Pore structure and thermal conductivity of basalt fiber reinforced foam concrete under freeze-thaw cycles

-

摘要:

为研究冻融循环作用下的玄武岩纤维泡沫混凝土(BFRFC)的孔结构及热传导特性。选取四种不同纤维掺量的BFRFC试样,采用X-CT技术和Avizo软件进行三维重构,分析其孔隙结构和纤维分布特征。通过热力学性能测试和COMSOL数值仿真,研究不同冻融循环次数下BFRFC的导热性能变化规律,并基于多孔介质Bruggeman模型以及纤维的串并联导热机理,提出BFRFC的理论导热模型。结果表明,BFRFC的孔径尺寸和形状因子近似对数正态分布,纤维极角和方位角分别在15°~90°和0°~360°范围内均匀分布;BFRFC导热系数处于0.2~0.4W/(m·K)之间,受孔隙率和冻融循环次数的影响,纤维掺量的影响较小;通过建立BFRFC的数值仿真模型,采用COMSOL模拟导热性能,与实验结果基本一致;基于多相介质Bruggeman模型,结合纤维的串并联模型建立的理论导热模型可以有效地预测不同纤维掺量和孔隙率下BFRFC的导热系数,为寒区工程中BFRFC的应用提供了理论依据。

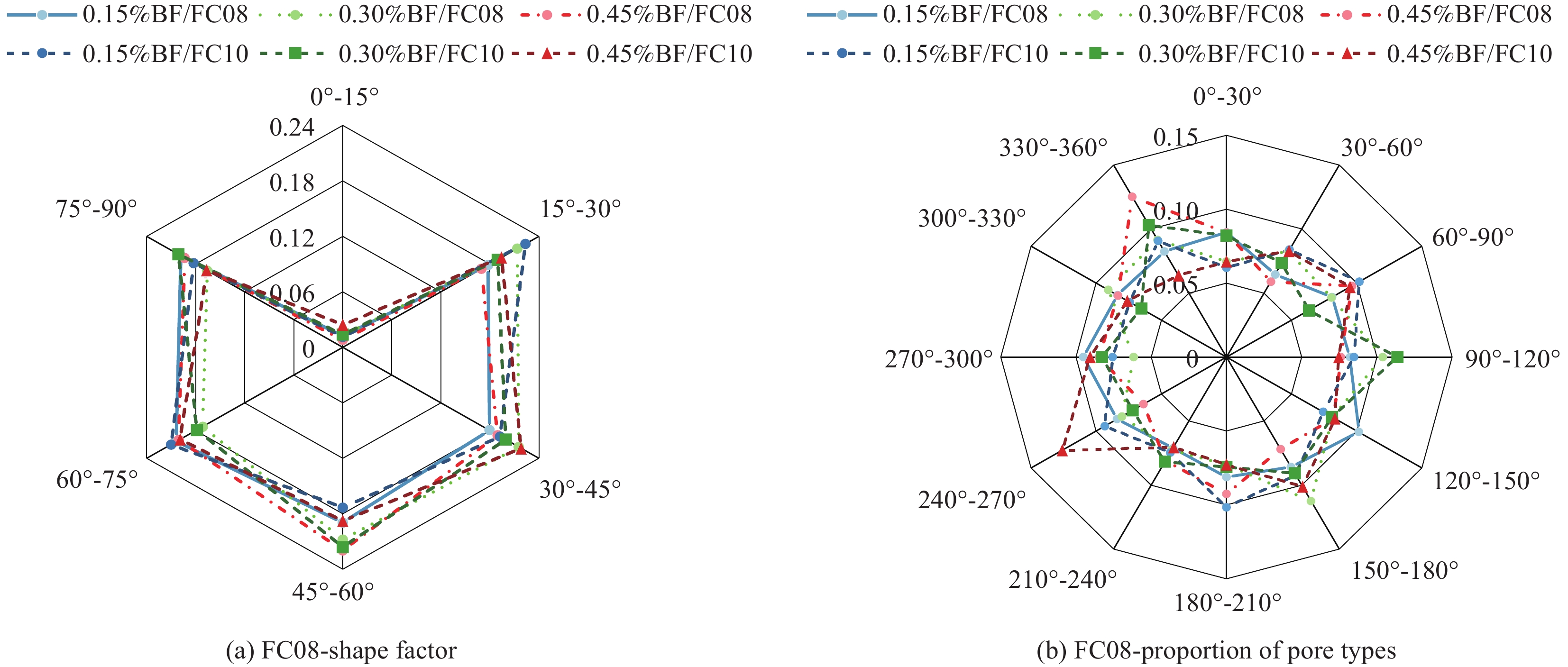

Abstract:To study the pore structure and thermal conductivity characteristics of basalt fiber reinforced foam concrete (BFRFC) under freeze-thaw cycles, four BFRFC samples with different fiber contents were selected. X-CT technology and Avizo software were employed for three-dimensional reconstruction to analyze the pore structure and fiber distribution characteristics. Thermodynamic performance tests and COMSOL numerical simulations were conducted to investigate the changes in thermal conductivity of BFRFC under different freeze-thaw cycles. Based on the Bruggeman model for porous media and the parallel and series conduction mechanisms of fibers, a theoretical thermal conductivity model for BFRFC was proposed. The results show that the pore size and shape factor of BFRFC approximately follow a log-normal distribution, with fiber polar and azimuthal angles uniformly distributed in the ranges of 15° to 90° and 0° to 360°, respectively. BFRFC's thermal conductivity ranges from 0.2 to 0.4 W/(m·K), primarily influenced by porosity and freeze-thaw cycles, with fiber content having a smaller impact. By establishing a numerical simulation model of BFRFC and using COMSOL to simulate thermal conductivity, the results were found to be consistent with experimental data. The theoretical thermal conductivity model, based on the Bruggeman model and the parallel-series fiber model, effectively predicts the thermal conductivity of BFRFC under different fiber contents and porosity conditions, providing a theoretical basis for the application of BFRFC in cold region engineering.

-

随着全球经济的发展和化石燃料的消耗剧增,全球石油的需求量在逐年增加,多次采油技术得到了更广泛应用[1],原油采出液的含水率也在逐年增加,正在给中国这一世界最大石油进口国带来严峻的挑战。同时,随着海上油气开发向深海迈进,深海平台的油水分离、采油井井底油水分离等都迫使人们探索新的油水分离技术。

工业生产运输过程中的各类不溶性有机物的泄露和排放导致了各种严重的环境问题[2-5]。例如石油加工和运输过程中的原油和成品泄露导致的水污染。皮革处理、食品加工、冶金、化工等工业生产过程中排放的含油废水。这些含油废水如不经处理直接排放,会对生态系统、农业生产构成严重破坏,危及人类健康,因此需要有效的油水分离技术来解决分离问题。目前主要的油水分离形式包括重力分离、离心、吸附和膜分离等[6-9]。将含油废水进行油水分离后,对废水的后续的处理难度和成本将会大大降低。膜分离技术作为一种先进的水净化技术,由于其经济、节能、易于操作的特点,已经成为一种不可或缺的选择[10-12]。然而,面对愈加复杂的含油污水(轻/重油和水的混合物、水包油乳液和油包水乳液的混合体系)以及不同酸碱环境,单一的除油型、除水型分离材料无法实现按需、高效和可持续的分离。因此,开发先进的智能油水分离材料是解决世界水环境恶化和石油短缺问题的迫切需要。

对某种外界刺激敏感并产生特殊反应的现象称为智能响应。具有可转换润湿行为的人工智能响应界面材料引起了人们越来越多的兴趣[13-15]。研究表明,可转换润湿行为通常可通过调节pH值[16],改变光源[17]、温度[18]、磁场强度[19]等方式实现。pH响应材料可定义为在其结构中包括弱酸性或碱性基团的聚电解质,酸性或碱性基团如羧基、吡啶、磺酸、磷酸盐、叔胺等通常被称为pH响应基团,这些基团响应于pH的变化。基团会随着环境pH变化而接受或释放质子,导致结构和性质的变化,从而实现材料的pH响应。例如,Liu等[20]合成了一种基于分子印迹聚合物的pH响应型纳米药物,该纳米药物在的模拟肿瘤微环境中表现出良好的 pH 响应性,可通过特定的分子印迹位点选择性地从前列腺肿瘤中螯合睾酮。Surapaneni等[21]合成了一种具有温度和 pH 双重刺激响应的聚N-乙烯基己内酰胺和聚赖氨酸的嵌段共聚物,该共聚物可在两种刺激单独或共同作用下增加细胞对聚合物囊泡的渗透性,用于增强细胞内化和溶酶体靶向药物运送。

光作为一种低成本、绿色环保的刺激方法,使含有光响应基团的材料具有非接触式的遥控特性。光响应性能可以通过引入光响应基团来实现,该基团在特定波长的照射下发生结构变化,从而导致材料的性能发生变化[22-24]。目前常用的光响应基团是偶氮苯及其衍生物。偶氮化合物有两种异构体,一种是稳定态的反式结构,另一种是亚稳态的顺式结构。偶氮苯官能团经紫外线照射后,反式的非极性异构体可以转化为顺式的极性异构体,并且这一过程具有可逆性。由于偶氮苯反式构象的极性较弱,顺式构象的极性较强,在顺反异构体转变的过程中会导致材料的极性发生变化,其亲疏水性也随之变化,可以利用这一特性制备光响应智能转换油水分离材料,因为偶氮苯顺反异构体转换的可逆性,所以亲疏水性能的变化过程也是可逆的[25-28]。Yang等[29]利用偶氮苯聚合物作为衬底,制备一种可光切换的超疏水表面,该表面可受紫外和可见光的影响,使聚合物膜发生亲水到疏水的可逆改变。Du等[30]制备了一种功能化的偶氮苯聚合物,制备的偶氮苯溶液在紫外和可见光交替暴露下表现出偶氮苯的光异构化转变以及亲水到亲油的可逆变化。偶氮苯衍生物因其良好的化学稳定性和多功能性在光响应材料的制备和应用中具有广阔的发展前景[31]。

本文采用可逆加成-断裂链转移(RAFT)一步聚合法,制备得到了具有pH/光刺激响应性能的三元无规共聚物,并将其与无纺布相结合,得到了具有智能化可逆响应性能复合织物的油水分离膜。这种油水分离膜在油水分离、工业复杂废水处理等方面具有巨大的应用潜力。

1. 实验材料及方法

1.1 原材料

四氢呋喃(THF)、盐酸(35%)、甲醇,西陇科学公司;二硫代苯甲酸异丙酯(CDB),阿拉丁生物技术有限公司;无纺布,深圳瑞都净化公司;偶氮二异丁腈(AIBN)、甲基丙烯酸羟乙酯(HEMA)、甲基丙烯酸二甲氨乙酯(DMAEMA)、对氨基苯甲酸、苯酚、氢氧化钠、亚硝酸钠、三乙胺、丙烯酰氯,麦克林公司。上述试剂均是分析纯,实验用水为去离子水。

1.2 样品表征

傅里叶红外光谱仪(VERTEX 70 Bruker)、 超导核磁共振波谱仪(BRUKER 500 MHz AVANCE NEO)、紫外可见分光光度计(UV-3600 Plus,日本岛津)、扫描电子显微镜(ZEISS GeminiSEM 500,德国卡尔蔡司) 、视频光学接触角测试仪(OCA25 Eastern-Dataphy)。

1.3 智能响应油水分离材料的合成

合成主要分为4个步骤:(1)重氮化-偶联反应;(2)酯化反应;(3)酯水解反应;(4)聚合反应。合成路线见图1。

1.3.1 4-(4'-羟基)苯偶氮基苯甲酸的合成

通过重氮化-偶联反应制备4-(4'-羟基)苯偶氮基苯甲酸。将35%的盐酸12 mL与等体积的蒸馏水混合,缓慢滴加到装有对氨基苯甲酸(4.10 g,30 mmol)的烧瓶中搅拌均匀后,将30 mL的NaNO2水溶液(1 mol/L)缓慢滴入烧瓶反应30 min后加300 mL冰水稀释。然后滴加20 mL苯酚(2.94 g,31 mmol)和NaOH (1.72 g,31 mmol)水溶液。0~5℃下反应2 h,用NaOH调节pH至5~6。过滤收集固体,蒸馏水洗涤,得到4-(4'-羟基)苯偶氮基苯甲酸(中间体a)的橘黄色固体6.97 g,产率85%。

1.3.2 丙烯酸-4-((4-(丙烯氧基)苯基)二氮基)苯甲酸酐的合成

将1.3.1制得的偶氮苯(2.42 g,10 mmol)与三乙胺(1.47 mL,10 mmol)溶于25 mL THF并滴加丙烯酰氯(0.8 mL,10 mmol),室温下反应24 h。滤去生成的盐,浓缩滤液并滴入甲醇中沉淀,得到丙烯酸-4-((4-(丙烯氧基)苯基)二氮基)苯甲酸酐黄色固体1.67 g (中间体b),产率57%。

1.3.3 4-((4-(丙烯氧基)苯基)二氮基)苯甲酸的合成

将1.3.2中制备的偶氮苯1.51 g溶解在20 mL THF中,用10%的氢氧化钠水溶液调节pH至7~8,室温反应24 h,后用5%的盐酸水溶液调节pH至2~4,过滤并用蒸馏水洗涤,得到橙色固体1.24 g (单体c),产率83%。

1.3.4 智能双响应聚合物的制备

采用可逆加成-断裂链转移聚合(RAFT),一步反应制得智能响应聚合物。这种聚合也被称为“活性”/可控自由基聚合。由于其反应条件温和、单体选择范围广、分子设计能力强等优点,已发展成为最通用、最强大的聚合技术之一。

将1.3.3中的产物(1.55 g,5 mmol)与 DMAEMA(0.339 g,2.16 mmol)、HEMA (0.280 g,2.16 mmol)溶于THF后通氮排氧,温度升至70℃后加入AIBN (0.08 g,0.5 mmol)、CDB (0.2 g,0.2 mmol)反应48 h,旋蒸去除溶剂,甲醇洗涤后,干燥,得到橘红色聚合物1.84 g (聚合物d),产率85%。

1.4 智能响应涂层的制备

将1.3.4中得到的聚合物均匀地涂膜在载玻片上,60℃下真空干燥,用于测量接触角。

1.5 智能油水分离膜的制备

将直径5 cm的无纺布用无水乙醇浸泡并超声清洁表面灰尘和油脂后,浸入未干燥的聚合物中,使聚合物均匀地涂在无纺布表面,60℃下真空干燥48 h,得到智能双响应油水分离膜。

2. 结果与讨论

2.1 表征与形貌

合成的各中间体、单体和聚合物的红外谱图如图2所示。

3452 cm−1处的吸收峰为偶氮苯中苯环上不饱和C—H键的伸缩振动,1606 cm−1为苯环骨架的C=C伸缩振动,807 cm−1为苯环上的C—H面外弯曲振动峰。a、c、d 在2942 cm−1处的吸收峰为羧基的O—H伸缩振动峰;b、c在1721 cm−1处存在C=C的伸缩振动;b在1786 cm−1处存在酸酐的C=O伸缩振动;聚合物d在3250 cm−1左右处存在DMAEMA中叔胺甲基上C—H伸缩振动峰和HEMA中的O—H伸缩振动峰。图3为偶氮苯单体及聚合物的1H NMR图,图3(a)中,8.13×10−6、8.01×10−6、7.45×10−6和5.88×10−6处的峰对应单体c结构中为A、B、C和D的氢。图3(b)中,1.13×10−6和1.26×10−6处的氢对应于聚合物d中F和G相应位置的氢,A、B、C和D的氢与单体结构中的峰位置基本一致。

将偶氮苯溶于DMF (0.15 g·L−1)中,用365 nm紫外灯(20 W)照射2 h,使溶液中的单体转化为顺式结构后,分别检测不同照射时间的UV-Vis吸收光谱,吸收光谱随时间变化的关系如图4所示。其中,图4(a)为用LED灯(445 nm,20 W)对溶液进行照射,直至吸光度不再变化的吸收光谱。图4(b)为继续用365 nm紫外灯对溶液进行照射后的吸收光谱。偶氮苯特征吸收峰主要是330~380 nm处的π-π*吸收峰和420~500 nm的n-π*吸收峰。从图4中单体在365 nm和445 nm光照射下吸收光谱的变化情况可以看出,365 nm和445 nm的光照下,随照射时间的增加,单体在溶液中π-π*吸收峰的位置几乎不发生移动,而吸光度会逐渐变化。n-π*特征峰处的吸光度和吸收峰的位置均变化很小。吸光度的变化归因于紫外-可见光照射引起的偶氮苯从顺式到反式的异构化。对比图4(a)与图4(b)中吸收光谱变化,可以看到偶氮苯的顺反异构化是一个可逆的过程。

未经处理的无纺布(图5(a))纤维表面相对光滑。经过涂膜的无纺布(油水分离膜,图5(b)),可以观察到纤维表面及相邻纤维间粘附的聚合物,作为基底的无纺布具有多孔结构和交错的纤维,有利于聚合物的粘附并为油水分离提供了必要的空间。无纺布的柔性还使油水分离膜具有良好的柔韧性,可以承受多次折叠而不损坏。

2.2 智能响应及油水分离测试

将聚合物均匀地涂抹在载玻片上烘干后,分别在自然条件、pH=3的缓冲溶液浸泡、紫外-可见光照射、缓冲溶液浸泡后继续用紫外-可见光照射等情况下进行接触角测量实验,每次滴液的量为5 μL,接触角变化如图6所示。

![]() 图 6 聚合物d的载玻片涂层在不同条件下的接触角变化:(a)自然条件下;(b)经pH=3缓冲溶液浸泡后;(c)经pH=10缓冲溶液浸泡后;(d)经365 nm光照射后;(e)经445 nm光照射后;(f)经pH=3缓冲溶液浸泡并用365 nm紫外光照射后Figure 6. Contact angle variation of polymer d slide coatings under different conditions: (a) The natural state; (b) After immersion with pH=3 buffer solution; (c) After immersion in pH=10 buffer solution; (d) After exposure to 365 nm light; (e) After exposure to 445 nm light; (f) After immersion in pH=3 buffer solution and irradiation with 365 nm ultraviolet light

图 6 聚合物d的载玻片涂层在不同条件下的接触角变化:(a)自然条件下;(b)经pH=3缓冲溶液浸泡后;(c)经pH=10缓冲溶液浸泡后;(d)经365 nm光照射后;(e)经445 nm光照射后;(f)经pH=3缓冲溶液浸泡并用365 nm紫外光照射后Figure 6. Contact angle variation of polymer d slide coatings under different conditions: (a) The natural state; (b) After immersion with pH=3 buffer solution; (c) After immersion in pH=10 buffer solution; (d) After exposure to 365 nm light; (e) After exposure to 445 nm light; (f) After immersion in pH=3 buffer solution and irradiation with 365 nm ultraviolet light图6显示了聚合物涂层在不同条件下的接触角的变化情况,该变化能够反映涂层材料的智能响应特性。在自然条件下的接触角143.7°,见图6(a)。将其在pH=3的缓冲溶液中浸泡1 h后烘干,接触角变化至109.9°,见图6(b)。该过程的接触角是由聚合物中DMAEMA单元和偶氮苯上羧基质子化共同作用导致的。随后将涂层置于pH=10的缓冲溶液中浸泡1 h后烘干,其接触角恢复至142.2°,见图6(c),将烘干后的涂层在365 nm (20 W)紫外灯下照射5 min,接触角变化至48.4°,见图6(d)。用LED灯照射15 min后,其接触角恢复至139.3°,如图6(e)所示。该过程接触角的变化是由于聚合物中偶氮苯单元经过紫外-可见光照射后发生构型转化使涂层的润湿性发生转变。最后将涂层置于pH=3的缓冲溶液中浸泡1 h后烘干,然后将其置于365 nm (20 W)紫外灯下照射15 min,该过程由pH响应单元与光响应单元共同作用,其接触角由139.3°变化至19.0°,见图6(f)。

上述过程证明了涂层具有良好的刺激响应能力。以相同的方法重复进行上述实验,接触角的变化如图7所示。实验结果表明,经过多次刺激响应,聚合物涂层发生亲水和疏水的多次转换,且接触角仍可恢复到初始状态,证明了涂层的转换润湿能力具有良好的可逆性。其中,光在转化过程中具有更加显著的效果,这也在随后的油水分离试验中得到证实,切换时间也与偶氮苯单体吸收光谱的转化时间基本对应。由于光照可以在没有物理接触的情况下实现转化,这增强了材料的实际应用的便利性。

为了测试光/pH双响应油水分离膜的分离效果,将柠檬黄染色的水100 mL与石油醚以2∶1的体积比混合后倒入滤杯中进行油水分离实验。为加快油/水的分离速度,在0.005 MPa的压力下用抽滤的方法模拟油水分离系统 (图8)。图8(a)中,抽滤30 s后,无色的石油醚被抽滤下来,不再有液体从上方流下,染色的水保留在上方滤杯中。在图8(b)中,用365 nm光照射分离膜12 h,以相同的方法进行油水分离,抽滤25 s后,染色的水被抽滤下来,石油醚被保留在上方。

分别测量分离后上方滤杯中的油或水的体积,计算得到分离效率分别为96.3% (图8(a))和95.8%(图8(b))。实验结果证明了分离膜具有良好的智能转换油水分离能力。

3. 结 论

(1)以合成的偶氮苯、甲基丙烯酸羟乙酯(HEMA)和甲基丙烯酸二甲氨乙酯(DMAEMA)为原料,采用可逆加成-断裂链转移(RAFT)法一步聚合,制得光和pH智能双响应三元无规共聚物。该聚合物以偶氮苯作为光响应单元,DMAEMA作为pH响应单元,HEMA使聚合物具有良好的柔性附着性能,FTIR和1HNMR谱图说明了聚合物的成功合成。

(2)通过在不同条件下的润湿性实验,验证了聚合物涂层的可转换润湿性。紫外线的照射导致偶氮苯单元的分子构型发生转变,结构上的变化导致聚合物的润湿性和渗透性的变化。在仅有pH=3的缓冲溶液浸泡后其最大接触角转变达到33.8°,仅有紫外光照射下其最大接触角转变达到93.8°,而在光和pH的共同作用下,其最大接触角变化可达到120.3°。说明了涂层在光照和pH的刺激下具有优异的刺激响应性。经过亲水与疏水的多次转换实验后,接触角仍可恢复到初始状态,证明了涂层对水的润湿能力切换具有可逆性。

(3)偶氮苯的引入使聚合物对光具有良好的响应性,DMAEMA上含有的叔胺基团和偶氮苯上的羧基共同增强了涂层的pH响应性和抗酸性,可以使涂层应对一些复杂情况下的油水分离,油水分离实验证明涂层在光照下的极性转变,单次分离效率分别达96.3%和95.8%。

综上,通过一步RAFT聚合制备得到的光/pH双响应的聚合物材料,可用来制备智能光/pH双响应油水分离膜,该膜具有优异的可逆刺激响应性能。

-

表 1 BFRFC的配合比(kg/m3)

Table 1 Mix ratio and of BFRFC (kg/m3)

Sample Cement Water BF Foams 0%BF/FC08* 416.67 208.33 0 35.49 0.15%BF/FC08 416.67 208.33 4.2 35.49 0.30%BF/FC08 416.67 208.33 8.4 35.49 0.45%BF/FC08 416.67 208.33 12.6 35.49 0%BF/FC10 743.05 371.53 0 21.83 0.15%BF/FC10 743.05 371.53 4.2 21.83 0.30%BF/FC10 743.05 371.53 8.4 21.83 0.45%BF/FC10 743.05 371.53 12.6 21.83 *Notes: 0.15% BF represents the basalt fiber content; FC08 represents the foam concrete matrix, where 08 and 10 denote densities of 800 kg/m³ and 1000 kg/m³, respectively.表 2 不同冻融次数下BFRFC的孔隙尺寸特征

Table 2 Pore size characteristics of BFRFC under different freeze-thaw cycles

Sample Freeze-thaw

CyclesPorosity/% Pore

numberPore diameter/ μm Distribution parameters X-CT Saturated water

absorptionError Max Min Average μ σ 0%BF/FC08 0 15.43 15.87 −2.85% 326725 4480.61 44.54 458.14 6.03 0.4 40 35.75 35.67 0.22% 300971 4657.25 44.54 642.03 6.35 0.43 80 43.79 43.87 −0.18% 294860 4721.06 44.54 768.12 6.54 0.45 0.15%BF/FC08 0 14.91 15.29 −2.55% 315854 4503.13 44.54 447.85 6.02 0.39 40 34.54 34.44 0.29% 275417 4678.84 44.54 624.54 6.32 0.42 80 42.54 42.67 −0.31% 288012 4745.87 44.54 723.01 6.48 0.39 0.30%BF/FC08 0 14.44 14.84 −2.77% 305145 4534.57 44.54 434.74 6.01 0.36 40 32.87 32.75 0.37% 289874 4705.89 44.54 594.47 6.23 0.43 80 41.87 41.94 −0.17% 281245 4765.47 44.54 688.17 6.42 0.4 0.45%BF/FC08 0 14.02 13.75 1.93% 294180 4556.17 44.54 425.15 5.99 0.34 40 31.82 31.64 0.57% 283498 4724.53 44.54 576.1 6.19 0.42 80 40.71 40.98 −0.66% 274507 4787.56 44.54 641.58 6.35 0.39 0%BF/FC10 0 10.94 11.51 −5.21% 483346 3000.06 44.54 307.18 5.77 0.22 40 19.92 19.90 0.10% 466913 3407.16 44.54 410.41 6.02 0.24 80 26.04 26.47 −1.65% 404889 3870.43 44.54 565.45 6.24 0.29 0.15%BF/FC10 0 10.69 10.45 2.25% 461487 3035.25 44.54 289.73 5.64 0.23 40 19.54 19.87 −1.69% 446674 3458.12 44.54 384.62 5.92 0.25 80 25.87 25.86 0.04% 398743 3954.78 44.54 501.41 6.15 0.27 0.30%BF/FC10 0 10.54 10.92 −3.61% 439784 3094.54 44.54 271.45 5.58 0.26 40 18.95 18.77 0.95% 425174 3536.89 44.54 358.14 5.83 0.27 80 25.71 25.87 −0.62% 394155 4001.34 44.54 479.54 6.13 0.24 0.45%BF/FC10 0 9.93 10.25 −3.22% 417611 3136.87 44.54 244.18 5.51 0.27 40 18.09 18.54 −2.49% 406178 3597.48 44.54 337.4 5.72 0.23 80 24.65 24.55 0.41% 384755 4068.15 44.54 461.34 6.06 0.28 Notes: Due to the testing accuracy and resolution limitations of the X-CT equipment, the smallest pore diameter recorded for the BFRFC specimens is 44.54 μm. However, it is expected that the actual minimum pore diameters of each specimen are likely to be less than 44.54 μm and vary between samples. 表 3 BFRFC各相材料属性

Table 3 Properties of Each Phase Material in BFRFC

Material Density/(kg·m−3) Elastic modulus/GPa Poisson's ratio Thermal conductivity/ (W·(m·K)−1) Specific heat capacity/ (J·(kg·K)−1) Cement 3150 34 0.200 0.508 850 BF 2800 65 0.227 0.035 700 Air 1.208 − − 0.023 1000 表 4 不同纤维掺量的BFRFC导热性能

Table 4 Thermal conductivity of BFRFC in different fiber contents

Materials Fiber fraction /% Thermal conductivity/ (W·(m·K)−1) Error

E=(λt−λsλt)Test result λt Comsol simulation λs FC08 0 0.372 0.382 −2.69% 0.15 0.382 0.370 3.14% 0.30 0.399 0.379 5.01% 0.45 0.394 0.373 5.33% FC10 0 0.433 0.440 −1.62% 0.15 0.428 0.437 −2.10% 0.30 0.414 0.401 3.14% 0.45 0.415 0.391 5.78% 表 5 BFRFC各项因素与导热系数的灰关联度

Table 5 Grey correlation of BFRFC influence factors with thermal conductivity

Factors Porosity Freeze-thaw cycle Fiber Grey correlation 0.95 0.72 0.51 -

[1] HEN J, CHEN B, CHEN X, et al. Study on pore structure of foamed cement paste by multi-approach synergetics[J]. Construction and Building Materials, 2023, 362: 129748. DOI: 10.1016/j.conbuildmat.2022.129748

[2] 高志涵, 陈波, 陈家林, 等. 冻融环境下泡沫混凝土的孔结构与力学性能[J/OL]. 复合材料学报: 1-11. GAO Zhihan, CHEN Bo, CHEN Jialin, et al. Pore structure and mechanical properties of foam concrete under freeze-thaw environment[J]. Journal of Composite Materials, 2024, 41(02): 827-838. (in Chinese).

[3] JIANG W, SHEN X, HONG S, et. al. Binding capacity and diffusivity of concrete subjected to freeze-thaw and chloride attack: A numerical study[J]. Ocean Engineering, 2019, 186: 106093. DOI: 10.1016/j.oceaneng.2019.05.075

[4] 童良玉, 刘清风. 纤维增强混凝土氯离子扩散系数的多尺度预测模型[J]. 复合材料学报, 2022, 39(11): 5181-5191. TONG Liangyu, LIU Qingfeng. Multi-scale prediction model of chloride diffusivity of fiber reinforced concrete[J]. Acta Materiae Compositae Sinica, 2022, 39(11): 5181-5191(in Chinese).

[5] 郭凌云, 陈波, 高志涵, 等. 基于细观数值模拟的玄武岩纤维泡沫混凝土力学性能[J/OL]. 复合材料学报, 1-14 2024-07-29 GUO Lingyun, CHEN Bo, GAO Zhihan, et. al. Mechanical properties of basalt fiber foam concrete based on microscopic numerical simulation[J]. Journal of Composite Materials: 1-14[: 2024-04-24]. (in Chinese).

[6] 王小娟, 崔浩儒, 周宏元, 等. 玄武岩纤维增强泡沫混凝土的单轴拉伸及准静态压缩性能[J]. 复合材料学报, 2023, 40(3): 1569-1585. WANG Xiaojuan, CUI Haoru, ZHOU Hongyuan, et al. Mechanical performance of basalt fiber reinforced foam concrete subjected to quasi-static tensile and compressive tests[J]. Journal of Composite Materials, 2023, 40(3): 1569-1585(in Chinese).

[7] 王静文, 王伟. 玄武岩纤维增强泡沫混凝土响应面多目标优化[J]. 材料导报, 2019, 33(24): 4092-4097. DOI: 10.11896/cldb.19010130 WANG Jingwen, WANG Wei. Response surface based multi-objective optimization of basalt fiber reinforced foamed concrete[J]. Materials Reports, 2019, 33(24): 4092-4097(in Chinese). DOI: 10.11896/cldb.19010130

[8] GENCEL O, NODEHI M, BAYRAKTAR O, et al. Basalt fiber-reinforced foam concrete containing silica fume: An experimental study[J]. Construction and Building Materials, 2022, 326.

[9] 周程涛, 陈波, 张娟, 等. 玄武岩纤维泡沫混凝土的细观结构及损伤特性[J/OL]. 复合材料学报: 1-11. ZHOU Chengtao, CHEN Bo, ZHANG Juan, et al. Microstructure and damage characteristics of basalt fiber reinforced foam concrete[J]. Journal of Composite Materials: 1-11[2024-06-23]. (in Chinese).

[10] 牛瀚仪, 陈波, 高志涵, 等. 冻融环境下玄武岩纤维泡沫混凝土损伤-声发射特征[J/OL]. 复合材料学报: 1-10 2024-06-22]. NIU Hanyi, CHEN Bo, GAO Zhihan, et al. Damage-acoustic emission characterization of basalt fiber foam concrete under freeze-thaw environment[J]. Journal of Composite Materials: 1-10. [2024-06-22]. (in Chinese).

[11] JG/T 266-2011, 泡沫混凝土 [S]. 北京: 中国建筑工业出版社, 2011. JG/T 266-2011, Foam Concrete [S]. Beijing: China Architecture & Building Press, 2011. (in Chinese).

[12] JGJ/T 341-2014, 泡沫混凝土技术应用规程 [S]. 北京: 中国建筑工业出版社, 2014. JGJ/T 341-2014, Technical Specification for Application of Foam Concrete [S]. Beijing: China Architecture & Building Press, 2014. (in Chinese).

[13] GB/T 10294-2008, 绝热材料稳态热阻及有关特性的测定 防护热板法 [S]. 北京: 中国标准出版社, 2008. GB/T 10294-2008, Determination of Steady-State Thermal Resistance and Relevant Properties of Thermal Insulating Materials—Guarded Hot Plate Method [S]. Beijing: Standards Press of China, 2008. (in Chinese).

[14] 高志涵, 陈波, 陈家林, 等. 基于X-CT的泡沫混凝土孔隙结构与导热性能[J]. 建筑材料学报, 2023, 26(7): 723-730. DOI: 10.3969/j.issn.1007-9629.2023.07.004 GAO Zhihan, CHEN Bo, CHEN Jialin, et al. Pore structure and thermal conductivity of foam concrete based on X-CT[J]. Journal of Building Materials, 2023, 26(7): 723-730(in Chinese). DOI: 10.3969/j.issn.1007-9629.2023.07.004

[15] EIK M, PUTTONEN J, HERRMANN H. An orthotropic material model for steel fibre reinforced concrete based on the orientation distribution of fibers[J]. Composite Structures, 2015, 121: 324-336. DOI: 10.1016/j.compstruct.2014.11.018

[16] KUMAR N, ARUNKUMAR C, SENTHIL S. Experimental study on mechanical and thermal behavior of foamed concrete[J]. Materials Today: Proceedings, 2018, 5(2): 8753-8760. DOI: 10.1016/j.matpr.2017.12.302

[17] 袁志颖, 陈波, 黄梓莘, 等. 基于细观数值模拟的泡沫混凝土热学性能研究[J]. 水电能源科学, 2022, 40(9): 167-171. YUAN Zhiying, CHEN Bo, HUANG Zishen, et al. Research on thermal performance of foamed concrete based on mesoscale numerical simulation.[J]. Water Resources and Power, 2022, 40(9): 167-171(in Chinese).

[18] 周程涛, 陈波. 基于三维结构光扫描的泡沫混凝土冻融损伤演化特性[J]. 复合材料学报, 2025, 42: 1-11. ZHOU Chengtao, CHEN Bo. Freeze-thaw damage evolution characteristics of foamed concrete based on three-dimensional laser scanning[J]. Acta Materiae Compositae Sinica, 2025, 42: 1-11 (in Chinese).

[19] SHI J, LIU Y, LIU B, et al. Temperature effect on the thermal conductivity of expanded polystyrene foamed concrete: Experimental investigation and model correction[J]. Advances in Materials Science and Engineering, 2019, (1): 8292379.

[20] WEI S, YUNSHENG Z, JONES M R. Three-dimensional numerical modeling and simulation of the thermal properties of foamed concrete[J]. Construction & Building Materials, 2014, 50: 421-431.

[21] MARKL D, WANG P, RIDGWAY C, et al. Characterization of the pore structure of functionalized calcium carbonate tablets by terahertz time-domain spectroscopy and X-Ray computed microtomography[J]. Journal of Pharmaceutical Sciences, 2017: 1586-1595.

[22] SHI X, ZHENG K, YIN B. Numerical method for gas-liquid two-phase flow with phase change heat transfer considering compressibility using OpenFOAM[J]. International Journal of Thermal Sciences, 2023: 108195.

[23] LI T, HUANG F, ZHU J, et al. Effect of foaming gas and cement type on the thermal conductivity of foamed concrete[J]. Construction and Building Materials, 2020, 231: 117197. DOI: 10.1016/j.conbuildmat.2019.117197

-

目的

玄武岩纤维增强泡沫混凝土(BFRFC)因其轻质和良好的隔热性能而受到广泛关注。尽管已有研究探讨了BFRFC的宏观力学性能,展现了其在建筑应用中的潜力,但对其导热性能的系统研究仍然不足,特别是冻融循环对其导热性能的影响尚未深入分析,已成为限制其应用的主要瓶颈。

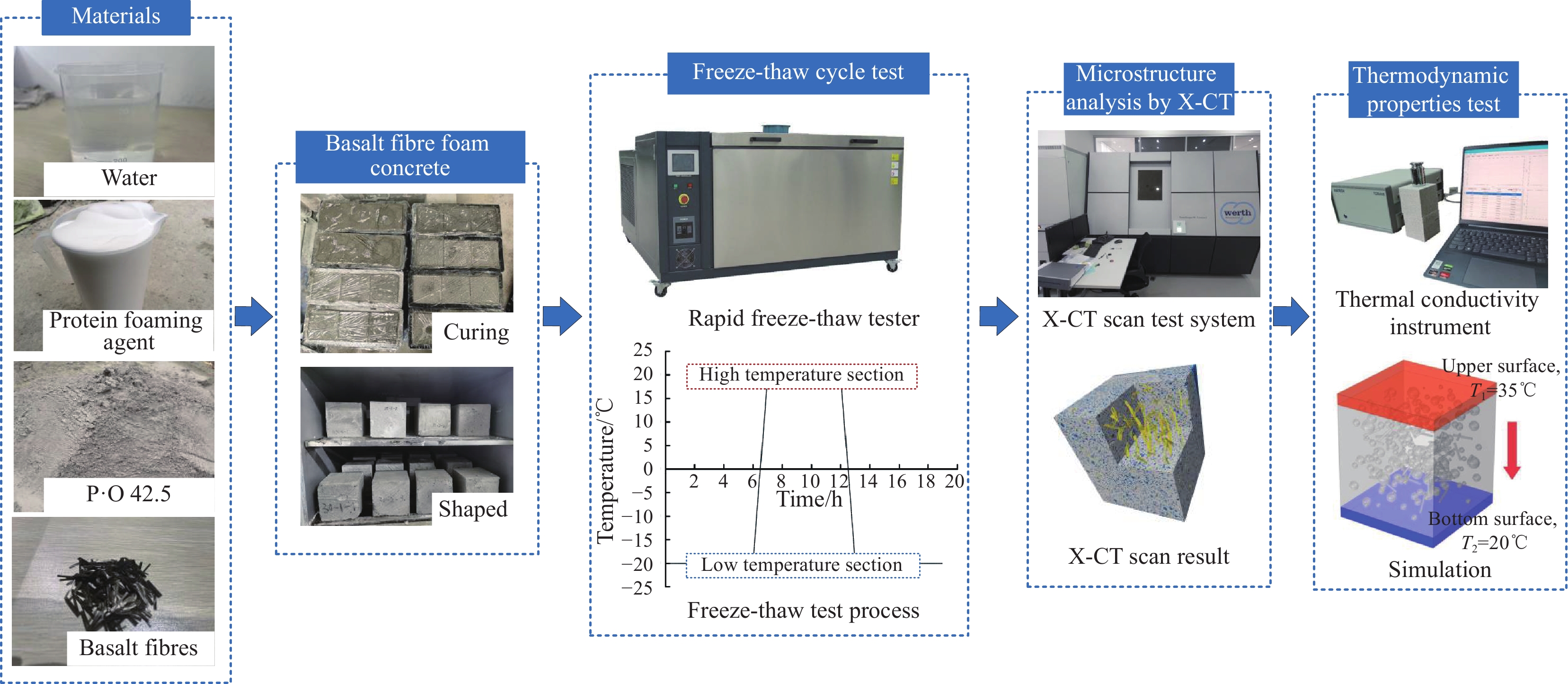

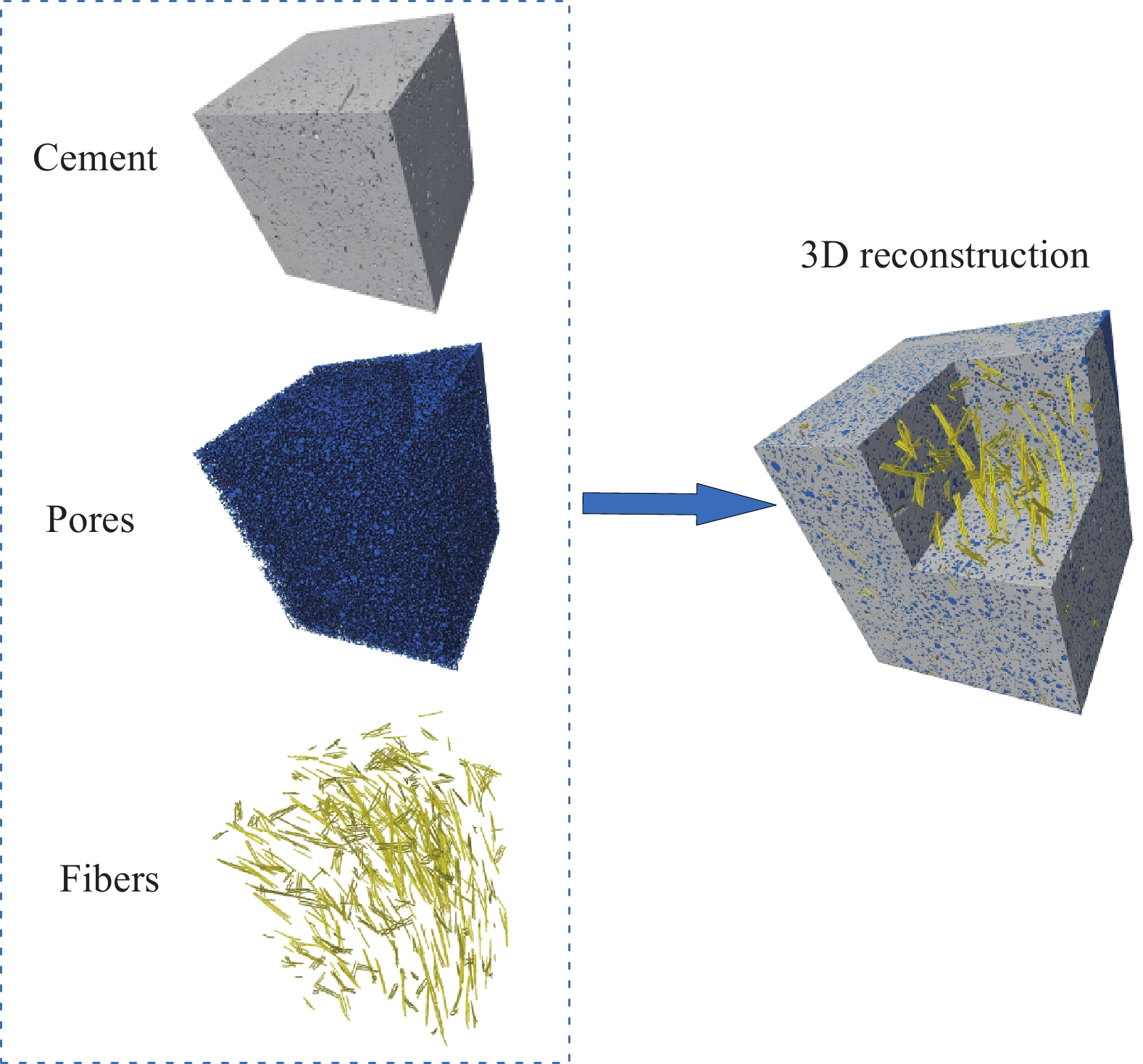

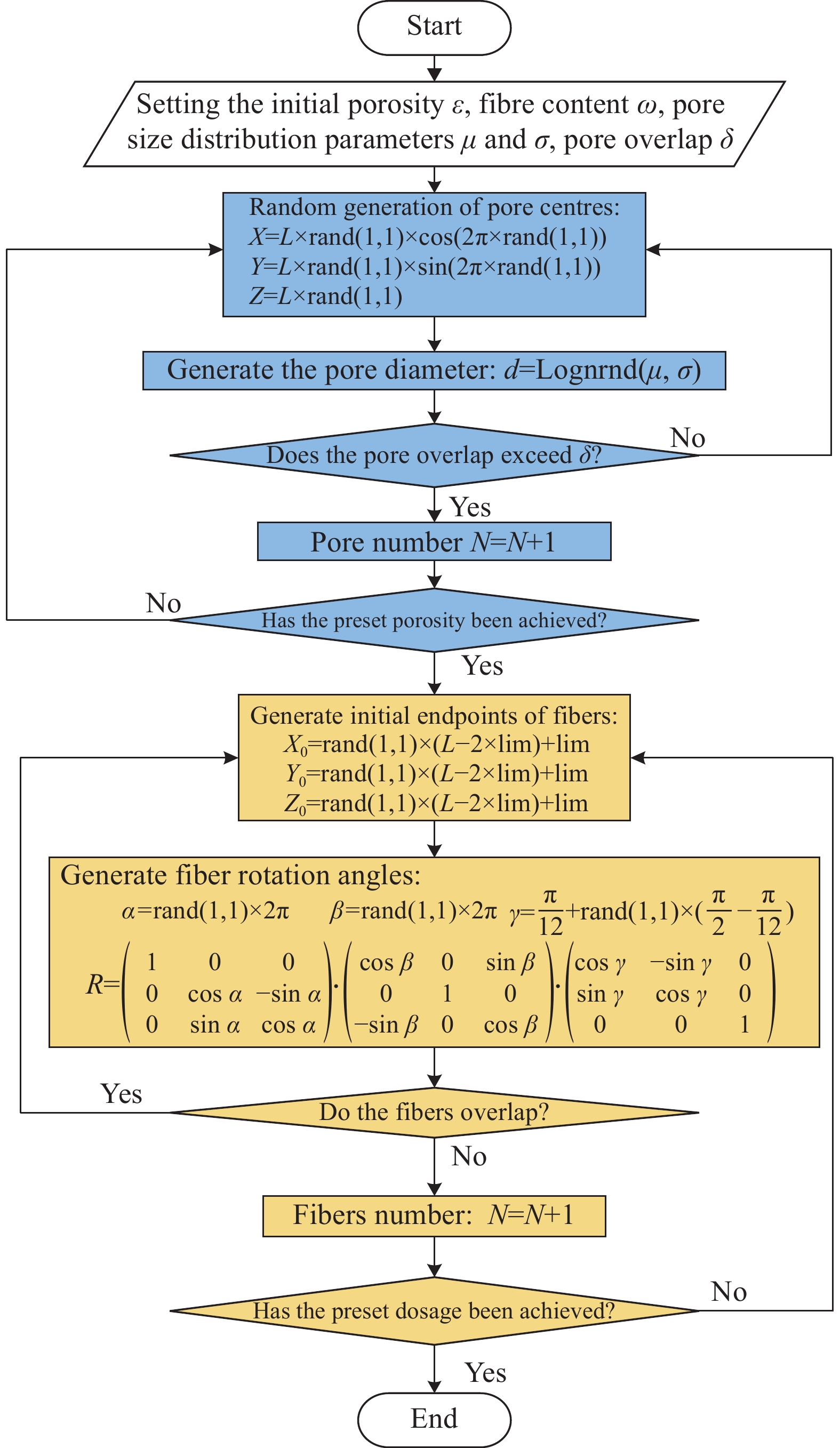

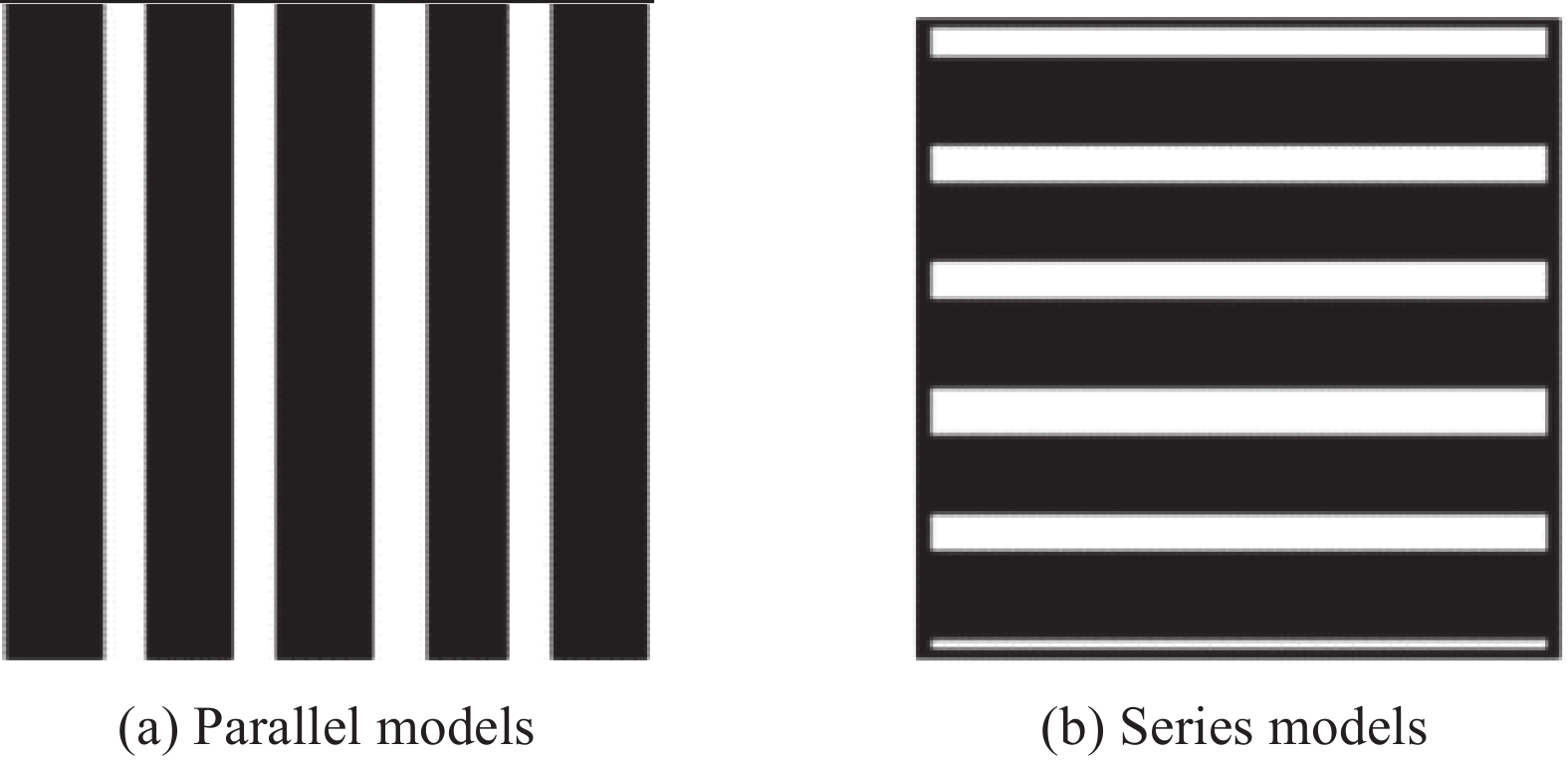

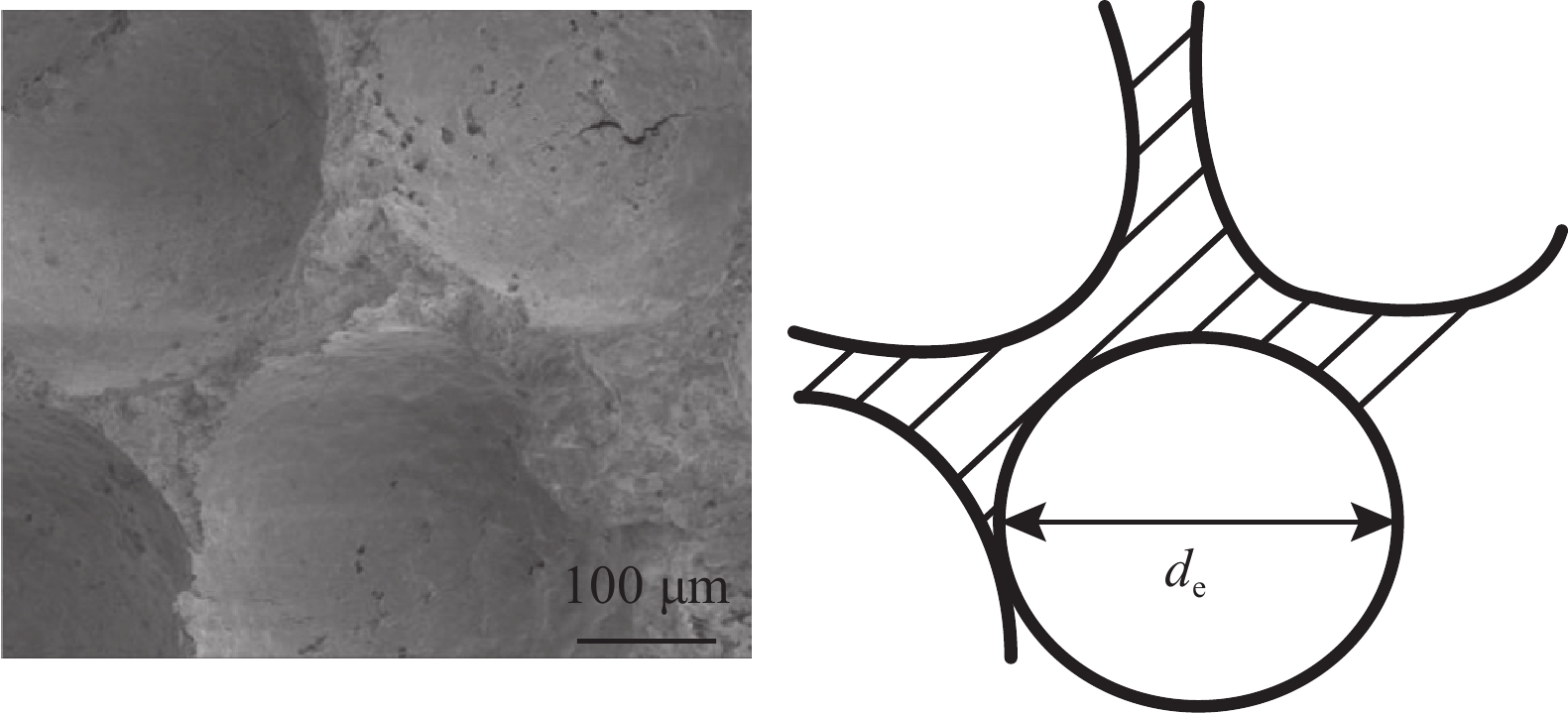

方法研究首先对4种不同纤维掺量的BFRFC试样进行冻融循环实验,利用X-CT技术获取BFRFC的细观结构特征,并通过Avizo软件对数据进行滤波、降噪和阈值分割处理,完成BFRFC细观结构的三维重构。在导热系数测试实验的基础上,利用Matlab软件生成包含随机孔隙和纤维的三维模型,并结合Comsol有限元方法进行导热模拟。此外,研究还通过多相介质Bruggeman模型和纤维串并联模型建立理论导热模型,对BFRFC的热力学特性及其在冻融劣化条件下的表现进行系统分析。

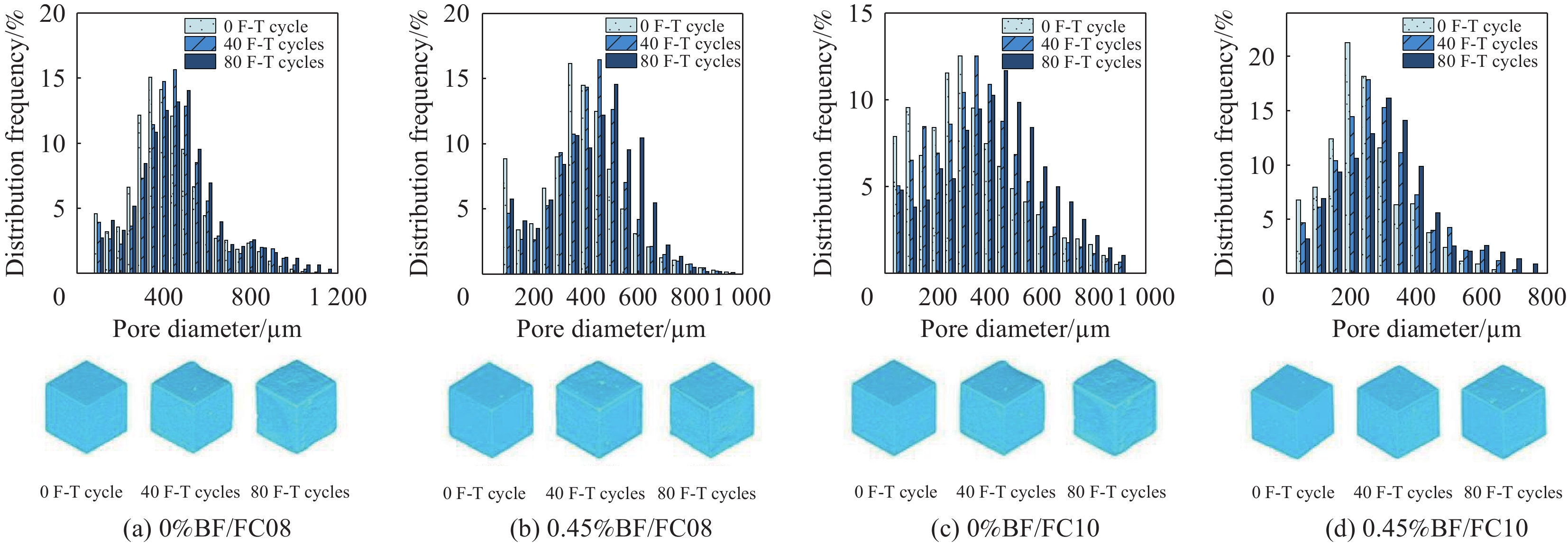

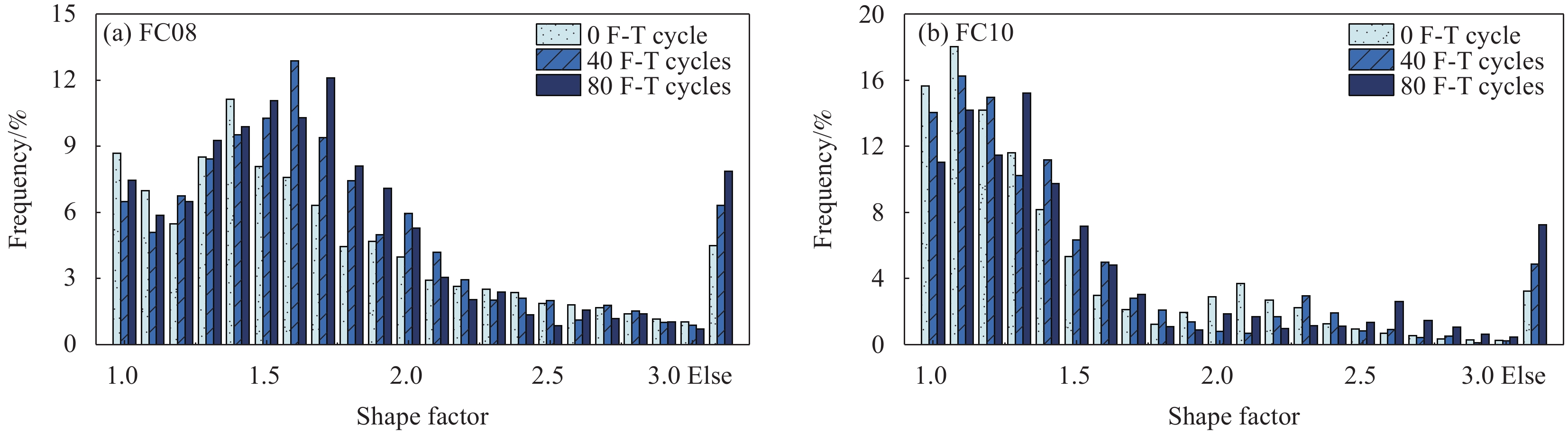

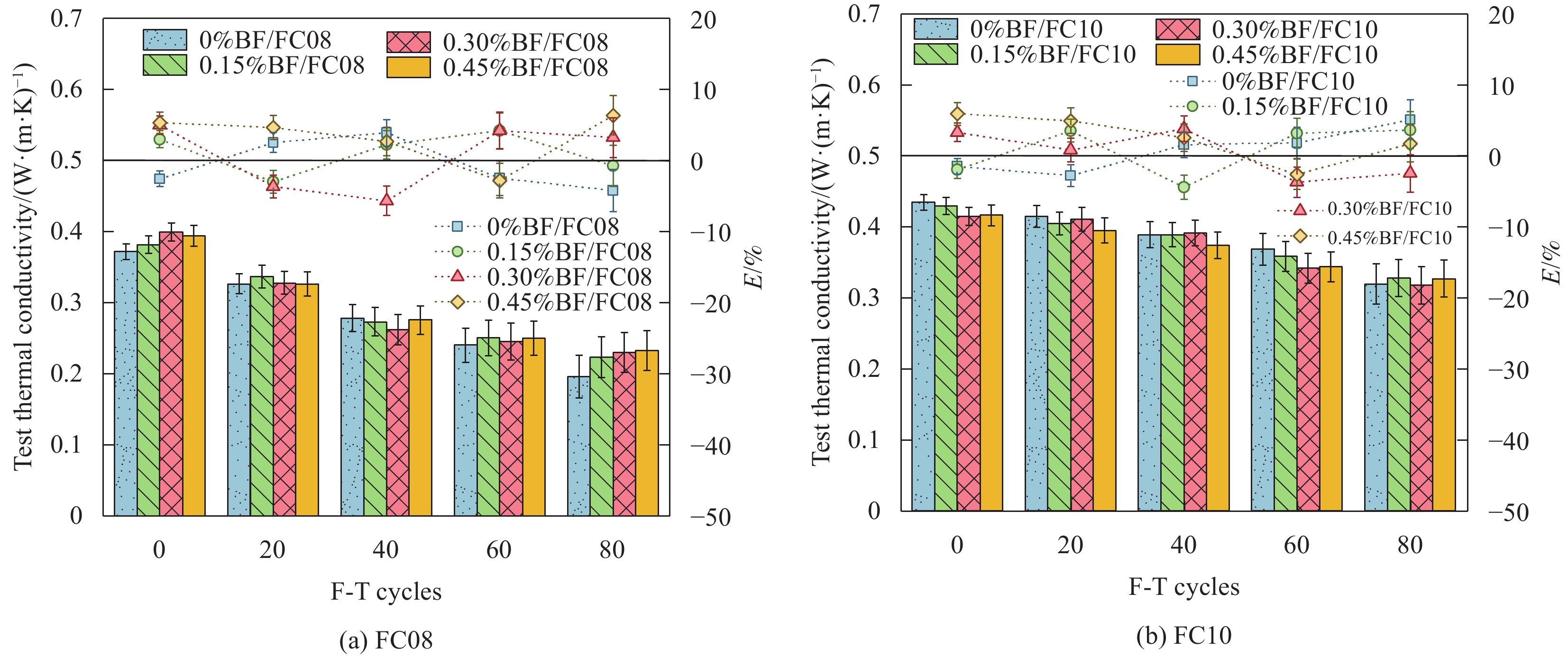

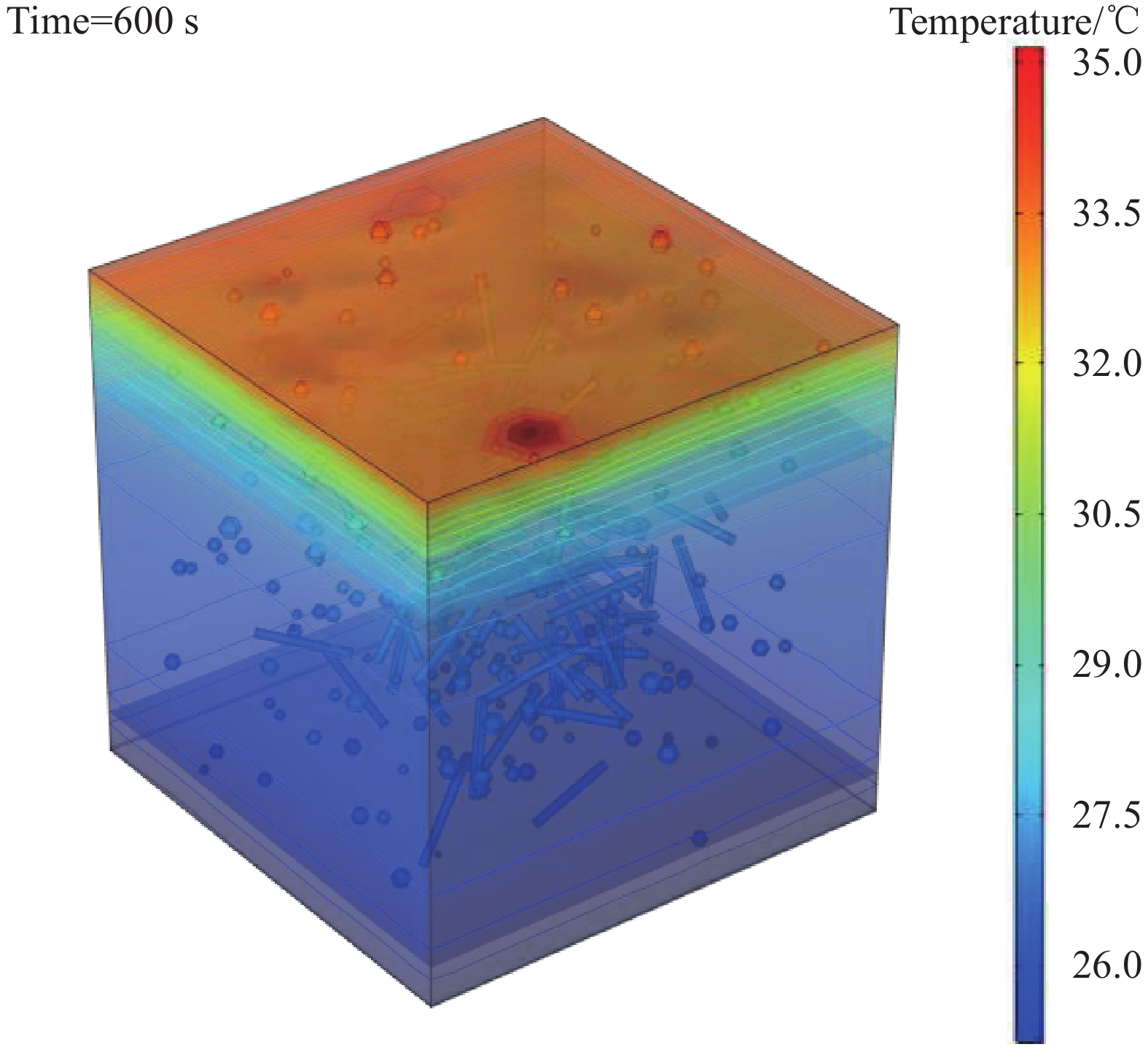

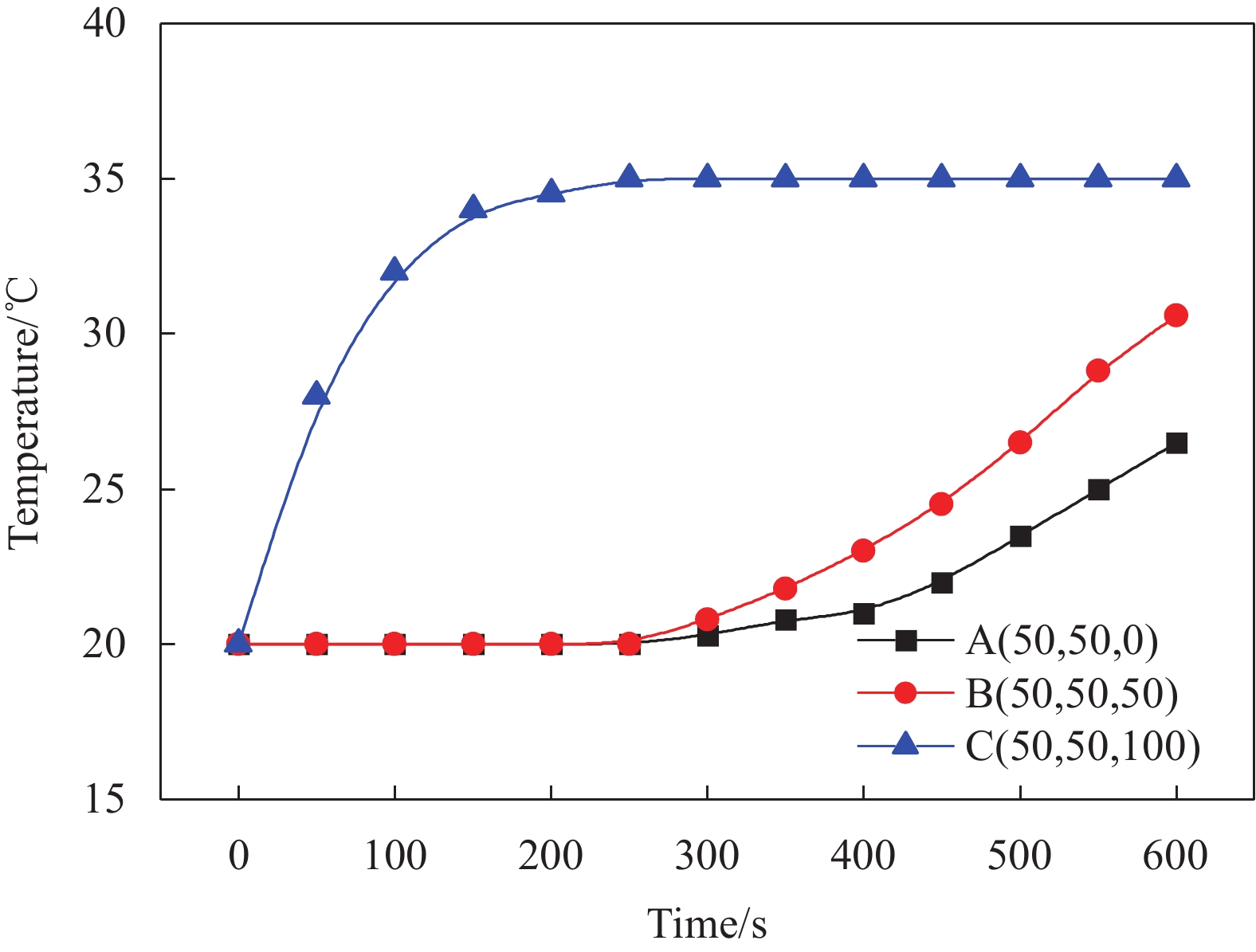

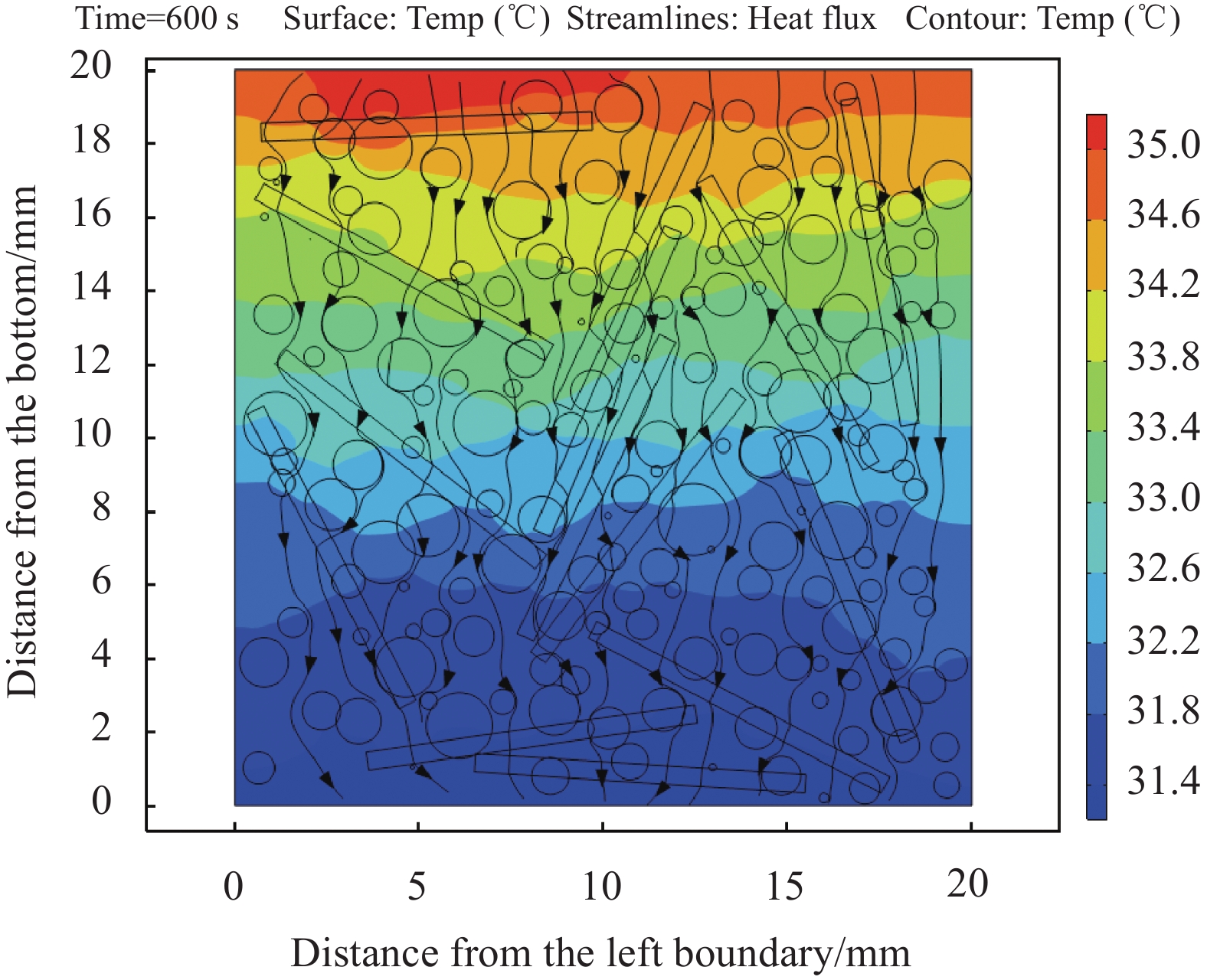

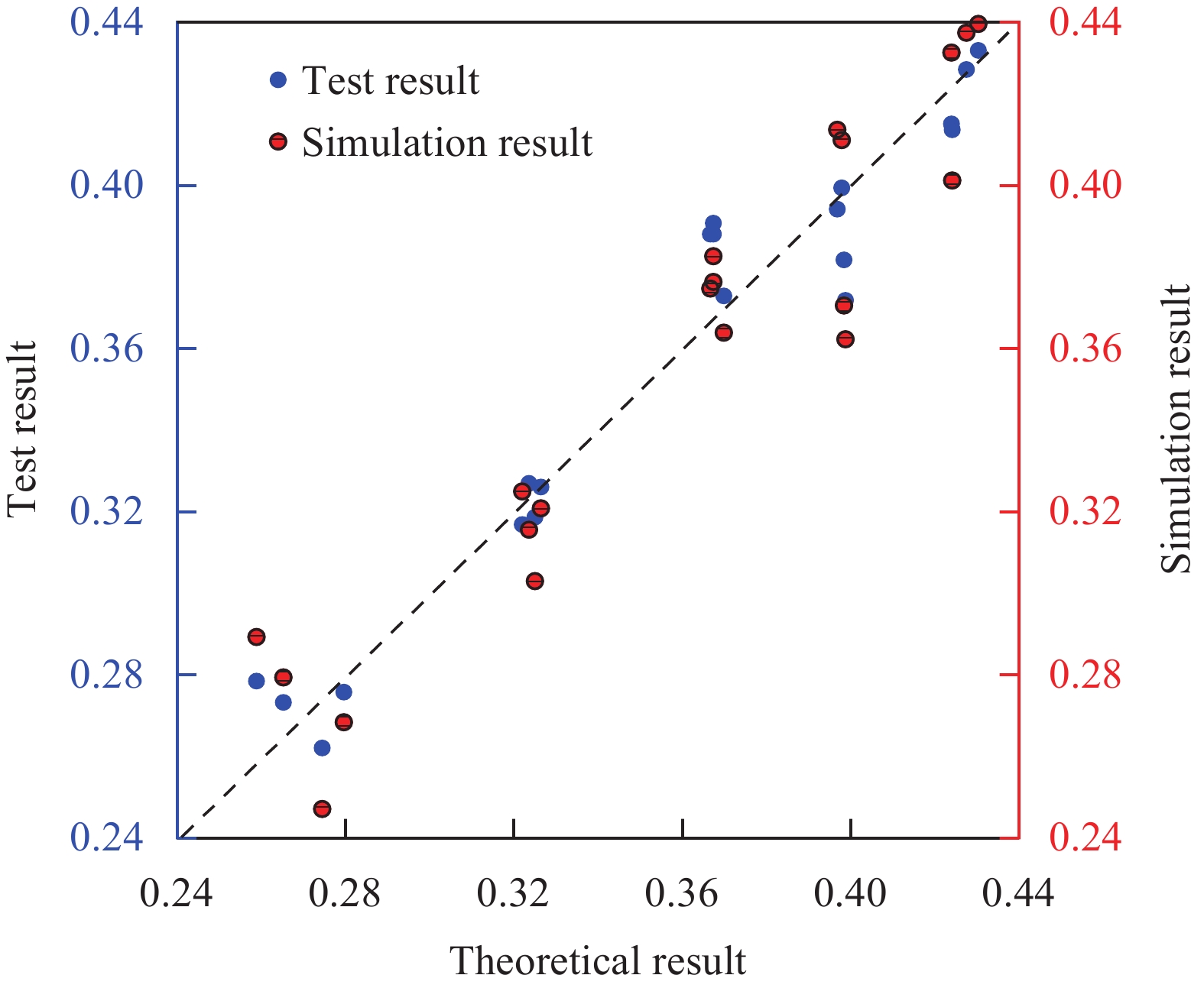

结果本文通过提取细观结构,建立了数值模拟方法,结合导热实验和构建理论模型研究BFRFC的冻融劣化作用下的导热性能变化。研究探讨了不同密度和纤维掺量对BFRFC孔隙特征及导热性能的影响,揭示了其内部热流分布及纤维导热路径,探究了BFRFC在冻融循环条件下的导热性能表现。结果表明:(1) 玄武岩泡沫混凝土(BFRFC)孔径尺寸和形状系数近似对数正态分布。随着冻融侵蚀,BFRFC的孔隙率和孔隙直径增加,孔隙形状变得更加不规则。提升材料密度和添加玄武岩纤维,可以有效缓解冻融损伤。(2)玄武岩纤维在BFRFC中的极角在15°至90°,方位角在0°至360°范围内均匀分布。随着纤维掺量增大,分散的均匀程度会有所影响,对于高纤维掺量材料需加强搅拌以提高BFRFC浆体中纤维的均匀分布。(3)BFRFC的导热系数受材料密度、冻融循环影响较大,这些因素通过改变孔隙率从而影响材料导热系数。纤维掺量对导热性能的影响主要通过纤维掺量和孔隙率耦合影响,影响程度相对较低。(4)BFRFC导热系数处于0.2至0.4W/(m·K)之间。在寒区环境下的保温隔热性能好,受冻融劣化作用的影响较小,性能稳定,适合用于寒区工程的保温防护。(5)基于BFRFC的微观结构所建立的数值仿真模型,采用Comsol 模拟导热系数与TC5000E导热系数仪所测的导热系数相差不大,可有效模拟材料的导热性能。(6)BFRFC的细观传热分布表明,其内部传热主要通过水泥基体进行传导。由于孔隙和纤维的低导热性,等温线在孔隙和纤维界面处容易发生波动。(7) 基于多相介质Bruggeman模型,结合纤维的串并联模型,建立了综合热传导、热交换和对流传热的BFRFC的理论导热模型。该模型可有效的预测不同纤维掺量和孔隙率下的BFRFC 导热系数。

结论冻融循环对BFRFC的孔隙结构和导热性能产生显著影响。随着冻融循环次数的增加,BFRFC的孔隙率上升,孔隙形状变得更加不规则,导热系数随之降低。然而,高密度和高纤维掺量的BFRFC表现出较强的抗冻融能力,导热性能变化较小。因此,玄武岩纤维的添加显著提升了BFRFC的保温隔热性能,使其在寒冷地区的工程应用中展现出优异的抗冻性。基于多相介质Bruggeman模型和纤维串并联模型的理论导热预测结果,与实验数据及基于微观结构的热力学有限元模型模拟结果一致,为预测BFRFC在寒冷地区的导热性能劣化提供了关键的理论依据。

-

传统的泡沫混凝土在耐久性、力学强度和抗冻融破坏方面性能不高,玄武岩纤维泡沫混凝土(BFRFC)因其优异的力学性能和隔热特性,在寒冷地区的工程应用中展现出广阔前景。然而,冻融循环对BFRFC的孔结构和导热性能的影响尚未得到系统研究,这成为限制其应用的主要瓶颈。

为了解决这一问题,本研究选取了四种不同纤维掺量的BFRFC试样,采用先进的X-CT技术对冻融循环作用下不同纤维掺量下的BFRFC试样进行分析,并使用Avizo软件BFRFC试样进行三维重构,详细分析其孔隙结构和纤维分布特征。基于其微观结构特征,通过有限元仿真进行导热性能数值测试,并结合热力学性能测试实验,深入探究不同冻融循环次数下BFRFC的导热性能变化规律。最后,基于多孔介质Bruggeman模型,联合纤维的串并联导热模型,揭示BFRFC材料导热机理,建立BFRFC的理论导热模型。研究发现:BFRFC的孔径尺寸和形状因子近似符合对数正态分布,高密度试样孔径更小,球形孔隙占比更高。随着冻融循环次数的增加,试样的孔隙率和孔隙直径增加,孔隙形状变得更加不规则,但高密度和高纤维掺量试样的冻融损伤程度较低。BFRFC的导热系数主要受孔隙率和冻融循环次数的影响,纤维掺量的影响较小。通过建立BFRFC的数值仿真模型,采用COMSOL模拟导热性能,结果与实验数据基本一致。提出的理论导热模型能够有效预测不同纤维掺量和孔隙率下BFRFC的导热系数,为寒区工程中BFRFC的应用提供理论依据。

冻融循环下BFRFC的导热性能

BFRFC传热温度分布图(t=600s)

下载:

下载: