Fatigue life and failure mode of CFRP-aluminum alloy single-lap adhesive joints

-

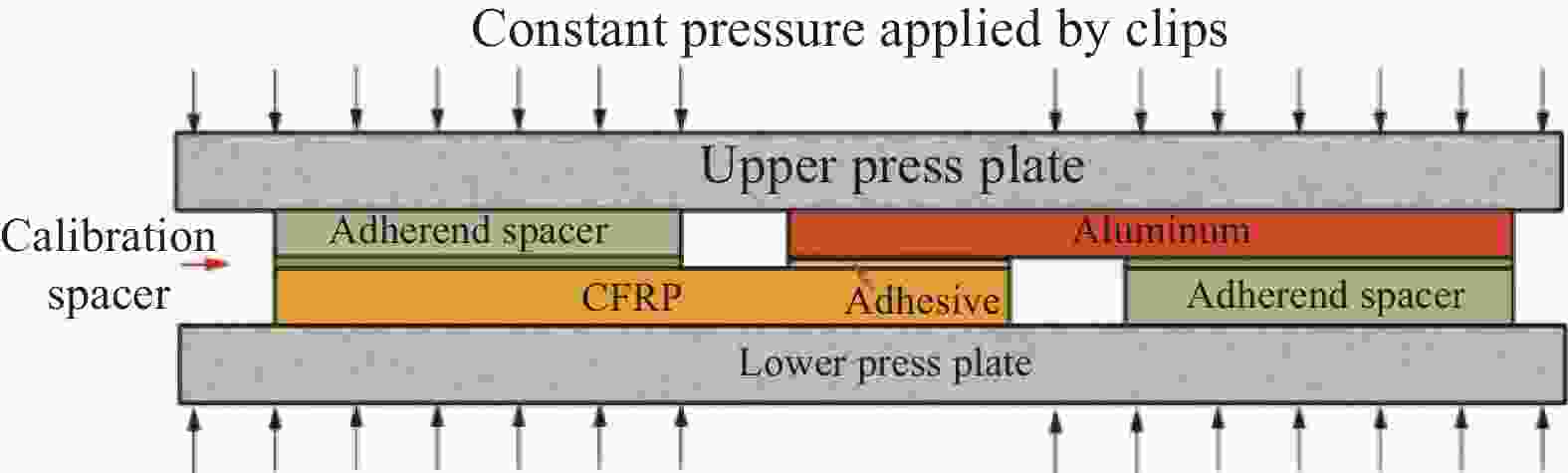

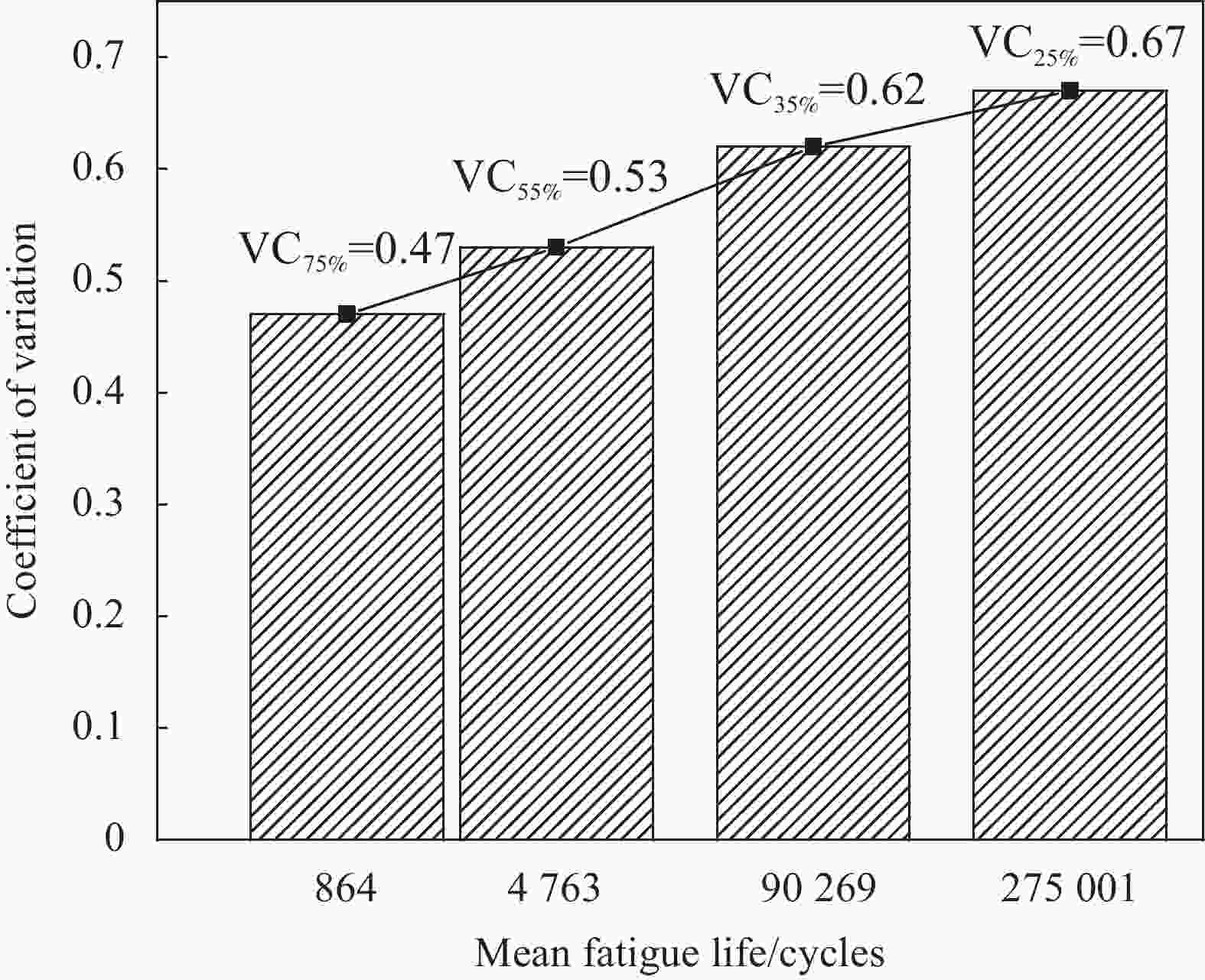

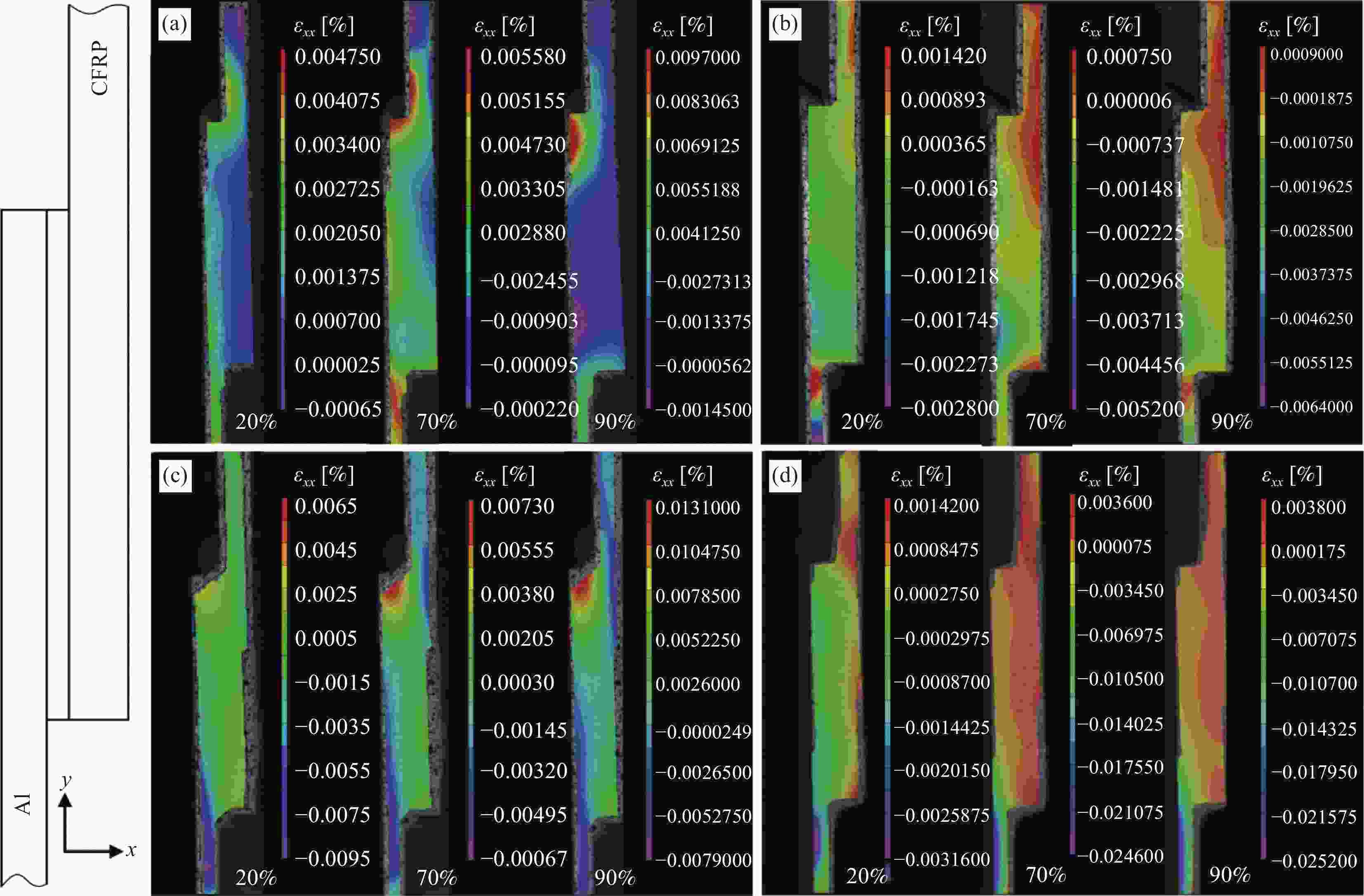

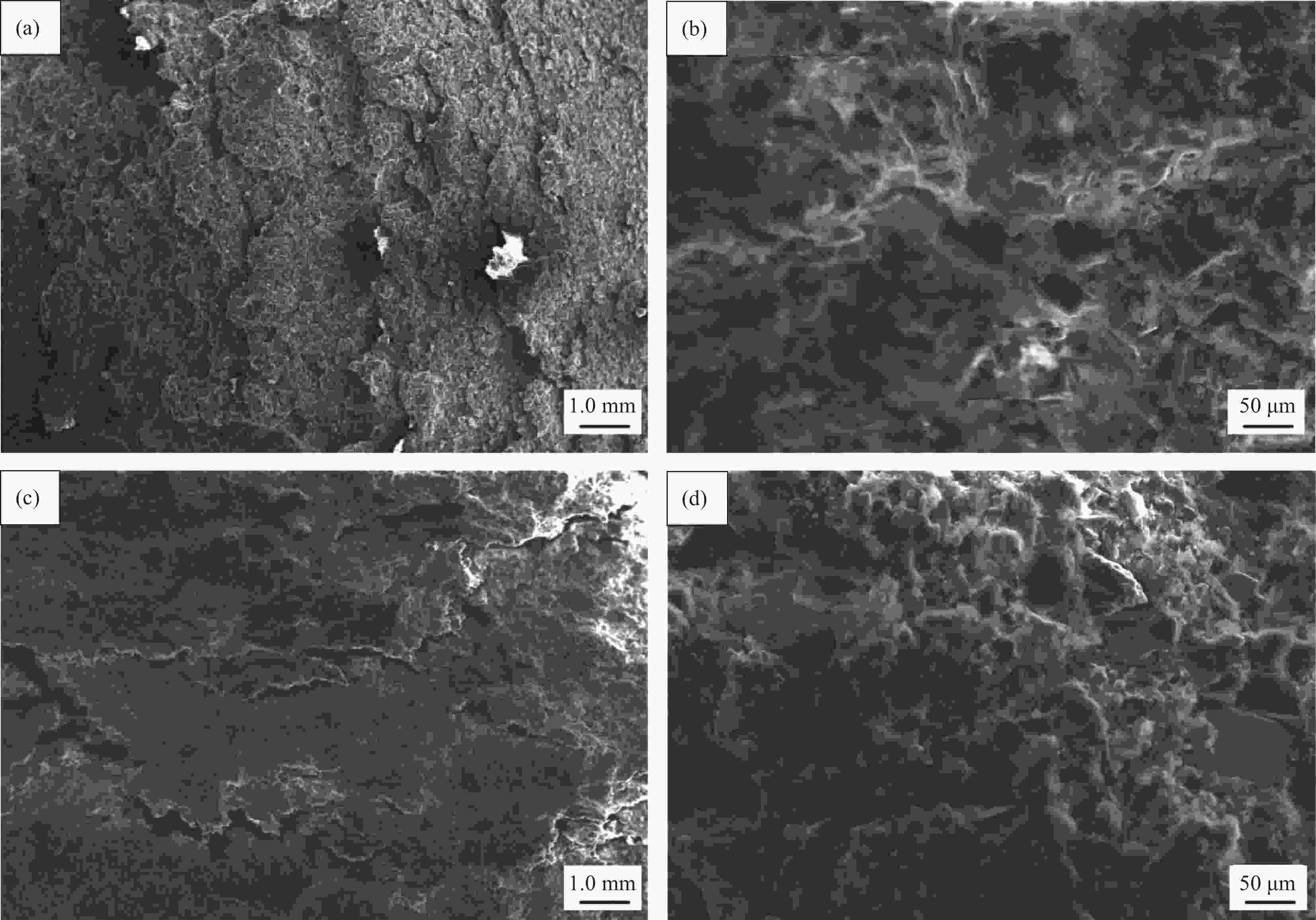

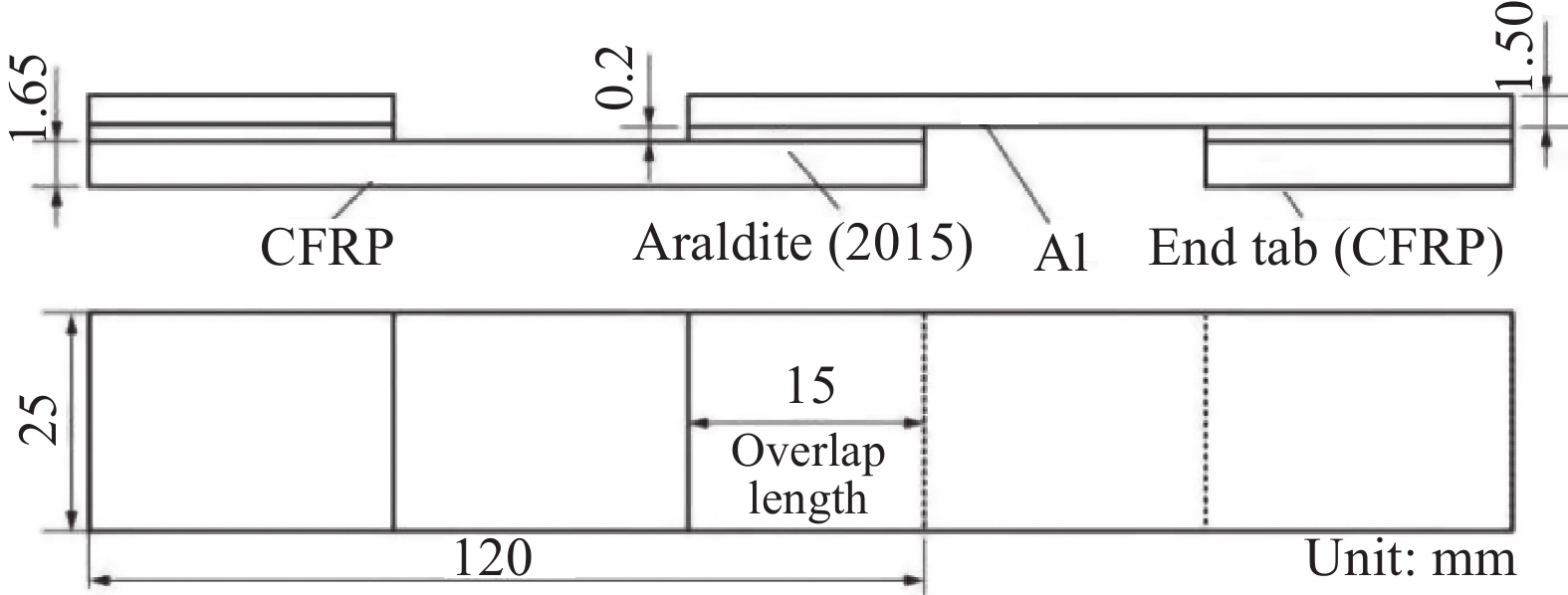

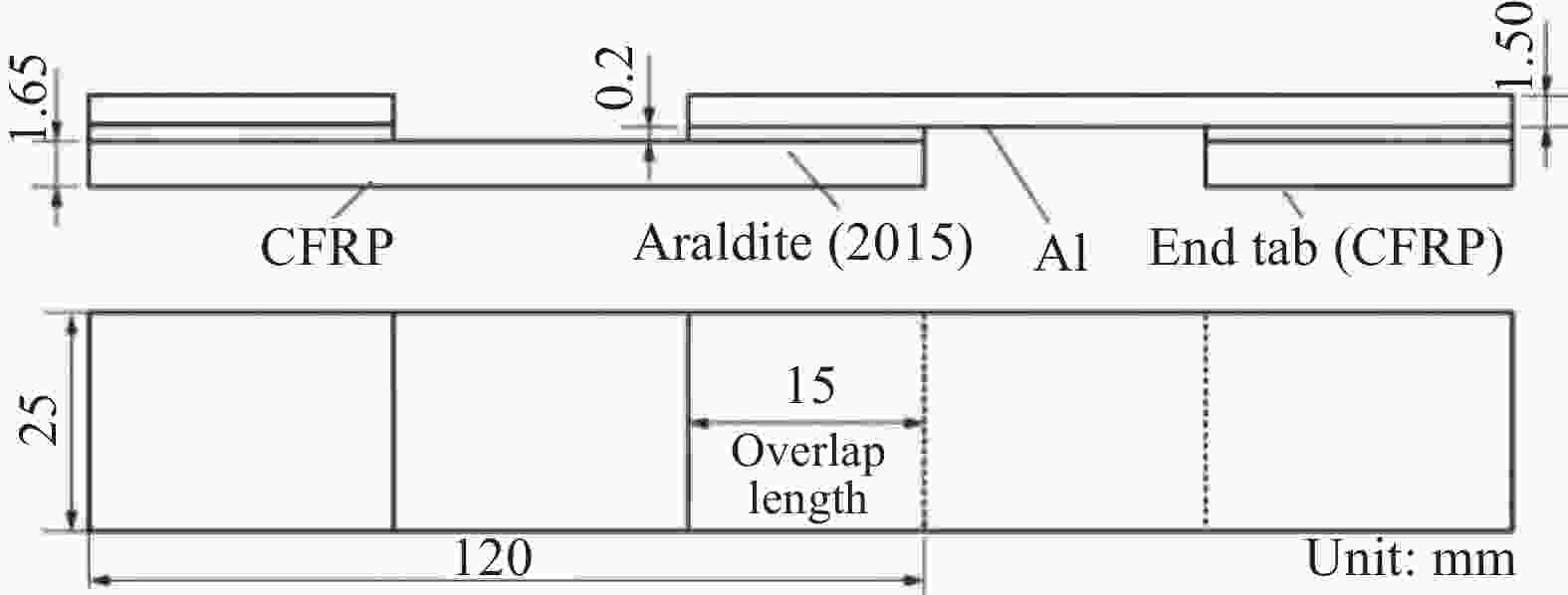

摘要: 在室温下制备碳纤维增强树脂复合材料(CFRP)-铝合金单搭接胶接试样。利用电子万能试验机和电液伺服疲劳试验机进行准静态拉伸和拉-拉疲劳试验,基于疲劳试验结果和双参数威布尔分布方法,采用多种函数模型对接头应力-寿命(S-N)曲线进行拟合。同时,利用三维数字图像相关技术(3D digital image correlation,3D-DIC)和SEM等设备,获得接头应变分布云图和失效形貌,揭示CFRP-铝合金胶接接头在循环载荷下的破坏机制。结果表明,幂函数对CFRP-铝合金单搭接胶接接头S-N曲线拟合度最高,相关系数R2为0.987,且接头疲劳寿命随着载荷水平的降低逐渐提高,变异系数逐渐增大。载荷水平为25%和35%失效载荷时,CFRP-铝合金单搭接接头破坏模式主要为胶层内聚破坏和铝合金-胶层界面破坏,且随着载荷水平的升高内聚破坏面积逐渐增加,载荷水平达到75%失效载荷时,CFRP-铝合金单搭接接头只发生胶层内聚破坏。在载荷水平为25%失效载荷下,接头由于内部温度上升主要发生韧性断裂,且随载荷水平上升至75%失效载荷时,接头由于受到较大拉应力逐渐向脆性断裂转变。Abstract: Carbon fiber reinforced polymer (CFRP)-Al single-lap adhesive joints were made at room temperature. Firstly, a universal testing machine as well as an electro-hydraulic servo fatigue testing machine were used for quasi-static tensile tests and tensile-tension fatigue tests, respectively. Based upon the fatigue test results and two-parameter Weibull distribution methods, multiple function models were applied to fit the stress-life (S-N) curves of joints. Meanwhile, 3D digital image correlation (3D-DIC) and SEM were used respectively to obtain the strain field distribution and failure morphology of joints, revealing the failure mechanism of joints under cyclic load. According to the test results, the power function has the highest fitting degree for the S-N curves of the joints, with the correlation coefficient R2 of 0.987. Besides, with the load level decreasing, the fatigue life and the coefficient of variation of the joints gradually increase. When the load levels are 25% and 35% of the failure load, the failure modes of joints are mainly cohesive failure and interface failure. And the cohesive failure area increases correspondingly with the increase of the load level. Even when the load level is up to 75% of the failure load, only cohesive failure occurs. Moreover, when the load level is 25% of the failure load, ductile fracture occurs due to the increase of the internal temperature of the joints. And when the load level rises to 75% of the failure load, the joints gradually change to brittle fracture as a result of large tensile stress.

-

表 1 碳纤维增强树脂复合材料(CFRP)层合板材料性能

Table 1. Material properties of carbon fiber reinforced polymer (CFRP) laminates

Property Value E11/MPa 121000 E22/MPa 8600 E33/MPa 8600 G12/MPa 3450 G13/MPa 2850 G23/MPa 2850 $\nu$ 0.301 ρ/(kg·m−3) 1467 Notes: E—Young’s modulus; $ i $ ($ i $=1, 2, 3)—Direction; G—Shear modulus; $\nu $—Poisson’s ratio; ρ—Density. 表 2 Al7075材料性能

Table 2. Material properties of Al7075

Property Value E/MPa 71700 $\nu$ 0.32 ρ/(kg·m−3) 3000 表 3 不同载荷水平下CFRP-铝合金单搭接胶接接头的疲劳寿命

Table 3. Fatigue life of CFRP-aluminum alloy single-lap adhesive joints under different load levels

Load level Fatigue life $\ln \ln \dfrac{1}{{R\left( t \right)}}$ $\ln t $ 100%

(5.93 kN)1 − − 75%

(4.45 kN)474 −1.753 6.161 638 −0.717 6.458 1026 −0.050 6.933 1248 0.609 7.129 55%

(3.26 kN)2442 −1.753 7.801 3283 −0.717 8.097 5235 −0.050 8.563 7562 0.609 8.931 35%

(2.08 kN)33364 −1.753 10.415 68903 −0.717 11.140 103672 −0.050 11.549 135573 0.609 11.817 25%

(1.48 kN)99998 −1.753 11.513 179375 −0.717 12.097 252329 −0.050 12.620 457897 0.609 13.034 15%

(0.89 kN)5301850 − − Notes: lnln[1/R(t)]—Result of taking the logarithm of reliability, and the calculation formula is shown in formula (4)-(5); lnt—Result of taking the logarithm of mean time to fatigue, and the calculation formula is shown in formula (6). 表 4 不同载荷水平下CFRP-铝合金单搭接胶接接头的Weibull参数

Table 4. Weibull parameters under different load levels

Load level α β TMTTF CV 75% 2.25 975.56 864 0.47 55% 1.98 5372.48 4763 0.53 35% 1.64 100859.46 90269 0.62 25% 1.53 305218.04 275001 0.67 Notes: α—Shape parameter; β—Scale parameter; TMTTF—Mean time to fatigue of the joints; CV—Coefficient of variation of the joints. -

[1] NING L, YANG S C, LENG Y, et al. Overview of the application of advance composite materials on aircraft and the development of its manufacturing technology[J]. Science and Engineering of Composite Materials,2020,5:123. [2] KITANO A. Characteristics of carbon-fiber-reinforced plastics (CFRP) and associated challenges—Focusing on carbon-fiber-reinforced thermosetting resins (CFRTS) for aircraft[J]. International Journal of Automation Technology,2016,10(3):300-309. doi: 10.20965/ijat.2016.p0300 [3] KGOETE F M, POPOOLA A P I, et al. Advancement in the application of alloys and composites in the manufacture of aircraft component: A review[J]. Journal of Physics Conference Series,2019,1378:032049. doi: 10.1088/1742-6596/1378/3/032049 [4] 马立敏, 张嘉振, 岳广全, 等. 复合材料在新一代大型民用飞机中的应用[J]. 复合材料学报, 2015, 32(2):317-322.MA Limin, ZHANG Jiazhen, YUE Guangquan, et al. Application of composites in new generation of large civil aircraft[J]. Acta Materiae Compositae Sinica,2015,32(2):317-322(in Chinese). [5] 郭磊, 刘检华, 张佳朋, 等. 航天工业中胶接技术的研究现状分析[J]. 中国机械工程, 2020, 32(12):1395-1404.GUO Lei, LIU Jianhua, ZHANG Jiapeng, et al. Analysis of the research status of adhesively connection technology in aerospace industry[J]. China Mechanical Engineering,2020,32(12):1395-1404(in Chinese). [6] BUDHE S, BANEA M D, BARROS S, et al. An updated review of adhesively bonded joints in composite materials[J]. International Journal of Adhesion and Adhesives,2016,72:30-42. [7] MARQUES A C, MOCANU A, TOMIC N Z, et al. Review on adhesives and surface treatments for structural applications: Recent developments on sustainability and implementation for metal and composite substrates[J]. Materials,2020,13(24):1-43. [8] KARATA M A, MOTORCU A R, GOKKAYA H. Optimization of machining parameters for kerf angle and roundness error in abrasive water jet drilling of CFRP composites with different fiber orientation angles[J]. Journal of the Brazilian Society of Mechanical Sciences and Engineering,2020,42(4):1-27. [9] 卓宁生, 付益战, 胡昭. 运8系列飞机结构疲劳定寿总结[J]. 航空科学技术, 2006(2):40-44. doi: 10.3969/j.issn.1007-5453.2006.02.011ZHUO Ningsheng, FU Yizhan, HU Zhao. Summary of determination of structures fatigue life for Y8 aircraft series[J]. Aeronautical Science & Technology,2006(2):40-44(in Chinese). doi: 10.3969/j.issn.1007-5453.2006.02.011 [10] PARK S M, ROY R, KWEON J H, et al. Strength and failure modes of surface treated CFRP secondary bonded single-lap joints in static and fatigue tensile loading regimes[J]. Composites Part A: Applied Science and Manufacturing,2020,134:105897. [11] GIOVANNI M, MARINO Q, RICOTTA M, et al. Damage mechanisms in composite bonded joints under fatigue loading[J]. Composites: Part B,2012,43(2):210-220. [12] 曹双辉, 高弄玥, 刘斌. 飞机复合材料阶梯式胶接结构的疲劳损伤与寿命[J]. 复合材料科学与工程, 2020(2):81-84, 96. doi: 10.3969/j.issn.1003-0999.2020.02.013CAO Shuanghui, GAO Nongyue, LIU Bin. Study on composite omiga stringer stiffened curved panel by automatic[J]. Compositea Science and Engineering,2020(2):81-84, 96(in Chinese). doi: 10.3969/j.issn.1003-0999.2020.02.013 [13] 赵京南. 钢-CFRP胶接接头疲劳损伤特性试验研究[D]. 大连: 大连理工大学, 2016ZHAO Jingnan. Experimental study on fatigue damage performance of CFRP-steel adhesively bonded joint[D]. Dalian: Dalian University of Technology, 2016(in Chinese) [14] 慕文龙, 那景新, 秦国锋, 等. 交变载荷对CFRP复合材料-铝合金粘接接头剩余强度的影响[J]. 复合材料学报, 2019, 36(5):1124-1131.MU Wenlong, NA Jingxin, QIN Guofeng, et al. Effect of alternating load on residual strength of adhesively bonded CFRP composite-aluminum alloy joints[J]. Acta Materiae Composite Sinica,2019,36(5):1124-1131(in Chinese). [15] 中国汽车工程学会. 汽车用聚合物基复合材料胶接性能测试方法复合材料/金属材料: T/CSAE 171—2020[S]. 北京: 中国汽车工程学会, 2020.China Society of Automotive Engineering. Test methods for mechanical properties of adhesively bonded joints for automotive polymer matrix composites-composite/metal: T/CSAE 171—2020[S]. Beijing: China Society of Automotive Engineering, 2020(in Chinese) [16] ASTM. Standard test method for lap shear adhesion for fiber reinforced plastic(FRP) bonding: ASTM D5868-01[S]. West Conshohocken: ASTM, 2001. [17] XU X X, CROCOMBE A D, SMITH P A. Fatigue crack growth rates in adhesive joints tested at different frequencies [J]. Taylor & Francis Group, 2006, 58(3-4): 191-204. [18] DATLA N V, AMELI A. Effects of hygrothermal aging on the fatigue behavior of two toughened epoxy adhesives[J]. Engineering Fracture Mechanics,2011,79:88-96. [19] RAZAVI S M J, BALE E S, BERTO F. Mechanical behavior of metallic fiber-reinforced adhesive under cyclic loading[J]. Procedia Structural Integrity,2020,26:225-228. doi: 10.1016/j.prostr.2020.06.026 [20] AHMED S H, JOSEPH W N, CARLOS H C. Weibull statistical analysis of Krouse type bending fatigue of nuclear materials[J]. Journal of Nuclear Materials,2016,470:244-250. [21] LIU X L, ZHENG G, LUO Q T, et al. Fatigue behavior of carbon fibre reinforced plastic and aluminum single-lap adhesive joints after the transverse pre-impact[J]. International Journal of Fatigue,2021,144:105973. [22] JIANG H, LUO T, LI G Y, et al. Fatigue life assessment of electromagnetic riveted carbon fiber reinforce plastic/aluminum alloy lap joints using Weibull distribution[J]. International Journal of Fatigue,2017,105:180-189. [23] 王中强, 张开富, 李原, 等. CFRP/Al复合构件胶接界面力学建模与强度分析[J]. 西北工业大学学报, 2010, 28(6):858-865.WANG Zhongqiang, ZHANG Kaifu, LI Yuan, et al. An interface stress model for strength analysis of CFRP/Al[J]. Journal of Northwestern Polytechnical University,2010,28(6):858-865(in Chinese). [24] GUDLADT H J, FRÖMMEL S T. Fatigue and fracture behavior of adhesive-bonded structures in the light of the surface morphology[J]. International Journal of Adhesion and Adhesives,2019,88:74-80. [25] WEI T, NA J X, WANG G B, et al. Effect of temperature on the fatigue performance and failure mechanism of a flexible adhesive butt joint[J]. The Journal of Adhesion,2021(365):1-31. -

下载:

下载: