Effect of the surface enrichment of coupling agent on the interfacial properties and interlaminar fracture toughness of GFRPs

-

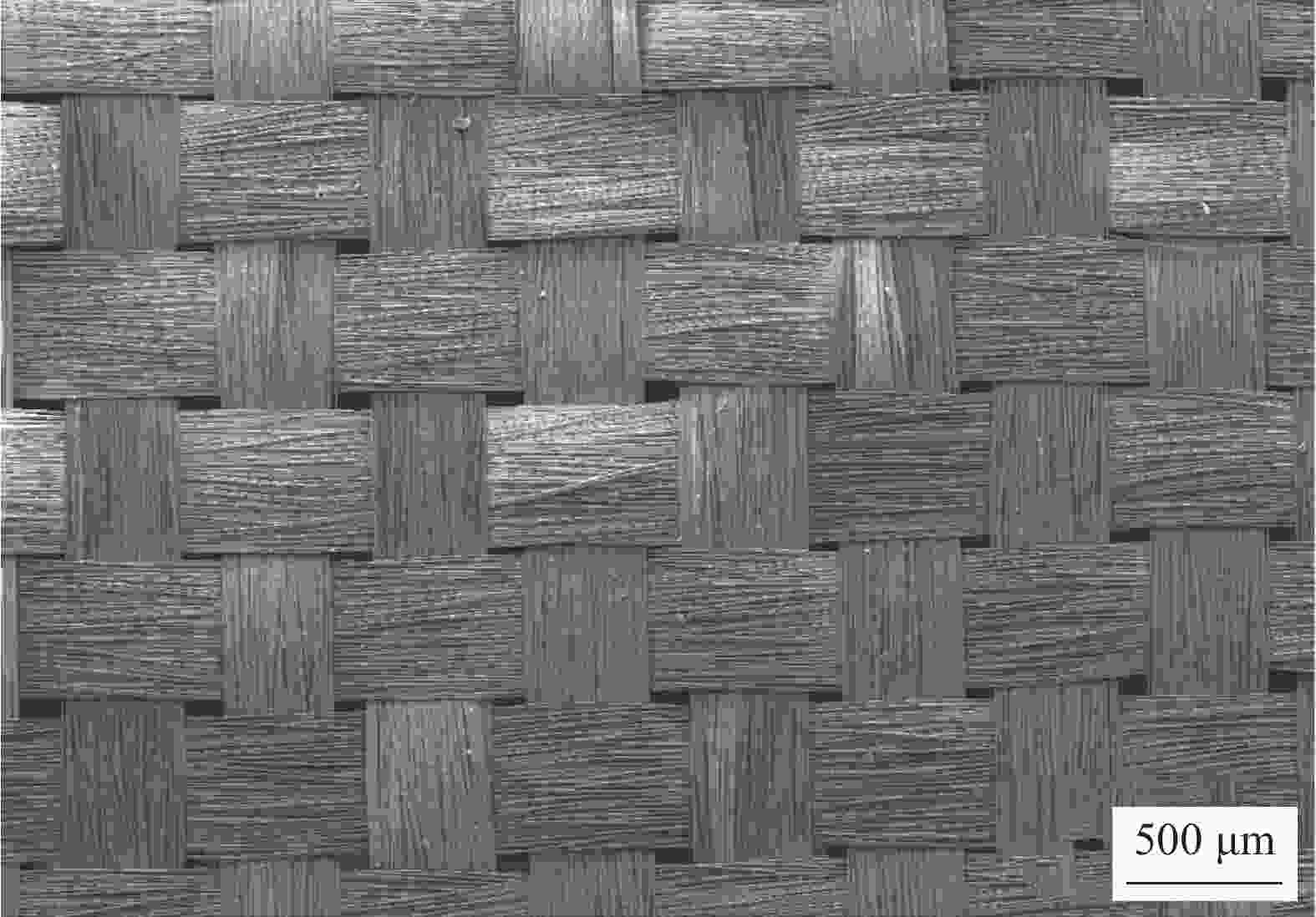

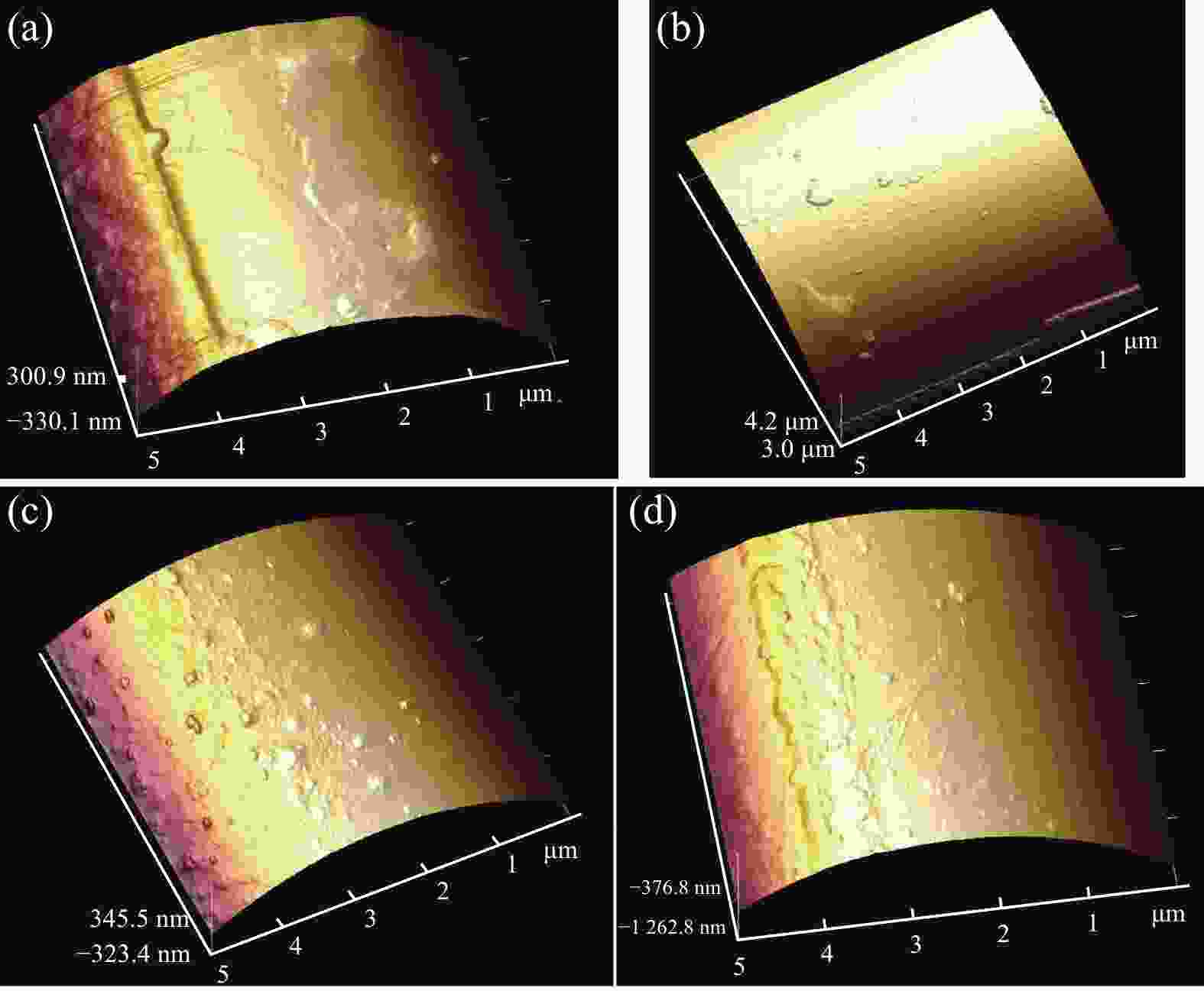

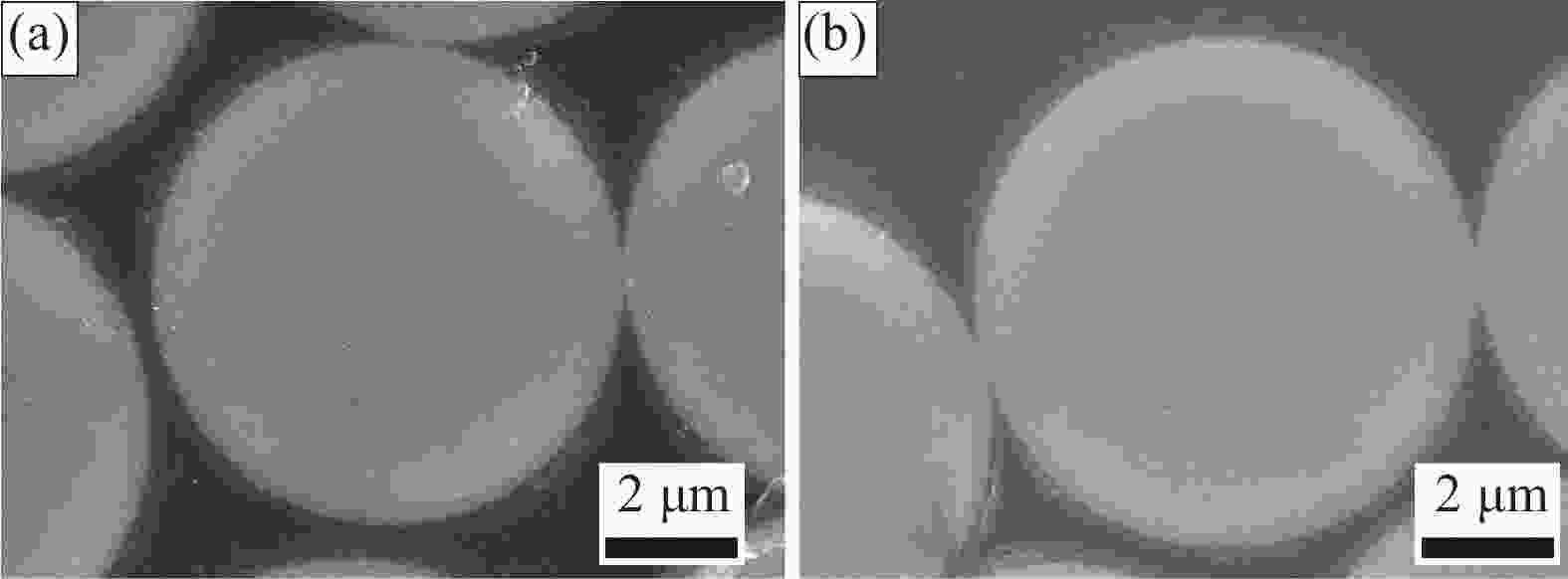

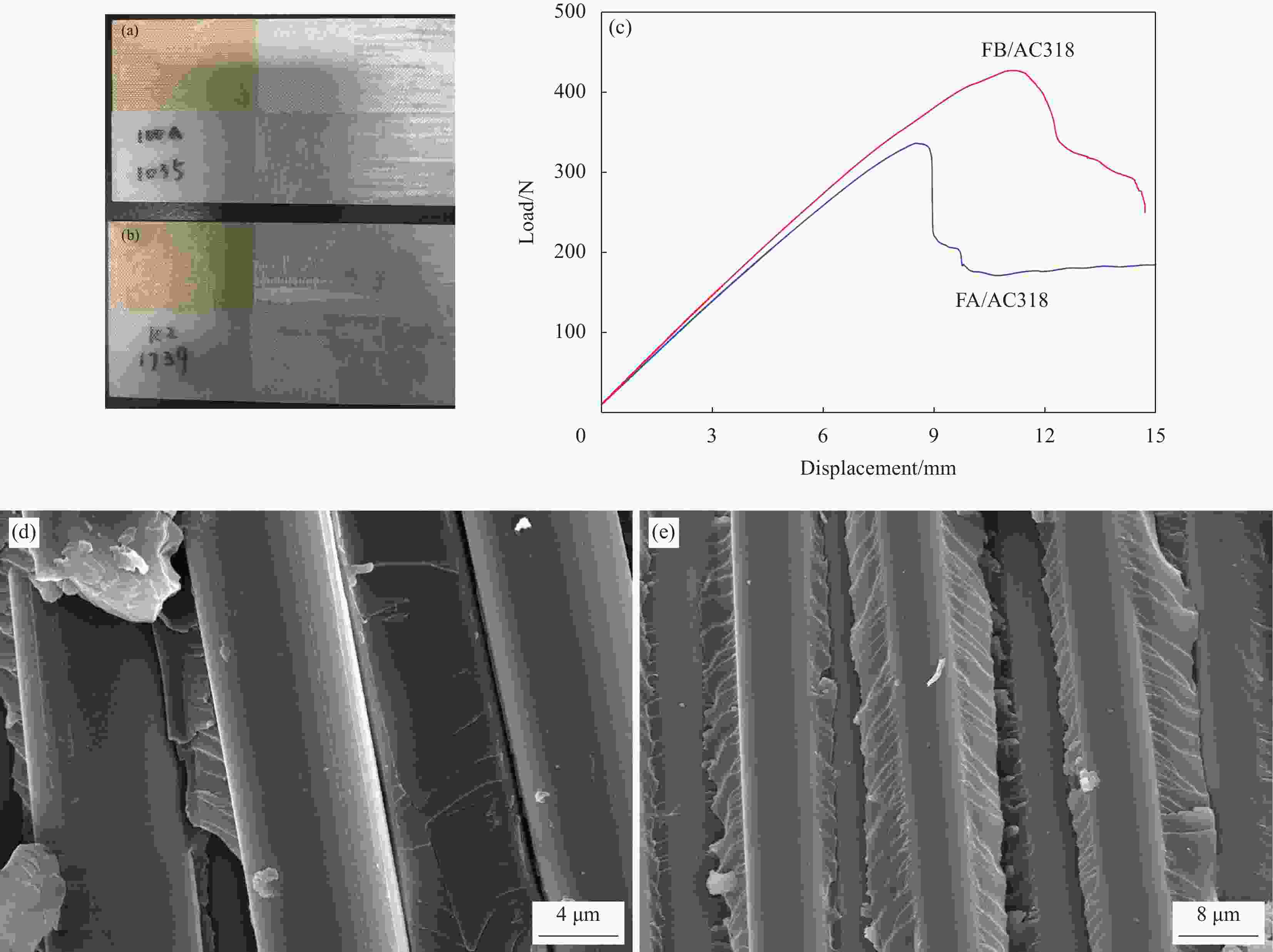

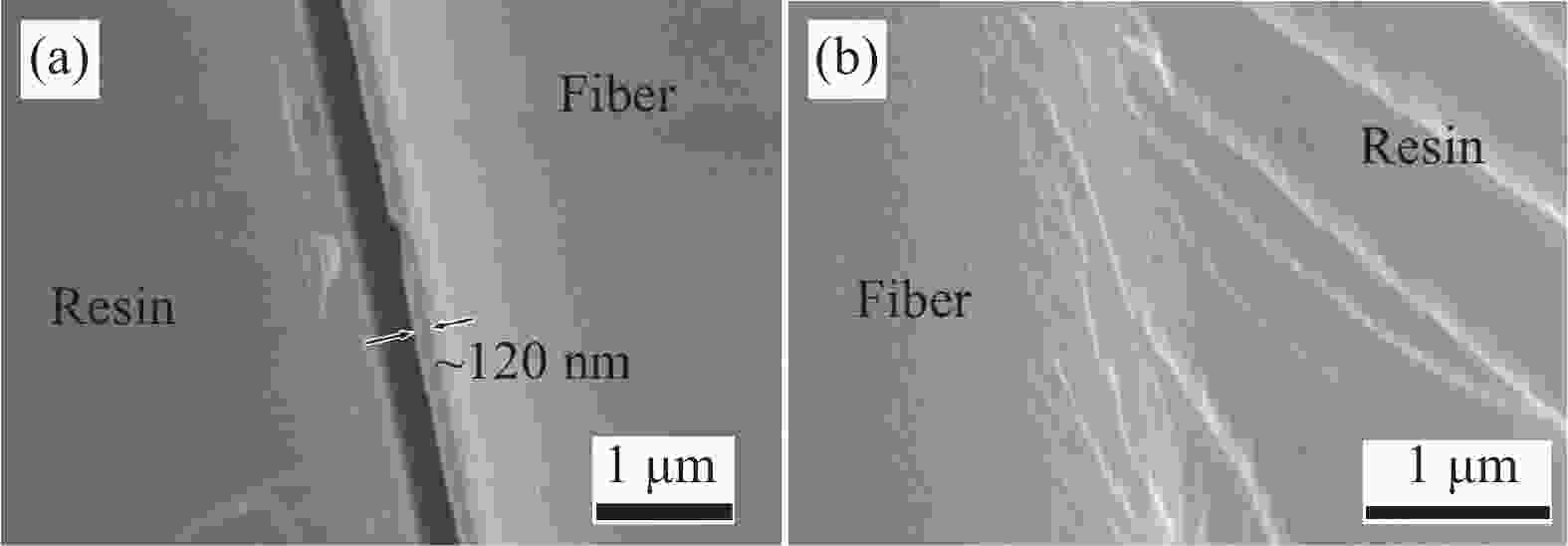

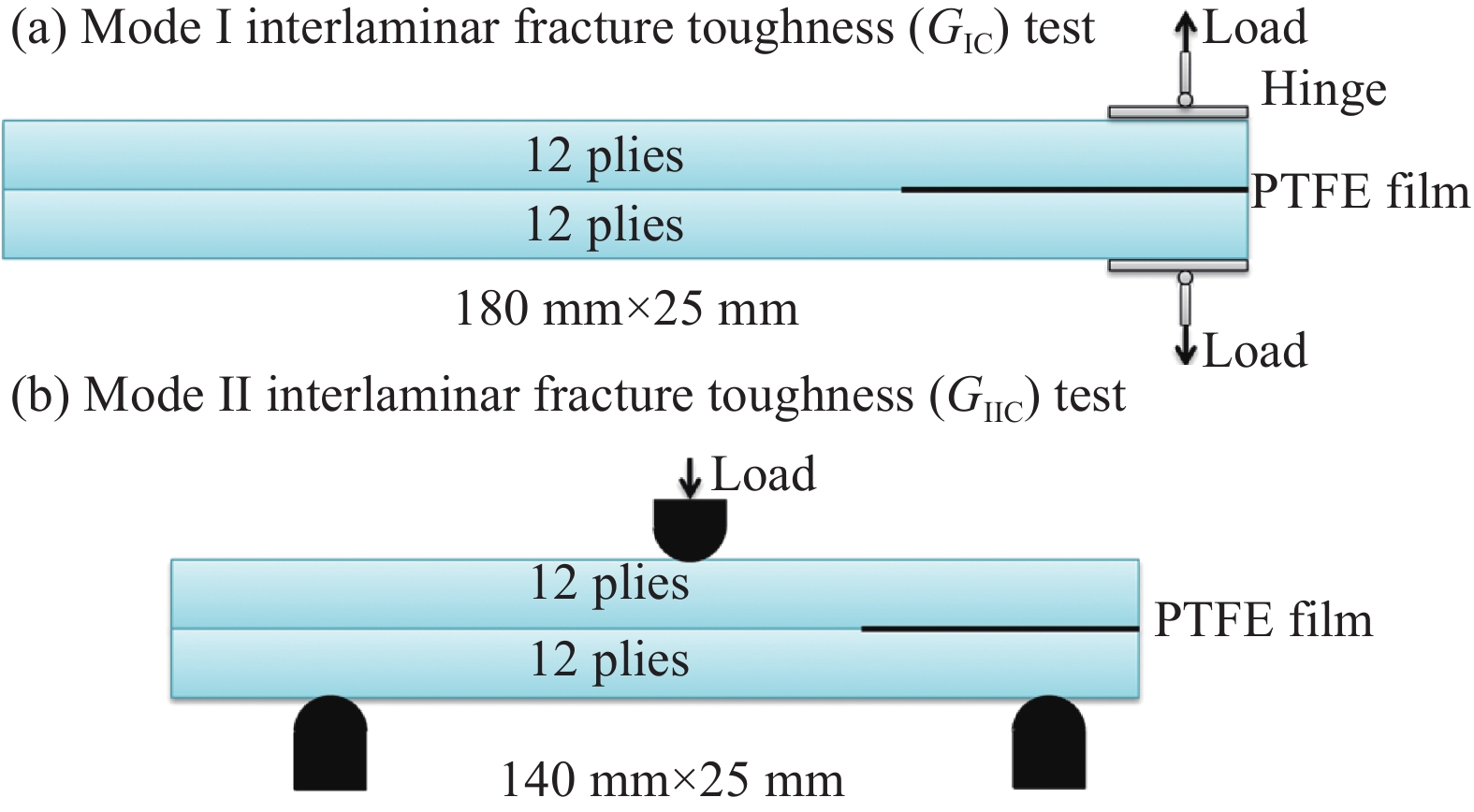

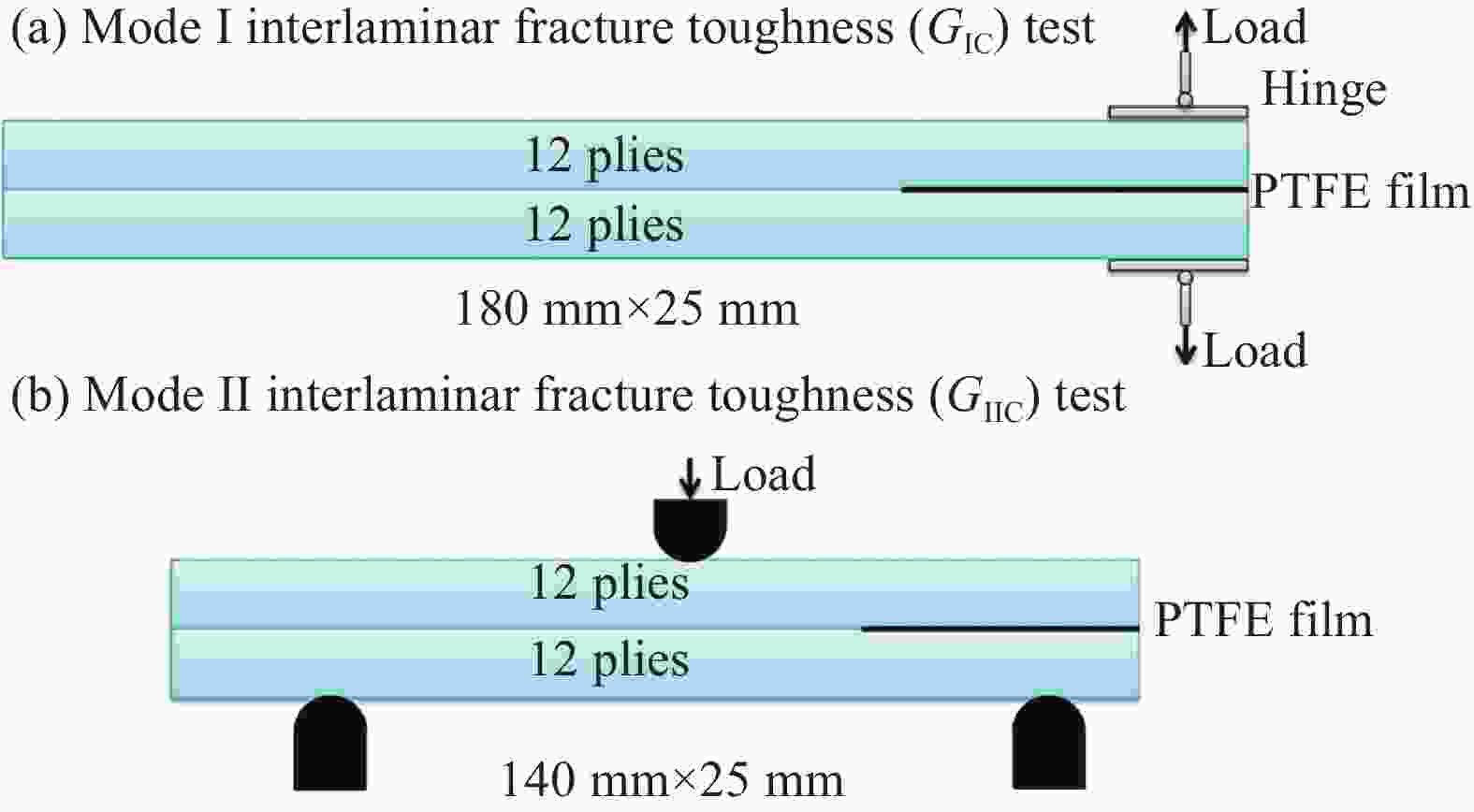

摘要: 浸润剂是形成复合材料界面的关键组成,理解浸润剂特性对复合材料界面和宏观力学的影响机制,对发展高性能复合材料有着重要的科学价值。本文研究了采用两种不同浸润剂体系的高强玻璃纤维织物的表面、界面和层间断裂韧性等性能,发现其中一种浸润剂体系的纤维表面发生了更显著的偶联剂表面富集,偶联剂表面富集导致纤维/树脂之间具有较高的动态接触角,同时纤维/树脂的界面剪切强度下降。作为对比,偶联剂较少表面富集的浸润剂体系,纤维/树脂之间的动态接触角较小,同时界面剪切强度较高。两种复合材料的I型、II型层间断裂韧性均基于纤维/树脂之间的界面脱粘机制,较多偶联剂表面富集的浸润剂降低了复合材料的界面连续性,而较少偶联剂表面富集的浸润剂则与树脂形成了连续的界面相,界面粘结良好,并诱导了层间断裂时的织物拔出机制,I型和II型层间断裂韧性分别比前者高56.5%和62.2%。Abstract: Sizing agents are the key component to form the composite interface. Understanding the influence of sizing agents on the interfacial and mechanical properties of composites has important scientific value for the development of high-performance composites. The surface structures, interfacial properties and interlaminar fracture toughness of two high strength glass fiber fabric reinforced epoxy resin composites (GFRPs) with two different sizing agents were studied. The results show that one of the sizing agent has significant surface enrichment of the silane coupling agent, resulting in the increase in dynamic contact angle and the decrease in interfacial shear strength between fiber and resin. Contrarily, another sizing agent has less surface enrichment of silane coupling agent. The corresponding fiber has smaller dynamic contact angle and higher interfacial shear strength with the epoxy resin. The mode I and mode II fracture of the composites with these two sizing agents are based on the same mechanism, i.e., the interfacial debonding between resin and fiber. The interfacial continuity is reduced for the composite with the sizing agent existing higher surface enrichment of silane coupling agent. While for the composite with the sizing agent with less silane coupling agent surface enrichment, a continuous interface formed between the interphase and resin, resulting in good interfacial adhesion. The mode I and mode II interlaminar fracture toughness increased by 56.5% and 62.2% compared with these of the former composite, respectively.

-

Key words:

- GFRPs /

- interface structure /

- sizing agent /

- coupling agent /

- interlaminar fracture toughness /

- contact angle

-

表 1 原始纤维和N, N-二甲基甲酰胺(DMF)处理纤维的表面元素组成

Table 1. Surface element compositions of original fibers and N, N-dimethylformamide (DMF) treated fibers

Fiber Si/at% C/at% N/at% O/at% FA untreated 7.73 56.88 9.89 25.51 FA treated 14.48 33.04 14.56 37.93 FB untreated 4.24 71.32 1.86 22.58 FB treated 7.93 61.27 3.30 27.52 表 2 纤维浸入树脂中的动态接触角

Table 2. Dynamic contact angles between fiber and resin

Fiber First

advancing

angle/(º)First

receding

angle/(º)Secondary advancing angle/(º) Secondary receding angle/(º) FA 68.4±1.8 0 28.7±5.9 0 FB 55.5±0.5 0 18.9±2.5 0 表 3 两种纤维去浸前后的微界面剪切强度

Table 3. Interfacial shear strength of the original and desized fibers

Fiber Original fiber/MPa Desized fiber/MPa FA 42.9±5.9 34.7±6.0 FB 47.1±4.7 42.6±4.3 表 4 复合材料的层间断裂韧性

Table 4. Interlaminar fracture toughness of the composites

Composite GIC/(J·m−2) GIIC/(J·m−2) FA/AC318 550.8±57.5 1062±215 FB/AC318 862.0±133.5 1723±325 -

[1] BEURA S, THATOI D N, CHAKRAVERTY A P, et al. Impact of the ambiance on GFRP composites and role of some inherent factors: A review report[J]. Journal of Reinforced Plastics and Composites,2018,37(8):533-547. doi: 10.1177/0731684418754359 [2] 肖何, 陈藩, 刘寒松, 等. 国产ZT7H碳纤维表面状态及其复合材料界面性能[J]. 复合材料学报, 2021, 38(8):2554-2567. doi: 10.13801/j.cnki.fhclxb.20201209.003XIAO He, CHEN Fan, LIU Hansong, et al. Surface state of domestic ZT7H carbon fiber and interface property of composites[J]. Acta Materiae Compositae Sinica,2021,38(8):2554-2567(in Chinese). doi: 10.13801/j.cnki.fhclxb.20201209.003 [3] GONZALEZ C, LLORCA J. Mechanical behavior of unidirectional fiber-reinforced polymers under transverse compression: Microscopic mechanisms and modeling[J]. Composites Science and Technology,2007,67(13):2795-2806. doi: 10.1016/j.compscitech.2007.02.001 [4] KOLOOR S S R, ABDULLAH M A, TAMIN M N, et al. Fatigue damage of cohesive interfaces in fiber-reinforced polymer composite laminates[J]. Composites Science and Technology,2019,183:107779. doi: 10.1016/j.compscitech.2019.107779 [5] WANG J, GANGARAO H, LIANG R, et al. Durability and prediction models of fiber-reinforced polymer composites under various environmental conditions: A critical review[J]. Journal of Reinforced Plastics and Composites,2016,35(3):179-211. doi: 10.1177/0731684415610920 [6] WU Z, YI X, WILKINSON A. Interlaminar fracture toughness of carbon fibre/RTM6-2 composites toughened with thermoplastic-coated fabric reinforcement[J]. Composites Part B: Engineering,2017,130:192-199. doi: 10.1016/j.compositesb.2017.08.003 [7] BOON Y D, JOSHI S C. A review of methods for improving interlaminar interfaces and fracture toughness of laminated composites[J]. Materials Today Communications,2020,22:100830. doi: 10.1016/j.mtcomm.2019.100830 [8] SPRENGER S. Improving mechanical properties of fiber-reinforced composites based on epoxy resins containing industrial surface-modified silica nanoparticles: Review and outlook[J]. Journal of Composite Materials,2015,49(1):53-63. doi: 10.1177/0021998313514260 [9] LIAO L, WANG X, FANG P, et al. Interface enhancement of glass fiber reinforced vinyl ester composites with flame-synthesized carbon nanotubes and its enhancing mechanism[J]. ACS Applied Materials & Interfaces,2011,3(2):534-538. [10] 樊序敏, 顾轶卓, 刘亚男, 等. 碳纳米管浸润剂对碳纤维/环氧树脂界面性能的影响[J]. 复合材料学报, 2012, 29(4):17-22.FAN Xumin, GU Yizhuo, LIU Yanan, et al. Effects of wetting agent containing carbon nanotubes on interfacial property of carbon fiber/epoxy resin[J]. Acta Materiae Compositae Sinica,2012,29(4):17-22(in Chinese). [11] ZHUANG R C, LIU J W, PLONKA R, et al. NaBF4 as a hygrothermal durability enhancer for glass fibre reinforced polypropylene composites[J]. Composites Science and Technology,2011,71(12):1461-1470. doi: 10.1016/j.compscitech.2011.06.002 [12] DIBENEDETTO A T. Tailoring of interfaces in glass fiber reinforced polymer composites: A review[J]. Materials Science and Engineering: A,2001,302(1):74-82. doi: 10.1016/S0921-5093(00)01357-5 [13] PAPE P G, PLUEDDEMANN E P. Silanes and other coupling agents[M]. Netherlands: VSP, 1992: 105-116. [14] QU Z, ZHAO B, WANG J, et al. Morphological and mechanical behavior of polyurethane/epoxy interpenetrating polymers and its flax fiber-reinforced composites[J]. Polymer Composites,2021,42(3):1258-1266. doi: 10.1002/pc.25898 [15] REN D, CHEN L, YUAN Y, et al. Designing and preparation of fiber-reinforced composites with enhanced interface adhesion[J]. Polymers,2018,10(10):1128. doi: 10.3390/polym10101128 [16] DIBENEDETTO A T, CONNELLY S M, LEE W C, et al. The properties of organosiloxane/polyester interfaces at an E-glass fiber surface[J]. The Journal of Adhesion,1995,52(1-4):41-64. doi: 10.1080/00218469508015185 [17] LIU Z, ZHANG J, TANG Y, et al. Optimization of PBO fibers/cyanate ester wave-transparent laminated composites via incorporation of a fluoride-containing linear interfacial compatibilizer[J]. Composites Science and Technology,2021,210:108838. doi: 10.1016/j.compscitech.2021.108838 [18] 中国航空工业总公司. 碳纤维复合材料层合板I型层间断裂韧性GIC试验方法: HB 7402-96[S]. 北京: 中国航空工业总公司, 1997.Aviation Industry Corporation of China. Test method for mode I interlaminar fracture toughness of carbon fiber-reinforced polymer matrix composites: HB 7402-96[S]. Beijing: Aviation Industry Corporation of China, 1997(in Chinese). [19] 中国航空工业总公司. 碳纤维复合材料层合板II型层间断裂韧性GIIC试验方法: HB 7403-96[S]. 北京: 中国航空工业总公司, 1997.Aviation Industry Corporation of China. Test method for mode II interlaminar fracture toughness of carbon fiber-reinforced polymer matrix composites: HB 7403-96[S]. Beijing: Aviation Industry Corporation of China, 1997(in Chinese). [20] 水兴瑶, 刘猛, 朱曜峰, 等. 水性上浆剂对碳纤维表面及碳纤维/环氧树脂复合材料界面性能的影响[J]. 复合材料学报, 2016, 33(2):273-279.SHUI Xingyao, LIU Meng, ZHU Yaofeng, et al. Effects of waterborne sizing agent on carbon fiber surface and properties of carbon fiber/epoxy composites interface[J]. Acta Materiae Compositae Sinica,2016,33(2):273-279(in Chinese). [21] 向东, 刘家良, 赵春霞, 等. 基于插层法协同提升碳纤维树脂基复合材料的导电性能与层间韧性[J]. 复合材料学报, 2022, 39(1):134-146.XIANG Dong, LIU Jialiang, ZHAO Chunxia, et al. Synergistic improvement of electrical conductivity and interlaminar toughness of carbon fiber resin matrix composites based on intercalation method[J]. Acta Materiae Compositae Sinica,2022,39(1):134-146(in Chinese). [22] RODRIGUEZ-GARCIA V, HERRAEZ M, MARTINEZ V, et al. Interlaminar and translaminar fracture toughness of automated manufactured bio-inspired CFRP laminates[J]. Composites Science and Technology,2022,219:109236. doi: 10.1016/j.compscitech.2021.109236 -

下载:

下载: