Preparation and properties of POSS/sodium polyacrylate conductive composite hydrogels with high stretchability, self-healable and self-adhesive properties

-

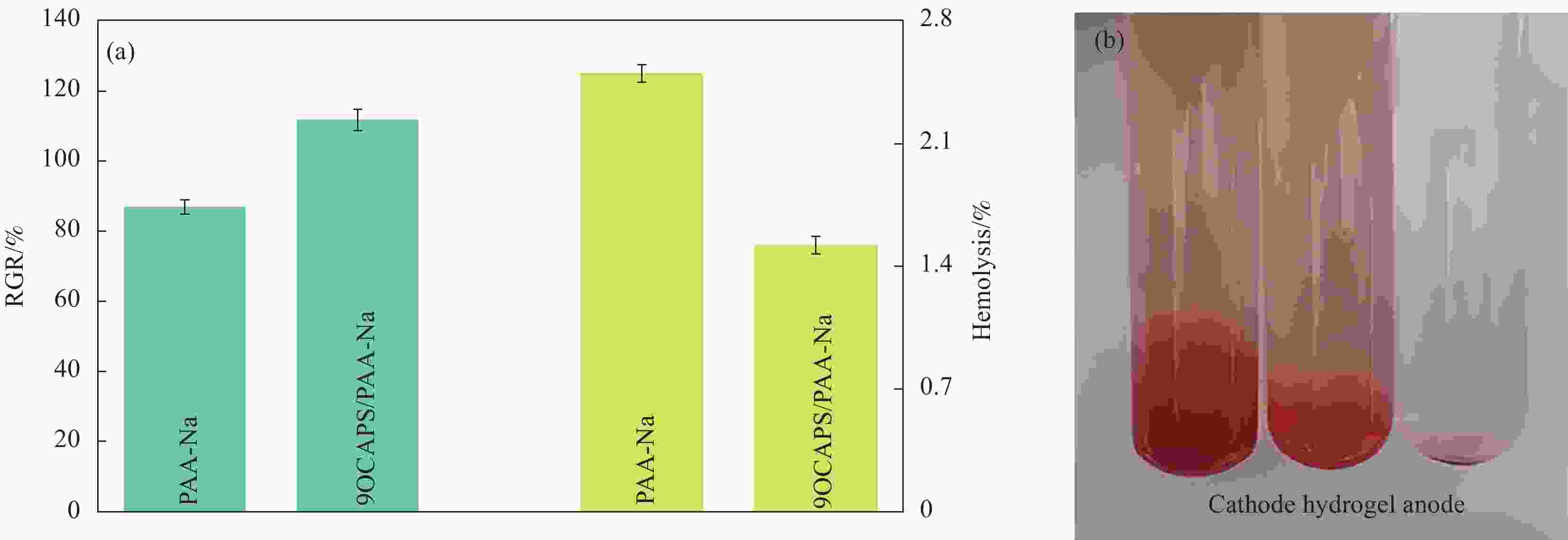

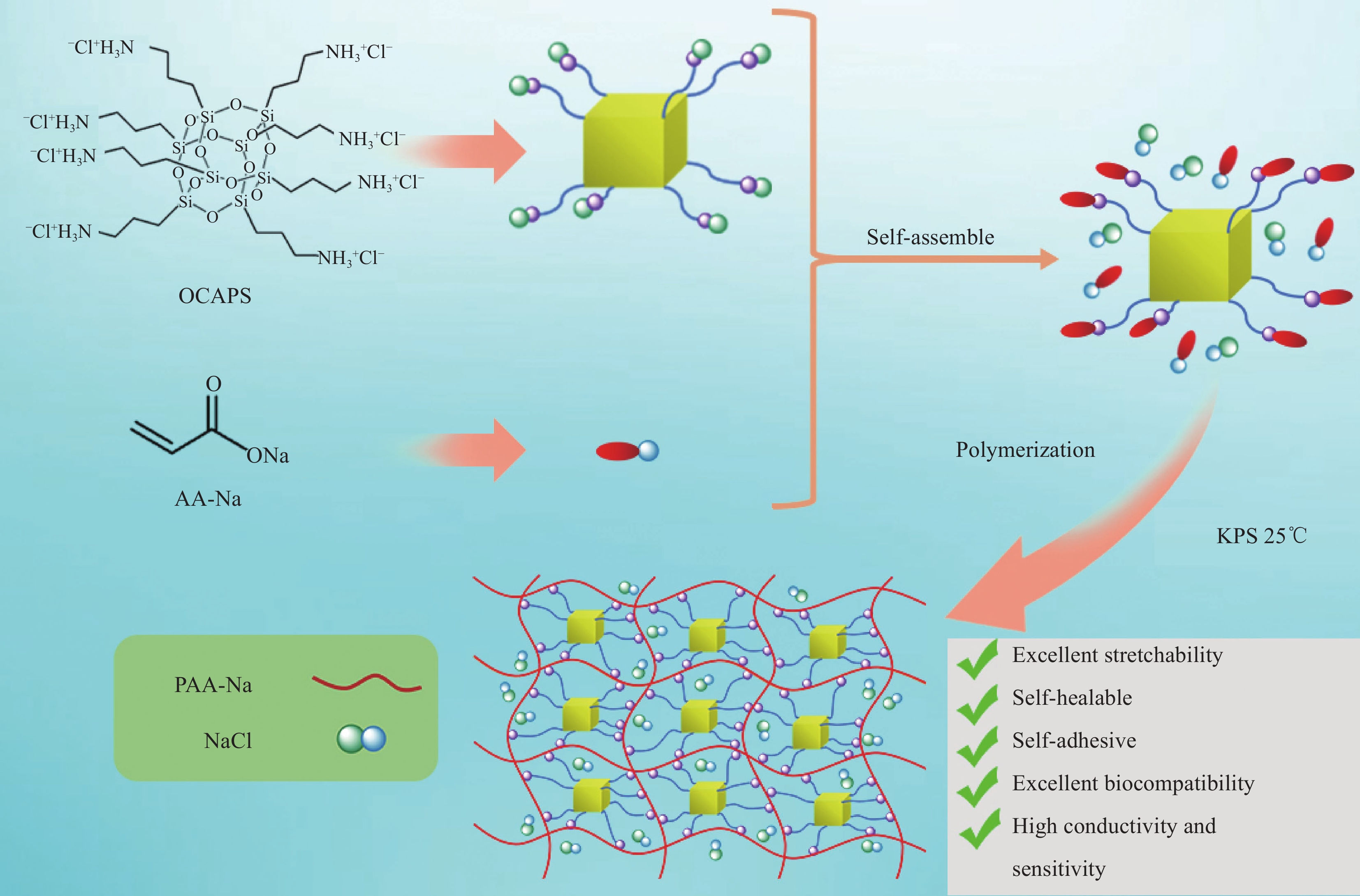

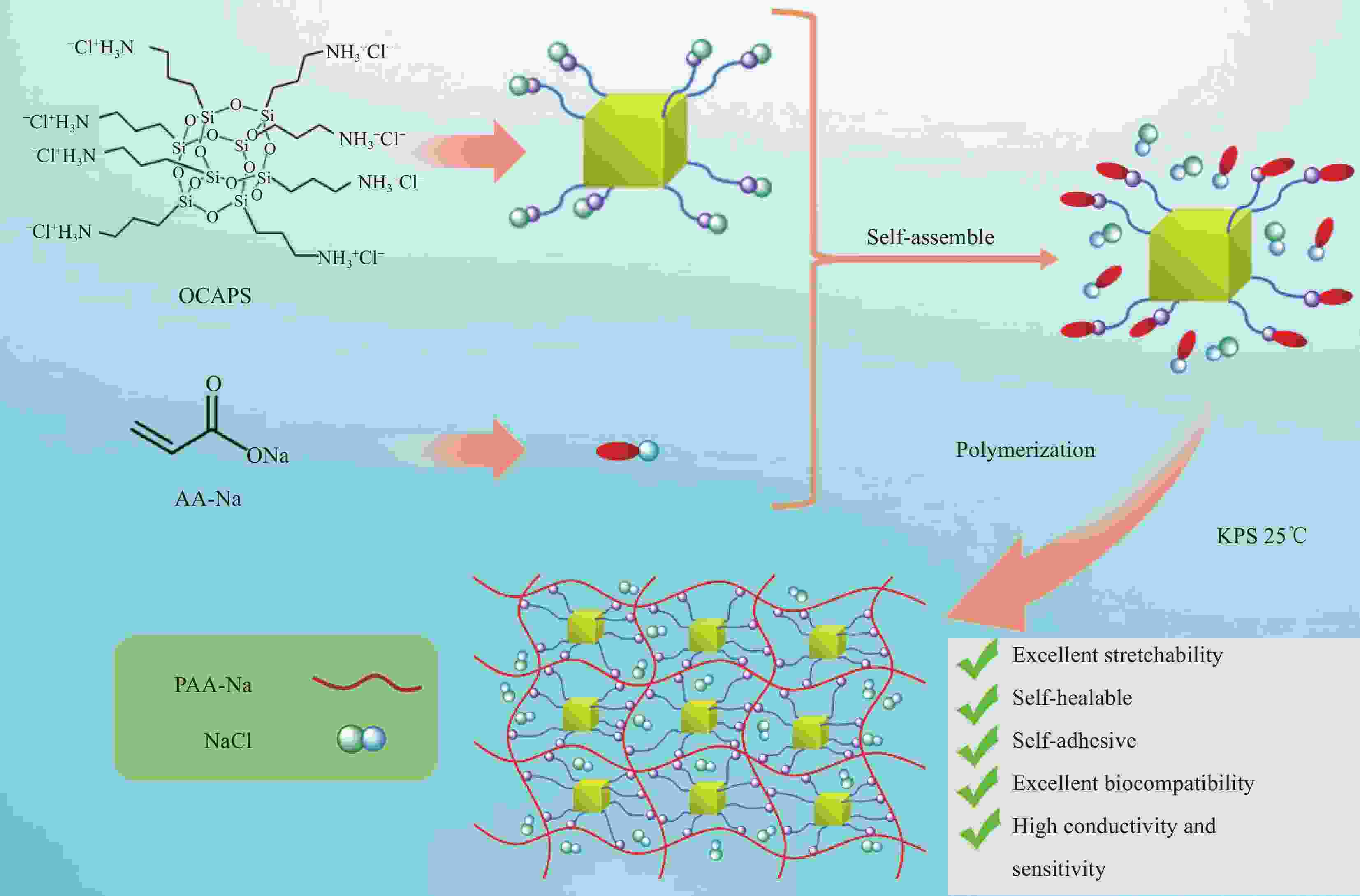

摘要: 导电水凝胶在柔性可穿戴设备、电子皮肤和生物电极等方面具有很大的应用潜力。然而,复杂多变的应用场景对导电水凝胶在可拉伸性、自愈合性、自黏附性和生物相容性等方面提出了更高的要求。利用水溶性多面体低聚倍半硅氧烷(POSS)与聚丙烯酸钠(PAA-Na)之间的非共价键交联设计了一种具有高可拉伸性、自愈合、自黏附性和良好生物相容性的导电复合水凝胶(OCAPS/PAA-Na)。OCAPS/PAA-Na水凝胶的断裂伸长率为2537.0%~4056.1%;POSS的加入提高了水凝胶的力学性能,拉伸强度由10.5 kPa提高到23.8 kPa,拉伸模量由7.1 kPa提高到27.8 kPa,断裂能由3.7 kJ·m−2提高到6.8 kJ·m−2。OCAPS/PAA-Na水凝胶具有优异的自愈合性能,自愈合效率达97.8%。该水凝胶对有机材料和无机材料均具有良好的黏附性,黏附强度最高分别达到19.6 kPa和18.2 kPa。细胞毒性试验和溶血试验表明,水凝胶具有优异的生物相容性。制备过程中原位生成的NaCl晶体,提高了水凝胶的电导率(由0.165 S·m−1增加到0.290 S·m−1)。OCAPS/PAA-Na水凝胶可作为应变式电阻传感器材料精确地检测一些细微的人体动作,传感灵敏系数值达5.17,在柔性智能可穿戴设备和电子皮肤领域具有良好的应用前景。Abstract: Conductive hydrogels have great potential applications in flexible wearable devices, electronic skin and biological electrodes. However, the complex and changing application scenarios put forward higher requirements on the stretchability, self-healable, self-adhesive and biocompatibility of conductive hydrogels. In this paper, a conductive composite hydrogel (OCAPS/PAA-Na) with high extensibility, self-healable, self-adhesive and excellent biocompatibility was designed by the non-covalent cross-linking between a water-soluble polyhedral oligomeric silsesquioxane (POSS) and sodium polyacrylate (PAA-Na). The elongation at break of OCAPS/PAA-Na hydrogel is 2537.0%-4056.1%. The addition of POSS improves the mechanical properties of hydrogels: The tensile strength increases from 10.5 kPa to 23.8 kPa; The tensile modulus increases from 7.1 kPa to 27.8 kPa; The fracture energy increases from 3.7 kJ·m−2 to 6.8 kJ·m−2. OCAPS/PAA-Na hydrogel has excellent self-healable property, and the self-healable efficiency is up to 97.8%. The hydrogel shows good adhesion to both organic and inorganic materials, with the highest adhesive strength of 19.6 kPa and 18.2 kPa, respectively. Cytotoxicity test and hemolysis test show that the hydrogel has excellent biocompatibility. The conductivity of the hydrogel increases from 0.165 to 0.290 S·m−1 with NaCl crystals is generated in situ during the preparation. OCAPS/PAA-Na hydrogel can be used as a strain resistance sensor material to accurately detect some subtle human actions and the gauge factor value can reach 5.17, which has a good application prospect in the field of flexible intelligent wearable devices and electronic skin.

-

Key words:

- conducting polymers /

- flexible sensor /

- POSS /

- composite materials /

- self-healing materials /

- self-adhesive materials

-

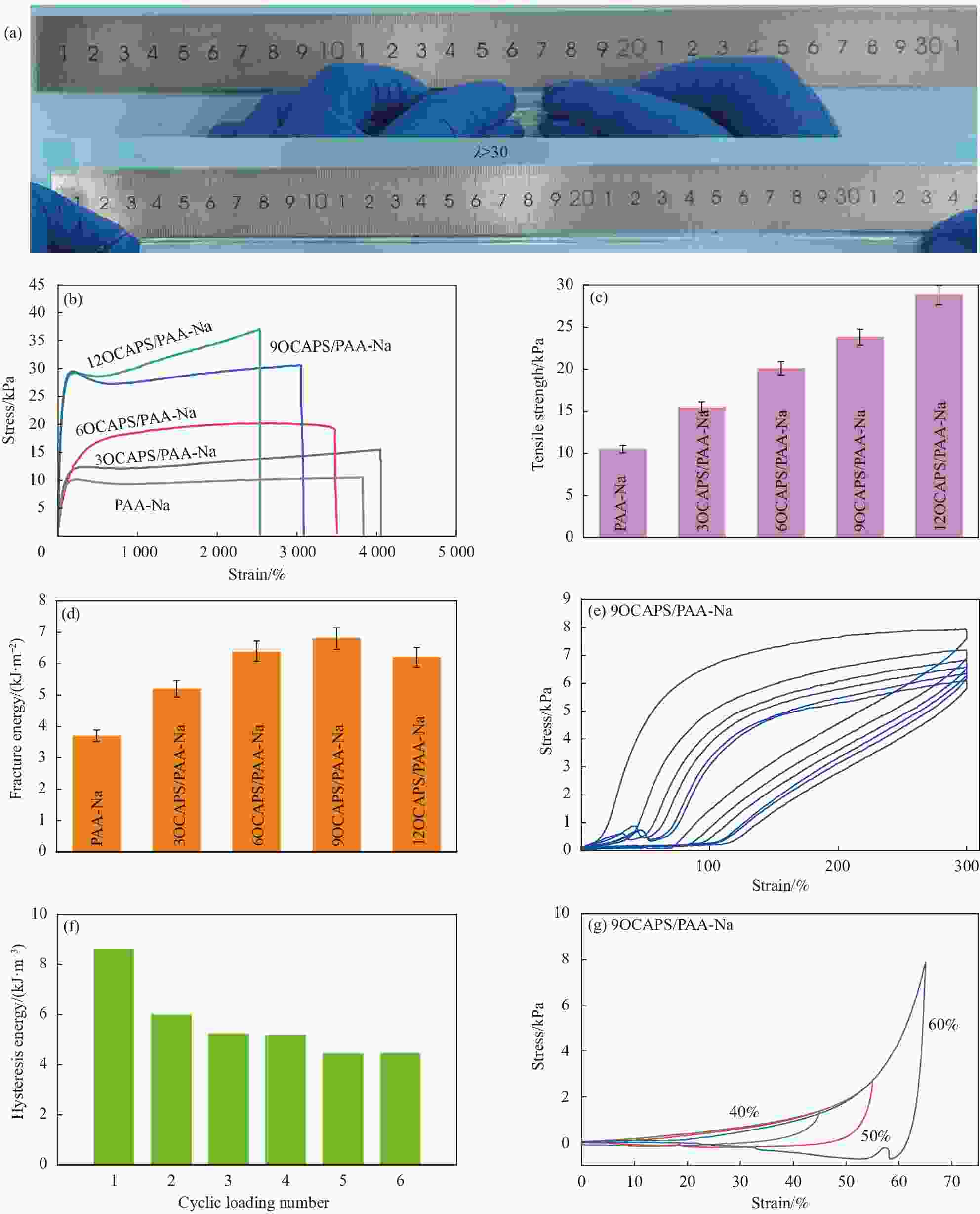

图 6 (a) 9OCAPS/PAA-Na水凝胶的的拉伸实物图;(b) PAA-Na和OCAPS/PAA-Na水凝胶的拉伸应力-应变曲线;(c) 拉伸强度;(d) 断裂能;9OCAPS/PAA-Na水凝胶循环拉伸曲线(e)、循环中相应的耗散能(f)和循环压缩曲线(g)

Figure 6. (a) Stretching picture of 9OCAPS/PAA-Na hydrogel; (b) Tensile stress-strain curves of PAA-Na and OCAPS/PAA-Na hydrogel; (c) Tensile strength; (d) Fracture energy; Cyclic tensile curves (e), corresponding dissipated energy in every cycle (f) and cyclic compression curves (g) of 9OCAPS/PAA-Na hydrogel

λ—Stretching factor

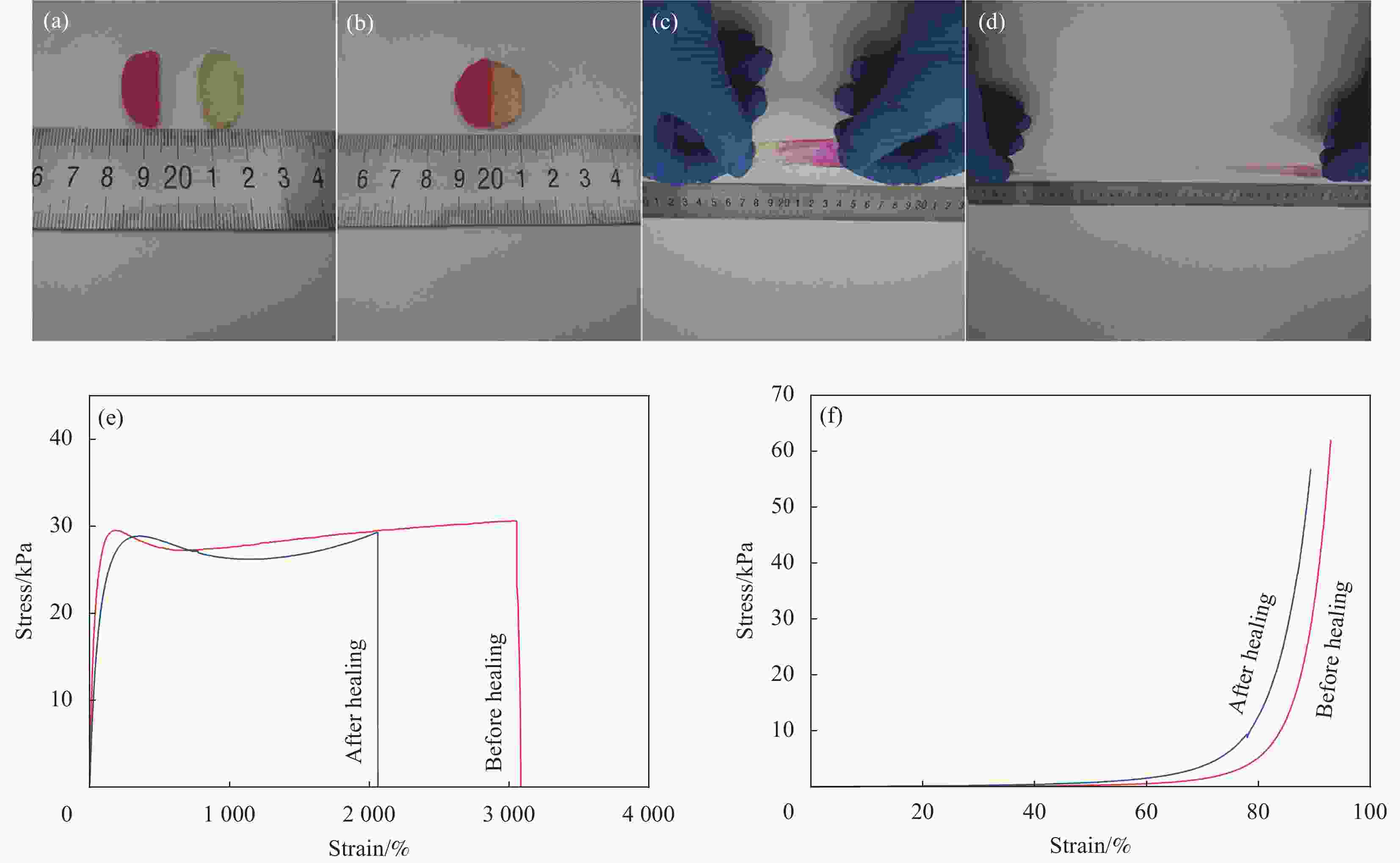

图 8 9OCAPS/PAA-Na水凝胶的自愈合性能:(a) 样品愈合前;(b) 样品愈合中;((c), (d)) 愈合5 min后的拉伸过程;9OCAPS/PAA-Na水凝胶自愈合前后的应力-应变曲线(e)和压缩曲线(f)

Figure 8. Self-healable property of 9OCAPS/PAA-Na hydrogel: (a) Before the sample healed; (b) During the sample healed; ((c), (d)) Stretching after 5 min; Stress-strain curves (e) and compression curves (f) of 9OCAPS/PAA-Na hydrogel before and after self-healable

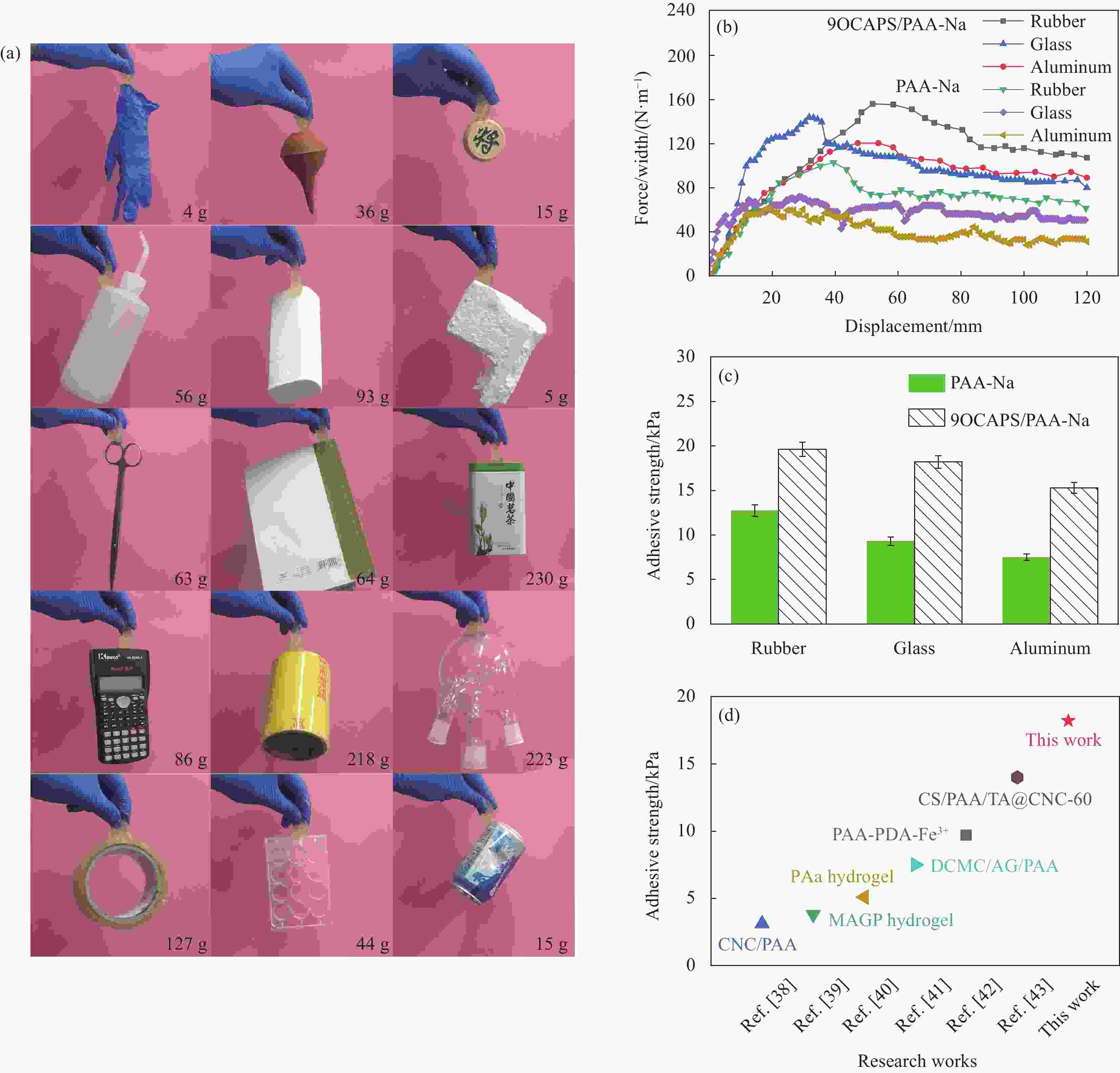

图 9 (a) 9OCAPS/PAA-Na水凝胶黏附不同材料的宏观照片;(b) PAA-Na和9OCAPS/PAA-Na水凝胶对不同材料的黏附曲线;(c) PAA-Na和9OCAPS/PAA-Na对不同材料的黏附强度;(d) 不同水凝胶的黏附强度比较

Figure 9. (a) Photoes of 9OCAPS/PAA-Na hydrogel adhesion to different materials; (b) Adhesive curves of PAA-Na and 9OCAPS/PAA-Na hydrogels to different materials; (c) Adhesive strength of PAA-Na and 9OCAPS/PAA-Na hydrogels to different materials; (d) Comparisons of adhesive strength of different hydrogels

CNC—Carboxylated nano cellulose; MAGP—Microfibrillar-associated glycoprotein; DCMC—Dimethylol dicyanurate; AG—Amino gelatin; PDA—Polydopamine; CS—Chitosan; TA—Tannic acid; PAa—Polyacrylamide/polydopamine

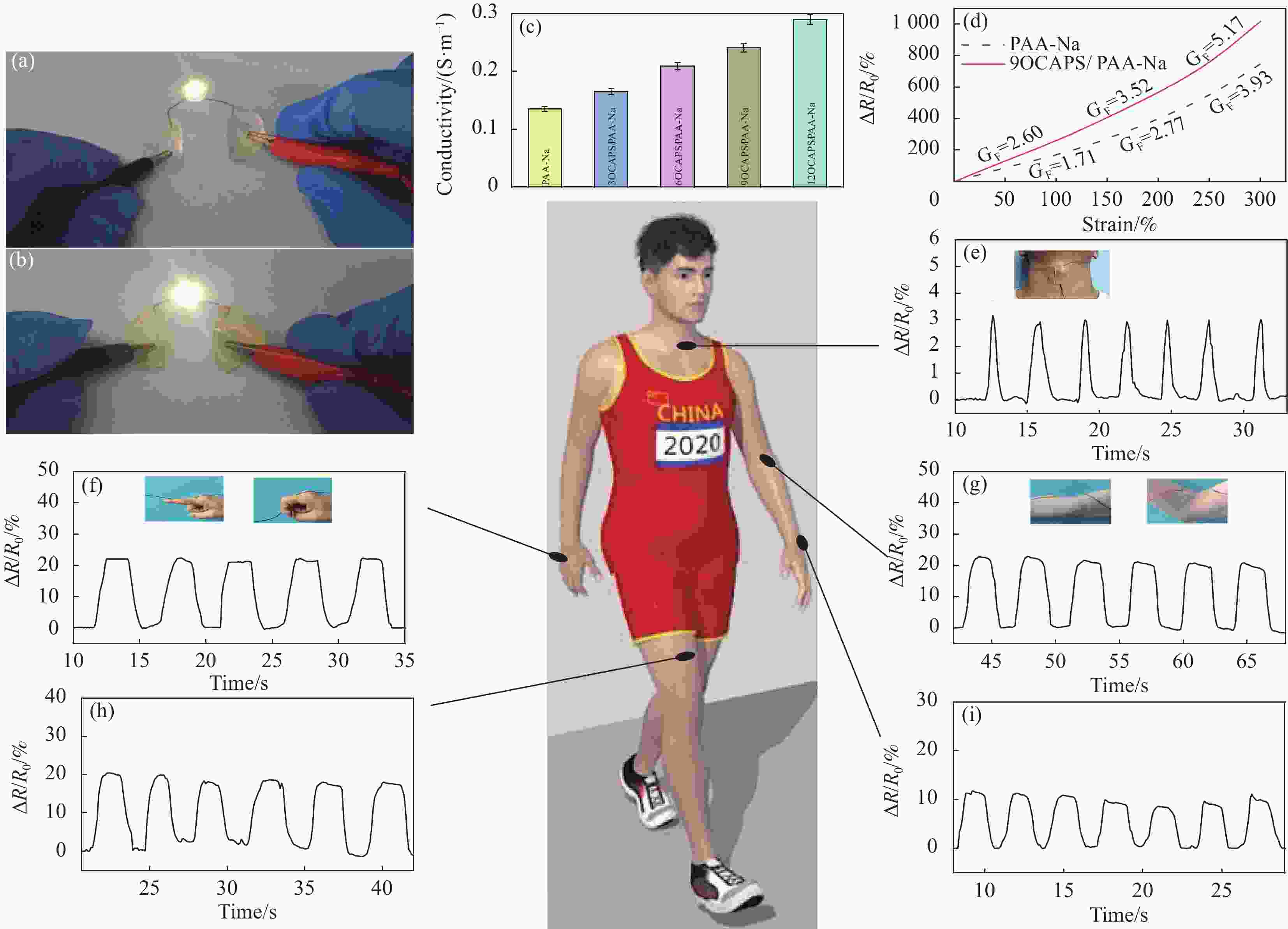

图 11 (a) PAA-Na水凝胶导电效果图;(b) 9OCAPS/PAA-Na水凝胶导电效果图;(c) PAA-Na和OCAPS/PAA-Na水凝胶的电导率;(d) PAA-Na和9OCAPS/PAA-Na水凝胶的传感灵敏度(GF);9OCAPS/PAA-Na水凝胶在不同肢体处的弯曲传感变化:(e) 喉咙循环发“A”时;(f) 食指0°至90°循环弯曲;(g) 肘部0°至60°循环弯曲;(h) 膝盖0°至90°循环弯曲;(i) 手腕0°至60°循环弯曲

Figure 11. (a) Photo of conductive performance of PAA-Na hydrogel; (b) Photo of conductive performance of 9OCAPS/PAA-Na hydrogel; (c) Conductivity of PAA-Na and 9OCAPS/PAA-Na hydrogels; (d) Gauge factor (GF) of PAA-Na and 9OCAPS/PAA-Na hydrogels; The bending sensing changes of 9OCAPS/PAA-Na hydrogel at different limbs: (e) When "A" is circulated for the throat; (f) Cycle the index finger from 0° to 90°; (g) Cycle from the elbow 0° to 60°; (h) Cycle knee flexion from 0° to 90°; (i) Cycle the wrist from 0° to 60°

ΔR—Quantifying the variations in hydrogel impedance pre and post stress application; R0—Impedance characterization of the hydrogel in unstressed state

表 1 样品命名

Table 1. Sample naming

Sample Molar ratio (OCAPS:AA-Na) PAA-Na 0∶100 3OCAPS/PAA-Na 0.3∶100 6OCAPS/PAA-Na 0.6∶100 9OCAPS/PAA-Na 0.9∶100 12OCAPS/PAA-Na 1.2∶100 Notes: PAA-Na—Sodium polyacrylate; OCAPS—Octa(3-chloro-ammoniumpropyl) silsesquioxane -

[1] 胡魁, 王映月, 王昊昱, 等. 高强度耐低温纳米纤维素/聚乙烯醇导电复合水凝胶的制备及其在柔性传感中的应用[J]. 复合材料学报, 2023, 40(2):1060-1070. doi: 10.13801/j.cnki.fhclxb.20220322.003HU Kui, WANG Yingyue, WANG Haoyu, et al. Preparation of high-strength and low-temperature-resistant nanocellulose/polyvinyl alcohol conductive composite hydrogel and its application in flexible sensing[J]. Acta Materiae Compositae Sinica,2023,40(2):1060-1070(in Chinese). doi: 10.13801/j.cnki.fhclxb.20220322.003 [2] HARDMAN D, THURUTHEL T G, LIDA F. Self-healing ionic gelatin/glycerol hydrogels for strain sensing applications[J]. NPG Asia Materials,2022,14(1):11. doi: 10.1038/s41427-022-00357-9 [3] ZHENG Y Q, WANG D Y, ZHAO L J, et al. Chemically modified silk fibroin hydrogel for environment-stable electronic skin[J]. Sensors and Actuators Reports,2022,4:100089. doi: 10.1016/j.snr.2022.100089 [4] RAJENDRAN B, CHEN X, LI Z, et al. How molecular interactions tune the characteristic time of nanocomposite colloidal sensors[J]. Journal of Colloid and Interface Science,2022,625:1023. doi: 10.1016/j.jcis.2022.06.077 [5] BAI L, JIN Y, SHANG X, et al. Bio-inspired visual multi-sensing interactive ionic skin with asymmetrical adhesive, antibacterial and self-powered functions[J]. Chemical Engineering Journal,2022,438:135596. doi: 10.1016/j.cej.2022.135596 [6] LI J W, YANG Z L, JIANG Z C, et al. A self-healing and self-adhesive chitosan based ion-conducting hydrogel sensor by ultrafast polymerization[J]. International Journal of Biological Macromolecules,2022,209:1975-1984. doi: 10.1016/j.ijbiomac.2022.04.176 [7] LI M, CHEN D, SUN X, et al. An environmentally tolerant, highly stable, cellulose nanofiber-reinforced, conductive hydrogel multifunctional sensor[J]. Carbohydrate Polymers,2022,284:119199. doi: 10.1016/j.carbpol.2022.119199 [8] QIN M, YUAN W F, ZHANG X M, et al. Preparation of PAA/PAM/MXene/TA hydrogel with antioxidant, healable ability as strain sensor[J]. Colloids and Surfaces B: Biointerfaces,2022,214:112482. doi: 10.1016/j.colsurfb.2022.112482 [9] WANG S Y, SUN Z J, ZHAO Y L, et al. A highly stretchable hydrogel sensor for soft robot multi-modal perception[J]. Sensors and Actuators A: Physical,2021,331:113006. doi: 10.1016/j.sna.2021.113006 [10] LIU R, WANG H Z, LU W J, et al. Highly tough, stretchable and resilient hydrogels strengthened with molecular springs and their application as a wearable, flexible sensor[J]. Chemical Engineering Journal,2021,415:128839. doi: 10.1016/j.cej.2021.128839 [11] LIU Y M, WANG Q S, LIU X T, et al. Highly adhesive, stretchable and breathable gelatin methacryloyl-based nanofibrous hydrogels for wound dressings[J]. ACS Applied Bio Materials,2022,5(3):1047-1056. doi: 10.1021/acsabm.1c01087 [12] ZHANG K M, WANG Z, LIU Y T, et al. Cephalopods-inspired repairable MWCNTs/PDMS conductive elastomers for sensitive strain sensor[J]. Chinese Journal of Polymer Science,2022,40(4):384-393. doi: 10.1007/s10118-022-2674-8 [13] FAN X, GENG J H, WANG Y L, et al. PVA/gelatin/β-CD-based rapid self-healing supramolecular dual-network conductive hydrogel as bidirectional strain sensor[J]. Polymer,2022,246:124769. doi: 10.1016/j.polymer.2022.124769 [14] LIU R X, CHEN J C, LUO Z Q, et al. Stretchable, self-adhesive, conductive, anti-freezing sodium polyacrylate-based composite hydrogels for wearable flexible strain sensors[J]. Reactive and Functional Polymers,2022,172:105197. doi: 10.1016/j.reactfunctpolym.2022.105197 [15] MAO H L, ZHAO S J, HE Y X, et al. Multifunctional polysaccharide hydrogels for skin wound healing prepared by photoinitiator-free crosslinking[J]. Carbohydrate Polymers,2022,285:119254. doi: 10.1016/j.carbpol.2022.119254 [16] 鲁程程, 于振坤, 杨园园, 等. 聚丙烯酸-Al3+/壳聚糖复合双网络水凝胶的制备与性能[J]. 复合材料学报, 2022, 39(12):5901-5911.LU Chengcheng, YU Zhenkun, YANG Yuanyuan, et al. Preparation and performances of polyacrylic acid-Al3+/chitosan composite double network hydrogel[J]. Acta Materiae Compositae Sinica,2022,39(12):5901-5911(in Chinese). [17] ZENG R P, QI C Y, LU S X, et al. Hydrophobic association and ionic coordination dual crossed-linked conductive hydrogels with self-adhesive and self-healing virtues for conformal strain sensors[J]. Journal of Polymer Science,2021,60(5):812-824. doi: 10.1002/pol.20210840 [18] DENG Z X, HU T L, LEI Q, et al. Stimuli-responsive conductive nanocomposite hydrogels with high stretchability, self-healing, adhesiveness, and 3D printability for human motion sensing[J]. ACS Applied Materials & Interfaces,2019,11(7):6796-6808. doi: 10.1021/acsami.8b20178 [19] KHAN A, KISANNAGAR R R, GOUDA C, et al. Highly stretchable supramolecular conductive self-healable gels for injectable adhesive and flexible sensor applications[J]. Journal of Materials Chemistry A,2020,8(38):19954-19964. doi: 10.1039/D0TA07543D [20] PANG C, KOO J H, NGUYEN A, et al. Highly skin-conformal microhairy sensor for pulse signal amplification[J]. Advanced Materials,2015,27(4):634-640. doi: 10.1002/adma.201403807 [21] LIAO M H, WAN P B, WEN J R, et al. Wearable, healable, and adhesive epidermal sensors assembled from mussel-inspired conductive hybrid hydrogel framework[J]. Advanced Functional Materials,2017,27(48):1703852. doi: 10.1002/adfm.201703852 [22] ZHAO L, REN Z J, LIU X, et al. A multifunctional, self-healing, self-adhesive, and conductive sodium alginate/poly(vinyl alcohol) composite hydrogel as a flexible strain sensor[J]. ACS Applied Materials & Interfaces,2021,13(9):11344-11355. doi: 10.1021/acsami.1c01343 [23] LI H L, DAI C J, XU Q, et al. Synthesis of thiol-terminated PEG-functionalized POSS cross-linkers and fabrication of high-strength and hydrolytic degradable hybrid hydrogels in aqueous phase[J]. European Polymer Journal,2019,116:74-83. doi: 10.1016/j.eurpolymj.2019.03.062 [24] LIU S J, GUO R Q, LI C, et al. POSS hybrid hydrogels: A brief review of synthesis, properties and applications[J]. European Polymer Journal,2021,143:110180. doi: 10.1016/j.eurpolymj.2020.110180 [25] ROMO-URIBE A, ALBANIL L. POSS-induced dynamic cross-links produced self-healing and shape memory physical hydrogels when copolymerized with N-isopropyl acrylamide[J]. ACS Applied Materials & Interfaces,2019,11(27):24447-24458. doi: 10.1021/acsami.9b06672 [26] ZHANG X J, SHEN W W, DOU J C, et al. Enhanced mechanical properties and self-healing behavior of PNIPAM nanocomposite hydrogel by using POSS as a physical crosslinker[J]. Journal of Applied Polymer Science,2019,137(12):48486. doi: 10.1002/app.48486 [27] KANNAN R Y, SALACINSHII H J, BUYLER P E, et al. Polyhedral oligomeric silsesquioxane nanocomposites: The next generation material for biomedical applications[J]. Accounts of Chemical Research,2005,38(11):879-884. doi: 10.1021/ar050055b [28] YANG C, HUANG H, FAN S C, et al. A novel dual-crosslinked functional hydrogel activated by POSS for accelerating wound healing[J]. Advanced Materials Technologies,2021,6(4):2001012. doi: 10.1002/admt.202001012 [29] ZHANG X J, LI C, HU Y L, et al. A novel temperature and pH dual-responsive hybrid hydrogel with polyhedral oligomeric silsesquioxane as crosslinker: synthesis, characterization and drug release properties[J]. Polymer International,2014,63(12):2030-2041. doi: 10.1002/pi.4757 [30] CHEN Y, ZENG G S, LIU W Y. Robust and stimuli-responsive POSS hybrid PDMAEMA hydrogels for controlled drug release[J]. Journal of Biomedical Materials Research Part A,2016,104(9):2345-2355. doi: 10.1002/jbm.a.35771 [31] WANG J, LI Y, SHAO L, et al. Preparation and properties of poly(vinyl alcohol)/polypyrrole composite conductive hydrogel strain sensor[J]. Chemical Journal of Chinese Universities-Chinese,2021,42(3):929-936. doi: 10.7503/cjcu20200480 [32] ZHANG X J, MENG Y, SHEN W W, et al. pH-responsive injectable polysaccharide hydrogels with self-healing, enhanced mechanical properties based on POSS[J]. Reactive and Functional Polymers,2021,158:104773. doi: 10.1016/j.reactfunctpolym.2020.104773 [33] LI R Z, ZHOU C, CHEN J, et al. Synergistic osteogenic and angiogenic effects of KP and QK peptides incorporated with an injectable and self-healing hydrogel for efficient bone regeneration[J]. Bioactive Materials,2022,18:267-283. doi: 10.1016/j.bioactmat.2022.02.011 [34] NIE M, KONG B, CHEN G P, et al. MSCs-laden injectable self-healing hydrogel for systemic sclerosis treatment[J]. Bioactive Materials,2022,17:369-378. doi: 10.1016/j.bioactmat.2022.01.006 [35] WEERAWAN N, CHALITANGKOON J, MONVISADE P. Self-healing hydrogels based on sodium carboxymethyl cellulose/poly (vinyl alcohol) reinforced with montmorillonite[J]. Biointerface Research in Applied Chemistry,2022,12(4):4770-4779. doi: 10.33263/BRIAC124.47704779 [36] CHEN C W, WANG Y, ZHANG H, et al. Responsive and self-healing structural color supramolecular hydrogel patch for diabetic wound treatment[J]. Bioactive Materials,2022,15:194-202. doi: 10.1016/j.bioactmat.2021.11.037 [37] PEYMANFAR R, SELSELEH-ZAKERIN E, AHMADI A, et al. Preparation of self-healing hydrogel toward improving electromagnetic interference shielding and energy efficiency[J]. Scientific Reports,2021,11(1):16161. doi: 10.1038/s41598-021-95683-3 [38] MA W J, CAO W X, LU T, et al. Healable, adhesive, and conductive nanocomposite hydrogels with ultrastretchability for flexible sensors[J]. ACS Applied Materials & Interfaces,2021,13(48):58048-58058. doi: 10.1021/acsami.1c20271 [39] DONG L, WANG M X, WU J J, et al. Stretchable, adhesive, self-healable, and conductive hydrogel-based deformable triboelectric nanogenerator for energy harvesting and human motion sensing[J]. ACS Applied Materials & Interfaces,2022,14(7):9126-9137. doi: 10.1021/acsami.1c23176 [40] ZHANG G Y, CHEN S, PENG Z F, et al. Topologically enhanced dual-network hydrogels with rapid recovery for low-hysteresis, self-adhesive epidemic electronics[J]. ACS Applied Materials & Interfaces,2021,13(10):12531-12540. doi: 10.1021/acsami.1c00819 [41] LING Q J, KE T, LIU W T, et al. Tough, repeatedly adhesive, cyclic compression-stable, and conductive dual-network hydrogel sensors for human health monitoring[J]. Industrial & Engineering Chemistry Research,2021,60(50):18373-18383. doi: 10.1021/acs.iecr.1c03358 [42] ZHOU H W, LI S L, LIU H B, et al. High-performance flexible sensors of self-Healing, reversibly adhesive, and stretchable hydrogels for monitoring large and subtle strains[J]. Macromolecular Materials and Engineering,2019,305(2):1900621. doi: 10.1002/mame.201900621 [43] CUI C, SHAO C Y, MENG L, et al. High-strength, self-adhesive, and strain-sensitive chitosan/poly(acrylic acid) double-network nanocomposite hydrogels fabricated by salt-soaking strategy for flexible sensors[J]. ACS Applied Materials & Interfaces,2019,11(42):39228-39237. doi: 10.1021/acsami.9b15817 [44] YAN Y G, WEI L X, QIU X Y, et al. A dual-responsive, freezing-tolerant hydrogel sensor and related thermal- and strain-sensitive mechanisms[J]. ACS Applied Polymer Materials,2021,3(3):1479-1487. doi: 10.1021/acsapm.0c01346 [45] CHEN S X, HUANG J R, ZHOU Z X, et al. Highly elastic anti-fatigue and anti-freezing conductive double network hydrogel for human body sensors[J]. Industrial & Engineering Chemistry Research,2021,60(17):6162-6172. doi: 10.1021/acs.iecr.1c00610 -

下载:

下载: