Preparation and research of high capacity/high cycle stability porous waste cotton carbon cloth electrode

-

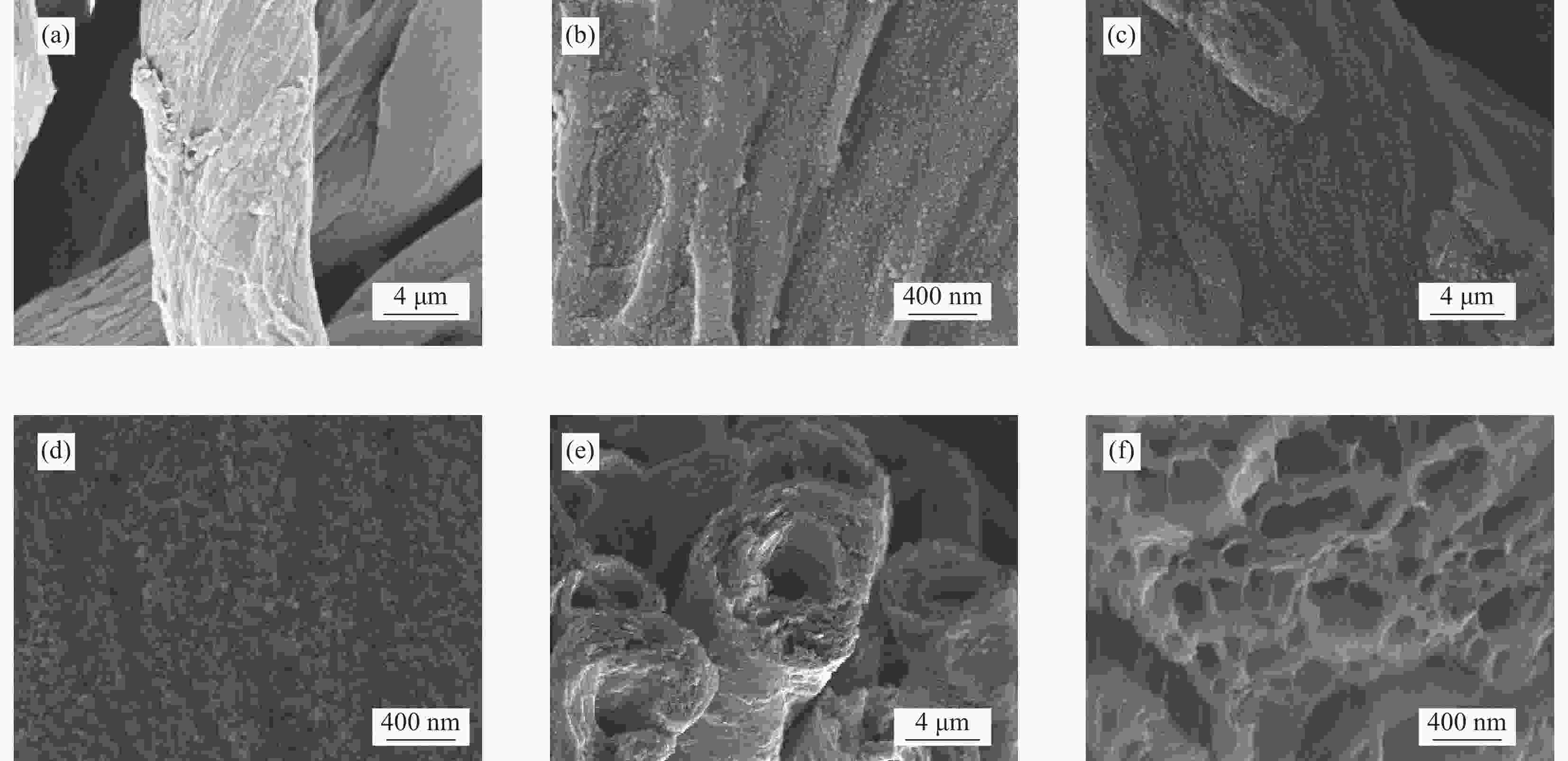

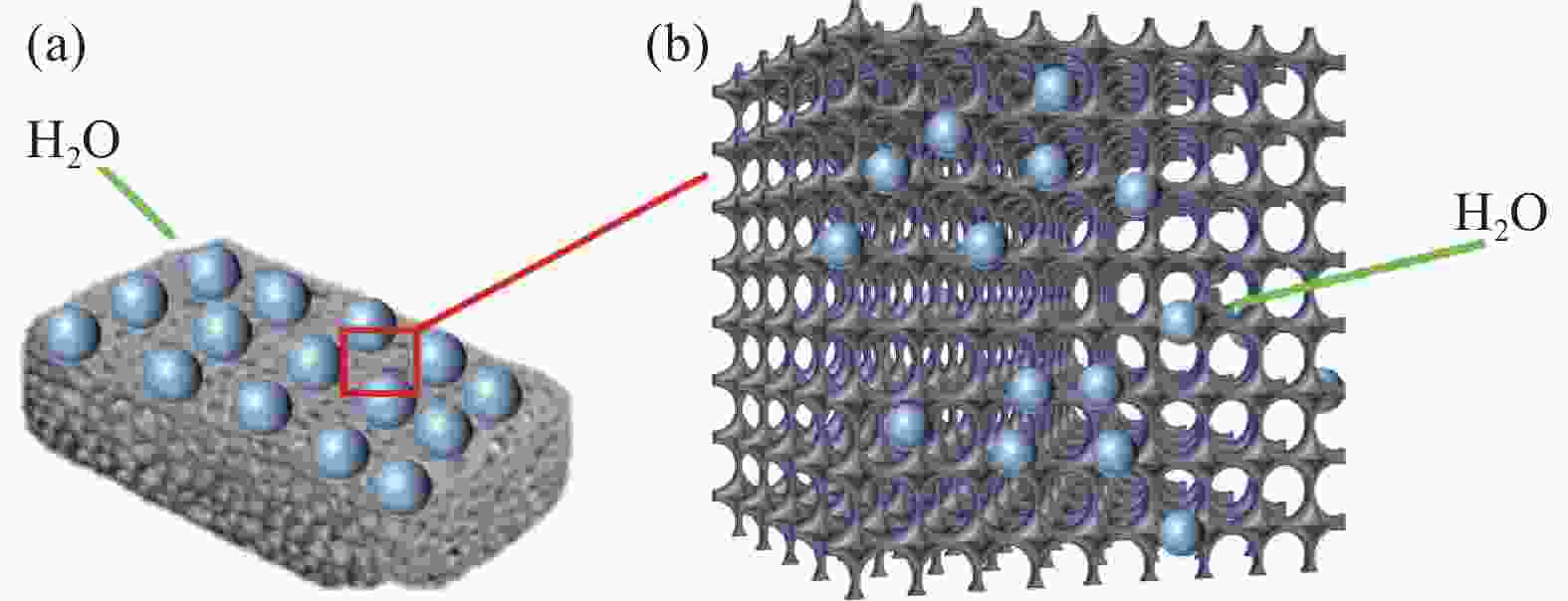

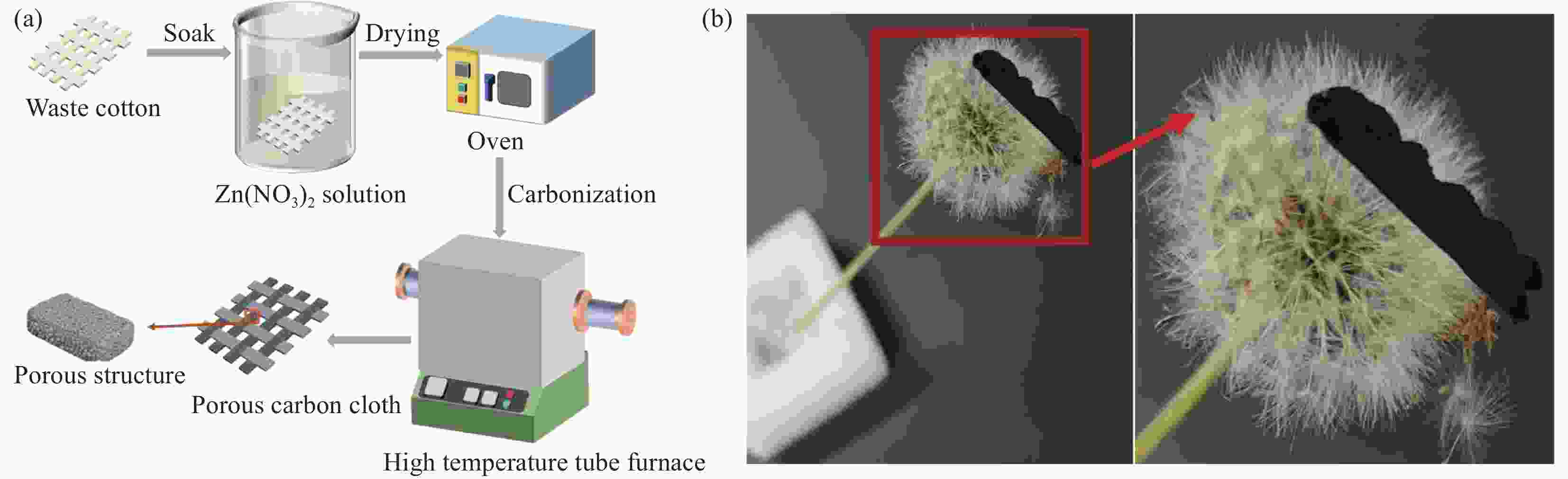

摘要: 随着生产力水平的提高,产生了大量的废旧纺织品,通过传统的焚烧和掩埋处理方法既造成了资源的浪费还产生了大量污染。为了使废旧棉具有更高的附加值,通过碳化技术制备为活性碳,使其在治理土壤污染、医药领域和储能领域都具有巨大应用价值,但其制备的碳材料具有比表面积小、容量低与电解质界面浸润性差等缺点。本文通过在废旧棉纺织品中首先引入Zn2+和NO3−离子,通过对Zn2+和NO3−离子浓度的调控,借助浸渍-烘干-碳化技术,制备了具有高比表面积的中空多孔碳布材料。结果表明,Zn(NO3)2具有优异的致孔能力,得到了具有微孔、介孔和大孔的多尺度孔洞结构的中空碳布,其比表面积高达1257.07 m2·g−1,界面浸润性优异。所制备的中空多孔碳布电极比电容高达251.5 F·g−1,5000次循环后容量保持率为100%,在储能领域中显示出了广阔的应用前景。Abstract: With the improvement of productivity level, a large number of waste textiles have been produced. The traditional incineration and burial treatment methods for waste textiles not only cause waste of resources but also generate a lot of pollution. In order to make waste cotton have higher added value, activated carbon is prepared by carbonization technology, which makes it have great application value in the field of soil pollution control, medicine, and energy storage. However, the prepared carbon material has disadvantages such as small specific surface area, low capacity, and poor wettability at the interface with the electrolyte. In this paper, Zn2+ and NO3− ions were first introduced into the waste cotton fabrics, and the hollow porous carbon cloth with a high specific surface area was prepared by adjusting the concentration of Zn2+ and NO3− ions and utilizing impregnation-drying-carbonization technology. The results show that Zn(NO3)2 has an excellent pore-forming ability, and a hollow carbon cloth with a multi-scale pore structure of micropores, mesopores, and macropores is obtained. The specific surface area is as high as 1257.07 m2·g−1, and the interfacial wettability is excellent. The prepared hollow porous carbon cloth electrode has a specific capacitance up to 251.5 F·g−1 and the capacity retention rate of 100% after 5000 cycles, showing a broad application prospect in the field of energy storage.

-

Key words:

- waste cotton /

- hollow /

- porous /

- carbon cloth /

- supercapacitor

-

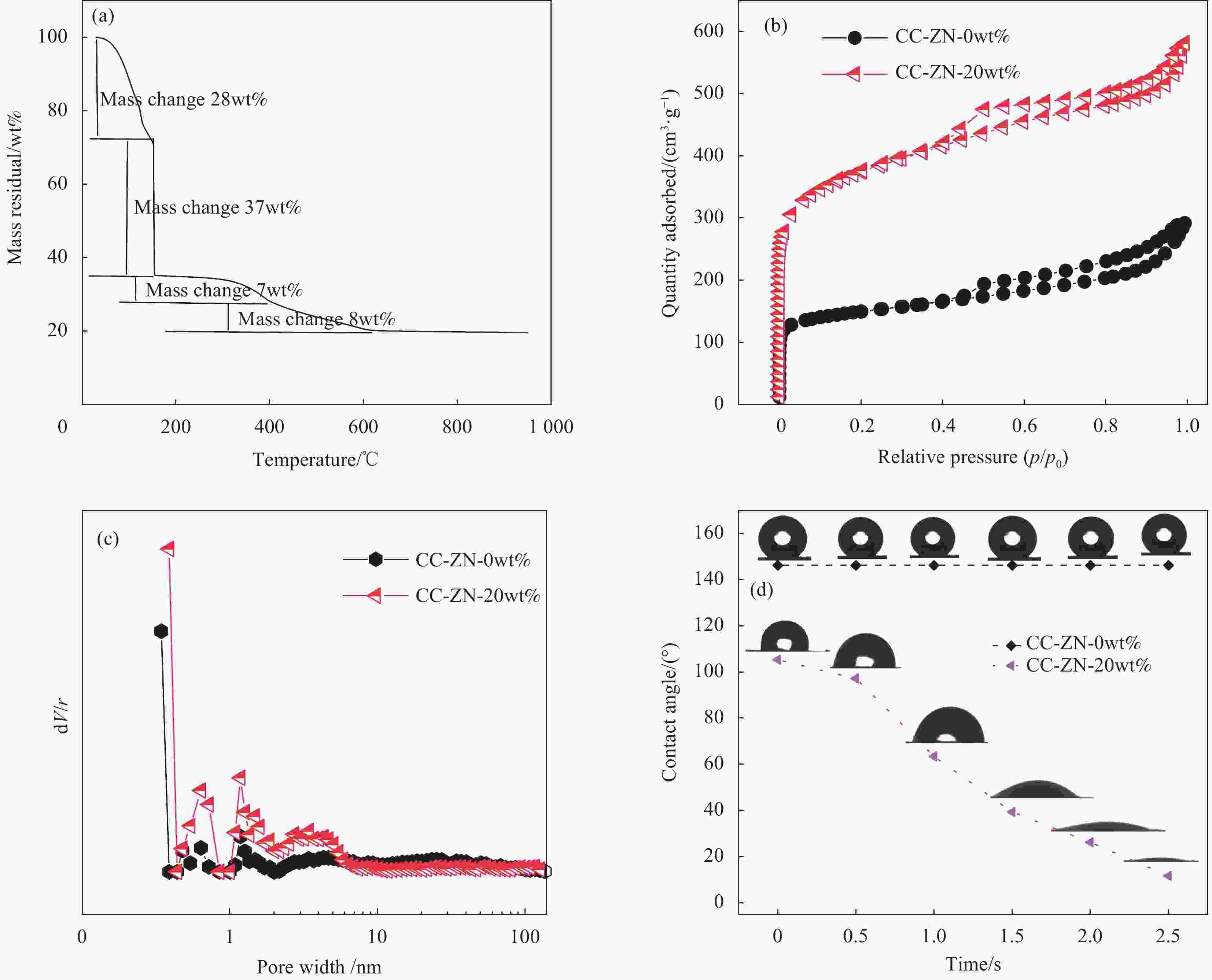

图 3 (a) N2氛围下CC-ZN-20wt%的TGA曲线;(b) 碳布的N2吸附-解吸等温曲线; (c) 密度泛函理论(DFT)的孔隙分布;(d) CC-ZN-0wt%与CC-ZN-20wt%的动态水接触角

Figure 3. (a) TGA curves of CC-ZN-20wt% measured under nitrogen atmosphere; (b) N2 adsorption-desorption isothermal curves of carbon cloth; (c) Pore distribution of density functional theory (DFT) of the carbon cloth; (d) Dynamic water contact angle between CC-ZN-0wt% and CC-ZN-20wt%

V—Volume; r—Radius

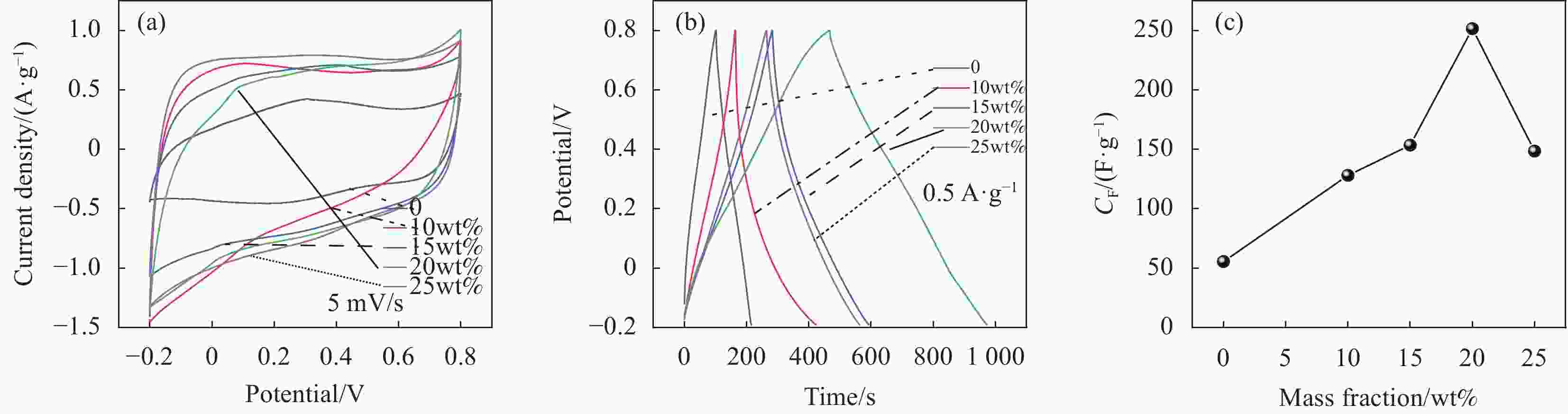

图 5 CC-ZN-x电极在三电极体系下电化学性能:(a) 不同质量分数 Zn(NO3)2浸泡的CC-ZN-x在5 mV/s 的CV曲线;(b) 不同质量分数Zn(NO3)2浸泡的CC-ZN-x在0.5 A·g−1GCD曲线;(c) 不同质量分数在0.5 A·g−1下的容量

Figure 5. Electrochemical performance of CC-ZN-x electrode in three-electrode system: (a) CV curves of CC-ZN-x at 5 mV/s for different mass fractions of Zn(NO3)2 immersion; (b) GCD curves of CC-ZN-x at 0.5 A·g−1 for different mass fractions of Zn(NO3)2 immersion; (c) Capacity for different mass fractions at 0.5 A·g−1

CF—Gravimetric capacitance

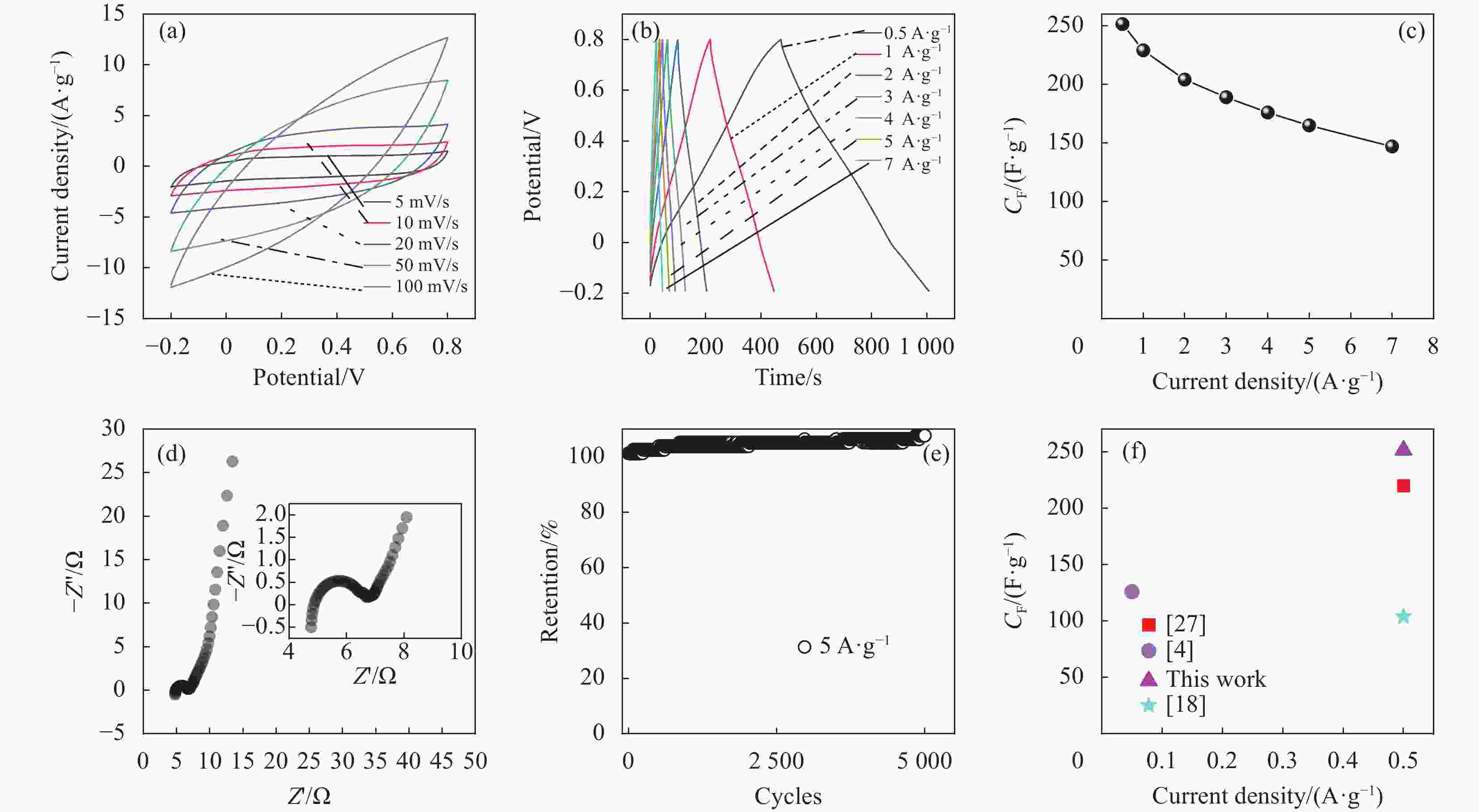

图 6 三电极体系下CC-ZN-20wt%的电化学性能:((a), (b)) 不同扫速下的CV曲线和不同电流密度下的GCD曲线;(c) 不同电流密度下的容量变化图;(d) 交流阻抗图谱;(e) 在5 A·g−1下5000次循环电容保持率;(f) 与其他多孔碳电极的比较

Figure 6. Electrochemical performance of CC-ZN-20wt% in a three-electrode system: ((a), (b)) CV curves at different scan rates and GCD curves at different current densities; (c) Capacity change diagram under different current densities; (d) EIS diagram; (e) Capacitance retention rate at 5 A·g−1 for 5000 cycles; (f) Comparison with other porous carbon electrodes

Z'—Real part of impedance; Z"—Imaginary part of impedance

图 7 对称电极体系下CC-ZN-20wt%的电化学性能:((a), (b)) 不同扫速下的CV曲线和不同电流密度下的GCD曲线;(c) 不同电流密度下的面积比容量;(d) 交流阻抗图;(e) 3 A·g−1下5000次循环容量保持率;(f) 基于CC-ZN-20wt%对称式超级电容器能量和功率密度图

Figure 7. Electrochemical performance of CC-ZN-20wt% at symmetrical electrode systems: ((a), (b)) CV curves at different scan rates and GCD curves at different current densities; (c) Area specific capacity at various current densities; (d) EIS diagram; (e) Capacity retention rate for 5000 cycles at 3 A·g−1; (f) Energy and power density diagram based on CC-ZN-20wt% symmetric supercapacitor

表 1 样品命名

Table 1. Sample naming

Sample Zn(NO3)2/wt% CC-ZN-0wt% 0 CC-ZN-10wt% 10 CC-ZN-15wt% 15 CC-ZN-20wt% 20 CC-ZN-25wt% 25 Notes: CC—Carbon cloth; ZN—Zn(NO3)2. 表 2 碳布孔隙结构参数

Table 2. Carbon cloth pore structure parameters

SBET/(m2·g−1) SM/(m2·g−1) Sext/(m2·g−1) Vtotal/(m2·g−1) Vmeso/(cm3·g−1) CC-ZN-0wt% 495.39 289.68 205.71 0.450 0.142 CC-ZN-20wt% 1257.07 661.22 595.85 0.897 0.318 Notes: SBET—Specific surface area by the BET method; SM—Specific surface area within micropores by the t-Plot method; Sext—t-Plot method external specific surface area; Vtotal—Total pore volume estimated by adsorption at p/p0=0.99; Vmeso—t-Plot method micropore volume. -

[1] HUANG J, WU J, DAI F, et al. 3D honeycomb-like carbon foam synthesized with biomass buckwheat flour for high-performance supercapacitor electrodes[J]. Chemical Communications,2019,55(62):9168-9171. doi: 10.1039/C9CC03039E [2] HUI S, JU T, LIN X, et al. Fabrication of NiCo2S4/carbon-filled nickel foam complex as an advanced binder-free electrode for supercapacitors[J]. Dalton Transactions,2020,49(35):12345-12353. doi: 10.1039/D0DT02160A [3] ONO Y, FUTAMURA R, HATTORI Y, et al. Adsorption-desorption mediated separation of low concentrated D2O from water with hydrophobic activated carbon fiber[J]. Journal of Colloid and Interface Science,2017,508:14-17. doi: 10.1016/j.jcis.2017.08.016 [4] SAGISAKA K, KONDO A, IIYAMA T, et al. Hollow structured porous carbon fibers with the inherent texture of the cotton fibers[J]. Chemical Physics Letters,2018,710:118-122. doi: 10.1016/j.cplett.2018.08.081 [5] REN J, BAI W, GUAN G, et al. Flexible and weaveable capacitor wire based on a carbon nanocomposite fiber[J]. Advanced Materials,2013,25(41):5965-5970. doi: 10.1002/adma.201302498 [6] SENTHILKUMAR N, GNANA KUMAR G, MANTHIRAM A. 3D hierarchical core-shell nanostructured arrays on carbon fibers as catalysts for direct urea fuel cells[J]. Advanced Energy Materials,2018,8(6):1702207. doi: 10.1002/aenm.201702207 [7] ZHAO G, LI Y, ZHU G, et al. Biomass-based N, P, and S self-doped porous carbon for high-performance supercapacitors[J]. ACS Sustainable Chemistry & Engineering,2019,7(14):12052-12060. [8] GUO D, SONG X, LI B, et al. Oxygen enriched carbon with hierarchical porous structure derived from biomass waste for high-performance symmetric supercapacitor with decent specific capacity[J]. Journal of Electroanalytical Chemistry,2019,855:113349. doi: 10.1016/j.jelechem.2019.113349 [9] DING C, LIU T, YAN X, et al. An ultra-microporous carbon material boosting integrated capacitance for cellulose-based supercapacitors[J]. Nano-Micro Letters,2020,12(1):1-17. doi: 10.1007/s40820-019-0337-2 [10] CHENG Y, ZHANG Q, FANG C, et al. Synthesis of N-doped porous carbon materials derived from waste cellulose acetate fiber via urea activation and its potential application in supercapacitors[J]. Journal of the Electrochemical Society,2019,166(6):A1231. doi: 10.1149/2.1081906jes [11] BO X, XIANG K, ZHANG Y, et al. Microwave-assisted conversion of biomass wastes to pseudocapacitive mesoporous carbon for high-performance supercapacitor[J]. Journal of Energy Chemistry,2019,39:1-7. doi: 10.1016/j.jechem.2019.01.006 [12] XUAN H, LIN G, WANG F, et al. Preparation of biomass-activated porous carbons derived from torreya grandis shell for high-performance supercapacitor[J]. Journal of Solid State Electrochemistry,2017,21(8):2241-2249. doi: 10.1007/s10008-017-3562-y [13] ZHAO Y, CUI Y, SHI J, et al. Two-dimensional biomass-derived carbon nanosheets and MnO/carbon electrodes for high-performance Li-ion capacitors[J]. Journal of Materials Chemistry A,2017,5(29):15243-15252. doi: 10.1039/C7TA04154C [14] 宋晓琪, 雷西萍, 樊凯, 等. 基于生物质衍生炭在超级电容器中的研究进展[J]. 复合材料学报, 2023, 40(3):1328-1339. doi: 10.13801/j.cnki.fhclxb.20220628.002SONG Xiaoqi, LEI Xiping, FAN Kai, et al. Research progress of biomass derived carbon in supercapacitors[J]. Acta Materiae Compositae Sinica,2023,40(3):1328-1339(in Chinese). doi: 10.13801/j.cnki.fhclxb.20220628.002 [15] 聂文琪, 孙江东, 许帅, 等. 纺织基超级电容器研究进展[J]. 复合材料学报, 2022, 39(3):977-988. doi: 10.13801/j.cnki.fhclxb.20211117.001NIE Wenqi, SUN Jiangdong, XU Shuai, et al. Textile-based for supercapacitors: A review[J]. Acta Materiae Compositae Sinica,2022,39(3):977-988(in Chinese). doi: 10.13801/j.cnki.fhclxb.20211117.001 [16] ZHAO J, LI X, LI X, et al. A flexible carbon electrode based on traditional cotton woven fabrics with excellent capacitance[J]. Journal of Materials Science,2017,52(16):9773-9779. doi: 10.1007/s10853-017-1161-z [17] SUN C, GUO Z, ZHOU M, et al. Heteroatoms-doped porous carbon electrodes with three-dimensional self-supporting structure derived from cotton fabric for high-performance wearable supercapacitors[J]. Journal of Power Sources,2021,482:228934. doi: 10.1016/j.jpowsour.2020.228934 [18] WANG Y, LU J, LIN X, et al. Synthesis of a cotton-derived flexible porous carbon fabric electrode using nickel-salt pore forming for supercapacitors[J]. Journal of Electronic Materials,2021,50(10):5557-5566. doi: 10.1007/s11664-021-09095-0 [19] HATTORI Y, KOJIMA R, SAGISAKA K, et al. Preparation and formation mechanism of porous carbon nanosheets by thermal decomposition of polyvinyl alcohol films impregnated with zinc (II) and nitrate ions[J]. Solid State Sciences,2017,65:33-40. doi: 10.1016/j.solidstatesciences.2017.01.002 [20] TAIT C W, HAPPE J A, SPRAGUE R W, et al. Kinetics of thermal decomposition of liquid nitric acid[J]. Journal of the American Chemical Society,1956,78(12):2670-2673. doi: 10.1021/ja01593a003 [21] ZHOU X, WANG P, ZHANG Y, et al. From waste cotton linter: A renewable environment-friendly biomass based carbon fibers preparation[J]. ACS Sustainable Chemistry & Engineering,2016,4(10):5585-5593. [22] JIANG L, ZHAO Y, ZHAI J. A lotus-leaf-like superhydrophobic surface: A porous microsphere/nanofiber composite film prepared by electrohydrodynamics[J]. Angewandte Chemie,2004,116(33):4438-4441. doi: 10.1002/ange.200460333 [23] BICO J, THIELE U, QUÉRÉ D. Wetting of textured surfaces[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects,2002,206(1-3):41-46. [24] HUANG W X, HUANG H, LI H, et al. Superhydrophilic nano-TiO2 film with porous surface structure[J]. Materials Research Innovations,2009,13(4):459-463. doi: 10.1179/143289109X12494867167486 [25] HAO J, WANG J, QIN S, et al. B/N co-doped carbon nanosphere frameworks as high-performance electrodes for supercapacitors[J]. Journal of Materials Chemistry A,2018,6(17):8053-8058. doi: 10.1039/C8TA00683K [26] JAYARAMULU K, DUBAL D P, NAGAR B, et al. Ultrathin hierarchical porous carbon nanosheets for high-performance supercapacitors and redox electrolyte energy storage[J]. Advanced Materials,2018,30(15):1705789. doi: 10.1002/adma.201705789 [27] LI Q, WANG J, LIU C, et al. Controlled design of a robust hierarchically porous and hollow carbon fiber textile for high-performance freestanding electrodes[J]. Advanced Science,2019,6(21):1900762. doi: 10.1002/advs.201900762 -

下载:

下载: