Mechanical characterization of mode I fracture at the interface of CFRP single-sided patch repair of damaged aerospace titanium alloy components

-

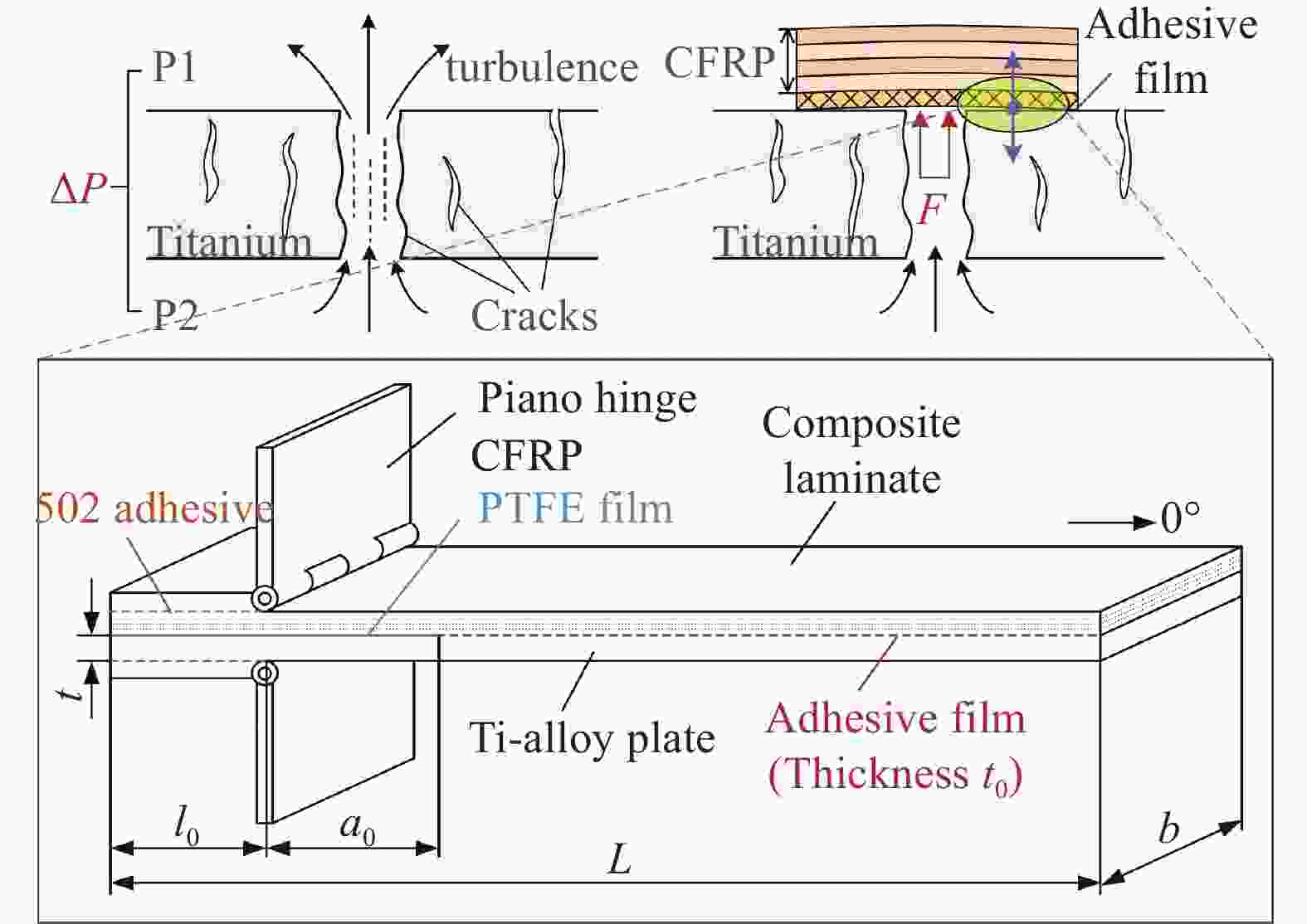

摘要: 针对航空钛合金损伤贴补修复结构在I型受载条件下的力学响应与断裂特性,本文采用共固化成型方法设计了碳纤维增强树脂基预浸料(Carbon Fiber Reinforced Polymer, CFRP)单面贴补钛合金构件的修复试样,通过双悬臂梁试验,系统的研究了补片厚度、铺层方向以及表面处理方法三个典型因素对修复界面I型断裂力学特性的影响规律,以峰值载荷和层间断裂韧性为指标评估整体修复效果。结合试样在宏观和微观尺度下的失效模式与断面形貌分析,揭示了钛合金/CFRP贴补修复试样I型静态分层扩展的破坏机制。研究结果表明,随着补片厚度的增加,试样弯曲刚度和纤维桥联规模呈上升趋势,修复界面的I型断裂性能明显提高,失效模式均表现为胶膜粘附失效与内聚破坏到CFRP界面破坏的演化过程;在复合铺层试样中,补片底部的0°铺层表现出最强的分层路径约束作用,而45°铺层能够诱发裂纹的层间迁移以提高增韧效果,二维编织型补片则具有最佳的修复效果;胶膜内聚破坏为表面处理试样的主要失效模式,其中硫酸阳极化的增韧效果最为显著,断裂韧性较石英喷砂和400#砂纸打磨分别提高3.8%和1.9%,相比无处理试样则提高了19.2%。该结论为I型受载条件下钛合金损伤复合材料贴补修复工艺的优化设计与应用实践提供参考。Abstract: To investigate the mechanical response and fracture characteristics of adhesively bonded titanium alloy structures under mode I loading conditions, this study employed a co-curing method to fabricate repair specimens with single-sided carbon fiber reinforced polymer (CFRP) patches bonded to titanium alloy substrates. The effects of patch thickness, ply orientation, and surface treatment on mode I interfacial fracture mechanics were systematically examined using double cantilever beam (DCB) tests. Peak load and interlaminar fracture toughness were utilized as quantitative metrics to evaluate the overall repair performance. Furthermore, failure modes and fracture surface morphologies at both macroscopic and microscopic scales were analyzed to elucidate the underlying failure mechanisms of mode I static delamination in the titanium alloy/CFRP repaired specimens. The results reveal that increasing the thickness of the patch leads to a rising trend in both the bending stiffness of the specimen and the extent of fiber bridging. The mode I fracture performance of the repair interface improves significantly, with failure modes consistently evolving from adhesive failure of the glue film and cohesive damage to failure at the CRFP interface. For multidirectional laminates, the 0° ply at the bottom of the patch exhibits the strongest constraint on delamination paths, while the 45° ply effectively induces inter-ply crack migration, enhancing the toughening effect. Notably, the two-dimensional woven patch demonstrates the best repair performance. For surface-treated specimens, cohesive failure of the adhesive film is the predominant failure mode. Specifically, sulfuric acid anodization provides the most significant toughening effect, increasing fracture toughness by 3.8% and 1.9% compared to quartz sandblasting and 400# sandpaper abrasion, respectively, and by 19.2% compared to untreated specimens. These conclusions provide references for the optimized design and practical application of damage repair processes under mode I loading conditions for titanium alloy components.

-

Key words:

- composite materials /

- patch repair /

- mode I fracture /

- fracture toughness /

- aviation metal /

- double cantilever beam

-

图 13 不同铺层方向修复试样分层断面的微观形貌:(a) [±45]2 s;(b) [0/90]2 s;(c) [90/0]2 s;(d) [0/±45/90]s;(e) [±45/02]s;(f) [(0/90)w]8

Figure 13. Microscopic morphology of delamination sections of repaired specimens with different layup orientations: (a) [±45]2 s; (b) [0/90]2 s; (c) [90/0]2 s;(d) [0/±45/90]s; (e) [±45/02]s; (f) [(0/90)w]8

图 17 经处理后的钛合金表面微观形貌:(a)无处理;(b)400#砂纸打磨;(c)硫酸阳极化;(d)石英喷砂;及修复试样粘接界面:(e)无处理;(f)400#砂纸打磨;(g)硫酸阳极化;(h)石英喷砂

Figure 17. Microstructure of the Ti-alloy substrate surfaces treated by: (a) Untreated; (b) Sandpapering-400#; (c) Sulphuric acid anodizing; (d) Quartz-blasting; and bonding interfaces in repaired specimens: (e) Untreated; (f) Sandpapering-400#; (g) Sulphuric acid anodizing; (h) Quartz-blasting

表 1 钛合金/CFRP单面贴补修复试样几何参数

Table 1. Geometric parameters of titanium alloy-CFRP single-sided patch repaired specimen

Parameter Description Value / mm l0 Hinge additional length 17 a0 Length of initial crack 50 L Total length 150 b Specimen width 25 t Ti-alloy thickness 1.5 t0 Thickness of adhesive film 0.12 表 2 结构胶膜、单向及平纹编织CFRP力学性能参数

Table 2. Mechanical properties of adhesive film unidirectional (UD) and plain weave (PW) CFRP

Adhesive

SY-24 CUD

Laminate

(T700/725)PW

Laminate

(T700/725)Property Value Property Value Property Value E/MPa 5750 E1/GPa 119 E1/GPa 66.28 G/MPa 1920 E2/GPa 9 E2/GPa 61.8 σ/MPa 451.6 E3/GPa 9 E3/GPa 10 τ/MPa 36.5 ν12, ν13 0.309 ν12 0.057 GC n /(N·mm−1) 0.48 ν23 0.35 ν13, ν23 0.25 GC s /(N·mm−1) 0.64 G12, G13 /GPa 4 G12/GPa 4.52 GC t /(N·mm−1) 0.64 G23/GPa 3.33 G13, G23 /GPa 4 Notes: E, G – Elastic modulus in tension and shear; σ, τ – Failure strengths in tension and shear; GC n– Toughness in tension; GC s, GC t– Toughness in shear; Eii (i =1, 2, 3) – Young’s modulus (i direction); Gij (i, j =1, 2, 3) – Shear modulus (i-j plane); vij (i, j=1, 2, 3) – Poisson’s ratio (i-j plane). 表 3 钛合金/CFRP单面贴补修复试样影响因素及参数设置

Table 3. Influencing factors and parameter setting of titanium alloy-CFRP single-sided patch repaired specimen

Repair factors Symbol Factor settings Patch thickness/mm TP 1.14, 1.52, 1.90, 2.28, 2.66 Lay-up direction/(°) θP [0]8, [±45]2 s, [0/90]2 s, [90/0]2 s, [(0/90)w]8, [0/±45/90]s, [±45/02]s Surface treatment RT Sandpapering, Quartz-blasting, Sulphuric acid anodizing, Untreated -

[1] 郝建滨, 李旭东, 穆志韬. 金属裂纹板复合材料胶接修补强度的弹塑性有限元预测[J]. 复合材料学报, 2016, 33(3): 643-649.HAO Jianbin, LI Xudong, MU Zhitao. Repair strength predictions of cracked metal plates bonded with composite patches using elastic-plastic finite element method[J]. Acta Materiae Compositae Sinica, 2016, 33(3): 643-649(in Chinese). [2] ABUSREA M R, ARAKAWA K. Improvement of an adhesive joint constructed from carbon fiber-reinforced plastic and dry carbon fiber laminates[J]. Composites Part B: Engineering, 2016, 97: 368-373. doi: 10.1016/j.compositesb.2016.05.005 [3] XIONG J J, SHENOI R A. Integrated experimental screening of bonded composites patch repair schemes to notched aluminum-alloy panels based on static and fatigue strength concepts[J]. Composite Structures, 2008, 83(3): 266-272. doi: 10.1016/j.compstruct.2007.04.019 [4] CHEN D, ARAKAWA K, JIANG S. Novel joints developed from partially un-moulded carbon-fibre-reinforced laminates[J]. Journal of composite materials, 2015, 49(14): 1777-1786. doi: 10.1177/0021998314540195 [5] SUN Y, TANG M, RONG Z, et al. An experimental investigation on the low-velocity impact response of carbon–aramid/epoxy hybrid composite laminates[J]. Journal of Reinforced Plastics and Composites, 2017, 36(6): 422-434. doi: 10.1177/0731684416680893 [6] KAHRAMAN R, SUNAR M, YILBAS B. Influence of adhesive thickness and filler content on the mechanical performance of aluminum single-lap joints bonded with aluminum powder filled epoxy adhesive[J]. Journal of Materials Processing Tech, 2008, 205(1-3): 183-189. doi: 10.1016/j.jmatprotec.2007.11.121 [7] SHAMS S S, EL-HAJJAR R F. Overlay patch repair of scratch damage in carbon fiber/epoxy laminated composites[J]. Composites Part A: Applied Science and Manufacturing, 2013, 49: 148-156. doi: 10.1016/j.compositesa.2013.03.005 [8] SUN L, LI C, TIE Y, et al. Experimental and numerical investigations of adhesively bonded CFRP single-lap joints subjected to tensile loads[J]. International Journal of Adhesion and Adhesives, 2019, 95: 102402. doi: 10.1016/j.ijadhadh.2019.102402 [9] HU J, LI C, FANG J, et al. Comparison of repair methods for cracked titanium alloy aircraft structures with single-sided adhesively bonded composite patches[J]. Materials, 2023, 16(19): 6361. doi: 10.3390/ma16196361 [10] CHOUDHURY M R, DEBNATH K. Experimental analysis of tensile and compressive failure load in single-lap adhesive joint of green composites[J]. International Journal of Adhesion and Adhesives, 2020, 99: 102557. doi: 10.1016/j.ijadhadh.2020.102557 [11] HU J, KANG R, FANG J, et al. An experimental and parametrical study on repair of cracked titanium airframe structures with single-side bonded carbon fiber-reinforced polymer prepreg patches[J]. Composite Structures, 2024, 338: 118102. doi: 10.1016/j.compstruct.2024.118102 [12] 毛振刚, 侯玉亮, 李成. 等. 搭接长度和铺层方式对CFRP复合材料层合板胶接结构连接性能和损伤行为的影响[J]. 复合材料学报, 2020, 37(1): 121-131.MAO Zhengang, HOU Yuliang, LI Cheng, et al. Effect of lap length and stacking sequence on strength and damage behaviors of adhesively bonded CFRP composite laminates[J]. Acta Ma-teriae Compositae Sinica, 2020, 37(1): 121-131(in Chinese). [13] SHAH O R, TARFAOUI M. Effect of adhesive thickness on the Mode I and II strain energy release rates. Comparative study between different approaches for the calculation of Mode I & II SERR's[J]. Composites Part B: Engineering, 2016, 96: 354-363. doi: 10.1016/j.compositesb.2016.04.042 [14] TIE Y, HOU Y, LI C, et al. An insight into the low-velocity impact behavior of patch-repaired CFRP laminates using numerical and experimental approaches[J]. Composite Structures, 2018, 190: 179-188. doi: 10.1016/j.compstruct.2018.01.075 [15] JEFFERSON ANDREW J, SRINIVASAN S M, AROCKIARAJAN A. The role of adhesively bonded super hybrid external patches on the impact and post-impact response of repaired glass/epoxy composite laminates[J]. Composite Structures, 2018, 184: 848-859 doi: 10.1016/j.compstruct.2017.10.070 [16] PARK S, ROY R, KWEON J, et al. Strength and failure modes of surface treated CFRP secondary bonded single-lap joints in static and fatigue tensile loading regimes[J]. Composites Part A: Applied Science and Manufacturing, 2020, 134: 105897. doi: 10.1016/j.compositesa.2020.105897 [17] ASTM International: Standard test method for mode I interlaminar fracture toughness of unidirectional fiber-reinforced polymer matrix composites: ASTM D5528-13[S]. US: West Conshohocken, 2013. [18] 章宇界, 赵鑫, 郭金海, 等. 复合材料胶接用金属喷砂工艺研究[J]. 玻璃钢/复合材料, 2019, (1): 71-74.ZHANG Yujie, ZHAO Xin, GUO Jinhai. Study on metal sandblasting process for bonding of composites[J]. Fiber Reinforced Plastics/Composites, 2019, (1): 71-74(in Chinese). [19] REHAN M S B M, ROUSSEAU J, FONTAINE S, et al. Experimental study of the influence of ply orientation on DCB mode-I delamination behavior by using multidirectional fully isotropic carbon/epoxy laminates[J]. Composite Structures, 2017, 161: 1-7. doi: 10.1016/j.compstruct.2016.11.036 [20] KIM B W, MAYER A H. Influence of fiber direction and mixed-mode ratio on delamination fracture toughness of carbon/epoxy laminates[J]. Composites Science and Technology, 2003, 63(5): 695-713. doi: 10.1016/S0266-3538(02)00258-0 [21] HASHEMI S, KINLOCH A J, WILLIAMS J G. Corrections needed in double-cantilever beam tests for assessing the interlaminar failure of fibre-composites[J]. Journal of Materials Science Letters, 1989, 8: 125-129. doi: 10.1007/BF00730701 [22] ZHOU Y, XIAO Y, WU Q, et al. A multi-state progressive cohesive law for the prediction of unstable propagation and arrest of Mode-I delamination cracks in composite laminates[J]. Engineering Fracture Mechanics, 2021, 248: 107684. doi: 10.1016/j.engfracmech.2021.107684 [23] ZAKARIA A Z, SHELESH-NEZHAD K, CHAKHERLOU T N, et al. Effects of aluminum surface treatments on the interfacial fracture toughness of carbon-fiber aluminum laminates[J]. Engineering Fracture Mechanics, 2017, 172: 139-151. doi: 10.1016/j.engfracmech.2017.01.004 [24] KUPSKI J, DE FREITAS S T, ZAROUCHAS D, et al. Composite layup effect on the failure mechanism of single lap bonded joints[J]. Composite Structures, 2019, 217: 14-26. doi: 10.1016/j.compstruct.2019.02.093 [25] 肖鹏程, 邓健, 王增贤, 等. 超高分子量聚乙烯纤维增强复合材料层合板层间断裂韧性[J]. 复合材料学报, 2023, 40(11): 6087-6097.XIAO Pengcheng, DENG Jian, WANG Zengexian, et al. Interlaminar fracture toughness of ultra-high molecular weight polyethylene fiber rein-forced composite laminates[J]. Acta Materiae Compositae Sinica, 2023, 40(11): 6087-6097(in Chinese). [26] 吴庆欣, 肖毅, 薛元德. 双悬臂梁试件裂纹动态扩展的准静态数值分析[J]. 复合材料学报, 2019, 36(5): 1179-1188.WU Qingxin, XIAO Yi, XUE Yuande. A quasi-static numerical analysis of crack dynamic propagation in double cantilever beam speci-mens[J]. Acta Materiae Compositae Sinica, 2019, 36(5): 1179-1188(in Chinese). [27] TAN W, Martinez-Paneda E. Phase field fracture predictions of microscopic bridging behaviour of composite materials[J]. Composite Structures, 2022, 286: 115242. doi: 10.1016/j.compstruct.2022.115242 [28] SEBAEY T A, BLANCO N, LOPES C S, et al. Numerical investigation to prevent crack jumping in Double Cantilever Beam tests of multidirectional composite laminates[J]. Composites Science and Technology, 2011, 71(13): 1587-1592. doi: 10.1016/j.compscitech.2011.07.002 [29] SUN C, ZHENG S. Delamination characteristics of double-cantilever beam and end-notched flexure composite specimens[J]. Composites Science and Technology, 1996, 56(4): 451-459. doi: 10.1016/0266-3538(96)00001-2 [30] DE MORAIS A B, DE MOURA M F, MARQUES A T, et al. Mode-I interlaminar fracture of carbon/epoxy cross-ply composites[J]. Composites Science and Technology, 2002, 62(5): 679-686. doi: 10.1016/S0266-3538(01)00223-8 [31] KIM B W, MAYER A H. Influence of fiber direction and mixed-mode ratio on delamination fracture toughness of carbon/epoxy laminates[J]. Composites Science and Technology, 2003, 63(5): 695-713. doi: 10.1016/S0266-3538(02)00258-0 [32] ALIF N, CARLSSON L A, BOOGH L. The effect of weave pattern and crack propagation direction on mode I delamination resistance of woven glass and carbon composites[J]. Composites Part B: Engineering, 1998, 29(5): 603-611. doi: 10.1016/S1359-8368(98)00014-6 -

点击查看大图

点击查看大图

计量

- 文章访问数: 44

- HTML全文浏览量: 17

- 被引次数: 0

下载:

下载: