Preparation and mechanical properties of tufting C/C composites

-

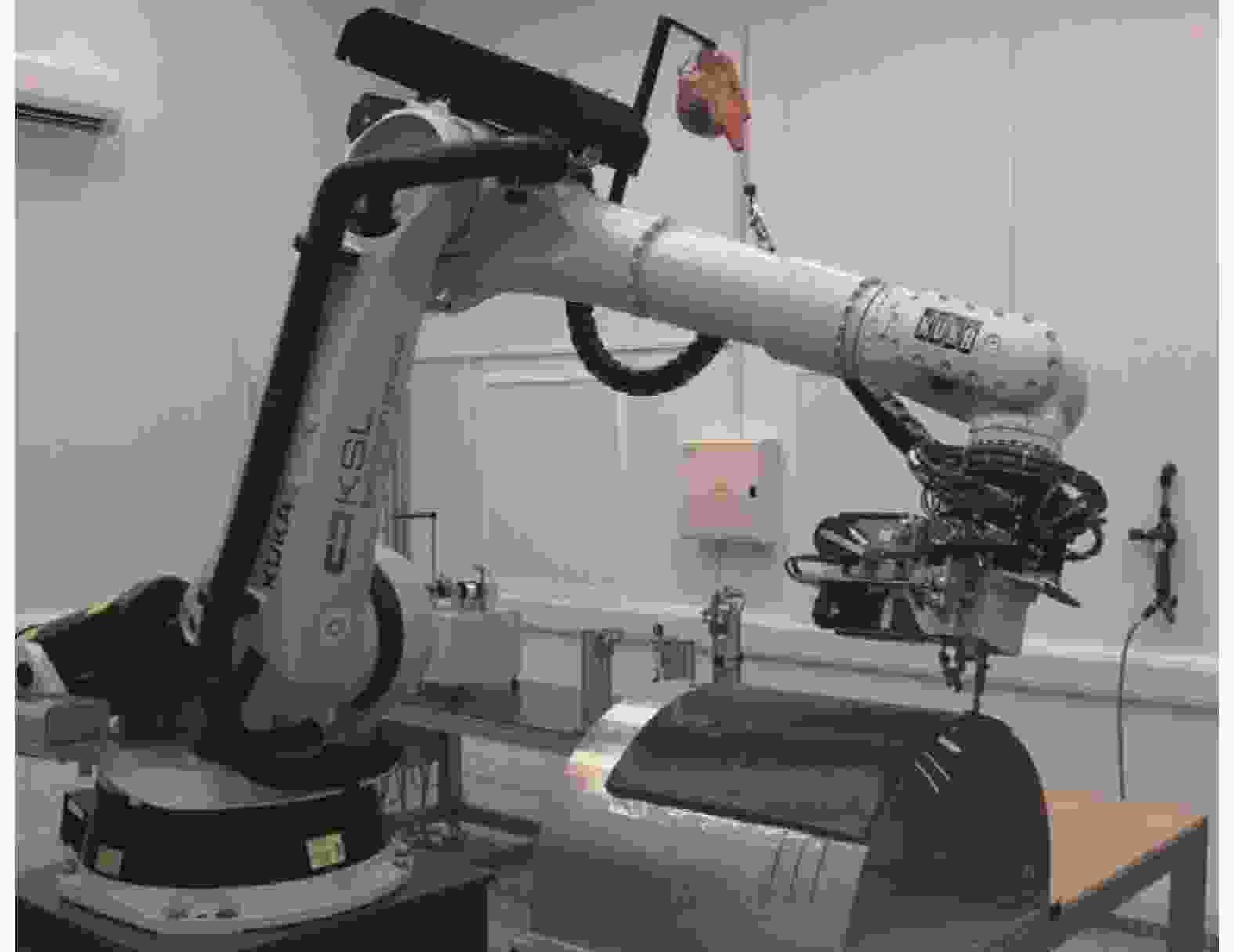

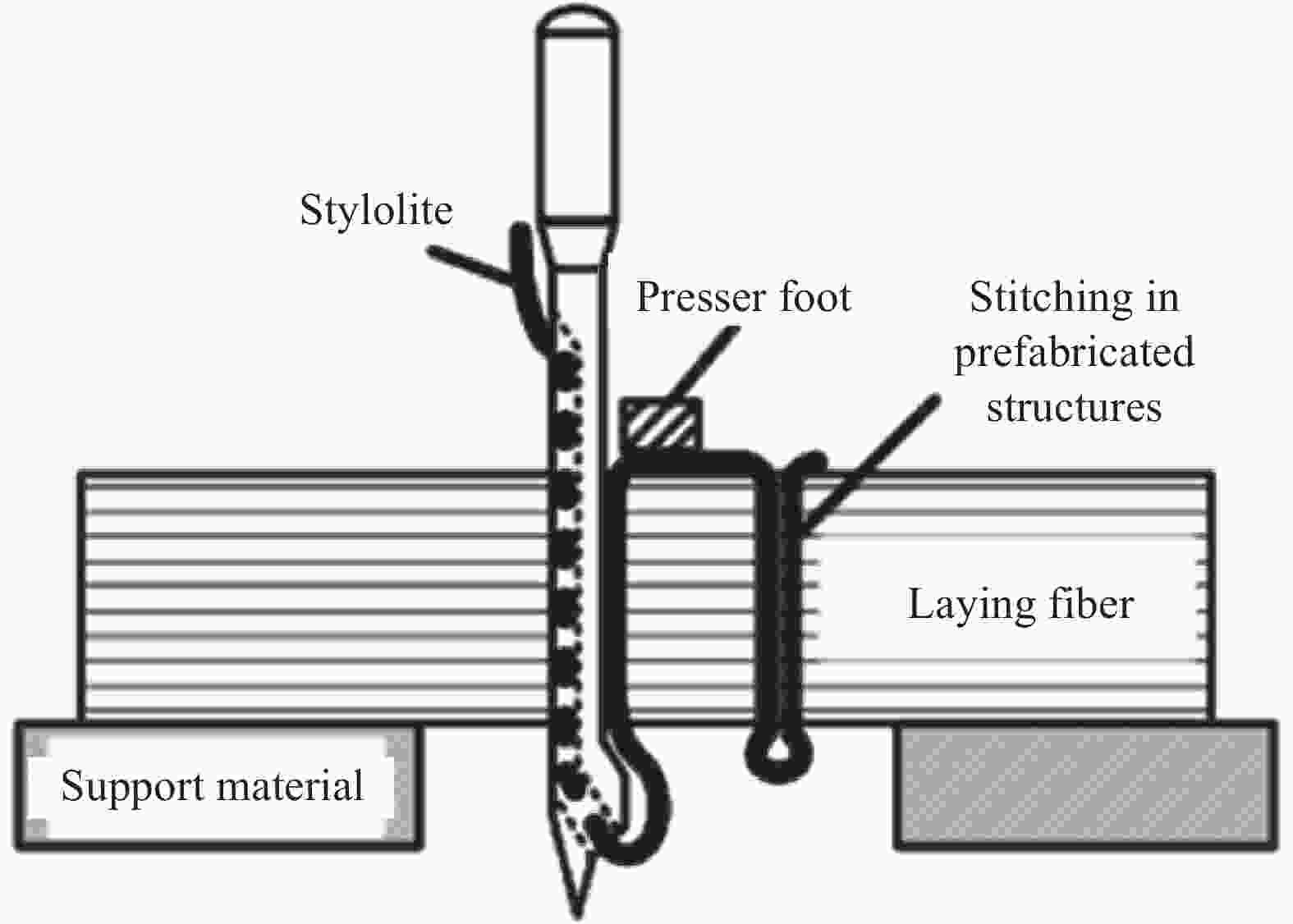

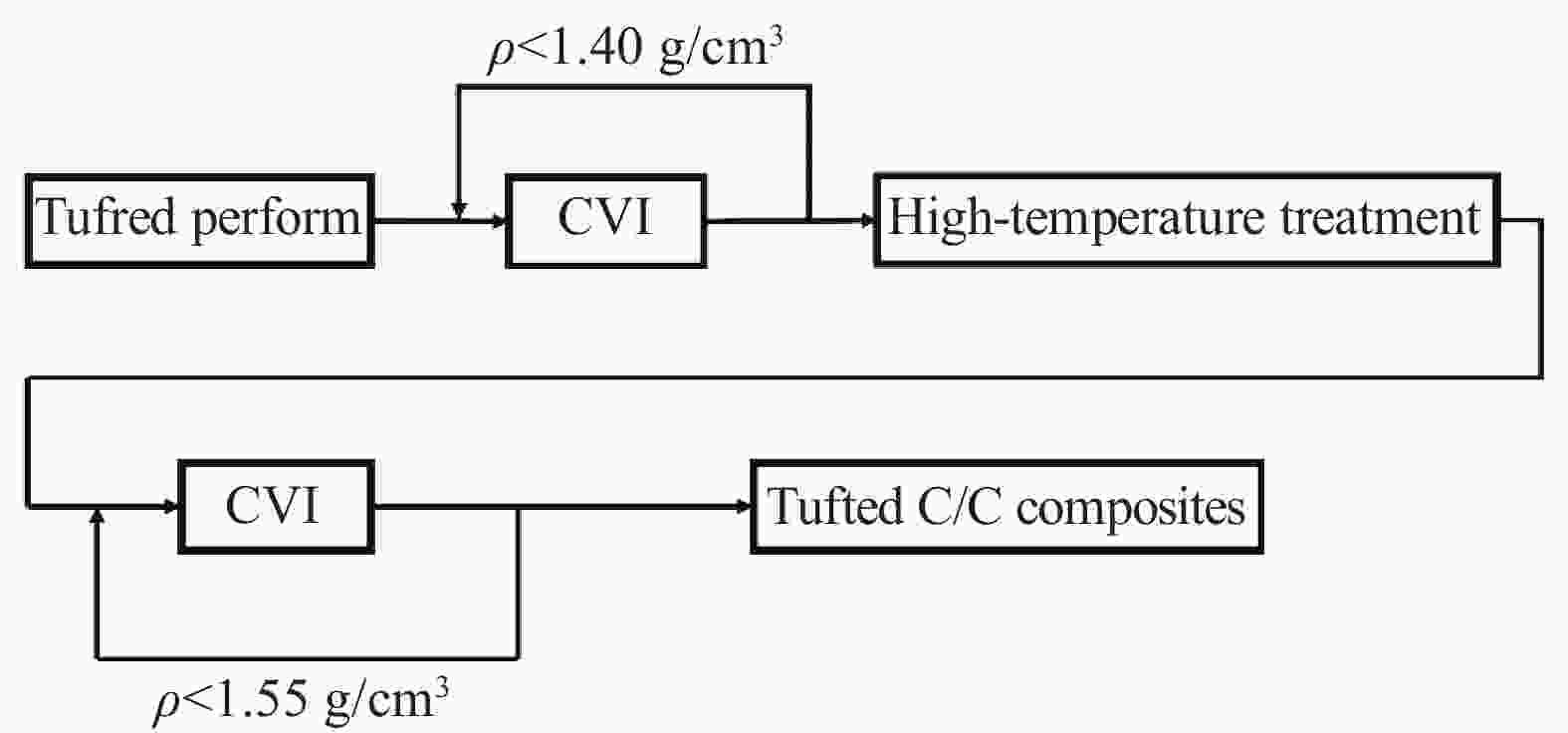

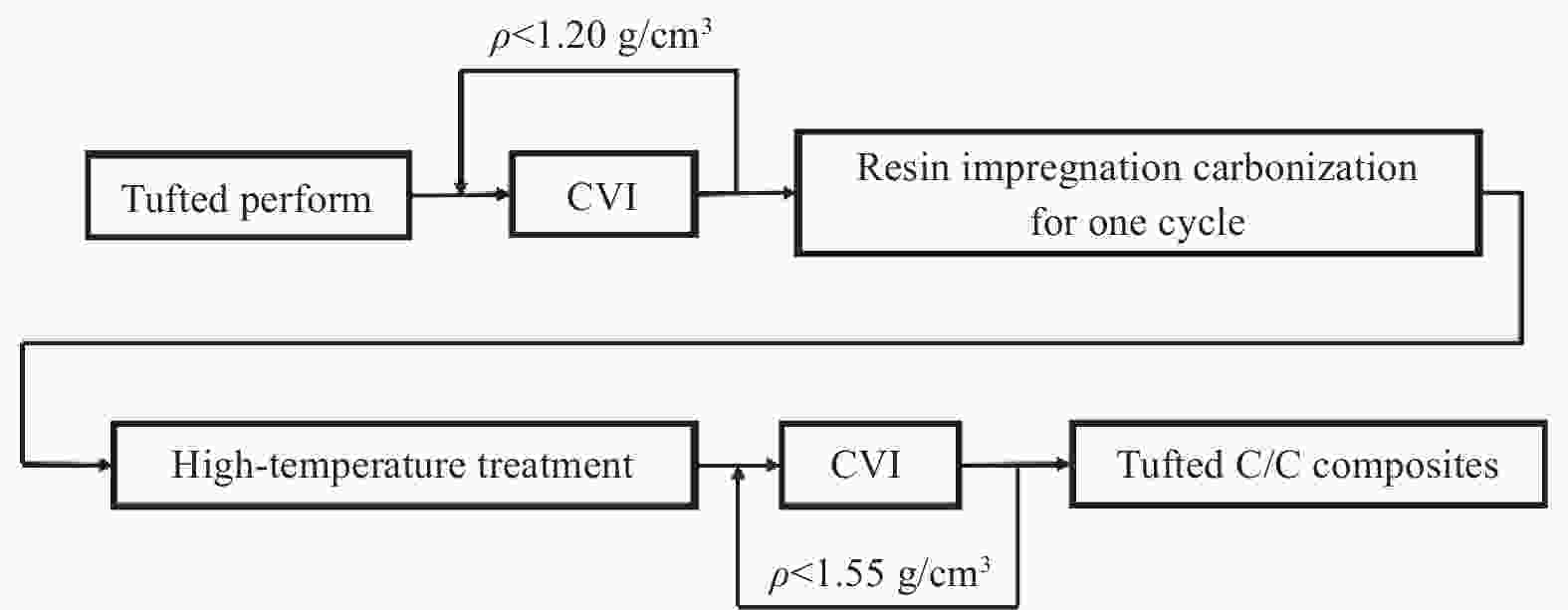

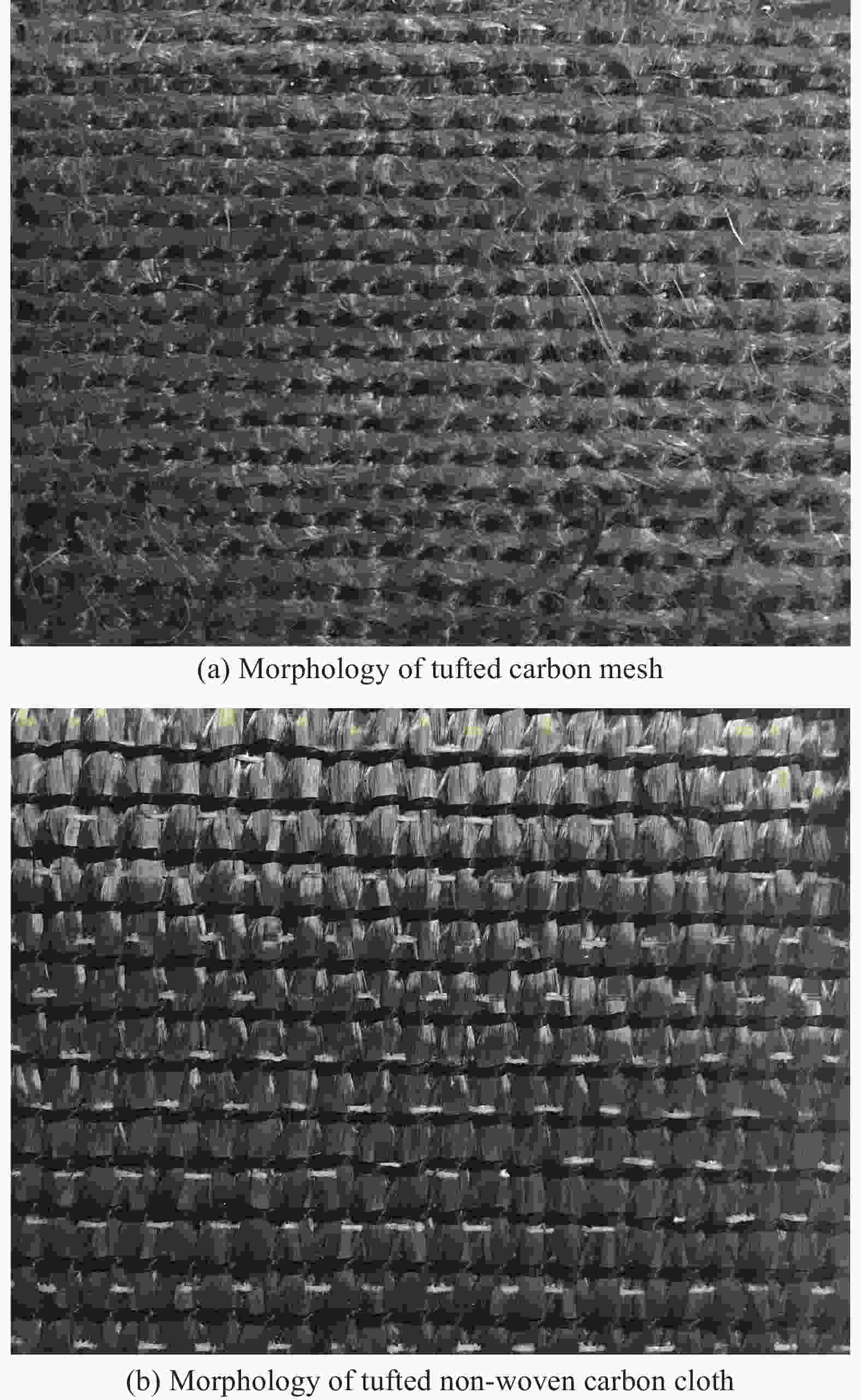

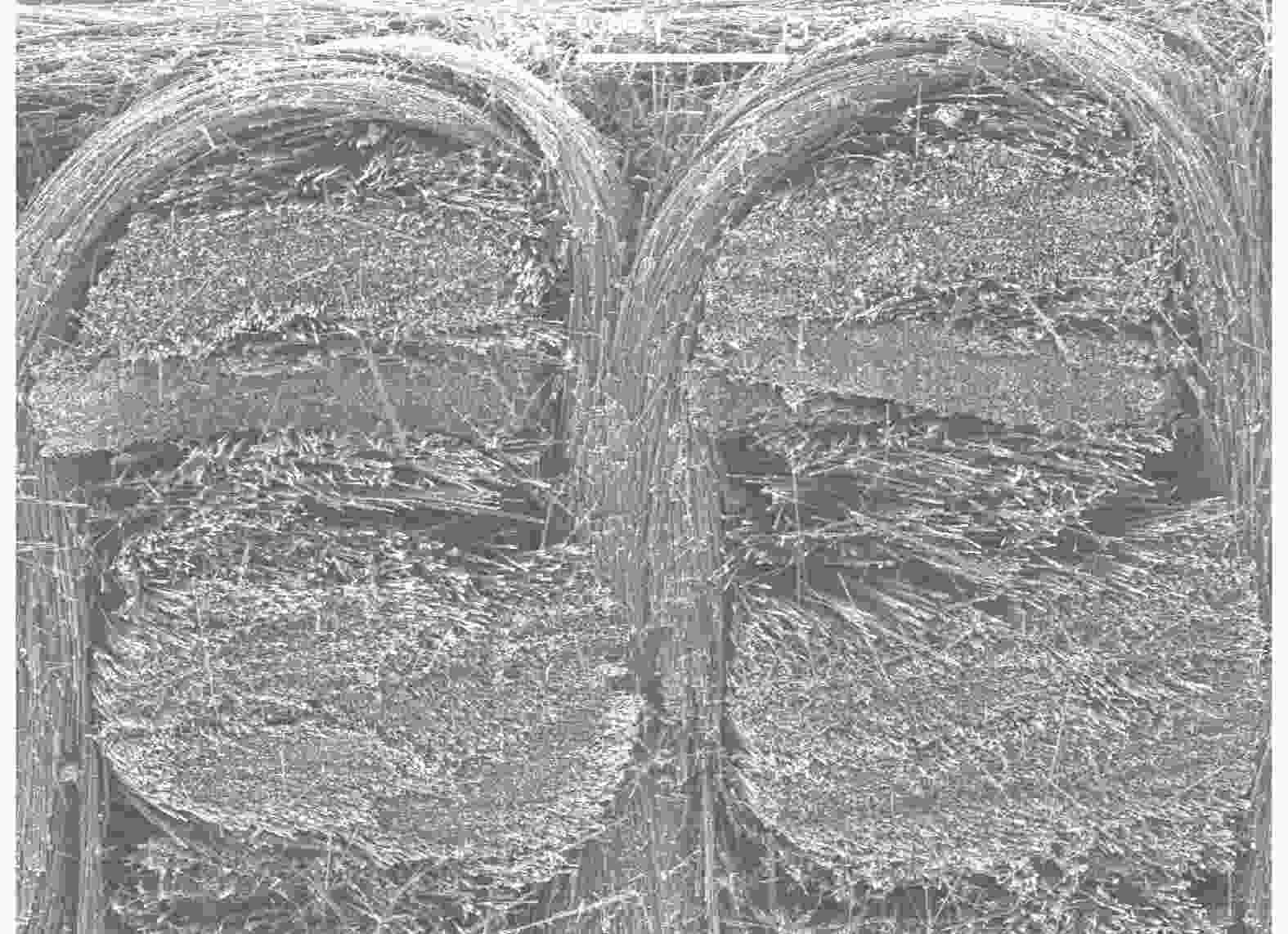

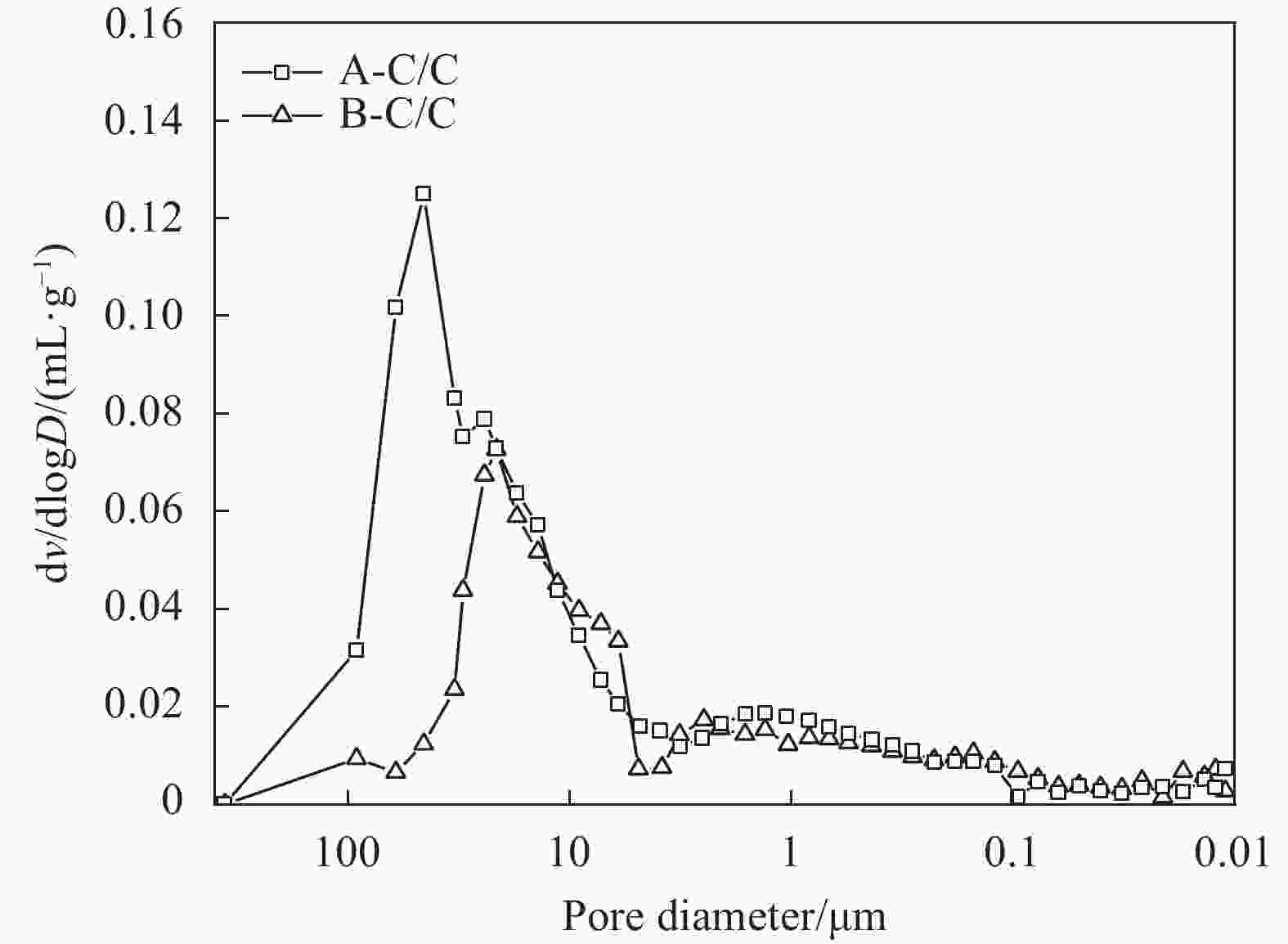

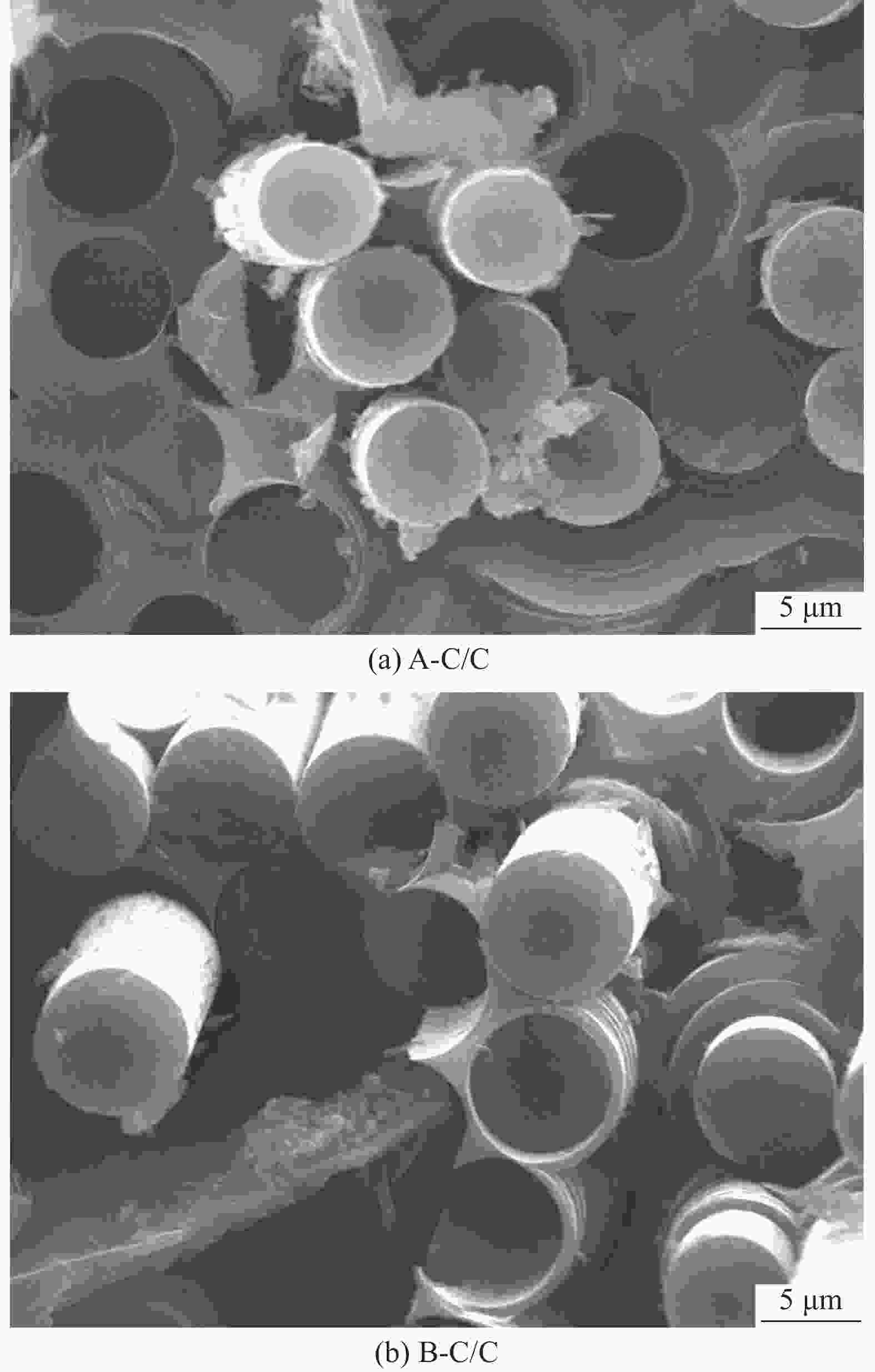

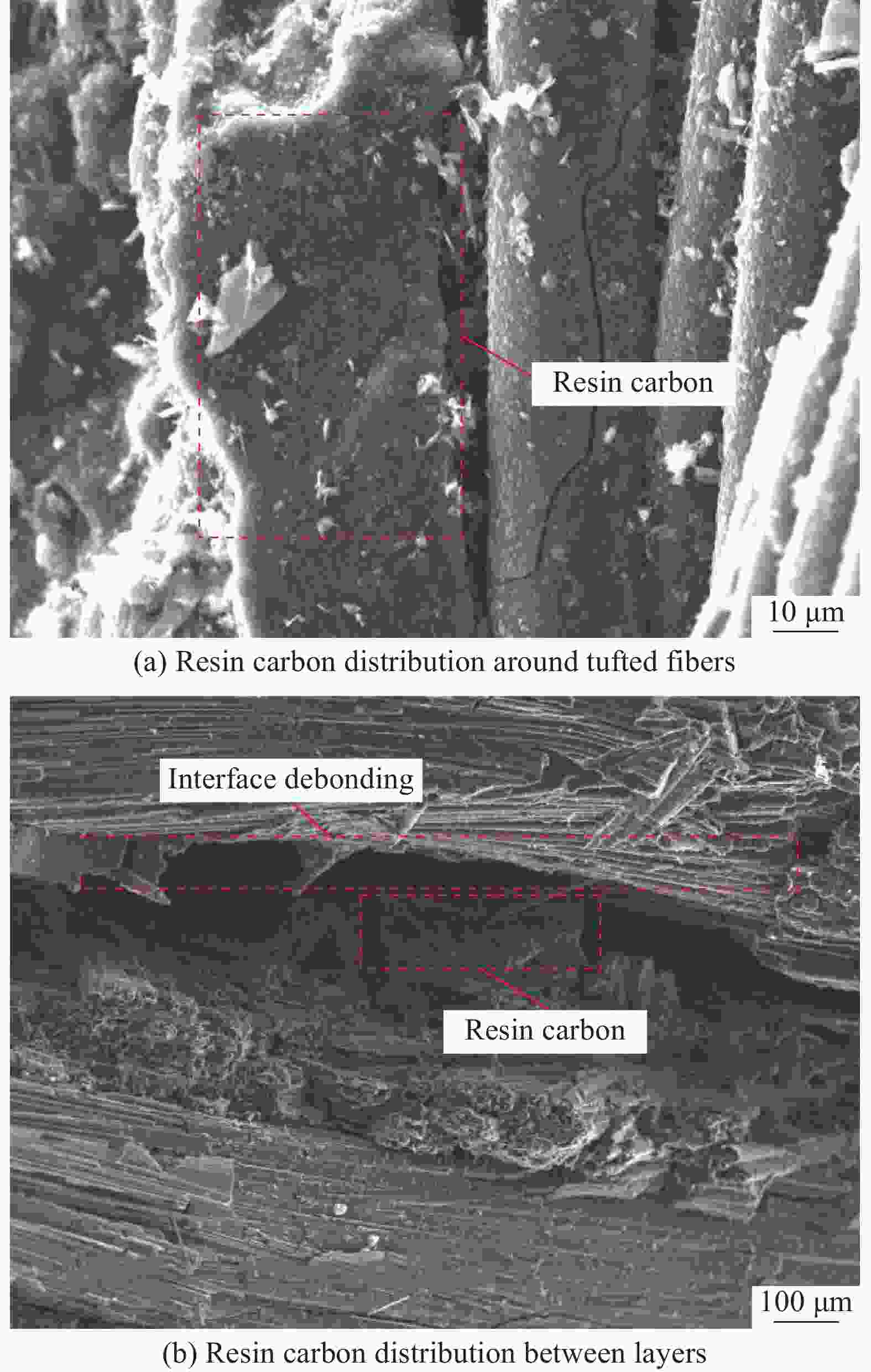

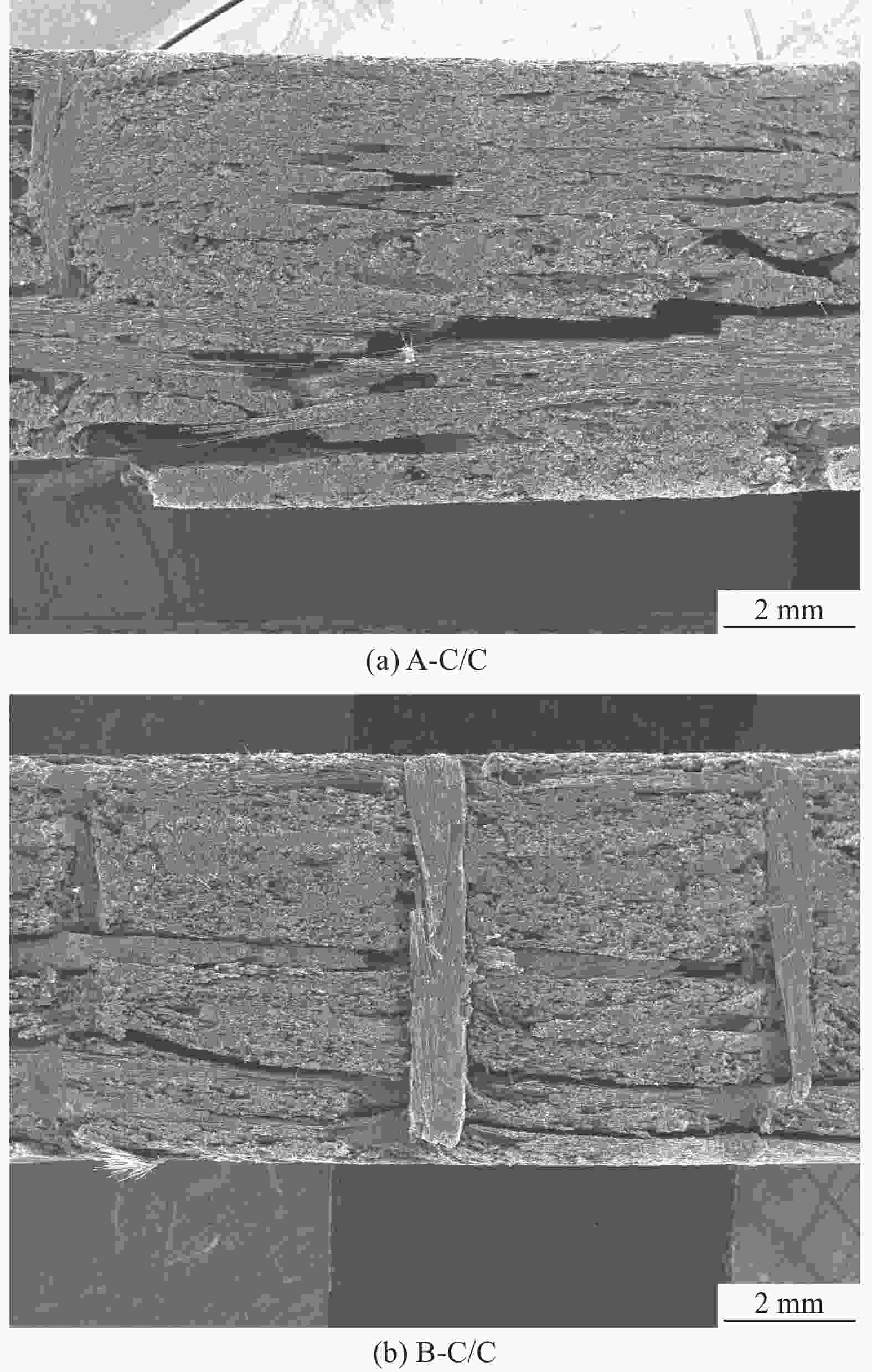

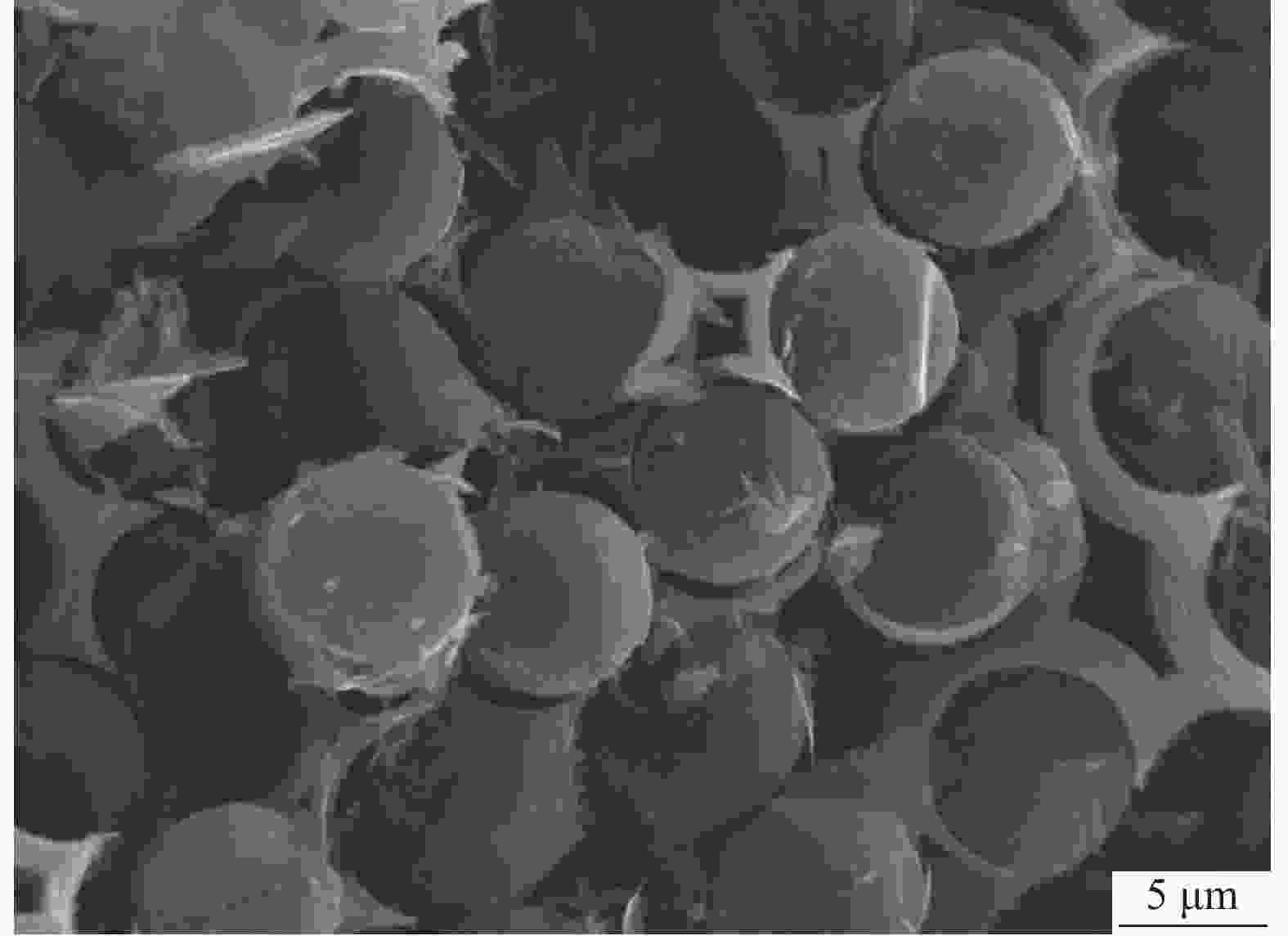

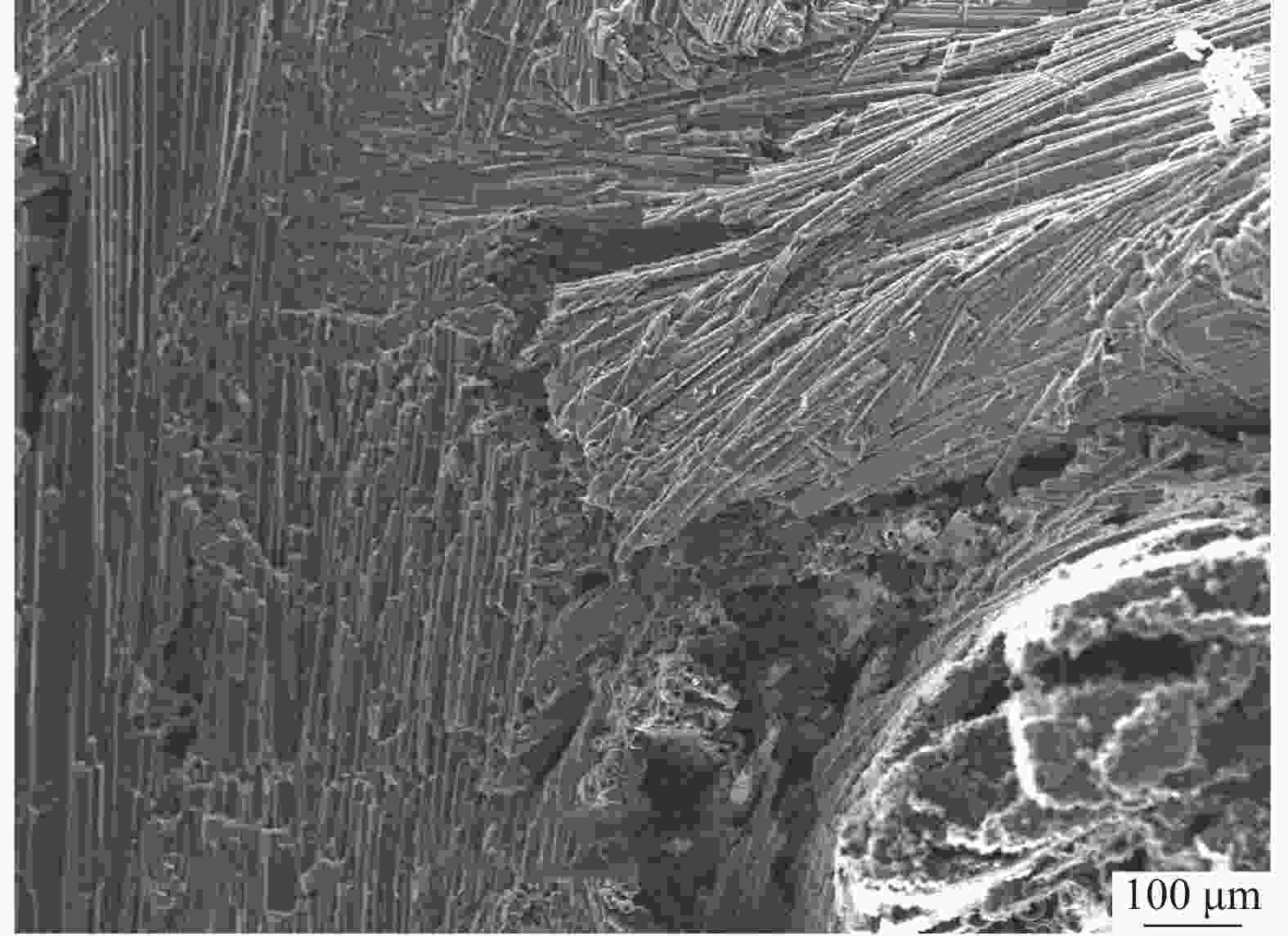

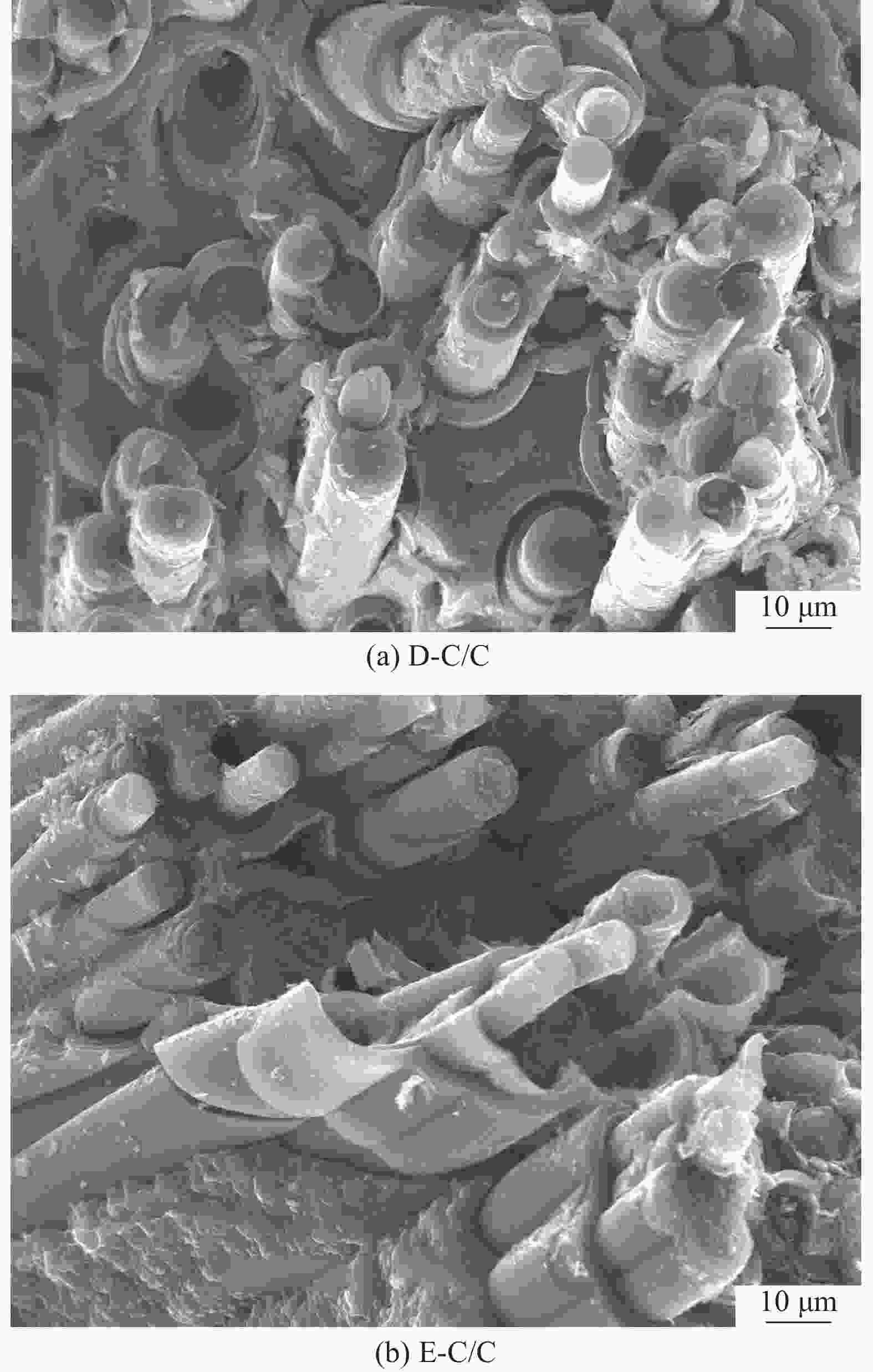

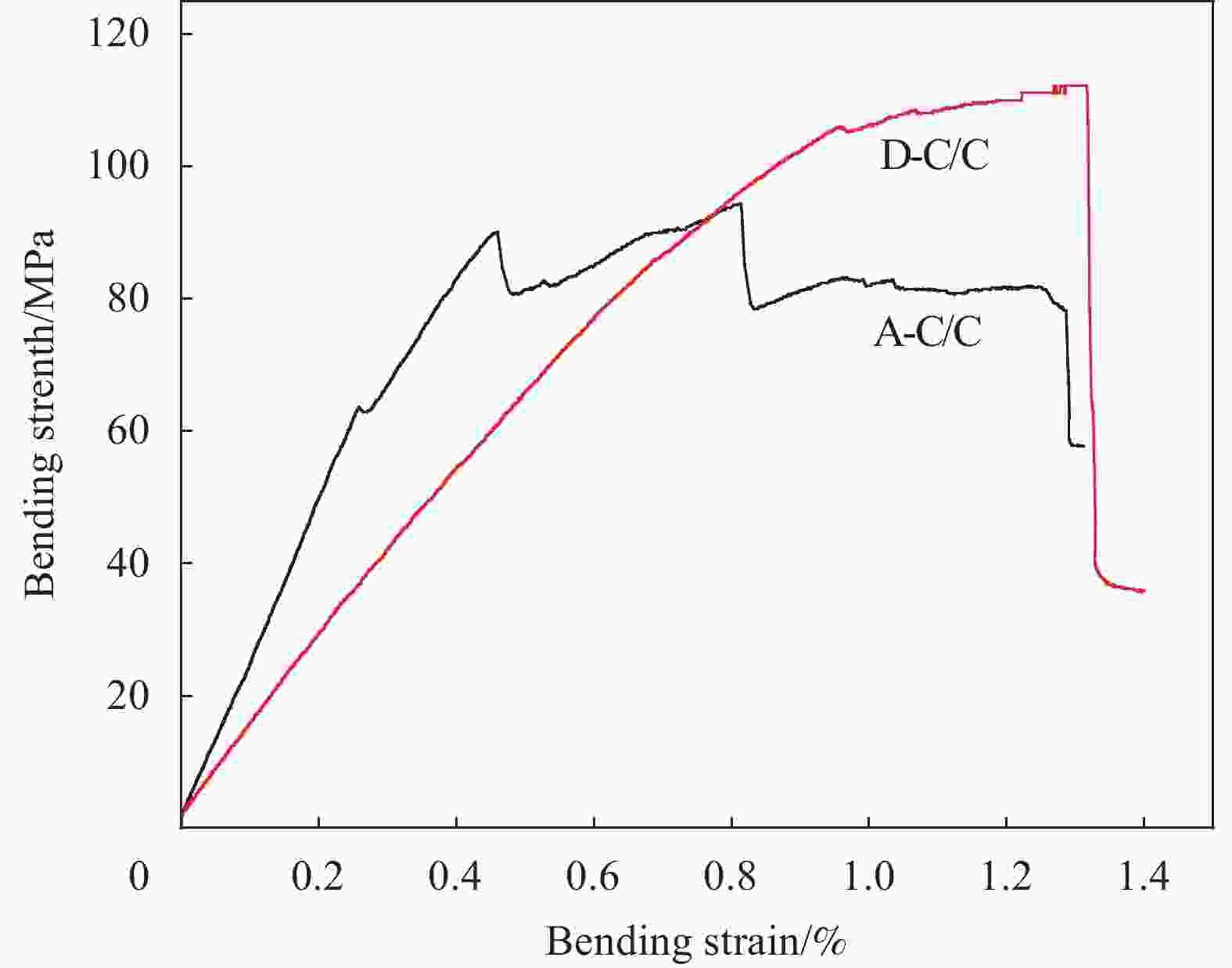

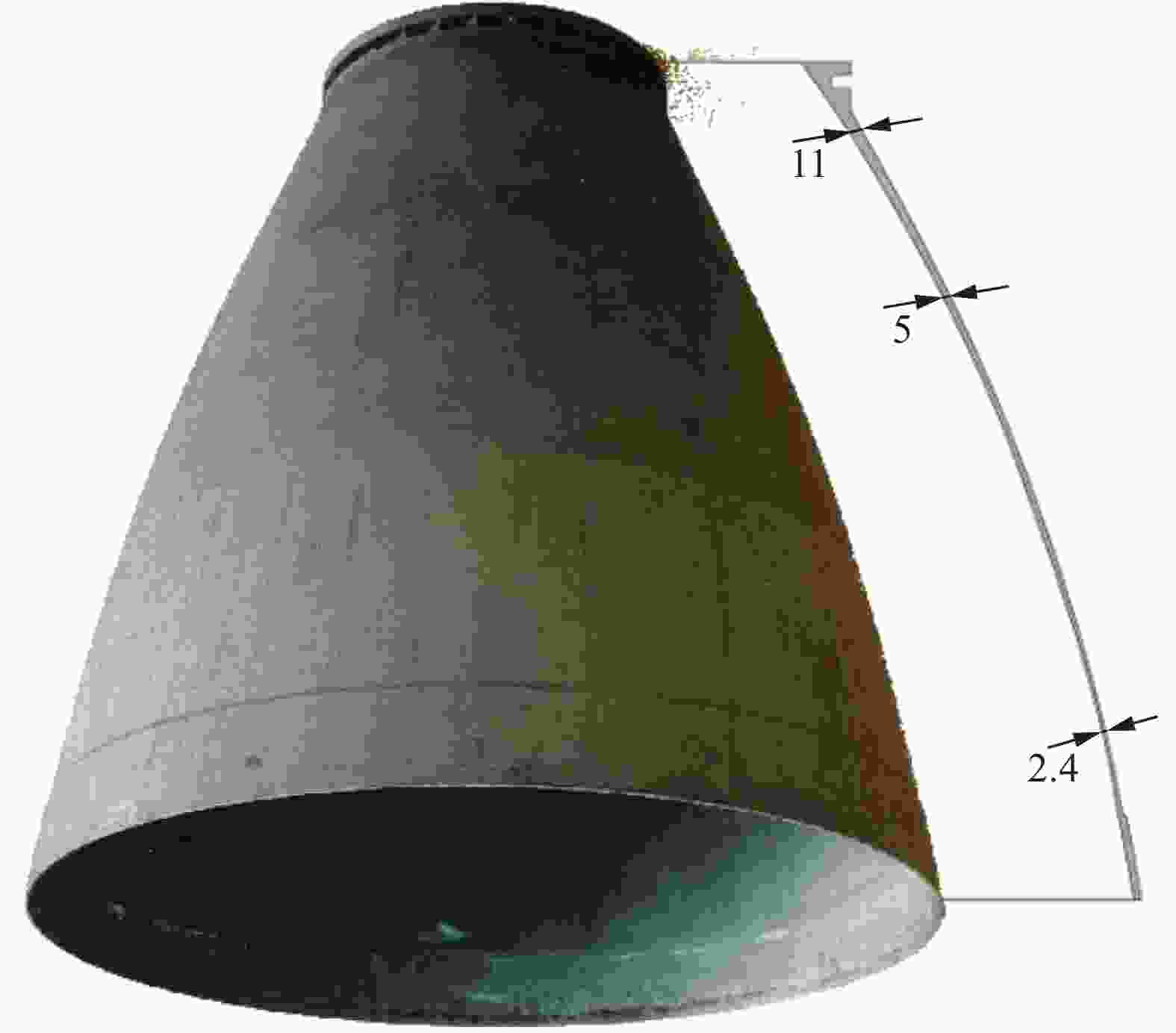

摘要: 采用Tufting缝合机器人研制碳纤维缝合预制体,通过改变预制体结构与致密化方式,制备具有不同结构的缝合C/C复合材料,探讨基体类型、网胎引入、针刺工艺等对缝合C/C复合材料力学性能的影响规律,并探讨力学性能影响机理。结果表明:在完全相同的预制体结构条件下,采用化学气相沉积工艺致密的缝合C/C拉伸模量和拉伸强度更高,采用化学气相沉积+糠酮树脂浸渍碳化工艺制备的缝合C/C具有更加优异的层间剪切性能与弯曲性能。在完全相同的复合致密条件下,网胎层的加入对于提高C/C复合材料弯曲、剪切性能有积极的作用,逐层针刺+缝合C/C复合材料强度性能优于缝合C/C复合材料,但因针刺工艺的引入削弱了缝合C/C复合材料的“假塑形”变形能力。Abstract: Using Tufting robot, carbon fiber tufted perform was developed. By changing the parameters of tufting and needle punching processes, tufted C/C composites with different structures and a combination of tufting and needle punching C/C composites were prepared. The effects of parameters such as matrix type, mesh felt and needle punching process on the mechanical properties of tufted C/C composites were studied, and the mechanism for the influence of preform structure on the mechanical properties of C/C composites were explored. The results showed that the addition of mesh layer or resin carbon matrix had a positive effect on improving the bending and shear performance of C/C composites. The strength performance of needle punched and tufted C/C composites was better than that of tufted C/C composites, but the introduction of needle punching technology weakened the “pseudo plastic” deformation of stitched C/C composites.

-

Key words:

- Tufting /

- C/C /

- Composite /

- Preform structure /

- Mechanical performance

-

表 1 缝合预制体结构类型

Table 1. Structure of tufted preforms

Number Forming method of preforms Layup type A Laying up + integral tufting Non-woven carbon fabrics + Carbon fiber mesh felts B C Laying up + integral tufting Non-woven carbon fabrics D Laying up + Layer by layer needling+ integral tufting Non-woven carbon fabrics + Carbon fiber mesh felts E Laying up + Cycle by Cycle needling + integral tufting Non-woven carbon fabrics + Carbon fiber mesh felts 表 2 缝合C/C复合材料密度

Table 2. Density of tufted preforms

Number Density of preforms g·cm−3 Density of composite g·cm−3 Preparation method A 0.578 1.55 CVI B 0.578 1.56 CVI+PIP C 0.792 1.58 CVI D 0.653 1.58 CVI E 0.575 1.57 CVI 表 3 缝合预制体纤维体积含量

Table 3. Fiber volume content of tufted preforms

Number Fiber volume

fractionFiber volume content

of mesh feltZ-direction

fiber contentXY-direction

fiber contentDensity of

preforms g·cm-3A 32.11% 4.23% 1.23% 26.66% 0.578 B C 44% 0 1.23% 42.77% 0.792 D 36.28% 4.77% 1.23% 30.27% 0.653 E 31.94% 4.20% 1.23% 26.51% 0.575 表 4 A-C/C与B-C/C力学性能对比

Table 4. Comparison of mechanical properties between A-C/C and B-C/C

Number Tensile modulus/GPa Tensile

strength/MPaFlexural modulus/GPa Flexural strength/MPa Shear strength/MPa A-C/C 42.73 82.40 17.57 95.53 9.95 B-C/C 35.41 71.38 19.75 125.67 12.09 表 5 C-C/C力学性能

Table 5. Mechanical properties of C-C/C

Number Tensile modulus/GPa Tensile strength/MPa Flexural modulus/GPa Flexural strength/MPa Shear strength/MPa C-C/C 37.35 95.50 7.75 43.14 5.39 表 6 D-C/C与E-C/C力学性能

Table 6. Mechanical properties of D-C/C and E-C/C

Number Tensile modulus/GPa Tensile strength/MPa Flexural modulus/GPa Flexural strength/MPa Shear strength/MPa D-C/C 32.60 91.34 13.70 114.55 16.82 E-C/C 35.26 80.13 20.80 102.63 9.37 -

[1] 杜善义. 先进复合材料与航空航天[I]. 复合材料学报, 2007, 24(1): l-12.DU Shanyi. Advanced composite materials and aerospace engineering[J]. Acta Materiae Compositae Sinica, 2007, 24(1): 1-12(in Chinese). [2] 李贺军. 碳/碳复合材料[J]. 新型碳材料, 200l, 16(2): 79-80.LI Hejun. Carbon/carbon composites[J]. New carbon materials, 2001, 16(2): 79-80 (in Chinese). [3] 苏君明, 周绍建, 李瑞珍, 等. 工程应用C/C复合材料的性能分析与展望[J]. 新型碳材料, 2015, (2): 106-114.SU Junming, ZHOU Shaojian, LI Ruizhen, et al. A review of carbon-carbon composites for engineering applications[J]. New carbon materials, 2015, (2): 106-114(in Chinese). [4] 李耿, 王周成, 生志斐, 等. C/C扩张段典型连接结构热应力对比分析及试验研究[J]. 固体火箭技术, 2017, 40(3): 289-294. doi: 10.7673/j.issn.1006-2793.2017.03.004LI Geng, WANG Zhoucheng, SHENG Zhifei, et al. Comparative analysis of thermal stress and test research for C/C divergent section with typical connecting structure[J]. Journal of Solid Rocket Technology, 2017, 40(3): 289-294(in Chinese). doi: 10.7673/j.issn.1006-2793.2017.03.004 [5] LANCOMBE A, LACOSTE M, PICHON T. 3D Novoltex and Naxeco SepcarbCarbon-Carbon Nozzle Extensions[R]. AIAA-2008-5236 [6] ALAIN L. High Temperature Composite Nozzle Extensions: A Mature and Efficient Technology to Improve Upper Stage Liquid Rocket Engine Performance. AIAA, 2007, 2007-5470. [7] 查柏林, 高勇, 王金金, 等. C/C复合材料在超声速富氧烧蚀环境下的烧蚀试验方法研究[J]. 固体火箭技术, 2024, 47(1): 87-98. doi: 10.7673/j.issn.1006-2793.2024.01.011ZHA Bailin, GAO Yong, WANG Jinjin, et al. Ablation test method for C/C composites in supersonic oxygen-enriched ablation environment[J]. Journal of Solid Rocket Technology, 2024, 47(1): 87-98(in Chinese). doi: 10.7673/j.issn.1006-2793.2024.01.011 [8] 白侠, 李辅安, 李崇俊, 等. 纤维单向缠绕制备C/C扩张段成型技术[J]. 宇航材料工艺, 2008, 38(4): 63-65,69. doi: 10.3969/j.issn.1007-2330.2008.04.016BAI Xia, LI Fuan, LI Chongjun, et al. Molding Technology of New C/C Divergent Section[J]. Aerospace Materials & Technology, 2008, 38(4): 63-65,69(in Chinese). doi: 10.3969/j.issn.1007-2330.2008.04.016 [9] 刘苏骅, 李崇俊, 嵇阿琳. Tufting缝合复合材料预制体的成型与研究进展[J]. 航空制造技术, 2017, (14): 88-92,96.LIU Suhua, LI Chongjun, JI Alin. Manufacture and Advances of Tufting Composite Preform[J]. Aeronautical Manufacturing Technology, 2017, (14): 88-92,96(in Chinese). [10] MOURITZ A P, BANNISTER M K, FALZON P J, et al. Review of applications for advanced three-fibre textile composites[J]. Composites Part A Applied Science & Manufacturing, 1999, 30(12): 1445-1461. [11] SICKINGER C, HERRMANN A S, SICKINGER C, et al. Structural stitching as a method to design high performance composites in future [C], International Techtextil-Symposium for Technical Textiles, Nonwovens and Textile-Reinforced Materials, Germany. 2001. [12] ING D, WITTING J. Recent development in robotic stitching technology for textile structural composites[J]. JTATM, 2001, 2(1): 1-8. [13] GRUNDMANN T, GRIES T, KORDI M T, et al. Robot-supported joining of reinforcement textiles with one-sided sewing heads[J]. Technical Textiles, 2006, 49(4): 200. [14] A. V. HAWLEY, Preliminary design of an advanced technology composite wing for a transport aircraft [C], Proceedings of the 53rd Annual Conference, Society of Allied Weight Engineers (SAWE), Long Beach, CA, 23–25 May, 1994. [15] THURM T. Applications of one-sided stitching techniques for resin infusion preforms and structures[J]. Sampe Journal, 2005, 41(1): 64-67. [16] TREIBER, JOHANNES W G. Performance of tufted carbin fibre/epoxy composites[J]. Cranfield University, 2011. [17] DELL’ANNO G, GIUSEPPE. Effect of tufting on the mechanical behaviour of carbon fabric/epoxy composites[J]. Cranfield University, 200730. [18] 李新涛, 赵高文, 许正辉, 等. 缝合结构C/C复合材料的制备及组织[J]. 宇航材料工艺, 2011, 41(1): 58-60,65. doi: 10.3969/j.issn.1007-2330.2011.01.014LI Xintao, ZHAO Gaowen, XU Zhenghui, et al. Fabrication and Microstructures of Stitched C/C Composites[J]. Aerospace Materials & Technology, 2011, 41(1): 58-60,65(in Chinese). doi: 10.3969/j.issn.1007-2330.2011.01.014 [19] 周红英, 张晓虎, 邹武, 等. 糠酮树脂碳及其碳/碳复合材料微观结构与性能研究[J]. 固体火箭技术, 2007, 30(3): 260-263. doi: 10.3969/j.issn.1006-2793.2007.03.019ZHOU Hongying, ZHANG Xiaohu, ZOU Wu, et al. Study on microstructure and performance of FA resin carbon and FA resin matrix carbon-carbon composites[J]. Journal of Solid Rocket Technology, 2007, 30(3): 260-263 (in Chinese). doi: 10.3969/j.issn.1006-2793.2007.03.019 [20] 王春敏, 董娟, 董孚允. 缝合复合材料的力学性能[J]. 纤维复合材料, 2002, 18(1): 18-22. doi: 10.3969/j.issn.1003-6423.2002.01.006WANG Chunmin, DONG Juan, DONG Fuyun. Mechanical Properties of Stitched Composites[J]. Fiber Composites, 2002, 18(1): 18-22(in Chinese). doi: 10.3969/j.issn.1003-6423.2002.01.006 [21] TANG Ssufang, ZHOU Xingming, DENG Jjingyi, et al. The preparation of 2D C/C composites by chemical vapor infiltra-tion[J]. New Carbon Materials, 2005, 20(2): 139-143. [22] 陶洋, 李存静, 逄增媛, 等. 展宽布/网胎针刺C/C复合材料制备及力学性能[J]. 复合材料学报, 2024, 41(4): 1934-1944.TAO Yang, LI Cunjing, PANG Zengyuan, et al. Preparation and mechanical properties of spreading cloth/carbon fiber felt needled C/C composites[J]. Acta Materiae Compositae Sinica, 2024, 41(4): 1934-1944(in Chinese). [23] 熊翔, 黄伯云, 李江鸿, 等. 准三维C/C复合材料的弯曲性能及其破坏机理[J]. 航空材料学报, 2006, 26(4): 88-91.XIONG Xiang, HUANG Baiyun, LI Jiang-hong, et al. Bending Property and Fracture Mechanism of Quasi-3D C/C Composites[J]. Journal of Aeronautical Materials, 2006, 26(4): 88-91. (in Chinese) [24] 刘宇峰, 李同起, 冯志海, 等. 薄层化碳布缝合碳/碳复合材料制备与性能[J]. 复合材料学报, 2021, 38(4): 1210-1222.LIU Yufeng, LI Tongqi, FENG Zhihai, et al. Preparation and properties of spreading carbon cloth stitched C/C composite[J]. Acta Materiae Compositae Sinica, 2021, 38(4): 1210-1222 (in Chinese). [25] 李艳, 崔红, 王斌, 等. 致密化工艺对厚壁针刺 C/C 复合材料性能的影响[J]. 复合材料学报, 2017, 34(10): 2337-2343.LI Yan, CUI Hong, WANG Bin, et al. Effect of densify-cation methods on properties of thick-wall needled C/Ccomposites[J]. Acta Materiae Compositae Sinica, 2017, 34(10): 2337-2343 (in Chinese). [26] XU H, LI L, LI G, et al. In situ characterization of the flexu-ral behavior and failure mechanism of 2D needle-punched carbon/carbon composites by digital image correlation[J]. Journal of Materials Science, 2022, 57(24): 11077-11091. doi: 10.1007/s10853-022-07272-y [27] 卢雪峰, 张洁, 钱坤, 等. 密度梯度变化预制体对 C/C 复合材料结 构 和 力 学 性 能 的 影响[J]. 化 工 新 型 材 料, 2015, 43(8): 160-162.LU Xuefeng, ZHANG Jie, QIAN Kun, et al. Effect of carbon fiber preform with variable density on the structure and mechanical property of C/C composites[J]. New Chemical Materials, 2015, 43(8): 160-162(in Chinese). -

点击查看大图

点击查看大图

计量

- 文章访问数: 84

- HTML全文浏览量: 29

- 被引次数: 0

下载:

下载: