Research process in self-powered electrochromic devices

-

摘要: 电致变色器件(ECDs)在外加电场下颜色可以发生可逆改变,通常ECDs需要接入外部电路提供驱动电压,这限制了ECDs的应用。近年来,研究者将供电器件与ECDs整合,制备成为自供能的ECDs,并取得了显著的进展。太阳能、化学能和力学能均可通过合理利用作为ECDs变色的驱动能源,有效满足了ECDs的实际使用需求,极大地促进了ECDs研究领域的发展。本文综述了近年来自供能ECDs的研究进展,并对未来自供能ECDs的实际应用进行了展望。Abstract: The electrochromic devices (ECDs) can achieve reversible color change under the applied electric field. Generally, an external circuit is necessary to provide driving voltage for ECDs, which limits the practical application to some extent. In recent years, researchers have paid attention to the integration of power supply devices and ECDs to prepare self-powered ECD, and remarkable progress has been made. Various kinds of energy, such as solar energy, chemical energy and mechanical energy, can be used as the driving energy, which effectively meet the needs and greatly promote the development of the ECDs. Here, the progress in self-powered ECDs is reviewed and the practical application of the self-powered ECDs is prospected.

-

Keywords:

- electrochromic /

- self-powered /

- solar energy cell /

- chemical energy /

- triboelectric nanogenerator

-

我国上世纪末和本世纪初曾修建了大量的混凝土桥梁,近年来在车辆荷载和自然环境因素的共同作用下,其中部分桥梁出现了诸如表层混凝土开裂和梁体下挠等不同程度的损伤[1]。为确保桥梁使用过程中的安全性和耐久性,桥梁加固技术在桥梁修复领域被大规模地使用。传统加固技术诸如粘贴钢板和增大混凝土截面等,虽然能改善桥梁使用情况,但不可避免地会带来材料自重大和加工工艺要求高等问题[2]。对比传统加固工艺,使用新型碳纤维增强复合材料(Carbon fibre reinforced polymer,CFRP)进行桥梁加固的技术在最近几年开始广受欢迎[3-5]。CFRP材料具有易于施工、良好的抗腐蚀性、较强的抗疲劳度、极高的抗拉强度和较低的密度等优点,这些工程上的优势让CFRP材料在混凝土结构加固补强工程中被广泛地应用[6]。

CFRP材料存在高强度和弹性模量不协调的问题,导致有时在CFRP板远未达到抗拉强度之前加固梁就已损坏,造成了CFRP材料的抗拉强度浪费。为此预应力CFRP加固技术在近年来得以大规模发展。现阶段预应力CFRP加固技术主要分为表面粘贴(Externally bonded,EB)技术和表层嵌贴(Near surface mounted,NSM)技术。其中,表面粘贴预应力CFRP技术将CFRP材料外贴于混凝土结构表面,并在端部使用锚具进行固定。表面粘贴技术的使用存在一定程度的粘结剥离风险,并且锚具的使用也会带来成本激增的问题。表层嵌贴预应力CFRP技术主要使用环氧树脂粘结剂将CFRP板条嵌贴在混凝土表面预先开的槽内,让CFRP板条与混凝土结构充分接触,共同受力,提升了CFRP-环氧树脂之间的界面粘结性能[7]。对比表面粘贴技术,表层嵌贴技术有着更高的加固效率及对外界环境因素的抗干扰性,嵌贴段较高的粘结性能也使CFRP板条不需要额外的锚具固定。然而,荷载在嵌贴CFRP板端容易形成应力集中,过早引起始于CFRP板端的混凝土保护层剥离破坏[8];另外在混凝土表面大规模开槽也对施工技术水平提出了高要求。

为了解决现有预应力CFRP加固方法的缺点,端部嵌贴(Near end enhanced embedment,NEEE)预应力CFRP加固技术被提出[9]:使用“端部嵌贴、跨中外贴”的方法,即CFRP板的中间大部分区段外贴在混凝土表面,仅两侧梁端的一小段CFRP被压入并嵌贴在混凝土预开槽中。该种新型加固技术较传统方法优势主要在于:(1) 端部嵌贴段在合理参数设计下能提供充分粘结力以锚固预应力CFRP,而无需依赖如EB技术中布置于CFRP端部的永久机械锚具;(2) 端部嵌贴段中CFRP弯折构造能够抑制结构跨中拉伸应力向梁端传递,进而抑制NSM加固混凝土结构时容易过早出现的板端混凝土保护层剥离破坏,提升结构承载性能;(3) 避免了大规模开槽。如上所述,端部嵌贴段中CFRP板与混凝土界面的粘结性能决定加固系统的可靠性,有必要针对其进行系统研究。仅有的相关研究针对端部嵌贴平嵌段的粘结性能开展,Lyu等[10]研究了混凝土槽尺寸、CFRP嵌贴深度、混凝土强度对粘结性能的影响,实验结果表明当混凝土槽宽与CFRP板的宽度比为1.5时,水平嵌贴CFRP-环氧树脂界面有充分的粘结性能,在此基础上提出了平嵌段的CFRP-混凝土界面粘结-滑移关系模型。然而,尚未有端部嵌贴斜嵌段粘结性能的研究实施。现有与CFRP-混凝土界面粘结性能相关研究一般针对EB与NSM技术进行,应能对本文试验提供参考。一般认为EB CFRP-混凝土界面易发生剥离破坏[11],且破坏过程极其迅速,带有显著的脆性特征[12]。相比之下,将CFRP嵌入混凝土表面预开槽中的方法,例如NSM技术,使CFRP-混凝土界面粘结面积增加,显著增强了界面抗剥离能力[13]。一些学者针对NSM CFRP-混凝土界面粘结性能的影响因素开展了试验研究。Lee等[14]发现,增加混凝土槽尺寸能显著地提高粘结强度;然而Novidis等[15]得到了不同观点,并认为当发生CFRP-粘结胶界面剥离时槽尺寸与粘结强度呈正相关,当发生粘结胶-混凝土界面剥离时槽尺寸与粘结强度呈负相关或没有相关性。粘结长度同样被认为是界面粘结性能的关键影响因素。De Lorenzis等[16]发现NSM CFRP-混凝土界面粘结承载力随着粘结长度的增加而增加,其增长率与局部粘结-滑移关系的脆性紧密相关,平均粘结强度则由于粘结应力沿粘结长度的不均匀分布而降低,这与Achillides等[17]的结论一致。除此之外,NSM CFRP埋深与界面粘结性能的相关性也得到了研究。彭晖等[18]研究了不同CFRP板埋深对CFRP-混凝土界面粘结性能的影响,发现CFRP板位于正中时粘结刚度最大,进一步增大或减小CFRP埋深均会削弱界面粘结性能;相比之下,Oehlers等[19]则认为CFRP板埋入深度越大时粘结性能越强。综上所述,混凝土槽尺寸、CFRP埋深和粘结长度是嵌入式加固技术中的关键影响因素,且因素与CFRP-混凝土界面粘结性能的相关性尚未明确,有必要予以研究。

采用端部嵌贴CFRP加固结构时,端部CFRP板需水平埋入梁端混凝土槽中,由此产生的与传统嵌入式CFRP加固方法的粘结构造区别在于:端部嵌贴CFRP与结构混凝土之间的粘结呈3种类型:(1) CFRP平贴于混凝土表面;(2) CFRP水平嵌贴于混凝土槽中;(3) 介于混凝土表面的CFRP板与水平嵌贴于混凝土中的CFRP板之间的斜向嵌贴。斜向嵌贴的CFRP板其上下两层的树脂层厚度沿粘结长度变化,会导致CFRP-环氧树脂的粘结-滑移本构关系随之变化。考虑以上差别,本文设计独特几何形状的混凝土棱柱体试件以模拟斜嵌CFRP的真实受力行为,研究了端部嵌贴技术中斜嵌段CFRP与混凝土之间的粘结性能,考察了混凝土斜槽角度、CFRP板埋深和粘结长度对CFRP-混凝土界面粘结承载力、沿粘结长度变化的峰值粘结剪应力、峰值相对滑移值及局部界面断裂能等的影响,建立了斜嵌段的粘结-滑移模型并验证了其准确性。

1. 试验设计

1.1 试验参数

端部嵌贴CFRP板加固梁的构造如图1所示,其中CFRP板端部被压入并嵌贴在混凝土梁端部的预开槽内部以锚固预应力,因此该加固法存在独特的端部嵌贴段。

图2描绘了端部嵌贴局部构造,本文试验针对斜嵌段CFRP板与混凝土界面粘结性能研究的参数主要有:(1) 混凝土斜槽倾斜角度,选取试验角度的区间为0°~12.4°,本次试验通过调整混凝土试件深槽高度值来改变混凝土槽倾斜角度;(2) CFRP板埋深比,选取30%、50%和70%为试验值;(3) CFRP板在斜嵌贴段中的粘结长度,选取200、300和400 mm为试验值。具体试验参数见表1。由于所使用的试验装置需固定于水平地面上(图3),混凝土试件的几何形状被设计为如图4所示的楔形,模拟斜嵌段环氧树脂层厚度变化的同时使CFRP板与地面平行(图4(b))。真实试件图见图4(d)。

表 1 试验参数设计Table 1. Design parameters of specimensSpecimen D/mm L/mm P/mm C/% β/(°) D30L5 30 5 300 50 4.8 D40L5 40 5 300 50 6.7 D50L5 50 5 300 50 8.6 D60L5 60 5 300 50 10.5 D70L5 70 5 300 50 12.4 D28L5P200* 28 5 200 50 6.7 D52L5P400* 52 5 400 50 6.7 D40L5C30 40 5 300 30 6.7 D40L5C70 40 5 300 70 6.7 D25L25* 25 25 300 50 0.0 Notes: D—Depth of deep groove; L—Depth of low groove; P—Bonding length; C—Depth ratio; β—Angle of inclined groove; D25L25*—Concrete groove depth of 25 mm horizontal mounted control specimen. 1.2 试验材料

本文试验使用的CFRP板由江苏海拓公司生产,加工后截面尺寸为1.2 mm×35 mm×1300 m (厚×宽×长)。采用的环氧树脂粘合剂为Sika-30 CN,一般情况下需要室温养护7天以达到标准强度。为避免试件在加载过程中提前开裂,混凝土试件强度选取C40,标准条件下养护28天,测得抗压强度为34.73 MPa。材料具体参数见表2。

表 2 材料性能Table 2. Properties of materialsMaterial Rm/MPa E/GPa δ/% CFRP 2625.50 180.00 1.70 Sika-30CN 31.90 2.63 1.47 Notes: Rm—Tensile strength; E—Elasticity modulus; δ—Elongation. 1.3 试验加载与数据量测

本文试验使用北京海创高科科技有限公司自主设计的地锚装置并配合生产的HC-30型锚杆拉拔仪对CFRP板施加轴向拉力(图3)。加载制度为每级加载4 kN并持载2 min,直至试件临近破坏时,改为每级加载2 kN并持载2 min。通过在CFRP板上沿长度布置应变片以监测CFRP受力行为,应变片间距为40 mm;为使加载端和自由端应变数据完好,局部应变片分别被布置于距两端10 mm (图5);当CFRP板在混凝土槽中滑移时,粘贴在CFRP表面的应变片可能会因界面错动而损坏,为得到更完整的粘结应变数据,本文试验将应变片粘贴在两条重叠并用树脂胶贴合的CFRP之间。试验过程中注意观察混凝土和树脂的损伤及裂缝发展,并使用江苏东华测试技术公司生产的DH3816N应变仪采集每级加载的CFRP板应变数据。

2. 试验结果与分析

2.1 CFRP与混凝土界面粘结行为及破坏形态

试验结果见表3,此次试验中混凝土试件最终破坏形态均是CFRP板-环氧树脂界面剥离(图6(a)),试件破坏时,加载端混凝土密集开裂,裂缝大致向45°斜向发展(图6(b)),由于加载端附近的环氧树脂层较薄,其在破坏时损伤明显,一般出现清晰的横向裂缝,内聚破坏特征明显。在拔出的CFRP板表面可以观察到清晰的界面滑移痕迹。根据树脂开裂位置不同观察到加载端开裂和槽内断裂等两种主要的界面剥离形式(图6(c)~6(d)),两种界面剥离破坏模式本质均属于环氧树脂内聚破坏,造成表观区别的原因在于加载端环氧树脂的破坏程度。斜槽角度和粘结长度的增大意味着树脂对CFRP板的约束作用增强,使加载端局部应力发展更充分,进而导致该局部较薄的环氧树脂层开裂更严重(破坏模式A);反之,则发生模式B的破坏。

表 3 CFRP与混凝土界面粘结性能试验结果Table 3. Test results of interfacial bonding behavior between CFRP and concreteSpecimen β/(°) P/mm C/% Ultimate bearing capacity/kN Failure mode D30L5 4.8 300 50 96 B D40L5 6.7 300 50 114 B D50L5 8.6 300 50 112 A D60L5 10.5 300 50 128 B D70L5 12.4 300 50 138 A D28L5P200* 6.7 200 50 72 B D52L5P400* 6.7 400 50 142 A D40L5C30 6.7 300 30 72 A D40L5C70 6.7 300 70 110 B D25L25* 0.0 300 50 88 A Notes: A indicates that the epoxy resin cracks only at the loading end when the specimen is destroyed; B indicates that the epoxy resin breaks in the concrete groove when the specimen is destroyed. 各试件的粘结承载力见表3。首先比较树脂体积近似条件下斜槽和水平槽构造的CFRP-混凝土粘结性能,使用斜槽的D40L5和D50L5试件的最终承载力为114 kN和112 kN,明显高于试件D25L25* (88 kN),意味着CFRP斜嵌构造相比NSM等传统技术中的CFRP水平构造具有更高粘结性能。

比较混凝土斜槽角度大小对承载力的影响。试件最终承载力随斜槽角度增加而增加,从D30L5的96 kN增大到D70L5的138 kN,提升幅度43.8%,这应是由于:(1) 对于CFRP板四面的约束来说,CFRP板上表面的环氧树脂层的约束最为薄弱,在拉拔过程中此处的环氧树脂最容易开裂剥离,随着深槽深度的增大,CFRP上表面的环氧树脂层厚度提升,抗裂能力增强,避免了CFRP板被提前拔出;(2) CFRP板拉力传递至呈楔形的环氧树脂块,并对混凝土斜槽底面形成压力;这一行为部分承担了拉力,且随着斜槽角度增大而愈发显著。以上试验结论表明,实际工程中可以通过适当增大斜槽倾斜角度来增加端部嵌贴段的锚固效果。

改变CFRP板埋深大小,研究其对承载力的影响。随着CFRP板在环氧树脂层中的埋深比从30% (D40L5C30)增加到50% (D40L5),承载力数值增长了42 kN,提升幅度58.3%,这是由于是相对埋深增大使环氧树脂对CFRP板的约束刚度更大。而埋深从50% (D40L5)增长至70%后 (D40L5C70),承载力几乎不改变,这是由于约110 kN的拉力使环氧树脂达到其剪切强度。基于试验结果认为CFRP板埋深不低于50%时有着较好的加固效率,这与彭晖等[18]研究NSM CFRP板-混凝土粘结性能时得出的结论相似。

粘结长度的改变也会对承载力大小产生影响。随着粘结长度从200 mm增加到300 mm再增加到400 mm,试件的承载力从72 kN (D28L5P200*)增长到114 kN (D40L5)再增加到142 kN (D52L5P400*)。这是由于在破坏过程中环氧树脂层先从较浅的加载端开始开裂剥离,并逐渐向自由端延伸,直至剩余的环氧树脂层所提供的承载力接近或达到破坏的临界值。粘结长度越长,这一破坏过程持续越长,所达到的承载力也越高。基于实际待加固结构的混凝土保护层厚度,在保证充分斜槽角度的前提下,可以适当增加倾斜端的粘结长度来获得更好的锚固效果。

2.2 CFRP板应变及应力传递长度

以试件D40L5为典型的CFRP板应变分布见图7,可以看出在加载进程中相邻两测点的应变差呈先增大后减小趋势,且最大应变差位置逐渐向自由端传递。这意味着剪应力峰值随荷载增大由加载端向自由端的传递行为,与之相应的应力传递长度能够揭示CFRP-混凝土界面的全局粘结性能。相同荷载下应力传递长度越大,则粘结性能越差。

图8(a)绘制了具有不同斜槽角度试件(D30L5~D70L5)在96 kN时的CFRP应变分布,可以发现在相同荷载下,随着斜槽角度变大,应力传递长度从249 mm (D30L5)减小到202 mm (D70L5),表明CFRP板与混凝土界面的剩余粘结承载力越高。具有不同埋深比(30%~70%)试件达到极限承载力时的CFRP应变曲线绘制于图8(b),可以发现随着埋深比提高,各试件的最长应力传递长度从170 mm (D40L5C30)提升至286 mm (D40L5),然后降低至256 mm (D40L5C70)。表明埋深比为50%时界面粘结性能最好,与上文结果一致。

2.3 CFRP板与混凝土界面局部粘结-滑移关系

2.3.1 局部粘结-滑移关系的计算

CFRP板与混凝土界面的粘结-滑移关系能够反映该界面本质受力行为[20],并可由CFRP板上相邻两应变测点之间的局部关系计算获得。其中,粘结剪应力通过力学平衡来求解,CFRP板所受到的拉力与其在环氧树脂层受到的粘结剪应力相平衡,对关系式进行变形和化简,可以得出相邻两测点之间的粘结剪应力计算公式:

τ(xi+xi+12)=Efbftf2(bf+tf)εi+1−εixi+1−xii=1,2⋯ (1) 式中:τ(xi,xi+1)为据加载端第i个与第i+1个测点之间的粘结剪应力;εi为第i个测点的应变值;Ef为CFRP板弹性模量;bf为CFRP板宽度;tf为CFRP板厚。

CFRP板的相对滑移值表现为CFRP板的位移减去环氧树脂相对混凝土位移得到的差值,对关系式进行变形和化简,得到相邻两侧点之间的相对滑移值计算公式:

s(x1)=s(0)+x1−x02(ε1+ε2) s(x2n)=s(x2n−2)+x2n−x2n−26(ε2n+4ε2n−1+ε2n−2) s(x2n+1)=s(x2n−1)+x2n+1−x2n−16(ε2n+1+4ε2n+ε2n−1) n=0,1,2⋯ (2) 式中,s(xi)为各计算点相对滑移值。

图9展示了典型试件D70L5的粘结-滑移曲线,其余试件具有类似特征。可以发现,随着距加载端长度的提升,粘结-滑移曲线的凸起部分逐渐向右上角方向发展,这表明峰值粘结剪应力τm和峰值相对滑移值sm随CFRP板上下树脂层厚度的增加而不断增加。下文将从τm、sm、界面粘结刚度、界面断裂能Gf等方面定量分析不同参数对粘结行为的影响。

2.3.2 峰值粘结剪应力τm及其对应滑移sm

倾斜角度0°~12.4°距离加载端110 mm处的τm和sm分别绘制于图10(a)和图10(b)。峰值粘结剪应力τm随着斜槽角度增大总体呈上升趋势,从6.7 MPa (D25L2,θ=0°)增长至11.6 MPa (D70L5,θ=12.4°),增幅约73%,这应是由于更厚的环氧树脂层对碳板的约束更有效。峰值相对滑移值sm在初期变化不明显,仅从0.221 mm (D25L25*)改变至0.209 mm (D50L5,θ=8.6°),变化幅度约5.4%,随着斜槽角度进一步增加,sm增长至0.442 mm (D70L5),增幅约133%,这是由于树脂层厚度增大后抗裂性明显提升,同时剪切变形刚度减小,导致峰值相对滑移值显著增加。

比较CFRP板埋深比对粘结-滑移关系的影响,选取D40L5C30、D40L5C70距离加载端30~110 mm处的平均τm和sm汇总于图11(a)和图11(b)。可见τm初始随着埋深比的增加而增大,增幅约22%,表明提升埋深比增厚了CFRP板上表面环氧树脂层,有效约束了CFRP板,从而提高了粘结强度;但埋深比从50%提高至70%时τm变化不明显。sm则随着埋深比的增大而减小,减幅约19%。

2.3.3 粘结刚度和断裂能

界面粘结刚度是粘结-滑移曲线在线弹性阶段的斜率。将不同斜槽角度和埋深比的试件距加载端110 mm处的界面粘结刚度汇总于图12(a)和图12(b)。可以发现,界面粘结刚度随斜槽角度的增加而降低,斜槽角度从4.8°增加至12.4°,界面粘结刚度从83.0 N/mm3 (D30L5)降低至56.6 N/mm3 (D70L5),减幅约46%,由于较厚的环氧树脂层延缓了CFRP板被完整拔出的过程,使剪应力-滑移较平缓,同时较厚胶层也导致剪切变形刚度下降。埋深比从30%增加到70%时,界面粘结刚度逐渐增大,从44.9 N/mm3 (D40L5C30)增加至79.6 N/mm3 (D40L5C70),增幅约77%,原因是CFRP板上表面增加的树脂层厚度对CFRP板渐强的约束作用,这验证了上述埋深比较大试件滑移值偏低的行为。

界面断裂能Gf是CFRP-混凝土粘结界面发生单位面积断裂(剥离)所需要吸收的能量[21],是数值分析中的重要材料参数。通过计算粘结-滑移曲线与x轴围成的面积便可以得到相应Gf的值。如图13(a)所示,随着混凝土槽倾斜角度增长,试件距加载端110 mm处的界面断裂能从D25L25的2.14 N/mm上升至D50L5的3.88 N/mm (增幅约80%),总体呈增大趋势。增大CFRP板的埋深,观察到试件距加载端30~110 mm处的总界面断裂能从D40L5C30的2.68 N/mm持续增长至D40L5的6.03 N/mm (图13(b)),增幅约125%,随着埋深的逐渐增加界面粘结性能也在提升,较大的埋深比能更好地约束住混凝土槽内的CFRP板;但随着埋深比从50%提升至70%后Gf变化不再显著。

选取D70L5为典型试件,分析其界面断裂能沿粘结长度方向距加载端30~110 mm的分布规律(图14)。以sm∈[0,0.44]为取值区间,可以发现随着CFRP板上下的粘结层厚度提升,Gf从2.38 N/mm一直递增到3.39 N/mm,增幅约42%,这表明在倾斜嵌贴段中由于胶层厚度改变界面粘结行为逐渐变化,有必要建立沿粘结长度分布的粘结-滑移关系模型。

尽管界面粘结性能随斜槽角度增加而增加,但实际工程中受限于混凝土保护层厚度限制无法无限增大树脂层厚度,可参考D50L5试件取8°~9°的斜槽角度,在加固结构条件允许的前提下选取较厚的胶结层厚度以获得较好的端部锚固能力;CFRP埋深比与界面粘结性能呈正相关,建议实际工程取埋深比区间50%~70%。

2.4 端部嵌贴CFRP板加固RC结构的斜嵌段粘结-滑移本构模型

2.4.1 含特征参数的粘结-滑移本构模型

建立起描述粘结-滑移曲线的数学本构模型,能直观反映界面粘结-滑移的整个流程,也是斜嵌段力学性能研究的基础[22-27]。在构建本构时,应选取构型完整的粘结-滑移曲线作为基础。在此选取D30L5~D70L5试件计算点中距离加载端110 mm的计算点数据作为基础,以D40L5为示例构造拟合函数。

观察D40L5粘结-滑移曲线,可以看出曲线图形存在两个明显的区段:第一个区段曲线首先以较大斜率上升又趋于平缓,第二个阶段曲线在短时间水平之后开始下降最终趋向某个值。因此将粘结-滑移曲线分开为上升段和下降段以方便各自匹配函数图形。

观察上升段,接近零点时,曲线上升段接近直线,有着较大的斜率,在比较靠近峰值剪应力时斜率下降,在较小的区段内变得平缓并达到峰值剪应力。这种图形与正弦函数在[0, π⁄2]较类似,因此选择正弦函数进行拟合。为了确保图形能较好吻合,同时选取常数A作为拟合参数。得出上升段拟合公式:

τ(s)=1sinAτmsin(Assm) (3) 观察下降段,在靠近峰值剪应力时,曲线接近水平,然后界面应力进入软化段,曲线大幅下降,下降区间接近直线,随着滑移值接近某个值时,曲线逐渐平缓并开始保持水平,总体上接近S型。考虑起始端峰值剪应力需对应峰值滑移值,选取Logistic曲线更能满足这种趋势。通过拟合得出下降段公式:

τ(s)=τm−τr1+(s/s0)p+τr (4) 式中:τm为峰值剪应力;sm为峰值滑移值;τr为残余剪应力;s0为下降段中点滑移值;A为上升段拟合参数;p为下降段拟合参数。拟合曲线见图15。

选取拟合的参数为混凝土槽倾斜角度和CFRP板埋深比的试件,不考虑CFRP板粘结长度参数试件的原因是粘结长度对加固试件的影响更体现在承载力而非界面粘结性能。曲线的特征值和拟合参数见表4。

表 4 试件粘结-滑移曲线特征值拟合结果Table 4. Results of the fitting of bond-slip characteristic value of the test blocksSpecimen l/mm τm/MPa sm/mm τr/MPa s0/mm A p D30L5 110 9.67 0.187 2.86 0.390 1.59 9.01 D40L5 30 3.68 0.039 1.74 0.108 1.60 7.22 70 10.03 0.209 5.32 0.410 1.52 7.56 110 8.99 0.207 2.03 0.411 1.57 10.13 D50L5 110 12.80 0.209 N/A N/A 1.53 N/A D70L5 30 6.63 0.308 4.61 0.459 1.65 9.30 70 9.19 0.286 6.61 0.550 1.49 11.32 110 11.59 0.442 N/A N/A 1.64 N/A D40L5C30 30 3.91 0.196 1.58 0.297 1.58 10.96 D40L5C70 30 7.14 0.216 2.01 0.406 1.62 12.24 70 6.11 0.059 2.13 0.271 1.52 10.53 110 9.83 0.152 N/A N/A 1.56 N/A Notes: τr—Residual shear stress; s0—Slip value corresponding to the midpoint of the descending segment; p—Fitting parameter for the descending segment; l—Distance from the loading end; N/A—No data; D50L5, D70L5 and D40L5C70—110 mm from the loading end of the bonded slip curve complete descending section before the emergence of the specimen has been destroyed. 2.4.2 考虑多参数影响的粘结-滑移本构模型

拟合函数中存在的峰值剪应力τm、峰值滑移值sm特征参数来源于试验结果,为了方便本构模型的使用,需要建立特征参数与有影响的试验参数之间的关系式。通过上文对粘结-滑移曲线的分析,认为除开倾斜角度和埋深比会影响τm和sm之外,环氧树脂层厚度随CFRP板长度的改变也导致τm和sm随着发生相应的变化,因此把距离加载端的长度、倾斜角度、埋深比作为影响特征参数的变量共同进行多因素非线性拟合。

基于试验结果和经验提出关系式如下:

τm=a1la2θa3ca4+a5 (5) sm=b1lb2θb3cb4+b5 (6) 式中:a1、a2、a3、a4、a5、b1、b2、b3、b4、b5为拟合参数;l为距离加载端的长度;θ为混凝土斜槽的倾斜角度;c为埋深比。

对于上述两个方程,使用Origin的非线性曲线拟合功能对目标数据进行拟合,得a1、a2、a3、a4、a5的最佳拟合值分别为0.97、0.41、0.27、0.13、−0.46,得b1、b2、b3、b4、b5的最佳拟合值分别为1.84×10−6、0.48、3.48、−1.41、0.14,最终公式为

τm=0.97l0.41θ0.27c0.13−0.46 (7) sm=1.84×10−6l0.48θ3.48c−1.41+0.14 (8) 对比τm、sm的试验值与计算值见图16,可以发现本文模型能够较好地预测实际峰值剪应力τm与峰值滑移值sm的大小。

在实际拟合中发现,上升段参数A始终在较小的范围内变动,为方便本构模型使用,选取A=1.6作为定值,经试用后发现拟合依然良好。同理,在保证拟合曲线合理变化的前提下,为方便计算使用,选取下降段参数p=10。

粘结-滑移本构最终公式为

上升段:

τ(s)=1sin(1.6)τmsin(1.6ssm) (9) 下降段:

τ(s)=τm−τr1+(s/s0)10+τr (10) 为进一步方便使用,对残余粘结剪应力τr与峰值粘结剪应力τm、下降段滑移中值s0与峰值滑移值sm进行拟合,得公式:

τr=0.40τm1.05 (11) s0=0.12sm1.28 (12) 3. 结 论

针对新型端部嵌贴预应力碳纤维增强复合材料(CFRP)板加固混凝土结构技术中的斜嵌段CFRP-混凝土粘结性能,开展CFRP-混凝土单剪拔出试验,研究了斜槽角度、CFRP埋深比、粘结长度对斜嵌段CFRP-混凝土界面粘结性能的影响,建立了斜嵌段界面粘结剪应力-滑移本构关系模型,得出以下结论:

(1) 树脂材料体积相近的情况下,倾斜嵌贴CFRP板比水平嵌贴粘结承载力更高。随着混凝土槽的倾斜角度增加,总体上斜嵌段试件的粘结承载力显著提高。这一方面是由于增加胶层厚度显著增强了树脂对CFRP的约束能力,另一方面胶层厚度增大也提高了环氧树脂抗裂能力,有利于粘结剪应力充分传递;

(2) CFRP板粘结长度和埋深比对加固性能具有显著影响。由于嵌入的CFRP板剥离后存在残余摩擦力,界面粘结承载力随着粘结长度的增加而增大,最终能够达到CFRP抗拉强度。界面粘结承载力随CFRP埋深比而增大,这是由于较大的埋深比意味着较大的树脂覆盖层厚度,能够避免树脂厚度不足而过早发生破坏。在埋深比增加至50%后,试件承载力和界面断裂能不再明显上升,尽管如此,粘结刚度能进一步提高;

(3) 考虑斜槽角度、CFRP埋深比和树脂层厚度,建立了斜嵌段粘结-滑移模型,能较准确地预测峰值剪应力τm、峰值滑移值sm和界面断裂能Gf等特征参数,可为开展端部嵌贴预应力CFRP加固混凝土结构数值模拟提供基础模型。

-

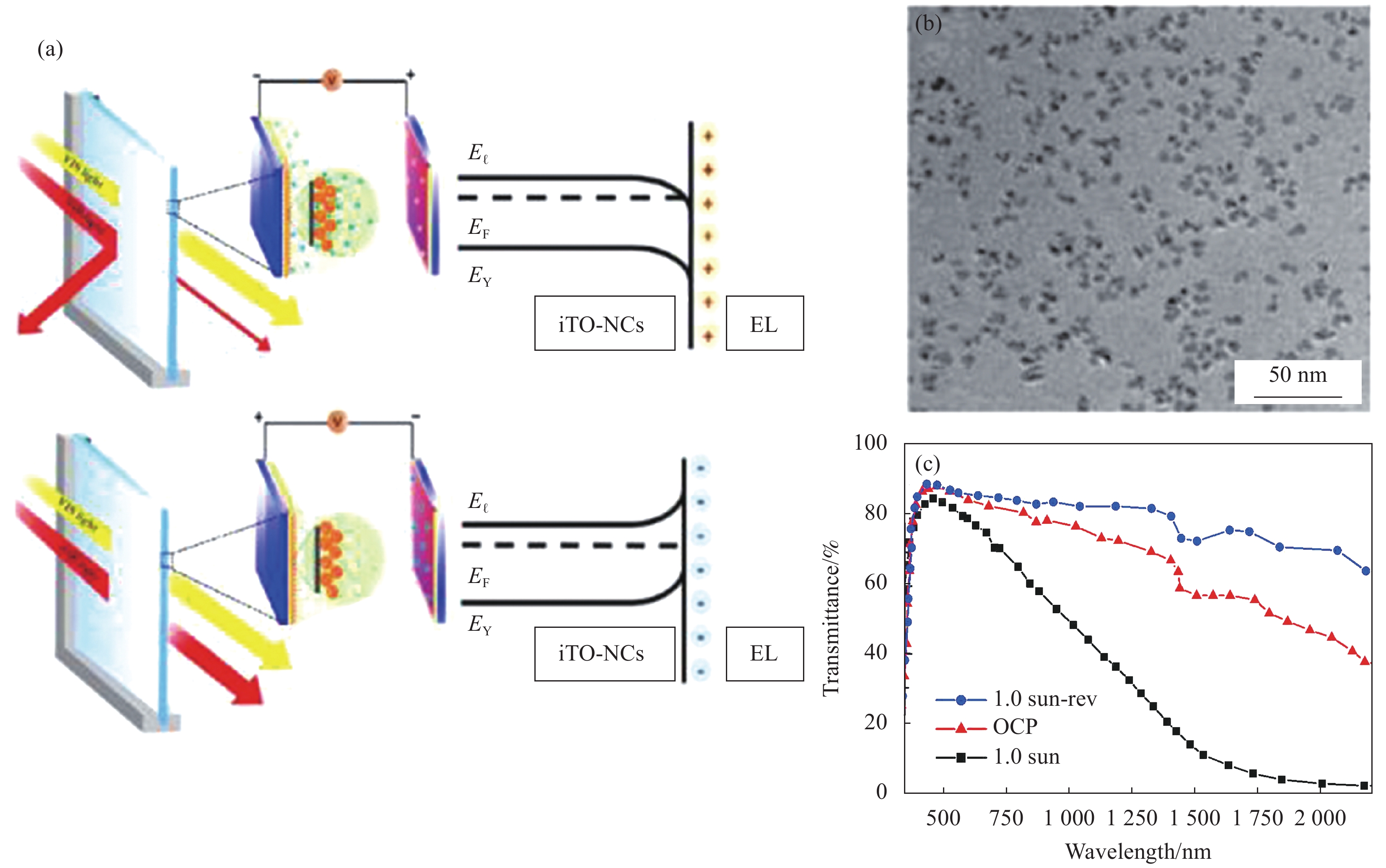

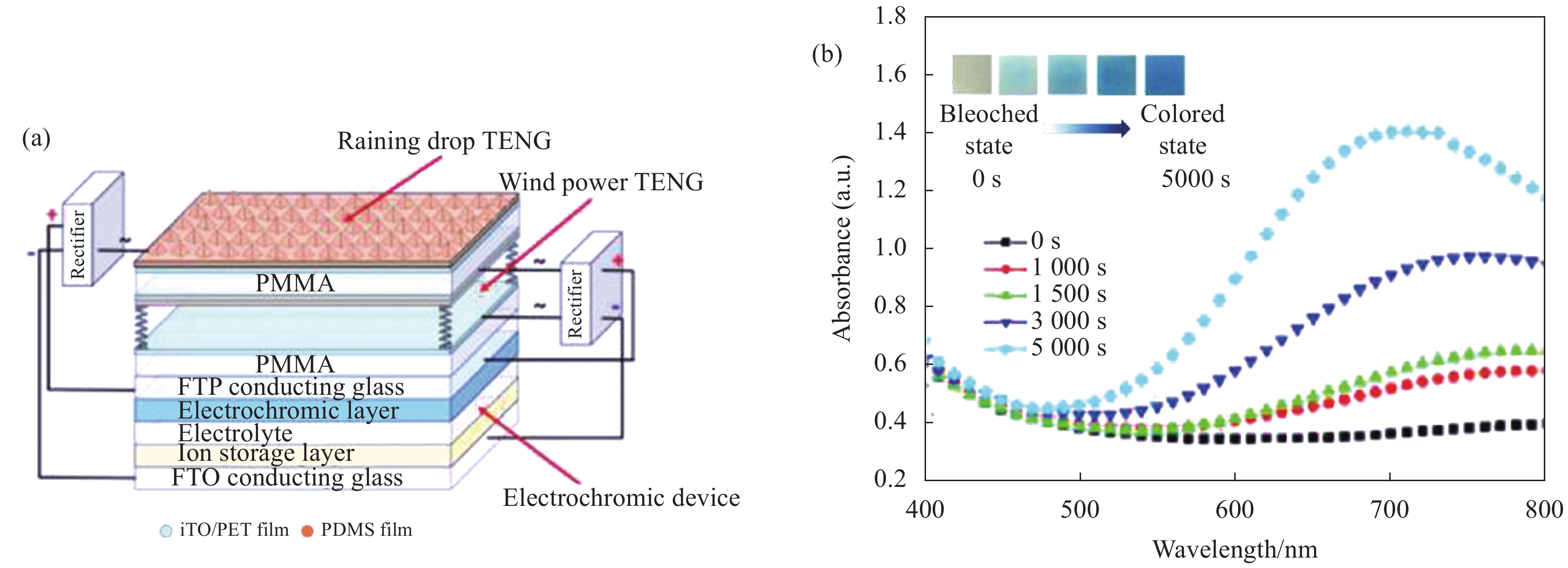

图 3 基于介孔ITO电极局部表面等离子体共振宽调谐的自供电近红外选择性动态窗示意图 (a)、10 nm的ITO胶体纳米晶的TEM图像 (b)、不同太阳光强度下近红外选择性ECDs的透射光谱 (c)[25]

Figure 3. Schematic diagrams of self-powered NIR-selective dynamic windows based on broad tuning of the localized surface plasmon resonance in mesoporous ITO electrodes (a), TEM image of 10 nm-sized ITO colloidal nanocrystals (b) and transmission spectra of the NIR selective ECDs unit upon exposure at different solar light intensities (c)[25]

Ec—Conduction band minimum; Ef—Fermi energy; Ev—valence band maximum; EL—Electrolyte layer; OCP—Open circuit potential

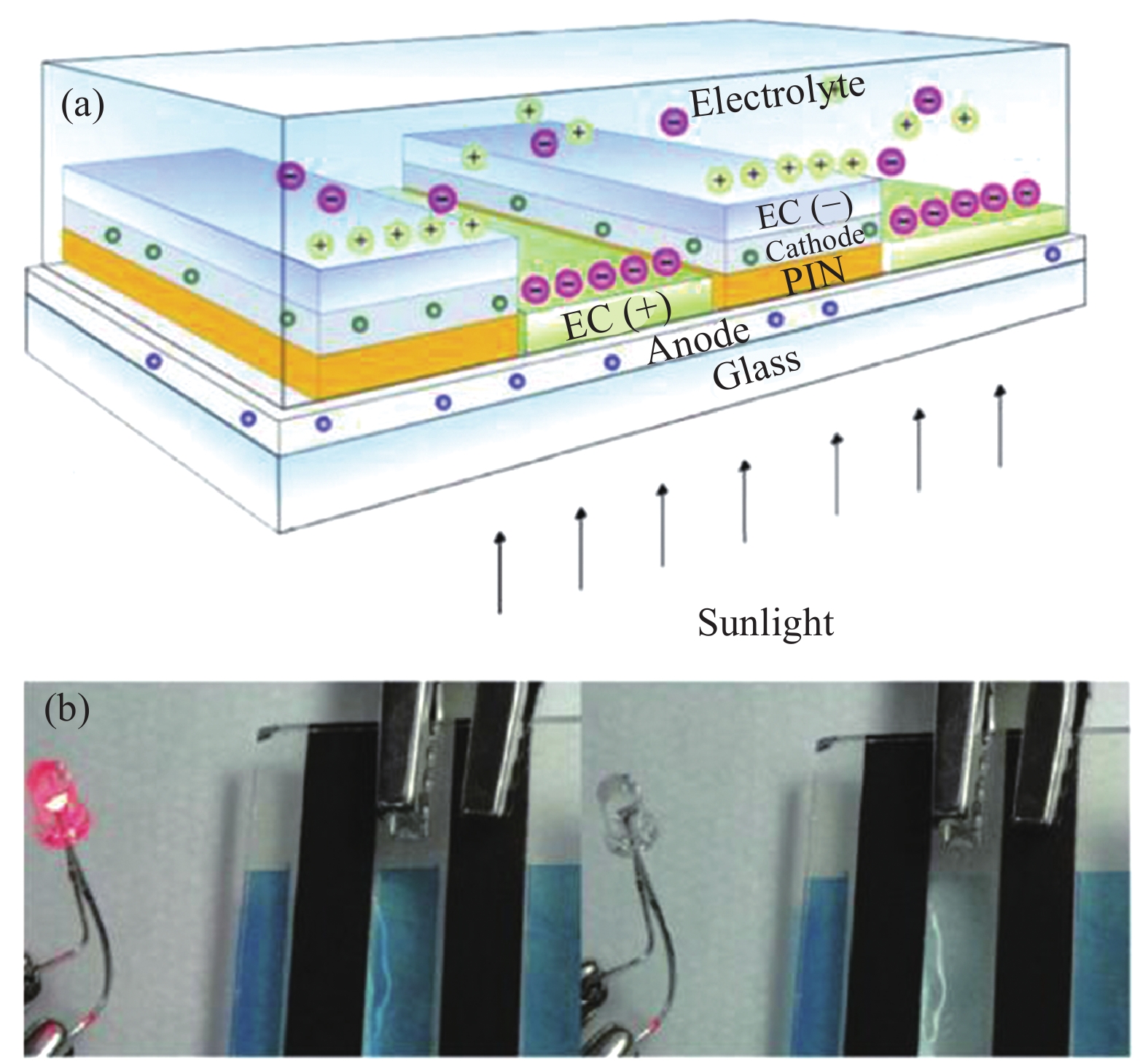

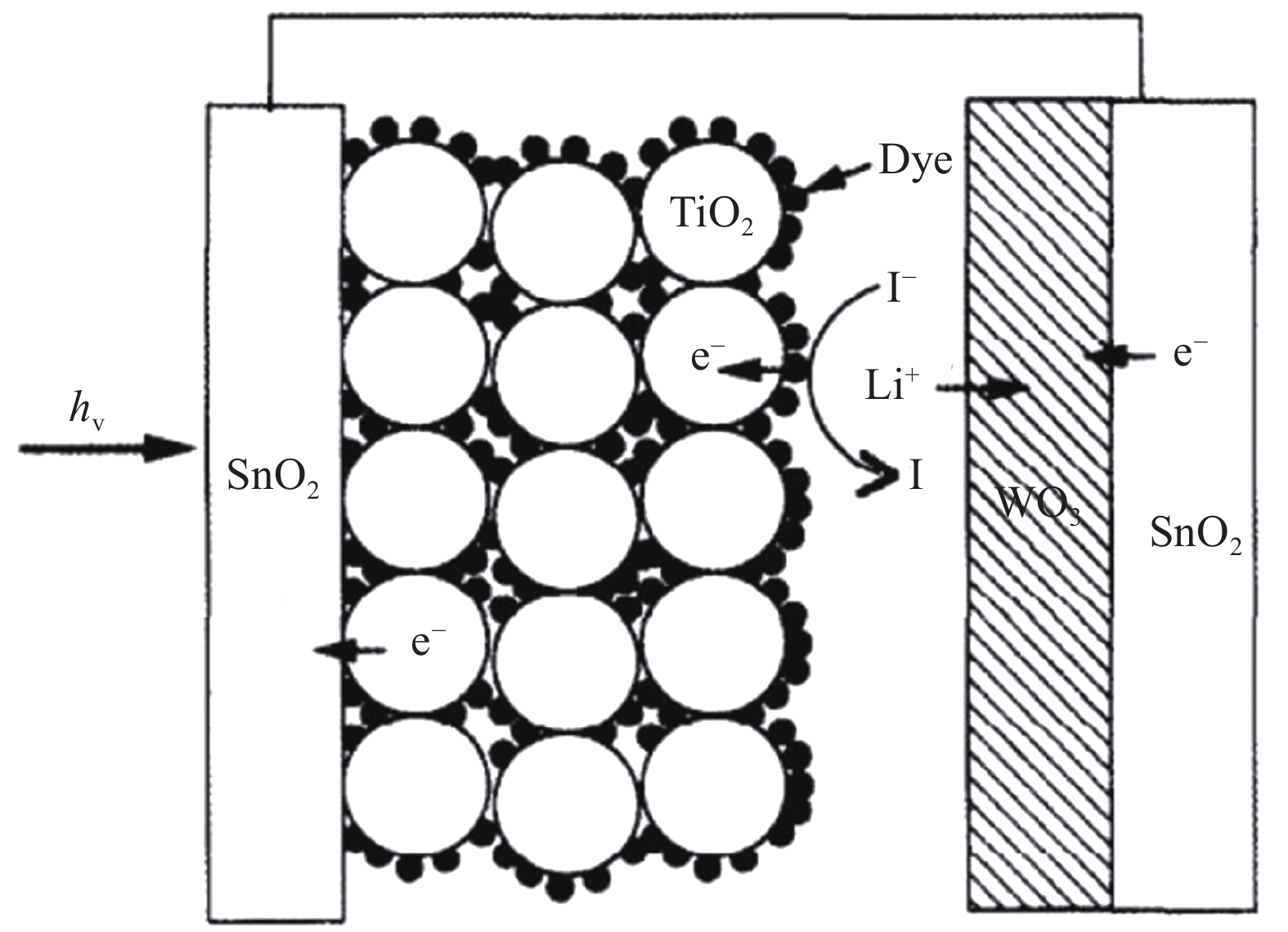

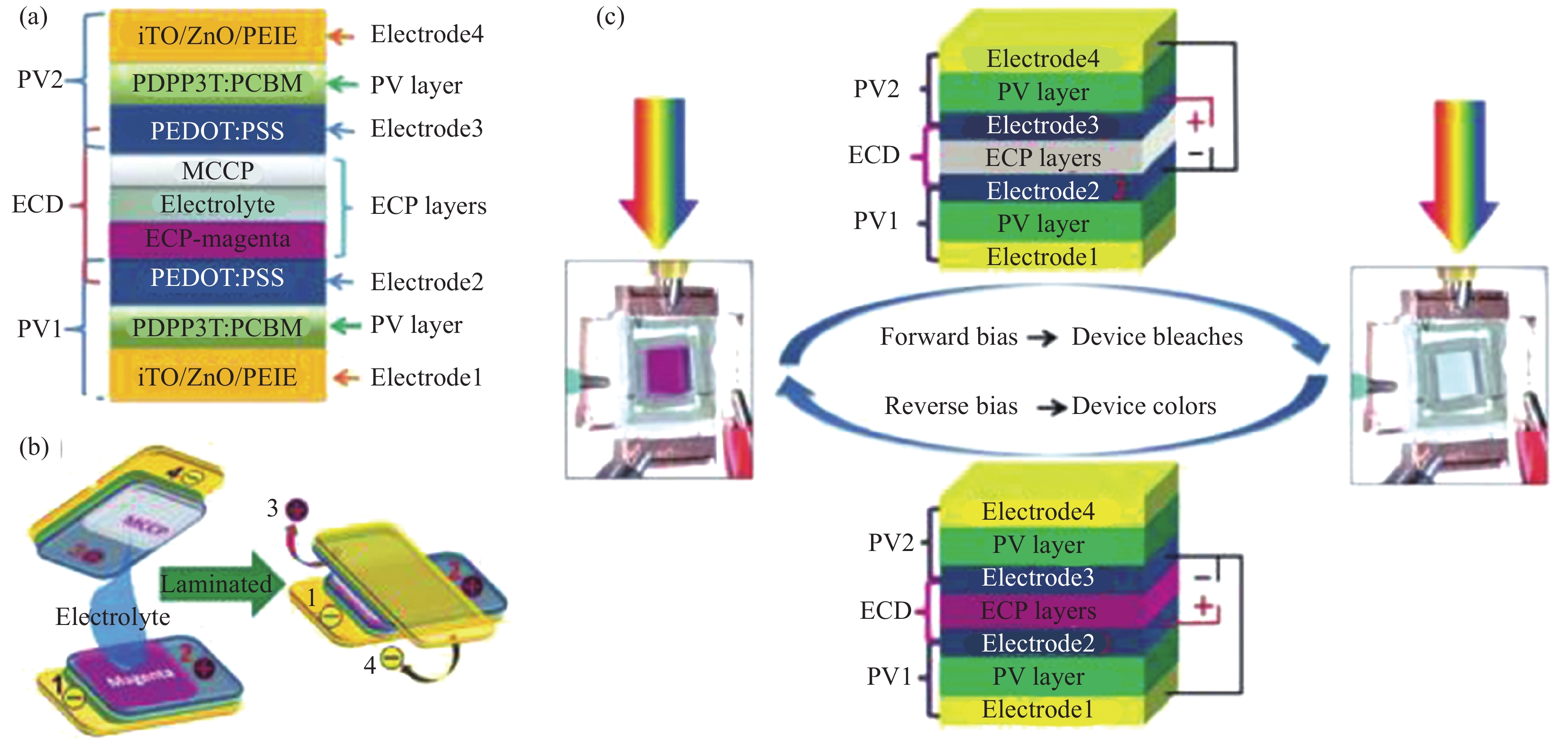

图 4 太阳能电致变色装置(ECDs)的概念和结构[40]

Figure 4. Concept and structure of solar-powered electrochromic device (ECDs) ((a) Schematic cross section structure of the photovoltaic-electrochromic laminated vertical stack; (b) Schematic of device layer components (numbering corresponds to electrodes in (a)); (c) Photograph and schematic of photovoltaic-electrochromic self-powering concept showing connections required to cause bleaching (top) or coloring (bottom) of ECD under illumination)[40]

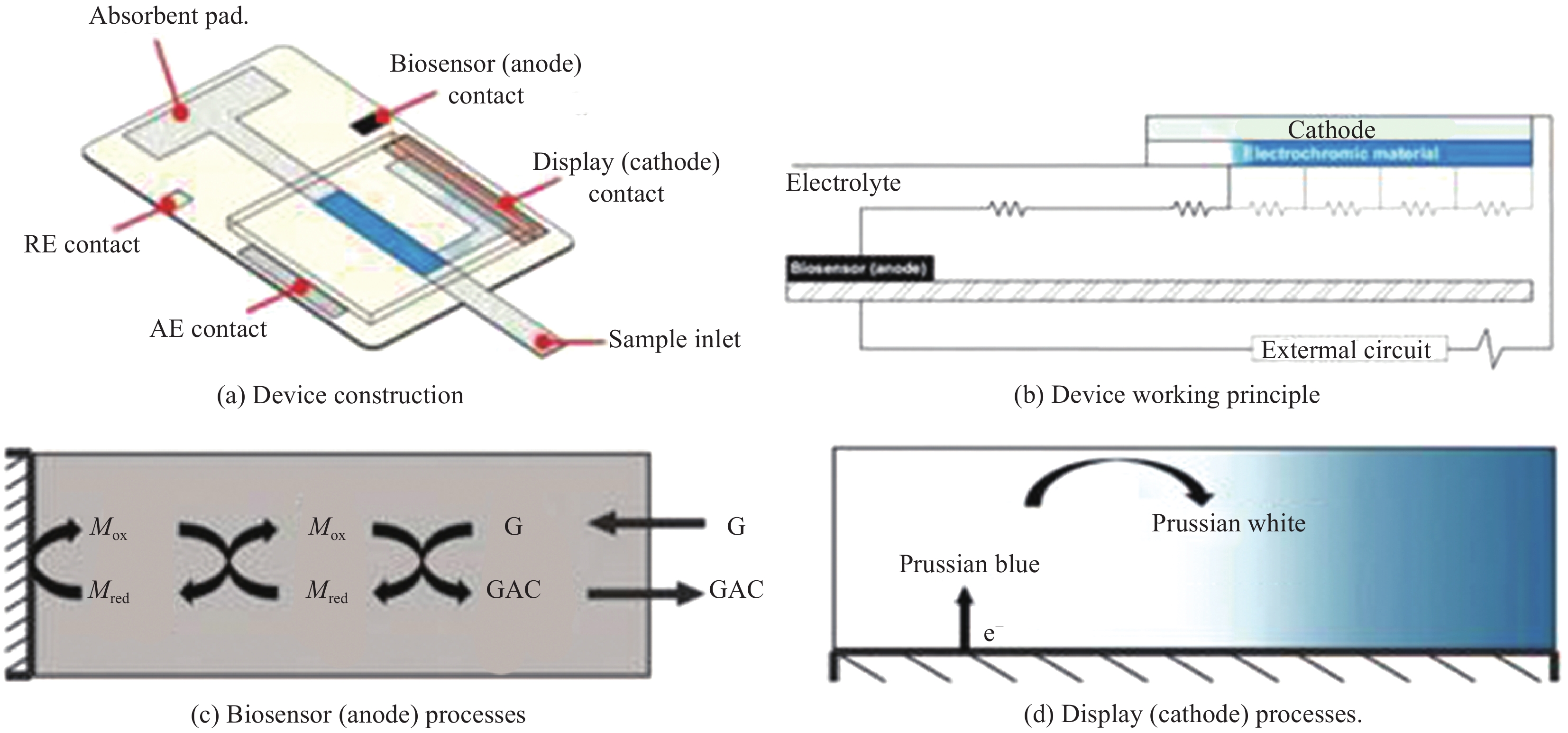

图 6 自供电ECDs示意图 (a)、器件的侧视图(b)、葡萄糖生物传感器中的反应序列 (c)、透明ITO电极上电致变色反应的表征 (d)[61-62]

Figure 6. Schematic representation of the self-powered ECDs (a), side view of the device (b), reaction sequences taking place in a general glucose biosensor (c), representation of the electrochromic reaction at the transparent ITO electrode (d)[61-62]

Mox—Oxidized form of the mediators; Mred—Reduced form of the mediators; Eox—Oxidized form of the enzyme active site; Ered—Reduced form of the enzyme active site; G—Analyte; GAC—Product of the enzyme reaction

-

[1] LI W J, ZHANG X, CHEN X, et al. Effect of independently controllable electrolyte ion content on the performance of all-solid-state electrochromic devices[J]. Chemical Engineering Journal,2020,398:125628. DOI: 10.1016/j.cej.2020.125628

[2] GRANQVIST C G. Electrochromics for smart windows: Oxide-based thin films and devices[J]. Thin Solid Films,2014,564:1-38. DOI: 10.1016/j.tsf.2014.02.002

[3] LEE S H, DESHPANDE R, PARILLA P A, et al. Crystalline WO3 nanoparticles for highly improved electrochromic applications[J]. Advanced Materials,2006,18:763-766. DOI: 10.1002/adma.200501953

[4] PURUSHOTHAMAN K K, MURALIDHARAN G, et al. The effect of annealing temperature on the electrochromic properties of nanostructured NiO films[J]. Solar Energy Materials & Solar Cells,2009,93:1195-1201.

[5] ZHANG S H, CHEN S, CAO Y, et al. Polyaniline nanoparticle coated graphene oxide composite nanoflakes for bifunctional multicolor electrochromic and supercapacitor applications[J]. Journal of Material Science: Materials in Electronics,2019,30(14):13497-13508. DOI: 10.1007/s10854-019-01717-y

[6] MACHER S, SCHOTT M, SASSI M, et al. New roll-to-roll processable PEDOT-based polymer with colorless bleached state for flexible electrochromic devices[J]. Advanced Functional Materials,2020,30(6):1906254.

[7] WU W, FANG H, MA H, et al. Boosting transport kinetics of ions and electrons simultaneously by Ti3C2Tx(MXene) addition for enhanced electrochromic performance[J]. Nano-Micro Letters,2021,13:20. DOI: 10.1007/s40820-020-00544-9

[8] HUANG Q, DONG G, XIAO Y, et al. Electrochemical studies of silicon nitride electron blocking layer for all-solid-state inorganic electrochromic device[J]. Electrochimica Acta,2017,252:331-337. DOI: 10.1016/j.electacta.2017.08.177

[9] ZHANG X, LI W J, CHEN X, et al. Inorganic all-solid-state electrochromic devices with reversible color change between yellow-green and emerald green[J]. Chemical Communications,2020,56:10062-10065. DOI: 10.1039/D0CC04129G

[10] BUCH V R, CHAWLA A K, RAWAL S K. Review on electrochromic property for WO3 thin films using different de-position techniques[J]. Materials Today Proceedings,2016,3:1429-1437. DOI: 10.1016/j.matpr.2016.04.025

[11] ZHANG X, DOU S L, LI W J, et al. Preparation of monolayer hollow spherical tungsten oxide films with enhanced near infrared electrochromic performances[J]. Electrochimica Acta,2019,297:223-229. DOI: 10.1016/j.electacta.2018.11.179

[12] BENSON D K, BRANZ H M. Design goals and challenges for a photovoltaic-powered electrochromic window covering[J]. Solar Energy Materials & Solar Cells,1995,39(2-4):203-211.

[13] BULLOCK J N, XU Y, BENSON D K, et al. Tandem self-powered photovoltaic-electrochromic window coatings[C]. SPIE's 1995 International Symposium on Optical Science, Engineering, and Instrumentation. 1995.

[14] BULLOCK J N, BECHINGER C, BENSON D K, et al. Semi-transparent a-SiC: H solar cells for self-powered photovoltaic-electrochromic devices[J]. Journal of Non-Crystalline Solids,1996,198:1163-1167.

[15] LEE S H, GAO W, TRACY C E, et al. Monolithic, self-powered photovoltaic-electrochromic coating for windows[J]. Journal of The Electrochemical Society,1998,145(10):3545-3550. DOI: 10.1149/1.1838840

[16] GAO W, LIU P, CRANDALL R S, et al. Approaches for large-area a-SiC: H photovoltaic-powered electrochromic window coatings[J]. Journal of Non-Crystalline Solids,2000,266:1140-1144.

[17] HUANG L M, HU C W, LIU H C, et al. Photovoltaic electrochromic device for solar cell module and self-powered smart glass applications[J]. Solar Energy Materials & Solar Cells,2012,99(3):154-159.

[18] HUANG L M, KUNG C P, HU C W, et al. Tunable photovoltaic electrochromic device and module[J]. Solar Energy Materials & Solar Cells,2012,107:390-395.

[19] WEI D, SCHERER M R, ASTLEY M, et al. Visualization of energy: Light dose indicator based on electrochromic gyroid nano-materials[J]. Nanotechnology,2015,26(22):225501. DOI: 10.1088/0957-4484/26/22/225501

[20] GREGG B A, BECHINGER C, PITTS R. Photoelectrochromic smart windows[J]. Proceedings of SPIE-The International Society for Optical Engineering,1997,3138:114-123.

[21] GREGG B A. Photoelectrochromic cells and their applications[J]. Endeavour,1997,21(2):52-55. DOI: 10.1016/S0160-9327(97)01026-0

[22] BECHINGER C, GREGG B A. Development of a new self-powered electrochromic device for light modulation without external power supply[J]. Solar Energy Materials & Solar Cells,1998,54(1-4):405-410.

[23] PICHOT F, GAO W, GREGG B A, et al. Self-powered electrochromic coatings[J]. Proceedings of SPIE,1999,3788:59-68. DOI: 10.1117/12.365773

[24] COSTA C, IVANOU D, PINTO J, et al. Impact of the architecture of dye sensitized solar cell-powered electrochromic devices on their photovoltaic performance and the ability to color change[J]. Solar Energy,2019,182:22-28. DOI: 10.1016/j.solener.2019.02.036

[25] PATTATHIL P, GIANNUZZI R, MANCA M. Self-powered NIR-selective dynamic windows based on broad tuning of the localized surface plasmon resonance in mesoporous ITO electrodes[J]. Nano Energy,2016,30:242-251. DOI: 10.1016/j.nanoen.2016.10.013

[26] 李不鱼, 张莉, 过家好, 等. 染料敏化TiO2/WO3薄膜电池的光电变色[J]. 化学物理学报, 2005(2):104-107. LI B Y, ZHANG L, GUO J H, et al. Photoelectrochromism of dye-sensitized nanoporous TiO2 film combined with electrodeposited WO3 film[J]. Chinese Journal of Chemical Physics,2005(2):104-107(in Chinese).

[27] XIE Z, JIN X J, CHEN G, et al. Integrated smart electrochromic windows for energy saving and storage applications[J]. Chemical Communications,2014,50(5):608-610. DOI: 10.1039/C3CC47950A

[28] YANG Q H, HAO Q, LEI J P, et al. Portable photoelectrochemical device integrated with self-powered electrochromic tablet for visual analysis[J]. Analytical Chemistry,2018,90(6):3703-3707. DOI: 10.1021/acs.analchem.7b05232

[29] MARTINA F, PUGLIESE M, SERANTONI M, et al. Large area self-powered semitransparent trifunctional device combining photovoltaic energy production, lighting and dynamic shading control[J]. Solar Energy Materials & Solar Cells,2017,160:435-443.

[30] QIANG P F, CHEN Z W, YANG P H, et al. TiO2 nanowires for potential facile integration of solar cells and electrochromic devices[J]. Nanotechnology,2013,24(43):435403. DOI: 10.1088/0957-4484/24/43/435403

[31] WU X M, ZHENG J M, LUO G, et al. Photoelectrochromic devices based on cobalt complex electrolytes[J]. RSC Advances,2016,6(85):81680. DOI: 10.1039/C6RA17666F

[32] 陈梅, 杨树威, 郑建明, 等. 三苯胺类自供能电致变色材料合成及器件开发[J]. 化学学报, 2013, 71(5):713-716. DOI: 10.6023/A13010091 CHEN Mei, YANG Shuwei, ZHENG Jianming, et al. Synthesis of a novel triphenylamine derivative and exploration of self-powered electrochromic device[J]. Acta Chimica Sinica,2013,71(5):713-716(in Chinese). DOI: 10.6023/A13010091

[33] LI Y L, HAGEN J, HAARER D. Novel photoelectrochromic cells containing a polyaniline layer and a dye-sensitized nanocrystalline TiO2 photovoltaic cell[J]. Synthetic Metals,1998,94(3):273-277. DOI: 10.1016/S0379-6779(98)00013-7

[34] YU X F, LI Y X, ZHU N F, et al. A polyaniline nanofibre electrode and its application in a self-powered photoelectrochromic cell[J]. Nanotechnology,2006,18(1):015201.

[35] YANG S W, ZHENG J M, LI M, et al. A novel photoelectrochromic device based on poly(3,4-(2,2-dimethylpropylenedioxy)thiophene) thin film and dye-sensitized solar cell[J]. Solar Energy Materials & Solar Cells,2012,97:186-190.

[36] CHOI D, PARK Y, LEE M, et al. Fabrication of an automatic color-tuned system with flexibility using a dry deposited photoanode[J]. International Journal of Precision Engineering and Manufacturing-Green Technology,2018,5(5):643-650. DOI: 10.1007/s40684-018-0067-9

[37] COSTA C, MESQUITA I, ANDRADE L, et al. Photoelectrochromic devices: Influence of device architecture and electrolyte composition[J]. Electrochimica Acta,2016,219:99-106. DOI: 10.1016/j.electacta.2016.09.142

[38] WU X M, ZHENG J M, XU C Y. A newly-designed self-powered electrochromic window[J]. Science China-Chemistry,2016,60(1):84-89.

[39] JENSEN J, DAM H F, REYNOLDS J R, et al. Manufacture and demonstration of organic photovoltaic-powered electrochromic displays using roll coating methods and printable electrolytes[J]. Journal of Polymer Science Part B: Polymer Physics,2012,50(8):536-545. DOI: 10.1002/polb.23038

[40] DYER A L, BULLOCH R H, ZHOU Y, et al. A vertically integrated solar-powered electrochromic window for energy efficient buildings[J]. Advanced Materials,2014,26(28):4895-4900. DOI: 10.1002/adma.201401400

[41] WU C C, LIOU J C, DIAO C C. Self-powered smart window controlled by a high open-circuit voltage InGaN/GaN multiple quantum well solar cell[J]. Chemical Communications,2015,51(63):12625-12628. DOI: 10.1039/C5CC04031K

[42] CANNAVALE A, EPERON G E, COSSARI P, et al. Perovskite photovoltachromic cells for building integration[J]. Energy & Environmental Science,2015,8(5):1578-1584.

[43] LEI Q, WANG Y, DONG W X, et al. Self-powered electrochromic sensing for visual determination of PSA in serum using PB as an indicator[J]. Journal of Electroanalytical Chemistry,2019,839:108-115. DOI: 10.1016/j.jelechem.2019.03.015

[44] WANG Y H, ZHANG L N, CUI K, et al. Solar driven electrochromic photoelectrochemical fuel cells for simultaneous energy conversion, storage and self-powered sensing[J]. Nanoscale,2018,10(7):3421-3428. DOI: 10.1039/C7NR09275J

[45] WANG Y H, GAO C M, GE S G, et al. Self-powered sensing platform equipped with Prussian blue electrochromic display driven by photoelectrochemical cell[J]. Biosens Bioelectron,2017,89:728-734. DOI: 10.1016/j.bios.2016.11.027

[46] HAN L, BAI L, DONG S J. Self-powered visual ultraviolet photodetector with Prussian blue electrochromic display[J]. Chemical Communications,2014,50(7):802-804. DOI: 10.1039/C3CC47080F

[47] REDDY B N, MUKKABLA R, DEEPA M, et al. Dual purpose poly(3,4-ethylenedioxypyrrole)/vanadium pentoxide nanobelt hybrids in photoelectrochromic cells and supercapacitors[J]. RSC Advances,2015,5(40):31422-31433. DOI: 10.1039/C5RA05015D

[48] KOLAY A, DAS A, GHOSAL P, et al. New Photoelectrochromic device with chromatic silica/tungsten oxide/copper hybrid film and photovoltaic polymer/quantum dot sensitized anode[J]. ACS Applied Energy Materials,2018,1(8):4084-4095. DOI: 10.1021/acsaem.8b00765

[49] WANG J M, ZHANG L, YU L, et al. A bi-functional device for self-powered electrochromic window and self-rechargeable transparent battery applications[J]. Nature Communications,2014,5:4921. DOI: 10.1038/ncomms5921

[50] NANDA O, GUPTA N, GROVER R, et al. Self-powered electrochromic window using green electrolyte[J]. AIP Advances,2018,8(9):095117. DOI: 10.1063/1.5037454

[51] YANG B, MA D Y, ZHENG E M, et al. A self-rechargeable electrochromic battery based on electrodeposited polypyrrole film[J]. Solar Energy Materials & Solar Cells,2019,192:1-7.

[52] LI X D, DU Z L, SONG Z Y, et al. Bringing hetero-polyacid-based underwater adhesive as printable cathode coating for self-powered electrochromic aqueous batteries[J]. Advanced Functional Materials,2018,28(23):1800599. DOI: 10.1002/adfm.201800599

[53] ORTEGA L, LLORELLA A, ESQUIVEL J P, et al. Self-powered smart patch for sweat conductivity monitoring[J]. Microsystems & Nanoengineering,2019,5(1):3.

[54] ZHAI Y L, LI Y, ZHANG H, et al. Self-rechargeable-battery-driven device for simultaneous electrochromic windows, ROS biosensing, and energy storage[J]. ACS Applied Materials & Interfaces,2019,11(31):28072-28077.

[55] SUN J Z, LI Y, SUN J K, et al. Reversible self-powered fluorescent electrochromic windows driven by perovskite solar cells[J]. Chemical Communications,2019,55(80):12060-12063. DOI: 10.1039/C9CC05779J

[56] ZHANG H, YU Y, ZHANG L L, et al. Self-powered fluorescence display devices based on a fast self-charging/recharging battery (Mg/Prussian blue)[J]. Chemical Science,2016,7(11):6721-6727. DOI: 10.1039/C6SC02347A

[57] MÖLLER M, LEYLAND N, COPELAND G, et al. Self-powered electrochromic display as an example for integrated modules in printed electronics applications[J]. The European Physical Journal Applied Physics,2010,51(3):33205. DOI: 10.1051/epjap/2010105

[58] ZHAI Y L, LI Y, ZHU Z J, et al. Self-driven multicolor electrochromic energy storage windows powered by a “Perpetual” rechargeable battery[J]. ACS Applied Materials & Interfaces,2019,11(51):48013-48020.

[59] ZHANG S L, CAO S, ZHANG T R, et al. Overcoming the technical challenges in Al anode–based electrochromic energy storage windows[J]. Small Methods,2019,4(1):1900545.

[60] YU Z Z, CAI G N, REN R R, et al. A new enzyme immunoassay for alpha-fetoprotein in a separate setup coupling an aluminium/Prussian blue-based self-powered electrochromic display with a digital multimeter readout[J]. Analyst,2018,143(13):2992-2996. DOI: 10.1039/C8AN00839F

[61] PELLITERO M A, GUIMERA A, KITSARA M, et al. Quantitative self-powered electrochromic biosensors[J]. Chemical Science,2017,8(3):1995-2002. DOI: 10.1039/C6SC04469G

[62] PELLITERO M A, GUIMERÀ A, VILLA R, et al. iR drop effects in self-powered and electrochromic biosensors[J]. The Journal of Physical Chemistry C,2018,122(5):2596-2607. DOI: 10.1021/acs.jpcc.7b11906

[63] ALLER-PELLITERO M, SANTIAGO-MALAGÓN S, RUIZ J, et al. Fully-printed and silicon free self-powered electrochromic biosensors: Towards naked eye quantification[J]. Sensors and Actuators B: Chemical,2020,306:127535. DOI: 10.1016/j.snb.2019.127535

[64] ZHANG X W, JING Y, ZHAI Q F, et al. Point-of-care diagnoses: Flexible patterning technique for self-powered wearable sensors[J]. Analytical Chemistry,2018,90(20):11780-11784. DOI: 10.1021/acs.analchem.8b02838

[65] ZHANG X W, ZHANG L L, ZHAI Q F, et al. Self-powered bipolar electrochromic electrode arrays for direct displaying applications[J]. Analytical Chemistry,2016,88(5):2543-2547. DOI: 10.1021/acs.analchem.6b00054

[66] BAI L, JIN L H, HAN L, et al. Self-powered fluorescence controlled switch systems based on biofuel cells[J]. Energy & Environmental Science,2013,6(10):3015-3021.

[67] KAI H, SUDA W, YOSHIDA S, et al. Organic electrochromic timer for enzymatic skin patches[J]. Biosens and Bioelectron,2019,123:108-113. DOI: 10.1016/j.bios.2018.07.013

[68] LIU H, CROOKS R M. Paper-based electrochemical sensing platform with integral battery and electrochromic read-out[J]. Analytical Chemistry,2012,84(5):2528-2532. DOI: 10.1021/ac203457h

[69] KIM S L, CHOI K, TAZEBAY A, et al. Flexible power fabrics made of carbon nanotubes for harvesting thermoelectricity[J]. ACS Nano,2014,8(3):2377-2386. DOI: 10.1021/nn405893t

[70] YANG X H, ZHU G, WANG S H, et al. A self-powered electrochromic device driven by a nanogenerator[J]. Energy & Environmental Science,2012,5(11):9462-9466.

[71] YEH M H, LIN L, YANG P K, et al. Motion-driven electrochromic reactions for self-powered smart window system[J]. ACS Nano,2015,9(5):4757-4765. DOI: 10.1021/acsnano.5b00706

[72] SUN J M, PU X, JIANG C Y, et al. Self-powered electrochromic devices with tunable infrared intensity[J]. Science Bulletin,2018,63(12):795-801. DOI: 10.1016/j.scib.2018.05.019

[73] LI S Q, MENG X Y, YI Q, et al. Structural and electrochemical properties of LiMn0.6Fe0.4PO4 as a cathode material for flexible lithium-ion batteries and self-charging power pack[J]. Nano Energy,2018,52:510-516. DOI: 10.1016/j.nanoen.2018.08.007

[74] SUN J G, YANG T N, KUO I S, et al. A leaf-molded transparent triboelectric nanogenerator for smart multifunctional applications[J]. Nano Energy,2017,32:180-186. DOI: 10.1016/j.nanoen.2016.12.032

[75] SONG Y, CHENG X L, CHEN H T, et al. Integrated self-charging power unit with flexible supercapacitor and triboelectric nanogenerator[J]. Journal of Materials Chemistry A,2016,4(37):14298-14306. DOI: 10.1039/C6TA05816G

[76] HE Z Z, GAO B B, LI T, et al. Piezoelectric-driven self-powered patterned electrochromic supercapacitor for human motion energy harvesting[J]. ACS Sustainable Chemistry & Engineering,2018,7(1):1745-1752.

[77] WANG F X, WANG M J, LIU H C, et al. Multifunctional self-powered e-skin with tactile sensing and visual warning for detecting robot safety[J]. Advanced Materials Interfaces,2020,7(19):2000536. DOI: 10.1002/admi.202000536

-

期刊类型引用(2)

1. 杨立伟. 钢筋混凝土结构加固用水性环氧树脂胶粘剂的制备及性能研究. 化学与粘合. 2025(01): 39-43 .  百度学术

百度学术

2. 陈鹏宇,杨冰晨,药天运,许方舟,赵煜,周勇军. 3D打印CFRP-Ⅰ型层间断裂韧性的断层替换测试法及参数化分析. 哈尔滨工业大学学报. 2024(11): 88-101 .  百度学术

百度学术

其他类型引用(0)

-

下载:

下载: