Influence of the rheological properties of paste on the early-age tensile creep of high-volume fly ash concrete

-

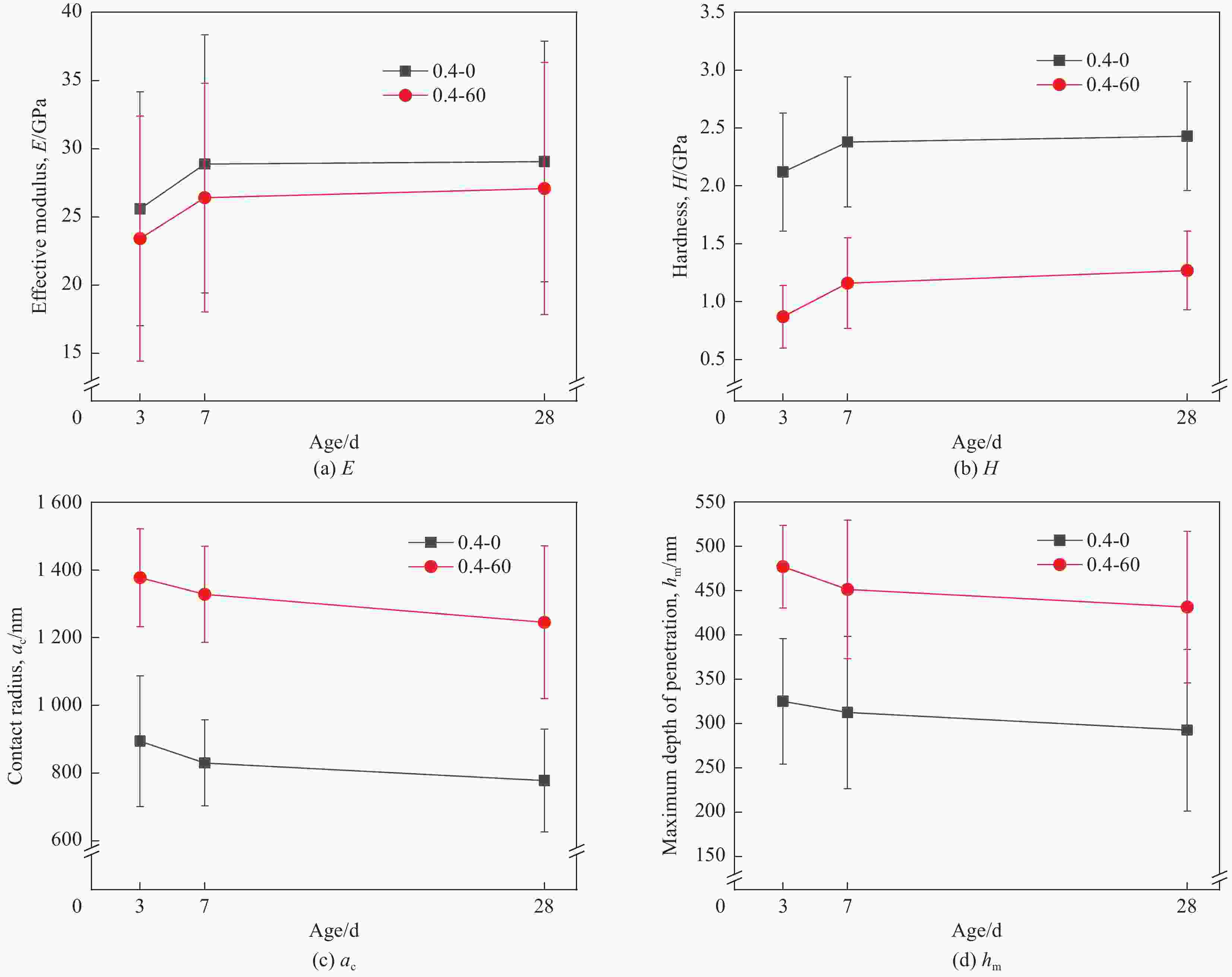

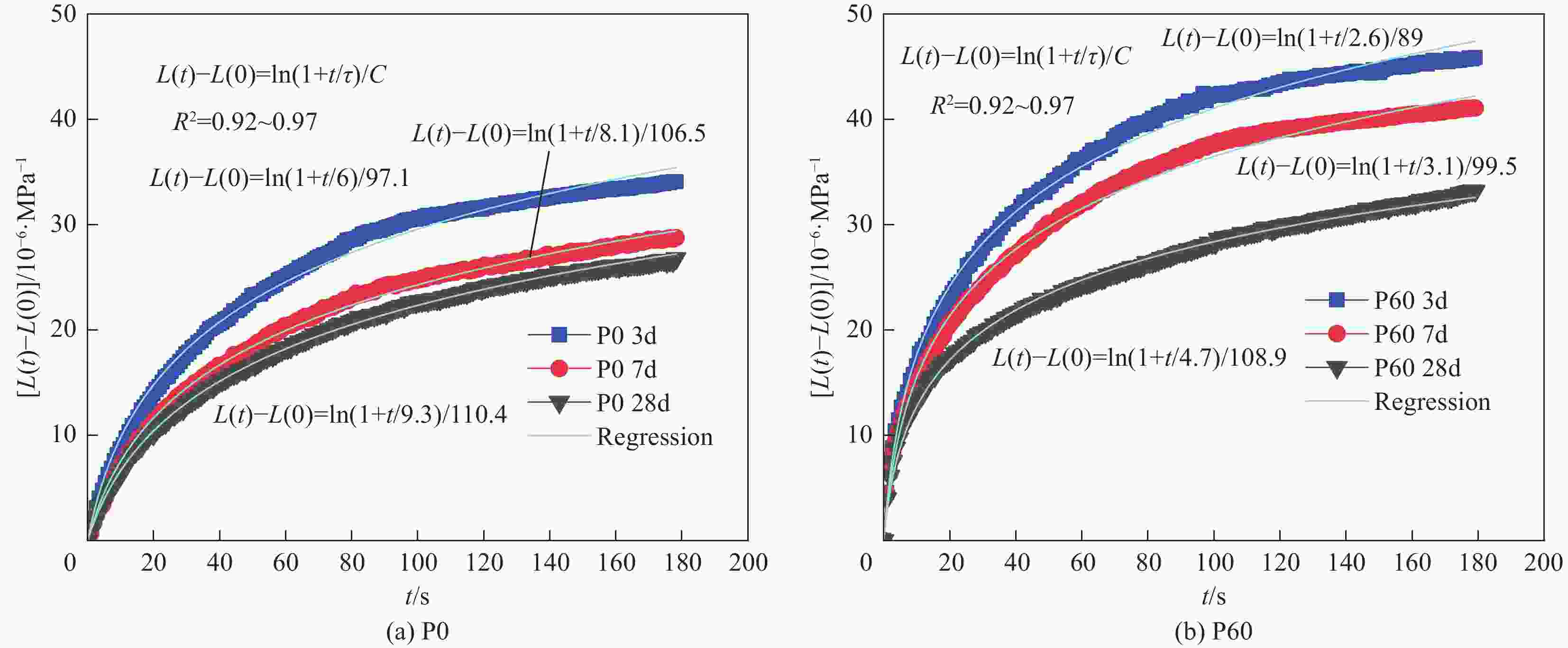

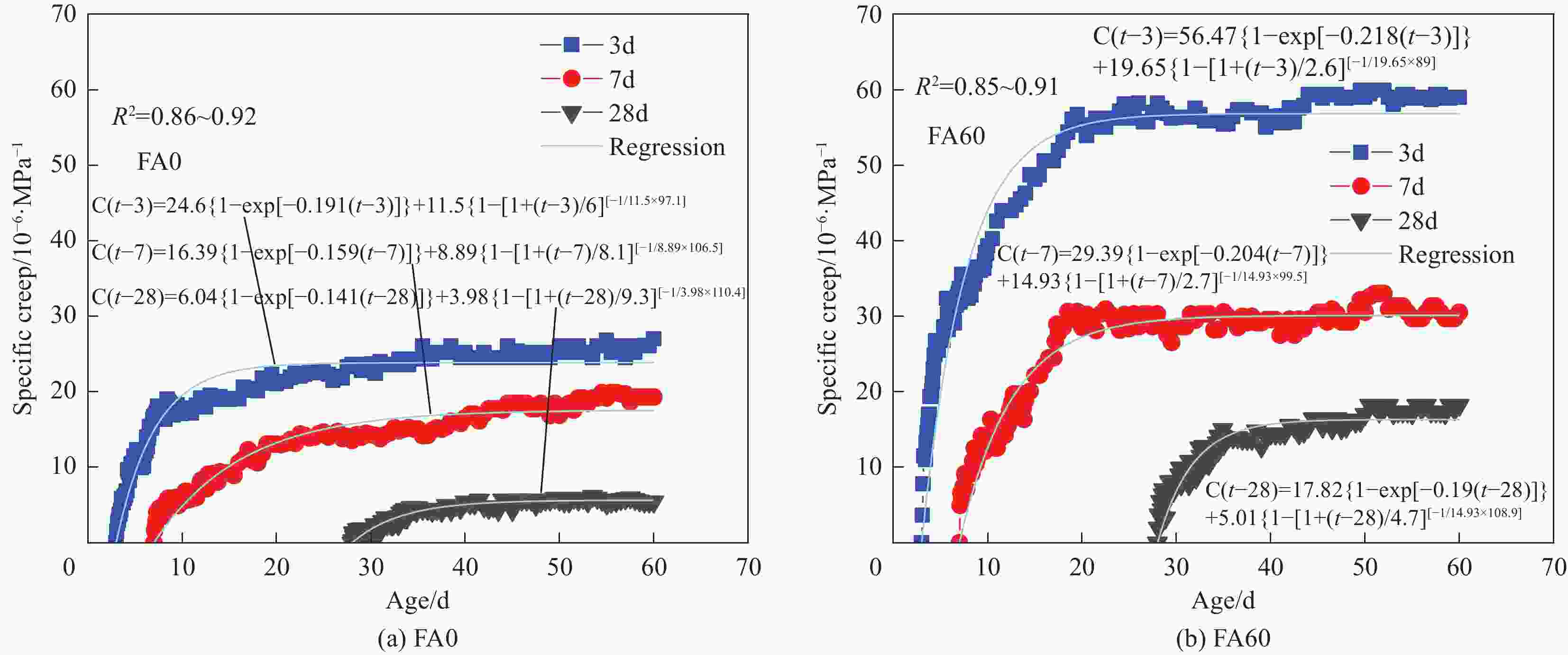

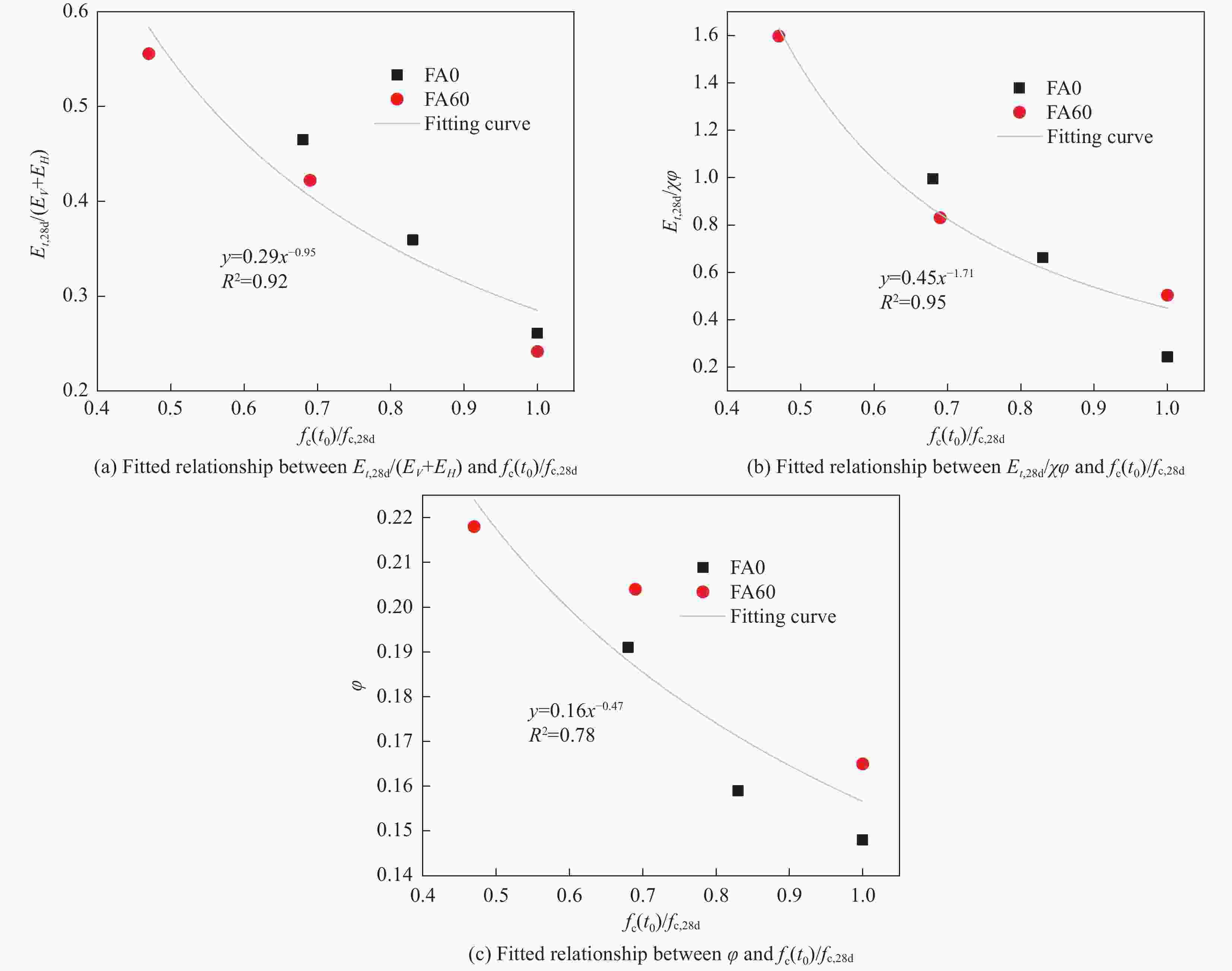

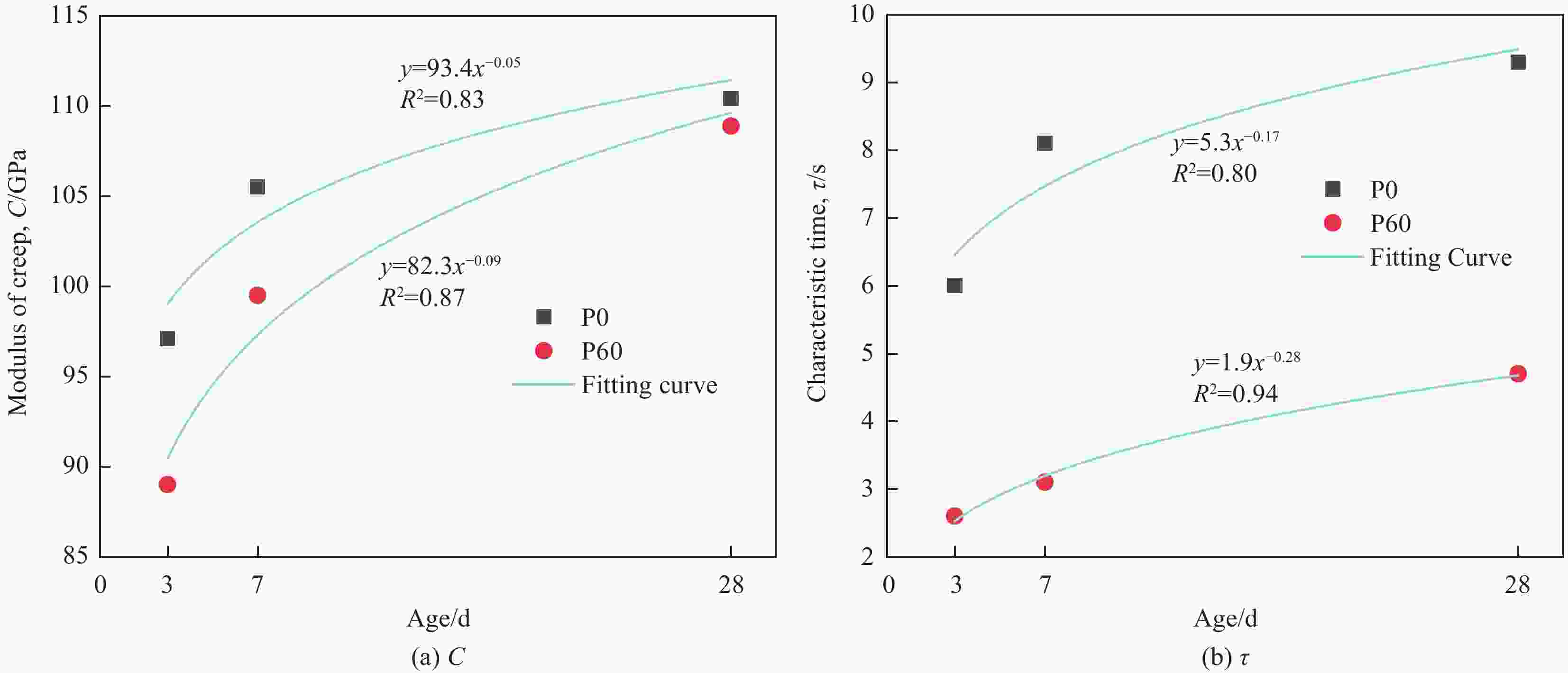

摘要: 混凝土中浆体的流变特性是影响其拉伸徐变的重要因素之一。通过纳米压痕技术分析大掺量粉煤灰水泥基浆体(掺量为60%)微观力学性能、微观徐变等流变特性;同时实验研究相同水泥基浆体的大掺量粉煤灰混凝土(HVFAC)拉伸徐变时变规律,提出考虑浆体流变特性的HVFAC拉伸徐变ZC模型预测表达式。结果表明:水泥基浆体在相同测试龄期时,粉煤灰对其微观徐变的发展有促进作用;而等质量粉煤灰替代时,微观徐变随着测试龄期的后延更快趋于收敛;粉煤灰、加载龄期对徐变发展的影响与其不含骨料水泥基浆体的微观徐变影响规律具有一致性。Et,28d/(EV+EH)、Et,28d/χφ、φ与相对抗压强度fc(t0)/fc,28d、C、τ与测试龄期相关性分析表明这些参数与函数y=axb有较好的吻合度。水泥基浆体流变特性参数与ZC拉伸徐变模型参数相结合建立考虑水泥浆体流变特性的HVFAC拉伸徐变发展的预测表达式能反映模型单元体结构。Abstract: It is one of important factors affecting on concrete tensile creep that the rheological properties of concrete paste. The microscopic mechanical properties and rheological characteristics of cementitious paste containing high volume fly ash (60%) were analyzed by nanoindentation. And the same time, the tensile creep law dependent on ages of high-volume fly ash concrete containing same cementitious paste was experimental studied. The predictive function expressions of the HVFAC tensile creep considering the rheological properties of paste were proposed. The nanoindentation results show that the fly ash promotes the paste’s micro creep development of paste at the same test ages, and the micro creep of paste tends to converge quickly with the delay of test age which the cement is replaced with the same quality fly ash. The influence of fly ash and loading age on the development of HVFAC creep is consistent with the influence law of cementitious paste’s micro creep without aggregate. Base on the correlation analysis on the parameters of Et,28d/(EV+EH), Et,28d/χφ, φ and relative compressive strength fc(t0)/fc,28d, the parameters of C, τ and test ages, it shows that these parameters are in good agreement with the function y = axb. The tensile creep prediction expression of ZC model considering the rheological properties of cement paste can reflect the structure of the model unit cell.

-

Key words:

- nanoindentation /

- tensile creep /

- rheological properties of paste /

- fly ash /

- ZC model

-

图 2 ZC模型单元体徐变机理及混凝土中浆体微观徐变

Figure 2. The creep mechanism of ZC model the paste micro creep of concrete

The EM(t) and EV(t) is the elastic coefficient of elastic element Maxwell and Kelvin, respectively; The ηM(t) and ηV(t) is the viscous coefficients of viscous element Maxwell and Kelvin respectively; and the EH(t) is the elasticity coefficient in Hooke's element.

表 1 水泥和粉煤灰的化学成分

Table 1. Chemical compositions of fly ash and cement

Material Mass fraction/wt % CaO SiO2 Al2O3 MgO Fe2O3 SO3 K2O Na2O Others Cement 62.04 22.07 4.23 4.01 3.04 2.71 0.762 0.392 0.746 Fly ash 4.43 51.63 33.98 1.16 4.40 0.260 0.905 0.888 2.347 表 2 净浆配合比

Table 2. Proportions of paste

No. W/(C+FA) FA/% C/% P0 0.4 0 100 P60 60 40 Notes: W—Water; C—Cement; FA—Fly ash; P0—Paste group without fly ash; P60—Paste group with 60% of fly ash replacing cement by equal mass. 表 3 HVFAC配合比(kg/m3)

Table 3. Proportions of HVFAC (kg/m3)

No. W/(C+FA) Cement Fly ash Water Fine aggregate Coarse aggregate Superplasticizer FA0 0.4 450 0 180 654 1113 0.720 FA60 180 270 180 654 1113 0.855 Notes: FA0—Group of concrete without fly ash; FA60—Group of concrete with 60% of fly ash replacing cement by equal mass. 表 4 HVFAC基本力学性能

Table 4. Basic Mechanical Properties of HVFAC

No. Age of testing/d Compressive strength/MPa Splitting tensile strength/MPa Tensile elastic modulus/GPa FA0 3 46.24 4.00 37.36 7 56.02 4.80 37.80 28 67.75 5.79 40.43 FA60 3 11.56 1.51 24.30 7 16.83 1.71 26.28 28 24.48 2.74 28.28 表 5 P0、P60的微观徐变参数

Table 5. Microscopic creep parameters for P0, P60

No. Age of testing /d C /GPa τ /s P0 3 97.1 6.0 7 106.5 8.1 28 110.4 9.3 P60 3 89.0 2.6 7 99.5 3.1 28 108.9 4.7 Notes: C—Contact creep modulus, τ—Characteristic time of the paste. 表 6 FA0、FA60的ZC模型参数

Table 6. ZC model parameters for FA0, FA60

No. Loading age/d φ 1/χφ/

10−6·MPa−11/(EV+EH) /

10−6·MPa−1FA0 3 0.191 24.60 11.50 7 0.159 16.39 8.89 28 0.148 6.04 3.98 FA60 3 0.218 56.47 19.65 7 0.204 29.39 14.93 28 0.165 17.82 5.01 Notes: φ—Coefficient affecting the growth rate of the coefficient of viscosity; The parameter of 1/χφ and 1/(EV+EH) is the final specific creep of the spring assemblies Maxwell and Kelvin, respectively. -

[1] 花素珍, 张家广, 高沛, 等. 增强再生骨料固载混菌的混凝土裂缝自修复性能[J]. 复合材料学报, 2023, 40(11): 6299-6310.HUA Suzhen, ZHANG Jiaguang, GAO Pei, et al. Self-healing of concrete cracks by immobilizing non-axenic bacteria with enhanced recycled aggregates[J]. Acta Materiae Compositae Sinica, 2023, 40(11): 6299-6310(in Chinese). [2] 阚黎黎, 王飞, 邬海江, 等. 不同养护条件下混杂钢纤维超高性能混凝土的早龄期力学性能及开裂特性[J]. 硅酸盐学报, 2022, 50(2): 429-437.KAN Lili, WANG Fei, WU Haijiang, et al. Mechanical properties and cracking characteristics of uhpc with hybrid steel fibers at early age under different curing conditions[J]. Journal Of The Chinese Ceramic Society, 2022, 50(2): 429-437(in Chinese). [3] BRIFFAUT M, BENBOUDJEMA F, TORRENTI J, et al. Concrete early age basic creep: Experiments and test of rheological modelling approaches[J]. Construction and Building Materials, 2012, 36: 373-380. doi: 10.1016/j.conbuildmat.2012.04.101 [4] NGUYEN D H, DAO V T N, LURA P. Tensile properties of concrete at very early ages[J]. Construction and Building Materials, 2017, 134: 563-573. doi: 10.1016/j.conbuildmat.2016.12.169 [5] 张霓. GFRP管空心钢筋混凝土构件试验研究与理论分析 [D]. 辽宁: 东北大学, 2019.Zhang Ni, Experimental Research and Theoretica Analysis on GFRP Tube Filled with Reinforced Hollow Concrete Members [D]. Liaoning: Northeastern University, 2019(in Chinese). [6] CHARPIN L, LEPAPE Y, COUSTABEAU É, et al. A 12 year EDF study of concrete creep under uniaxial and biaxial loading[J]. Cement and Concrete Research, 2018, 103: 140-159. doi: 10.1016/j.cemconres.2017.10.009 [7] HUYNH T, HWANG C, LIMONGAN A. The long-term creep and shrinkage behaviors of green concrete designed for bridge girder using a densified mixture design algorithm[J]. Cement and Concrete Composites, 2018, 87: 79-88. doi: 10.1016/j.cemconcomp.2017.12.004 [8] ZHAO Z, WANG K, LANGE D, et al. Creep and thermal cracking of ultra-high volume fly ash mass concrete at early age[J]. Cement and Concrete Composites, 2019, 99: 191-202. doi: 10.1016/j.cemconcomp.2019.02.018 [9] PARK B, CHOI Y. Hydration and pore-structure characteristics of high-volume fly ash cement pastes[J]. Construction and Building Materials, 2021, 278: 122390. doi: 10.1016/j.conbuildmat.2021.122390 [10] WYRZYKOWSKI M, SCRIVENER K, LURA P. Basic creep of cement paste at early age - the role of cement hydration[J]. Cement and Concrete Research, 2019, 116: 191-201. doi: 10.1016/j.cemconres.2018.11.013 [11] KRISTIAWAN S, NUGROHO A. Creep behaviour of self-compacting concrete incorporating high volume fly ash and its effect on the long-term deflection of reinforced concrete beam[J]. Procedia Engineering, 2017, 171: 715-724. doi: 10.1016/j.proeng.2017.01.416 [12] LIANG S, WEI Y. Effects of water-to-cement ratio and curing age on microscopic creep and creep recovery of hardened cement pastes by microindentation[J]. Cement and Concrete Composites, 2020, 113: 103619. doi: 10.1016/j.cemconcomp.2020.103619 [13] SUWANMANEECHOT P, AILI A, MARUYAMA I. Creep behavior of C-S-H under different drying relative humidities: Interpretation of microindentation tests and sorption measurements by multi-scale analysis[J]. Cement and Concrete Research, 2020, 132: 106036. doi: 10.1016/j.cemconres.2020.106036 [14] MALLICK S, ANOOP M, RAO K. Creep of cement paste containing fly ash - An investigation using microindentation technique[J]. Cement and Concrete Research, 2019, 121: 21-36. doi: 10.1016/j.cemconres.2019.04.006 [15] Yao, J. , Yao, S. , Huang, S. , et al. The Influence of Fly Ash on the Tensile Creep Prediction of High-Strength Concrete at Early Ages[J]. Materials, 2023, 16(4), 1337. [16] 倪彤元. 掺合料高强混凝土早龄期拉伸徐变特性及其评价. [D], 杭州, 浙江工业大学, 2020.NI Tongyuan, Tensile Creep Characteristics and Its Evaluation of High Strength Concrete Containing Mineral Admixtures at Early Ages. [D], Hangzhou, Zhejiang University of Technology, 2020(in Chinese). [17] 周伟玲, 孙伟, 陈翠翠, 等. 应用纳米压痕技术表征水泥基材料微观力学性能[J]. 东南大学学报(自然科学版), 2011, 41(2): 370-375. doi: 10.3969/j.issn.1001-0505.2011.02.030ZHOU Weiling, SUN Wei, CHEN Cuicui, et al. Characterization for micro mechanical properties of cementitious materials by nanoindentation technique[J]. Journal of Southeast University (Natural Science Edition), 2011, 41(2): 370-375(in Chinese). doi: 10.3969/j.issn.1001-0505.2011.02.030 [18] CHEN S, WU C, YAN D. Binder-scale creep behavior of metakaolin-based geopolymer[J]. Cement and Concrete Research, 2019, 124: 105810. doi: 10.1016/j.cemconres.2019.105810 [19] LAVERGNE F, BARTHeLeMY J. Confronting a refined multiscale estimate for the aging basic creep of concrete with a comprehensive experimental database[J]. Cement and Concrete Research, 2020, 136: 106163. doi: 10.1016/j.cemconres.2020.106163 [20] 刘巧玲, 李汉彩, 彭玉娇, 等. 多壁碳纳米管增强水泥基复合材料的纳米力学性能[J]. 复合材料学报, 2020, 37(4): 952-961.LIU Qiaoyun, LI Hancai, PENG Yujiao, et al. Nanomechanical properties of multi-wall carbon nanotubes/cementitious composites[J]. Acta Materiae Compositae Sinica, 2020, 37(4): 952-961(in Chinese). [21] 梁思明, 魏亚. 硬化水泥净浆微观结构对微观徐变及力学性能的影响[J]. 硅酸盐学报, 2016, 44(2): 181-188.LIANG Siming, WEI Ya. Influence of microstructure on micro creep and mechanical properties of hardened cement paste[J]. Journal Of The Chinese Ceramic Society, 2016, 44(2): 181-188(in Chinese). [22] 张璇, 刘娟红. 纳米压痕技术在水泥基材料中的研究进展[J]. 电子显微学报, 2015, 34(6): 530-539. doi: 10.3969/j.issn.1000-6281.2015.06.014ZHANG Xuan, LIU Juanhong. Progress of nanoindentation in cementitious materials[J]. Journal of Chinese Electron Microscopy Society, 2015, 34(6): 530-539(in Chinese). doi: 10.3969/j.issn.1000-6281.2015.06.014 [23] 曹丰泽, 阎培渝. 氧化镁膨胀剂对混凝土长期体积变化的影响[J]. 硅酸盐学报, 2018, 46(8): 1126-1132.CAO Fengze, YAN Peiyu. Effects of reactivity and dosage of magnesium oxide expansive agents on long-term volume variation of concret[J]. Journal of The Chinese Ceramic Society, 2018, 46(8): 1126-1132(in Chinese). [24] OLIVER W, PHARR G. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments[J]. Journal of Materials Research, 2011, 7(6): 1564-1583. [25] VANDAMME M, TWEEDIE C A, CONSTANTINIDES G, et al. Quantifying plasticity-independent creep compliance and relaxation of visco-elasto-plastic materials under contact loading[J]. J Mater Res, 2012, 27(1): 302-312. doi: 10.1557/jmr.2011.302 [26] SORELLI L, CONSTANTINIDES G, ULM F, et al. The nano-mechanical signature of Ultra High Performance Concrete by statistical nanoindentation techniques[J]. Cement and Concrete Research, 2008, 38(12): 1447-1456. doi: 10.1016/j.cemconres.2008.09.002 [27] 楼晓天. 基于ZC模型的掺合料高强混凝土早龄期拉伸徐变评价 [D]. 杭州: 浙江工业大学, 2017.LOU Xiaotian. Evaluation of tensile creep of high strength concrete containing mineral admixtures at early ages based on ZC model [D]. Hangzhou: Zhejiang University of Technology, 2017(in Chinese). [28] GU C, WANG Y, GAO F, et al. Early age tensile creep of high performance concrete containing mineral admixtures: Experiments and modeling[J]. Construction and Building Materials, 2019, 197: 766-777. doi: 10.1016/j.conbuildmat.2018.11.218 [29] 杨杨, 许四法, 叶德艳, 等. 早龄期高强混凝土拉伸徐变特性[J]. 硅酸盐学报, 2009, 37(7): 1124-1129. doi: 10.3321/j.issn:0454-5648.2009.07.011YANG Yang, XU Sifa, YE Deyan, et al. Tensile creep behavior of high strength concrete at early ages[J]. Journal of The Chinese Ceramic Society, 2009, 37(7): 1124-1129(in Chinese). doi: 10.3321/j.issn:0454-5648.2009.07.011 [30] 阎培渝, 陈志城. 不同水胶比的粉煤灰混凝土的自收缩(英文)[J]. 硅酸盐学报, 2014, 42(5): 585-589. doi: 10.7521/j.issn.0454-5648.2014.05.05YAN Peiyu, CHEN Zhicheng. Autogenous shrinkage of fly ash concrete with different water-binder ratios[J]. Journal of The Chinese Ceramic Society, 2014, 42(5): 585-589(in Chinese). doi: 10.7521/j.issn.0454-5648.2014.05.05 [31] 沙东, 王宝民, 潘宝峰, 等. 地质聚合物强化增韧方法研究综述[J]. 复合材料学报, 2023, 1-10.SHA Dong, WANG Baomin, PAN Baofeng, et al. A review on reinforcing and toughening methods of geopolymers[J]. Acta Materiae Compositae Sinica, 2023, 1-10(in Chinese). [32] 马成畅, 徐斐熙, 杨杨, 等. 大掺量粉煤灰混凝土早龄期拉伸徐变特性研究[J]. 浙江工业大学学报, 2023, 51(2): 131-138. doi: 10.3969/j.issn.1006-4303.2023.02.003MA Chengchang, XU Feixi, YANG Yang, et al. Study on tensile creep characteristics of high volume fly ash concrete at early ages[J]. Journal of Zhejiang University of Technology, 2023, 51(2): 131-138(in Chinese). doi: 10.3969/j.issn.1006-4303.2023.02.003 [33] HASHMI A, SHARIQ M, BAQI A. An investigation into age-dependent strength, elastic modulus and deflection of low calcium fly ash concrete for sustainable construction[J]. Construction and Building Materials, 2021, 283: 122772. doi: 10.1016/j.conbuildmat.2021.122772 [34] LI L, DABARERA A, DAO V. Basic tensile creep of concrete with and without superabsorbent polymers at early ages[J]. Construction and Building Materials, 2022, 320: 126180. doi: 10.1016/j.conbuildmat.2021.126180 -

点击查看大图

点击查看大图

计量

- 文章访问数: 110

- HTML全文浏览量: 84

- 被引次数: 0

下载:

下载: