Research on hot sizing mechanism and simulation model of composite cylindrical grid structures

-

摘要: 复合材料回转体网格结构呈现多特征复杂结构属性,工艺固化变形限制了结构的制造装配精度。基于双马树脂的粘弹性,开展航天802双马树脂高温蠕变拉伸测试,证实双马树脂蠕变卸载后存在不可恢复的粘性流动应变,揭示了可以通过热矫形减少大型复合材料网格结构工艺变形的微观组分材料机理。推导建立复合材料网格结构的应变能增量理论,模拟复合材料网格结构热矫形荷载施加、松弛以及回弹过程,确定网格结构矫形回弹轮廓,与实验结果对比验证应变能理论模型有效性。分析复合材料网格结构热矫形内应力失效、矫形点个数、基于时温等效的工艺条件等影响因素,形成了复合材料网格舱段结构热矫形变形控制工艺变形仿真方法。Abstract: The composite cylindrical grid structures exhibit quite a few features and complex structural characteristics, and its precision in manufacturing is restricted due to the curing deformation. Based on the viscoelasticity of the bismaleimide resin, high temperature creep tensile testing of the aerospace 802 bismaleimide resin was performed, confirming the existence of unrecoverable viscous flow strain after the unloading of the bismaleimide resin creep. The micro component material mechanism was revealed to reduce the process curing deformation of large composite grid structures through hot sizing. The deformation energy increment theory for composite grid structures was derived and established. The process of hot sizing load application, relaxation, and rebound of composite grid structures was simulated. The correction rebound profile of grid structures was determined, comparing with experimental results to verify the effectiveness of the deformation energy increment theory. The failure of internal stress, number of correction points and process conditions based on time temperature equivalence of hot sizing composite grid structure was analyzed. A complete process for the deformation simulation method of hot sizing deformation control for composite grid structures formed.

-

Key words:

- composite /

- grid structure /

- high temperature creep /

- hot sizing /

- finite element analysis

-

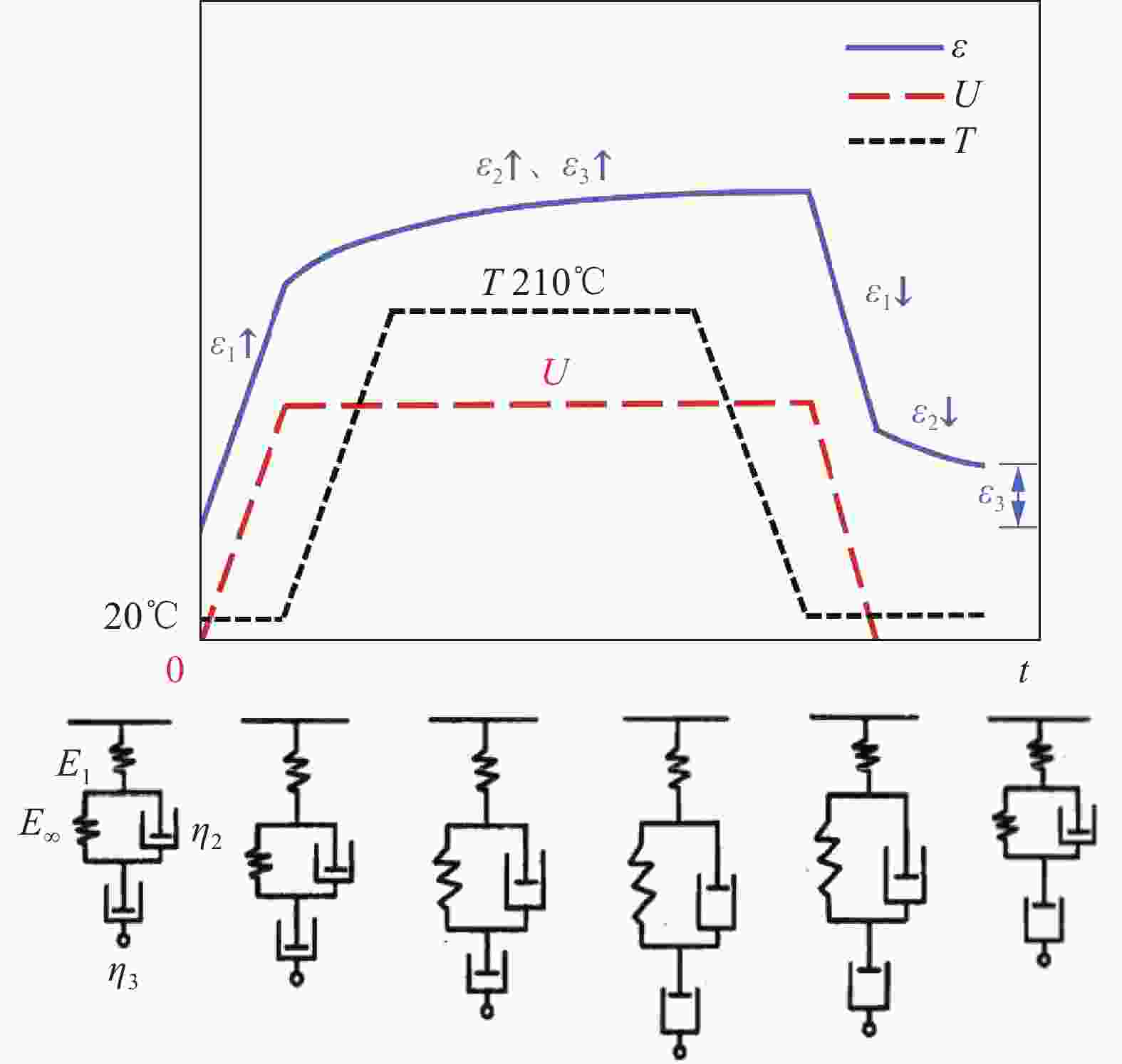

图 1 树脂基复合材料结构热矫形机理

Figure 1. Mechanism of hot sizing of polymer matrix composite structures

U—Displacement imposed by the correction; T—Temperature imposed by the correction; $ {{ \varepsilon }}_{\text{1}} $—General elastic deformation; $ {{ \varepsilon }}_{\text{2}} $—High elastic deformation; $ {{ \varepsilon }}_{\text{3}} $—Viscous flow deformation; E—Modulus of elasticity; $ \eta $—Coefficient of viscous flow

图 2 复合材料网格结构热矫形全过程轮廓变化

Figure 2. Profile changes throughout the entire process of hot sizing of composite gird structures

$ {\overset{\lower0.5em\hbox{$\smash{\scriptscriptstyle\rightharpoonup}$}} {u } _1} $—Field of change of applied corrective displacement; $ {\overset{\lower0.5em\hbox{$\smash{\scriptscriptstyle\rightharpoonup}$}} {u } _2} $—Field of displacement change when deformation rebound occurs in the interstage segment; $ {\overset{\lower0.5em\hbox{$\smash{\scriptscriptstyle\rightharpoonup}$}} {u } _3} $—Difference between the residual deformation and the initial deformation displacement field after the cabin segment has undergone creep

图 6 圆度定义(a)、TG800/802双马树脂复合材料网格舱段结构(b)、TG800/802双马树脂复合材料网格舱段固化变形预报结果((c)、(d))

Figure 6. Definition of roundness (a), TG800/802 bismaleimide resin composite grid interstage segment (b), predicted results of curing deformation of TG800/802 bismaleimide resin composite grid interstage segment ((c), (d))

表 1 TG800/802双马树脂复合材料室温力学性能

Table 1. TG800/802 bismaleimide resin composite properties at room temperature

E11/MPa E22/MPa G12/MPa G23/MPa $ {\mu }_{\text{12}} $ $ {\sigma }_{\text{11}}\text{/MPa} $ $ {\sigma}_{\text{22}}\text{/MPa} $ ILSS/MPa $ {\sigma}_{\text{12}}\text{/MPa} $ 164000 9310 5690 3280 0.38 2482 59 101 88 Notes: E—Modulus of elasticity; G—Modulus of shear; μ—Poisson’s ratio; σ—Intensity of stress; ILSS—Interlaminar shear strength. 表 2 TG800/802复合材料平板及舱段结构铺层

Table 2. Plying of TG800/802 composite laminate and grid interstage segment

Composite Ply Skin [45/−45/0/90/0/0/90/0/−45/45] End frame [45/−45/0/90/0/0/90/0/−45/45]3 Thickened zone [45/0/−45/0/15/0/−15/0/15/90]6 表 3 网格舱段层合板单元失效指数

Table 3. Failure index of grid interstage segment laminate unit

Failure mode Hashin Fiber tensile failure 0.008 Fiber compression failure 0.000 Matrix tension failure 0.889 Matrix compression failure 0.157 表 4 树脂模量等效衰减程度对应残留应力水平

Table 4. Equivalent attenuation degree of resin modulus corresponding to residual stress

Decay of

resin

modulusInternal stress/MPa Maximum

principal stressS22 S12 S13 5% 194.7 17.1 6.9 19.6 6% 227.4 19.8 8.1 22.9 9% 410.8 33.2 18.6 40.5 -

[1] 杜善义. 先进复合材料与航空航天[J]. 复合材料学报, 2007, (1): 1-12. doi: 10.3321/j.issn:1000-3851.2007.01.001DU Shanyi. Advanced composite materials and aerospace engineering[J]. Acta Materiae Compositae Sinica, 2007, (1): 1-12(in Chinese). doi: 10.3321/j.issn:1000-3851.2007.01.001 [2] 蒋贵刚, 孙天峰, 陈静, 等. 先进复合材料网格结构制备工艺及关键技术研究进展[J]. 纤维复合材料, 2020, 37(04): 101-105+109.JIANG Guigang, SUN Tianfeng, CHEN Jing, et al. Overview of Preparation Process and Key Technology on Advanced Composite Grid Structures[J]. 2020, 37(04): 101-105+109(in Chinese). [3] Vasiliev V, Barynin V, Rasin A. Anisogrid lattice structures-survey of development and application[J]. Composite Structures, 2001, 54(2): 361-370. [4] Giusto G, Totaro G, Spena P, et al. Composite grid structure technology for space applications[J]. Materials today: proceedings, 2021, 34(1): 332-340. [5] 周磊, 姚凯, 李会民, 等. 复合材料双向波纹夹层结构力学性能[J]. 复合材料学报, 2021, 38(11): 3661-3671.ZHOU Lei, YAO Kai, LI Huimin, et al. Mechanical properties of composite bi-directional corrugated sandwich structure[J]. Acta Materiae Compositae Sinica, 2021, 38(11): 3661-3671(in Chinese). [6] Vasiliev V, Barynin V, Razin A. Anisogrid composite lattice structures–Development and aerospace applications[J]. Composite Structures, 2011, 94(3): 1117-1127. [7] Totaro G, Nicola D F. Recent advance on design and manufacturing of composite anisogrid structures for space launchers[J]. Acta Astronautica, 2012, 81(2): 570-577. doi: 10.1016/j.actaastro.2012.07.012 [8] Totaro G, Gürdal Z. Optimal design of composite lattice shell structures for aerospace applications[J]. Aerospace Science and Technology, 2008, 13(4): 157-164. [9] 熊健, 李志彬, 刘惠彬, 等. 航空航天轻质复合材料壳体结构研究进展[J]. 复合材料学报, 2021, 38(06): 1629-1650.XIONG Jian, LI Zhibin, LIU Huibin, et al. Advances in aerospace lightweight composite shell structure[J]. 2021, 38(06): 1629-1650(in Chinese). [10] 祖磊, 范文俊, 张骞, 等. 基于非线性有限元理论的复合材料壳体缠绕参数优化设计[J]. 复合材料科学与工程, 2022(10): 5-12+32.ZU Lei, FAN Wenjun, ZHANG Qian et al. Optimization design of winding parameters of composite shell based on nonlinear finite element theory[J]. COMPOSITES SCIENCE AND ENGINEERING, 022(10): 5-12+32(in Chinese). [11] 陈小平, 杨杰, 刘建超. 复合材料网格结构的研究现状[J]. 宇航材料工艺, 2009, 39(02): 6-11.CHEN Xiaoping, YANG Jie, LIU Jianchao. Actuality research on composite grid structures[J]. Aerospace Materials and Technology, 2009, 3 9(2): 6-11(in Chinese). [12] 王世勋, 石玉红, 张希, 等. 复合材料格栅结构研究进展与应用[J]. 宇航材料工艺, 2017, 47(1): 5-12. doi: 10.12044/j.issn.1007-2330.2017.01.002WANG Shixun, SHI Yuhong, ZHANG Xi, et al. Application and research progress of composite lattice grids structure[J]. Aerospace Materials and Technology, 2017, 47(1): 5-12(in Chinese). doi: 10.12044/j.issn.1007-2330.2017.01.002 [13] 韩振宇, 张鹏, 郑天宇, 等. 纤维增强树脂复合材料网格结构成型工艺研究进展[J]. 复合材料学报, 2020, 37(4): 45-858.HAN Zhenyu, ZHANG Peng, ZHANG Tianyu, et al. Research progress grid structure of forming process of fiber reinforced polymer composite[J]. Acta Materiae Compositae Sinica, 2020, 37(4): 45-858(in Chinese). [14] 陈浩, 曲中兴, 张立武. 航空航天整体结构件新型校形技术研究现状[J]. 航天制造技术, 2017, (1): 11-16. doi: 10.3969/j.issn.1674-5108.2017.01.004CHEN Hao, QU Zhongxing, ZHANG Liwu. Research Status of New Correction Technology of Aerospace Monolithic Component[J]. Aerospace Manufacturing Technology, 2017, (1): 11-16(in Chinese). doi: 10.3969/j.issn.1674-5108.2017.01.004 [15] 于云程, 李春峰, 江洪伟, 等. 管件端口电磁校形的实验研究[J]. 锻压技术, 2005, (4): 9-12. doi: 10.3969/j.issn.1000-3940.2005.04.004YU Yuncheng, LI Chunfeng, JIANG Hongwei, et al. Experimental study of the tube ends sizing with electromagnetic bulging[J]. Forging and Stamping Technology, 2005, (4): 9-12(in Chinese). doi: 10.3969/j.issn.1000-3940.2005.04.004 [16] 胡建华, 宁博文, 蔡衡, 等. 铝合金曲面板料回弹的电磁成形校正试验[J]. 塑性工程学报, 2013, 20(4): 104-108. doi: 10.3969/j.issn.1007-2012.2013.04.020HU Jianhua, NING Bowen, CAI Heng, et al. Experimental study on springback of Aluminum alloy sheet by electromagnetic forming[J]. Journal of Plasticity Engineering, 2013, 20(4): 104-108(in Chinese). doi: 10.3969/j.issn.1007-2012.2013.04.020 [17] Ueda T , Sentoku E , Wakimura Y , et al. Flattening of sheet metal by laser forming[J]. Optics and Lasers in Engineering, 2009, 47(11): 1097-1102. [18] 陈星. 超声波喷丸校形的应用研究[D]. 南京航空航天大学, 2013.CHEN Xing. Research of Ultrasonic Shot Peening Technology In Straigthening[D]. Nanjing University of Aeronautics and Astronautics, 2013(in Chinese). [19] 姚少非, 张宏彬, 李健, 等. TC4钛合金筒形件热校形仿真分析[J]. 导航与控制, 2021, 20(3): 93-98. doi: 10.3969/j.issn.1674-5558.2021.03.012YAO Shaofei, ZHANG Hongbin, LI Jian, et al. Simulation Analysis on Hot Sizing Technology of TC4 Titanium Alloy Cylindrical Workpiece[J]. NAVIGATION AND CONTROL, 2021, 20(3): 93-98(in Chinese). doi: 10.3969/j.issn.1674-5558.2021.03.012 [20] LuL , GuoK, SunJ, et al. Investigation on hot sizing process based on creep mechanism for laser cladded thin-walled titanium alloy components[J]. Journal of Laser Applications, 2019, 31(4): 042002. [21] 罗玲. 基于机器学习的碳纤维复合材料热压罐成型工艺缺陷高通量预测方法[D]. 北京航空航天大学, 2021.LUO Ling. High Throughput Prediction Method for Defects in Autoclave Forming Processes of Carbon Fiber Composites Based on Machine Learning[D]. Beihang University, 2021(in Chinese). [22] Li H, Zhang B. A new viscoelastic model based on generalized method of cells for fiber-reinforced composites[J]. International Journal of Plasticity, 2015, 6522-32. [23] 马宁, 刘书田. 复合材料粘弹性本构关系与热应力松弛规律研究 Ⅱ: 数值分析[J]. 复合材料学报, 2005, (1): 158-163. doi: 10.3321/j.issn:1000-3851.2005.01.028MA Ning, LIU Shutian. Study on the thermal stress relaxation and constitutive equations of viscoelastic composite materials, part II: numerical simulation[J]. Acta Materiae Compositae Sinica, 2005, (1): 158-163(in Chinese). doi: 10.3321/j.issn:1000-3851.2005.01.028 [24] 许英杰, 孙勇毅, 杨儒童, 等. 考虑强度与固化变形的复合材料加筋壁板铺层优化方法[J]. 计算力学学报, 2021, 38(3): 297-304.XU Yingjie, SUN Yongyi, YANG Rutong, et al. An optimization method for ply placement of stiffened composite panels considering strength and cure deformation[J]. Chinese Journal of Computational Mechanics, 2021, 38(3): 297-304(in Chinese). [25] 王浩军, 黄雪萌, 房晓斌, 等. 复合材料C型梁类零件变形控制工艺方法的研究[J]. 橡塑技术与装备, 2018, 44(22): 34-37.WANG Haojun, HUANG Xuemeng, FANG Xuebin. Research on deformation control technology of composite C beam parts[J]. CHINA RUBBER/PLASTICS TECHNOLOGY AND EQUIPMENT (PLASTICS), 2018, 44(22): 34-37(in Chinese). [26] 王海雷, 刘凯, 张博明, 等. 复合材料机翼结构热矫形工艺实验及数值模拟[J]. 复合材料学报, 2021, 38(5): 1487-1496.WANG Hailei, LIU Kai, ZHANG Boming, et al. Simulation and experimental studies of hot sizing process for composite wing structures[J]. Acta Materiae Compositae Sinica, 2021, 38(5): 1487-1496(in Chinese). [27] Liu K, Ye J, Zhang B, et al. Experimental and finite element studies on hot sizing process for L-shaped composite beams[J]. Composites Part A, 2016, 87161-169. [28] Sallah M. A mathematical model of autoclave age forming[J]. Journal of Materials Processing Technology, 1991, 28(1-2): 211-219. doi: 10.1016/0924-0136(91)90220-9 [29] 陈春奎, 黄永坚, 王以璠, 等. 钛和钛合金钣金零件的热校形[J]. 金属科学与工艺, 1985, (2): 89-100.CHEN Chunkui, HUANG Yongjian, WANG Yifan, et al. Thermal shaping of titanium and titanium alloy sheet metal parts[J]. METAL SCIENCE & TECHNOLOGY, 1985, (2): 89-100(in Chinese). [30] 陈明和, 高霖, 翟建军. TC4钛板飞行器蒙皮零件热校形研究[J]. 航空精密制造技术, 1999, 35(5): 19-21. doi: 10.3969/j.issn.1003-5451.1999.05.006CHEN Minghe, GAO Lin, ZHAI Jianjun. Thermal shaping of skin parts of TC4 titanium sheet vehicle[J]. Aviation Precision Manufacturing Technology, 1999, 35(5): 19-21(in Chinese). doi: 10.3969/j.issn.1003-5451.1999.05.006 [31] Shong Z. C. , Ling Z. R. , Peklenik J. A Study of the Hot Sizing and High Temperature Mechanical Behaviour for Titanium Alloy Sheet[J]. CIRP Annals-Manufacturing Technology, 1983, 32, (1): 161–165. [32] Masuko Y, Kawai M. Application of a phenomenological viscoplasticity model to the stress relaxation behavior of unidirectional and angle-ply CFRP laminates at high temperature[J]. Composites Part A: Applied Science & Manufacturing, 2004, 35(7): 817-826. [33] Chung I. , Sun C. T. , Chang I. Y. Modeling Creep in Thermoplastic Composites[J]. Journal of Composite Materials, 1993, 27: 1009-1029. [34] 过梅丽. 高分子物理[J]. 北京: 北京航空航天大学出版社, 2005, 9: 174-178.GUO Meili. Thermally corrected polymers[J]. Beijing: Beihang University Press, 2005, 9: 174-178(in Chinese). [35] 方征平. 关于模拟聚合物非线性黏弹行为的四元件模型[J]. 高分子通报, 2018, (12): 63-69.FANG Zhenping, On the Four-Element Model of Polymer Viscoelasticity[J]. Polymer Bulletin, 2018, (12): 63-69(in Chinese). [36] 朱迅, 王明寅, 王荣国, 等. 纤维增强聚合物基复合材料的蠕变力学研究进展[J]. 纤维复合材料, 2004, (3): 51-53. doi: 10.3969/j.issn.1003-6423.2004.03.016ZHU Xun, WANG Mingyin, WANG Rongguo, et al. Progress in the Development of Creep Behavior of Fiber Reinforced Polymer Composites[J]. FIBER COMPOSITES, 2004, (3): 51-53(in Chinese). doi: 10.3969/j.issn.1003-6423.2004.03.016 [37] NELSON R B, LORCH D R. A Refined Theory for Laminated Orthotropic Plates[J/OL]. Journal of Applied Mechanics, 1974: 177-183. [38] Paley, M, Aboudi, J. Micromechanical analysis of composites by the generalized cells model[J]. Mechanics of Materials, 1992, 14(2): 127-139. doi: 10.1016/0167-6636(92)90010-B [39] 唐占文, 张博明. 复合材料设计制造一体化中的固化变形预报技术[J]. 航空制造技术, 2014, (15): 32-37. doi: 10.3969/j.issn.1671-833X.2014.15.003TANG Zhanwen, ZHANG Boming. Prediction of Curing Deformation in Integrated Design and Manufacture of Composites[J]. Aeronautical Manufacturing Technology, 2014, (15): 32-37(in Chinese). doi: 10.3969/j.issn.1671-833X.2014.15.003 [40] 罗玲, 张涛, 田智立, 等. 碳纤维复合材料固化变形预报方法对比[J]. 复合材料科学与工程: 1-102023-12-14]. LUO Ling, ZHANG Tao, TIAN Zhili, et al. Comparison of process-induced distortion prediction methods of carbon fiber composites[J]. Composites Science and Engineering. 1-10 [2023-12-14](in Chinese). [41] Affdl J C H , Kardos J L . The Halpin-Tsai equations: A review[J]. Polymer Engineering & Science, 1976, 16(5): 344-352. [42] HASHIN Z. Failure criteria for unidirectional fiber composites[J]. ASME Journal of Applied Mechanics, 1980, 47: 329-334. doi: 10.1115/1.3153664 -

点击查看大图

点击查看大图

计量

- 文章访问数: 71

- HTML全文浏览量: 20

- 被引次数: 0

下载:

下载: