Preparation of polyvinyl alcohol/sodium alginate composite aerogel and its application in efficient seawater desalination

-

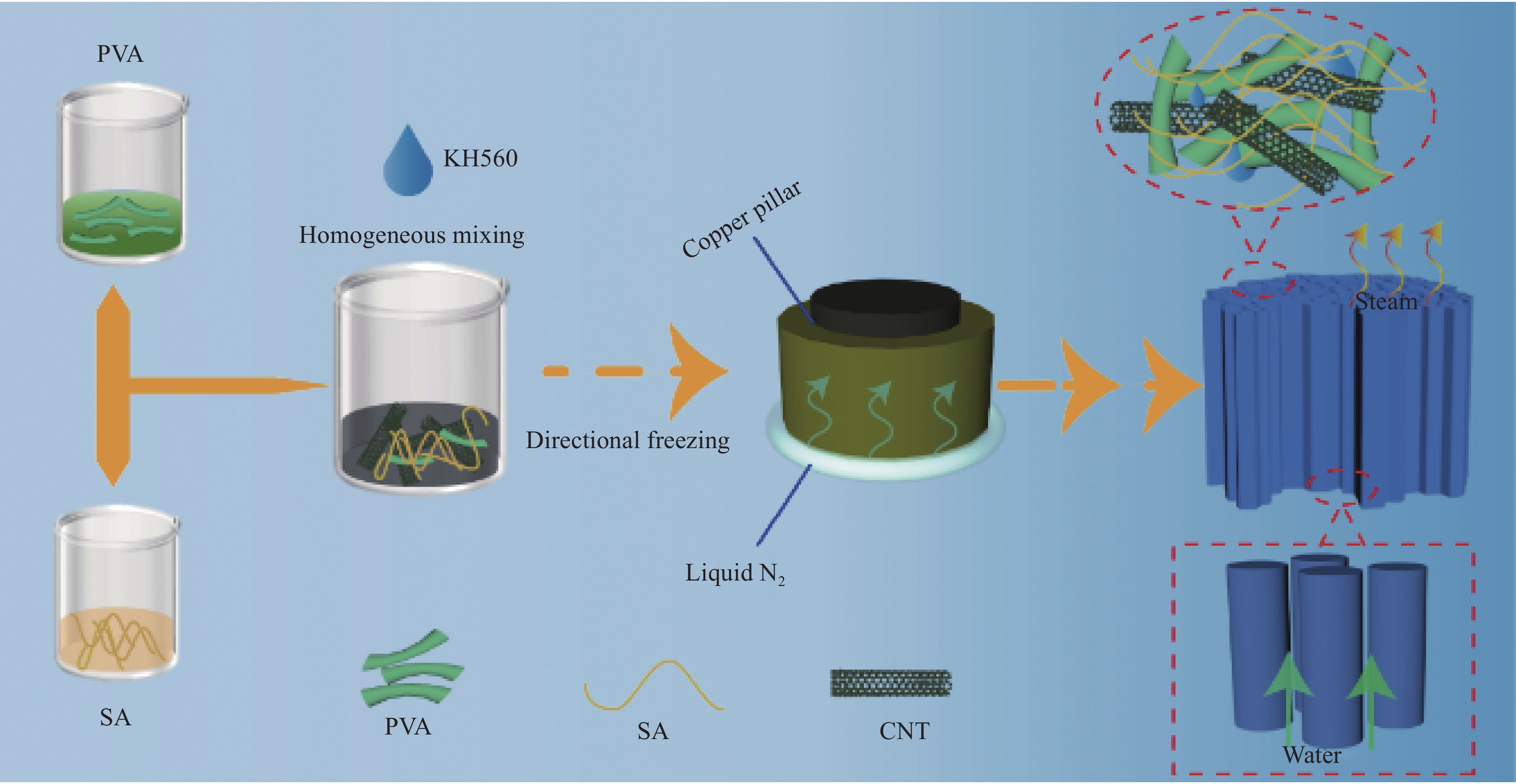

摘要: 基于太阳能界面水蒸发技术的海水淡化蒸发器可以实现海水的淡化提纯,但目前蒸发器的蒸发速率较低。本文通过定向冷冻的方法制备了聚乙烯醇与海藻酸钠的复合气凝胶,同时采用碳纳米管作为光吸收材料,探索了复合气凝胶组分、比例和光吸收材料含量等因素对蒸发器水蒸发性能的影响。结果发现该复合气凝胶蒸发器有高达97%的光吸收率和优异的海水淡化性能,一个太阳光下的水蒸发速率能够达到2.7 kg·m−2·h−1,并且在长期的光照和黑暗的交替过程中,蒸发器表面积累的盐晶体会自动融化消失,起到自清洁的效果,可以实现长期的可持续蒸发,在海水淡化领域具有广阔的应用前景。Abstract: The desalination evaporator based on the solar interface water evaporation technology can realize the desalination and purification of seawater, but the evaporation rate of the evaporator is low at present. In this work, the composite aerogel of polyvinyl alcohol and sodium alginate was prepared by directional freezing. At the same time, carbon nanotubes were used as light absorbing material. The effects of the composition, proportion and content of light absorbing material of the composite aerogel on the evaporation performance of evaporator water were explored. The results show that the composite aerogel evaporator has a light absorption rate of up to 97% and excellent seawater desalination performance. The water evaporation rate under a sun light can reach 2.7 kg·m−2·h−1.In the long-term alternating process of light and darkness, the salt crystals accumulated on the surface of the evaporator will automatically melt and disappear, playing a self-cleaning effect, and can achieve long-term sustainable evaporation. It has broad application prospects in the field of seawater desalination.

-

Key words:

- aerogel /

- directional freezing /

- seawater desalination /

- water evaporation /

- self-cleaning /

- sodium alginate /

- carbon nanotubes /

- polyvinyl alcohol

-

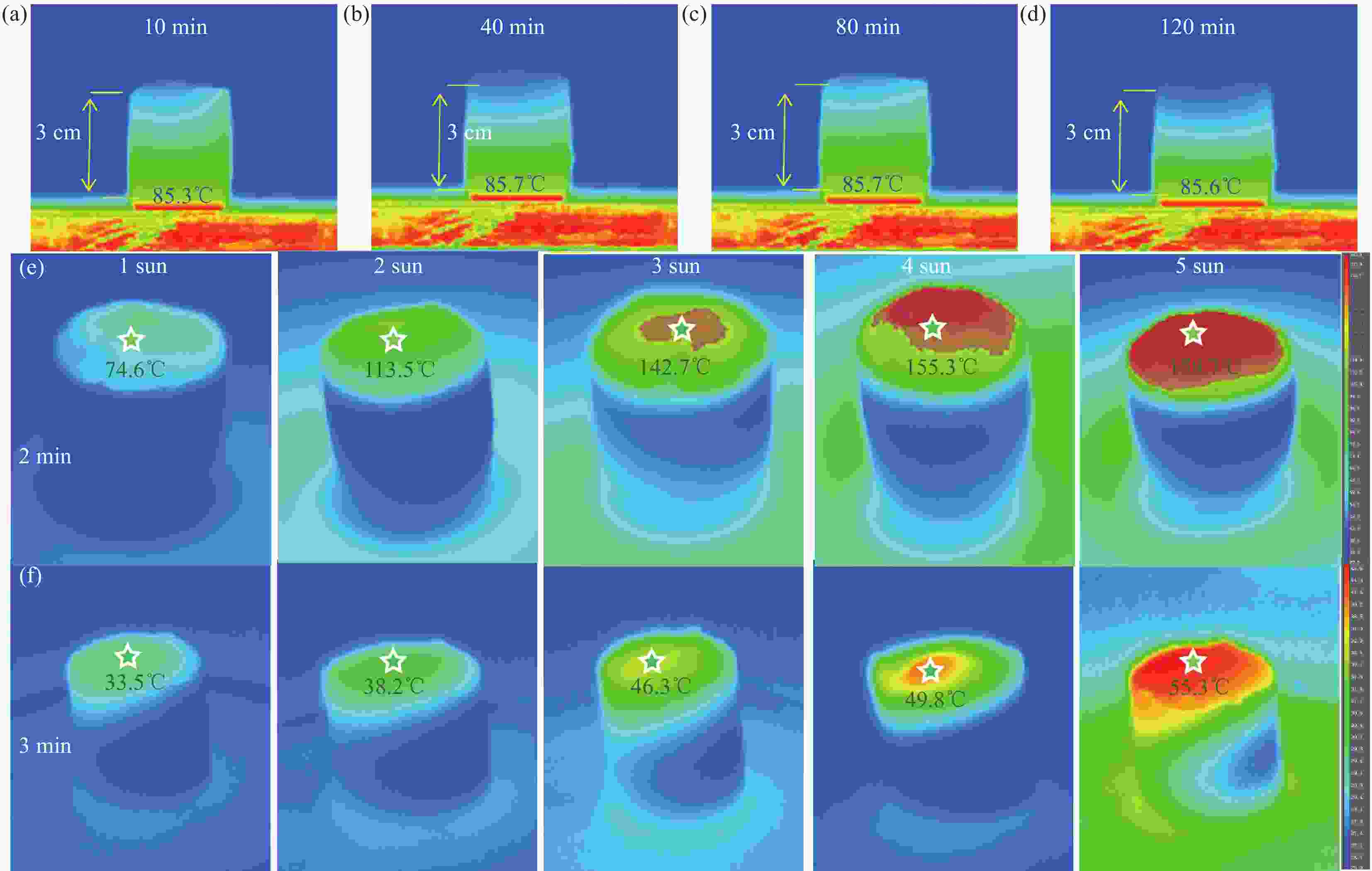

图 4 ((a)~(d)) CNT10/PVA-SA(6)在热板上的红外图像;(e) 干态CNT10/PVA-SA(6)在1~5个太阳光照射(1~5 sun)下的红外图像; (f) 湿态CNT10/PVA-SA(6)在1~5 sun下的红外图像

Figure 4. ((a)-(d)) Infrared image of CNT10/PVA-SA(6) on hot plate; (e) Infrared image of dry CNT10/PVA-SA(6) under 1-5 sun; (f) Infrared image of wet CNT10/PVA-SA(6) under 1-5 sun

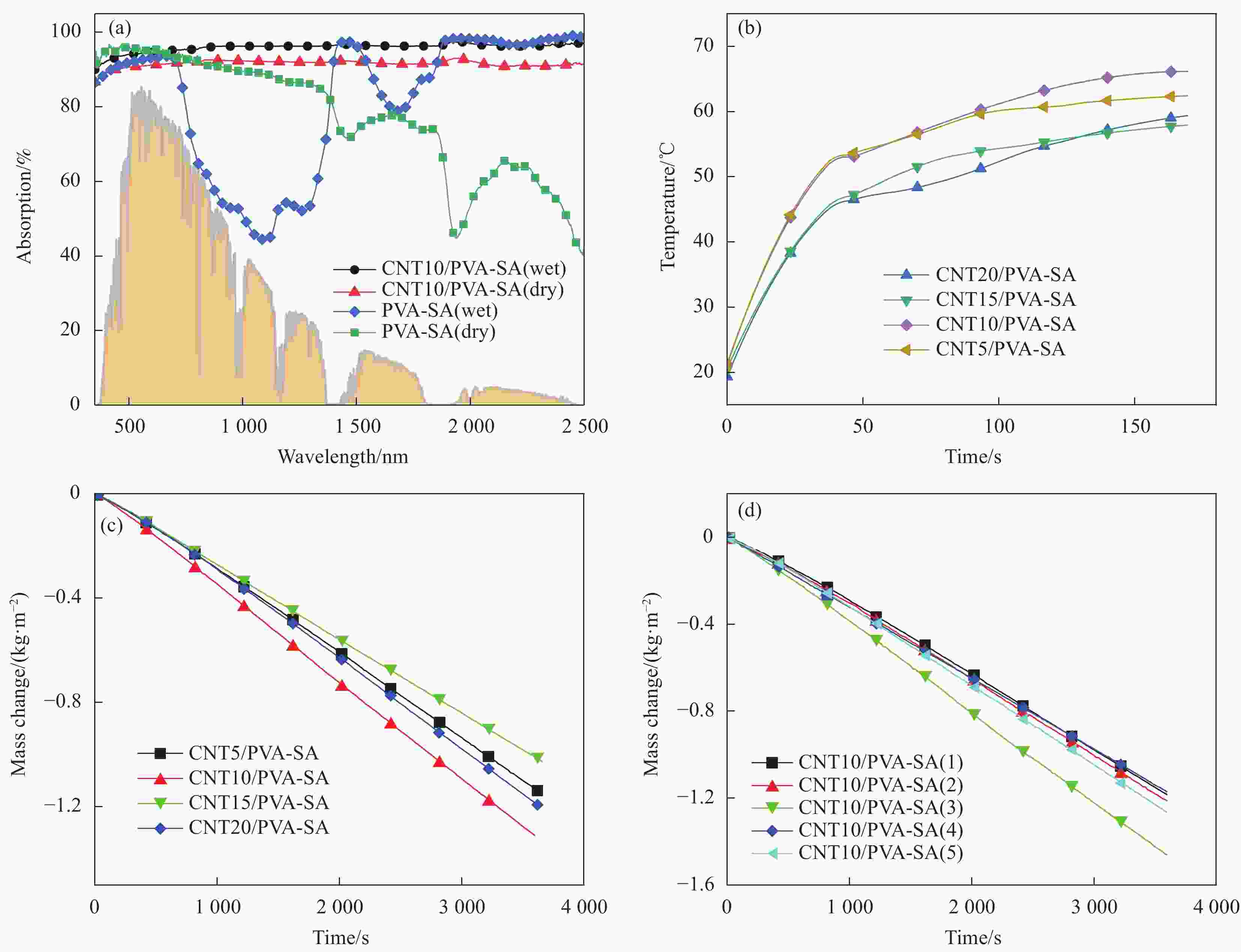

图 5 (a) PVA-SA和CNT10/PVA-SA的吸收光谱;(b) 在1 sun下CNT(5~20)/PVA-SA的表面温度变化曲线;(c) 在1 sun下CNT(5~20)/PVA-SA的水蒸发质量变化;(d) 在1 sun下不同比例CNT10/PVA-SA(1~5)的水蒸发质量变化

Figure 5. (a) Absorption spectra of PVA-SA and CNT10/PVA-SA; (b) Surface temperature change curves of CNT(5-20)/PVA-SA under 1 sun; (c) Water evaporation mass change of CNT(5-20)/PVA-SA under 1 sun; (d) Water evaporation mass change of CNT10/PVA-SA(1-5) with different proportions under 1 sun

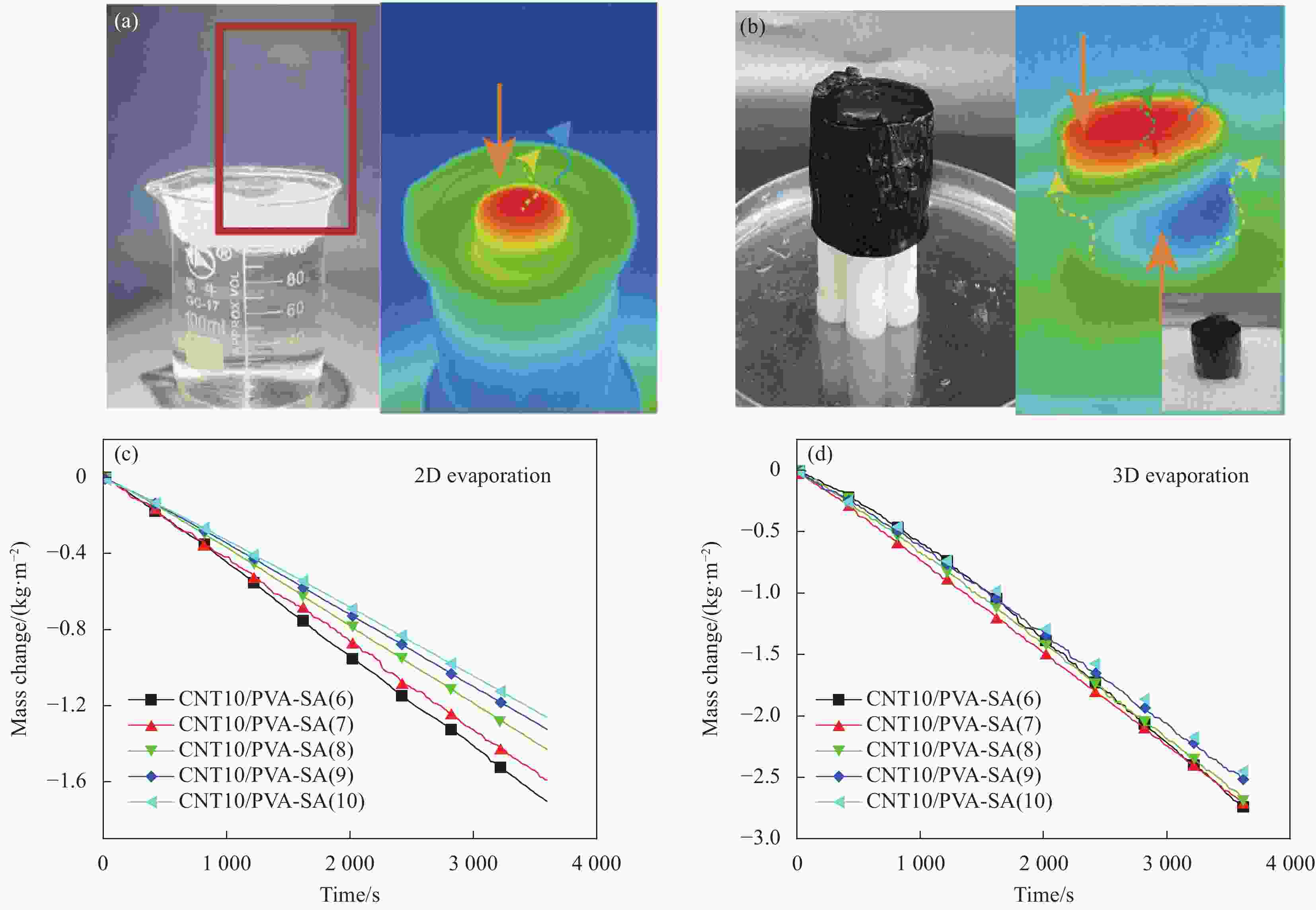

图 6 (a) 在3 kW·m−2太阳光下产生的水蒸气的图像(左)和在2D蒸发下的红外图像(右);(b) 3D水蒸发测试示意图(左)和在3D蒸发下的红外图像(右);(c) 在1 sun下不同浓度CNT10/PVA-SA(6~10)的2D水蒸发质量变化;(d) 在1 sun下不同浓度CNT10/PVA-SA(6~10)的3D水蒸发质量变化

Figure 6. (a) Photo of water vapor generated under the sunlight of 3 kW·m−2 (left), infrared image under 2D evaporation (right); (b) Schematic diagram of 3D water evaporation test (left), infrared image under 3D evaporation (right); (c) Change of 2D water evaporation quality with different concentrations of CNT10/PVA-SA(6-10) under 1 sun; (d) Change of 3D water evaporation quality with different concentrations of CNT10/PVA-SA(6-10) under 1 sun

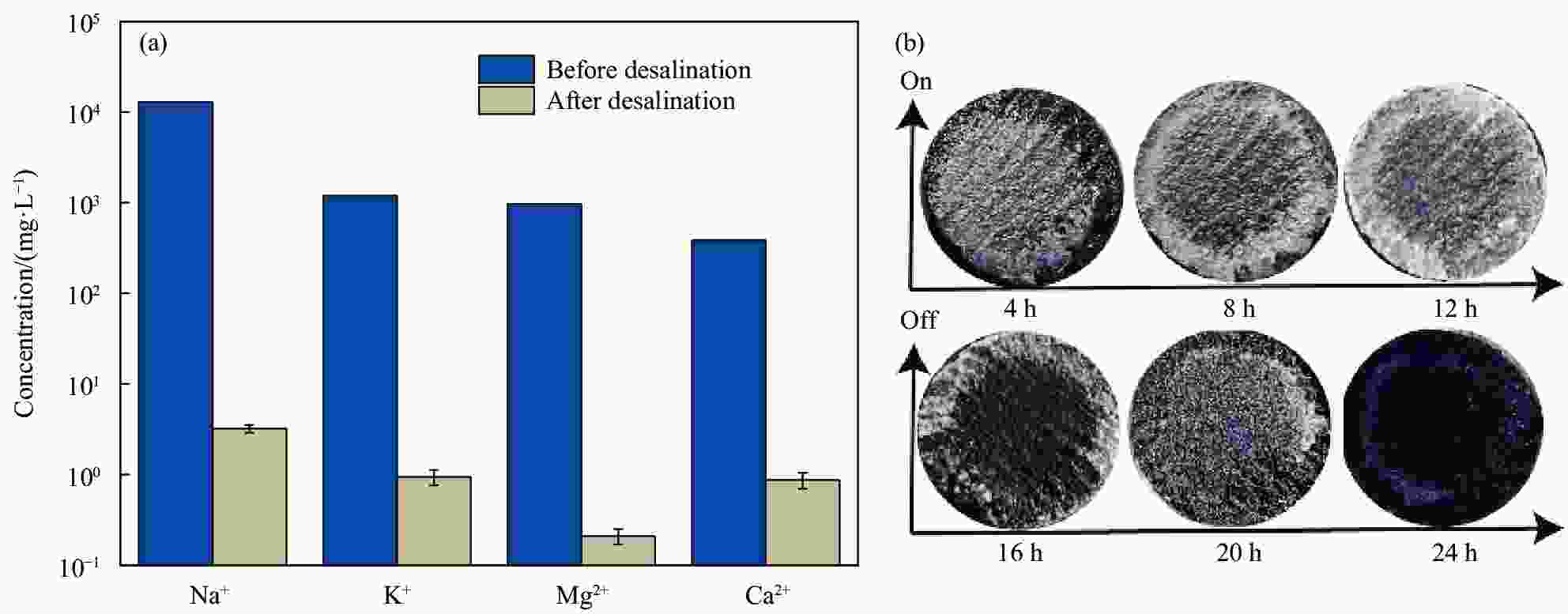

图 7 (a) 脱盐前后,真实海水(中国黄海)中4种主要阳离子的浓度;(b) CNT10/PVA-SA蒸发器表面模拟自然环境的盐沉积/自清洁照片

Figure 7. (a) Concentrations of four main cations in real seawater (Yellow Sea, China) before and after desalination; (b) Photos of salt deposition/self-cleaning on the surface of CNT10/PVA-SA evaporator simulating the natural environment

表 1 不同CNT含量和PVA与SA不同比例的复合气凝胶

Table 1. Composite aerogels with different CNT content and different proportions of PVA and SA

Sample 3wt%PVA/mL 3wt%SA/mL CNT/g PVA 20 — — PVA-SA 10 10 — CNT5/PVA-SA 10 10 5 CNT10/PVA-SA 10 10 10 CNT15/PVA-SA 10 10 15 CNT20/PVA-SA 10 10 20 CNT10/PVA-SA(1) 10 10 10 CNT10/PVA-SA(2) 6.66 13.3 10 CNT10/PVA-SA(3) 5 15 10 CNT10/PVA-SA(4) 15 5 10 CNT10/PVA-SA(5) 13.3 6.66 10 表 2 不同PVA与SA浓度的复合气凝胶

Table 2. Composite aerogels with different PVA and SA concentrations

Sample 5 mL PVA/wt% 15 mL SA/wt% CNT/g CNT10/PVA-SA(6) 1 1 10 CNT10/PVA-SA(7) 2 2 10 CNT10/PVA-SA(8) 3 3 10 CNT10/PVA-SA(9) 4 4 10 CNT10/PVA-SA(10) 5 5 10 -

[1] WANG X, LIU Q, WU S, et al. Multilayer polypyrrole nanosheets with self-organized surface structures for flexible and efficient solar-thermal energy conversion[J]. Advanced Materials,2019,31(19):1807716. doi: 10.1002/adma.201807716 [2] CHEN C, LI Y, SONG J, et al. Highly flexible and efficient solar steam generation device[J]. Advanced Materials, 2017, 29(30): 1701756. [3] ZHU M, LI Y, CHEN G, et al. Tree-inspired design for high-efficiency water extraction[J]. Advanced Materials, 2017, 29(44): 1704107. [4] SUN F, LIU Q D, XIN X P, et al. Attapulgite modulated thorny nickel nanowires/graphene aerogel with excellent electromagnetic wave absorption performance[J]. Chemical Engineering Journal, 2021, 415: 128976. [5] ZHU M W, LI Y J, CHEN F J, et al. Plasmonic wood for high-efficiency solar steam generation[J]. Advanced Energy Materials, 2018, 8(4): 1701028. [6] LI Z T, WANG C B, Multi-scale Ag/CuO photothermal materials: Preparation and application in seawater desalination[J]. Chinese Journal of Inorganic Chemistry, 2020, 36(8): 1457-1464. [7] LI T, LIU H, ZHAO X P, et al. Scalable and highly efficient mesoporous wood-based solar steam generation device: Localized heat, rapid water transport[J]. Advanced Functional Materials, 2018, 28(16): 1707134. [8] YU Z C, WU P Y. Biomimetic MXene-polyvinyl alcohol composite hydrogel with vertically aligned channels for highly efficient solar steam generation[J]. Advanced Materials Technologies, 2020, 5(6): 2000065. [9] LEI Z W, SUN X T, ZHU S F, et al. Nature inspired MXene decorated 3D honeycomb-fabric architectures toward efficient water desalination and salt harvesting[J]. Nano-Micro Letters, 2021, 14(1): 1-16. [10] QIN H F, ZHANG Y F, JIANG J G, et al. Multifunctional superelastic cellulose nanofibrils aerogel by dual ice-templating assembly[J]. Advanced Functional Materials, 2021, 31(46): 2106269. [11] MA Q L, YIN P F, ZHAO M T, et al. MOF-based hierarchical structures for solar-thermal clean water production[J]. Advanced Materials, 2019, 31(17): 1808249. [12] LIU K, ZHANG W Y, CHENG H, et al. A nature-inspired monolithic integrated cellulose aerogel based evaporator for efficient solar desalination[J]. ACS Applied Materials & Interfaces, 2021, 13(8): 10612-10622. [13] STORER D P, PHELPS J L, WU X, et al. Graphene and rice straw-fiber-based 3D photothermal aerogels for highly efficient solar evaporation[J]. ACS Applied Materials & Interfaces,2020,12(13):15279-15287. doi: 10.1021/acsami.0c01707 [14] LIU Z, QING R K, XIE A O, et al. Self-contained Janus aerogel with antifouling and salt rejecting properties for stable solar evaporation[J]. ACS Applied Materials & Interfaces, 2021, 13(16): 18829-18837. [15] LU Y, FAN D Q, WANG Y D, et al. Surface patterning of two-dimensional nanostructure-embedded photothermal hydrogels for high-yield solar steam generation[J]. ACS Nano, 2021, 15(6): 10366-10376. [16] LI J L, WANG X Y, LIN Z H, et al. Over 10 kg·m−2·h−1 evaporation rate enabled by a 3D interconnected porous carbon foam[J]. Joule, 2020, 4(4): 928-937. [17] LEI Z W, ZHU S F, SUN X T, et al. A multiscale porous 3D-fabric evaporator with vertically aligned yarns enables ultra-efficient and continuous water desalination[J]. Advanced Functional Materials, 2022, 32(40): 2205790. [18] 高靖阳. 淀粉基气凝胶的制备及其性质测定[D]. 广州: 华南理工大学, 2020.GAO Jingyang. Preparation and characterization of starch based aerogels[D]. Guangzhou: South China University of Technology, 2020(in Chinese). [19] ZHENG M L. The model and experiment for heat transfer characteristics of nanoporous silica aerogel[J]. Korean Journal of Materials Research, 2020, 30(4): 155-159. [20] KONG Y, DAN H B, KONG W J, et al. Self-floating maize straw/graphene aerogel synthesis based on microbubble and ice crystal templates for efficient solar-driven interfacial water evaporation[J]. Journal of Materials Chemistry A, 2020, 8(46): 24734-24742. [21] JOUKHDAR H, SEIFERT A, JÜNGST T, et al. Ice templating soft matter: Fundamental principles and fabrication approaches to tailor pore structure and morphology and their biomedical applications[J]. Advanced Materials, 2021, 33(34): 2100091. [22] 罗伟, 王林生, 陈裕欣, 等. 有机-无机复合气凝胶的制备及其阻燃性能研究进展[J]. 复合材料学报, 2021, 38(7):2056-2069. doi: 10.13801/j.cnki.fhclxb.20210324.002LUO Wei, WANG Linsheng, CHEN Yuxin, et al. Research progress on preparation and flame retardant properties of organic-inorganic composite aerogel[J]. Acta Materiae Compositae Sinica,2021,38(7):2056-2069(in Chinese). doi: 10.13801/j.cnki.fhclxb.20210324.002 [23] JIANG Y Z, HOU Y J, FANG J J, et al, Preparation and characterization of PVA/SA/HA composite hydrogels for wound dressing[J]. International Journal of Polymer Analysis and Characterization, 2019, 24(2): 132-141. -

下载:

下载: