Research progress of microorganism-carbonization modified steel slag and its effect on hydration characteristics of cement

-

摘要: 微生物诱导碳酸盐沉淀(MICP)是一种新型环保处理技术,其独特的矿化及生物酶催化机制在固废处理及利用方面展现出广阔前景。基于钢渣水化特性,本文探讨了碳化条件及生物酶特性对碳酸盐成核影响,分析并总结了MICP与碳化反应机制、生物-碳化改性中钢渣的物相演变规律、碳酸钙成核及晶体生长等研究进展,从力学性能、水化热及体积稳定性角度进一步综述了改性钢渣对水泥基胶凝材料水化特性影响机制,指出了现阶段微生物-碳化技术在钢渣改性研究中存在的不足,为实现钢渣低污染、高质化利用提供有益参考。Abstract: Microbially induced calcium carbonate precipitation (MICP) is a novel environmentally friendly treatment technology, which shows broad prospects in solid waste treatment and utilization due to its unique mineralization and bio-enzymatic catalysis mechanism. Based on the hydration characteristics of steel slag, this paper explores the influence of carbonation conditions and enzymatic characteristics on carbonate nucleation, analyzes and summarizes the research progress on the reaction mechanism of MICP and carbonation, phase evolution of steel slag in bio-carbonation modification, carbonate nucleation, and crystal growth. Furthermore, from the perspectives of mechanical properties, hydration heat, and volume stability, the impact mechanism of modified steel slag on the hydration characteristics of cement-based cementitious materials is further reviewed. The paper points out the current deficiencies in microorganism-carbonation technology in the research of steel slag modification, providing valuable references for achieving low-pollution and high-quality utilization of steel slag.

-

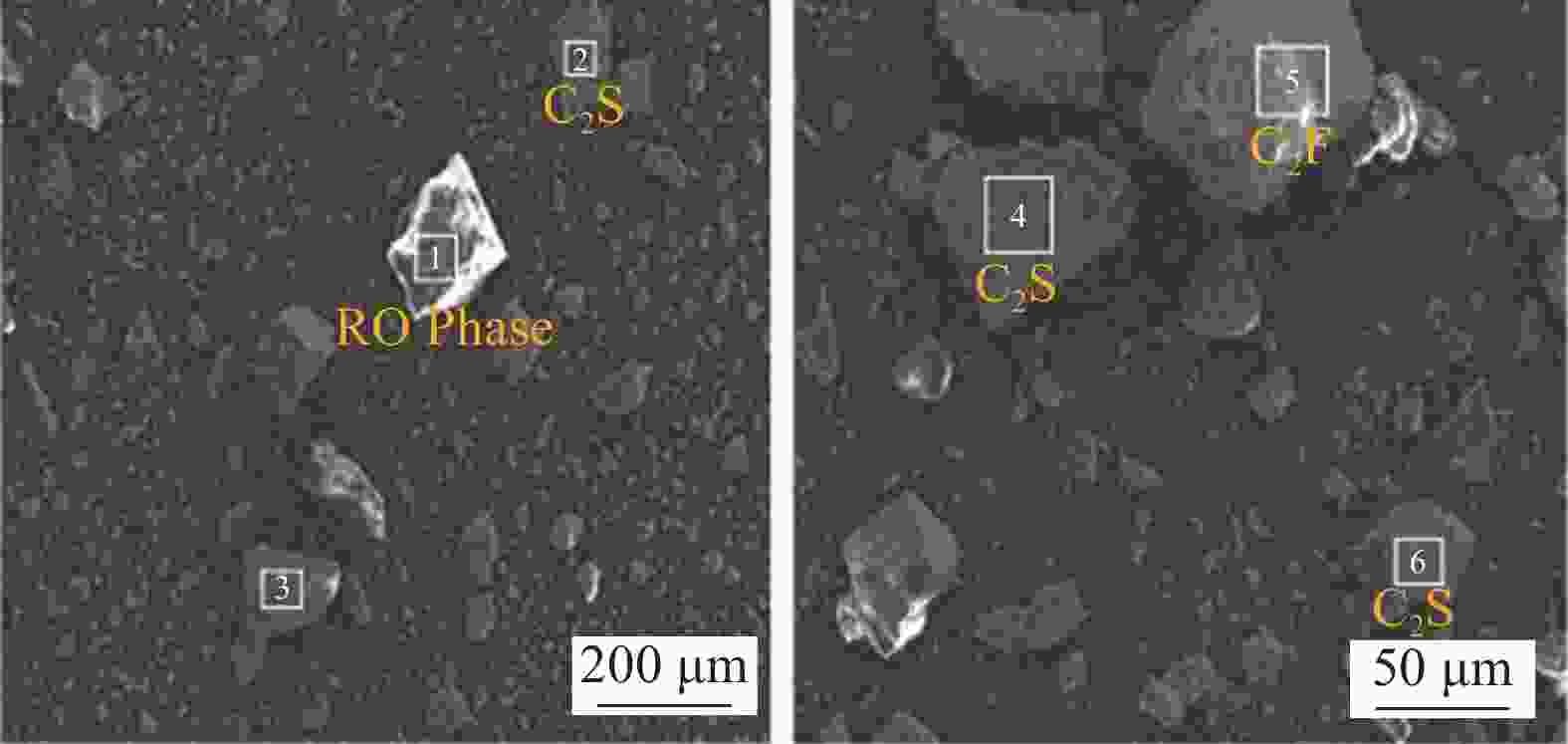

图 1 钢渣BES微观形貌[25]

Figure 1. BES morphology of steel slag

表 1 不同因素对钢渣碳化效果影响

Table 1. Influence of different factors on carbonization effect of steel slag

Factor Influencing mechanism References Temperature Raising the carbonization temperature facilitates the leaching of carbonate ions, but excessively high temperatures reduce the solubility of CO2 in the liquid phase. [34, 35] Time In the initial stages of carbonization, the rate of calcium conversion increases linearly with carbonization time; however, in the later stages, it is restricted by the carbonized layer, leading to a significant decrease in the diffusion rate of silicate ions. [36] Air pressure High pressure is conducive to enhancing the uniform distribution of calcium carbonate and accelerating the diffusion and dissolution of CO2. However, in the later stages, the carbonized layer restricts further reaction between CO2 and carbonate ions. [37, 38] Concentrations of CO2 High CO2 concentration provides an ample carbon source for the carbonization reaction, accelerating the rate of calcium conversion. However, in the later stages, the reaction rate of carbonization no longer increases due to the influence of solution supersaturation. [39] Size of steel slag Smaller steel slag particle size increases the contact area with the carbon source, leading to a more thorough reaction between steel slag particles and CO2, resulting in more carbonization products. [40] Humidity The increase in moisture accelerates the dissolution of CO2 and the leaching of Ca2+, but excessive moisture can block the surface pores of steel slag, thereby restricting the penetration of CO2. [38, 41] Catalytic enzyme type High activity range Catalytic object Typical microorganism Chemical construction Temperature PH Urease 30-40℃ 7.0-8.0 Urea Bacillus pasteurelli

Carbonic anhydrase 35-55℃ 7.0-10.0 CO2 Bacillus mucosus

-

[1] REZENDE CARVALHO V, BARBOSA COSTA L C, ELOI F, et al. Performance of low-energy steel slag powders as supplementary cementitious materials[J]. Construction and Building Materials, 2023, 392(7): 131888. [2] ZHUANG S Y, QIANG W. Inhibition mechanisms of steel slag on the early-age hydration of cement[J]. Cement and Concrete Research, 2021, 140(3): 106283. [3] CHEN Z, LI R, ZHENG X, et al. Carbon sequestration of steel slag and carbonation for activating RO phase[J]. Cement and Concrete Research, 2021, 139(1): 106271. [4] 史志新, 刘锦燕, 王春梅. 不同碱度钢渣显微形貌及物相变化分析研究[J]. 冶金分析, 2015, 35(11): 16-22.SHI Z X, LIU J Y, WANG C M. Analysis and researchonmicro-morphology and phase change of steel slag with differental kalinity[J]. Metallurgical Analysis, 2015, 35(11): 16-22. [5] QIANG W, WANG D Q, ZHUANG S Y. The soundness of steel slag with different free CaO and MgO contents[J]. Construction and Building Materials, 2017, 151(1): 138-146. [6] DONG Q, WANG G T, CHEN X Q, et al. Recycling of steel slag aggregate in portland cement concrete: An overview[J]. Journal of Cleaner Production, 2020, 282(3): 124447. [7] JIANG Y, LING T C, SHI C J, et al. Characteristics of steel slags and their use in cement and concrete—A review[J]. Resources Conservation and Recycling, 2018, 136: 187-197. doi: 10.1016/j.resconrec.2018.04.023 [8] LI Z, XING Y, MA M, et al. Towards the co-benefits of carbon capture, utilization and sequestration: A life cycle assessment study for steel slag disposal[J]. Journal of Cleaner Production, 2024, 443(1): 141166. [9] SUN L, WANG H, WANG Y L. Properties of Carbonated Steel Slag Admixture in the Cementitious System[J]. Advances in Civil Engineering, 2023, 2023(9): 1-12. [10] SONG Q F, GUO M-Z, WANG L, et al. Use of steel slag as sustainable construction materials: A review of accelerated carbonation treatment[J]. Resources Conservation and Recycling, 2021, 173(9): 105740. [11] GHOULEH Z, CELIKIN M, GUTHRIE R, et al. Microstructure of Carbonation-Activated Steel Slag Binder[J]. Journal of Materials in Civil Engineering, 2018, 30(9): 1-11. [12] DUAN S Y, WU H, ZHANG K, et al. Effect of curing temperature on the reaction kinetics of cementitious steel slag-fly ash-desulfurized gypsum composites system[J]. Journal of Building Engineering, 2022, 62(12): 105368. [13] JAKUBOVSKIS R, IVAŠKĖ A, MALAIŠKIENĖ J, et al. Impact of Portland cement type on bacterial viability in biological concrete[J]. Cement and Concrete Composites, 2022, 127(17): 104413. [14] KAUR P, JOSHI S, SHINDE O, et al. Utilization of Biomineralized Steel Slag in Cement Mortar to Improve Its Properties[J]. Journal of Materials in Civil Engineering, 2021, 33(6): 1-9. [15] ZHANG X, SU Y, LIU S. The effect of carbonation pressure on microbial assisted steel slag-based carbon sequestration material[J]. Journal of Building Engineering, 2024, 86(1): 108974. [16] ZHANG X, MA Z Y, LI F. Study on preparation of supplementary cementitious material using microbial CO2 fixation of steel slag powder[J]. Construction and Building Materials, 2022, 326(6): 126864. [17] YANG C, WU S P, CUI P D, et al. Performance characterization and enhancement mechanism of recycled asphalt mixtures involving high RAP content and steel slag[J]. Journal of Cleaner Production, 2022, 336(15): 130484. [18] LI J S, YU J Y, WU S P, et al. The Mechanical Resistance of Asphalt Mixture with Steel Slag to Deformation and Skid Degradation Based on Laboratory Accelerated Heavy Loading Test[J]. Materials, 2022, 15(3): 911. doi: 10.3390/ma15030911 [19] XIAO B L, WEN Z J, MIAO S J, et al. Utilization of steel slag for cemented tailings backfill: Hydration, strength, pore structure, and cost analysis[J]. Case Studies in Construction Materials, 2021, 15: e00621. doi: 10.1016/j.cscm.2021.e00621 [20] LI L, ZHAO F, LIU S. The Activation of Steel Slag and its Application in Construction and Building Materials[J]. Advanced Materials Research, 2014, 884-885: 702-705. doi: 10.4028/www.scientific.net/AMR.884-885.702 [21] LI P F, JI J, WEN L, et al. Quantitative characterization and evaluation of key physicochemical characteristics of steel slag[J]. Construction and Building Materials, 2024, 414(2): 134959. [22] QIANG W, YAN P Y. Hydration properties of basic oxygen furnace steel slag[J]. Construction and Building Materials, 2010, 24(7): 1134-1140. doi: 10.1016/j.conbuildmat.2009.12.028 [23] HOU J W, CHEN Z M, LIU J X. Hydration Activity and Expansibility Model for the RO Phase in Steel Slag[J]. Metallurgical and Materials Transactions B, 2020, 51: 1697-1704. doi: 10.1007/s11663-020-01847-3 [24] SHI C J. Steel Slag—Its Production, Processing, Characteristics, and Cementitious Properties[J]. Cheminform, 2005, 36(22): 230-236. [25] YAN J J, WU S P, YANG C, et al. Influencing mechanisms of RO phase on the cementitious properties of steel slag powder[J]. Construction and Building Materials, 2022, 350(3): 128926. [26] IACOBESCU R, ANGELOPOULOS G, JONES P, et al. Ladle metallurgy stainless steel slag as a raw material in Ordinary Portland Cement production: A possibility for industrial symbiosis[J]. Journal of Cleaner Production, 2015, 112(1): 872-881. [27] ZHAO H T, JIANG K D, YANG R, et al. Experimental and theoretical analysis on coupled effect of hydration, temperature and humidity in early-age cement-based materials[J]. International Journal of Heat and Mass Transfer, 2020, 146(3): 118784. [28] GARTNER E, MARUYAMA I, CHEN J. A new model for the C-S-H phase formed during the hydration of Portland cements[J]. Cement and Concrete Research, 2017, 97: 95-106. doi: 10.1016/j.cemconres.2017.03.001 [29] LACKNER K S, WENDT C H, BUTT D P, et al. Carbon dioxide disposal in carbonate minerals[J]. Energy, 1995, 20(11): 1153-1170. doi: 10.1016/0360-5442(95)00071-N [30] BASARAN Z, KIRISITS M, FERRON R. Biomineralized cement-based materials: Impact of inoculating vegetative bacterial cells on hydration and strength[J]. Cement and Concrete Research, 2015, 67: 237-245. doi: 10.1016/j.cemconres.2014.10.002 [31] LI M, WANG Q, YANG J D, et al. Strength and Mechanism of Carbonated Solidified Clay with Steel Slag Curing Agent[J]. KSCE Journal of Civil Engineering, 2020, 25: 805-821. [32] COSTA G, POLETTINI A, POMI R, et al. Leaching modelling of slurry-phase carbonated steel slag[J]. Journal of hazardous materials, 2015, 302(25): 415-425. [33] YADAV S, MEHRA A. Dissolution of steel slags in aqueous media[J]. Environmental science and pollution research international, 2017, 24(19): 16306-16315. [34] PAN S Y, CHUNG T C, HO C C, et al. CO2 Mineralization and Utilization using Steel Slag for Establishing a Waste-to-Resource Supply Chain[J]. Scientific Reports, 2017, 7(1): 17227. doi: 10.1038/s41598-017-17648-9 [35] PAN S Y, LIU H L, CHANG E E, et al. Multiple model approach to evaluation of accelerated carbonation for steelmaking slag in a slurry reactor[J]. Chemosphere, 2016, 154: 63-71. doi: 10.1016/j.chemosphere.2016.03.093 [36] CHANG E E, CHEN C H, CHEN Y H, et al. Performance evaluation for carbonation of steel-making slags in a slurry reactor[J]. Journal of hazardous materials, 2011, 186: 55864. [37] ZHONG X Z, LI L F, JIANG Y, et al. Elucidating the dominant and interaction effects of temperature, CO2 pressure and carbonation time in carbonating steel slag blocks[J]. Construction and Building Materials, 2021, 302(7): 124158. [38] NIELSEN P, BOONE M, HORCKMANS L, et al. Accelerated carbonation of steel slag monoliths at low CO2 pressure–microstructure and strength development[J]. Journal of CO2 Utilization, 2019, 36: 124-134. [39] HUMBERT P, CASTRO-GOMES J, JR H. Clinker-free CO2 cured steel slag based binder: Optimal conditions and potential applications[J]. Construction and Building Materials, 2019, 210: 413-421. doi: 10.1016/j.conbuildmat.2019.03.169 [40] SHEN W G, LIU Y, WU M M, et al. Ecological carbonated steel slag pervious concrete prepared as a key material of sponge city[J]. Journal of Cleaner Production, 2020, 256(20): 120244. [41] MO L W, ZHANG F, DENG M, et al. Accelerated carbonation and performance of concrete made with steel slag as binding materials and aggregates[J]. Cement and Concrete Composites, 2017, 83: 138-145. doi: 10.1016/j.cemconcomp.2017.07.018 [42] FAVRE N, CHRIST M L, PIERRE A C. Biocatalytic capture of CO2 with carbonic anhydrase and its transformation to solid carbonate[J]. Journal of Molecular Catalysis B: Enzymatic, 2009, 60(3): 163-170. [43] JUN S Y, KIM S, KANTH B, et al. Expression and characterization of a codon-optimized alkaline-stable carbonic anhydrase from Aliivibrio salmonicida for CO2 sequestration applications[J]. Bioprocess and Biosystems Engineering, 2017, 40(3): 413-421. doi: 10.1007/s00449-016-1709-3 [44] CASTRO A, MONTAñEZ-HERNANDEZ L, MUñOZ M, et al. Microbially Induced Calcium Carbonate Precipitation (MICP) and Its Potential in Bioconcrete: Microbiological and Molecular Concepts[J]. Frontiers in Materials, 2019, 103: 4693-4718. [45] MWANDIRA W, NAKASHIMA K, KAWASAKI S. Bioremediation of Lead-Contaminated Mine Waste Using Microbially Induced Carbonate Precipitation[J]. International Symposium on Earth Resources Management & Environment, 2017, 109: 57-64. [46] WANG Z, SU J F, ALI A, et al. Microbially induced calcium precipitation based simultaneous removal of fluoride, nitrate, and calcium by Pseudomonas sp. WZ39: Mechanisms and nucleation pathways[J]. Journal of Hazardous Materials, 2021, 416(21): 125914. [47] TANG C S, YIN J, NING J J, ZHU C, et al. Factors affecting the performance of microbial-induced carbonate precipitation (MICP) treated soil: a review[J]. Environmental Earth Sciences, 2020, 79: 1-23. doi: 10.1007/s12665-019-8746-6 [48] AL-THAWADI S, CORD-RUWISCH R. Calcium Carbonate Crystals Formation by Ureolytic Bacteria Isolated from Australian Soil and Sludge[J]. Journal of Advanced Science and Engineering Research, 2012, 2: 12-26. [49] ANBU P, KANG C H, SHIN Y J, et al. Formations of calcium carbonate minerals by bacteria and its multiple applications[J]. SpringerPlus, 2016, 5: 1-26. doi: 10.1186/s40064-015-1659-2 [50] ZOU C X, XIAO M, JIANG Q H, et al. Properties and mechanisms of steel slag strengthening microbial cementation of cyanide tailings[J]. Chemosphere, 2024, 346: 140645. doi: 10.1016/j.chemosphere.2023.140645 [51] ZHANG J K, SU P D, LI L. Microbial induced carbonate precipitation modified steel slag: Mechanical improvement and erosion resistance to sulfate attack[J]. Journal of Cleaner Production, 2023, 405(4): 136982. [52] ZHANG Y S, LIU Y, SUN X D, et al. Application of microbially induced calcium carbonate precipitation (MICP) technique in concrete crack repair: A review[J]. Construction and Building Materials, 2024, 411: 134313. doi: 10.1016/j.conbuildmat.2023.134313 [53] LIU Y, ALI A, SU J F, et al. Microbial-induced calcium carbonate precipitation: Influencing factors, nucleation pathways, and application in waste water remediation[J]. Science of The Total Environment, 2022, 860(10): 160439. [54] NERELLA S G, THACKER P, MOHAMMED A, et al. Tumor associated carbonic anhydrase inhibitors: Rational approaches, design strategies, structure activity relationship and mechanistic insights[J]. European Journal of Medicinal Chemistry Reports, 2024, 10: 100131. doi: 10.1016/j.ejmcr.2024.100131 [55] LI T X, HU Y L, ZHANG B J. Biomineralization Induced by Colletotrichum acutatum: A Potential Strategy for Cultural Relic Bioprotection[J]. Frontiers in Microbiology, 2018, 9: 1884. doi: 10.3389/fmicb.2018.01884 [56] DECHO A, GUTIERREZ T. Microbial Extracellular Polymeric Substances (EPSs) in Ocean Systems[J]. Frontiers in Microbiology, 2017, 8: 922. doi: 10.3389/fmicb.2017.00922 [57] MUYNCK W, DE BELIE N, VERSTRAETE W. Microbial carbonate precipitation in construction materials: A review[J]. Ecological Engineering, 2013, 36(2): 118-136. [58] FISHMAN M, GIGLIO K, FAY D, et al. Physiological and genetic characterization of calcium phosphate precipitation by Pseudomonas species[J]. Scientific Reports, 2018, 8(1): 10156. doi: 10.1038/s41598-018-28525-4 [59] YI H H, QIAN C X. Synthesis and Characterization of Calcium Carbonate Nanoparticles via Bacterial Mineralization in Steel Slag Comprising Cementitious Materials[J]. Science of Advanced Materials, 2020, 12: 760-768. doi: 10.1166/sam.2020.3733 [60] WEI Y, XU H, XU S M, et al. Synthesis and characterization of calcium carbonate on three kinds of microbial cells templates[J]. Journal of Crystal Growth, 2020, 547(1): 125755 [61] 王丹. 钢渣碳酸化过程中碳酸钙生长与性能关系[D]. 大连理工大学, 大连, 2020.WANG D. The relationship between growth of calcium carbonate and properties during carbonation process of steel slag[D]. Dalian University of Technology, Dalian, 2020. [62] REN X W, RUI Y F, WANG K. Characteristics of bio-CaCO3 from microbial bio-mineralization with different bacteria species[J]. Biochemical Engineering Journal, 2021, 176: 108180. doi: 10.1016/j.bej.2021.108180 [63] LI L S, CHEN T F, GAO X J, et al. New insights into the effects of different CO2 mineralization conditions on steel slag as supplemental cementitious material[J]. Journal of Building Engineering, 2024, 84(11): 108566. [64] 伊海赫. 微生物提升钢渣胶凝材料安定性和利用率的作用及机制[D]. 东南大学, 南京, 2020.YI H H. Effect and Mechanism of Microorganism on Volume Stability and Utilization Efficiency of Steel Slag Cementitious Materials[D]. Southeast University, Nanjing, 2020. [65] GHOULEH Z, GUTHRIE R, SHAO Y. High-strength KOBM steel slag binder activated by carbonation[J]. Construction and Building Materials, 2015, 99(30): 175-183. [66] KO M S, CHEN Y L, JIANG J H. Accelerated carbonation of basic oxygen furnace slag and the effects on its mechanical properties[J]. Construction and Building Materials, 2015, 98(15): 286-293. [67] SIRIWARDENA D, PEETHAMPARAN S. Quantification of CO2 sequestration capacity and carbonation rate of alkaline industrial byproducts[J]. Construction and Building Materials, 2015, 91(2): 216-224. [68] MAHOUTIAN M, GHOULEH Z, SHAO Y. Carbon dioxide activated ladle slag binder[J]. Construction and Building Materials, 2014, 66(15): 214-221. [69] YADAV S, MEHRA A. Experimental study of dissolution of minerals and CO2 sequestration in steel slag[J]. Waste management, 2017, 64: 348-357. doi: 10.1016/j.wasman.2017.03.032 [70] FANG Y F, CHANG J, SHANG X P. The role of β-C2S and γ-C2S in carbon capture and strength development[J]. Materials and Structure, 2016, 49: 4417-4424. doi: 10.1617/s11527-016-0797-5 [71] MU Y D, LIU Z C, WANG F Z, et al. Carbonation characteristics of γ-dicalcium silicate for low-carbon building material[J]. Construction and Building Materials, 2018, 177(20): 322-331. [72] QIAN L, LIU J X, QI L Q. Effects of temperature and carbonation curing on the mechanical properties of steel slag-cement binding materials[J]. Construction and Building Materials, 2016, 124(15): 999-1006. [73] 詹悦, 王新, 宋雨轩, 等. 碳酸酐酶的固定化及其在二氧化碳转化中的应用[J]. 环境化学, 2023, 42(9): 3157-3166. doi: 10.7524/j.issn.0254-6108.2022040302ZHAN Y, WANG X, SONG Y X, et al. Immobilization of carbonic anhydrase and its application in carbon dioxide conversion[J]. Environmental Chemistry, 2023, 42(9): 3157-3166. doi: 10.7524/j.issn.0254-6108.2022040302 [74] LANG C P, LI M D, DAI R H, et al. Discussion on the Review and Outlook of Microbial Geotechnical Mineralization Technology[J]. IOP Conference Series: Earth and Environmental Science, 2020, 455(1): 012078. doi: 10.1088/1755-1315/455/1/012078 [75] AL QABANY A, SOGA K, SANTAMARINA J. Factors Affecting Efficiency of Microbially Induced Calcite Precipitation[J]. Journal of Geotechnical and Geoenvironmental Engineering, 2012, 138(8): 992-1001. doi: 10.1061/(ASCE)GT.1943-5606.0000666 [76] LI W Z, CAO M L, WANG D, et al. Increase in volume stability of RO phases in steel slag by combined treatment of alkali and dry carbonation[J]. Construction and Building Materials, 2023, 396(3): 132345. [77] FOULADI A, ARULRAJAH A, CHU J. Application of Microbially Induced Calcite Precipitation (MICP) technology in construction materials: A comprehensive review of waste stream contributions[J]. Construction and Building Materials, 2023, 388(1): 131546. [78] HUANG X L, ZHANG J F, ZHANG L. Accelerated carbonation of steel slag: A review of methods, mechanisms and influencing factors[J]. Construction and Building Materials, 2024, 411: 134603. doi: 10.1016/j.conbuildmat.2023.134603 [79] MO L W, YANG S, HUANG B, et al. Preparation, microstructure and property of carbonated artificial steel slag aggregate used in concrete[J]. Cement and Concrete Composites, 2020, 113: 103715. doi: 10.1016/j.cemconcomp.2020.103715 [80] WANG Y, SURANENI P. Experimental Methods to Determine the Feasibility of Steel Slags as Supplementary Cementitious Materials[J]. Construction and Building Materials, 2019, 204(6): 458-467. [81] RUI Y F, ZHANG X, MA Z Y. Different carbon treatments for steel slag powder and their subsequent effects on properties of cement-based materials[J]. Journal of Cleaner Production, 2022, 362(15): 132407. [82] RUI Y F, WANG C Y, WANG X M, et al. Bio-mineralization induced by Bacillus mucilaginosus in crack mouth and pore solution of cement-based materials[J]. Materials Science and Engineering: C, 2021, 126(47): 112120. [83] XUE B, QIAN C X. Mitigation of efflorescence of wallboard by means of bio-mineralization[J]. Frontiers in microbiology, 2015, 6: 1155. [84] PAN S Y, ADHIKARI R, CHEN Y H, et al. Integrated and innovative steel slag utilization for iron reclamation, green material production and CO2 fixation via accelerated carbonation[J]. Journal of Cleaner Production, 2016, 137(20): 617-631. [85] MEHTA A, ASHISH D. Silica fume and waste glass in cement concrete production: A review[J]. Journal of Building Engineering, 2020, 29: 100888. doi: 10.1016/j.jobe.2019.100888 [86] LIU P, MO L, ZHANG Z. Effects of carbonation degree on the hydration reactivity of steel slag in cement-based materials[J]. Construction and Building Materials, 2023, 370(17): 130653. [87] MARTINS A, FRANCO DE CARVALHO J M, DO NASCIMENTO DUARTE M, et al. Influence of a LAS-based modifying admixture on cement-based composites containing steel slag powder[J]. Journal of Building Engineering, 2022, 53(1): 104517. [88] LOTHENBACH B, SAOUT G, GALLUCCI E, et al. Influence of Limestone on the Hydration of Portland Cement[J]. Cement and Concrete Research, 2008, 38(6): 848-860. doi: 10.1016/j.cemconres.2008.01.002 [89] RUI Y F. CO2-fixing steel slag on hydration characteristics of cement-based materials[J]. Construction and Building Materials, 2022, 354(4): 129193. [90] LI W Z, CAO M L, WANG D, et al. Improving the hydration activity and volume stability of the RO phases in steel slag by combining alkali and wet carbonation treatments[J]. Cement and Concrete Research, 2023, 172: 107236. doi: 10.1016/j.cemconres.2023.107236 [91] CHEN Z M, LIU J X, LI R. Simulation and property prediction of MgO-FeO-MnO solid solution in steel slag[J]. Materials Letters, 2020, 273(15): 127930. [92] PANG B, ZHOU Z H, XU H X. Utilization of carbonated and granulated steel slag aggregate in concrete[J]. Construction and Building Materials, 2015, 84(1): 454-467. [93] CHEN Z W, GONG Z L, JIAO Y Y, et al. Moisture stability improvement of asphalt mixture considering the surface characteristics of steel slag coarse aggregate[J]. Construction and Building Materials, 2020, 251(10): 118987. [94] ZHENG T W. Influencing factors and formation mechanism of CaCO3 precipitation induced by microbial carbonic anhydrase[J]. Process Biochemistry, 2019, 91: 271-281. [95] YI H H, DU W X. Bacteria fixing CO2 to enhance the volume stability of ground steel slag powder as a component of cement-based materials aiming at clean production[J]. Journal of Cleaner Production, 2021, 314(6): 127821. -

点击查看大图

点击查看大图

计量

- 文章访问数: 93

- HTML全文浏览量: 37

- 被引次数: 0

下载:

下载: