微胶囊改性砂浆界面传热机理研究[J]. 新型建筑材料, 2023, 50(2): 141-146.WEN Ying, TANG Sheng, SUN Sailing, et al. Re search on interfacial heat transfer mechanism of mortar modified by phase change microcapsules[J]. New Building Materials, 2023, 50(2): 141-146(in Chinese). [31] 史巍, 艾斌, 侯景鹏. 复合相变储能砂浆性能实验研究[J]. 硅酸盐通报, 2014, 33(5): 1004-1007.SHI Wei, AI Bin, HOU Jingpeng. Experimental study on the performance of composite phase change energy storage mortar[J]. Silicate Bulletin, 2014, 33(5): 1004-1007(in Chinese). -

点击查看大图

点击查看大图

计量

- 文章访问数: 50

- HTML全文浏览量: 21

- 被引次数: 0

下载:

下载: