Experimental study on the flexural behavior of textile/steel wire strand mesh reinforced ECC-RC composite beam

-

摘要:

为探究不同类型网格增强工程水泥基复合材料(ECC)层加固钢筋混凝土梁的抗弯性能,通过四点弯曲试验,分析了纤维网格和钢绞线网格对复合梁承载力、控裂能力、延性和刚度等抗弯性能的影响。研究结果表明:与ECC-钢筋混凝土(RC)梁相比,采用纤维网格和钢绞线网格增强ECC-RC复合梁裂缝宽度减小,裂缝数量增加25%~70%,纤维网格和钢绞线网格增强ECC层可提高复合梁的控裂能力,抑制裂缝扩展;纤维网格和钢绞线网格增强ECC层可提高复合梁的开裂荷载、屈服荷载、极限荷载、延性及刚度;受弯过程中,所有ECC-RC复合梁截面满足平截面假设,纤维网格和钢绞线网格增强ECC层与混凝土粘结良好;基于理论分析与试验结果,考虑纤维网格利用率,建立了纤维网格和高强钢绞线网格增强ECC-RC复合梁抗弯承载力计算公式,计算结果与试验结果吻合良好。钢绞线网格增强ECC层对ECC-RC复合梁抗弯性能加固效果最佳,可显著提高复合梁承载力、延性及抗裂性。

Abstract:In order to explore the flexural performance of reinforced concrete beams strengthened with different types of grid reinforced engineered cementitious composites (ECC) layer, the effects of textile and steel wire strand mesh on the bearing capacity, crack control ability, ductility and stiffness of composite beams were analyzed by four-point bending test. The experimental results show that compared with ECC-RC beam, the crack width of ECC-RC composite beams reinforced by textile or steel wire strand mesh decreases, and the number of cracks increases by 25%-70%. The textile-reinforced ECC layer can improve the crack control ability of composite beams and inhibit crack propagation. The textile or steel wire strand mesh reinforced ECC layer can improve the cracking load, yield load, ultimate load, ductility and stiffness of the composite beam. During the bending loading, the section of textile or steel wire strand mesh rein-forced ECC-reinforced concrete (RC) composite beam meets the plane section assumption, and the textile-reinforced ECC layer is well bonded to concrete. Based on theoretical analysis and the experimental results and considering the utilization rate of textile, the calculation formula of the flexural capacity of textile or steel wire strand mesh reinforced ECC-RC composite beams is established. The calculation results are in good agreement with the experimental results. The high-strength-reinforced ECC layer has the best reinforcement effect on the flexural performance of ECC-RC composite beams, which can significantly improve the bearing capacity, ductility and crack resistance of composite beams.

-

Keywords:

- bridge engineering /

- flexural performance /

- ECC /

- textile /

- high-strength steel wire strand mesh

-

膜分离技术具有高能效、易操作、环境友好和占地面积小等优点,近年来在气体分离领域受到广泛关注[1-4]。传统气体分离膜多以聚合物膜为主,然而由于聚合物分离膜固有的选择性和渗透性的制约关系(Trade-off效应),使其性能很难再提升[5-6]。研究者发现将多孔材料与聚合物基体共混制成混合基质膜,通过结合两种材料的优点,能够同时提升膜的气体渗透性和选择性,从而突破聚合物膜的Trade-off效应[7-8]。因此,制备混合基质膜是改善膜气体分离性能的一种有效方法。

对于混合基质膜,填料和聚合物基体材料的选择尤为重要。聚酰亚胺由于其优异的热稳定性、良好的力学性能以及可加工性,已经在气体分离膜领域发展多年,是混合基质膜聚合物基体候选材料之一[9-11]。对于填料材料的选择,共价有机框架材料(COFs)是一种由有机单元通过共价键构成的多孔材料,由于其具有优异的稳定性,易功能化、永久空隙率以及高比表面积等优点,在气体分离领域展现出不俗的潜力[12]。由于COFs全有机的性质,使其能够均匀地分散在聚合物基质中,减少了混合基质膜中由于界面缺陷产生的非选择性孔[13-14]。然而,大部分COFs的孔径很难做到2 nm以下,相对于气体分子动力学直径(N2:0.36 nm;O2:0.35 nm;CO2:0.33 nm)还是较大,难以实现对气体的高效分离,从而降低了气体选择性[15-16]。因此,需要对COFs的孔径大小调控或引入一些功能性吸附位点进行改善。研究表明,引入氟原子能够有效改善COFs的孔径大小且能够提供与气体相互作用的吸附位点。Alahakoon等[17]通过使用含氟单体制备出两种氟化COFs,将氟化COFs与未氟化的相比,发现氟化COFs具有更大的比表面积、更小且更明确的孔径。Gao等[18]报道了3种具有—H、—Me和—F取代基的同构三维共价有机骨架,对比不含氟的COFs,氟化COFs具有更高的CO2亲和力,对CO2/N2有着更高的IAST选择性。Yang等[19]制备了一种氟化CTF,通过氟原子的强静电作用以及C—F键与CO2的偶极-四极作用,使其具有优异的CO2吸附能力。

基于上述讨论,本文合成出一种具有较小孔径、高比表面积的氟化共价有机框架材料(TpPa-CF3)。随后,以TpPa-CF3为填料,聚酰亚胺(6FDA-ODA)为基体,制备出不同负载量的TpPa-CF3/6FDA-ODA混合基质膜。表征了其结构和表面、截面的微观形貌,探究了其热性能、力学性能以及疏水性能,最后讨论了混合基质膜的气体渗透性以及在烟道气分离(CO2/N2)和空气分离(O2/N2)上的应用前景。

1. 实验材料及方法

1.1 原材料

4,4-二氨基二苯醚(ODA,98%)、4,4-(六氟异丙烯)二酞酸酐(6FDA,98%+)、2,4,6-三甲酰间苯三酚(Tp,98%)、2-三氟甲基-1,4-苯二胺(Pa-CF3,97%)、1,3,5-三甲基苯(99%+)、1,4-二氧六环(99%)均购自上海阿达玛斯试剂有限公司;乙酸(AR)、N,N-二甲基甲酰胺(DMF,AR)均购自西陇科学股份有限公司;间甲酚(m-Cresol,99%)、异喹啉(97%)均购自上海阿拉丁试剂有限公司;丙酮(Acetone,AR),成都市科隆化学品有限公司;工业酒精(95%),弘昊实验设备有限公司。

1.2 TpPa-CF3的合成

将Tp (63.0 mg,0.30 mmol)、Pa-CF3 (79.0 mg,0.45 mmol)、1,3,5-三甲基苯(1.5 mL)、1,4-二氧六环(1.5 mL)依次加入到Pyrex管(25 mL)中。为使混合物均匀分散,超声处理0.5 h,再加入3 mol/L乙酸溶液(0.5 mL)。随后,用液氮将Pyrex管骤冻抽出空气,再在室温下解冻,此操作循环3次。密闭封管,将Pyrex管在120℃下油浴3天。反应完毕后冷却至室温,过滤收集产物,先用DMF溶液搅拌洗涤3次,再通过索氏提取法进行提纯(提纯溶剂采用丙酮)。随后,收集产物,在真空烘箱中120℃下干燥12 h后,得到橘红色粉末样品TpPa-CF3。

1.3 聚酰亚胺(6FDA-ODA)的合成

在N2氛围下,向装有机械搅拌、冷凝回流的150 mL三口烧瓶内依次加入ODA (2.00 g,9.99 mmol)、间甲酚(28 mL),待ODA完全溶解后再依次加入6FDA (4.44 g,9.99 mmol)、间甲酚(28 mL),随后将温度升到50℃待反应物完全溶解后,滴加5~6滴异喹啉后升温至80℃反应3 h,120℃反应3 h,180℃反应3 h,最后200℃反应12 h。反应结束冷却至室温后,将聚酰亚胺溶液缓慢倒入大量工业酒精中拉丝沉淀,过滤收集产物,在真空烘箱中150℃干燥8 h。随后,使用适量DMF重新溶解并进行二次沉淀以除去聚酰亚胺中残留杂质。

1.4 TpPa-CF3/6FDA-ODA混合基质膜的制备

取一定量的TpPa-CF3粉末分散在DMF (3 mL)中,使用细胞粉碎机,在300 W功率下超声0.5 h后再搅拌6 h,保证TpPa-CF3粉末在DMF溶液中分散均匀。同时,称取0.2 g 6FDA-ODA溶解在DMF (2 mL)中,用针式滤头(0.45 μm,尼龙)过滤除去杂质。随后,将TpPa-CF3的分散液滴加到6FDA-ODA溶液中搅拌12 h,确保TpPa-CF3和6FDA-ODA充分混合。最后,将混合溶液缓慢流延到光滑平整的玻璃板(5 cm×5 cm)上,在80℃下蒸发12 h除去溶剂,待冷却至室温后在温水中脱膜,最后在150℃的真空烘箱中干燥12 h以除去残留的溶剂分子。按以上步骤分别制备含量为0wt%、1wt%、3wt%、5wt%、7wt%的TpPa-CF3/6FDA-ODA混合基质膜。

1.5 表征测试

X射线衍射(XRD):采用荷兰帕纳科公司的X'Pert Pro型X射线衍射仪对制备的TpPa-CF3粉末与薄膜进行晶型及结构表征,扫描范围在3°~40°,扫描速度为2°/min。

傅里叶变换红外光谱(FTIR):采用美国尼高力公司的Nicolette 6700-NXR型傅里叶变换红外光谱仪分析TpPa-CF3和薄膜的化学键组成及官能团。对于粉末样品通过溴化钾压片的方式测试,对于薄膜样品通过制成厚度约为20 μm的薄膜直接测试。扫描范围为400~

4000 cm−1,扫描次数64次以上。固态核磁共振(ssNMR):通过德国布鲁克公司的Avance Neo 400 WB型固体核磁共振波谱仪测试TpPa-CF3的13C NMR,分析其化学键连接方式。所需样品压实后的体积应多于0.5 cm3。

X射线光电子能谱(XPS):采用美国热电公司的Escalab 250 Xi型X射线光电子能谱仪分析TpPa-CF3的化学元素及化学态。采用粉末压片的方式制样。

扫描电子显微镜(SEM):通过日本日立公司的SU 4800型扫描电子显微镜表征TpPa-CF3和薄膜表面、截面的微观形貌。对于粉末样品,用牙签将少量样品涂在导电胶上制样;对于薄膜样品,膜表面直接粘在导电胶上,膜断面通过液氮脆断选取平整截面制样。全部样品在测试前通过喷金处理提高样品导电性。

N2吸附-脱附测试:通过美国康塔公司的Autosorb IQ型比表面及孔隙度分析仪器表征TpPa-CF3的比表面积及孔径分布。采用BET (Brunauer-Emmett-Teller)法计算比表面积,密度泛函理论(DFT)计算孔径分布。

热重分析(TGA):通过德国耐驰公司的STA 449C型综合热分析仪测试TpPa-CF3和薄膜的热稳定性。在N2氛围下测试,升温速率为10℃/min,测试范围在50~800℃。

差示扫描量热分析(DSC):通过德国耐驰公司的DSC 214型差示扫描量热仪测试薄膜的玻璃化转变温度,在N2氛围下以10℃/min的速率升温,测试范围在30~350℃,所有结果均采用消除热历史后的二次升温曲线。

力学性能:通过美国美特斯公司的CMT2103型万能试验机来表征薄膜的力学性能。薄膜样品尺寸为50 mm×10 mm,拉伸载荷为5 kN,拉伸速率为2 mm/min,标距为20 mm。

水接触角测试:通过中国承德优特仪器有限公司JY-PHb型接触角分析仪测定薄膜的亲疏水性能。薄膜样品尺寸为20 mm×20 mm,测试次数至少3次。

气体渗透性测试:通过中国济南兰光公司的VAC-V1型气体渗透仪测试薄膜的气体渗透性能。测试方法为恒体积变压法,测试气体为高纯气体(CO2、O2、N2),测试条件为4 bar,35℃。测试过程如下,将厚度均匀的待测薄膜装入膜腔中,测试前将上下腔气压抽至20 Pa以下,随后下腔关闭,上腔通入待测纯气体形成压差。压差推动气体自上腔(高压侧)向下腔(低压侧)渗透,通过系统计算得到膜的气体渗透系数P。

2. 结果与讨论

2.1 TpPa-CF3的表征

通过粉末X射线衍射(PXRD)对合成的TpPa-CF3的晶体结构进行分析,图1(a)中2θ=4.79°处出现的强峰对应于COF的(100)晶面,其他峰也出现在2θ=7.81°、26.14°处,分别对应于(200)、(001)晶面,其中(001)晶面也是其π-π堆叠峰,通过布拉格方程计算得出其堆叠层间距为0.33 nm。将测试结果与模拟的晶体模型的衍射峰进行对比,结果表明二者衍射峰的位置与强度均匹配良好。TpPa-CF3在Pawley精修后得到的晶胞参数为a=

2.290351 nm,b=2.236760 nm,c=0.423813 nm,α=89.56415 ,β=89.73479 ,γ=120.51471 。实验结果与精修后的PXRD之间的残差值较小,Rwp=1.24%,Rp=0.91%。以上结果初步说明成功合成出了目标晶体结构,且具有良好的结晶性。为进一步说明TpPa-CF3成功合成,通过FTIR对TpPa-CF3以及其构筑单元测试,从图1(b)中可以看到,构筑单元2,4,6-三甲酰间苯三酚(Tp)在

2894 cm−1处醛基的CH=O特征峰和构筑单元2-三氟甲基-1,4-苯二胺(Pa-CF3)在3318 cm−1和3210 cm−1处的—NH2特征峰在产物TpPa-CF3中消失,表明醛胺缩合反应完全。在1282 cm−1处的C—N的特征吸收峰表明烯醇-酮异构的发生。因为框架是以酮的形式存在,结构中有强的分子内氢键及共轭作用,所以在1592 cm−1处的C=C的特征峰和1610 cm−1处的C=O特征峰合并呈肩状[20]。在1128 cm−1处出现了C—F的特征峰。13C固体NMR分析如图1(c)所示,图中显示化学位移在184.2×10−6和108.1×10−6处有两个较明显的信号峰,分别对应于烯醇-酮异构反应所形成的C=O键和C—N键上的C原子,123.6×10−6处归属于C—F上的C原子。其余在119.0×10−6、134.1×10−6和146.5×10−6处的信号峰则归属于芳香单元上的C原子。

FTIR和固体核磁分析结果证实TpPa-CF3的成功合成且以稳定的β-酮胺形式存在。

通过XPS测量TpPa-CF3的全谱和各个元素的光谱,由图2(a)的全谱可知TpPa-CF3是由C、N、O、F 4种元素组成的。图2(b)是C1s的高分辨率XPS光谱,其能够被卷积为4个峰,分别对应于TpPa-CF3中的C=C/C—C(284.8 eV)、C—N(286.2 eV)、C=O(288.9 eV)和C—F(292.9 eV)键,N1s的高分辨率XPS如图2(c)所示,其被卷积为2个峰,分别归属于N—C(400.2 eV)和N—H(403.9 eV)键,F1s的高分辨率XPS如图2(d)所示,其只有一个卷积峰归属于C—F(688.3 eV)。所有以上结果说明TpPa-CF3形成目标结构,由C1s和N1s证明该结构发生了烯醇-酮异构。

通过扫描电镜(SEM)观察TpPa-CF3的微观形貌。如图3(a)所示,TpPa-CF3具有均匀的微观形貌,呈现为“米粒”形颗粒堆积形成的团簇,每一颗“米粒”的尺寸在(100±30) nm。

为了解TpPa-CF3的多孔性,对其进行N2吸附-脱附测试。图3(b)中N2吸脱附曲线呈现出I型曲线特征,TpPa-CF3在相对压力较低的区域(p/p0<0.1),N2的吸附量快速增加,说明材料中存在丰富的微孔结构。通过计算分析得出TpPa-CF3具有较大的比表面积(791.83 m2·g−1),图3(c)显示TpPa-CF3具有较小的孔径(1.18 nm)。这归因于TpPa-CF3中氟原子的高电负性增强了框架中芳香环之间的相互作用力,这种相互作用力有助于COF形成较大的比表面积以及较小的孔径[17]。

通过热重分析TpPa-CF3的热性能。热重曲线如图3(d)所示,从图中看到热损失分为两个阶段,大约在400℃之前的损失可能为残留在孔道里的高沸点溶剂(DMF)的挥发。400℃后出现明显的质量损失,从DTG曲线上可以看到在416℃质量损失的速度最快,这主要归因于TpPa-CF3框架的分解。以上结果可以看出TpPa-CF3具有较好的热稳定性。

2.2 TpPa-CF3/6FDA-ODA混合基质膜的表征

通过XRD对膜结构表征,评价了填料对聚合物链排列的影响。从图4(a)中可以看到所有曲线在2θ=15°左右均出现典型的聚合物宽峰。通过布拉格方程计算,得到膜的分子链间距。纯6FDA-ODA膜的分子链间距为0.574 nm,随着填料TpPa-CF3负载量的增加,链间距呈现先增大后下降的趋势,7%TpPa-CF3/6FDA-ODA膜的链间距最小(0.566 nm)。分子链间距先增大主要是由于小负载量的掺入破坏了分子链的堆积,随着负载量的增大,填料与聚合物基质的相互作用逐渐增强,限制了分子链的迁移率,链间距减小有利于提高气体的选择性。同时,在TpPa-CF3/6FDA-ODA混合基质膜中没有观察到TpPa-CF3粉末的特征峰,这主要是由于在超声搅拌过程中COF填料的部分剥落[21]。

混合基质膜的FTIR图谱如图4(b)所示,所有膜都表现出6FDA-ODA的特征峰,包括C=O的对称(

1783 cm−1)和不对称拉伸(1733 cm−1)、C—N的拉伸振动(1378 cm−1)、C—O—C的拉伸振动(1157 cm−1)、C—F键的吸收峰(1110 cm−1),以及酰亚胺环的弯曲振动(721 cm−1),值得注意的是在1597 cm−1处的特征峰,随着填料的增加而增强,这主要归因于TpPa-CF3和6FDA-ODA中芳香环上的C=C的吸收峰重叠[22]。以上结果说明聚酰亚胺基体和填料之间具有良好的相容性,填料的加入并没有破坏聚酰亚胺的结构。为分析TpPa-CF3的加入对混合基质膜热稳定性的影响,对6FDA-ODA及TpPa-CF3/6FDA-ODA混合基质膜进行了热重测试。如图5(a)所示,混合基质膜的分解分为两个阶段,第一阶段是400℃左右TpPa-CF3框架的分解,第二阶段是500℃左右6FDA-ODA基体膜的分解,填料的加入对膜的热稳定性影响不大。所有混合基质膜都表现出高达500℃的良好热稳定性,远高于工业中膜的操作温度,表明这些膜具有良好的适用性。DSC曲线用于分析膜的玻璃化转变温度(Tg)。如图5(b)所示,6FDA-ODA膜的Tg出现在297.5℃。随着TpPa-CF3负载量的增加,TpPa-CF3/6FDA-ODA膜的Tg从297.5℃逐渐增加到302.1℃,说明TpPa-CF3与6FDA-ODA之间具有良好的界面相互作用,这有利于提升混合基质膜的气体选择性[23]。

膜表面、截面的扫描电镜表征能够反映出填料在膜内的分散情况。如图6(a1)~6(e1)所示,与表面光滑平整的纯膜相比,混合基质膜的表面随着填料负载量的增加逐渐变得粗糙,在负载量达到7wt%时可以看到膜表面出现不平整及大颗粒团聚的现象。图6(a2)~6(e2)为纯膜及其混合基质膜的截面扫描电镜图,纯膜的截面表现出均匀、致密的微观结构,在1wt%~5wt%混合基质膜的截面图中能够观察到随着负载量的增加其截面形貌逐渐变粗糙,同时在膜内能够观察到TpPa-CF3颗粒很好地被聚合物包裹且分散均匀。当填料负载量达到7wt%时膜内出现填料与聚合物基质相分离的现象,说明此时负载量已经达到聚合物基质所能承受的上限,5wt%为其最优负载量。

通过接触角测试仪分析纯膜及其混合基质膜的水接触角(θw)。如图7(a)和表1所示,6FDA-ODA膜的水接触角为79.9°,TpPa-CF3/6FDA-ODA混合基质膜的水接触角为81.4°~89.1°,呈现逐渐增大的趋势。这主要归因于TpPa-CF3框架中含有—CF3疏水基团,因此随着TpPa-CF3含量的增加相应负载量的混合基质膜水接触角也逐渐增加。提升膜的疏水性能有助于阻止水汽进入,提升其气体传输性能。

表 1 不同负载量下TpPa-CF3/6FDA-ODA混合基质膜的力学性能Table 1. Mechanical properties of TpPa-CF3/6FDA-ODA mixed matrix membranes at different loadingsTpPa-CF3 loadings/wt% Tensile strength/MPa Elongation at break/% Young's modulus/GPa θw/(°) 0 74.1 10.1 1.59 79.9 1 79.6 9.7 1.63 81.4 3 82.9 8.6 1.70 83.1 5 93.0 7.8 1.82 84.1 7 84.5 7.3 1.76 89.1 Note: θw—Water contact angle. 对混合基质膜进行拉伸实验以此来检验其力学性能。测试结果如图7(b)和表1所示。从表中可以看出,TpPa-CF3/6FDA-ODA混合基质膜的抗拉强度和杨氏模量随着TpPa-CF3负载量的增加呈现出先增加后下降的趋势,而断裂伸长率呈现逐渐下降的趋势。这主要归因于,在混合基质膜中TpPa-CF3与6FDA-ODA之间较好的相互作用力使得填料与聚合物之间具有良好的界面相容性,增强了膜的刚性。然而,当负载量达到7wt%时,抗拉强度和杨氏模量略微下降,这主要是过量的TpPa-CF3颗粒之间发生团聚,使得界面出现缺陷导致应力集中,降低了膜的力学性能[24]。

利用3种纯气体(CO2、O2、N2)渗透测试来评估不同负载量下TpPa-CF3/6FDA-ODA混合基质膜的渗透性及CO2/N2和O2/N2的理想选择性。结果如表2所示,每一种膜气体渗透系数的大小均与气体分子动力学直径呈反比,即膜的3种气体渗透系数大小排列为P(CO2)>P(O2)>P(N2),3种气体分子动力学直径大小排列为N2(0.36 nm)>O2(0.35 nm)>CO2(0.33 nm)。同6FDA-ODA膜相比所有混合基质膜的气体渗透性都有所提升。由图8(a)中可得,随着TpPa-CF3含量的增加,膜的气体渗透性呈现出先增大后下降的趋势,其中5%TpPa-CF3/6FDA-ODA膜气体渗透性能最佳,P(CO2)提升了149%,P(O2)提升了138%,P(N2)提升了98%。这主要归因于TpPa-CF3的高孔隙率提高了TpPa-CF3/6FDA-ODA膜的比表面积及固有孔隙率,为气体传输提供了快速通道。TpPa-CF3负载量到7wt%时,气体的渗透性明显下降,但仍然比6FDA-ODA膜高。这主要是由于负载量过大,造成TpPa-CF3在膜内团聚堵塞了气体传输的孔道。

表 2 6FDA-ODA及TpPa-CF3/6FDA-ODA混合基质膜的气体渗透系数P和理想选择性Table 2. Gas permeability coefficient P and ideal selectivity of 6FDA-ODA and TpPa-CF3/6FDA-ODA mixed matrix membranesMembrane Permeability/Barrer Ideal selectivity α CO2 O2 N2 α(CO2/N2) α(O2/N2) 6FDA-ODA 12.47 2.55 0.64 19.5 4.0 1%TpPa-CF3/6FDA-ODA 16.91 3.76 0.98 17.2 3.8 3%TpPa-CF3/6FDA-ODA 22.77 4.43 1.03 22.0 4.3 5%TpPa-CF3/6FDA-ODA 31.08 6.08 1.27 24.5 4.8 7%TpPa-CF3/6FDA-ODA 18.62 4.16 1.11 16.8 3.8 Notes: 1 Barrer=10−10 cm3(STP)·cm·cm−2·s−1·cmHg−1; Ideal selectivity α=P(A)/P(B), A and B are two different pure gases. TpPa-CF3/6FDA-ODA膜的气体选择性变化趋势和气体渗透性变化趋势不同,如图8(b)所示,CO2/N2和O2/N2均呈现出先下降后上升再下降的趋势,CO2/N2及O2/N2的理想选择性范围分别在16.8~24.4和3.8~4.8。其中,当TpPa-CF3负载量为5wt%时,混合基质膜的CO2/N2和O2/N2选择性最好,分别是6FDA-ODA膜的125%和119%。理想选择性的提高主要归因于两个方面:一个方面是CO2和O2的分子动力学直径要小于N2的分子动力学直径,从而CO2和O2分子倾向于优先通过。另一个方面,TpPa-CF3中富含大量对CO2具有亲和力的N、O和F等电负性原子,同时框架内还存在能与CO2发生偶极-四极相互作用的强极性C—F键,因此CO2/N2选择性相较于O2/N2的提升更明显[25]。然而,当负载量到7wt%时,混合基质膜的CO2/N2和O2/N2选择性大幅下降,略低于6FDA-ODA膜,这主要归因于当TpPa-CF3的负载量增加一定程度时,其在膜内发生团聚,并和聚合物基质产生部分相分离,产生一些非选择的孔,从而造成CO2/N2和O2/N2理想选择性的大幅下降。

对TpPa-CF3/6FDA-ODA混合基质膜进行72 h的连续气体渗透性测试,以验证膜的稳定性。如图8(c)所示,该膜在72 h的运行试验中P(CO2)下降了18%,CO2/N2的选择性下降了16%,总体表现出了良好的分离稳定性。

为了评估混合基质膜的气体分离性能,图9显示了不同负载量的TpPa-CF3/6FDA-ODA混合基质膜的气体分离性能与Robeson上限的对比。当负载量为5wt%时,其气体分离性能更靠近Robeson上限,气体的渗透性与选择性同步提升。说明适量的引入TpPa-CF3能够改善聚合物膜的气体分离性能。此外,表3显示了文献[26-30]中报道的混合基质膜气体分离性能与本工作的对比,TpPa-CF3/6FDA-ODA混合基质膜显示出适中的气体渗透性以及适中的气体选择性,说明TpPa-CF3/6FDA-ODA混合基质膜还有进一步提升的潜力。

表 3 文献中报道的混合基质膜气体分离性能与本工作的对比Table 3. Comparison of gas separation performance of mixed matrix membranes reported in the literature with the present workMembrane type P(CO2)/Barrer P(O2)/Barrer α(CO2/N2) α(O2/N2) Ref. TpPa-1-nc/Pebax 21 — 72 — [26] COFp-PVAm 270 — 86 — [27] TpBD@PBI-BuI 14.8 — 23 — [28] ZIF-7-I/(BPDA/6FDA-ODA) — 2.9 — 0.19 [29] PBI-PI-based carbon 293.5 93.1 8.3 2.6 [30] 5%TpPa-CF3/6FDA-ODA 31.08 6.08 24.4 4.8 This work Notes: TpPa-1-nc—; COFp—; TpBD—; BPDA—; Pebax—Poly(ether-block-amide); PVAm—Polyvinylamine; PBI-BuI—Tert-butylpolybenzimidazole; ZIF-7-I—Wide-pore ZIF-7; PBI—Polybenzimidazoles; PI—Polyimide. 3. 结 论

(1)采用溶剂热法合成了一种氟化共价有机框架材料(TpPa-CF3),其具有高比表面积(791.83 m2·g−1),较小且均一的孔径(1.18 nm)以及良好的热稳定性。

(2)采用共混法成功制备TpPa-CF3/聚酰亚胺(6FDA-ODA)混合基质膜。通过表征得出,所得膜具有良好的界面相容性以及较高的热稳定性(热分解温度在500℃左右)。水接触角的范围在81.4°~89.1°,且膜具有良好的力学性能,有利于膜在分离过程中的稳定性。

(3) TpPa-CF3的掺入提高了混合基质膜的气体渗透性,随着膜中TpPa-CF3负载量的增加,混合基质膜的气体渗透性呈现先减小后增大再减小的趋势。其中,5%TpPa-CF3/6FDA-ODA膜的气体分离性能最好,其CO2和O2的渗透性能分别提高了149%和138%,CO2/N2和O2/N2的分离性能分别是6FDA-ODA基体膜的125%和119%。

-

图 12 试验梁正截面应力分布简图

Figure 12. Distribution of stresses and strains along cross-section of test beam

h—Height of beam; b—Width of beam; htg— Distance from the grid to the top of the composite beam; as—The distance from the tensile steel bar to the bottom of the composite beam; h0—Effective height of composite beam; he—ECC thickness; As—The cross section area of tensile reinforcement; A′s—The cross section area of compressive steel bar; εcu—Concrete ultimate compressive strain; ε's—Compressive steel bar strain; εs—Tensile steel bar strain; εe—ECC tensile strain; εtg—Textile or the high-strength steel wire strand mesh strain; xc—Compression zone height; yc—The distance from the concrete resultant point to the top of the composite beam; σc—Concrete compressive stress; σec—ECC tensile stress; Cc—Concrete resultant force; T′s—Compressed steel bar resultant force; Ts—Tensile steel bar resultant force; Ttg—Grid resultant force.

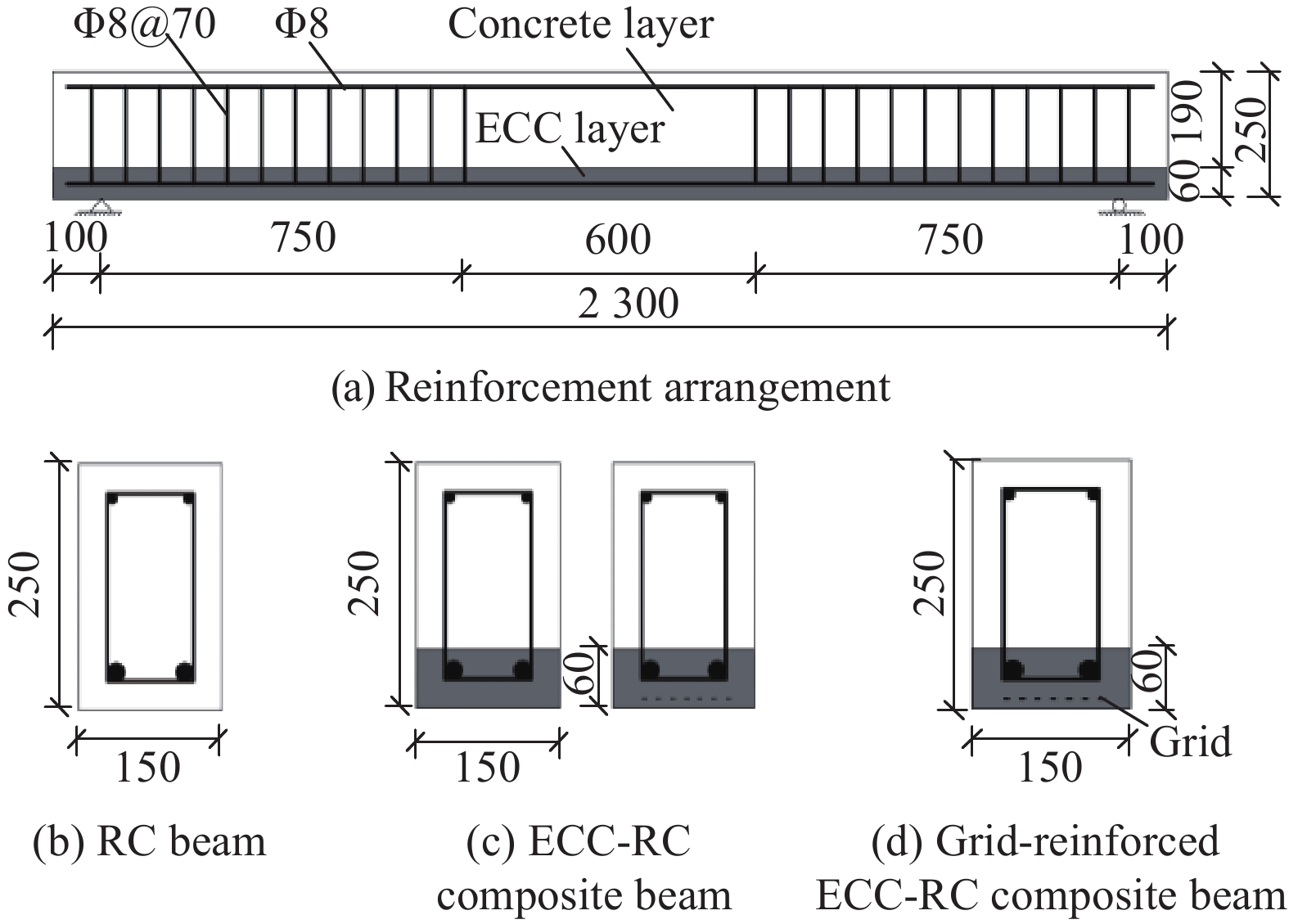

表 1 试件设计参数

Table 1 Design parameters of specimens

Specimen number Thickness of

ECC/mmDistance from

grid to beam

bottom/mmGrid type RC 0 — — ECC-RC 60 — — CFRP/ECC-RC 60 10 CFRP textile BFRP/ECC-RC 60 10 BFRP textile HSSWS/ECC-RC 60 10 High-strength steel wire strand mesh Notes: ECC—Engineered cementitious composite; RC—Reinforced concrete; CFRP—Carbon fiber reinforced polymer; BFRP—Basalt fiber reinforced polymer; HSSWS—High strength steel wire strand. 表 2 ECC的配合比(单位:kg/m3)

Table 2 Mix proportion of ECC (Unit: kg/m3)

Material Fumed silica/mm P·O 52.5 Sand Water Water

reducerExpansion agent Fiber Silica

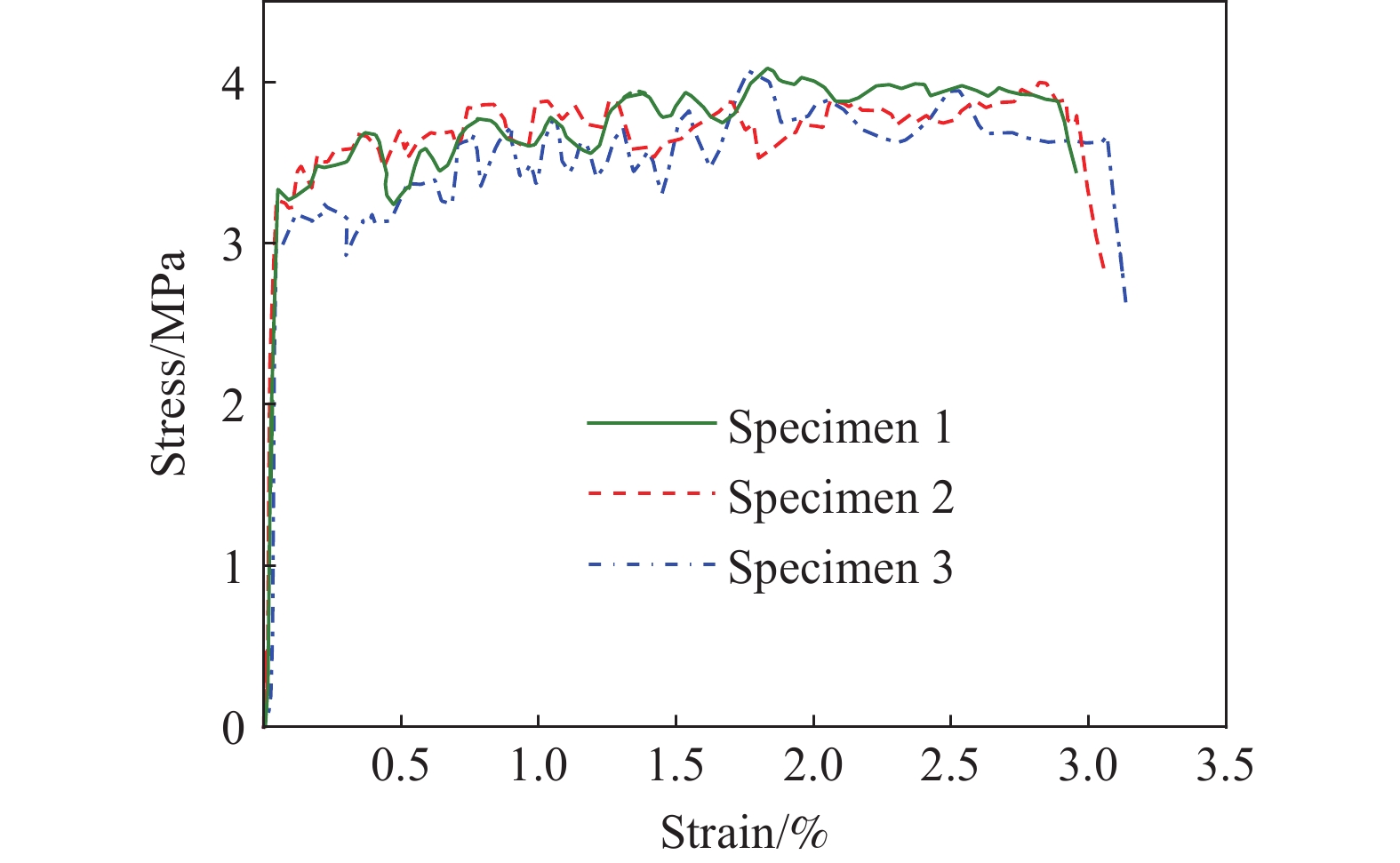

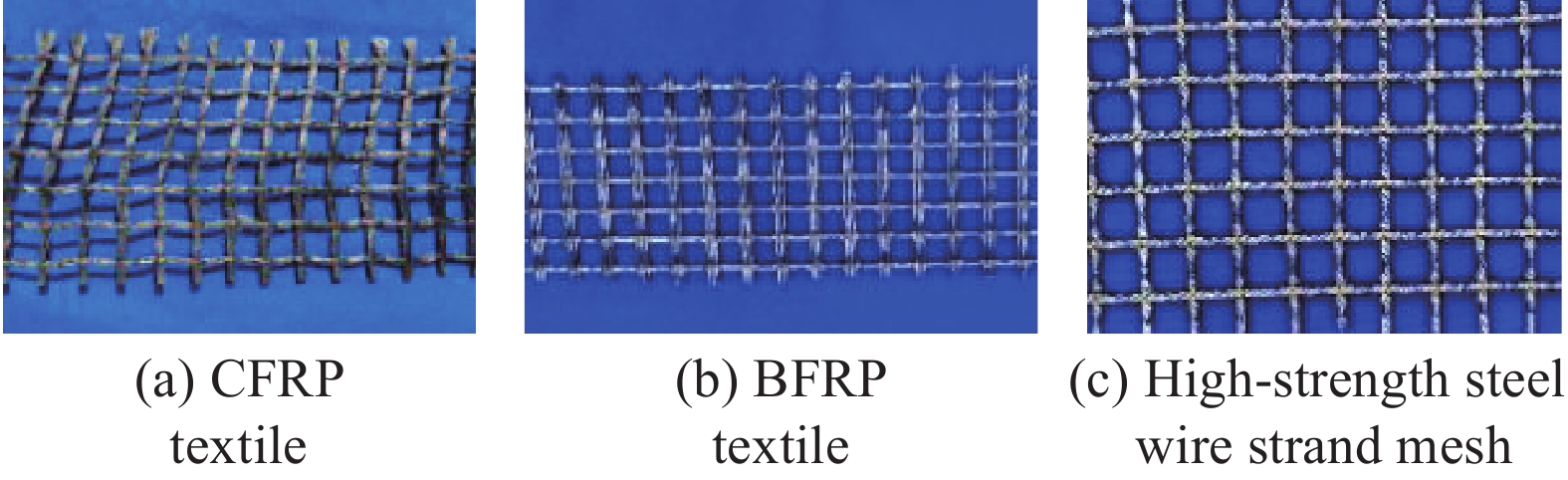

fume5-16 16-32.5 C50 471 706 520 706 161 7.8 — — — ECC — — 500 600 190 3 25 23 25 表 3 纤维网格和高强钢绞线网格力学性能

Table 3 Mechanical properties of textile and high-strength steel wire strand mesh

Grid type Ultimate tensile strength/MPa Elastic modulus/GPa Ultimate tensile strain/% Cross-sectional area/mm2 CFRP textile 4815 252 1.90 0.89 BFRP textile 3330 90 3.70 0.89 High-strength steel wire strand mesh 1845 180 2.96 4.71 表 4 试验梁特征数据结果

Table 4 Characteristic data results of test beams

Specimen number Pcr/kN Mcr/(kN·m) Dcr/% Py/kN My/(kN·m) Dy/% Pu/kN Mu/(kN·m) Du/% Δy/mm Δu/mm DΔu/% RC 14 5.25 — 104 39.00 — 121 45.38 — 9.99 25.51 — ECC-RC 16 6.00 — 113 42.38 — 127 47.63 — 10.05 27.77 — CFRP/ECC-RC 27 10.13 68.83 125 46.88 10.62 141 52.88 11.02 10.46 29.39 5.83 BFRP/ECC-RC 22 8.25 37.50 122 45.75 7.95 139 52.13 9.45 9.78 31.97 15.12 HSSWS/ECC-RC 28 10.50 75.00 143 53.62 26.52 170 63.75 33.84 10.28 34.36 23.73 Notes: Pcr—Cracking load; Mcr—Cracking moment; Py—Yielding load; My—Yielding moment; Pu—Ultimate load; Mu—Ultimate moment; Δy—Deflection of the specimen at My; Δu—Deflection of the specimen at Mu; Dcr, Dy, Du, DΔu represent the increase of cracking load, yield load, ultimate load and ultimate deflection compared with ECC-RC beam, respectively. 表 5 试验梁受弯承载力计算值和试验值对比

Table 5 Comparison of flexural bearing capacity between experimental and theoretical results of test beams

Specimen number Muc/(kN·m) Mut/(kN·m) Muc/Mut Error/% CFRP/ECC-RC 52.00 52.88 0.98 1.7 BFRP/ECC-RC 51.40 52.13 0.99 1.4 HSSWS/ECC-RC 61.85 63.75 0.97 3.0 ECC-RC 49.96 47.63 1.05 4.9 BA-1[23] 15.75 14.80 1.06 5.7 BB-1[23] 16.66 15.70 1.06 5.5 BC-1[23] 17.46 16.60 1.05 4.9 Notes: Muc—Calculated value of ultimate bending moment of composite beam; Mut—Experimental value of ultimate bending moment of composite beam; BA-1, BB-1, BC-1—Specimen name from literature[23]. -

[1] LI V C, STANG H, KRENCHEL H. Micromechanics of crack bridging in fiber-reinforced concrete[J]. Materials and Structures, 1993, 26(8): 486-494.

[2] LI V C, LEUNG C K Y. Steady state and multiple cracking of short random fiber composites[J]. Journal of Engineering Mechanics, 1992, 188(11): 2246-2264.

[3] SHANOUR A S, SAID M, ARAFA A I, et al. Flexural performance of concrete beams containing engineered cementitious composites[J]. Construction and Building Materials, 2018, 180: 23-34. DOI: 10.1016/j.conbuildmat.2018.05.238

[4] 崔涛, 何浩祥, 闫维明, 等. 带ECC底板的装配式梁受弯性能及损伤分析[J]. 哈尔滨工业大学学报, 2019, 51(12): 104-112. DOI: 10.11918/j.issn.0367-6234.201812126 CUI Tao, HE Haoxiang, YAN Weiming, et al. Bending performance test and damage analysis of precast beams with ECC plate[J]. Journal of Harbin Institute of Technology, 2019, 51(12): 104-112(in Chinese). DOI: 10.11918/j.issn.0367-6234.201812126

[5] 王新玲, 罗鹏程, 钱文文, 等. 高强不锈钢绞线网增强工程水泥基复合材料薄板受弯承载力研究[J]. 建筑结构学报, 2022, 43(1): 164-172. WANG Xinling, LUO Pengcheng, QIAN Wenwen, et al. Study on flexural bearing capacity of high-strength stainless steel wire mesh reinforced ECC thin plate[J]. Journal of Building Structures, 2022, 43(1): 164-172(in Chinese).

[6] 朱俊涛, 张凯, 王新玲, 等. 高强不锈钢绞线网与ECC粘结-滑移关系模型[J]. 土木工程学报, 2020, 53(4): 83-92. ZHU Juntao, ZHANG Kai, WANG Xinling, et al. Bond-slip relational model between high-strength stainless steel wire mesh and ECC[J]. China Civil Engineering Journal, 2020, 53(4): 83-92(in Chinese).

[7] 王新玲, 陈永杰, 钱文文, 等. 高强不锈钢绞线网增强工程水泥基复合材料弯曲性能试验[J]. 复合材料学报, 2021, 38(4): 1292-1301. WANG Xinling, CHEN Yongjie, QIAN Wenwen, et al. Experiment on bending performance of engineered cementitious composites reinforced by high-strength stainless steel wire strand mesh[J]. Acta Materiae Compositae Sinica, 2021, 38(4): 1292-1301(in Chinese).

[8] 李传秀, 尹世平, 赵俊伶. 纤维编织网增强ECC的拉伸和弯曲性能[J]. 建筑材料学报, 2021, 24(4): 736-741. DOI: 10.3969/j.issn.1007-9629.2021.04.009 LI Chuanxiu, YIN Shiping, ZHAO Junling. Tensile and bending properties of textile reinforced ECC[J]. Journal of Building Materials, 2021, 24(4): 736-741(in Chinese). DOI: 10.3969/j.issn.1007-9629.2021.04.009

[9] 徐世烺, 李庆华, 李贺东. 碳纤维编织网增强超高韧性水泥基复合材料弯曲性能的试验研究[J]. 土木工程学报, 2007, 40(12): 69-76. DOI: 10.3321/j.issn:1000-131x.2007.12.009 XU Shilang, LI Qinghua, LI Hedong. An experimental study on the flexural properties of carbon textile reinforced ECC[J]. China Civil Engineering Journal, 2007, 40(12): 69-76(in Chinese). DOI: 10.3321/j.issn:1000-131x.2007.12.009

[10] 王新玲, 苏会晓, 李可, 等. FRP网格增强ECC加固素混凝土柱受压性能数值分析[J]. 建筑科学, 2018, 34(3): 22-29. WANG Xinling, SU Huixiao, LI Ke, et al. Numerical analysis of compressive performance of plain concrete columns strengthened with FRP-grid and ECC[J]. Building Science, 2018, 34(3): 22-29(in Chinese).

[11] 郭瑞, 任宇, 顾天宇. 纤维增强复材网格-工程水泥基复合材料加固钢筋混凝土梁的抗剪性能试验研究[J]. 工业建筑, 2019, 49(9): 145-151. GUO Rui, REN Yu, GU Tianyu. Experimental research on shear behavior of RC beams reinforced with FRP grid-ECC[J]. Cement Science & Concrete Technology, 2019, 49(9): 145-151(in Chinese).

[12] ZHENG Y Z, WANG W W, MOSALAM K M, et al. Experimental investigation and numerical analysis of RC beams shear strengthened with FRP/ECC composite layer[J]. Composite Structures, 2020, 246: 112436. DOI: 10.1016/j.compstruct.2020.112436

[13] GUO R, REN Y, LI M Q, et al. Experimental study on flexural shear strengthening effect on low-strength RC beams by using FRP grid and ECC[J]. Engineering Structures, 2021, 227: 111434. DOI: 10.1016/j.engstruct.2020.111434

[14] ZHENG A H, LIU Z Z, LI F P, et al. Experimental investigation of corrosion-damaged RC beams strengthened in flexure with FRP grid-reinforced ECC matrix composites[J]. Engineering Structures, 2021, 244: 112779. DOI: 10.1016/j.engstruct.2021.112779

[15] YANG X, GAO W Y, DAI J G. Flexural strengthening of RC beams with CFRP grid-reinforced ECC matrix[J]. Composite Structures, 2018, 189: 9-26. DOI: 10.1016/j.compstruct.2018.01.048

[16] ZHENG Y Z, WANG W W, BRIGHAM J C. Flexural behaviour of reinforced concrete beams strengthened with a composite reinforcement layer: BFRP grid and ECC[J]. Construction and Building Materials, 2016, 115: 424-437. DOI: 10.1016/j.conbuildmat.2016.04.038

[17] 郑宇宙. FRP格栅增强ECC复合加固混凝土梁试验与计算方法研究[D]. 南京: 东南大学, 2018. ZHENG Yuzhou. Experimental and calculation method research on reinforced concrete (RC) beams strengthened with the composite of FRP grid and ECC[D]. Nanjing: Southeast University, 2018(in Chinese).

[18] 郑宇宙, 王文炜. 复材网格-UHTCC复合增强钢筋混凝土梁抗弯性能试验研究[J]. 土木工程学报, 2017, 50(6): 23-32. ZHENG Yuzhou, WANG Wenwei. Experimental research on flexural behavior of RC beams strengthened with FRP grid-UHTCC composite[J]. China Civil Engineering Journal, 2017, 50(6): 23-32(in Chinese).

[19] 张振. 玄武岩纤维网-ECC复合材料加固RC梁抗弯性能研究[D]. 长春: 吉林建筑大学, 2022. ZHANG Zhen. Study on flexural behavior of RC beams strengthened by basalt fiber grid-ECC composite material[D]. Changchun: Jilin Jianzhu University, 2022(in Chinese).

[20] 李可, 赵佳丽, 李志强, 等. 高强钢绞线网增强ECC抗弯加固无损RC梁试验[J]. 复合材料学报, 2022, 39(7): 3428-3440. LI Ke, ZHAO Jiali, LI Zhiqiang, et al. Experiment on non-damaged RC beams strengthened by high-strength steel wire strand meshes reinforced ECC in bending[J]. Acta Materiae Compositae Sinica, 2022, 39(7): 3428-3440(in Chinese).

[21] 李可, 王宇, 李志强, 等. 高强钢绞线网增强ECC加固无损RC梁受弯承载力研究[J]. 建筑结构学报, 2022, 43(12): 82-90. LI Ke, WANG Yu, LI Zhiqiang, et al. Research on flexural bearing capacity of non-damaged RC beams strengthened by high-strength steel wire strand mesh-reinforced ECC[J]. Journal of Building Structures, 2022, 43(12): 82-90(in Chinese).

[22] 李可, 任魁, 李志强, 等. 高强钢绞线网增强ECC加固无损RC梁截面刚度计算[J]. 铁道科学与工程学报, 2022, 19(10): 3046-3054. LI Ke, REN Kui, LI Zhiqiang, et al. Calculation of section rigidity of non-damaged RC beams strengthened by high-strength steel wire strand meshes reinforced ECC[J]. Journal of Railway Science and Engineering, 2022, 19(10): 3046-3054(in Chinese).

[23] 盛杰, 尹世平, 裴浩. 纤维编织网-ECC加固RC梁受弯性能试验[J]. 中国公路学报, 2022, 35(9): 287-297. DOI: 10.3969/j.issn.1001-7372.2022.09.022 SHENG Jie, YIN Shiping, PEI Hao. Experimental study on flexural behavior of RC beams strengthened with textile and ECC[J]. China Journal of Highway and Transport, 2022, 35(9): 287-297(in Chinese). DOI: 10.3969/j.issn.1001-7372.2022.09.022

[24] 葛文杰, 宗耀锋, 仇胜伟, 等. 碳纤维布粘贴加固BFRP筋-ECC-混凝土组合梁受弯性能研究[J]. 建筑结构学报, 2021, 42(S1): 302-311. GE Wenjie, ZONG Yaofeng, QIU Shengwei, et al. Study on flexural behavior of BFRP reinforced-ECC-concrete composite beams strengthened with carbon fiber sheets[J]. Journal of Building Structures, 2021, 42(S1): 302-311(in Chinese).

[25] 高培琦, 葛文杰, 虞佳敏, 等. 碳纤维布加固钢筋ECC/混凝土复合梁受弯性能试验研究[J]. 建筑科学, 2019, 35(11): 103-110. GAO Peiqi, GE Wenjie, YU Jiamin, et al. Experimental study on flexural behavior of ECC/concrete composite beams strengthened with carbon fiber sheets[J]. Building Science, 2019, 35(11): 103-110(in Chinese).

[26] 黄华. 高强钢绞线网—聚合物砂浆加固混凝土梁式桥试验研究与机理分析[D]. 西安: 长安大学, 2008. HUANG Hua. Experimental study and theoretical analysis on strengthening RC girder bridge with steel wire mesh and polymer mortar[D]. Xi'an: Chang'an University, 2008(in Chinese).

[27] 中华人民共和国住房和城乡建设部. 混凝土结构设计规范: GB 50010—2010[S]. 北京: 中国建筑工业出版社, 2015. Ministry of Housing and Urban-Rural Development of the People's Republic of China. Code for design of concrete structures: GB 50010—2010[S]. Beijing: China Architecture & Building Press, 2015(in Chinese).

[28] 董志芳, 邓明科, 张聪. 纤维织物增强高延性混凝土单轴拉伸性能试验研究[J]. 土木工程学报, 2020, 53(10): 13-25. DONG Zhifang, DENG Mingke, ZHANG Cong. Experimental investigation on uniaxial tension behavior of textile-reinforced highly ductile concrete[J]. China Civil Engineering Journal, 2020, 53(10): 13-25(in Chinese).

-

其他相关附件

-

目的

ECC因其具有应变硬化特征及优异的裂缝分散能力和控制力,被广泛用于混凝土结构加固领域。本文探究CFRP网格、BFRP网格、高强钢绞线网格增强ECC层对钢筋混凝土梁抗弯性能的影响,以及对钢筋混凝土加固效果最优的网格增强ECC层。

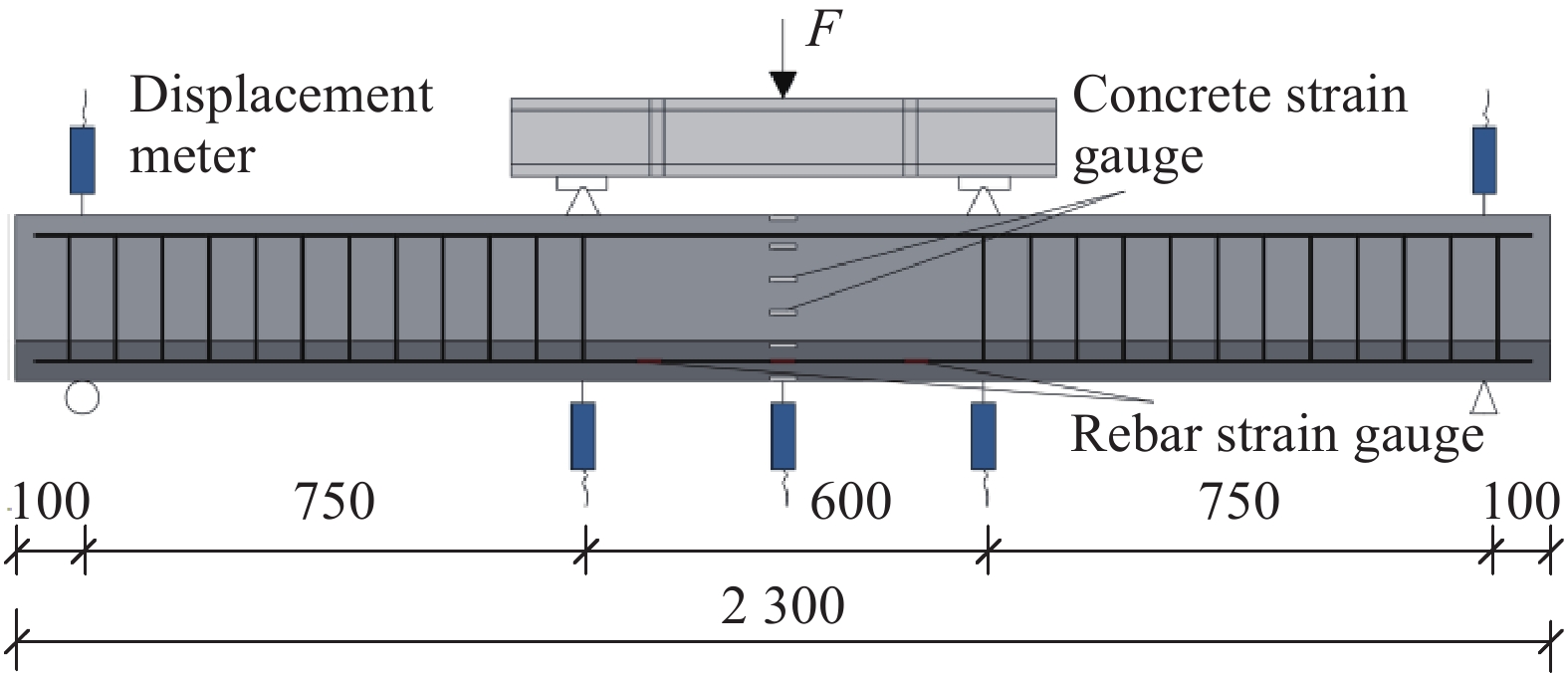

方法本文采用了一种新的钢筋混凝土梁加固方式,采用网格增强ECC层替换受拉区混凝土的加固方式,形成ECC-RC复合梁。本文主要采用试验对比方法,一共设置了两片对比梁,一片钢筋混凝土梁,一片不含网格的ECC-RC复合梁;三片不同类型网格增强ECC-RC复合梁。结合四点弯曲加载试验和数字图像技术,收集试验梁支座两端位移、跨中挠度、混凝土/钢筋应变以及荷载等级等数据,采用Origin软件对相对数据进行分析;依据钢筋混凝土正截面抗弯承载能力计算公式,在考虑纤维网格利用率的基础上,推导网格增强ECC-RC复合梁正截面抗弯承载能力计算公式。

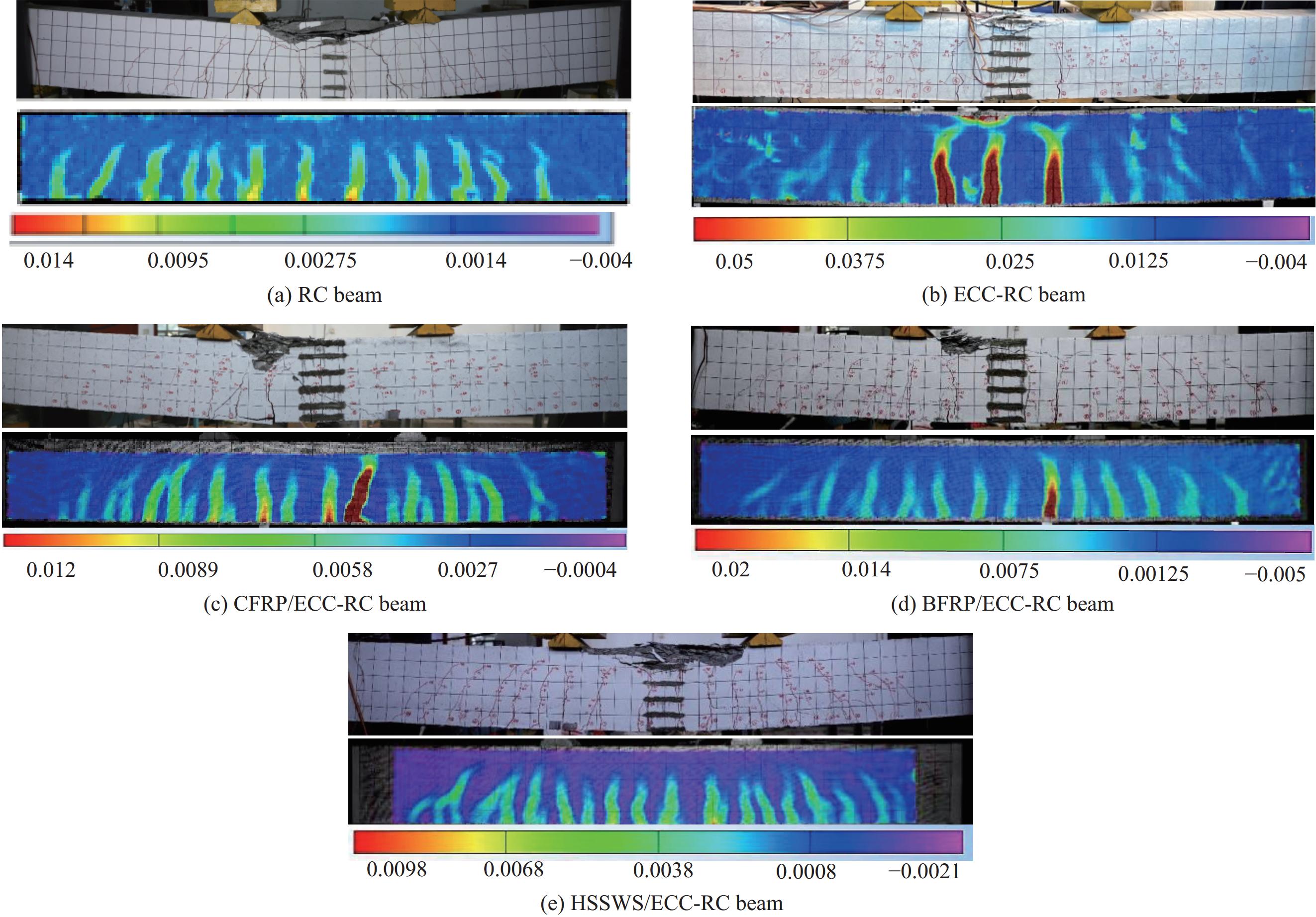

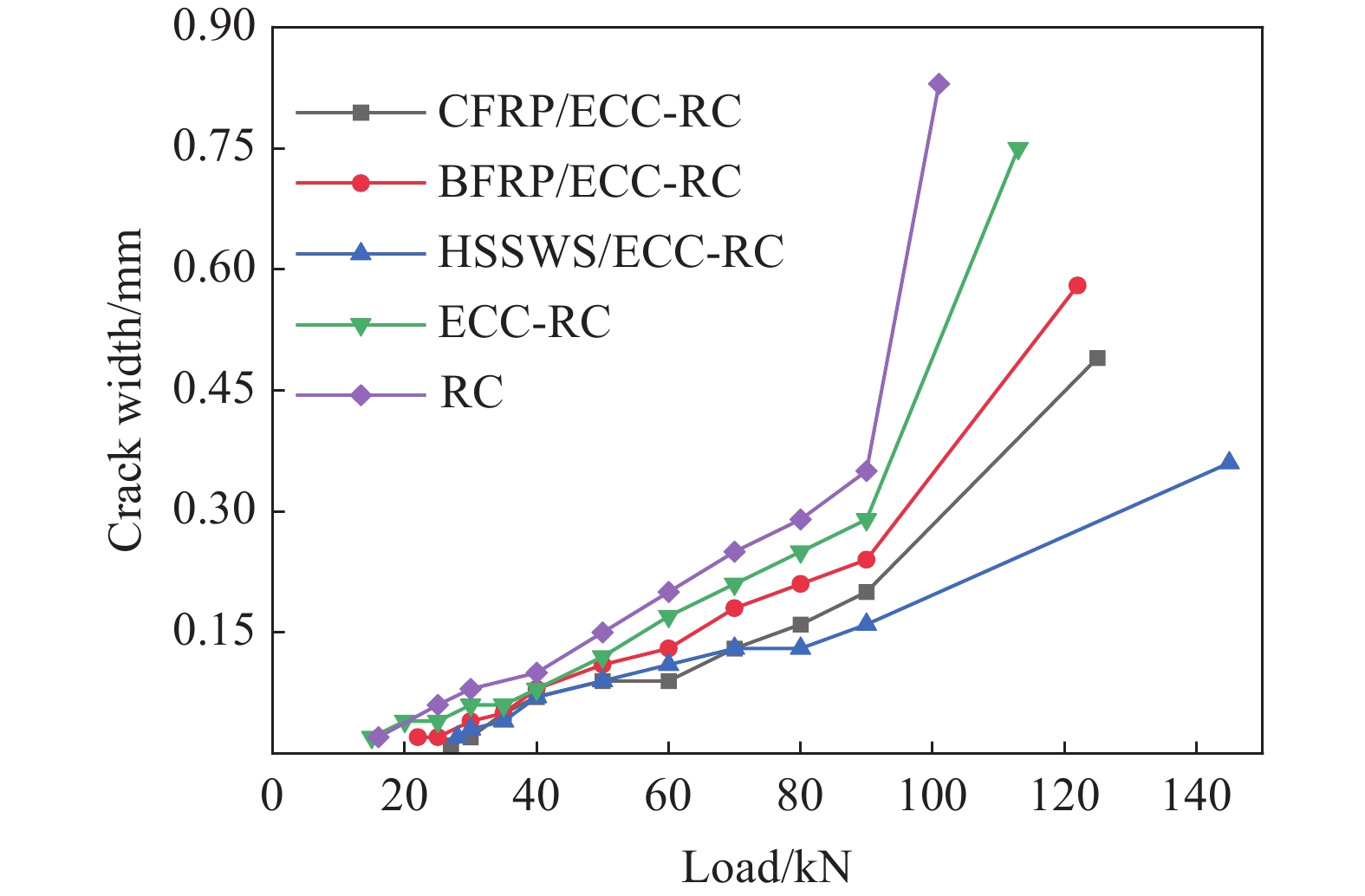

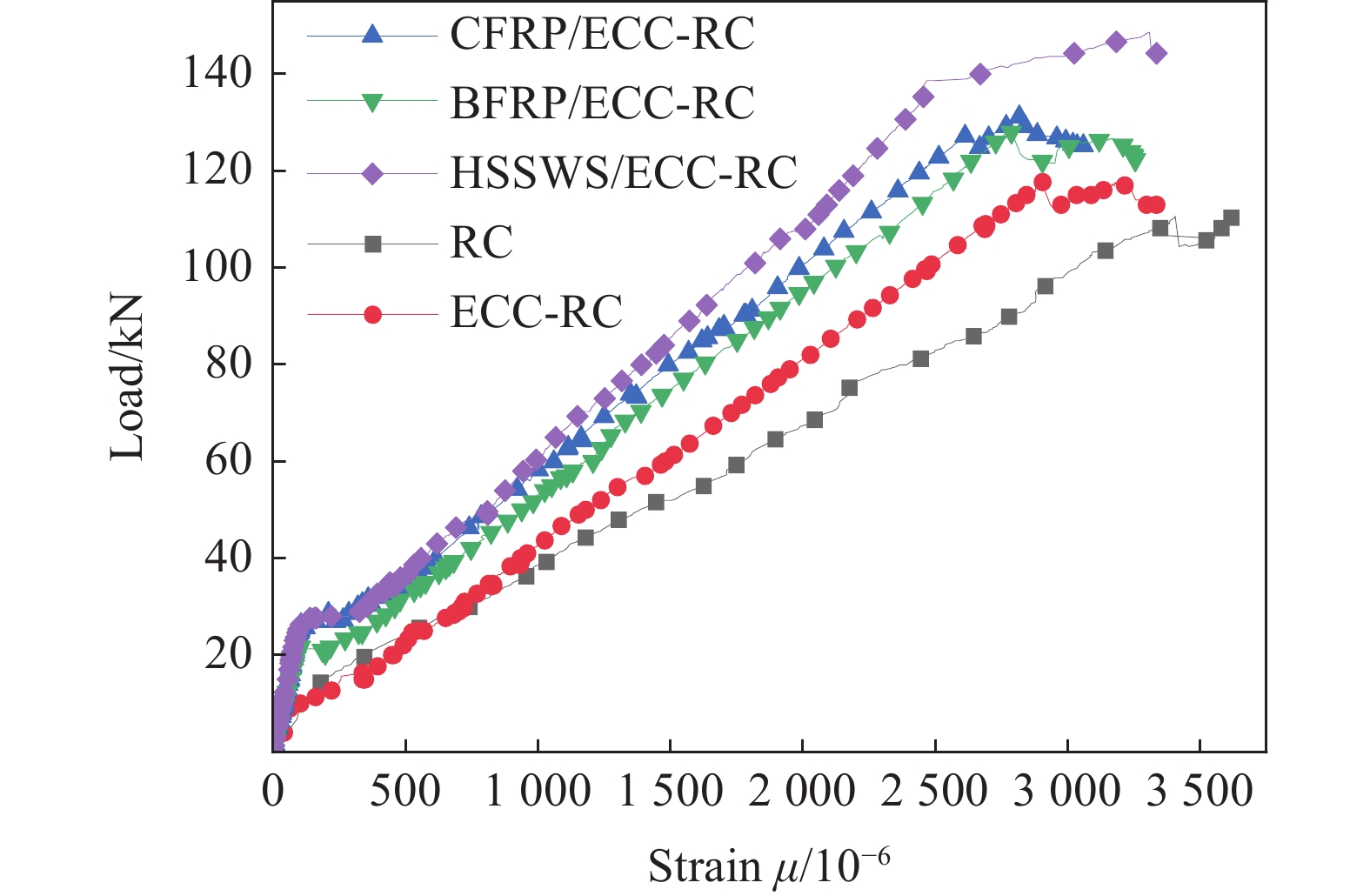

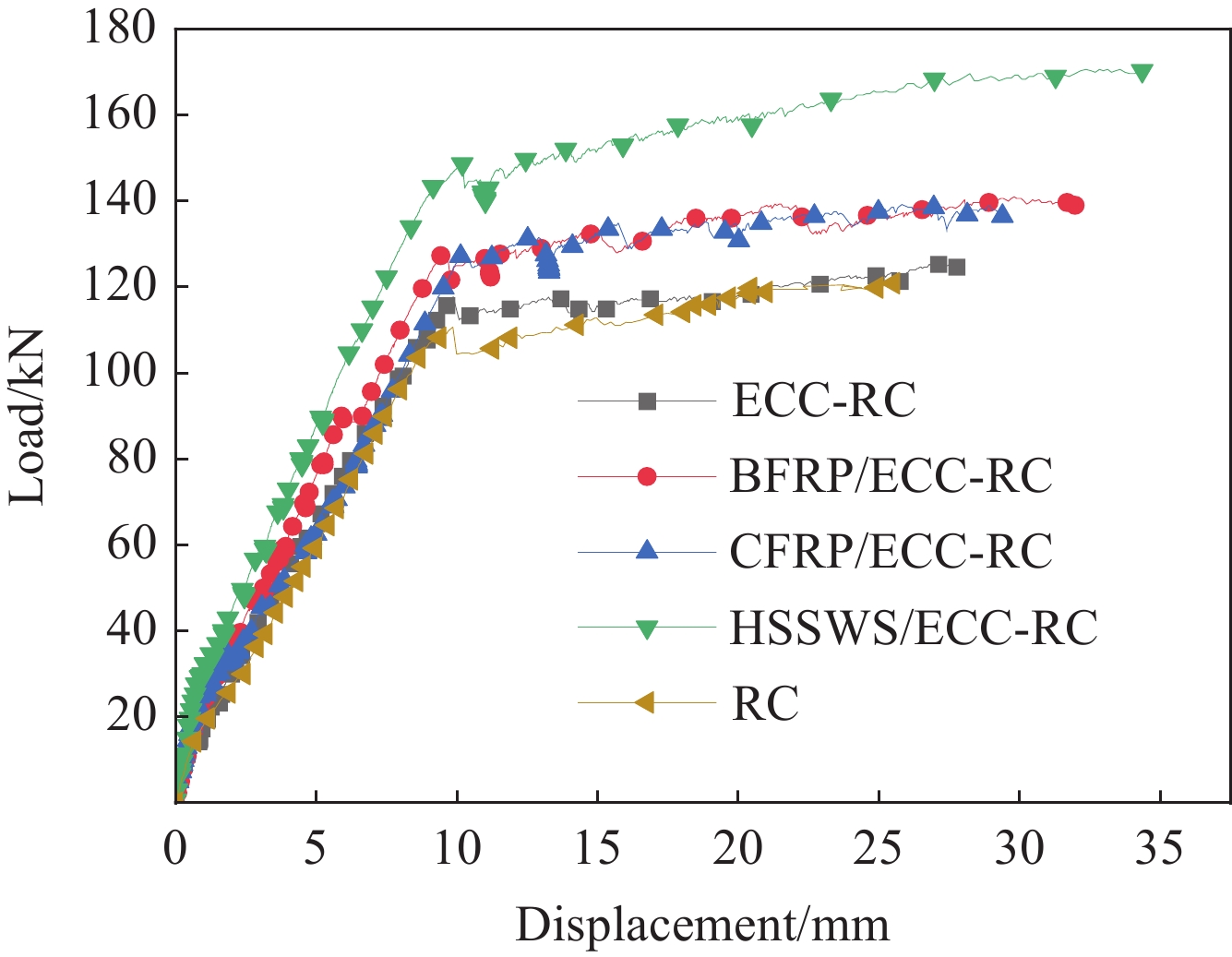

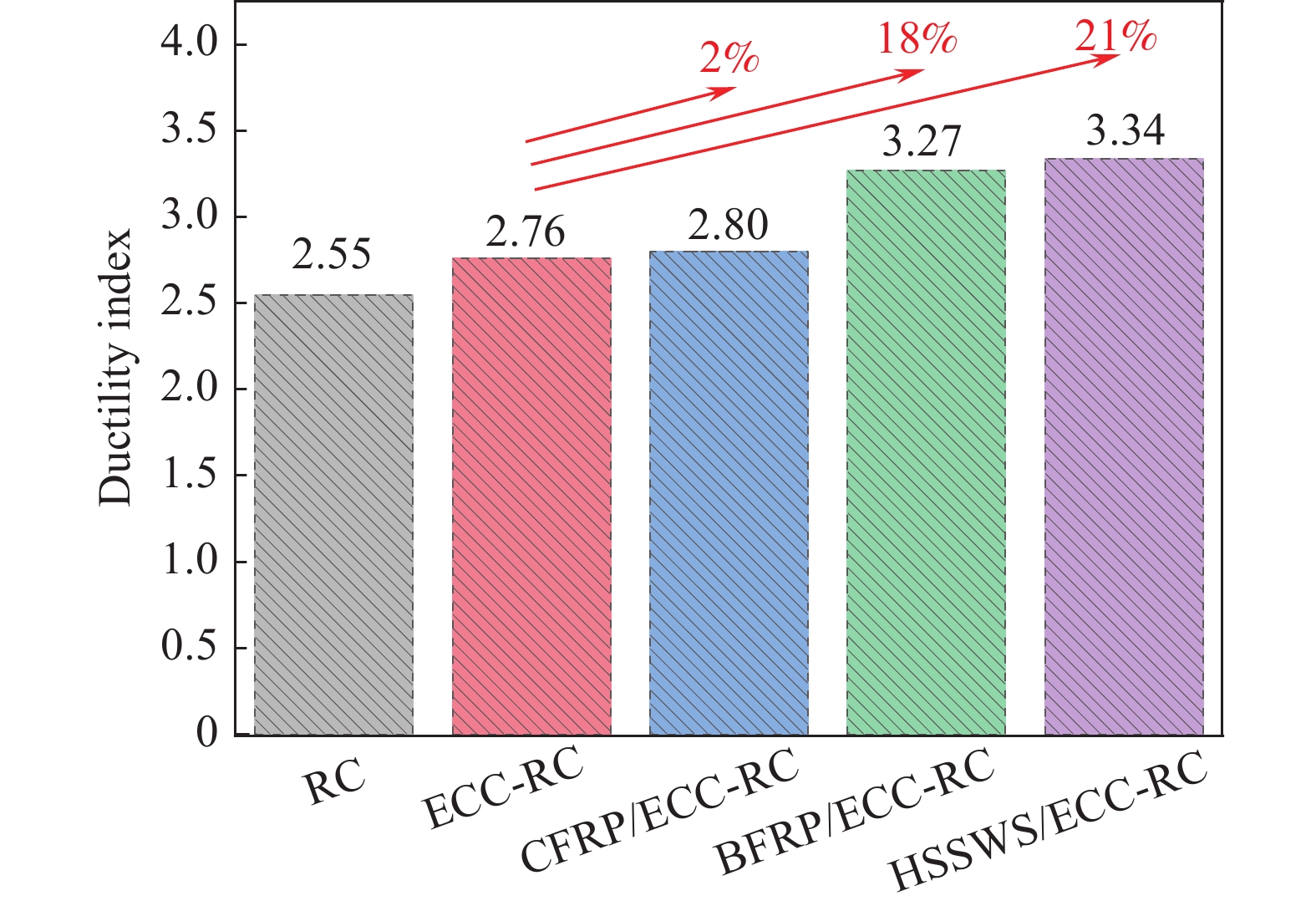

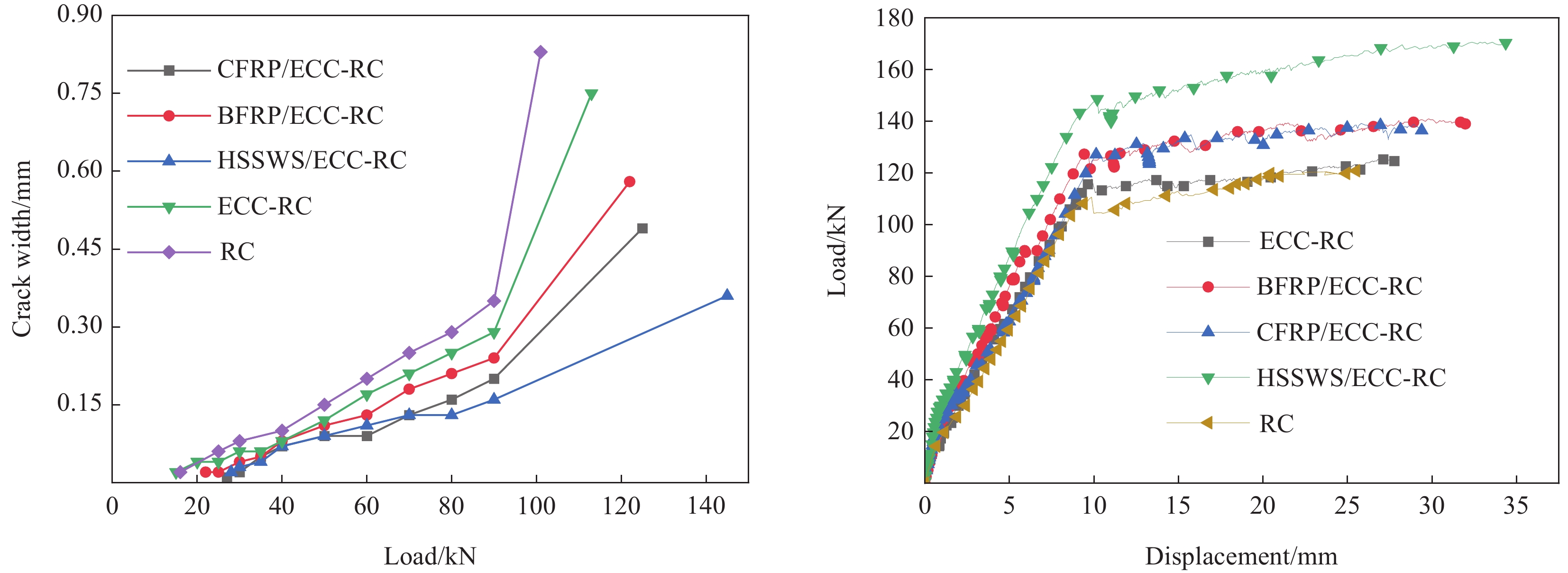

结果从根据四点弯曲加载试验,所有网格增强ECC-RC试验梁破坏过程为受拉钢筋先屈服,随着荷载等级增加,受压区混凝土压碎,随即试验梁破坏;纤维网格增强ECC-RC梁在加载过程中存在纤维网格受力不均导致断裂的现象。根据混凝土跨中截面不同高度处的混凝土应变分析可知,沿截面高度平行于梁中和轴的各纵向混凝土应变与其到中和轴的距离大致成线性分布。相对不含网格增强ECC-RC复合梁,CFRP网格增强ECC-RC梁、BFRP网格增强ECC-RC梁、高强钢绞线网格增强ECC-RC复合梁裂缝数量分别增加了25%、70%和40%,同时网格增加ECC-RC最大裂缝宽度均减小。从极限荷载分析,相对不含网格增强ECC-RC复合梁,CFRP网格增强ECC-RC梁、BFRP网格增强ECC-RC梁、高强钢绞线网格增强ECC-RC复合梁分别提高11.02%、9.45%和33.84%。从极限荷载对应的跨中挠度分析,相对不含网格增强ECC-RC复合梁,CFRP网格增强ECC-RC梁、BFRP网格增强ECC-RC梁、高强钢绞线网格增强ECC-RC复合梁分别提高5.83%、15.12%和23.73%。采用位移延性系数评价试验梁的延性,相对不含网格增强ECC-RC复合梁,CFRP网格增强ECC-RC梁、BFRP网格增强ECC-RC梁、高强钢绞线网格增强ECC-RC复合梁分别提高2%、18%和21%。采用黄华定义的截面刚度,即跨中弯矩与挠度的比值,分析各试验梁刚度。在受力全过程中,CFRP网格增强ECC-RC梁、BFRP网格增强ECC-RC梁、高强钢绞线网格增强ECC-RC复合梁的刚度较对比梁更大。此外,本文依据试验结果和理论分析,建立网格增强ECC-RC复合梁正截面抗弯承载能力计算公式。

结论网格增强ECC-RC复合梁破坏形态为延性破坏,在加载全过程中满足平截面假定,ECC与纤维网格或高强钢绞线网格、ECC层和混凝土黏结性能良好,二者能协调变形,且网格增强ECC层显著提高ECC-RC复合梁的裂缝分散能力和抗裂性。CFRP/BFRP/高强钢绞线网格增强ECC层对ECC-RC复合梁受弯承载力、变形能力、延性及刚度有不同程度的提升,对受弯承载力、刚度提升效果:高强钢绞线网格>CFRP网格>BFRP网格;对变形能力和延性的提高效果:高强钢绞线网格>BFRP网格>CFRP网格。在考虑纤维网格利用率基础上,建立网格增强ECC-RC复合梁正截面抗弯承载能力计算公式,且与试验结果吻合良好。

-

工程水泥基材料(ECC)因其应变硬化和多缝开裂的特点被广泛用于钢筋混凝土梁加固领域,主要加固方式为在混凝土梁底部外粘贴ECC层。但在外荷载作用下加固梁会发生剥离破坏,且承载能力、变形、延性等抗弯性能提升有限。

本文采用纤维网格和钢绞线网格增强ECC层替换受拉区混凝土层的加固方式,分析了CFRP网格、BFRP网格替换层以及钢绞线网格替换层替换层对ECC-RC复合梁承载能力、变形、延性等抗弯性能和抗裂性能的影响。经试验结果分析,纤维网格和钢绞线网格增强ECC-RC复梁中ECC层的网格可以承担部分拉应力,延缓受拉钢筋的屈服,故ECC-RC复合梁的承载能力均提高。其次,RC梁受拉区ECC层中PVA纤维通过桥联作用,在裂缝处可以有效地向未开裂ECC层区域传递拉应力,限制裂缝宽度的扩展,在复合梁受拉区裂缝细密分布,其抗裂性得到显著提高。

网格增强ECC-RC复合梁荷载-裂缝宽度曲线和荷载挠度曲线

下载:

下载: