Defects in additive manufacturing of fiber-reinforced composites: research progress on formation causes and online monitoring

-

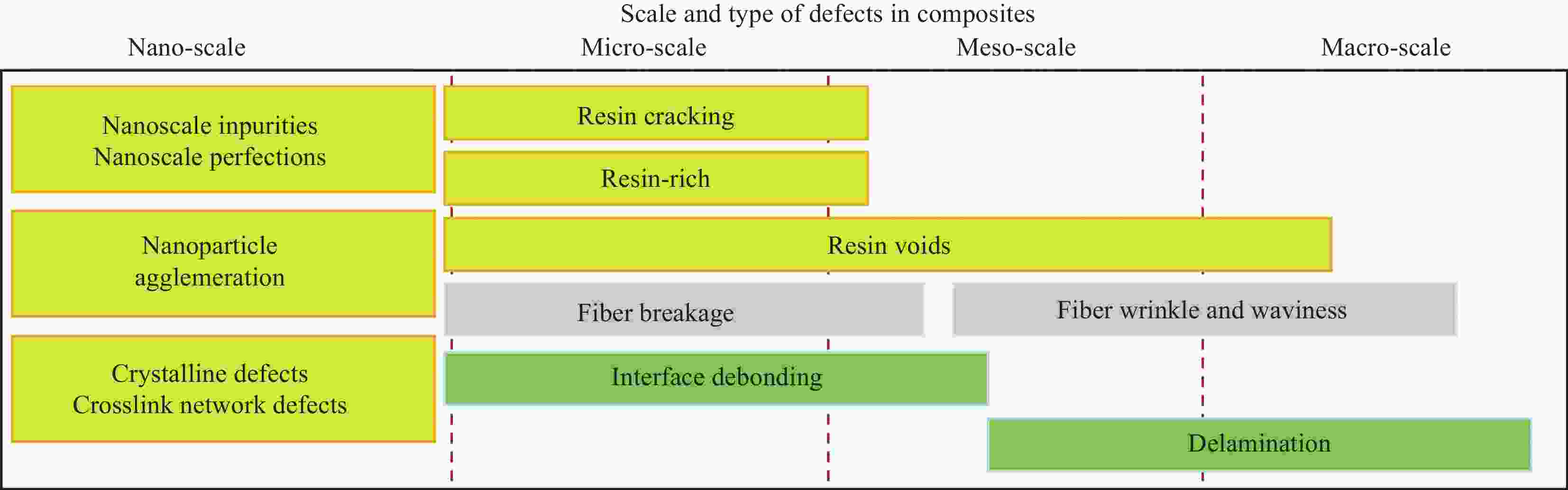

摘要: 纤维增强树脂基复合材料(FRC)因其高比强度、耐腐蚀和低成本等优异特性而被广泛应用于航空航天、轨道交通、风电能源等领域。然而,复合材料在成型过程中会发生复杂的物理与化学变化,不可避免地会产生内部缺陷;特别是在增材制造(AM)过程中,快速的升温-降温循环进一步增加了缺陷形成的概率。因此,成形缺陷与在线监测的研究对于提高纤维增强复合材料增材制造的质量具有重要意义。本文总结了复合材料树脂基体中残余应力、孔洞缺陷、富树脂缺陷以及界面缺陷的形成机制,分析了上述缺陷对于复合材料宏观力学性能的影响,探明了各类缺陷的微观成因。继而,结合缺陷的形成原因归纳了基于光纤布拉格光栅传感器、应变和位移传感器、声发射技术和热力学监测的在线监测技术,对其技术特点、应用案例及局限性展开了深入讨论,以期为相关的科学研究提供参考和借鉴。Abstract: Fiber-reinforced resin matrix composites (FRC) are extensively utilized in sectors such as aerospace, rail transportation, and wind energy due to their exceptional properties, including high specific strength, corrosion resistance, and cost-effectiveness. However, during the molding process, these composites undergo complex physical and chemical transformations that inevitably lead to the formation of internal defects. Notably, the rapid thermal cycling associated with additive manufacturing (AM) processes further escalates the likelihood of defect formation. Consequently, research into manufacturing defects and online monitoring is crucial for enhancing the quality of FRC produced through additive manufacturing. This study provides an in-depth summary of the mechanisms behind the formation of defects within the resin matrix of composites, including residual stress, porosity, resin-rich areas, and interfacial defects. It analyzes the impact of these defects on the macroscopic mechanical properties of the composites and elucidates the micro-level origins of each defect type. Subsequently, the paper consolidates online detection techniques based on Fiber Bragg Grating (FBG) sensors, strain and displacement sensors, acoustic emission technology, and thermodynamic monitoring. It discusses the technical characteristics, application scenarios, and limitations of these techniques, aiming to offer insights and references for scientific research in this field.

-

Key words:

- additive manufacturing /

- defects /

- fiber-reinforced composites /

- online monitoring /

- formation causes

-

图 8 (a)带有预热部分的打印喷嘴;(b) 预热部分关闭、加热块温度设置为410℃时打印喷嘴和复合丝的温度分布;(c)当预热温度设置为405℃、加热块温度设置为410℃时打印喷嘴和复合丝的温度分布[68]

Figure 8. (a) Printing nozzle with preheating part; (b) Temperature distribution of the printing nozzle and composite filament when the preheating part is off, and the temperature of heating block is set equal to 410℃; (c) Temperature distribution of the printing nozzle and composite filament when preheating temperature is set equal to 405℃, and the temperature of heating block is set equal to 410℃[68]

图 10 (a) 3D 打印CFRC0°方向纤维增强方向的示意图以及FBG传感器和热电偶的位置,(b)包含嵌入式FBG传感器和热电偶的3D打印CFRC试样[70]

Figure 10. (a) Schematic of the midplane of a 0° fiber reinforcement orientation of a 3D printed CFRTPC with the location of the FBG sensor and the thermocouple, and (b) picture of a 3D printed CFRTPC specimen containing an embedded FBG sensor and a thermocouple[70]

表 1 热塑性树脂结晶理论模型

Table 1. Theoretical model for thermoplastic resin crystallization

Purpose of model Equation Reference Crystallization kinetic equation $ {X}_{\mathrm{v}\mathrm{c}}={X}_{\mathrm{v}\mathrm{c}}^{\infty }\left[{w}_{1}{F}_{\mathrm{v}\mathrm{c}1}+\left(1-{w}_{1}\right){F}_{\mathrm{v}\mathrm{c}2}\right] $ [31] Isothermal crystallization process $ {F}_{\mathrm{v}\mathrm{c}\mathrm{i}}=1-exp\left({-K}_{\mathrm{i}}\left(T\right){n}_{\mathrm{i}}\cdot {t}^{\mathrm{n}-1}\right) $ [31] Non-isothermal crystallization process $ {F}_{\mathrm{v}\mathrm{c}\mathrm{i}}=1-exp\left[-{\int }_{0}^{t}{K}_{\mathrm{i}}\left(T\right){n}_{\mathrm{i}}\cdot {t}^{{\mathrm{n}}_{\mathrm{i}}-1}dt\right] $ [31] Crystallization of PEEK $ {X}_{\mathrm{v}\mathrm{c}}={X}_{\mathrm{v}\mathrm{c}}^{\infty }\left(1-exp\left(-{K}_{\mathrm{P}\mathrm{E}\mathrm{E}\mathrm{K}}\left(T\right)\cdot {t}^{\mathrm{n}}\right)\right) $ [32] Crystallization shrinkage strain $ {\dot{\varepsilon }}_{\mathrm{r}}^{\mathrm{c}}=\dfrac{-1+\sqrt{1+\left(4/3\right)\left[\dfrac{\rho {\left({X}_{\mathrm{v}\mathrm{c}}\right)}^{\mathrm{n}+1}-\rho {\left({X}_{\mathrm{v}\mathrm{c}}\right)}^{\mathrm{n}}}{\rho {\left({X}_{\mathrm{v}\mathrm{c}}\right)}^{\mathrm{n}}}\right]}}{2} $ [29] Linear solid kinetic-viscoelastic $ {S}^{\prime}={{S}^{\prime}_{\mathrm{a}\mathrm{m}}}\left(1-{X}_{\mathrm{v}\mathrm{c}}\right)+{{S}^{\prime}_{\mathrm{c}\mathrm{r}}}\left({X}_{\mathrm{v}\mathrm{c}}\right) $

$ {S}^{\prime\prime}={{S}^{\prime\prime}_{{\mathrm{a}}\mathrm{m}}}\left(1-{X}_{\mathrm{v}\mathrm{c}}\right)+{{S}^{\prime\prime}_{{\mathrm{c}\mathrm{r}}}}\left({X}_{\mathrm{v}\mathrm{c}}\right) $[30] Notes:Xmc is the ratio of the mass of the crystalline phase (mc) to the mass of the total crystalline phase; Xvc is the ratio of mass (mt) or crystal volume (Vc) to total volume; S' and S'' are the storage and loss bending compliance; S'am and S''am are the storage and loss bending compliance of non-crystal volume; S'cr and S''cr are the storage and loss bending compliance of crystal volume; Fvci is the normalized volume fraction crystallinity for the ith mechanism; w1 is the weight factors; Ki is the crystallization rate constant for the ith mechanism; ni is the Avrami exponent -

[1] TAKAGI H. Review of functional properties of natural fiber-reinforced polymer composites: Thermal insulation, biodegradation and vibration damping properties[J]. Advanced Composite Materials, 2019, 28(5): 525-543. doi: 10.1080/09243046.2019.1617093 [2] 陈意伟, 单忠德, 杨旭静, 等. 连续纤维增强PEEK增材制造力学性能与成型质量优化[J]. 工程塑料应用, 2022, 50(5): 61-67. doi: 10.3969/j.issn.1001-3539.2022.05.011CHEN Yiwei, SHAN Zhongde, YANG Xujing, et al. Parameter Optimization of Mechanical Properties and Forming Accuracy for Continuous Fiber Reinforced PEEK Additive Manufacturing[J]. Engineering Plastics Application, 2022, 50(5): 61-67(in Chinese). doi: 10.3969/j.issn.1001-3539.2022.05.011 [3] SWOLFS Y, MORTON H, SCOTT A E, et al. Synchrotron radiation computed tomography for experimental validation of a tensile strength model for unidirectional fibre-reinforced composites[J]. Composites Part A: Applied Science and Manufacturing, 2015, 77: 106-113. doi: 10.1016/j.compositesa.2015.06.018 [4] CHEN C H, CHENG C H. Effective elastic moduli of misoriented short-fiber composites[J]. International journal of solids and structures, 1996, 33(17): 2519-2539. doi: 10.1016/0020-7683(95)00160-3 [5] 杨磊, 周磊, 林宇东, 等. 激光增材制造连续碳纤维增强复合材料[J]. 机械工程学报, 2023, 59(19): 411-428. doi: 10.3901/JME.2023.19.411Yang Lei, Zhou Lei, Lin Yudong, et al. Laser Additive Manufacturing of Continuous Carbon Fiber Reinforced Composites[J]. Journal of Mechanical Engineering, 2023, 59(19): 411-428(in Chinese). doi: 10.3901/JME.2023.19.411 [6] POODTS E, MINAK G, MAZZOCCHETTI L, et al. Fabrication, process simulation and testing of a thick CFRP component using the RTM process[J]. Composites Part B: Engineering, 2014, 56: 673-680. doi: 10.1016/j.compositesb.2013.08.088 [7] NING F, CONG W, QIU J, et al. Additive manufacturing of carbon fiber reinforced thermoplastic composites using fused deposition modeling[J]. Composites Part B: Engineering, 2015, 80: 369-378. doi: 10.1016/j.compositesb.2015.06.013 [8] 陈杨, 何继敏, 常义, 等. 连续纤维增强复合材料模内混合注射成型研究进展[J]. 工程塑料应用, 2021, 49(09): 145-149+154.CHEN Yang, HE Jimin, CHANG Yi, et al. Research progress of in-mold hybrid injection molding of continuous fiber reinforced composites[J]. Engineering Plastics Application, 2021, 49(9), 145–149, 154(in Chinese). [9] 于天淼, 高华兵, 王宝铭, 等. 碳纤维增强热塑性复合材料成型工艺的研究进展[J]. 工程塑料应用, 2018, 46(4): 139-144. doi: 10.3969/j.issn.1001-3539.2018.04.027YU Tianmiao, GAO Huabing, WANG Baoming, et al. Research progress of molding process of carbon fiber reinforced thermoplastic composites[J]. Engineering Plastics Application, 2018, 46(4): 139-144(in Chinese). doi: 10.3969/j.issn.1001-3539.2018.04.027 [10] RAHIM T N A T, ABDULLAH A M, MD Akil H. Recent developments in fused deposition modeling-based 3D printing of polymers and their composites[J]. Polymer Reviews, 2019, 59(4): 589-624. doi: 10.1080/15583724.2019.1597883 [11] CHEN Z, ZHAO D, LIU B, et al. 3D printing of multifunctional hydrogels[J]. Advanced Functional Materials, 2019, 29(20): 1900971. doi: 10.1002/adfm.201900971 [12] 张峻瀚, 杨宇, 刘贞鹏, 等. 连续碳纤维/环氧树脂基复合材料增材制造设备研制[J]. 轻纺工业与技术, 2024, 53(2): 14-18. doi: 10.3969/j.issn.2095-0101.2024.02.005ZHANG Junhan, YANG Yu, LIU Zhenpeng, et al. Development of additive manufacturing equipment for continuous carbon fiber/epoxy resin-based composite materials[J]. Light and Textile Industry and Technology, 2024, 53(2): 14-18(in Chinese). doi: 10.3969/j.issn.2095-0101.2024.02.005 [13] SHARMA R, SINGH R, PENNA R, et al. Investigations for mechanical properties of Hap, PVC and PP based 3D porous structures obtained through biocompatible FDM filaments[J]. Composites Part B: Engineering, 2018, 132: 237-243. doi: 10.1016/j.compositesb.2017.08.021 [14] MING Y, DUAN Y, WANG B, et al. A novel route to fabricate high-performance 3D printed continuous fiber-reinforced thermosetting polymer composites[J]. Materials, 2019, 12(9): 1369. doi: 10.3390/ma12091369 [15] HAO W, LIU Y, ZHOU H, et al. Preparation and characterization of 3D printed continuous carbon fiber reinforced thermosetting composites[J]. Polymer Testing, 2018, 65: 29-34. doi: 10.1016/j.polymertesting.2017.11.004 [16] ZANJANIJAM A R, MAJOR I, LYONS J G, et al. Fused filament fabrication of peek: A review of process-structure-property relationships[J]. Polymers, 2020, 12(8): 1665. doi: 10.3390/polym12081665 [17] CHANDRASEKHAR A, MIRZENDEHDEL A, BEHANDISH M, et al. FRC-TOuNN: Topology Optimization of Continuous Fiber Reinforced Composites using Neural Network[J]. Computer-Aided Design, 2023, 156: 103449. doi: 10.1016/j.cad.2022.103449 [18] CHENG P, WANG K, Le Duigou A, et al. A novel dual-nozzle 3D printing method for continuous fiber reinforced composite cellular structures[J]. Composites Communications, 2023, 37: 101448. doi: 10.1016/j.coco.2022.101448 [19] CHEN R, BRATTEN A, RITTENHOUSE J, et al. Additive manufacturing of continuous carbon fiber-reinforced SiC ceramic composite with multiple fiber bundles by an extrusion-based technique[J]. Ceramics International, 2022, 49(6): 9839-9847. [20] DONG W, BAO C, LU W, et al. Fabrication of a continuous carbon fiber-reinforced phenolic resin composites via in situ-curing 3D printing technology[J]. Composites Communications, 2023, 38: 101497. doi: 10.1016/j.coco.2023.101497 [21] GUO A, LIU C, LI S, et al. Water absorption rates and mechanical properties of material extrusion-printed continuous carbon fiber-reinforced nylon composites[J]. Journal of Materials Research and Technology, 2022, 21: 3098-3112. doi: 10.1016/j.jmrt.2022.10.134 [22] BRENKEN B, BAROCIO E, FAVALORO A, et al. Fused filament fabrication of fiber-reinforced polymers: A review[J]. Additive Manufacturing, 2018, 21: 1-16. doi: 10.1016/j.addma.2018.01.002 [23] ALIHEIDARI N, CHRIST J, TRIPURANENI R, et al. Interlayer adhesion and fracture resistance of polymers printed through melt extrusion additive manufacturing process[J]. Materials & Design, 2018, 156: 351-361. [24] YANG C, TIAN X, LIU T, et al. 3D printing for continuous fiber reinforced thermoplastic composites: mechanism and performance[J]. Rapid Prototyping Journal, 2017, 23(1): 209-215. doi: 10.1108/RPJ-08-2015-0098 [25] NING F, CONG W, QIU J, et al. Additive manufacturing of carbon fiber reinforced thermoplastic composites using fused deposition modeling[J]. Composites Part B: Engineering, 2015, 80: 369-378. doi: 10.1016/j.compositesb.2015.06.013 [26] BLOK L G, LONGANA M L, YU H, et al. An investigation into 3D printing of fibre reinforced thermoplastic composites[J]. Additive Manufacturing, 2018, 22: 176-186. doi: 10.1016/j.addma.2018.04.039 [27] CAI J, QIU L, YUAN S, et al. Structural health monitoring for composite materials[M]//Composites and their applications. IntechOpen, 2012. [28] YUAN S, LI S, ZHU J, et al. Additive manufacturing of polymeric composites from material processing to structural design[J]. Composites Part B: Engineering, 2021, 219: 108903. doi: 10.1016/j.compositesb.2021.108903 [29] BARAN I, CINAR K, ERSOY N, et al. A review on the mechanical modeling of composite manufacturing processes[J]. Archives of computational methods in engineering, 2017, 24: 365-395. doi: 10.1007/s11831-016-9167-2 [30] BRAUNER C, PETERS C, BRANDWEIN F, et al. Analysis of process-induced deformations in thermoplastic composite materials[J]. Journal of Composite Materials, 2014, 48(22): 2779-2791. doi: 10.1177/0021998313502101 [31] TIERNEY J J, GILLESPIE Jr J W. Crystallization kinetics behavior of PEEK based composites exposed to high heating and cooling rates[J]. Composites Part A: Applied science and manufacturing, 2004, 35(5): 547-558. doi: 10.1016/j.compositesa.2003.12.004 [32] CHEN P, CAI H, LI Z, et al. Crystallization kinetics of polyetheretherketone during high temperature-selective laser sintering[J]. Additive Manufacturing, 2020, 36: 101615. doi: 10.1016/j.addma.2020.101615 [33] JUDD N C W. VOIDS AND THEIR EFFECTS ON THE MECHANICAL PROPERTIES OF COMPOSITES. AN APPROVISAL[J]. 1978. [34] HUANG H, TALREJA R. Effects of void geometry on elastic properties of unidirectional fiber reinforced composites[J]. Composites Science and Technology, 2005, 65(13): 1964-1981. doi: 10.1016/j.compscitech.2005.02.019 [35] KARDOS J L, DUDUKOVIĆ M P, DAVE R. Void growth and resin transport during processing of thermosetting—Matrix composites[J]. Epoxy resins and composites IV, 1986: 101-123. [36] TEKINALP H L, KUNC V, VELEZ-GARCIA G M, et al. Highly oriented carbon fiber–polymer composites via additive manufacturing[J]. Composites Science and Technology, 2014, 105: 144-150. doi: 10.1016/j.compscitech.2014.10.009 [37] VAN DE Werken N, TEKINALP H, KHANBOLOUKI P, et al. Additively manufactured carbon fiber-reinforced composites: State of the art and perspective[J]. Additive Manufacturing, 2020, 31: 100962. doi: 10.1016/j.addma.2019.100962 [38] BLOK L G, LONGANA M L, YU H, et al. An investigation into 3D printing of fibre reinforced thermoplastic composites[J]. Additive Manufacturing, 2018, 22: 176-186. doi: 10.1016/j.addma.2018.04.039 [39] TIAN X, LIU T, YANG C, et al. Interface and performance of 3D printed continuous carbon fiber reinforced PLA composites[J]. Composites Part A: Applied Science and Manufacturing, 2016, 88: 198-205. doi: 10.1016/j.compositesa.2016.05.032 [40] CAMINERO M A, CHACÓN J M, GARCÍA-MORENO I, et al. Interlaminar bonding performance of 3D printed continuous fibre reinforced thermoplastic composites using fused deposition modelling[J]. Polymer Testing, 2018, 68: 415-423. doi: 10.1016/j.polymertesting.2018.04.038 [41] JUSTO J, TÁVARA L, GARCÍA-GUZMÁN L, et al. Characterization of 3D printed long fibre reinforced composites[J]. Composite Structures, 2018, 185: 537-548. doi: 10.1016/j.compstruct.2017.11.052 [42] HOU Z, TIAN X, ZHENG Z, et al. A constitutive model for 3D printed continuous fiber reinforced composite structures with variable fiber content[J]. Composites Part B: Engineering, 2020, 189: 107893. doi: 10.1016/j.compositesb.2020.107893 [43] JOSHI S C, SHEIKH A A. 3D printing in aerospace and its long-term sustainability[J]. Virtual and physical prototyping, 2015, 10(4): 175-185. doi: 10.1080/17452759.2015.1111519 [44] VALINO A D, DIZON J R C, ESPERA Jr A H, et al. Advances in 3D printing of thermoplastic polymer composites and nanocomposites[J]. Progress in Polymer Science, 2019, 98: 101162. doi: 10.1016/j.progpolymsci.2019.101162 [45] FU Y, YAO X. Multi-scale analysis for 3D printed continuous fiber reinforced thermoplastic composites[J]. Composites Science and Technology, 2021, 216: 109065. doi: 10.1016/j.compscitech.2021.109065 [46] FU Y, KAN Y, FAN X, et al. Novel designable strategy and multi-scale analysis of 3D printed thermoplastic fabric composites[J]. Composites Science and Technology, 2022, 222: 109388. doi: 10.1016/j.compscitech.2022.109388 [47] LI X, SHONKWILER S, MCMAINS S. Detection of resin-rich areas for statistical analysis of fiber-reinforced polymer composites[J]. Composites Part B: Engineering, 2021, 225: 109252. doi: 10.1016/j.compositesb.2021.109252 [48] ZHANG G, WANG Y, QIU W, et al. Geometric characteristics of single bead fabricated by continuous fiber reinforced polymer composite additive manufacturing[J]. Materials Today: Proceedings, 2022, 70: 431-437. doi: 10.1016/j.matpr.2022.09.361 [49] HUANG F, PANG X, ZHU F, et al. Transverse mechanical properties of unidirectional FRC including resin-rich areas[J]. Computational Materials Science, 2021, 198: 110701. doi: 10.1016/j.commatsci.2021.110701 [50] GHAYOOR H, MARSDEN C C, HOA S V, et al. Numerical analysis of resin-rich areas and their effects on failure initiation of composites[J]. Composites Part A: Applied Science and Manufacturing, 2019, 117: 125-133. doi: 10.1016/j.compositesa.2018.11.016 [51] AHMADIAN H, YANG M, SOGHRATI S. Effect of resin-rich zones on the failure response of carbon fiber reinforced polymers[J]. International Journal of Solids and Structures, 2020, 188: 74-87. [52] AL-SHAWK A, TANABI H, SABUNCUOGLU B. Investigation of stress distributions in the resin rich region and failure behavior in glass fiber composites with microvascular channels under tensile loading[J]. Composite Structures, 2018, 192: 101-114. doi: 10.1016/j.compstruct.2018.02.061 [53] LIU T, TIAN X, ZHANG M, et al. Interfacial performance and fracture patterns of 3D printed continuous carbon fiber with sizing reinforced PA6 composites[J]. Composites Part A: Applied Science and Manufacturing, 2018, 114: 368-376. doi: 10.1016/j.compositesa.2018.09.001 [54] LIU X, SHAN Z, LIU J, et al. Mechanical and dielectric properties of continuous glass fiber reinforced poly-ether-ether-ketone composite components prepared by additive manufacturing[J]. Additive Manufacturing, 2024, 81: 103978. doi: 10.1016/j.addma.2024.103978 [55] QIAO J, LI Y, LI L. Ultrasound-assisted 3D printing of continuous fiber-reinforced thermoplastic (FRTP) composites[J]. Additive Manufacturing, 2019, 30: 100926. doi: 10.1016/j.addma.2019.100926 [56] WANG F, WANG G, NING F, et al. Fiber–matrix impregnation behavior during additive manufacturing of continuous carbon fiber reinforced polylactic acid composites[J]. Additive Manufacturing, 2021, 37: 101661. doi: 10.1016/j.addma.2020.101661 [57] TIAN X, LIU T, YANG C, et al. Interface and performance of 3D printed continuous carbon fiber reinforced PLA composites[J]. Composites Part A: Applied Science and Manufacturing, 2016, 88: 198-205. doi: 10.1016/j.compositesa.2016.05.032 [58] OMURO R, UEDA M, MATSU-ZAKI R, et al. MECHANICAL TESTING[J]. SAMPE Journal, 2018, 54(5). [59] LUO M, TIAN X, SHANG J, et al. Impregnation and interlayer bonding behaviours of 3D-printed continuous carbon-fiber-reinforced poly-ether-ether-ketone composites[J]. Composites Part A: Applied Science and Manufacturing, 2019, 121: 130-138. doi: 10.1016/j.compositesa.2019.03.020 [60] LUO M, TIAN X, ZHU W, et al. Controllable interlayer shear strength and crystallinity of PEEK components by laser-assisted material extrusion[J]. Journal of Materials Research, 2018, 33(11): 1632-1641. doi: 10.1557/jmr.2018.131 [61] LUO M, TIAN X, SHANG J, et al. Bi-scale interfacial bond behaviors of CCF/PEEK composites by plasma-laser cooperatively assisted 3D printing process[J]. Composites Part A: Applied Science and Manufacturing, 2020, 131: 105812. doi: 10.1016/j.compositesa.2020.105812 [62] MCILROY C, OLMSTED P D. Disentanglement effects on welding behaviour of polymer melts during the fused-filament-fabrication method for additive manufacturing[J]. Polymer, 2017, 123: 376-391. doi: 10.1016/j.polymer.2017.06.051 [63] KUMRAI-WOODRUFF R, WANG Q. Temperature control to increase inter-layer bonding strength in fused deposition modelling[C]//International Design Engineering Technical Conferences and Computers and Information in Engineering Conference. American Society of Mechanical Engineers, 2020, 83952: V006T06A002. [64] LUO M, TIAN X, SHANG J, et al. Impregnation and interlayer bonding behaviours of 3D-printed continuous carbon-fiber-reinforced poly-ether-ether-ketone composites[J]. Composites Part A: Applied Science and Manufacturing, 2019, 121: 130-138. doi: 10.1016/j.compositesa.2019.03.020 [65] RAVI A K, DESHPANDE A, HSU K H. An in-process laser localized pre-deposition heating approach to inter-layer bond strengthening in extrusion based polymer additive manufacturing[J]. Journal of Manufacturing Processes, 2016, 24: 179-185. doi: 10.1016/j.jmapro.2016.08.007 [66] KISHORE V, AJINJERU C, NYCZ A, et al. Infrared preheating to improve interlayer strength of big area additive manufacturing (BAAM) components[J]. Additive Manufacturing, 2017, 14: 7-12. doi: 10.1016/j.addma.2016.11.008 [67] ZHANG J, YANG W, LI Y. Process-dependent multiscale modeling for 3D printing of continuous fiber-reinforced composites[J]. Additive Manufacturing, 2023, 73: 103680. 、 [68] LIU X, SHAN Z, LIU J, et al. Mechanical and electrical properties of additive manufactured high-performance continuous glass fiber reinforced PEEK composites[J]. Composites Part B: Engineering, 2022, 247: 110292. doi: 10.1016/j.compositesb.2022.110292 [69] LEWIS J, MOORE A L. In situ infrared temperature sensing for real-time defect detection in additive manufacturing[J]. Additive Manufacturing, 2021, 47: 102328. doi: 10.1016/j.addma.2021.102328 [70] KOUSIATZA C, KARALEKAS D. In-situ monitoring of strain and temperature distributions during fused deposition modeling process[J]. Materials & Design, 2016, 97: 400-406. [71] KOUSIATZA C, TZETZIS D, Karalekas D. In-situ characterization of 3D printed continuous fiber reinforced composites: A methodological study using fiber Bragg grating sensors[J]. Composites Science and Technology, 2019, 174: 134-141. doi: 10.1016/j.compscitech.2019.02.008 [72] CHEN J, LIU B, ZHANG H. Review of fiber Bragg grating sensor technology[J]. Frontiers of Optoelectronics in China, 2011, 4: 204-212. doi: 10.1007/s12200-011-0130-4 [73] DENG J, RASHID K, LI X, et al. Comparative study on prestress loss and flexural performance of rectangular and T beam strengthened by prestressing CFRC plate[J]. Composite Structures, 2021, 262: 113340. doi: 10.1016/j.compstruct.2020.113340 [74] RAHMAN M T, MOSER R, ZBIB H M, et al. 3D printed high performance strain sensors for high temperature applications[J]. Journal of Applied Physics, 2018, 123(2). [75] GOODING J, FIELDS T. 3d printed strain gauge geometry and orientation for embedded sensing[C]//58th AIAA/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference. 2017: 0350. [76] DIJKSHOORN A, WERKMAN P, WELLEWEERD M, et al. Embedded sensing: Integrating sensors in 3-D printed structures[J]. Journal of Sensors and Sensor Systems, 2018, 7(1): 169-181. doi: 10.5194/jsss-7-169-2018 [77] SHEMELYA C, BANUELOS-CHACON L, MELENDEZ A, et al. Multi-functional 3D printed and embedded sensors for satellite qualification structures[C]//2015 IEEE SENSORS. IEEE, 2015: 1-4. [78] MUNASINGHE N, WOODs M, MILES L, et al. 3-D printed strain sensor for structural health monitoring[C]//2019 IEEE International Conference on Cybernetics and Intelligent Systems (CIS) and IEEE Conference on Robotics, Automation and Mechatronics (RAM). IEEE, 2019: 275-280. [79] MUTH J T, VOGT D M, TRUBY R L, et al. Embedded 3D printing of strain sensors within highly stretchable elastomers[J]. Advanced materials, 2014, 26(36): 6307-6312. doi: 10.1002/adma.201400334 [80] AN B, MA Y, LI W, et al. Three-dimensional multi-recognition flexible wearable sensor via graphene aerogel printing[J]. Chemical Communications, 2016, 52(73): 10948-10951. doi: 10.1039/C6CC05910D [81] ZHANG Z, LONG Y, YANG Z, et al. An investigation into printing pressure of 3D printed continuous carbon fiber reinforced composites[J]. Composites Part A: Applied Science and Manufacturing, 2022, 162: 107162. doi: 10.1016/j.compositesa.2022.107162 [82] DE BACKER W, SINKEZ P, CHHABRA I, et al. In-process monitoring of continuous fiber additive manufacturing through force/torque sensing on the nozzle[C]//AIAA scitech 2020 forum. 2020: 1632. [83] ZHANG P, ZHOU W, YIN H, et al. Progressive damage analysis of three-dimensional braided composites under flexural load by micro-CT and acoustic emission[J]. Composite Structures, 2019, 226: 111196. doi: 10.1016/j.compstruct.2019.111196 [84] PAN Z, ZHOU W, ZHANG K, et al. Flexural damage and failure behavior of 3D printed continuous fiber composites by complementary nondestructive testing technology[J]. Polymer Composites, 2022, 43(5): 2864-2877. doi: 10.1002/pc.26582 [85] YANG Z, JIN L, YAN Y, et al. Filament breakage monitoring in fused deposition modeling using acoustic emission technique[J]. Sensors, 2018, 18(3): 749. doi: 10.3390/s18030749 [86] LU L, YUAN S, YAO X, et al. In-situ process evaluation for continuous fiber composite additive manufacturing using multisensing and correlation analysis[J]. Additive Manufacturing, 2023, 74: 103721. doi: 10.1016/j.addma.2023.103721 [87] LU L, HOU J, YUAN S, et al. Deep learning-assisted real-time defect detection and closed-loop adjustment for additive manufacturing of continuous fiber-reinforced polymer composites[J]. Robotics and Computer-Integrated Manufacturing, 2023, 79: 102431. doi: 10.1016/j.rcim.2022.102431 -

点击查看大图

点击查看大图

计量

- 文章访问数: 41

- HTML全文浏览量: 26

- 被引次数: 0

下载:

下载: