Effect of nano-SiO2/CaCO3 compound incorporation on the properties of fully recycled coarse aggregate concrete

-

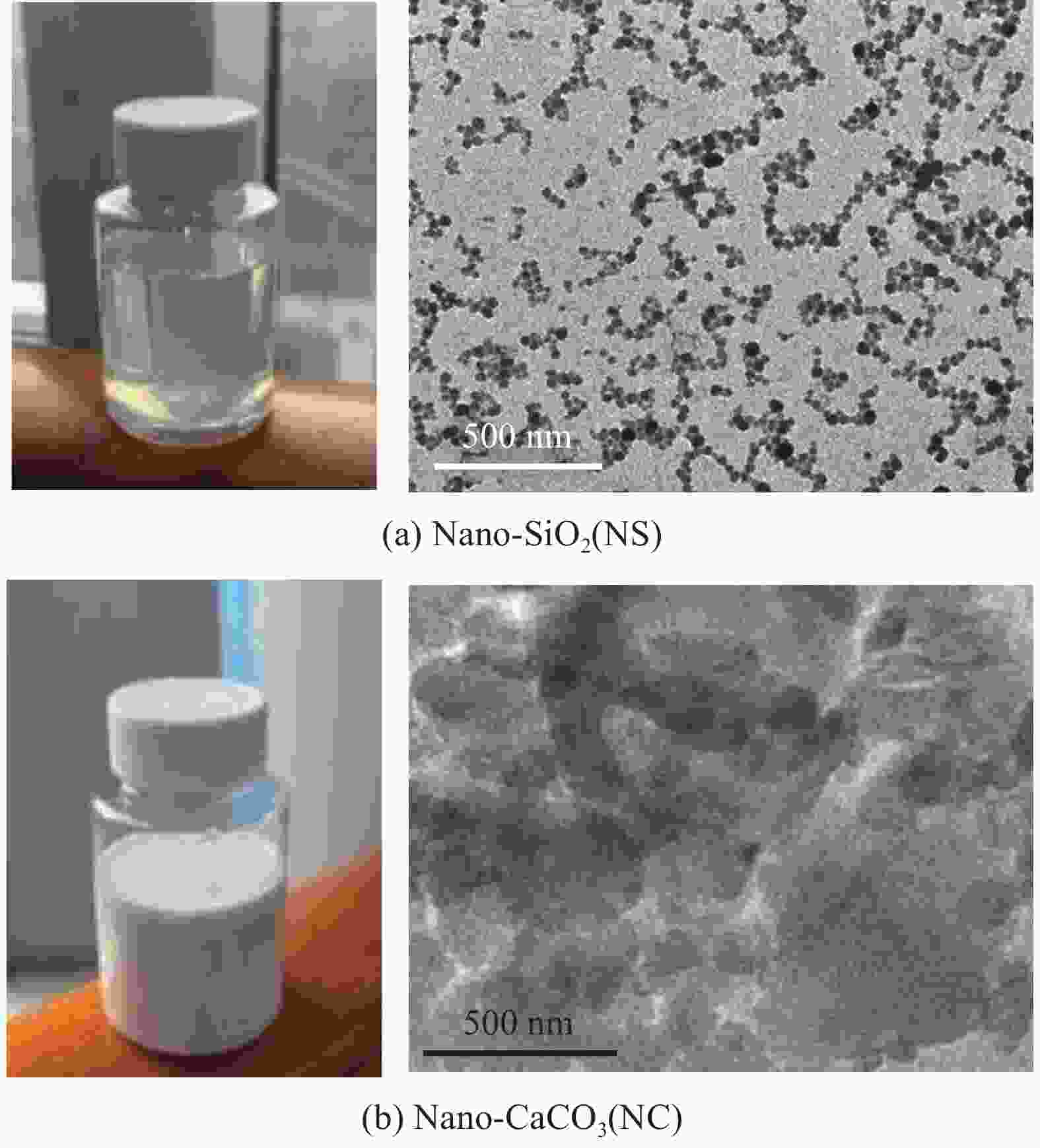

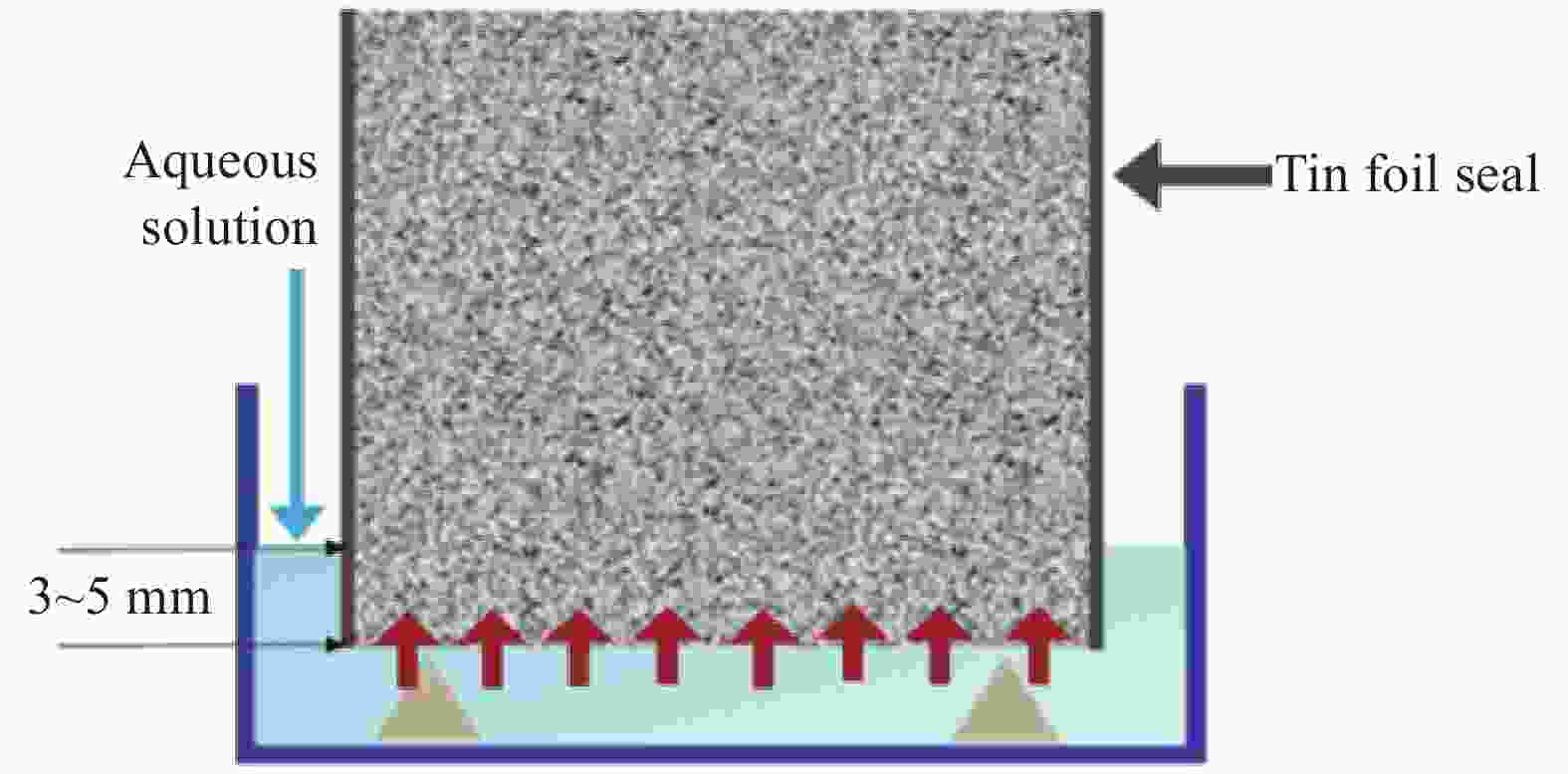

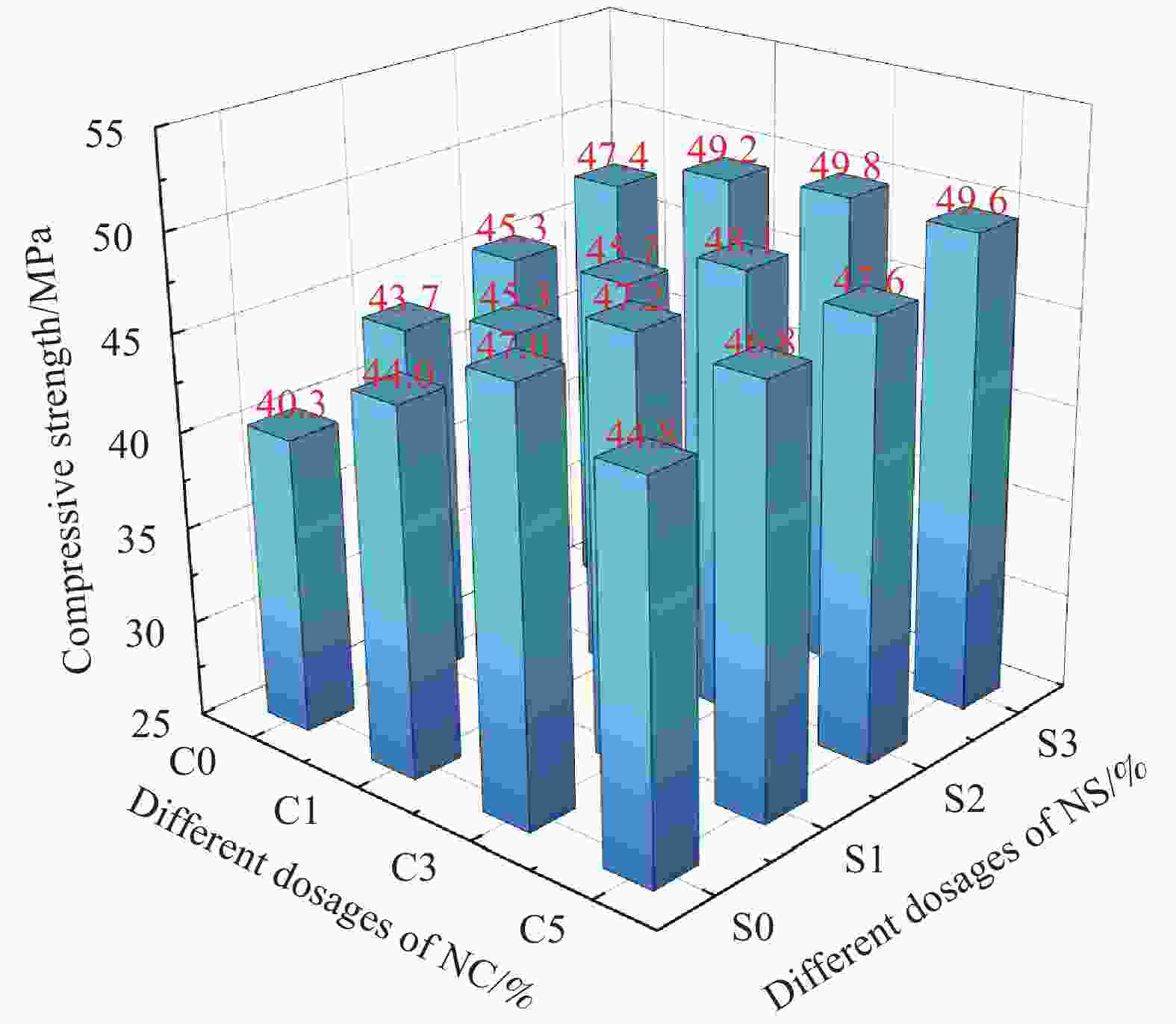

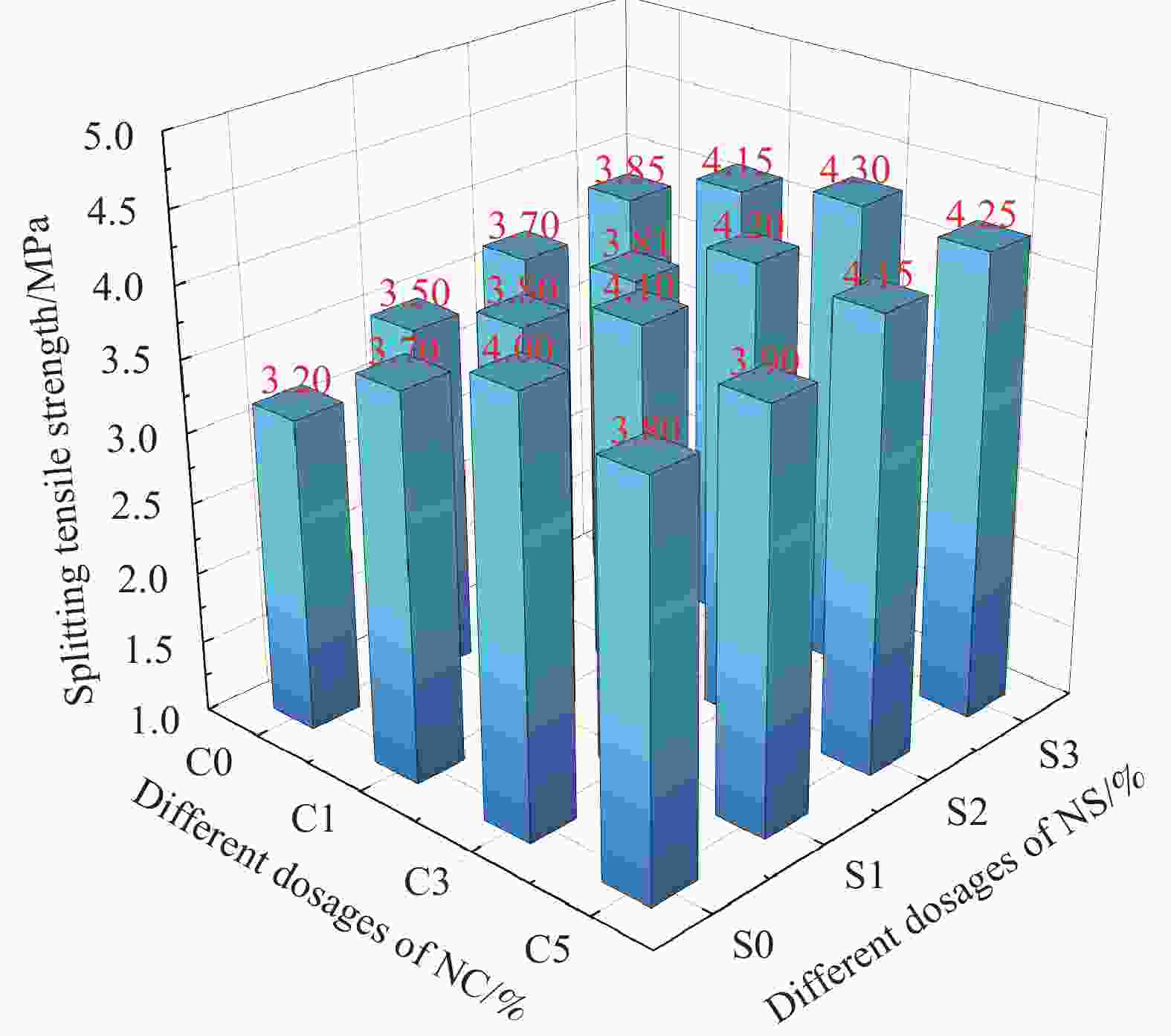

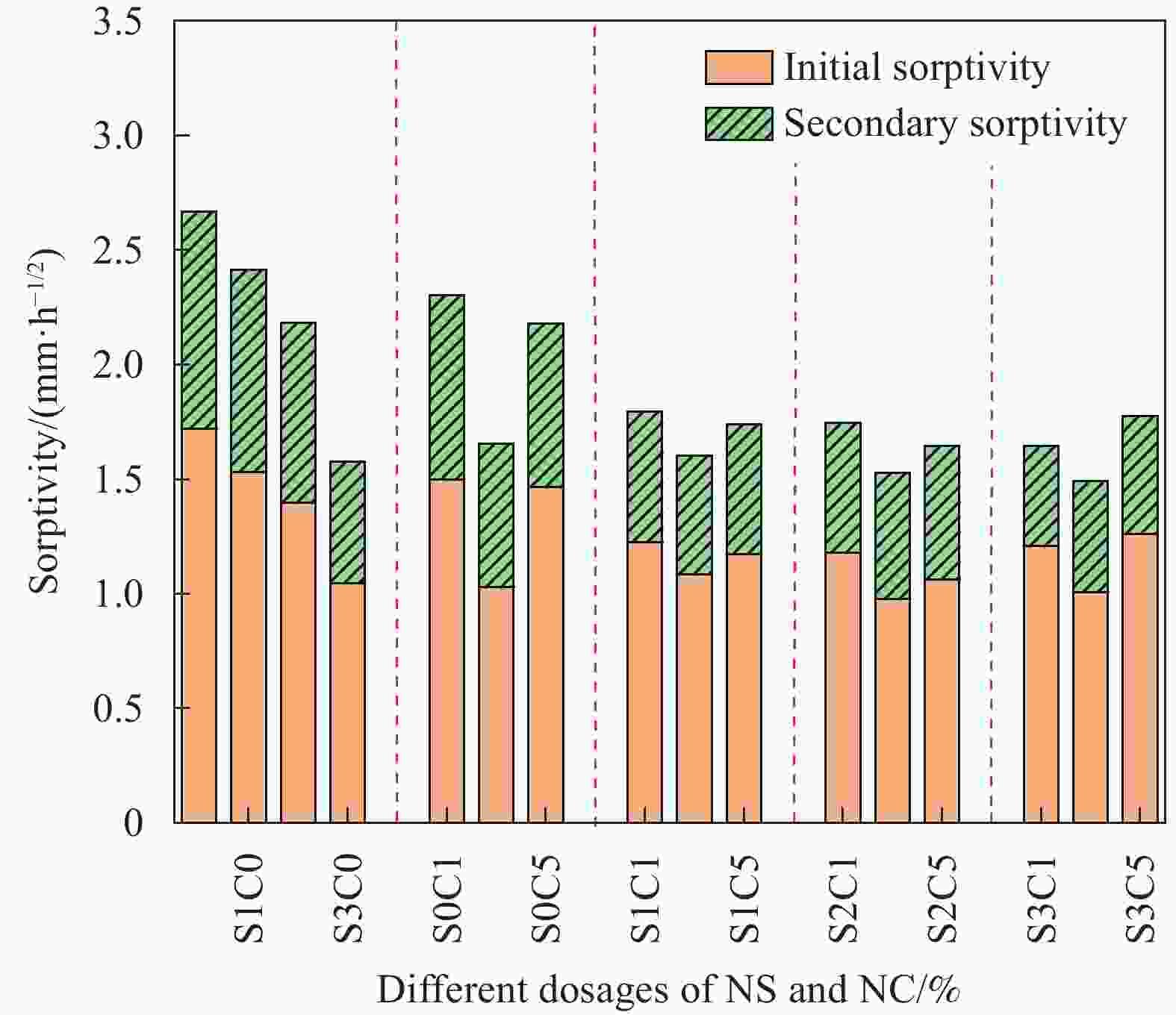

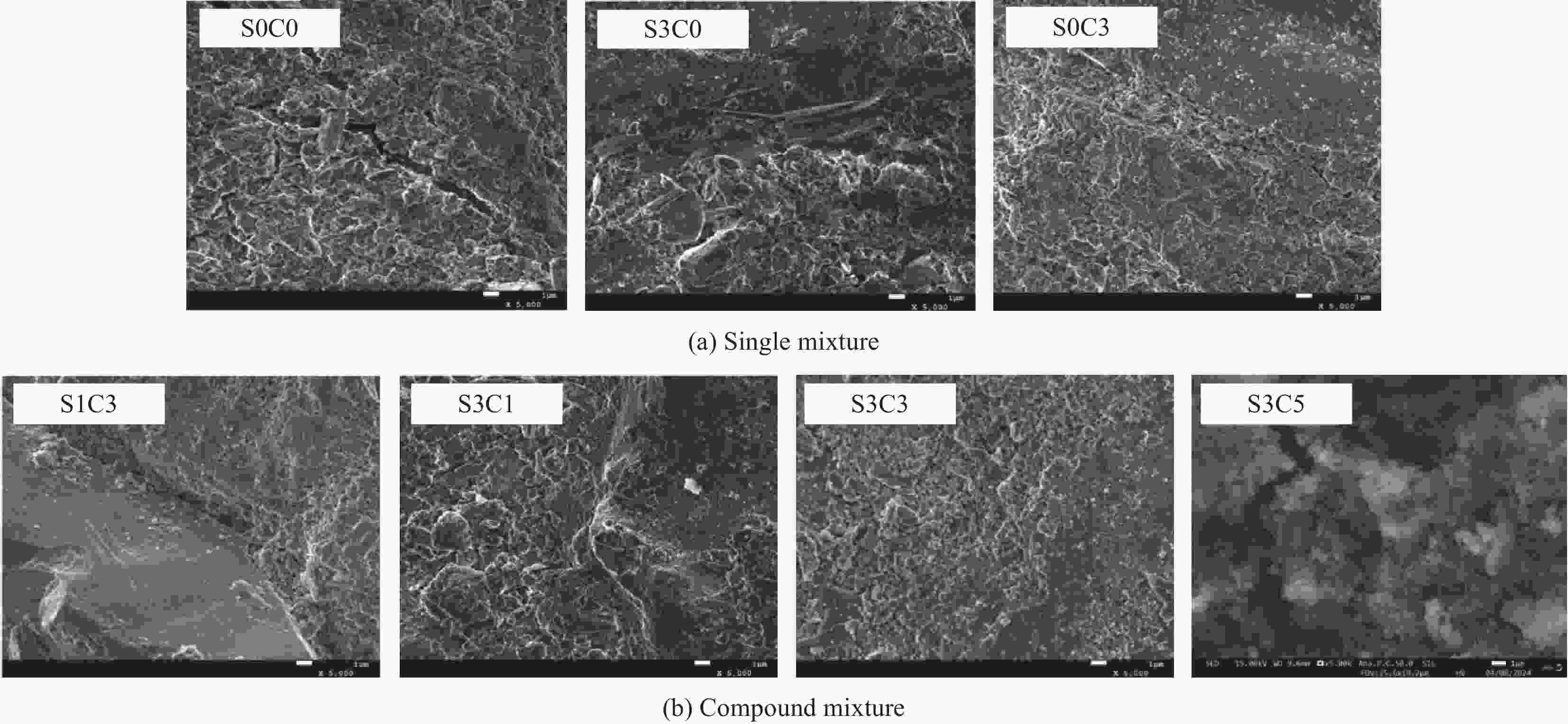

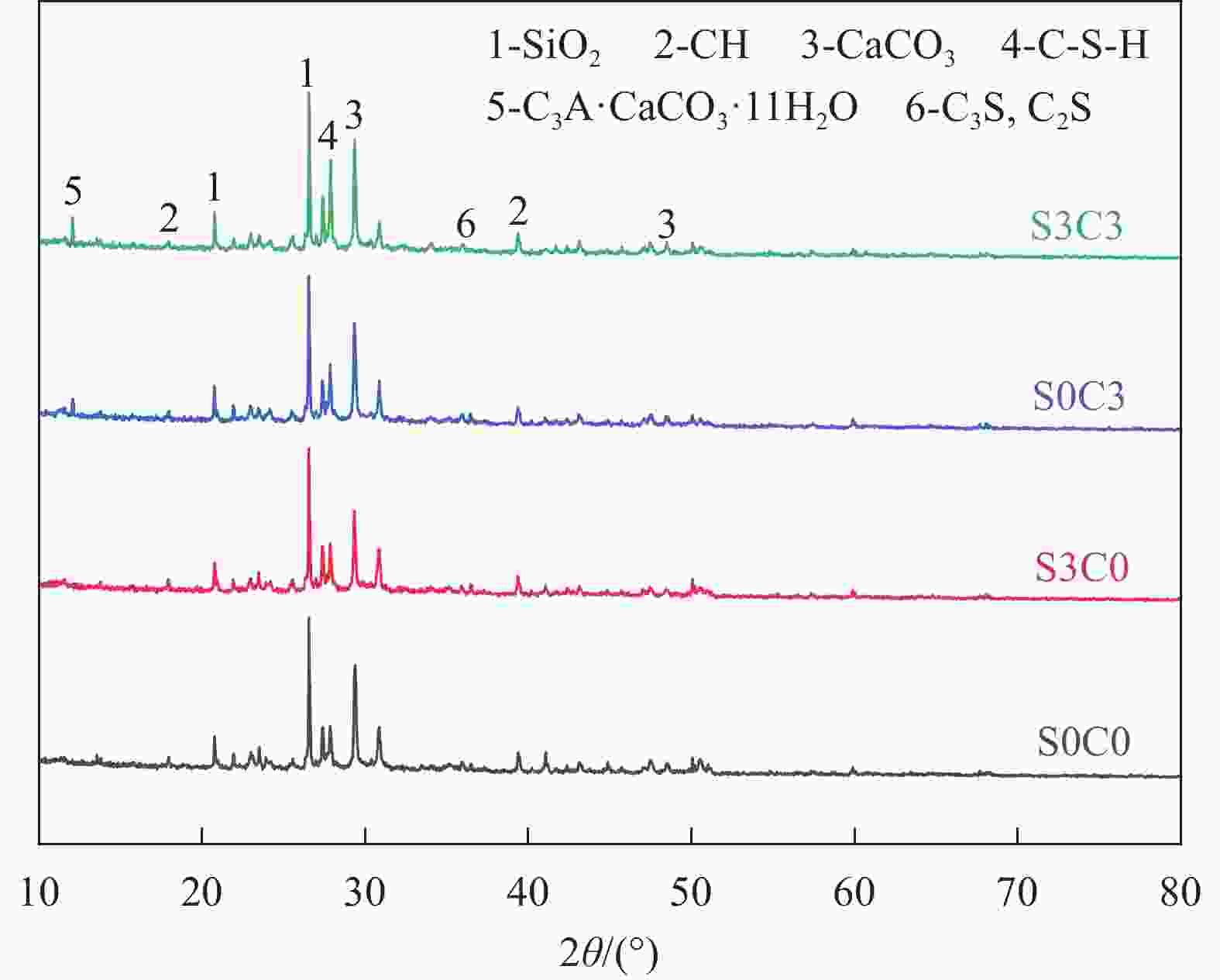

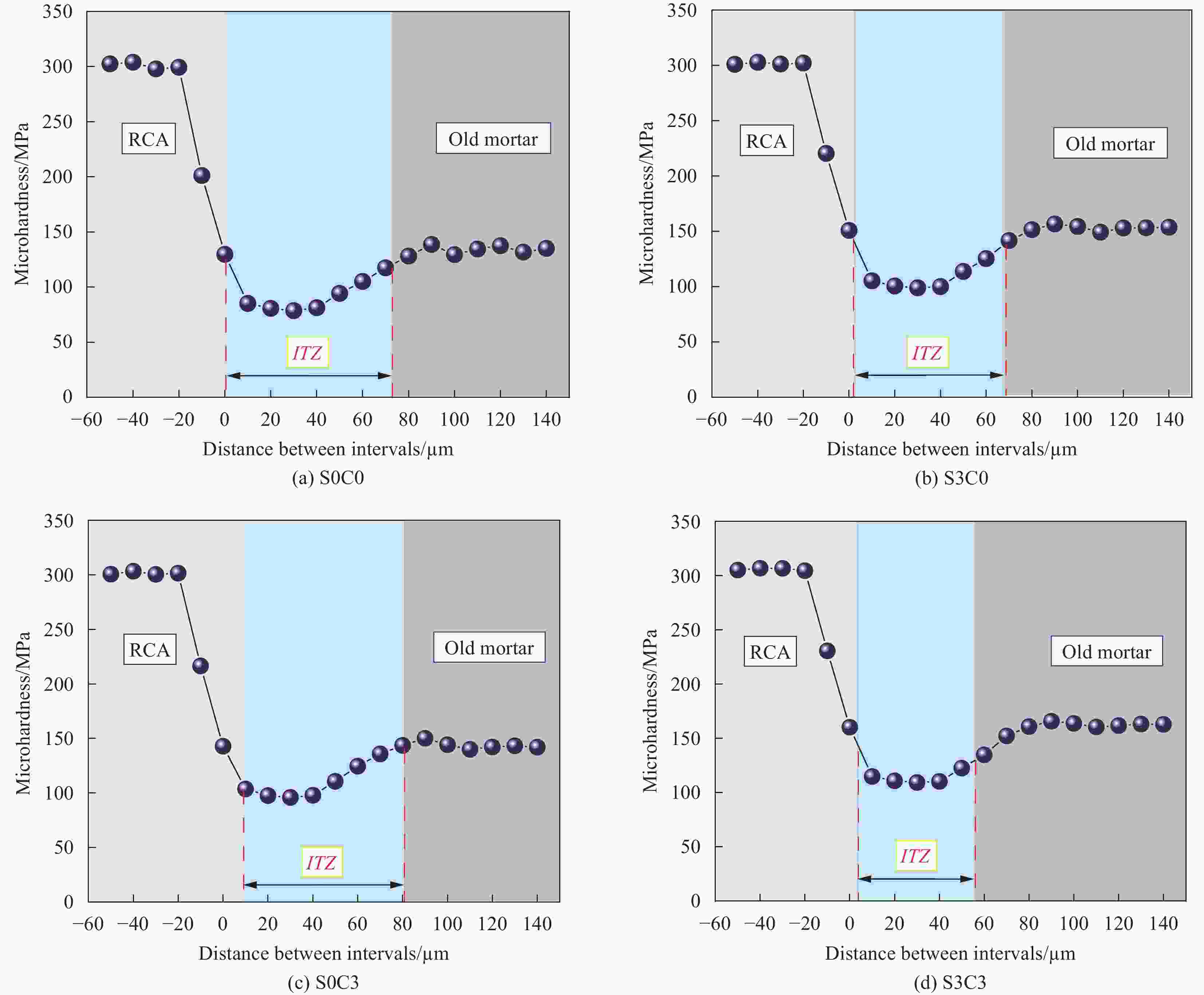

摘要: 与天然粗骨料相比,再生粗骨料因其破碎过程中产生不可避免的损伤以及附着的旧砂浆使其基本物理性能较差,制备所形成再生混凝土(RAC)因其多重界面而使其力学及耐久性能较差。为了进一步提升RAC性能,基于此,开展了不同纳米SiO2(NS)与纳米CaCO3(NC)单/复掺改性全再生粗骨料混凝土(FRAC)力学及吸水性能的试验研究,其中NS掺量为S=1%、2%、3%,NC掺量为C=1%、3%、5%,并通过SEM方法在微观尺度上表征了纳米材料单/复掺对其微观形貌的改性效果。结果表明:无论纳米材料单掺还是复掺形式,在适量的掺入范围内,RAC抗压强度和劈裂抗拉强度均随着纳米材料掺量的增加而增大;但当NC掺量达到5%时,会生成过量的低碳型水化碳铝酸钙,其发生团聚后RAC强度会出现一定程度的降低,但总体仍高于未改性前的强度,当复掺比例为1%NS和3%NC时,可达到3%NS单掺的效果。RAC毛细吸水质量和吸水率随着纳米材料掺量的增加呈现下降的趋势,总体上复掺改善效果好于单掺情况,且纳米材料最佳掺量为3%。SEM结果也进一步证实,当两种纳米材料复掺量为3%时(S3C3),RAC内部孔隙和微裂缝最少,且界面过渡区(ITZ)更致密,表明纳米材料复掺改性效果较好。Abstract: Compared with natural coarse aggregate, the basic physical properties of recycled coarse aggregate are relatively poor due to the inevitable damage in the crushing process and the attached old mortar, and the mechanical properties and durability of the prepared recycled aggregate concrete (RAC) are worse due to its formed multiple interface structures. To further improve the performance of RAC, based on this, the mechanical properties and water absorption behavior of fully recycled coarse aggregate concrete (FRAC) modified by different nano-SiO2 (NS) and nano-CaCO3 (NC) single-mixed or compound-mixed were respectively investigated. The NS content (S) was 1%, 2% and 3%, and the NC content (C) was 1%, 3% and 5%. The modification effect of single/compound-mixed nanomaterials on the micromorphology was characterized by SEM observation. The results show that the compressive strength and splitting tensile strength of RAC increase with the addition of nanomaterials within the appropriate incorporation range no matter the single-mixed and multiple-mixed forms. However, when the NC content reaches up to 5%, excessive low-carbon hydrated calcium carboaluminate will be generated, and the RAC strength will decrease to a certain extent after agglomeration, but the overall strength is still higher than that before modification, the effect of 3%NS single admixture can be achieved when the complex admixture ratio is 1%NS and 3%NC. The cumulative mass of capillary water absorption and water absorption rate of RAC decrease with the increase of nanomaterial content. In general, the improvement effect of compound mixing is better than that of single mixing, and the optimal content of nanomaterial is 3% in this study. The results of SEM observation also further confirm that when the mixture amount of the two nanomaterials is 3% (S3C3), the least internal pores and microcracks and the denser interfacial transition zone (ITZ) in RAC indicate the better modification effect of the nanomaterials.

-

Key words:

- recycled aggregate concrete /

- nano-SiO2 /

- nano-CaCO3 /

- mechanical properties /

- durability

-

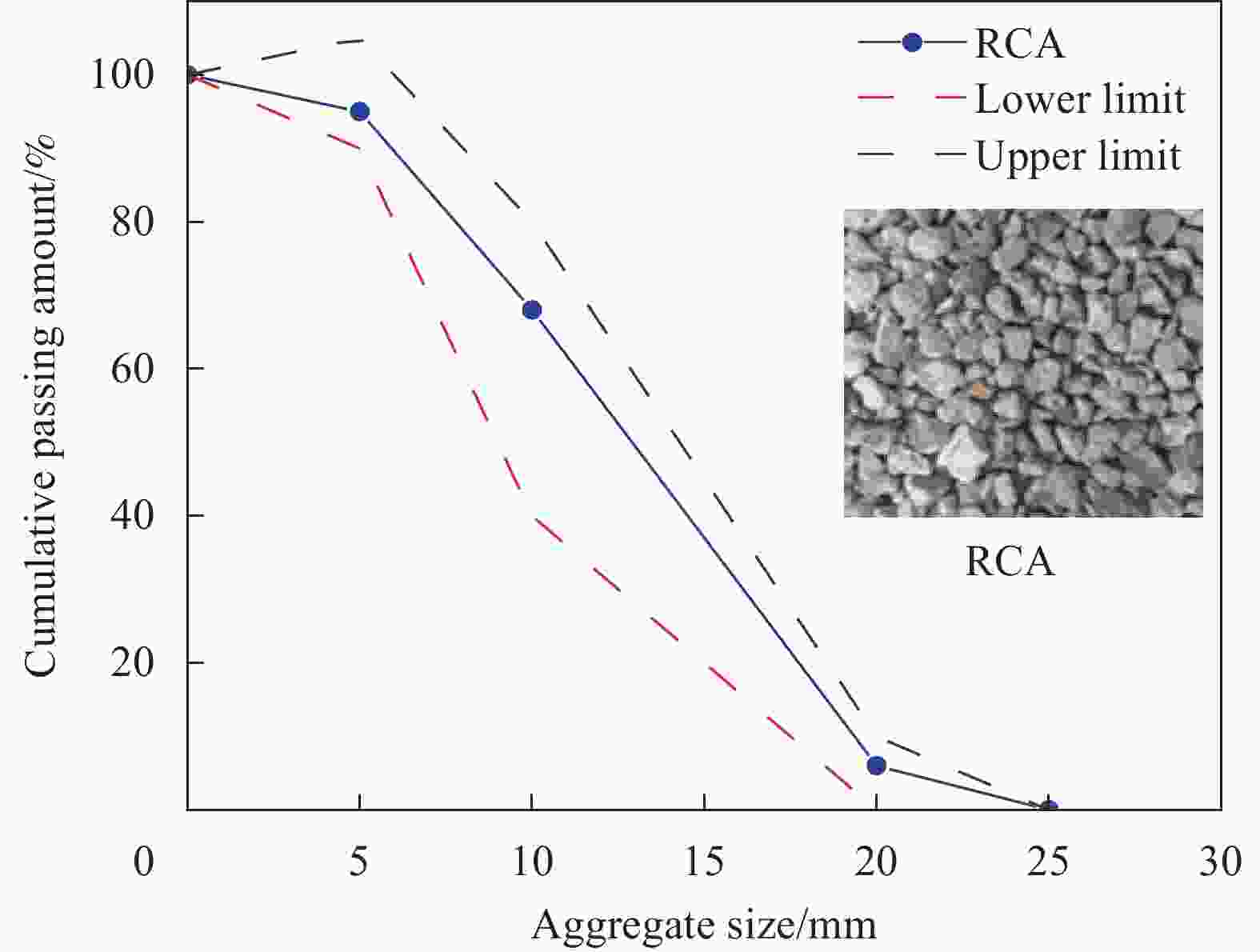

表 1 再生粗骨料的物理性能指标

Table 1. Physical properties index of recycled coarse aggregate

Type Water

absorption/

%Moisture

content/

%Crush

index/

%Apparent

density/

(kg·m−3)RCA 5.2 4.0 19.12 2706.2 表 2 NS和NC分散剂溶液的物理性质

Table 2. Physical properties of NS and NC dispersant solution

Type Appearance Granular size Mass concentration pH NS Clear liquid 155 nm 30% 9.0-11.0 NC Clear liquid 402 nm 20% 9.5-10.5 表 3 全再生混凝土(FRAC)配合比(kg/m3)

Table 3. Mix proportion of fully recycle aggregate concrete (FRAC) (kg/m3)

Groups C W AW S RCA SP NS NC S0C0 380 152 26 627 1269 2.28 0 0 S1C0 380 152 26 627 1269 2.28 12.7 0 S2C0 380 152 26 627 1269 2.28 25.3 0 S3C0 380 152 26 627 1269 2.28 38 0 S0C1 380 152 26 627 1269 2.28 0 19 S0C3 380 152 26 627 1269 2.28 0 57 S0C5 380 152 26 627 1269 2.28 0 95 S1C1 380 152 26 627 1269 2.28 12.7 19 S1C3 380 152 26 627 1269 2.28 12.7 57 S1C5 380 152 26 627 1269 2.28 12.7 95 S2C1 380 152 26 627 1269 2.28 25.3 19 S2C3 380 152 26 627 1269 2.28 25.3 57 S2C5 380 152 26 627 1269 2.28 25.3 95 S3C1 380 152 26 627 1269 2.28 38 19 S3C3 380 152 26 627 1269 2.28 38 57 S3C5 380 152 26 627 1269 2.28 38 95 Notes: C represents cement; W and AW means water content and additional water content in the RAC mix; S means the used sand; RCA means recycled coarse aggregate; SP means polycarboxylate superplasticizer; NS and NC mean the nano-silica and nano calcium carbonate, respectively. -

[1] Zheng Y, Zhuo J, Zhang P. A review on durability of nano-SiO2 and basalt fiber modified recycled aggregate concrete[J]. Construction and Building Materials, 2021, 304: 124659. doi: 10.1016/j.conbuildmat.2021.124659 [2] 鲍玖文, 王云伟, 牟新宇, 等. 持压荷载与干湿循环作用下再生混凝土氯盐侵蚀行为[J]. 复合材料学报, 2023, 40(2): 1015-1024.BAO Jiuwen, WANG Yunwei, MOU Xinyu, et al. Chloride ingress behavior of recycled aggregate concrete subjected to sustained compressive loading and drying-wetting cycles[J]. Acta Materiae Compositae Sinica, 2023, 40(2): 1015-1024(in Chinese). [3] 牟新宇, 王云伟, 卢石宝, 等. 基于多尺度分析的再生混凝土有效氯离子扩散系数预测[J]. 复合材料学报, 2023, 40(5): 2876-2884.MOU Xinyu, WANG Yunwei, LU Shibao, et al. Prediction of effective chloride diffusion coefficient of recycled aggregate concrete based on multiscale analysis[J]. Acta Materiae Compositae Sinica, 2023, 40(5): 2876-2884(in Chinese). [4] 胡建城, 吕阳, 何晨昊, 等. 纳米二氧化硅粉末对水泥-粉煤灰体系泡沫混凝土力学性能及水化的影响[J]. 硅酸盐通报, 2019, 38(5): 1390-1394.HU Jiancheng, LYU Yang, He Chenhao, et al. Effect of nano-silica powder on mechanical properties and hydration of foamed concrete with cement-fly Ash system[J]. Chinese Journal of Ceramics, 2019, 38(5): 1390-1394(in Chinese). [5] Ghafari E, Costa H, Júlio E, et al. The effect of nanosilica addition on flowability, strength and transport properties of ultra high performance concrete[J]. Materials & Design, 2014, 59: 1-9. [6] Sivasankaran U, Raman S, Nallusamy S. Experimental analysis of mechanical properties on concrete with nano silica additive[C]//Journal of nano research. Trans Tech Publications Ltd, 2019, 57: 93-104. [7] 王冲, 刘俊超, 张超, 等. 纳米CaCO3对水泥基材料性能与结构的影响及机理[J]. 湖南大学学报: 自然科学版, 2016, 43(6): 22-28.WANG Chong, LIU Junchao, ZHANG Chao, et al. Effect and mechanism of nano-CaCO3 on properties and structure of cement-based materials[J]. Journal of Hunan University: Natural Science Edition, 2016, 43(6): 22-28(in Chinese). [8] 卫益辰. 纳米碳酸钙和聚丙烯纤维对再生混凝土性能影响研究[D]. 武汉: 武汉工程大学, 2022.WEI Yi Cheng. Study on the influence of nano-calcium carbonate and polypropylene fiber on the properties of recycled concrete[D]. Wuhan: Wuhan Institute of Technology, 2022. (in Chinese). [9] Shaikh F U A, Supit S W M. Chloride induced corrosion durability of high volume fly ash concretes containing nano particles[J]. Construction and Building Materials, 2015, 99: 208-225. doi: 10.1016/j.conbuildmat.2015.09.030 [10] Yue Y, Zhou Y, Xing F, et al. An industrial applicable method to improve the properties of recycled aggregate concrete by incorporating nano-silica and micro-CaCO3[J]. Journal of Cleaner Production, 2020, 259: 120920. doi: 10.1016/j.jclepro.2020.120920 [11] 苏鑫. 纳米二氧化硅和纳米碳酸钙减胶剂改性混凝土性能研究[D]. 广州: 广州大学, 2022.SU Xin. Study on properties of concrete modified by nano-silica and nano-calcium carbonate reducing agents [D]. Guangzhou: Guangzhou University, 2022. (in Chinese). [12] 鲍玖文, 张洪锐, 方晓龙, 等. 纳米二氧化硅改性再生粗骨料混凝土性能的研究进展[J]. 硅酸盐学报, 2023, 51(8): 2045-2053.BAO Jiowen, ZHANG Hongrui, FANG Xiaolong, et al. Research progress on properties of reclaimed coarse aggregate concrete modified by nano-silica[J]. Journal of the Chinese Ceramics, 2023, 51(8): 2045-2053(in Chinese). [13] GB 175-2020. 通用硅酸盐水泥[S]. 北京: 中国标准出版社, 2020.GB 175-2020. Portland cement for general purpose [S]. Beijing: Standards Press of China, 2020. [14] Ma Z, Liu M, Tang Q, et al. Chloride permeability of recycled aggregate concrete under the coupling effect of freezing-thawing, elevated temperature or mechanical damage[J]. Construction and Building Materials, 2020, 237: 117648. doi: 10.1016/j.conbuildmat.2019.117648 [15] 司博旸. 搅拌时间对现代混凝土拌合物匀质性的影响[D]. 北京: 北京建筑大学, 2017.Si Boyang. Effect of mixing time on the homogeneity of modern concrete mixes [D]. Beijing: Beijing University of Civil Engineering and Architecture, 2017. (in Chinese). [16] GB/T 50081-2019. 混凝土物理力学性能试验方法标准[S]. 北京: 中国建筑工业出版社, 2019.GB/T 50081-2019. Test method standard for Physical and Mechanical properties of concrete [S]. Beijing: China Building and Construction Press, 2019. (in Chinese). [17] ASTM C 1585-04. Standard test method for measurement of rate of absorption of water by hydraulic-cement concretes[S]. West Conshohochen: PA: ASTM International, 2004. [18] 李振东, 孟丹, 王智鹏, 等. 纳米二氧化硅改性混凝土宏观性能及微观调控机理分析[J]. 硅酸盐通报, 2020, 39(7): 2145-2153.LI Zhendong, MENG Dan, WANG Zhipeng, et al. Analysis of macro properties and micro control mechanism of nano-silica modified concrete[J]. Bulletin of Silicate, 2020, 39(7): 2145-2153(in Chinese). [19] 朱靖塞, 许金余, 白二雷, 等. 纳米颗粒SiO2和CaCO3对混凝土动力特性的影响[J]. 硅酸盐通报, 2015, 34(10): 2974-2978.ZHU Jingsai, XU Jinyu, BAI Erlei, et al. Effects of nano-particles SiO2 and CaCO3 on dynamic properties of concrete[J]. Bulletin of Silicate, 2015, 34(10): 2974-2978(in Chinese). [20] 黄政宇, 祖天钰. 纳米CaCO3对超高性能混凝土性能影响的研究[J]. 硅酸盐通报, 2013, 32(6): 1103-1109.HUANG Zhengyu, ZU Tianyu. Effect of nano-CaCO3 on properties of ultra-high performance concrete[J]. Bulletin of Silicate, 2013, 32(6): 1103-1109(in Chinese). [21] Adetukasi A O, Olowofoyeku A M, Adebayo O, et al. Improving the strength properties of concrete containing recycled coarse aggregate with nano-silica[J]. Materials Today: Proceedings, 2023, 86: 96-103. doi: 10.1016/j.matpr.2023.03.293 [22] 辜琳然, 刘文娟, 熊欢, 等. 纳米 CaCO3增韧混凝土复合材料的制备及机理研究[J]. 功能材料, 2022, 53(4): 4150-4154.Gu Linran, Liu Wenjuan, Xiong Huan, et al. Preparation and mechanism of nano-CaCO3 toughened concrete composite[J]. Journal of Functional Materials, 2022, 53(4): 4150-4154(in Chinese). [23] Song X, Li C, Chen D, et al. Interfacial mechanical properties of recycled aggregate concrete reinforced by nano-materials[J]. Construction and Building Materials, 2021, 270: 121446. doi: 10.1016/j.conbuildmat.2020.121446 [24] Liu X, Xie X, Liu R, et al. Research on the durability of nano-SiO2 and sodium silicate co-modified recycled coarse aggregate (RCA) concrete[J]. Construction and Building Materials, 2023, 378: 131185. doi: 10.1016/j.conbuildmat.2023.131185 [25] 徐庆磊. 纳米二氧化硅对水泥基材料性能的影响及作用机理研究[D]. 杭州: 浙江大学, 2013.XU Qinglei. Effect of nano-silica on properties of cement-based materials and its mechanism[D]. Hangzhou: Zhejiang University, 2013. (in Chinese). -

点击查看大图

点击查看大图

计量

- 文章访问数: 82

- HTML全文浏览量: 66

- 被引次数: 0

下载:

下载: