A graphene/polyurea composite with both thermal conduction and self-healing functions based on dual dynamic networks

-

摘要: 开发能够快速修复的导热材料引起了越来越多的关注。然而,材料的导热性能与自修复性能一直难以平衡,制备具有自愈性的导热聚脲复合材料具有挑战性。为了解决这一难题,本论文提出利用氢键和动态亚胺键的双动态网络构筑自修复聚脲(D-PUA)柔性膜。氢键和亚胺键的动态断裂和重构不断耗散能量,使D-PUA具有良好的弹性和自修复性。实验结果表明,在短时间内(60 ℃、8 min) D-PUA膜上的划痕可完全修复,切断愈合72 h后拉伸强度的修复效率为84.62%。在动态聚脲基体中填充石墨烯(GNP)制备得到兼具自修复、导热性和可回收性的GNP/D-PUA复合膜。基于GNP本身的高导热性,负载量为10 wt%时,复合膜的面内导热系数为2.57 W·m−1·K−1,相对于本征膜提升了571%。GNP10/D-PUA在90 ℃,60 min能够使划痕愈合,切断愈合72 h后拉伸强度的修复效率为83.94%。此外,由于动态键的存在复合膜经过五次热压重塑后,没有明显的机械损失,且面内热导率的回复率均在80.93%以上。Abstract: The development of thermal conductivity materials that can be quickly repaired has attracted increasing attention. However, due to the trade-off between thermal conductivity and self-healing properties of materials, it is challenging to prepare thermal conductivity polyurea composites with self-healing properties. To solve this problem, this paper proposes to construct self-healing polyurea (D-PUA) flexible membrane by using the double dynamic network of hydrogen bonds and dynamic imine bonds. The dynamic breaking and reconstruction of hydrogen bonds and imine bonds dissipates energy continuously, which makes D-PUA have good elasticity and self-repair. The experimental results demonstrate that scratches on the D-PUA film can be completely repaired in a short time (60 ℃, 8 min), and the repair efficiency of tensile strength reaching 84.62% after 72 h of cutting and healing. The GNP/D-PUA composite membrane with self-healing, thermal conductivity and recyclability was prepared by incorporating graphene (GNP) as a filler. Due to the high thermal conductivity of graphene itself, the in-plane thermal conductivity of the composite film is 2.57 W·m−1·K−1 when the GNP content is 10 wt%, which is 571% higher than that of the pure film. GNP10/D-PUA can also heal scratches at 90 ℃ for 60 min, and the repair efficiency of tensile strength after 72 h of cutting and healing is 83.94%. Additionally, due to the presence of dynamic bonds, there is no significant mechanical loss after five hot pressing remodeling of the composite film, and the repair rate of in-plane thermal conductivity is above 80.93% in all cases.

-

Key words:

- Polyurea /

- Self-healing /

- Hydrogen bonds /

- Imine bonds /

- Heat conduction /

- Composite materia

-

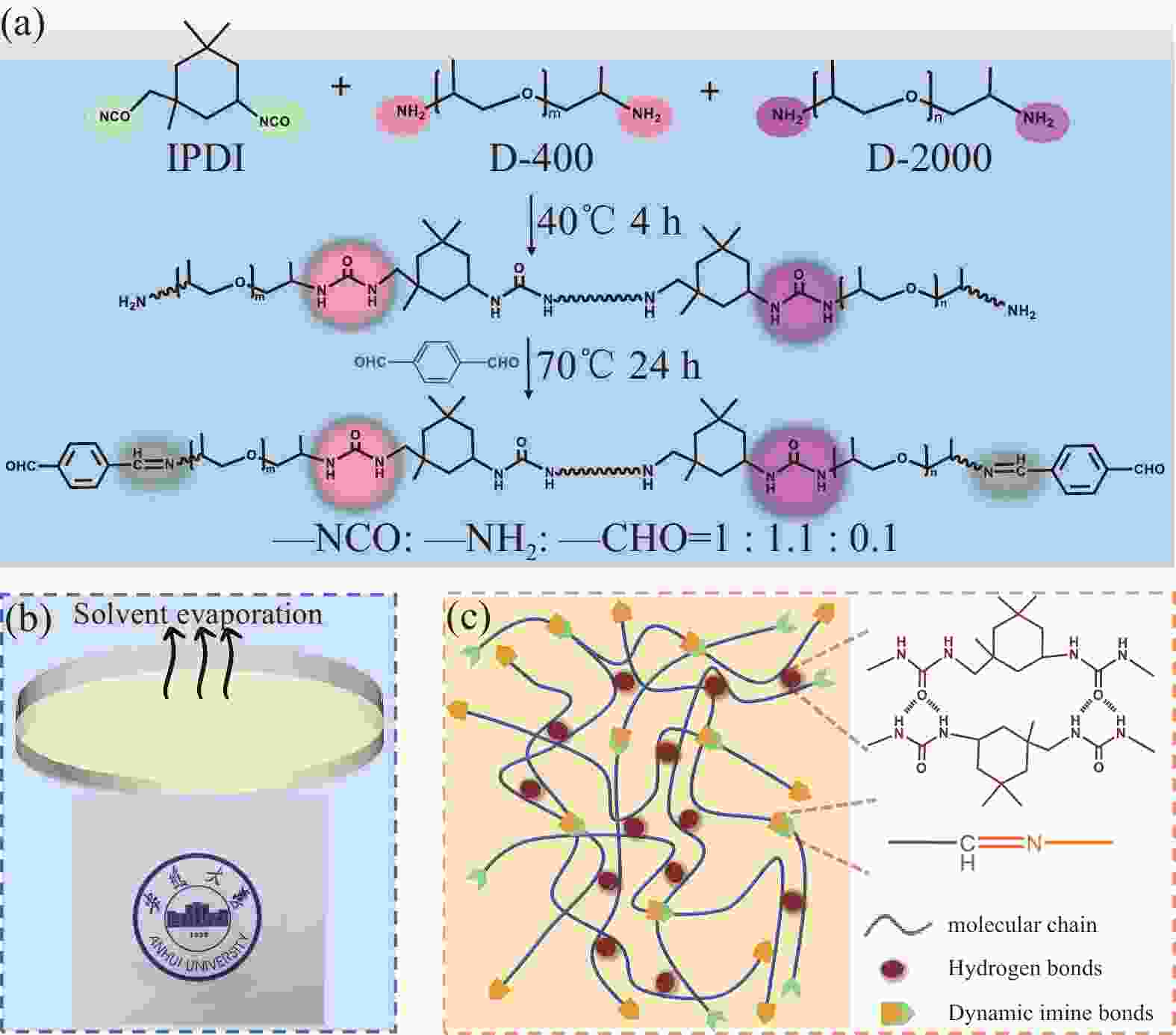

图 1 (a) 自修复聚脲(D-PUA)的合成路线图; (b) D-PUA薄膜的制备过程示意图; (c) D-PUA双动态网络结构示意图,包含氢键和动态亚胺键

Figure 1. (a) The synthetic route of self-healing polyurea (D-PUA); (b) Schematic demon-stration of the preparation process of the D-PUA films; (c) D-PUA dual dynamic network structure diagram, including hy-drogen bonds and dynamic imine bonds

图 4 (a) PUA和D-PUA划痕自修复的光学显微镜图像; (b) 染色和未染色D-PUA样品在60℃下修复72 h的数码照片; (c) D-PUA切断后在60℃下不同愈合时间的应力-应变曲线; (d) D-PUA切断后在60℃下不同愈合时间的韧性及修复效率; (e) D-PUA自修复机制图

Figure 4. (a) Optical microscope images of PUA and D-PUA scratch self-healing; (b) Digital photos of dyed and undyed D-PUA samples repaired at 60 ° C for 72 h; (c) Stress-strain curves of D-PUA after cutting at different healing times at 60℃; (d) Toughness and repair efficiency of D-PUA after cutting at different healing time at 60℃; (e) Self-healing mechanism diagram of D-PUA

图 5 (a) 具有不同质量分数石墨烯(GNP)复合材料的应力-应变曲线;(b) GNP10/D-PUA划痕自修复的光学显微镜图像;(c) GNP10/D-PUA切断后在90℃下不同愈合时间的应力-应变曲线;(d) GNP10/D-PUA切断后在90℃下不同愈合时间的韧性及修复效率

Figure 5. (a) Stress-strain curves of composites with different mass fractions graphene (GNP); (b) Optical microscope images of GNP10/D-PUA scratch self-healing; (c) Stress-strain curves of GNP10/D-PUA after cutting at different healing times at 90℃; (d) Toughness and repair efficiency of GNP10/D-PUA after cutting at different healing time at 90℃

图 9 (a) 不同填料含量的GNP/D-PUA平面内导热系数; (b) GNP/D-PUA 的传热机制图; (c) 放置在加热板边缘的GNP/D-PUA复合材料的热红外图像; (d) GNP/D-PUA在散热器的LED间通电前后的红外热像图和 (e)不同时间点对应的表面温度

Figure 9. (a) The in-plane thermal conductivity of GNP/D-PUA with different stuffing contents; (b) Heat transfer mechanism diagram of GNP/D-PUA composite; (c) Thermal infrared images of GNP/D-PUA composites placed on the edge of a heating plate; (d) Infrared thermal images of GNP/D-PUA before and after power is applied between the LED of the radiator and (e) corresponding surface temperature at different time points

-

[1] ZHAO L W, SHI X R, YIN Y, et al. A self-healing silicone/BN composite with efficient healing property and improved thermal conductivities[J]. Composites Science and Technology, 2020, 186: 107919. doi: 10.1016/j.compscitech.2019.107919 [2] HUYNH T P, SONAR P, HAICK H. Advanced materials for use in soft self-healing devices[J]. Advanced Materials, 2017, 29(19): 1604973. doi: 10.1002/adma.201604973 [3] 叶娟, 祖兆基, 林子谦, 等. 本征型自修复聚硅氧烷材料: 从单重动态交联网络到多重动态交联网络[J]. 高分子学报, 2023, 54(7): 1028-1054.YE Juan, ZU Zhaoji, LIN Ziqian, et al. Intrinsic self-healing polysiloxane materials: from single dynamic crosslinked network to multiple dynamic crosslinked networks[J]. Acta Polymerica Sinica, 2023, 54(7): 1028-1054(in Chinese). [4] ZHAO J, ZHANG Z M, WANG C Y, et al. Synergistic dual dynamic bonds in covalent adaptable networks[J]. CCS Chemistry, 2024, 6: 41-56. doi: 10.31635/ccschem.023.202303045 [5] XIE J, YANG M, LIANG J, et al. Self-healing of internal damage in mechanically robust polymers utilizing a reversibly convertible molecular network[J]. Journal of Materials Chemistry A, 2021, 9(29): 15975-15984. doi: 10.1039/D1TA03512F [6] LI H L, XU F C, WANG J L, et al. Self-healing fluorinated poly (urethane urea) for mechanically and environmentally stable, high performance, and versatile fully self-healing triboelectric nanogenerators[J]. Nano Energy, 2023, 108: 108243. doi: 10.1016/j.nanoen.2023.108243 [7] WANG D, XU J H, CHEN J Y, et al. Transparent, mechanically strong, extremely tough, self-recoverable, healable supramolecular elastomers facilely fabricated via dynamic hard domains design for multifunctional applications[J]. Advanced Functional Materials, 2020, 30(3): 1907109. doi: 10.1002/adfm.201907109 [8] COOPER C B, ROOST S E, MICHALEK L, et al. Autonomous alignment and healing in multilayer soft electronics using immiscible dynamic polymers[J]. Science, 2023, 380(6648): 935-941. doi: 10.1126/science.adh0619 [9] MING X Q, DU J Y, ZHANG C G, et al. All-solid-state self-healing ionic conductors enabled by ion-dipole interactions within fluorinated poly (ionic liquid) copolymers[J]. ACS Applied Materials & Interfaces, 2021, 13(34): 41140-41148. [10] LIU Y, ZHANG Y, CHEN T, et al. A stable and self-healing thermochromic polymer coating for all weather thermal regulation[J]. Advanced Functional Materials, 2023, 33(49): 2307240. doi: 10.1002/adfm.202307240 [11] XIONG H, WU H T, ZHANG J Q, et al. Healable and recyclable polyurethane with natural-rubber-like resilience via π-type tweezer structure stabilizing dynamical hard domains[J]. Macromolecules, 2023, 56(21): 8581-8591. doi: 10.1021/acs.macromol.3c01770 [12] ZHAO D, ZHOU X Z, Li Q R, et al. Unprecedented toughness in transparent, luminescent, self-healing polymers enabled via hierarchical rigid domain design[J]. Materials Horizons, 2022, 9(10): 2626-2632. doi: 10.1039/D2MH00820C [13] CHEN L, XU J H, ZHU M M, et al. Self-healing polymers through hydrogen-bond cross-linking: synthesis and electronic applications[J]. Materials Horizons, 2023, 10(10): 4000-4032. doi: 10.1039/D3MH00236E [14] ZHANG R, HUANG W B, LYU P, et al. Polyurea for blast and impact protection: a review[J]. Polymers, 2022, 14(13): 2670. doi: 10.3390/polym14132670 [15] LIU W, HE Y, LENG J. Humidity-responsive shape memory polyurea with a high energy output based on reversible cross-linked networks[J]. ACS Applied Materials & Interfaces, 2022, 15: 2163-2171. [16] WAN B Q, XIAO M Y, DONG X D, et al. Dynamic covalent adaptable polyimide hybrid dielectric films with superior recyclability[J]. Advanced Materials, 2023, 2304175. [17] YU P, WANG H, LI T, et al. Mechanically robust, recyclable, and self-healing polyimine networks[J]. Advanced Science, 2023, 10(19): 2300958. doi: 10.1002/advs.202300958 [18] WAN B, YANG X, DONG X, et al. Dynamic sustainable polyimide film combining hardness with softness via a "mimosa-like" bionic strategy[J]. Advanced Materials, 2023, 35(2): 2207451. doi: 10.1002/adma.202207451 [19] DING S J, ZHU G C, ZHAO S, et al. Simultaneously optimized healing efficiency and mechanical strength in polymer composites reinforced by ultrahigh loading fillers based on interfacial energy and dynamic disulfide bonds[J]. Polymer, 2022, 251: 124711. doi: 10.1016/j.polymer.2022.124711 [20] WANG D, LIU D, XU J, et al. Highly thermoconductive yet ultraflexible polymer composites with superior mechanical properties and autonomous self-healing functionality via a binary filler strategy[J]. Materials Horizons, 2022, 9(2): 640-652. doi: 10.1039/D1MH01746B [21] ZAREPOUR A, AHMADI S, RABIEE N, et al. Self-healing mxene and graphene-based composites: properties and applications[J]. Nano-Micro Letters, 2023, 15(1): 100. doi: 10.1007/s40820-023-01074-w [22] YU H, CHEN C, SUN J, et al. Highly thermally conductive polymer/graphene composites with rapid room-temperature self-healing capacity[J]. Nano-Micro Letters, 2022, 14(1): 135. doi: 10.1007/s40820-022-00882-w [23] NIU W, LI Z, LIANG F, et al. Ultrastable, superrobust, and recyclable supramolecular polymer networks[J]. Angewandte Chemie-International Edition, 2024: 18434. [24] WU P X, CHENG H Y, WANG Y, et al. New kind of thermoplastic polyurea elastomers synthesized from CO2 and with self-healing properties[J]. ACS Sustainable Chemistry & Engineering, 2020, 8(33): 12677-12685. [25] ZHANG Z, QIAN L, CHENG J, et al. Room-temperature self-healing polyurea with high puncture and impact resistances[J]. Chemistry of Materials, 2023, 35(4): 1806-1817. doi: 10.1021/acs.chemmater.2c03782 [26] CHAO A, NEGULESCU I, ZHANG D. Dynamic covalent polymer networks based on degenerative imine bond exchange: tuning the malleability and self-healing properties by solvent[J]. Macromolecules, 2016, 49(17): 6277-6284. doi: 10.1021/acs.macromol.6b01443 [27] ZHANG S, QIN B, XU J F, et al. Multi-recyclable shape memory supramolecular polyurea with long cycle life and superior stability[J]. ACS Materials Letters, 2021, 3(4): 331-336. doi: 10.1021/acsmaterialslett.1c00053 [28] 邹佳利, 于云鹏, 闫雨晴等. 木质素增强可自修复聚脲弹性体的制备与性能[J]. 复合材料学报, 2023, 40(10): 5666-5677.ZOU Jiali, YU Yunpeng, YAN Yuqing, et al. Fabrication and properties of lignin-reinforced self-healing polyurea elastomer[J]. Acta Materiae Compositae Sinica, 2023, 40(10): 5666-5677(in Chinese). [29] YU J, WANG K, FAN C C, et al. An ultrasoft self-fused supramolecular polymer hydrogel for completely preventing postoperative tissue adhesion[J]. Advanced Materials, 2021, 33(16): 2008395. doi: 10.1002/adma.202008395 [30] TU J, XU H, TIAN J Q, et al. A novel, high strength, ultra-fast room temperature self-healing elastomers via structural functional region optimization strategy[J]. Chemical Engineering Journal, 2023, 465: 142887. doi: 10.1016/j.cej.2023.142887 [31] LUO J C, ZHAO X, JU H, et al. Highly recyclable and tough elastic vitrimers from a defined polydimethylsiloxane network[J]. Angewandte Chemie-International Edition, 2023, 62(47). [32] RAO S P, FAN J F, ZHOU Y, et al. High damping, soft and reprocessable thermal interface materials inspired by the microstructure of skin tissue[J]. Composites Science and Technology, 2024, 247: 110428. doi: 10.1016/j.compscitech.2023.110428 [33] CHEN M, YOU W, WANG J, et al. Enhancing the toughness and strength of polymers using mechanically interlocked hydrogen bonds[J]. Journal of the American Chemical Society, 2023, 146(1): 1109-1121. [34] WANG S Y, URBAN M W. Self-healing polymers[J]. Nature Reviews Materials, 2020, 5(8): 562-583. doi: 10.1038/s41578-020-0202-4 [35] XU J H, LI Y K, LIU T, et al. Room-temperature self-healing soft composite network with unprecedented crack propagation resistance enabled by a supramolecular assembled lamellar structure[J]. Advanced Materials, 2023, 35(26): 2300937. doi: 10.1002/adma.202300937 [36] WANG C Y, GENG X, CHEN J, et al. Multiple H-bonding cross-linked supramolecular solid-solid phase change materials for thermal energy storage and management[J]. Advanced Materials, 2023, 2309723. [37] WANG Y Y, HUANG X, ZHANG X X. Ultrarobust, tough and highly stretchable self-healing materials based on cartilage-inspired noncovalent assembly nanostructure[J]. Nature Communications, 2021, 12(1): 1291 doi: 10.1038/s41467-021-21577-7 [38] GUO H, HAN Y, ZHAO W, et al. Universally autonomous self-healing elastomer with high stretchability[J]. Nature Communications, 2020, 11(1): 2037. doi: 10.1038/s41467-020-15949-8 [39] WU Y C M, CHYR G, PARK H, et al. Stretchable, recyclable thermosets via photopolymerization and 3D printing of hemiacetal ester-based resins[J]. Chemical Science, 2023, 14(44): 12535-12540. doi: 10.1039/D3SC03623E [40] 陈灿, 俞慧涛, 冯奕钰, 等. 兼具导热和自修复功能的聚合物复合材料[J]. 高分子学报, 2021, 52(3): 272-280.CHEN Can, YU Huitao, FENG Yiyu, et al. Polymer composite material with both thermal conduction and self-healing functions[J]. Acta Polymerica Sinica, 2021, 52(3): 272-280(in Chinese). [41] LI X, WU B, LV Y, et al. Effect of regulating the interfacial structure of multiple non-covalent bonding on improving thermal management capability[J]. Journal of Materials Chemistry A, 2024, 12(2): 864-875. doi: 10.1039/D3TA05936G [42] YUE D W, WANG H Q, TAO H Q, et al. A fast and room-temperature self-healing thermal conductive polymer composite[J]. Chinese Journal of Polymer Science, 2021, 39(10): 1328-1336. doi: 10.1007/s10118-021-2620-1 -

点击查看大图

点击查看大图

计量

- 文章访问数: 53

- HTML全文浏览量: 48

- 被引次数: 0

下载:

下载: