Preparation and thermal conductivity of flexible phase change composite materials with oriented thermal conductivity structure

-

摘要: 为解决高分子基复合材料固有热导率较差这一问题,本研究采用简单高效、易工业化的开炼法在聚乙烯辛烯共弹性体(POE)基体中构建有序的取向结构,制备了一种具有优异综合性能的柔性相变复合材料。在开炼机的强剪切场作用下,石蜡(PW)和氮化硼(BN)在POE基体内部沿剪切场方向发生了定向取向排列,促进了导热通路的构建。当石墨烯纳米片(GNPs)和BN添加量分别为2wt%和25wt%时,PW-2wt%GNPs-25wt%BN/POE相变复合材料热导率(λ)从1.01W·m−1·K−1 (PW/POE)提高到2.59 W·m−1·K−1,提高了156%。并且PW-2wt%GNPs-25wt%BN/POE相变复合材料具有优异的拉伸强度(18.3MPa)和断裂伸长率(720%),在弯曲、折叠成复杂的形状后不会出现任何的破裂,在10次循环往复拉伸测试中具有良好的可回复性。此外,添加30wt%的PW能够赋予PW-2wt%GNPs-25wt%BN/POE一定的焓值44.1 J·g−1;当施加80 mW·cm−2的光照强度时,表面贴有PW-2wt%GNPs-25wt%BN/POE复合材料的瓶内温度高达54.3℃,较未添加GNPs的PW/POE提高了20℃,并且在光照条件下,PW-2wt%GNPs-25wt%BN/POE复合材料具有优异的光驱动可恢复性能,使其具有潜在的光热转换应用前景,在实际应用和工业化生产方面具备巨大潜力。Abstract: To address the issue of poor inherent thermal conductivity in polymer-based composites, this study employed a simple, efficient, and industrially viable kneading method to construct an ordered orientation structure within a polyolefin elastomer (POE) matrix, resulting in a flexible phase-change composite material with outstanding comprehensive performance. Under the strong shear field of the kneader, paraffin wax (PW) and boron nitride (BN) were oriented and arranged along the shear field direction within the POE matrix, facilitating the construction of thermal conduction pathways. When the graphene nanoplatelets (GNPs) and BN content were 2wt% and 25wt%, respectively, the thermal conductivity (λ) of the PW-2wt%GNPs-25wt%BN/POE phase-change composite material increased from 1.01 W·m−1·K−1 (PW/POE) to 2.59 W·m−1·K−1, representing a 156% enhancement. Moreover, the PW-2wt%GNPs-25wt%BN/POE phase-change composite material exhibited excellent tensile strength (18.3 MPa) and elongation at break (720%), with no signs of rupture after bending and folding into complex shapes, and demonstrated good recoverability in 10 cycles of tensile testing. Furthermore, adding 30wt% PW can endow PW-2wt%GNPs-25wt%BN/POE composite material with a certain enthalpy value of 44.1 J·g−1. Under an illumination intensity of 80 mW cm−2, the temperature inside a bottle coated with the PW-2wt%GNPs-25wt%BN/POE composite material reached 54.3°C, which was 20°C higher than that of the PW/POE without GNPs. Moreover, under illumination conditions, the PW-2wt%GNPs-25wt%BN/POE composite material exhibited excellent light-driven recoverable performance, suggesting its potential application in photothermal conversion, and thereby possessing significant potential for practical applications and industrial production.

-

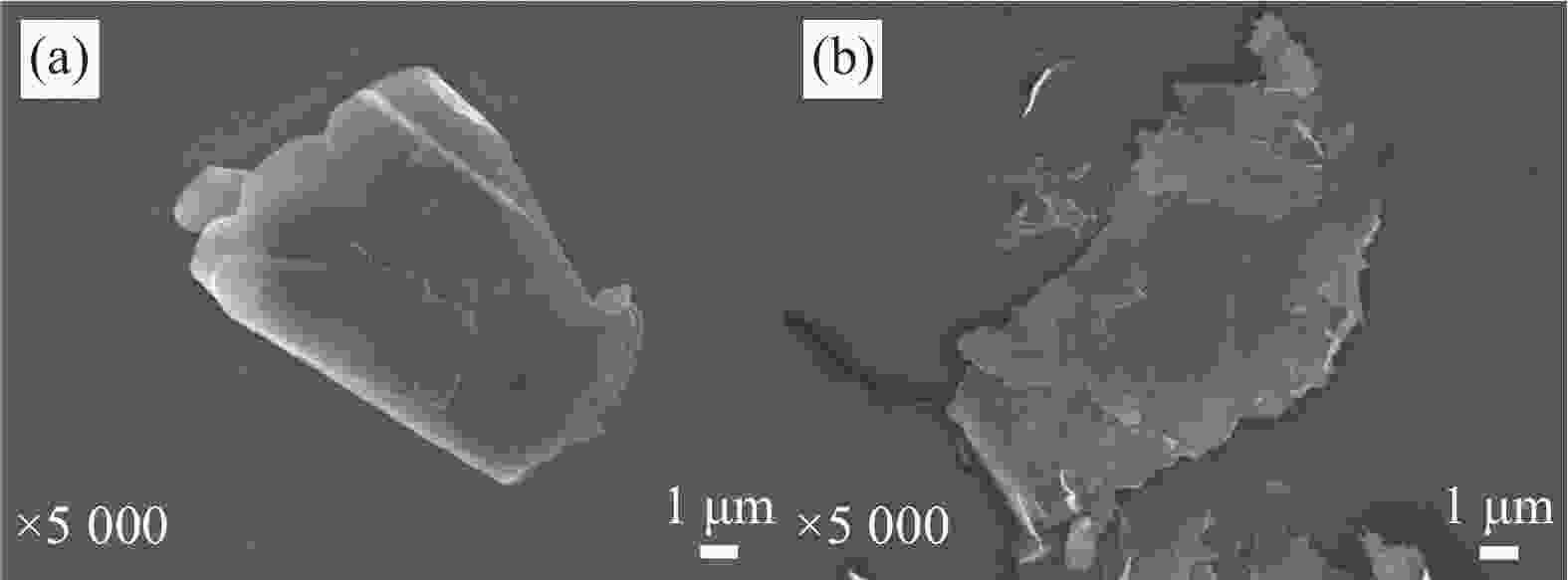

图 3 SEM图像:(a)PW/POE,(a1)高温处理的PW/POE,(b) PW-2wt%GNPs/POE,(c) PW-25wt%BN/POE,(d) PW-2wt%GNPs-5wt%BN/POE,(e) PW-2wt%GNPs-10wt%BN/POE,(f) PW-2wt%GNPs-15wt%BN/POE,(g) PW-2wt%GNPs-25wt%BN/POE以及局部放大图(g1) PW-2wt%GNPs-25wt%BN/POE

Figure 3. SEM images: (a) PW/POE, (a1) thermal heated PW/POE, (b) PW-2wt%GNPs/POE, (c) PW-25wt%BN/POE, (d) PW-2wt%GNPs-5wt%BN/POE, (e) PW-2wt%GNPs-10wt%BN/POE, (f) PW-2wt%GNPs-15wt%BN/POE, (g) PW-2wt%GNPs-25wt%BN/POE and local magnified image (g1) PW-2wt%GNPs-25wt%BN/POE

图 6 PW-GNPs-BN/POE相变复合材料的力学性能曲线:(b):1#、2#、3#、4#、5#、6#和7#分别代表PW/POE、PW-2wt%GNPs/POE、PW-2wt%GNPs-5wt%BN/POE、PW-2wt%GNPs-10wt%BN/POE、PW-2wt%GNPs-15wt%BN/POE、PW-2wt%GNPs-25wt%BN/POE和PW-25wt%BN/POE

Figure 6. Mechanical property curve of PW-GNPs-BN/POE phase change composite materials: (b): 1#, 2#, 3#, 4#, 5#, 6#, and 7# represent PW/POE, PW-2wt%GNPs/POE, PW-2wt%GNPs-5wt%BN/POE, PW-2wt%GNPs-10wt%BN/POE, PW-2wt%GNPs-15wt%BN/POE, PW-2wt%GNPs-25wt%BN/POE, and PW-25wt%BN/POE, respectively.

图 7 PW-GNPs-BN/POE相变复合材料的(a)热扩散系数,(b)λ。其中,1#、2#、3#、4#、5#、6#和7#分别代表PW/POE、PW-2wt%GNPs/POE、PW-2wt%GNPs-5wt%BN/POE、PW-2wt%GNPs-10wt%BN/POE、PW-2wt%GNPs-15wt%BN/POE、PW-2wt%GNPs-25wt%BN/POE和PW-25wt%BN/POE

Figure 7. (a) Thermal diffusion coefficient, (b) λ of PW-GNPs-BN/POE phase change composite materials. Among them, 1#, 2#, 3#, 4#, 5#, 6#, and 7# represent PW/POE, PW-2wt%GNPs/POE, PW-2wt%GNPs-5wt%BN/POE, PW-2wt%GNPs-10wt%BN/POE, PW-2wt%GNPs-15wt%BN/POE, PW-2wt%GNPs-25wt%BN/POE, and PW-25wt%BN/POE respectively.

图 8 POE-PW-GNPS/BN相变复合材料的导热提高率,其中,1#、2#、3#、4#、5#、6#和7#分别代表PW/POE、PW-2wt%GNPs/POE、PW-2wt%GNPs-5wt%BN/POE、PW-2wt%GNPs-10wt%BN/POE、PW-2wt%GNPs-15wt%BN/POE、PW-2wt%GNPs-25wt%BN/POE和PW-25wt%BN/POE

Figure 8. Thermal conductivity enhancement of PW-GNPs-BN/POE phase change composite materials. Among them, 1#, 2#, 3#, 4#, 5#, 6#, and 7# represent PW/POE, PW-2wt%GNPs/POE, PW-2wt%GNPs-5wt%BN/POE, PW-2wt%GNPs-10wt%BN/POE, PW-2wt%GNPs-15wt%BN/POE, PW-2wt%GNPs-25wt%BN/POE, and PW-25wt%BN/POE respectively.

图 10 (a)光-热转换测量装置示意图,PW-GNPs-BN/POE相变复合材料分别在(b) 80 mW·cm−2和(c)在不同光照强度下的光热转换曲线图。其中,1#、2#、3#、4#、5#、6#和7#分别代表PW/POE、PW-2wt%GNPs/POE、PW-2wt%GNPs-5wt%BN/POE、PW-2wt%GNPs-10wt%BN/POE、PW-2wt%GNPs-15wt%BN/POE、PW-2wt%GNPs-25wt%BN/POE和PW-25wt%BN/POE

Figure 10. (a) Schematic diagram of the light-to-heat conversion measurement device, photothermal conversion curve of PW-GNPs-BN/POE phase change composite materials (b) under 80 mW cm−2 and (c) under different light intensities. Among them, 1#, 2#, 3#, 4#, 5#, 6#, and 7# represent PW/POE, PW-2wt%GNPs/POE, PW-2wt%GNPs-5wt%BN/POE, PW-2wt%GNPs-10wt%BN/POE, PW-2wt%GNPs-15wt%BN/POE, PW-2wt%GNPs-25wt%BN/POE, and PW-25wt%BN/POE respectively.

图 11 通过模拟热管理应用得到不同样品的时间-温度曲线。其中,1#、2#、6#和7#分别代表PW/POE、PW-2wt%GNPs/POE、PW-2wt%GNPs-25wt%BN/POE和PW-25wt%BN/POE

Figure 11. Time-temperature curves of different samples obtained by simulated thermal management application. Among them, 1#, 2#, 6#, and 7# represent PW/POE, PW-2wt%GNPs/POE, PW-2wt%GNPs-25wt%BN/POE, and PW-25wt%BN/POE respectively.

表 1 样品配方

Table 1. Sample Formula

Samples POE/wt% PW/wt% Mass ratio of PW/POE GNPs/wt% BN/wt% PW/POE 70 30 7:3 0 0 PW-2wt%GNPs/POE 68.6 29.4 7:3 2 0 PW-2wt%GNPs-5wt%BN/POE 65.1 27.9 7:3 2 5 PW-2wt%GNPs-10wt%BN/POE 61.6 26.4 7:3 2 10 PW-2wt%GNPs-15wt%BN/POE 58.1 24.9 7:3 2 15 PW-2wt%GNPs-25wt%BN/POE 51.1 21.9 7:3 2 25 PW-25wt%BN/POE 52.5 22.5 7:3 0 25 表 2 PW-GNPs-BN/POE相变复合材料的取向度

Table 2. Orientation degree of PW-GNPs-BN/POE phase change composite materials

Samples Orientation factor PW-2wt%GNPs-5wt%BN/POE 0.49 PW-2wt%GNPs-10wt%BN/POE 0.51 PW-2wt%GNPs-15wt%BN/POE 0.57 PW-2wt%GNPs-25wt%BN/POE 0.83 PW-25wt%BN/POE 0.55 表 3 在融化过程中PW和PW-GNPs-BN/POE相变复合材料的相变参数

Table 3. Phase transition parameters of PW and PW-GNPs-BN/POE phase change composite materials during the melting process.

Samples TM/℃ HM/(J·g−1) PW 56.2 141.2 PW/POE 52.3 46.6 PW-2wt%GNPs/POE 49.6 56.6 PW-2wt%GNPs-5wt%BN/POE 50.16 51.9 PW-2wt%GNPs-10wt%BN/POE 49.8 51.9 PW-2wt%GNPs-15wt%BN/POE 49.8 47.5 PW-2wt%GNPs-25wt%BN/POE 49.8 44.1 PW-25wt%BN/POE 49.8 45.1 Notes:TM: Melting temperature; HM: Melting enthalpy. -

[1] FAN L W, FANG X, WANG X, et al. Effects of various carbon nanofillers on the thermal conductivity and energy storage properties of paraffin-based nanocomposite phase change materials[J]. Applied Energy, 2013, 110(10): 163-172. [2] ZHENG J L, DENG Y, LIU Y L, et al. Paraffin/polyvinyl alcohol/MXene flexible phase change composite films for thermal management applications[J]. Chemical Engineering Journal, 2023, 453 (P1). [3] SATHISHKUMAR A S, BALASUBRAMANIAN K A, RAMKUMAR T. Investigations on thermal properties of MWCNT-NBN Paraffin Wax phase change material for thermal storage applications[J]. Journal of Thermal Analysis and Calorimetry, 2023, 148(13): 3263-3271. [4] LI R F, ZHOU Y, DUAN X L. A novel composite phase change material with paraffin wax in tail-ings porous ceramics[J]. Applied thermal engi-neering: Design, processes, equipment, econom-ics, 2019, 151-115. [5] QI G Q, YANG J, BAO R Y, et al. Enhanced comprehensive performance of polyethylene glycol based phase change material with hybrid graphene nanomaterials for thermal energy storage[J]. Carbon: An International Journal Sponsored by the American Carbon Society, 2015, 88: 196-205. [6] 杨效田, 沈梁玉, 王彩龙, 等. 石蜡对无机复合相变储热体系的改性研究[J]. 复合材料学报, 2022, 39(5): 2421-2429.YANG Xiaotian, SHEN Liangyu, WANG Cailong, et al. Modification of inorganic composite phase change thermal storage systems by paraffin waxes[J]. Acta Materiae Compositae Sinica, 2022, 39(5): 2421-2429(in Chinese). [7] GUO Z J, LiIN F K, QIAO J X, et al. A modified kapok fiber based phase change composite for highly-efficient solar-thermal conversion[J]. Nano Energy, 2023, 108: 108205-108214. doi: 10.1016/j.nanoen.2023.108205 [8] WANG Z K, ZHANG X G, XU Y F, et al. Preparation and thermal properties of shape-stabilized composite phase change materials based on paraffin wax and carbon foam[J]. Polymer, 2021, 237: 124361-124370. doi: 10.1016/j.polymer.2021.124361 [9] SHEN J P, LIU Z T, XU B, et al. Tuning the thermal, mechanical, and combustion properties of NC-TEGDN-RDX propellants via incorporation of graphene nanoplates[J]. Journal of Energetic Materials, 2020, 38(1/4): 326-335. [10] MO Z J, MO P J, YI M M, et al. Ti3C2TX@Polyvinyl alcohol foam-Supported Phase Change Materials with Simultaneous Enhanced Thermal Conductivity and Solar-Thermal Conversion Performance[J]. Solar Energy Materials and Solar Cells, 2021, 219(1): 110813. [11] YAO Y M, ZHU X D, ZENG X L, et al. Vertically Aligned and Interconnected SiC Nanowire Networks Leading to Significantly Enhanced Thermal Conductivity of Polymer Composites[J]. ACS applied materials interfaces, 2018, 10(11): 9669-9678. doi: 10.1021/acsami.8b00328 [12] ZHAO Y H, WU Z K, BAI S L, et al. Study on thermal properties of graphene foam/graphene sheets filled polymer composites[J]. Composites Part A: Applied Science and Manufacturing, 2015, 72: 200-206. doi: 10.1016/j.compositesa.2015.02.011 [13] ZHANG L B, LI R Y, TANG B, et al. Solar-thermal conversion and thermal energy storage of graphene foam-based composites[J]. Nanoscale, 2016, 8(30): 14600-14607. doi: 10.1039/C6NR03921A [14] FENG C P, BAI L, BAO R Y, et al. Electrically insulating POE/BN elastomeric composites with high through-plane thermal conductivity fabricated by two-roll milling and hot compression[J]. Advanced Composites and Hybrid Materials, 2018, 1: 160-167. doi: 10.1007/s42114-017-0013-2 [15] 冯昌平, 孙凯印, 倪海鹰, 等. 具有有序导热网络结构的UHMWPE基复合材料的制备[J]. 塑料工业, 2022, 50(10): 164-168.Feng Changping, Sun Kaiyin, Ni Haiying, et al. Preparation of UHMWPE based composite materials with ordered thermal conductivity network structure[J]. China Plastics Industry, 2022, 50(10): 164-168(in Chinese). [16] TAKAHASHI S, LMAI Y, KAN A, et al. Dielectric and thermal properties of isotactic polypropylene/hexagonal boron nitride composites for high-frequency applications[J]. Journal of alloys and compounds, 2014, 615: 141-145. doi: 10.1016/j.jallcom.2014.06.138 [17] CHO H B, NAKAYAMA T, SUEMATSU H, et al. Insulating polymer nanocomposites with high-thermal-conduction routes via linear densely packed boron nitride nanosheets[J]. Composites Science and Technology, 2016, 129(6): 205-213. [18] DANESHPAYEH S, GHASEMI F A, GHASEMI I. Experimental investigation on mechanical properties of nanocomposites based on poly lactic acid/ polyolefin elastomer reinforced with multi-walled carbon nanotubes, and graphene nanoplatelets[J]. Polymers and Polymer Composites, 2022, 30. [19] WANG R, XIE C Z, GOU B, et al. Preparation and properties of carbon-based epoxy nanocomposites: Dynamic mechanical, dielectric, and thermal properties[J]. Polymer Composites, 2020, 41(12): 4974-4982. doi: 10.1002/pc.25767 [20] Khamaj A, Farouk W M, Shewakh W M, et al. Effect of lattice structure evolution on the thermal and mechanical properties of Cu-Al2O3/GNPs nanocomposites[J]. Ceramics International, 2021, 47(12): 16511-16520. doi: 10.1016/j.ceramint.2021.02.219 [21] 张正国, 龙娜, 方晓明. 石蜡/膨胀石墨复合相变储热材料的性能研究[J]. 功能材料, 2009, 6(5): 1313-1315.Zhang Zhengguo, Long Na, Fang Xiaoming. A Study on the Properties of Paraffin/Expanded Graphite Composite Phase Change Thermal Storage Materials[J]. Journal of Functional Materials, 2009, 6(5): 1313-1315(in Chinese). [22] FENG C P, BAI L, SHAO Y, et al. A facile route to fabricate highly anisotropic thermally conductive elastomeric POE/NG composites for thermal management[J]. Advanced Materials Interfaces, 2018, 5(2). [23] GU J, XIA D H, WANG L, et al. Low concentration graphene nanoplatelets for shape stabilization and thermal transfer reinforcement of Mannitol: a phase change material for a medium-temperature thermal energy system[J]. Materials Research Express, 2018, 5(3). [24] 陆逊, 王君豪, 朱大志, 等. 撕裂模式下乙烯-乙酸乙烯酯共聚物/氯丁橡胶热塑性硫化胶的Mullins效应及其可逆回复[J]. 合成橡胶工业, 2023, 046(01): 14-18.Lu Xun, Wang Junhao, Zhu Dazhi, et al. Mullins effect and reversible recovery of ethylene vinyl acetate co-polymer/chloroprene rubber thermoplastic vulcanizate under tearing mode[J]. China Synthetic Rubber Industry, 2023, 046(01): 14-18(in Chinese). [25] CUI S F, WU W, LIU C, et al. Modification of the three-dimensional graphene aerogel self-assembled network using a titanate coupling agent and its thermal conductivity mechanism with epoxy composites[J]. Nanoscale, 2021, 13(43): 18247-18255. doi: 10.1039/D1NR04075H [26] WANG Y, LENG S, HUANG J, et al. Modeling of cancer photothermal therapy using near-infrared radiation and functionalized graphene nanosheets[J]. International journal for numerical methods in biomedical engineering, 2020, 36(1): e3275.1-e3275.10. -

点击查看大图

点击查看大图

计量

- 文章访问数: 48

- HTML全文浏览量: 28

- 被引次数: 0

下载:

下载: