Biomechanical properties of a customizable thermoplastic polyurethane/ polycaprolactone blended esophageal stent fabricated by 3D printing

-

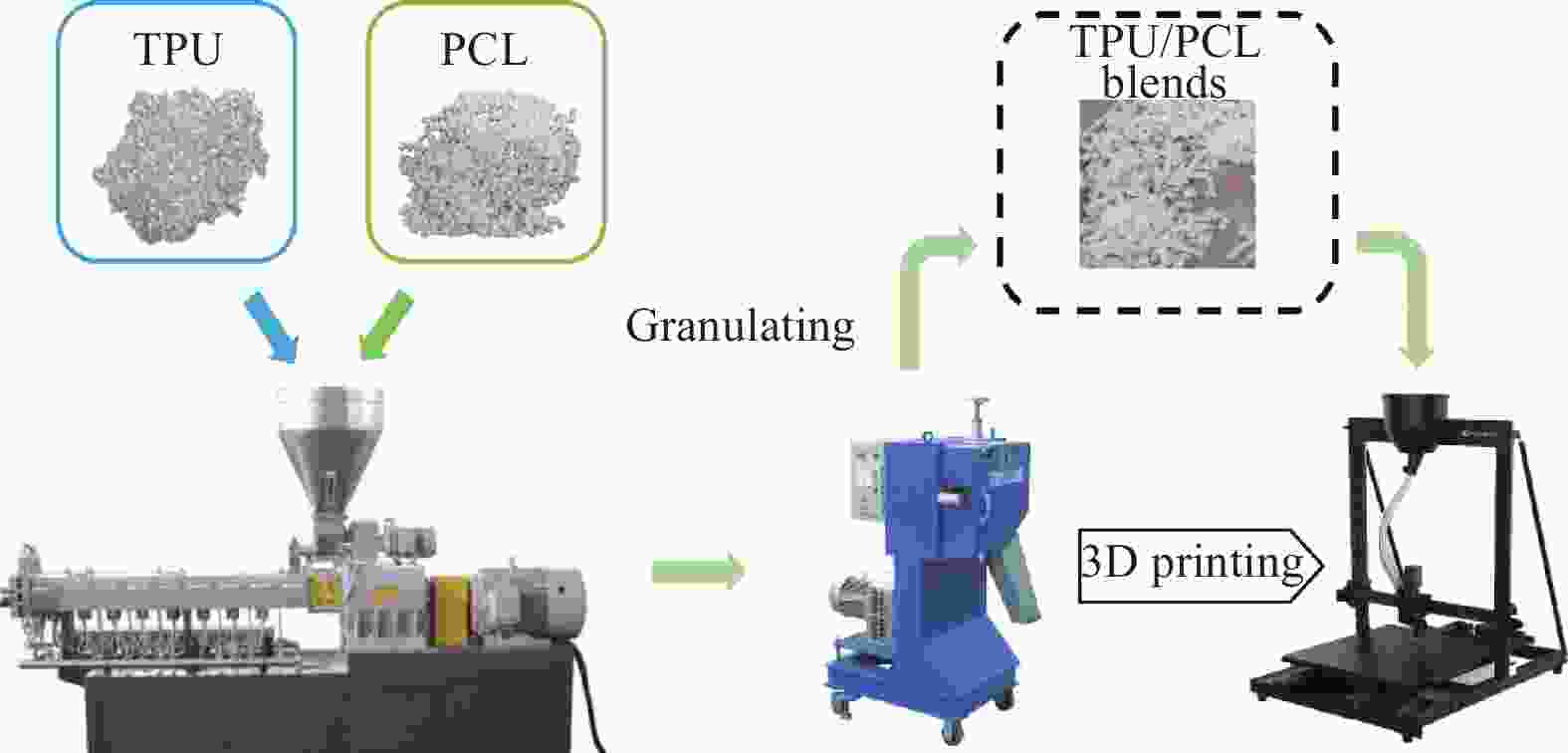

摘要: 食管支架在食管疾病的临床治疗中有广泛的应用。但商业食管支架尺寸固定,无法根据患者食管的几何形状进行个性化定制。通过熔融共混结合3D打印技术的方式制备了一种热塑性聚氨酯(TPU)/聚己内酯(PCL)共混物食管支架,并基于对TPU/PCL组分比例的调节,实现了对支架力学性能的调控。通过差示扫描量热、热重分析、力学试验、体外降解试验和细胞毒性检测研究了TPU/PCL共混物的理化特性及支架的各项关键指标。结果表明,TPU/PCL共混物具有良好的材料相容性和力学性能,且细胞活性为72.9%,对细胞无潜在毒性。经过为期8周的体外降解试验,支架的重量损失均小于2%,且力学性能无明显变化。3D打印TPU/PCL共混物支架优越的力学和生物学性能证明了其在食管狭窄的临床个性化治疗中具有潜在应用前景。Abstract: Esophageal stents were widely used in the clinical therapy of esophageal diseases. However, commercial esophageal stents had fixed sizes and cannot be personalized according to esophageal geometry of patient. A thermoplastic polyurethane (TPU)/polycaprolactone (PCL) blend esophageal stent was prepared by melt blending combined with 3D printing technology. Based on the adjustment of TPU/PCL component ratio, the mechanical properties of the stent were regulated. The physicochemical properties of TPU/PCL blends and the key parameters of the stents were investigated by differential scanning calorimetry, thermogravimetric analysis, mechanical tests, in vitro degradation tests and cytotoxicity assays. The results show that the TPU/PCL blends exhibit favorable compatibility and mechanical properties, and the cellular activity is 72.9% with no potential toxicity to cells. The weight of the stents is less than 2%, and the mechanical properties do not change significantly after 8-week in vitro degradation test. The superior mechanical and biologic features of 3D printed TPU/PCL blended stent demonstrate the potential application in the clinical personalized treatment of esophageal stenosis.

-

Key words:

- 3D printing /

- Esophageal stent /

- Mechanical property /

- TPU/PCL /

- Biocompatibility

-

表 1 不同组分比TPU/PCL共混物的打印参数

Table 1. Printing parameters of TPU/PCL blends with different component ratios

Sample Nozzle

temperature/℃Build plate

temperature /℃TPU 210 50 80TPU/20PCL 210 35 70TPU/30PCL 210 35 60TPU/40PCL 210 35 PCL 100 35 Notes: Printing speed: 20 mm/s. Layer height: 0.1 mm. 表 2 不同组分比TPU/PCL共混物的弯曲力学性能

Table 2. Flexural mechanical properties of TPU/PCL blends with different component ratios

Sample Flexural modulus/MPa Flexural strength/MPa Maximal force/N TPU 9.0±0.27 0.8±0.01 1.2±0.03 80TPU/20PCL 23.7±0.47 1.6±0.05 3.1±0.22 70TPU/30PCL 42.0±0.00 2.3±0.04 3.8±0.06 60TPU/40PCL 62.0±4.08 3.0±0.04 5.0±0.07 PCL 416.7±4.72 13.9±0.03 23.1±0.05 -

[1] YANG K, CAO J, YUAN T W, et al. Silicone-covered biodegradable magnesium stent for treating benign esophageal stricture in a rabbit model[J]. World Journal of Gastroenterology, 2019, 25(25): 3207-3217. doi: 10.3748/wjg.v25.i25.3207 [2] 贺迎, 崔永. 食管支架的研究进展[J]. 中国胸心血管外科临床杂志, 2018, 25(2): 164-170.HE Ying, CUI Yong. Advance in research of esophageal stent[J]. Chinese Journal of Clinical Thoracic and Cardiovascular Surgery, 2018, 25(2): 164-170(in Chinese). [3] MANGIAVILLANO B, PAGANO N, ARENA M, et al. Role of stenting in gastrointestinal benign and malignant diseases[J]. World Journal of Gastrointestinal Endoscopy, 2015, 7(5): 460-480. doi: 10.4253/wjge.v7.i5.460 [4] DIDDEN P, SPAANDER M C W, BRUNO M J, et al. Esophageal Stents in malignant and benign disorders[J]. Current Gastroenterology Reports, 2013, 15(4): 319. doi: 10.1007/s11894-013-0319-3 [5] 徐元丰, 黄优华, 沈涛, 等. 金属覆膜支架在食管癌术后食管-气管瘘的临床应用[J]. 中国卫生产业, 2014, 11(29): 133-134.XU Yuanfeng, HUANG Youhua, SHEN Tao, et al. Clinical application of metal-coated stents in postoperative esophageal-tracheal fistula after esophageal cancer surgery[J]. China Health Industry, 2014, 11(29): 133-134(in Chinese). [6] JAIN P. Self-expanding metallic esophageal stents: A long way to go before a particular stent can be recommended[J]. World Journal of Gastroenterology, 2011, 17(48): 5327-5328. doi: 10.3748/wjg.v17.i48.5327 [7] FIORELLI A, ESPOSITO G, PEDICELLI I, et al. Large tracheobronchial fistula due to esophageal stent migration: Let it be![J]. Asian Cardiovascular & Thoracic Annals, 2015, 23(9): 1106-1109. [8] GROSS B C, ERKAL J L, LOCKWOOD S Y, et al. Evaluation of 3D printing and its potential impact on biotechnology and the chemical sciences[J]. Analytical Chemistry, 2014, 86(7): 3240-3253. doi: 10.1021/ac403397r [9] CHIA H N, WU B M. Recent advances in 3D printing of biomaterials[J]. Journal of Biological Engineering, 2015, 9(1). [10] ZHU Yizhen, JORALMON D, SHAN W T, et al. 3D printing biomimetic materials and structures for biomedical applications[J]. Bio-Design and Manufacturing, 2021, 4(2): 405-428. doi: 10.1007/s42242-020-00117-0 [11] 贾李涵, 李岩. 3D打印纳米纤维素增强聚乳酸血管支架的体外力学性能研究[J]. 复合材料科学与工程, 2021, 2021(5): 61-67.JIA Lihan, LI Yan. In vitro experimental study on the mechanical properties of vascular stents prepared by 3D printing nanocellulose/poly (lactic acid) nanocomposites[J]. Composites Science and Engineering, 2021, 2021(5): 61-67(in Chinese). [12] YANG Y, YANG S B, WANG Y G, et al. Anti-infective efficacy, cytocompatibility and biocompatibility of a 3D-printed osteoconductive composite scaffold functionalized with quaternized chitosan[J]. Acta Biomaterialia, 2016, 46: 112-128. doi: 10.1016/j.actbio.2016.09.035 [13] WANG X, JIANG M, ZHOU Z W, et al. 3D printing of polymer matrix composites: A review and prospective[J]. Composites Part B, 2016, 110: 442-458. [14] JAYSWAL A, ADANUR S. Characterization of PLA/TPU composite filaments manufactured for 3D printing with FDM[J]. Journal of Thermoplastic Composite Materials, 2023, 36(4): 1450-1471. doi: 10.1177/08927057211062561 [15] SIDDIQUI N, ASAWA S, BIRRU B, et al. PCL-Based Composite Scaffold Matrices for Tissue Engineering Applications[J]. Molecular Biotechnology, 2018, 60(7): 506-532. doi: 10.1007/s12033-018-0084-5 [16] WANG Q F, MA Z Y, WANG Y, et al. Fabrication and characterization of 3D printed biocomposite scaffolds based on PCL and zirconia nanoparticles[J]. Bio-Design and Manufacturing, 2021, 4(1): 60-71. doi: 10.1007/s42242-020-00095-3 [17] MALIKMAMMADOV E, TANIR T E, KIZILTAY A, et al. PCL and PCL-based materials in biomedical applications[J]. Journal of Biomaterials Science-Polymer Edition, 2018, 29(7-9): 863-893. doi: 10.1080/09205063.2017.1394711 [18] FRYN P, JEWLOSZEWICZ B, BOGDANOWICZ A B, et al. Research of binary and ternary composites based on selected aliphatic or aliphatic–aromatic polymers, 5CB or SWCN toward biodegradable electrodes[J]. Materials, 2020, 13(11). [19] 曾娇, 汪艳, 何畯涛, 等. 3D打印具有形状记忆效应的TPU/PCL复合材料研究[J]. 工程塑料应用, 2021, 49(9): 77-81. doi: 10.3969/j.issn.1001-3539.2021.09.015ZENG Jia, WANG Yan, HE Juntao, et al. Research on 3D Printing TPU/PCL composite material with shape memory effect[J]. Engineering Plastics Application, 2021, 49(9): 77-81(in Chinese). doi: 10.3969/j.issn.1001-3539.2021.09.015 [20] JING X, MI H Y, HUANG H X, et al. Shape memory thermoplastic polyurethane (TPU) /poly(ε-caprolactone) (PCL) blends as self-knotting sutures[J]. Journal of the Mechanical Behavior of Biomedical Materials, 2016, 64: 94-103. doi: 10.1016/j.jmbbm.2016.07.023 [21] SABAHI N, ROOHANI I, Wang C H, et al. Thermoplastic polyurethane-based shape memory polymers with potential biomedical application: The effect of TPU soft-segment on shape memory effect and cytocompatibility[J]. Polymer, 2023, 283: 126189. doi: 10.1016/j.polymer.2023.126189 [22] 王慧. FDM型打印机打印骨软骨双层支架用于骨软骨损伤修复的研究[D]. 长春: 吉林大学, 2022.WANG Hui. Research on repairing osteochondral injury with double-layer scaffolds printed by FDM printer[D]. Changchun: Jilin University, 2022(in Chinese). [23] 李颖, 左龙, 陈宝书. 热塑性聚氨酯/聚己内酯共混物的形状记忆和力学性能[J]. 高分子材料科学与工程, 2017, 33(10): 72-75.LI Ying, ZUO Long, CHEN Baoshu. Shape memory and mechanical properties of Polyurethane/Polycaprolactone blends[J]. Polymer Materials Science & Engineering, 2017, 33(10): 72-75(in Chinese). [24] International Organization for Standardization. Plastics-Determination of tensile properties-Part 2: Test conditions for moulding and extrusion plastics: ISO 527-2[S]. Switzerland, 2012. [25] International Organization for Standardization. Plastics—Determination of flexural properties: ISO 178-2019[S]. Switzerland, 2019. [26] LIN M H, FIROOZI N, TSAI C T, et al. 3D-printed flexible polymer stents for potential applications in inoperable esophageal malignancies[J]. Acta Biomaterialia, 2019, 83: 119-129. doi: 10.1016/j.actbio.2018.10.035 [27] International Organization for Standardization. Biological evaluation of medical devices-Part 5: Tests for in vitro cytotoxicity: ISO 10993-5: 2009[J]. Switzerland, 2009. [28] GARBEY M, SALMON R, FIKFAK V, et al. Esophageal stent migration: Testing few hypothesis with a simplified mathematical model[J]. Computers in Biology and Medicine, 2016, 79: 259-265. doi: 10.1016/j.compbiomed.2016.10.024 [29] HINDY P, HONG J, LAM-TSAI Y, et al. A comprehensive review of esophageal stents[J]. Gastroenterology & Hepatology, 2012, 8(8): 526-34. [30] SINGH J, PANDEY P M, KAUR T, et al. A comparative analysis of solvent cast 3D printed carbonyl iron powder reinforced polycaprolactone polymeric stents for intravascular applications[J]. Journal of Biomedical Materials Research Part B-Applied Biomaterials, 2021, 109(9): 1344-1359. doi: 10.1002/jbm.b.34795 [31] SINGH J, SINGH G, PANDEY P M. Multi-objective optimization of solvent cast 3D printing process parameters for fabrication of biodegradable composite stents[J]. The International Journal of Advanced Manufacturing Technology, 2021, 115(11-12): 3945-3964. doi: 10.1007/s00170-021-07423-6 [32] RINCON O N, MADRIGAL A H, RODRIGUEZ B M, et al. Esophageal obstruction due to a collapsed biodegradable esophageal stent[J]. Endoscopy, 2011, 43: E189-E190. doi: 10.1055/s-0030-1256324 [33] YANG K, LING C, YUAN T W, et al. Polymeric biodegradable stent insertion in the esophagus[J]. Polymers, 2016, 8(5): 158. doi: 10.3390/polym8050158 [34] PILES L, REIG M J, JESUS SEGUI V, et al. Reverse engineering applied to biomodelling and pathological bone manufacturing using FDM technology[J]. Procedia Manufacturing, 2019, 41: 739-746. doi: 10.1016/j.promfg.2019.09.065 [35] 施伟, 罗飞. 基于CT数据的颌骨支架材料有限元分析及3D打印模型研究[J]. 基因组学与应用生物学, 2018, 37(10): 4553-4559.SHI Wei, LUO Fei. Research on finite element analysis of jaw bone scaffold materials and the 3D printing model based on CT datas[J]. Genomics and Applied Biology, 2018, 37(10): 4553-4559(in Chinese). -

点击查看大图

点击查看大图

计量

- 文章访问数: 57

- HTML全文浏览量: 31

- 被引次数: 0

下载:

下载: