Experimental study on the flexural behavior of textile/steel wire strand mesh reinforced ECC-RC composite beam

-

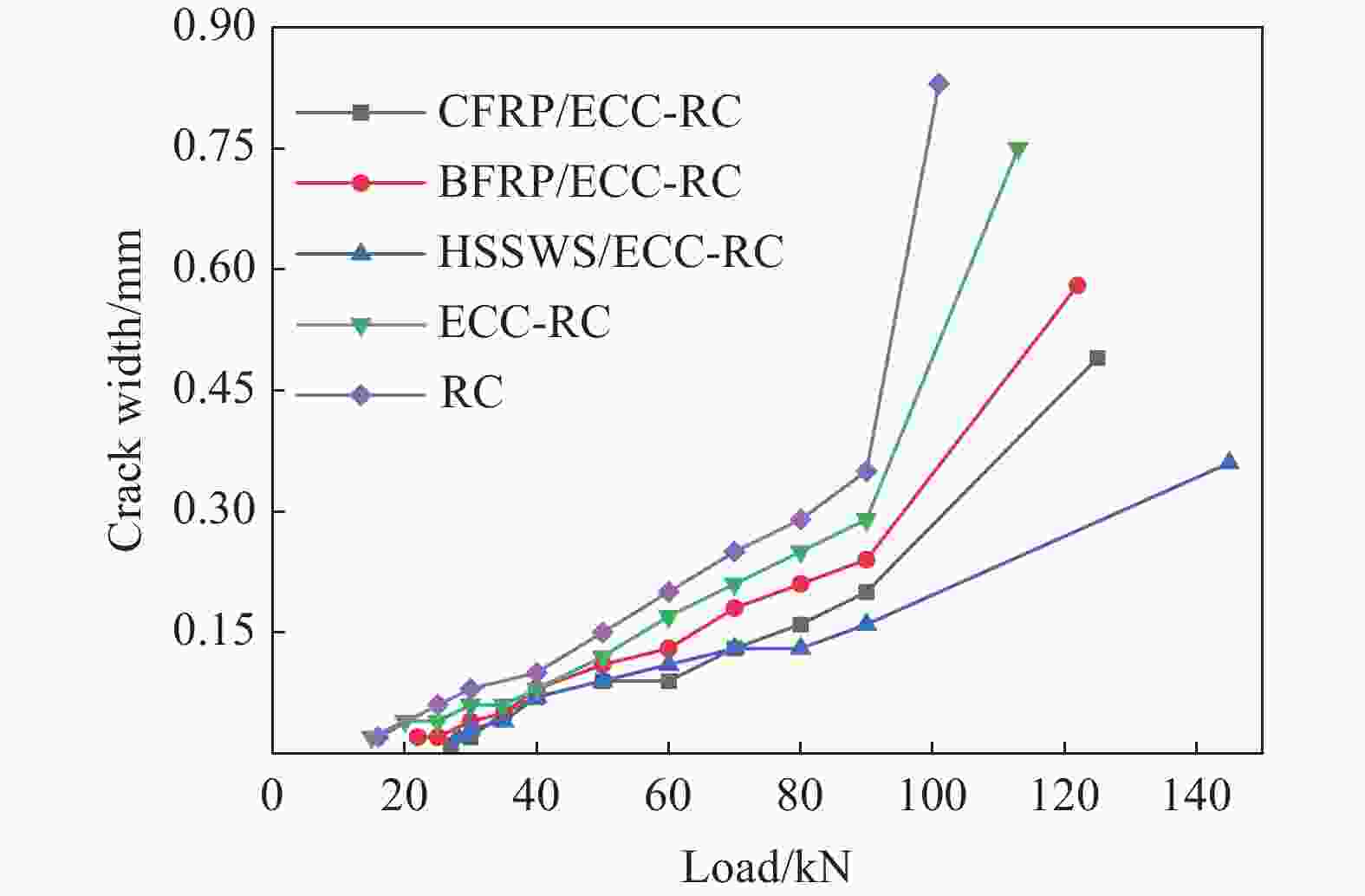

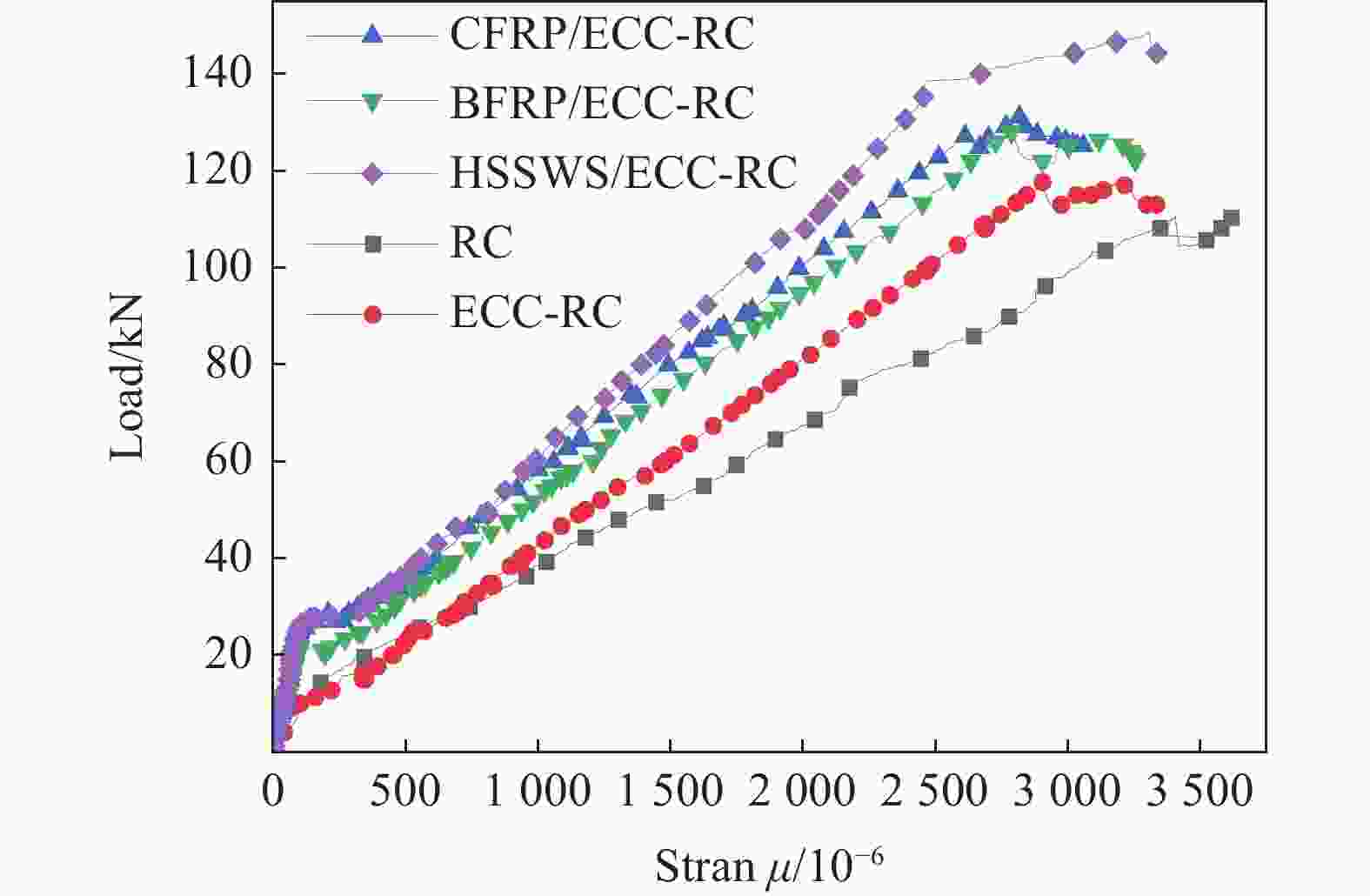

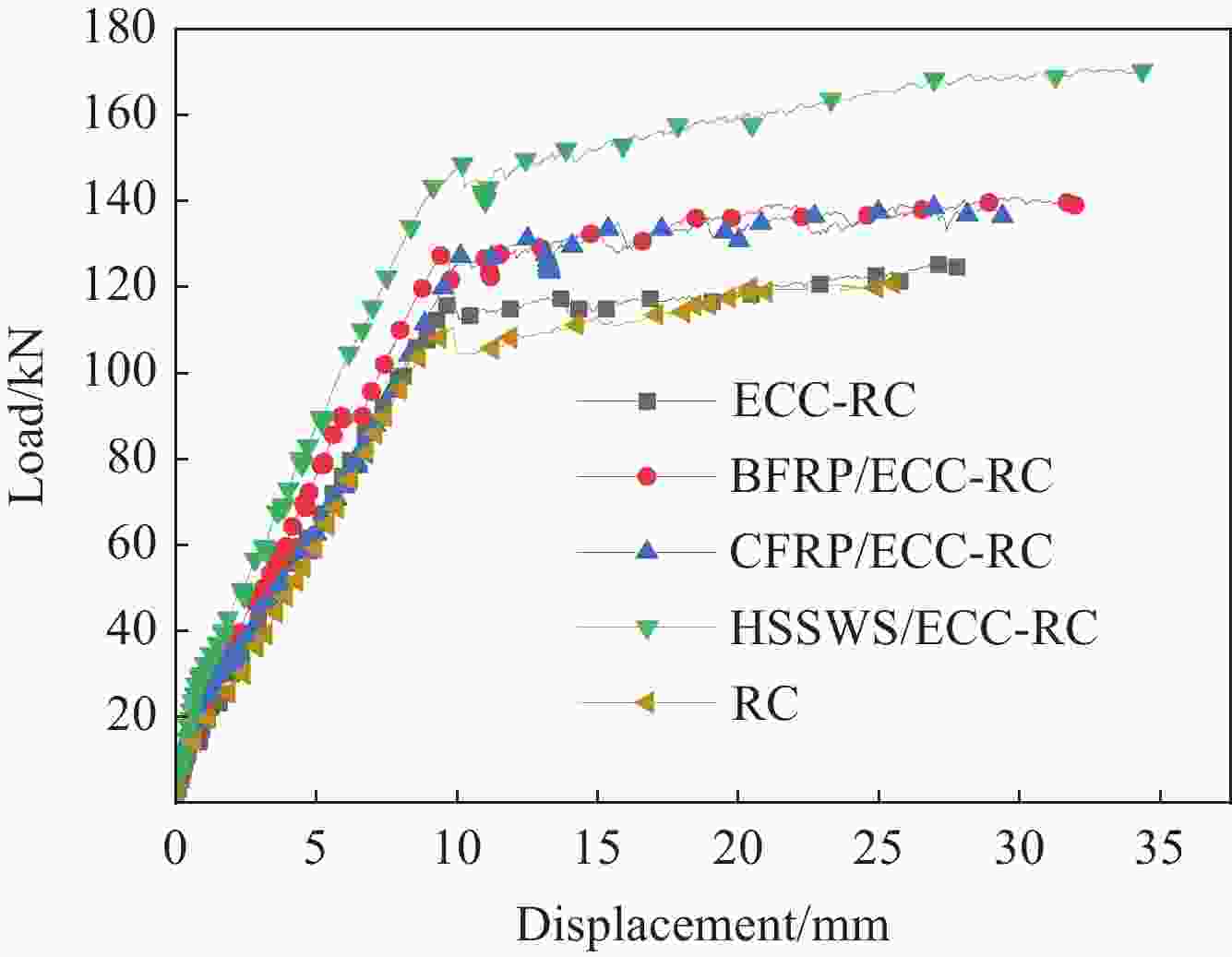

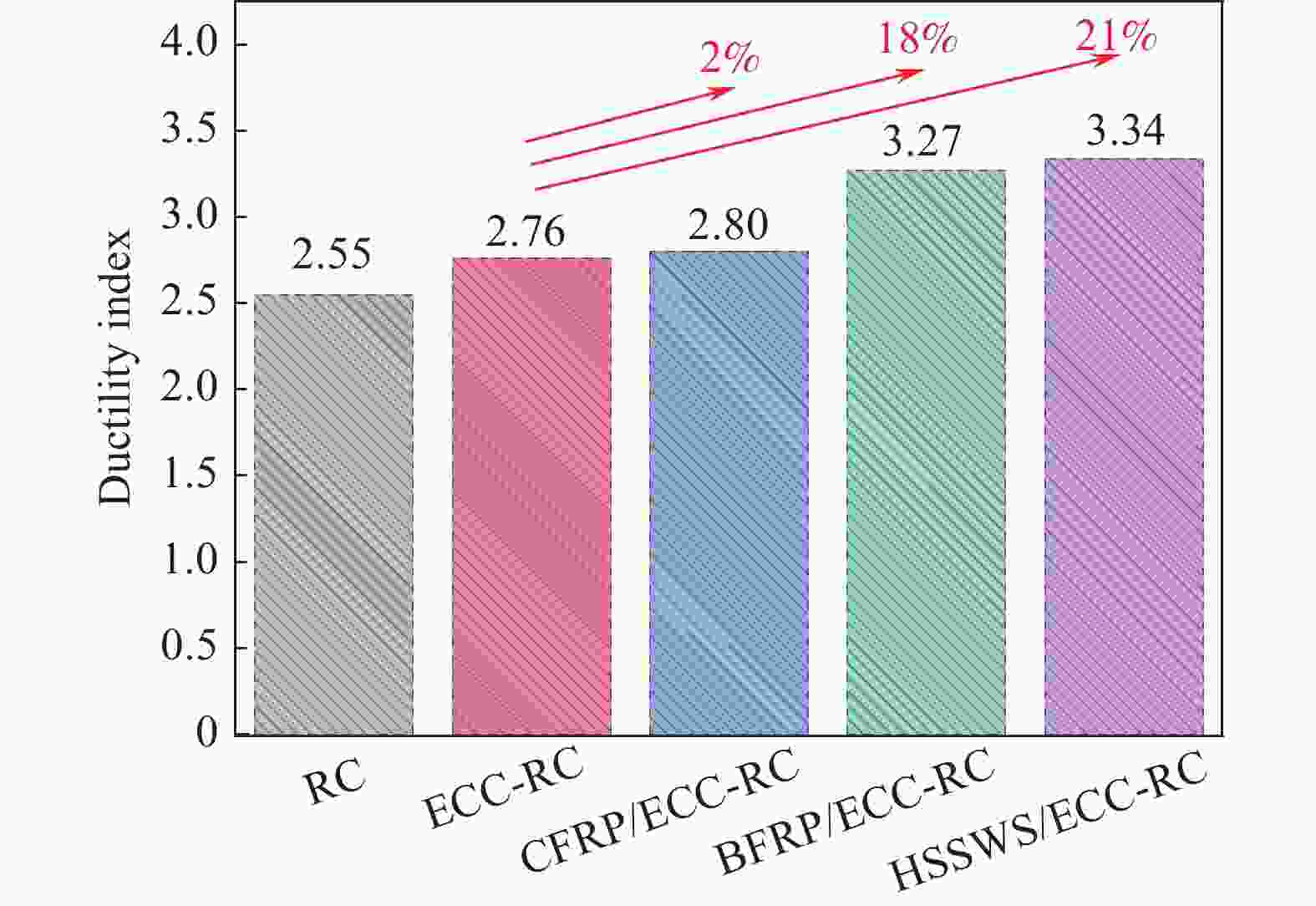

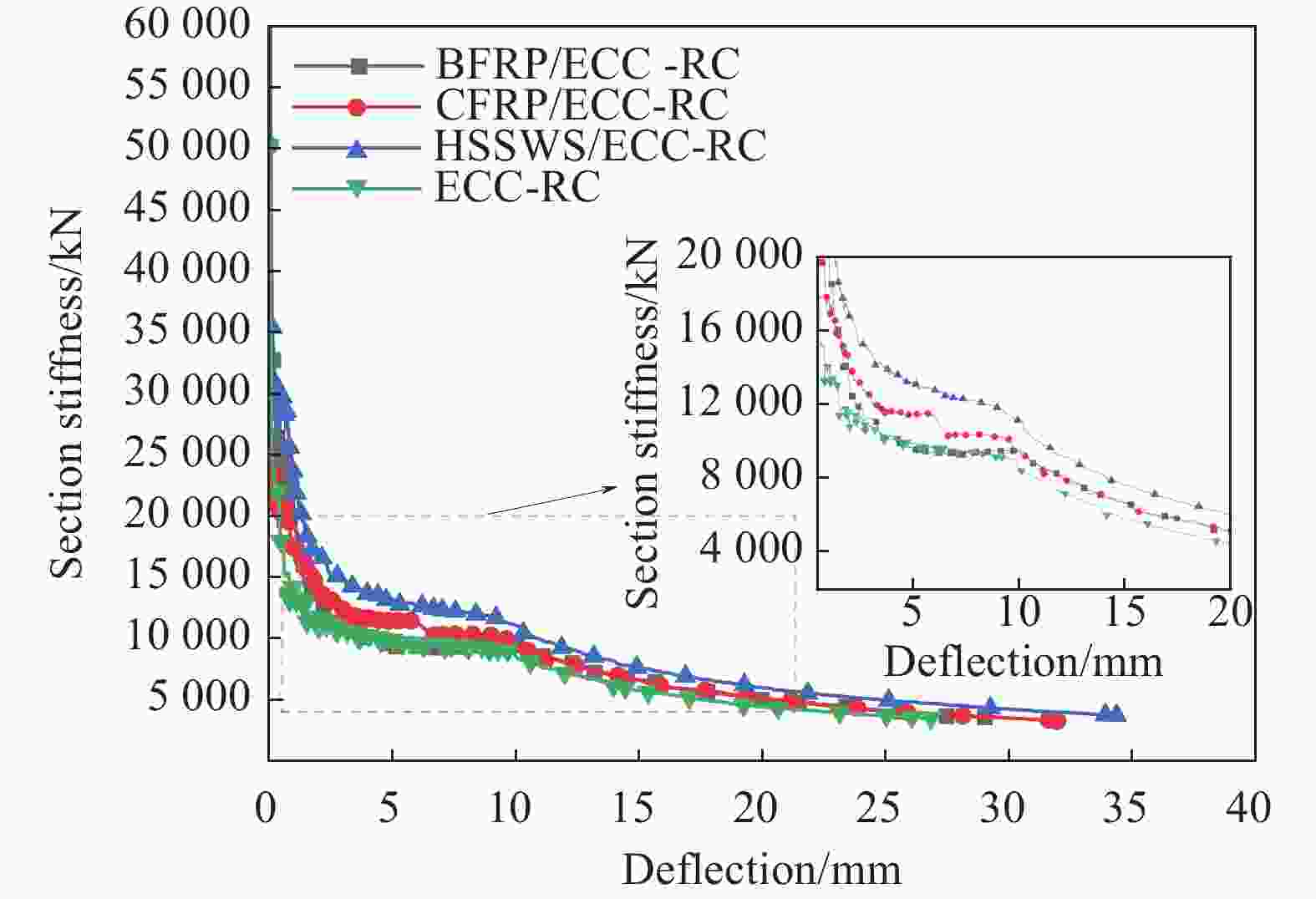

摘要: 为探究不同类型网格增强ECC层加固钢筋混凝土梁的抗弯性能,通过四点弯曲试验,分析了纤维网格和钢绞线网格对复合梁承载力、控裂能力、延性和刚度等受弯性能的影响。研究结果表明:与ECC-RC梁相比,采用纤维网格和钢绞线网格增强ECC-RC复合梁裂缝宽度减小, 裂缝数量增加25%~70%,纤维网格和钢绞线网格增强ECC层可提高复合梁的控裂能力,抑制裂缝扩展;纤维网格和钢绞线网格增强ECC层可提高复合梁的开裂荷载、屈服荷载、极限荷载、延性及刚度;受弯过程中,所有ECC-RC复合梁截面满足平截面假设,纤维网格和钢绞线网格增强ECC层与混凝土黏结良好;基于理论分析与试验结果,考虑纤维网格利用率,建立了纤维网格和高强钢绞线网格增强ECC-RC复合梁受弯承载力计算公式,计算结果与试验结果吻合良好。钢绞线网格增强ECC层对ECC-RC复合梁受弯性能加固效果最佳,可显著提高复合梁承载力、延性及抗裂性。Abstract: In order to explore the flexural performance of reinforced concrete beams strengthened with different types of grid reinforced ECC layer, the effects of textile and steel wire strand mesh on the bearing capacity, crack control ability, ductility and stiffness of composite beams were analyzed by four-point bending test. The experimental results show that compared with ECC-RC beam, the crack width of ECC-RC composite beams reinforced by textile or steel wire strand mesh decreases, and the number of cracks increases by 25%-70%. The textile-reinforced ECC layer can improve the crack control ability of composite beams and inhibit crack propagation. The textile or steel wire strand mesh reinforced ECC layer can improve the cracking load, yield load, ultimate load, ductility and stiffness of the composite beam. During the bending loading, the section of textile or steel wire strand mesh rein-forced ECC-RC composite beam meets the plane section assumption, and the textile-reinforced ECC layer is well bonded to concrete. Based on theoretical analysis and the experimental results and considering the utilization rate of textile, the calculation formula of the flexural capacity of textile or steel wire strand mesh reinforced ECC-RC composite beams is established. The calculation results are in good agreement with the experimental results. The high-strength-reinforced ECC layer has the best reinforcement effect on the flexural performance of ECC-RC composite beams, which can significantly improve the bearing capacity, ductility and crack resistance of composite beams.

-

Key words:

- bridge engineering /

- flexural performance /

- ECC /

- textile /

- high-strength steel wire strand mesh

-

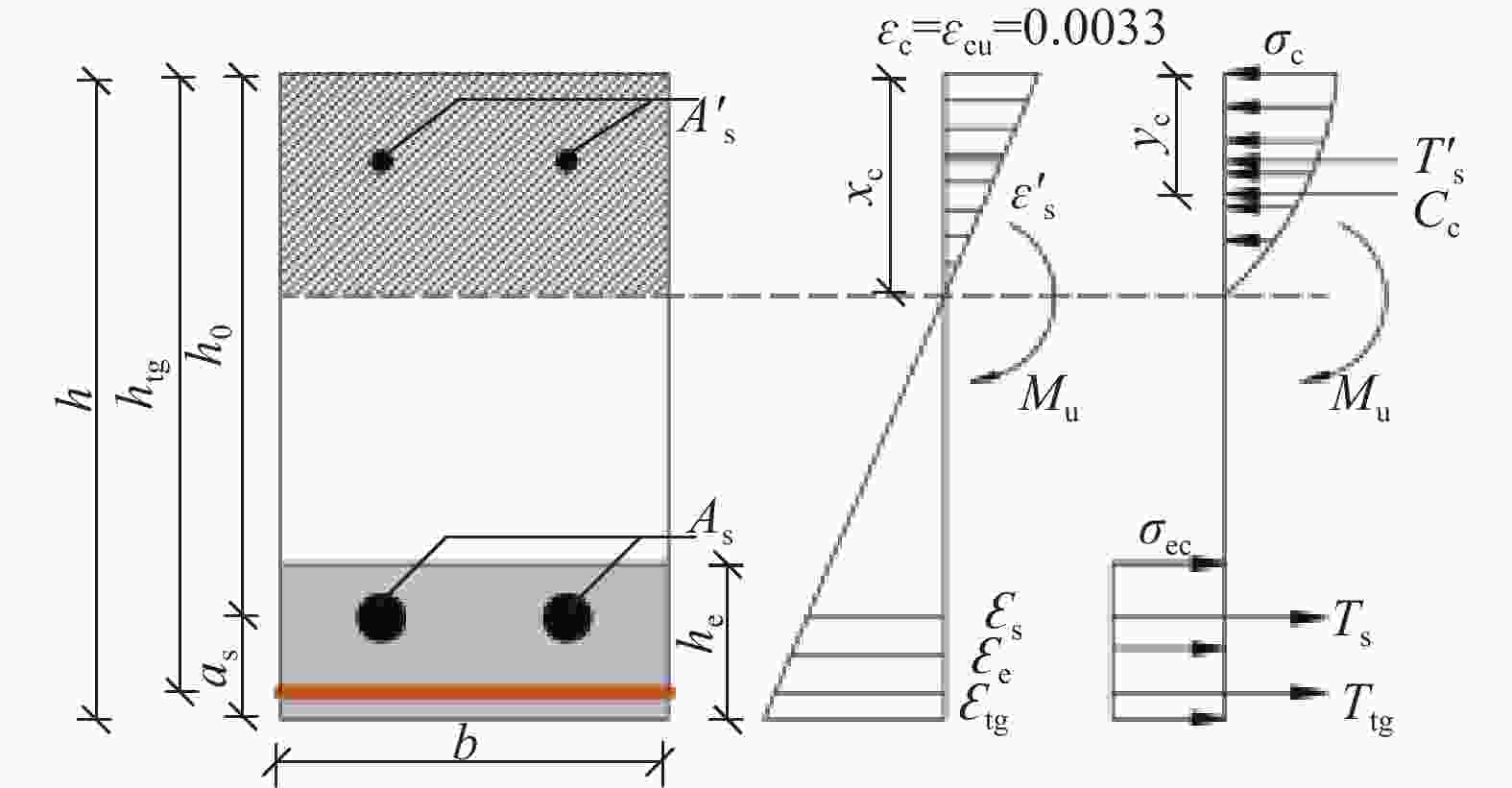

图 12 试验梁正截面应力分布简图

Figure 12. Distribution of stresses and strains along cross-section of test beam of test beams

h—Height of beam;b—Width of beam;hg— Distance from the grid to the top of the composite beam;as—The distance from the tensile steel bar to the bottom of the composite beam;h0—Effective height of composite beam;he—ECC thickness;As—The cross section area of tensile reinforcement;$A_{\text{s}}^{'}$—The cross section area of compressive steel bar;εcu—Concrete ultimate compressive strain;ε's—Compressive steel bar strain;εs—Tensile steel bar strain;εe—ECC tensile strain;εtg—Textile or the high-strength steel wire strand mesh strain;xc—Compression zone height;yc—The distance from the concrete resultant point to the top of the composite beam;σc—Concrete compressive stress;σec—ECC tensile stress;Cc—Concrete resultant force;$T_{\text{s}}^{\text{'}}$—Compressed steel bar resultant force;Ts—Tensile steel bar resultant force;Ttg—Grid resultant force;Mu—Section bending moment

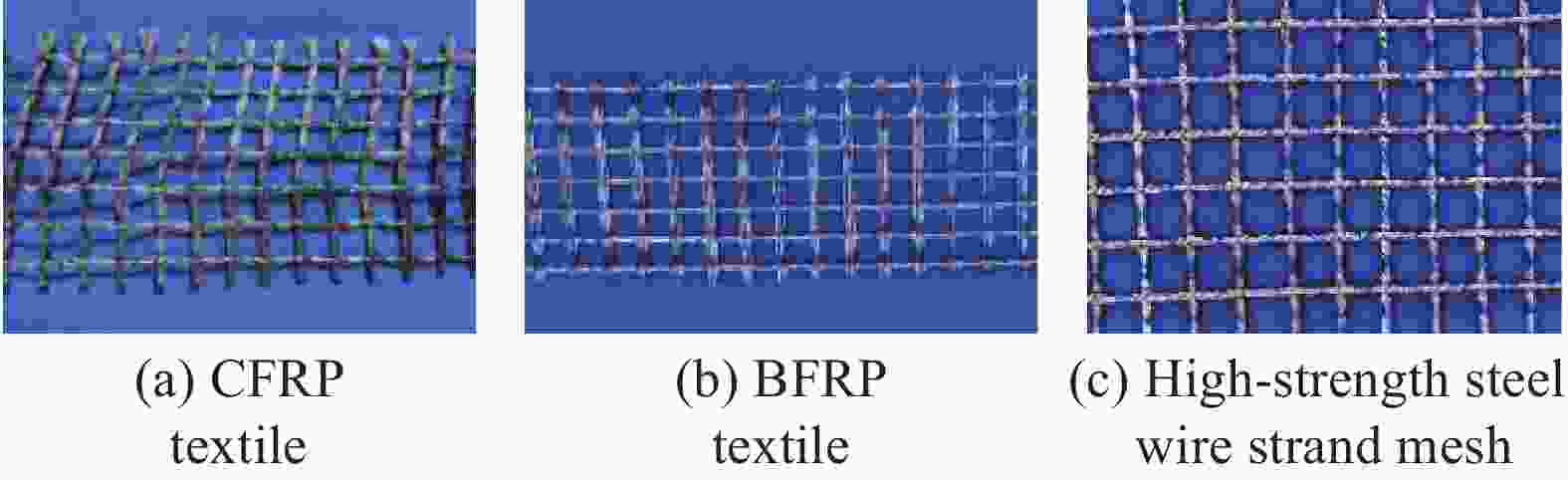

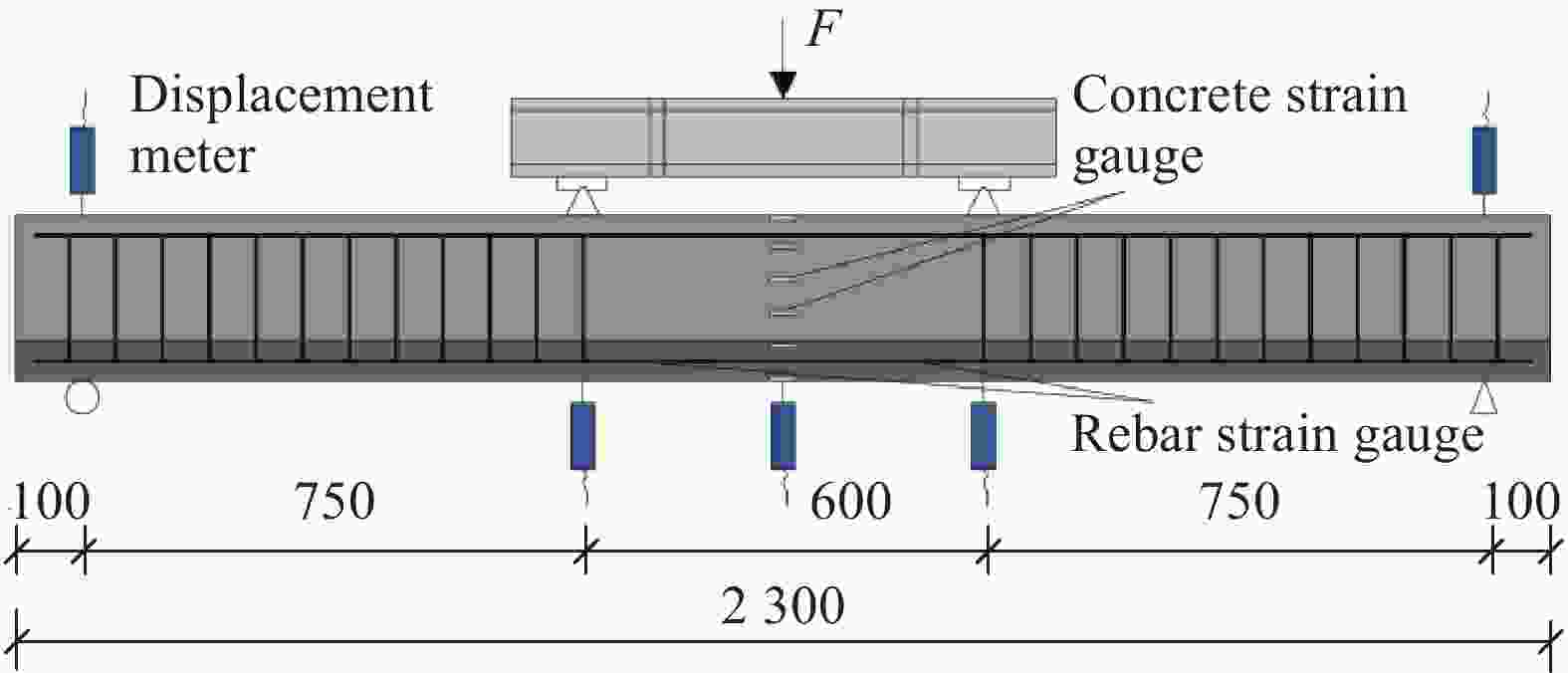

表 1 试件设计参数

Table 1. Design parameters of specimens

Specimen number Thickness of

ECC/mmDistance from

grid to beam

bottom/mmGrid type RC 0 - - ECC-RC 60 - - CFRP/ECC-RC 60 10 CFRP textile BFRP/ECC-RC 60 10 BFRP textile HSSWS/ECC-RC 60 10 High-strength steel wire strand mesh 表 2 配合比(单位:kg/m3)

Table 2. Mix proportion (Unit: kg/m3)

Materials Fumed silica/mm P.O 52.5 Sand Water Water

reducerExpansion agent Fiber Silica

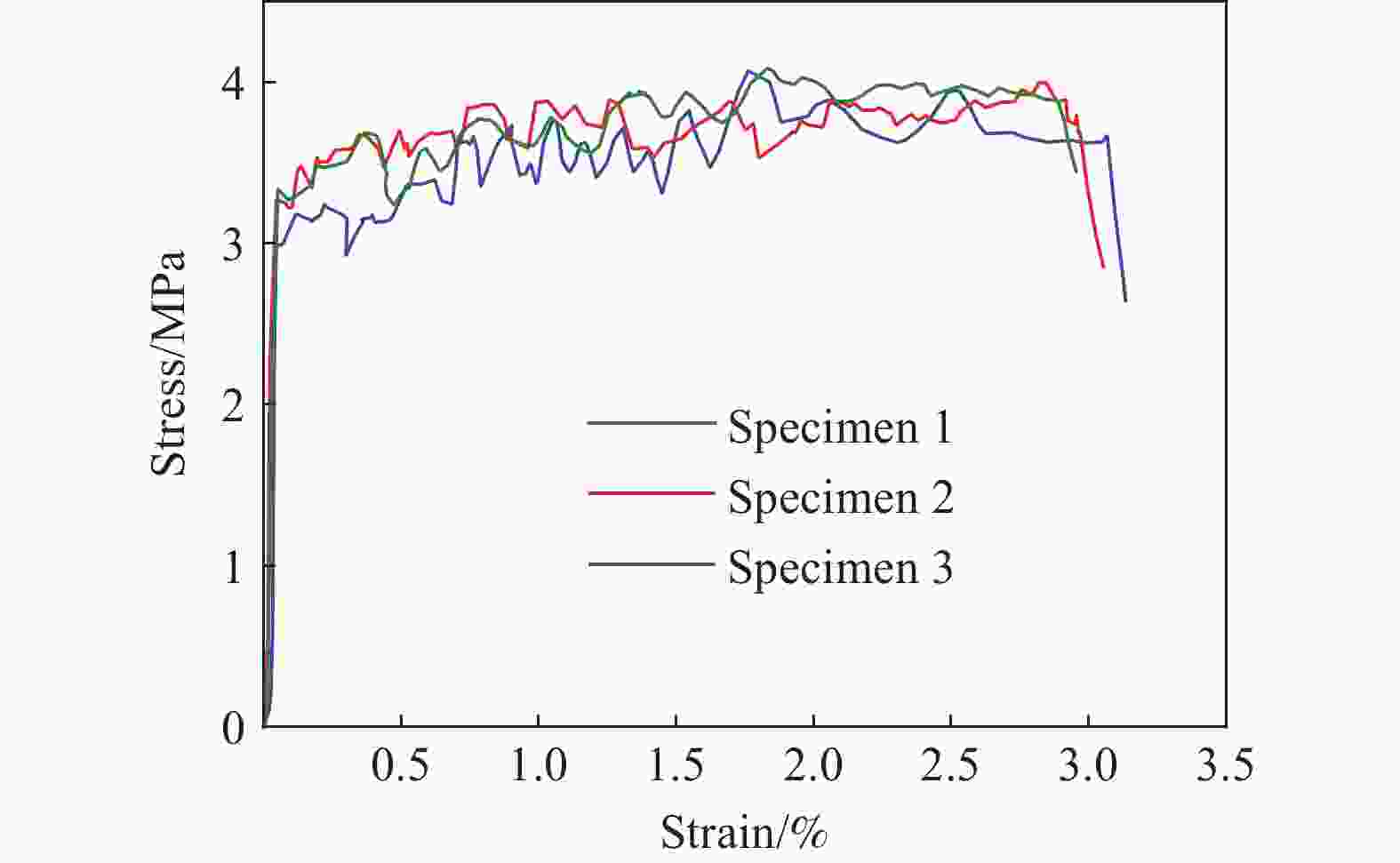

fume5-16 16-32.5 C50 471 706 520 706 161 7.8 - - - ECC - - 500 600 190 3 25 23 25 表 3 纤维网格和高强钢绞线网格力学性能

Table 3. Mechanical properties of textile and high-strength steel wire strand mesh

Grid type Ultimate tensile strength/MPa Elastic modulus/GPa Ultimate tensile strain/% The cross-sectional area/mm2 CFRP textile 4815 252 1.90 0.89 BFRP textile 3330 90 3.70 0.89 High-strength steel wire strand mesh 1845 180 2.96 4.71 表 4 试验梁结果

Table 4. Results of test beams

Specimen number Pcr/kN Mcr/(kN·m) Dcr/% Py/kN My/(kN·m) Dy/% Pu/kN Mu/(kN·m) Du/% Δy/mm Δu/mm DΔu/% RC 14 5.25 - 104 39.00 - 121 45.38 - 9.99 25.51 - ECC-RC 16 6.00 - 113 42.38 - 127 47.63 - 10.05 27.77 - CFRP/ECC-RC 27 10.13 68.83 125 46.88 10.62 141 52.88 11.02 10.46 29.39 5.83 BFRP/ECC-RC 22 8.25 37.50 122 45.75 7.95 139 52.13 9.45 9.78 31.97 15.12 HSSWS/ECC-RC 28 10.50 75.00 143 53.62 26.52 170 63.75 33.84 10.28 34.36 23.73 Notes: Pcr−Cracking load;Mcr−Cracking moment;Py−Yielding load;My−Yielding moment;Pu−Ultimate load;Mu−Ultimate moment;Δy−Deflection of the specimen at My;Δu−Deflection of the specimen at Mu;Dcr、Dy、Du、DΔu represent the increase of cracking load, yield load, ultimate load and ultimate deflection compared with ECC-RC beam, respectively. 表 5 试验梁延性系数

Table 5. Ductility index of test beams

Specimen number Py/kN Pu/kN Δy/mm Δu/mm μΔ ${D_{{\mu _\Delta }}}$/% RC 104 121 9.99 25.51 2.55 - ECC-RC 113 127 10.05 27.77 2.76 - CFRP/ECC-RC 125 138 10.46 29.39 2.80 2 BFRP/ECC-RC 122 139 9.78 31.97 3.27 18 HSSWS/ECC-RC 143 170 10.28 34.36 3.34 21 Notes: μΔ−Ductility index,${D_{{\mu _\Delta }}}$−Increasing range of grid-reinforced ECC-RC composite beam compared with ECC-RC beam; the meaning of other symbols in the table is the same as that in table 4. 表 6 试验梁受弯承载力计算值和试验值对比

Table 6. Comparison of flexural bearing capacity between experimental and theoretical results of test beams

-

[1] LI V. C. , STANG H. , KRENCHEL H. Micromechanics of crack bridging in fiber-reinforced concrete[J]. Materials and Structures, 1993, 26(8): 486-494. [2] LI V. C. , Y Leung C. K. Steady state and multiple cracking of short random fiber composites[J]. Journal of Engineering Mechanics, 1992, 188(11): 2246-2264. [3] SHANOUR Ali S. , SAID Mohamed, ARAFA Alaa Ibrahim, et al. Flexural performance of concrete beams containing engineered cementitious composites[J]. Construction and Building Materials, 2018, 180: 23-34. doi: 10.1016/j.conbuildmat.2018.05.238 [4] 崔涛, 何浩祥, 闫维明, 等. 带ECC底板的装配式梁受弯性能及损伤分析[J]. 哈尔滨工业大学学报, 2019, 51(12): 104-112. doi: 10.11918/j.issn.0367-6234.201812126CUI Tao, HE Haoxiang, YAN Weiming, et al. Bending performance test and damage analysis of precast beams with ECC plate[J]. Journal of Building Structures, 2019, 51(12): 104-112(in Chinese). doi: 10.11918/j.issn.0367-6234.201812126 [5] 王新玲, 罗鹏程, 钱文文, 等. 高强不锈钢绞线网增强工程水泥基复合材料薄板受弯承载力研究[J]. 建筑结构学报, 2022, 43(1): 164-172.WANG Xin-ling, LUO Pengcheng, QIAN Wenwen, et al. Study on flexural bearing capacity of high-strength stainless steel wire mesh reinforced ECC thin plate[J]. Journal of Building Structures, 2022, 43(1): 164-172(in Chinese). [6] 朱俊涛, 张凯, 王新玲, 等. 高强不锈钢绞线网与ECC黏结-滑移关系模型[J]. 土木工程学报, 2020, 53(4): 83-92.ZHU Juntao, ZHANG Kai, WANG Xinling, et al. Bond-slip relational model between high-strength stainless steel wire mesh and ECC[J]. China Civil Engineering Journal, 2020, 53(4): 83-92(in Chinese). [7] 王新玲, 陈永杰, 钱文文, 等. 高强不锈钢绞线网增强工程水泥基复合材料弯曲性能试验[J]. 复合材料学报, 2021, 38(4): 1292-1301.WANG Xin-ling, CHEN Yongjie, QIAN Wenwen, et al. Experiment on bending performance of engineered cementitious composites reinforced by high-strength stainless steel wire strand mesh[J]. Acta Materiae Compositae Sinica, 2021, 38(4): 1292-1301(in Chinese). [8] 李传秀, 尹世平, 赵俊伶. 纤维编织网增强ECC的拉伸和弯曲性能[J]. 建筑材料学报, 2021, 24(4): 736-741. doi: 10.3969/j.issn.1007-9629.2021.04.009LI Chuan-xiu, YIN Shi-ping, ZHAO Jun-ling. Tensile and bending properties of textile reinforced ECC[J]. Journal of Building Materials, 2021, 24(4): 736-741(in Chinese). doi: 10.3969/j.issn.1007-9629.2021.04.009 [9] 徐世烺, 李庆华, 李贺东. 碳纤维编织网增强超高韧性水泥基复合材料弯曲性能的试验研究[J]. 土木工程学报, 2007, 40(12): 69-76. doi: 10.3321/j.issn:1000-131x.2007.12.009XU Shilang, LI Qinghu, LI Hedong. An experimental study on the flexural properties of carbon textile reinforced ECC[J]. CHINA CIVIL ENGINEERING JOURNAL, 2007, 40(12): 69-76(in Chinese). doi: 10.3321/j.issn:1000-131x.2007.12.009 [10] 王新玲, 苏会晓, 李可, 等. FRP网格增强ECC加固素混凝土柱受压性能数值分析[J]. 建筑科学, 2018, 34(3): 22-29.WANG Xinling, SU Huixiao, LI Ke, et al. Numerical analysis of compressive performance of plain concrete columns strengthened with FRP-grid and ECC[J]. Building Science, 2018, 34(3): 22-29(in Chinese). [11] 郭瑞, 任宇, 顾天宇. 纤维增强复材网格-工程水泥基复合材料加固钢筋混凝土梁的抗剪性能试验研究[J]. 工业建筑, 2019, 49(9): 145-151.GUO Rui, REN Yu, GU Tianyu. Experimental research on shear behavior of RC beams reinforced with FRP grid-ECC[J]. Cement Science & Concrete Technology, 2019, 49(9): 145-151(in Chinese). [12] ZHENG YuZhou, WANG WenWei, MOSALAM Khalid M. , et al. Experimental investigation and numerical analysis of RC beams shear strengthened with FRP/ECC composite layer[J]. Composite Structures, 2020, 246: 112436. doi: 10.1016/j.compstruct.2020.112436 [13] GUO Rui, REN Yu, LI Mengqi, et al. Experimental study on flexural shear strengthening effect on low-strength RC beams by using FRP grid and ECC[J]. Engineering Structures, 2021, 227: 111434. doi: 10.1016/j.engstruct.2020.111434 [14] ZHENG Aohan, LIU Zhenzhen, LI Faping, et al. Experimental investigation of corrosion-damaged RC beams strengthened in flexure with FRP grid-reinforced ECC matrix composites[J]. Engineering Structures, 2021, 244: 112779. doi: 10.1016/j.engstruct.2021.112779 [15] YANG Xu, GAO WanYang, DAI Jian-Guo, et al. Flexural strengthening of RC beams with CFRP grid-reinforced ECC matrix[J]. Composite Structures, 2018, 189: 9-26. doi: 10.1016/j.compstruct.2018.01.048 [16] ZHENG YuZhou, WANG WenWei, BRIGHAM John C. Flexural behaviour of reinforced concrete beams strengthened with a composite reinforcement layer: BFRP grid and ECC[J]. Construction and Building Materials, 2016, 115: 424-437. doi: 10.1016/j.conbuildmat.2016.04.038 [17] 郑宇宙. FRP格栅增强ECC复合加固混凝土梁试验与计算方法研究[D]. 东南大学, 2018.ZHENG Yuzhou. Experimental and calculation method research on reinforced concrete (RC) beams strengthened with the composite of FRP grid and ECC[D]. Southeast University, 2018. (in Chinese) [18] 郑宇宙, 王文炜. 复材网格-UHTCC复合增强钢筋混凝土梁抗弯性能试验研究[J]. 土木工程学报, 2017, 50(6): 23-32.ZHENG Yuzhou, WANG Wenwei. Experimental research on flexural behavior of RC beams strengthened with FRP grid-UHTCC composite[J]. China Civil Engineering Journal, 2017, 50(6): 23-32(in Chinese). [19] 张振. 玄武岩纤维网-ECC复合材料加固RC梁抗弯性能研究[D]. 吉林建筑大学, 2022.ZHANG Zhen. Study on flexural behavior of RC beams strengthened by basalt fiber grid-ECC composite material[D]. Jilin Jianzhu University, 2022. (in Chinese) [20] 李可, 赵佳丽, 李志强, 等. 高强钢绞线网增强ECC抗弯加固无损RC梁试验[J]. 复合材料学报, 2022, 39(7): 3428-3440.LI Ke, ZHAO Jiali, LI Zhiqiang, et al. Experiment on non-damaged RC beams strengthened by high-strength steel wire strand meshes reinforced ECC in bending[J]. Acta Materiae Compositae Sinica, 2022, 39(7): 3428-3440(in Chinese). [21] 李可, 王宇, 李志强, 等. 高强钢绞线网增强ECC加固无损RC梁受弯承载力研究[J]. 建筑结构学报, 2022, 43(12): 82-90.LI Ke, WANG Yu, LI Zhiqiang, et al. Research on flexural bearing capacity of non-damaged RC beams strengthened by high-strength steel wire strand mesh-reinforced ECC[J]. Journal of Building Structures, 2022, 43(12): 82-90(in Chinese). [22] 李可, 任魁, 李志强, 等. 高强钢绞线网增强ECC加固无损RC梁截面刚度计算[J]. 铁道科学与工程学报, 2022, 19(10): 3046-3054.LI Ke, REN Kui, LI Zhiqiang, et al. Calculation of section rigidity of non-damaged RC beams strengthened by high-strength steel wire strand meshes reinforced ECC[J]. Journal of Railway Science and Engineering, 2022, 19(10): 3046-3054(in Chinese). [23] 盛杰, 尹世平, 裴浩. 纤维编织网-ECC加固RC梁受弯性能试验[J]. 中国公路学报, 2022, 35(9): 287-297. doi: 10.3969/j.issn.1001-7372.2022.09.022SHENG Shijie, YIN Shiping, PEI Hao. Experimental Study on Flexural Behavior of RC Beams Strengthened with Textile and ECC[J]. China Journal of Highway and Transport, 2022, 35(9): 287-297(in Chinese). doi: 10.3969/j.issn.1001-7372.2022.09.022 [24] 葛文杰, 宗耀锋, 仇胜伟, 等. 碳纤维布粘贴加固BFRP筋-ECC-混凝土组合梁受弯性能研究[J]. 建筑结构学报, 2021, 42(S1): 302-311.GE Wenjie, ZONG Yafeng, QIU Shengwei, et al. Study on flexural behavior of BFRP reinforced-ECC-concrete composite beams strengthened with carbon fiber sheets[J]. Journal of Building Structures, 2021, 42(S1): 302-311(in Chinese). [25] 高培琦, 葛文杰, 虞佳敏, 等. 碳纤维布加固钢筋ECC/混凝土复合梁受弯性能试验研究[J]. 建筑科学, 2019, 35(11): 103-110.GAO Peiqi, GE Wenjie, YU Jiamin, et al. Experimental study on flexural behavior of ECC/concrete composite beams strengthened with carbon fiber sheets[J]. Building Science, 2019, 35(11): 103-110(in Chinese). [26] 黄华. 高强钢绞线网—聚合物砂浆加固混凝土梁式桥试验研究与机理分析[D]. 西安: 长安大学, 2008.HUANG Hua. Experimental Study and Theoretical Analysis on Strengthening RC Girder Bridge with Steel Wire Mesh and Polymer Mortar[D]. XIan: Chang'an University, 2008. (in Chinese) [27] 中华人民共和国住房和城乡建设部. GB510010-2010, 混凝土结构设计规范 [S]. 北京: 中国建筑工业出版社, 2015.Code for design of concrete structures: GB 50010—2010[S]. China Architecture & Building Press, 2015. (in Chinese) [28] 董志芳, 邓明科, 张聪. 纤维织物增强高延性混凝土单轴拉伸性能试验研究[J]. 土木工程学报, 2020, 53(10): 13-25.DONG Zhifang, DENG Mingke, ZHANG Cong. Experimental investigation on uniaxial tension behavior of textile-reinforced highly ductile concrete[J]. China Civil Engineering Journal, 2020, 53(10): 13-25(in Chinese). -

点击查看大图

点击查看大图

计量

- 文章访问数: 74

- HTML全文浏览量: 42

- 被引次数: 0

下载:

下载: