Properties of barium-calcium zirconate titanate ceramics-polymer composites

-

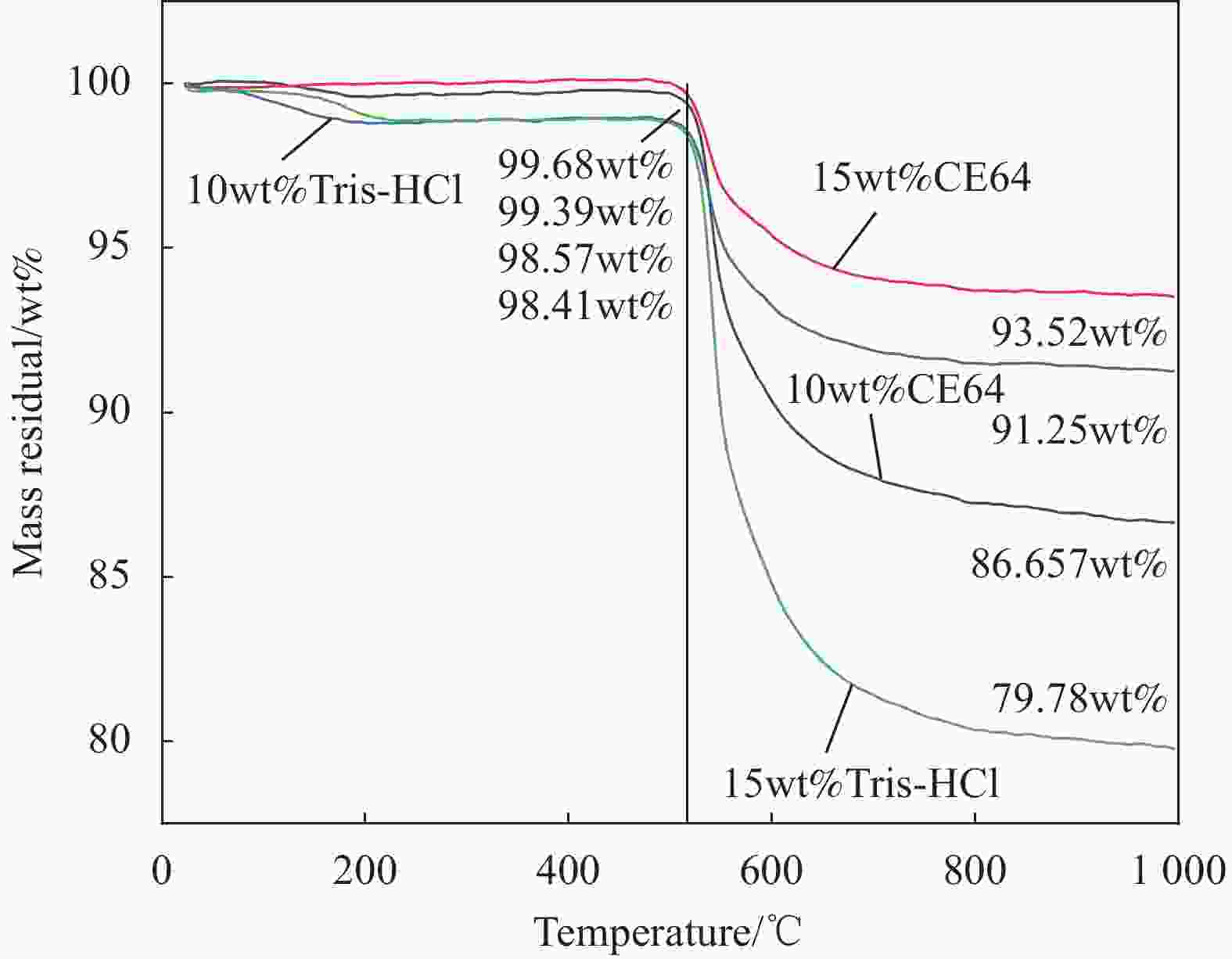

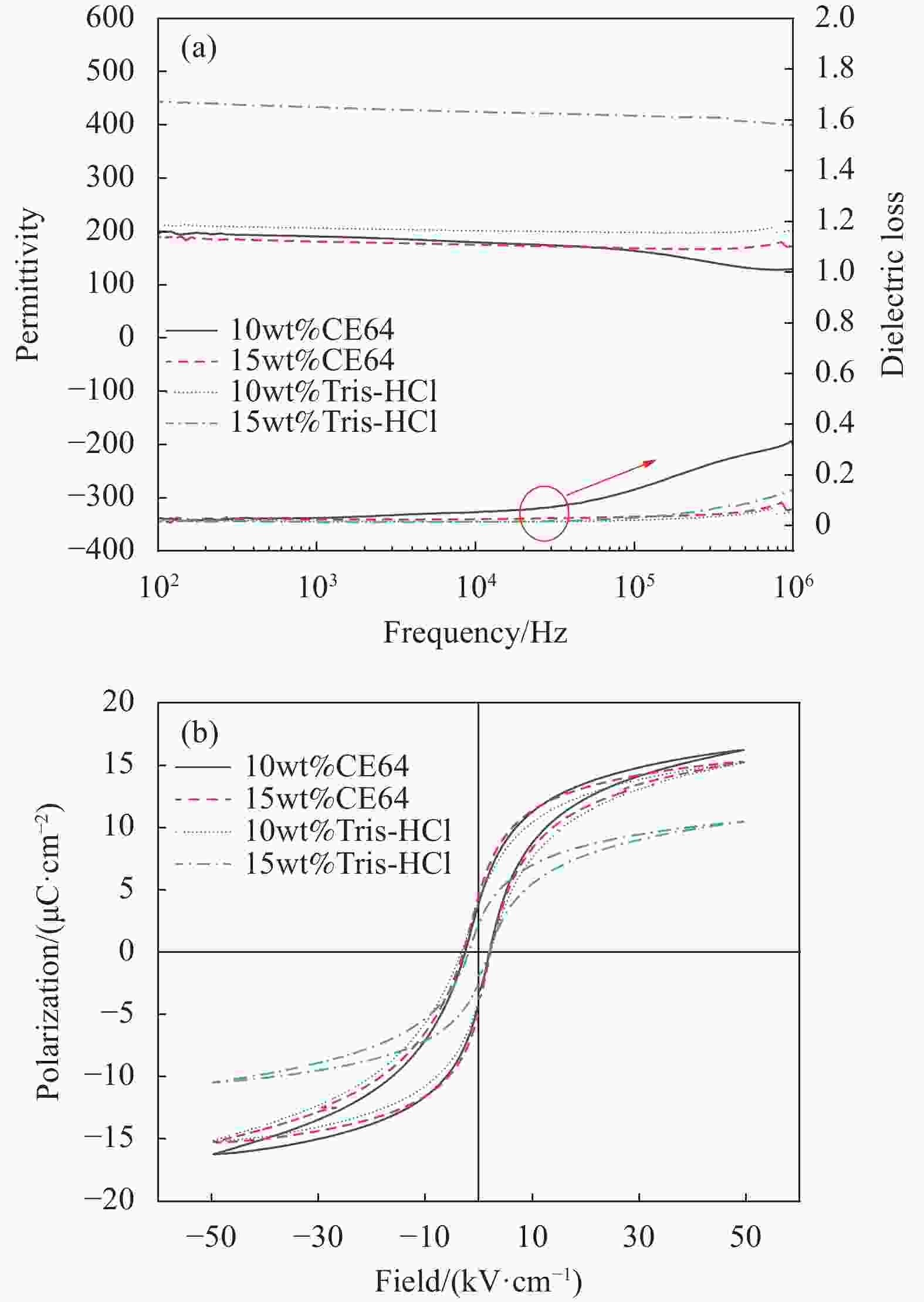

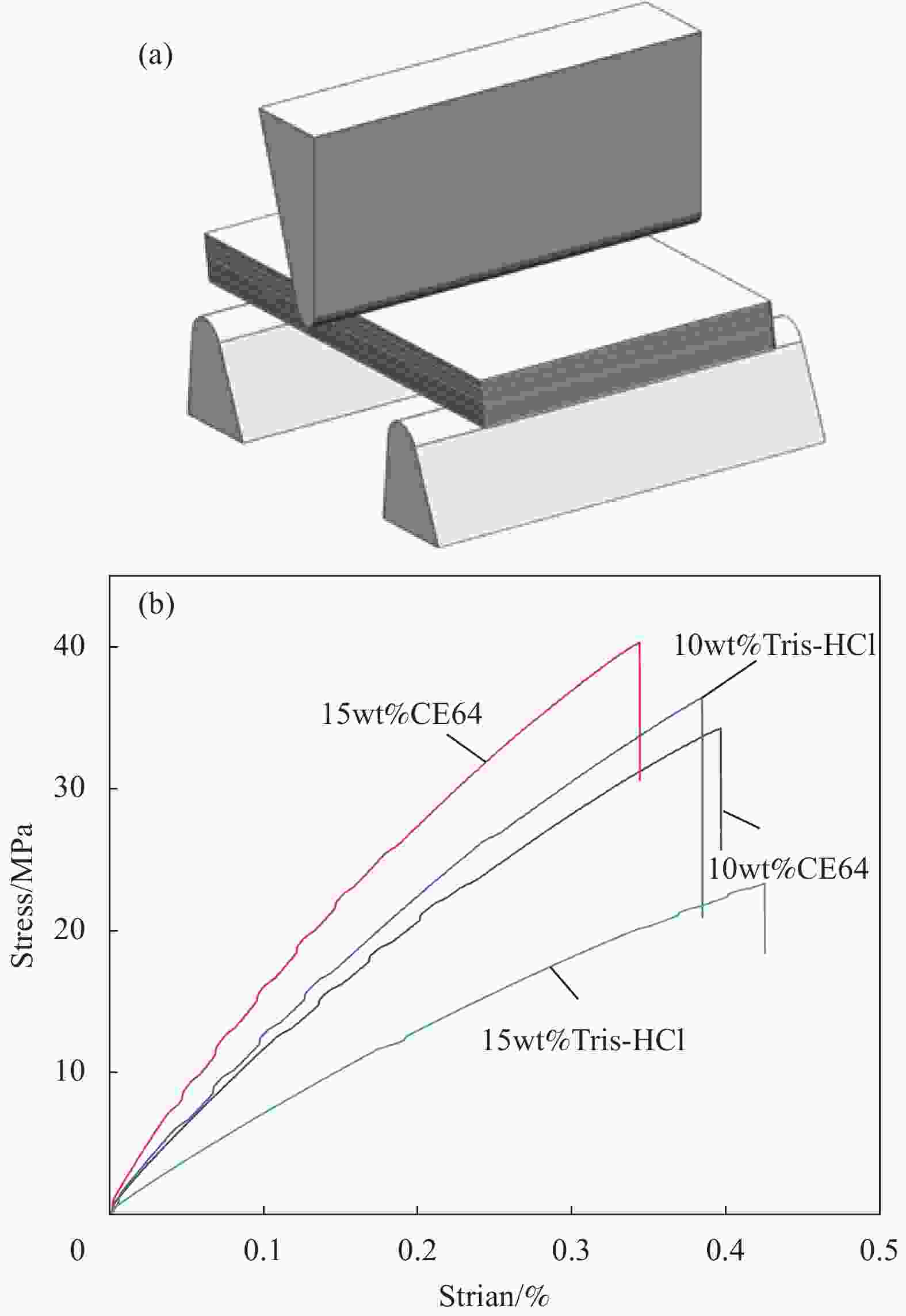

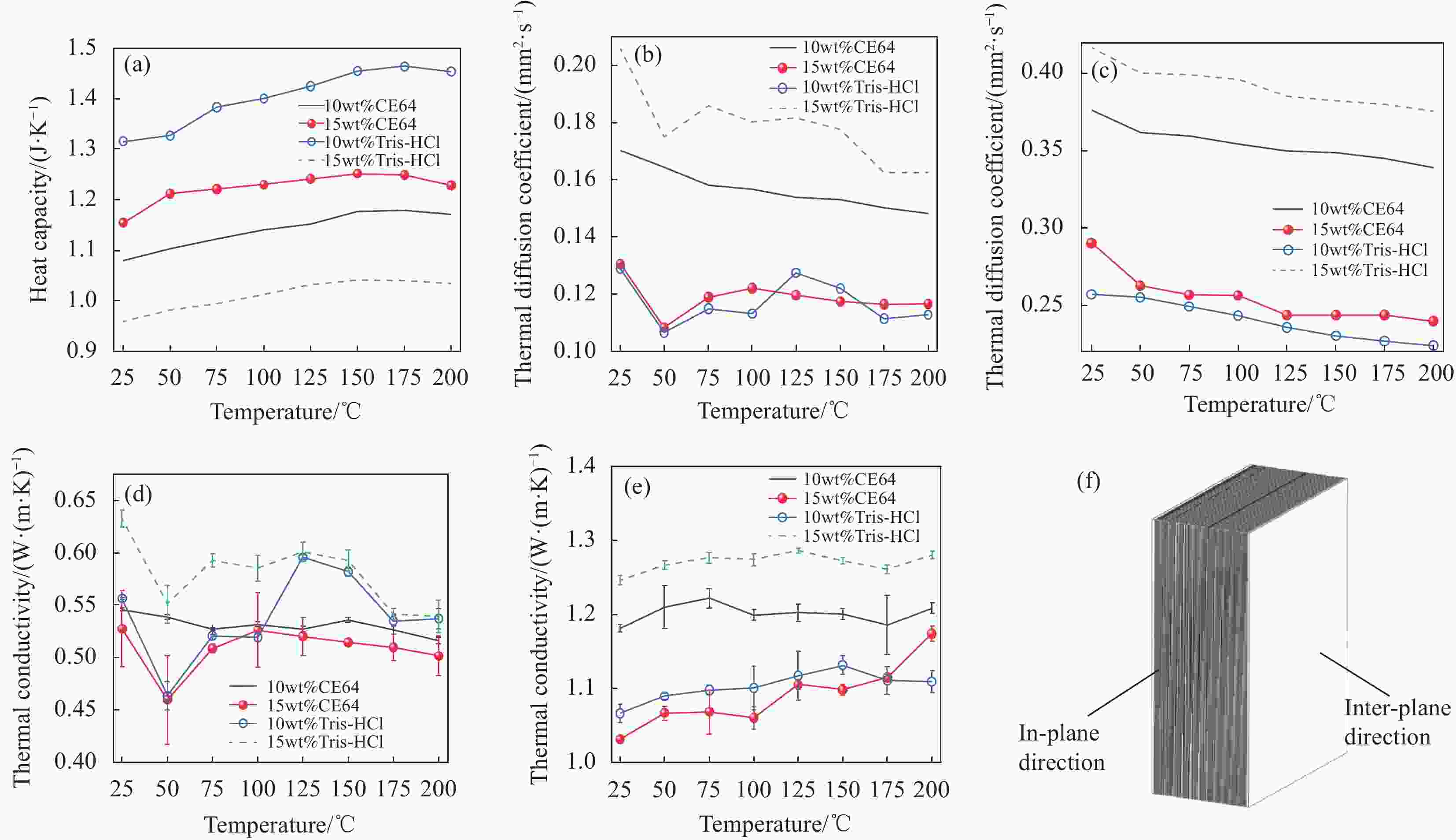

摘要: 利用冷冻取向的方法制备得到了锆钛酸钡钙陶瓷的二维框架结构,通过在这个结构中填充聚醚酰亚胺(PEI),制备成一种陶瓷复合材料。结果发现:陶瓷浆料固体载荷量为30vol%时可以得到更好的陶瓷片层状二维结构体。其中,三羟甲基氨基甲烷盐酸盐(Tris-HCl)作为分散剂的分散效果较好。聚合物在陶瓷复合材料中的填充率受浆料的分散剂种类及填充液浓度的影响,复合材料介电常数大多在100 以下,而本实验制备的锆钛酸钡钙基陶瓷-聚合物复合材料的相对介电常数达到了446。结果表明:Tris-HCl的分散效果最好,此时,当聚醚酰亚胺/二氯甲烷(PEI/DCM)溶液的浓度为15wt%时,陶瓷复合材料的聚合物填充率最高(18.63%)。随着PEI填充率的增大,陶瓷样品的最大应变值增大,最大应力值减小;面内的导热系数则随温度的升高而升高,在保证其具有一定力学强度的同时,提高了材料的介电性能。Abstract: The two-dimensional framework structure of barium-calcium zirconate titanate ceramics was prepared by the freezing orientation method. The ceramic composite material was prepared by filling polyetherimide (PEI) into this structure. The results show that a better two-dimensional structure of ceramic sheets can be obtained when the solid loading of ceramic paste is 30vol%. Among them, TRIS hydrochloride (Tris-HCl) as a dispersant has a better dispersion effect. The filling rate of polymer in ceramic composites is affected by the type of dispersant and the concentration of the filling solution. The permittivity of most composites is below 100, while the relative permittivity of barium zirconate titanate ceramic/polymer composites prepared in this experiment is 446. It is found that Tris-HCl has the best dispersion effect. At this time, when the concentration of polyetherimide/dichloromethane (PEI/DCM) solution is 15wt%, the polymer filling rate of ceramic composites is the highest (18.63%). With the increase of PEI filling rate, the maximum strain value of the ceramic sample increases and the maximum stress value decreases. The in-plane thermal conductivity increases with the increase of temperature. Ensure that it has a certain mechanical strength and improves the permittivity of the material.

-

Key words:

- freezing orientation /

- composite materials /

- polymer filling /

- dispersant /

- dielectric properties

-

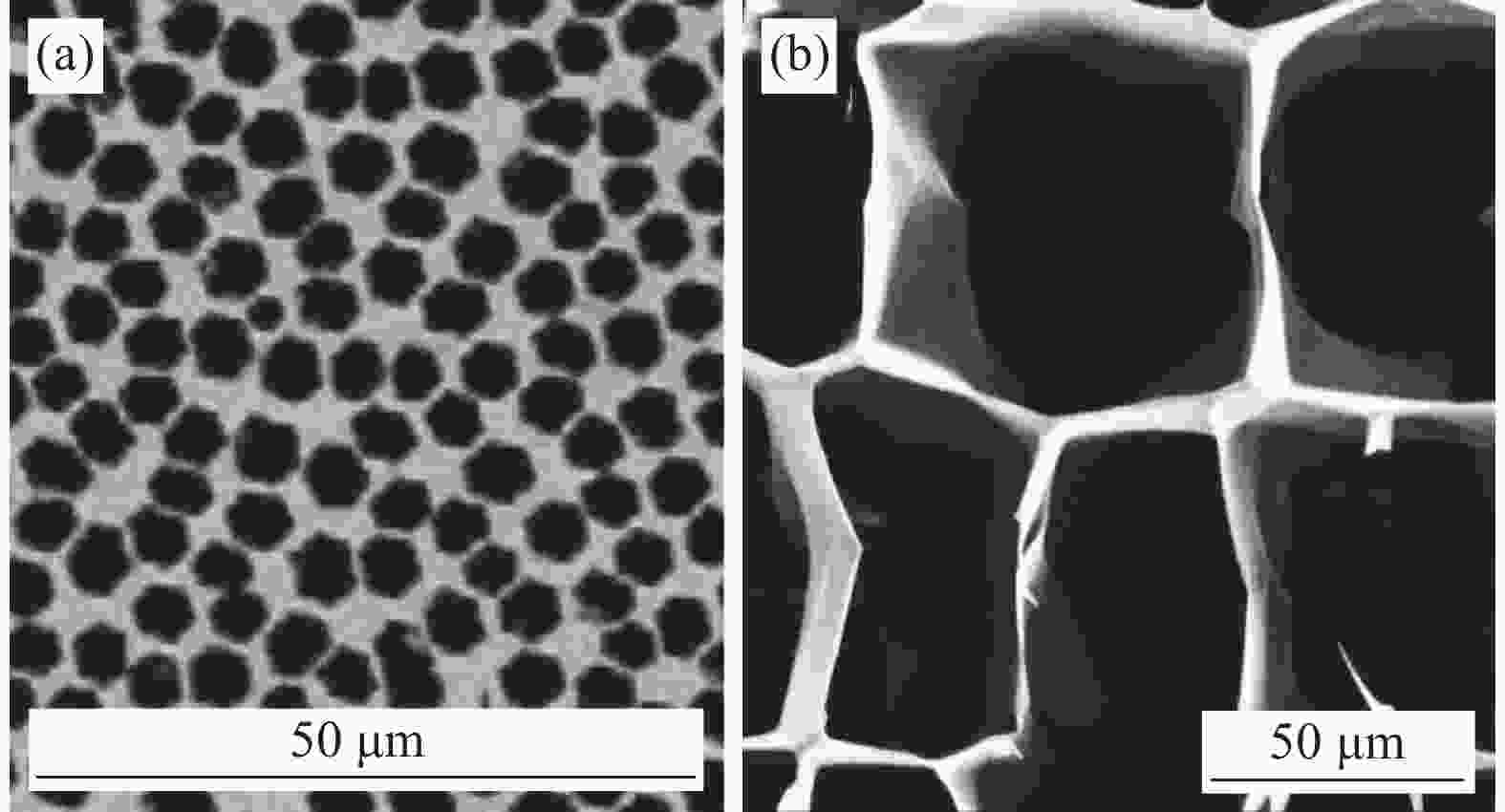

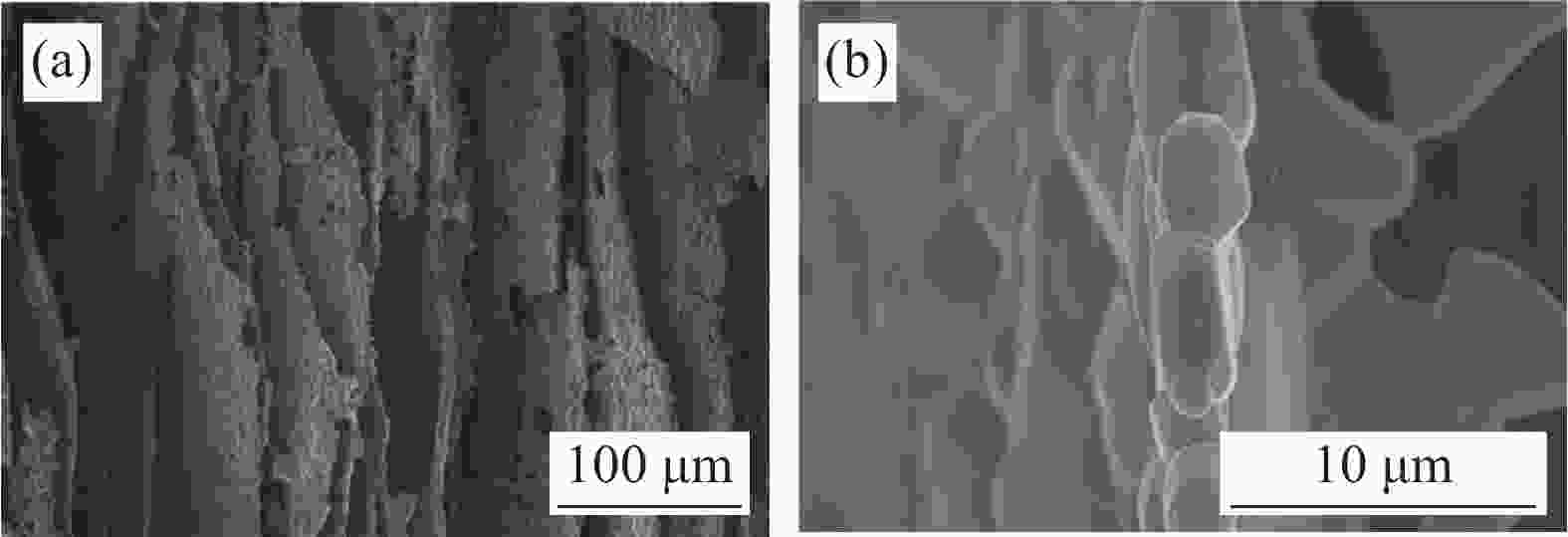

图 5 悬浮液分散剂为CE64时的陶瓷SEM图像:(a)固体载荷量为30vol%的冰晶生长方向;(b)固体载荷量为30vol%的冷冻方向;(c)固体载荷量为40vol%的冷冻方向;(d)固体载荷量为50vol%的冷冻方向

Figure 5. SEM images of ceramics with CE64 suspension dispersant: (a) Ice crystal growth direction with solid load of 30vol%; (b) Freezing direction with solid load of 30vol%; (c) Freezing direction with solid load of 40vol%; (d) Freezing direction with solid load of 50vol%

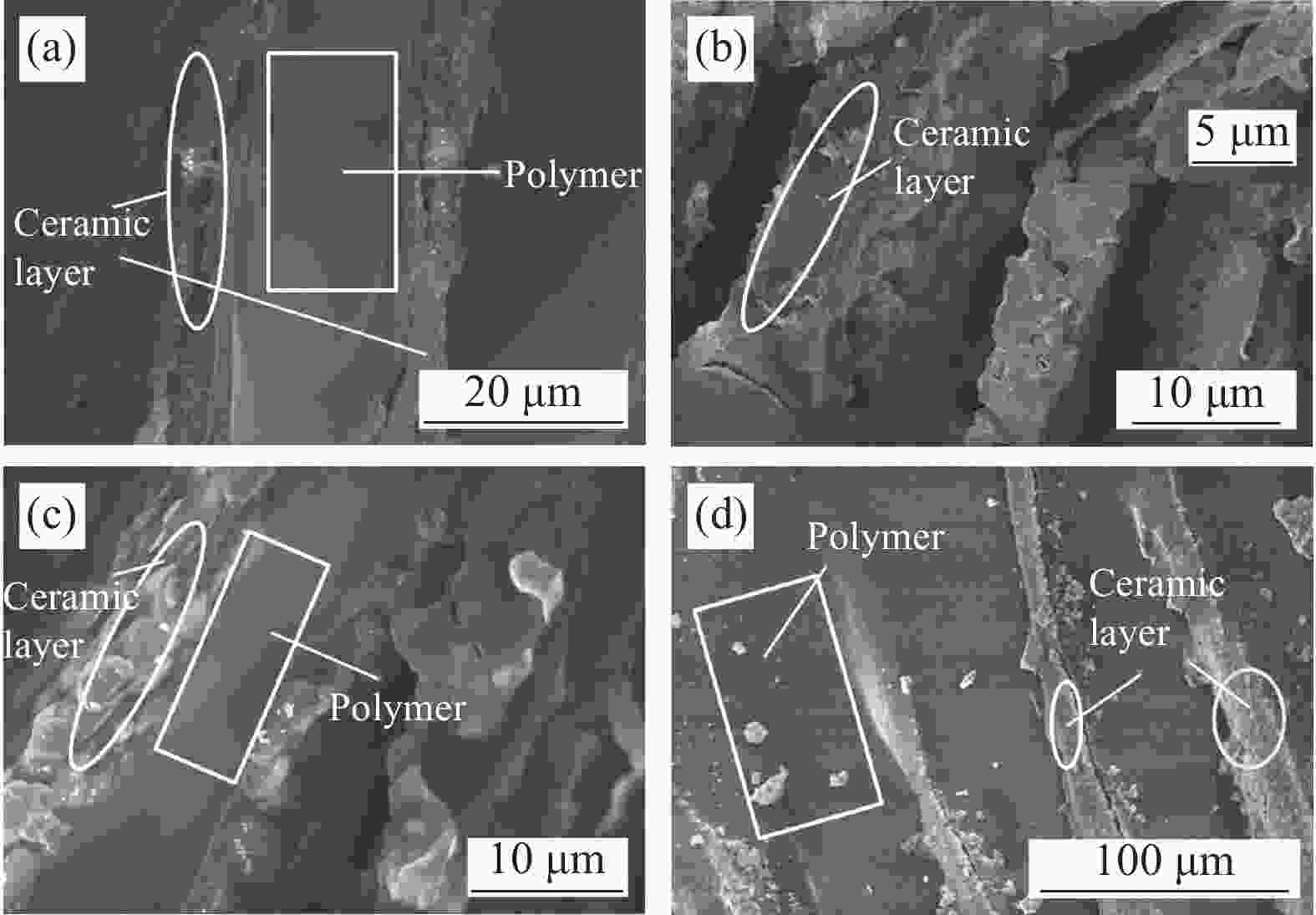

图 7 固体载荷量为30vol%时被聚合物填充后的陶瓷SEM图像:(a)分散剂为CE64,聚醚酰亚胺/二氯甲烷(PEI/DCM)溶液浓度为10wt%;(b)分散剂为CE64,PEI/DCM溶液浓度为15wt%;(c)分散剂为Tris-HCl,PEI/DCM溶液浓度为10wt%;(d)分散剂为Tris-HCl,PEI/DCM溶液浓度为15wt%

Figure 7. SEM images of ceramic filled with polymer when the solid loading is 30vol%: (a) Dispersant is CE64, the concentration of polyethylenimine/dichloromethane (PEI/DCM) solution is 10wt%; (b) Dispersant is CE64, the concentration of PEI/DCM solution is 15wt%; (c) Dispersant is Tris-HCl, the concentration of PEI/DCM solution is 10wt%; (d) Dispersant is Tris-HCl, and the concentration of PEI/DCM solution is 15wt%

图 12 陶瓷复合材料:(a)热容;(b)面间热扩散系数;(c)面内热扩散系数;(d)面间导热系数;(e)面内导热系数;(f)面间与面内方向示意图

Figure 12. Ceramic composites: (a) Heat capacity; (b) Inter-plane thermal diffusion coefficient; (c) In-plane thermal diffusion coefficient; (d) Inter-plane thermal conductivity; (e) In-plane thermal conductivity; (f) Inter-plane and in-plane direction diagram

-

[1] VERMA R, CHAUHAN A, BATOO K M, et al. Structural, optical, and electrical properties of vanadium-doped, lead-free BCZT ceramics[J]. Journal of Alloys and Compounds,2021,869:159520. doi: 10.1016/j.jallcom.2021.159520 [2] ABDMOULEH H, KRIAA I, ABDELMOULA N, et al. The effect of Zn2+ and Nb5+ substitution on structural, dielectric, electrocaloric properties, and energy storage density of Ba0.95Ca0.05Ti0.95Zr0.05O3 ceramics[J]. Journal of Alloys and Compounds,2021,878:160355. doi: 10.1016/j.jallcom.2021.160355 [3] SHI Z, CAO S, ARAÚJO A J M, et al. Plate-like Ca3Co4O9: A novel lead-free piezoelectric material[J]. Applied Surface Science,2021,536:147928. doi: 10.1016/j.apsusc.2020.147928 [4] NAYAK R L, DASH S S, ZHANG Y J, et al. Enhanced dielectric, thermal stability, and energy storage properties in compositionally engineered lead-free ceramics at morphotropic phase boundary[J]. Ceramics International,2021,47(12):17220-17233. doi: 10.1016/j.ceramint.2021.03.033 [5] KOZIELSKI L, WILK A, BUĆKO M M, et al. A large piezoelectric strain recorded in BCT ceramics obtained by a modified pechini method[J]. Materials,2020,13(7):1620. doi: 10.3390/ma13071620 [6] HAERTLING G H. Ferroelectric ceramics: History and technology[J]. Journal of the American Ceramic Society,1999,82(4):797-818. doi: 10.1111/j.1151-2916.1999.tb01840.x [7] VERMA R, CHAUHAN A, BATOO K M, et al. Structural, morphological, and optical properties of strontium doped lead-free BCZT ceramics[J]. Ceramics International,2021,47(11):15442-15457. doi: 10.1016/j.ceramint.2021.02.110 [8] HONG Q X, XU Z X, ZHANG Y Y, et al. Improved upconversion photoluminescence properties of 0.965K0.4Na0.58Li0.02Nb0.96Sb0.04O3-0.035 Bi0.5K0.5ZrO3: 0.25% Er/xIn lead-free piezoelectric ceramics with balanced piezoelectric coefficient and curie temperature.[J]. Journal of Materials Science Materials in Electronics,2018,29(24):20923-20930. doi: 10.1007/s10854-018-0236-1 [9] WANG K, YAO F Z, JO W, et al. Temperature-insensitive (K, Na)NbO3-based lead-free piezoactuator ceramics[J]. Advanced Functional Materials,2013,23(33):4079-4086. doi: 10.1002/adfm.201203754 [10] XU K, LI J, LYU X, et al. Superior piezoelectric properties in potassium-sodium niobate lead-free ceramics[J]. Advanced Materials,2016,28(38):8519-8523. doi: 10.1002/adma.201601859 [11] LEE M H, KIM D J, PARK J S, et al. High-performance lead-free piezoceramics with high curie temperatures[J]. Advanced Materials,2015,27(43):6976-6982. doi: 10.1002/adma.201502424 [12] TAKENAKA T, MARUYAMA K M K, SAKATA K S K. (Bi0.5Na0.5)TiO3-BaTiO3 system for lead free piezoelectric ceramics[J]. Japanese Journal of Applied Physics,1991,30(9S):2236. [13] CHEN M, XU Q, KIM B H, et al. Structure and electrical properties of (Na0.5Bi0.5)1-xBaxTiO3 piezoelectric ceramics[J]. Journal of the European Ceramic Society,2008,28(4):843-849. doi: 10.1016/j.jeurceramsoc.2007.08.007 [14] ZHANG S T, KOUNGA A B, AULBACH E, et al. Giant strain in lead-free piezoceramics Bi0.5Na0.5TiO3-BaTiO3-K0.5Na0.5NbO3 system[J]. Applied Physics Letters,2007,91(11):112906. doi: 10.1063/1.2783200 [15] TAN L M, WANG X C, ZHU W J, et al. Excellent piezoelectric performance of KNNS-based lead-free piezoelectric ceramics through powder pretreatment by hydrothermal method[J]. Journal of Alloys and Compounds,2021,874:159770. doi: 10.1016/j.jallcom.2021.159770 [16] LIU W F, REN X B. Large piezoelectric effect in Pb-free ceramics[J]. Physical Review Letters,2009,103(25):257602. doi: 10.1103/PhysRevLett.103.257602 [17] CHEN M, YIN J, FENG Y, et al. Effect of content on dielectric performance of barium titanate/polyimide films[C]//Proceedings of 2011 International Conference on Electronic & Mechanical Engineering and Information Technology. Harbin: Institute of Electrical and Electronics Engineers (IEEE) , 2011, 4: 2033-2036. [18] GUO J, ZHAO X T, HERISSON DE BEAUVOIR T, et al. Recent progress in applications of the cold sintering process for ceramic-polymer composites[J]. Advanced Functional Materials,2018,28(39):1801724. doi: 10.1002/adfm.201801724 [19] ZHANG Q Q, GAO F, HU G X, et al. Characterization and dielectric properties of modified Ba0.6Sr0.4TiO3/poly(vinylidene fluoride) composites with high dielectric tunability[J]. Composites Science and Technology,2015,118:94-100. doi: 10.1016/j.compscitech.2015.08.013 [20] GUO Y T, MENG N, ZHANG Y M, et al. Characterization and performance of plate-like Ba0.6Sr0.4TiO3/poly(vinylidene fluoride-trifluoroethylene-chlorotrifluoroethylene) composites with high permittivity and low loss[J]. Polymer,2020,203:122777. doi: 10.1016/j.polymer.2020.122777 [21] XIA W M, XU Z, WEN F, et al. Electrical energy density and dielectric properties of poly(vinylidene fluoride-chlorotrifluoroethylene)/BaSrTiO3 nanocomposites[J]. Ceramics International,2012,38(2):1071-1075. doi: 10.1016/j.ceramint.2011.08.033 [22] GUPTA P, KUMAR A, TOMAR M, et al. Enhanced dielectric properties and suppressed leakage current density of PVDF composites flexible film through small loading of submicron Ba0.7Sr0.3TiO3 crystallites[J]. Journal of Materials Science: Materials in Electronics,2017,28(16):11806-11812. doi: 10.1007/s10854-017-6987-2 [23] JO H, KIM M J, CHOI H, et al. Morphological study of directionally freeze-cast nickel foams[J]. Metallurgical and Materials Transactions E,2016,3(1):46-54. doi: 10.1007/s40553-016-0068-y [24] ROUSSEL D, LICHTNER A, JAUFFRÈS D, et al. Strength of hierarchically porous ceramics: Discrete simulations on X-ray nanotomography images[J]. Scripta Materialia,2016,113:250-253. doi: 10.1016/j.scriptamat.2015.11.015 [25] SEPULVEDA P, BINNER J G P. Processing of cellular ceramics by foaming and in situ polymerisation of organic monomers[J]. Journal of the European Ceramic Society,1999,19(12):2059-2066. doi: 10.1016/S0955-2219(99)00024-2 [26] MILLER S M, XIAO X, FABER K T. Freeze-cast alumina pore networks: Effects of freezing conditions and dispersion medium[J]. Journal of the European Ceramic Society,2015,35(13):3595-3605. doi: 10.1016/j.jeurceramsoc.2015.05.012 [27] PEKOR C M, KISA P, NETTLESHIP I. Effect of polyethylene glycol on the microstructure of freeze-cast alumina[J]. Journal of the American Ceramic Society,2008,91(10):3185-3190. doi: 10.1111/j.1551-2916.2008.02616.x [28] CLEARFIELD D, WEI M. Investigation of structural collapse in unidirectionally freeze cast collagen scaffolds[J]. Journal of Materials Science: Materials in Medicine,2016,27(1):1-8. doi: 10.1007/s10856-015-5616-y [29] AN S, KIM B, LEE J. Incomparable hardness and modulus of biomimetic porous polyurethane films prepared by directional melt crystallization of a solvent[J]. Journal of Crystal Growth,2017,469:106-113. doi: 10.1016/j.jcrysgro.2016.08.057 [30] DEVILLE S. Freeze-casting of porous ceramics: A review of current achievements and issues[J]. Advanced Engineering Materials,2008,10(3):155-169. doi: 10.1002/adem.200700270 [31] SCOTTI K L, DUNAND D C. Freeze casting–A review of processing, microstructure and properties via the open data repository[J]. Progress in Materials Science,2018,94:243-305. doi: 10.1016/j.pmatsci.2018.01.001 [32] DURÁN P, LACHÉN J, PLOU J, et al. Behaviour of freeze-casting iron oxide for purifying hydrogen streams by steam-iron process[J]. International Journal of Hydrogen Energy,2016,41(43):19518-19524. doi: 10.1016/j.ijhydene.2016.06.062 [33] NALEWAY S E, YU C F, PORTER M M, et al. Bioinspired composites from freeze casting with clathrate hydrates[J]. Materials & Design,2015,71:62-67. [34] GHOSH D, DHAVALE N, BANDA M, et al. A comparison of microstructure and uniaxial compressive response of ice-templated alumina scaffolds fabricated from two different particle sizes[J]. Ceramics International,2016,42(14):16138-16147. doi: 10.1016/j.ceramint.2016.07.131 [35] WANG L, TIU C, LIU T J. Effects of nonionic surfactant and associative thickener on the rheology of polyacrylamide in aqueous glycerol solutions[J]. Colloid and Polymer Science,1996,274(2):138-144. doi: 10.1007/BF00663445 [36] DEVILLE S, VIAZZI C, LELOUP J, et al. Ice shaping properties, similar to that of antifreeze proteins of a zirconium acetate complex[J]. PlOS One,2011,6(10):e26474. doi: 10.1371/journal.pone.0026474 [37] ARABI N, ZAMANIAN A. Effect of cooling rate and gelatin concentration on the microstructural and mechanical properties of ice template gelatin scaffolds[J]. Biotechnology and Applied Biochemistry,2013,60(6):573-579. doi: 10.1002/bab.1120 -

下载:

下载: