Performance evolution of carbon fiber composites under moisture absorption coupled four-point bending load

-

摘要: 为研究吸湿耦合四点弯曲载荷条件下碳纤维增强环氧树脂基复合材料的性能演变规律,通过自行设计的夹具施加四点弯曲载荷,并耦合5倍浓度模拟海水吸湿环境以模拟复合材料承载结构在海水中的服役条件。通过裂纹观测系统原位监测复合材料在力学实验过程中的损伤萌生与扩展,对比分析不同预处理条件对复合材料剩余力学性能及损伤模式的影响,分别通过四点弯曲、三点弯曲及短梁剪切力学试验,对预处理中复合材料的加载区域、等弯矩段进行评估。结果表明,预处理后复合材料的四点弯曲性能降低,一端加载处出现损伤破坏后,随之继续发生多次载荷下降直至最终失效发生;复合材料的等弯矩段短梁剪切性能无明显变化,三点弯曲力学试验结果表明预处理条件对等弯矩段的应力集中作用不显著。从而,预处理条件对加载区域影响显著,使其在失效过程中呈现出多断口扩展,伴随有层间裂纹扩展现象,而对等弯矩段无显著影响。Abstract: In order to study the performance evolution of carbon fiber reinforced epoxy composites under moisture absorption coupling four-point bending load, a four-point bending loading fixture was self-designed to provide the load condition, and 5 times concentration of seawater simulating moisture environment was coupled to simulate the service condition. The damage initiation and propagation process of composite under mechanical loading were monitored in situ by self-designed crack observation system. The effects of different pretreatment conditions on mechanical properties and damage modes were compared and analyzed. The loading area and equal bending moment area of composite under four-point bending pretreatment conditions were evaluated by four-point bending, three-point bending and short beam shearing test, respectively. The results show that the four-point bending property is decreased after pretreatment, the composite is damaged at one end of the loading at first, and then the load continues to decline for several times until the final failure occurs. There is no obvious change in the short beam shearing performance of the equal bending moment section. The three-point bending mechanical test results show that the pretreatment has no significant stress concentration effect on the equal bending moment area. Thus, the pretreatment conditions had a significant effect on the loading area but insignificant on the equal bending moment area. Multiple fracture propagation was observed on the loading area during the failure process, accompanied by interlayer crack propagation.

-

Key words:

- carbon fiber composite /

- four-point bending /

- simulated seawater /

- moisture absorption /

- damage mode

-

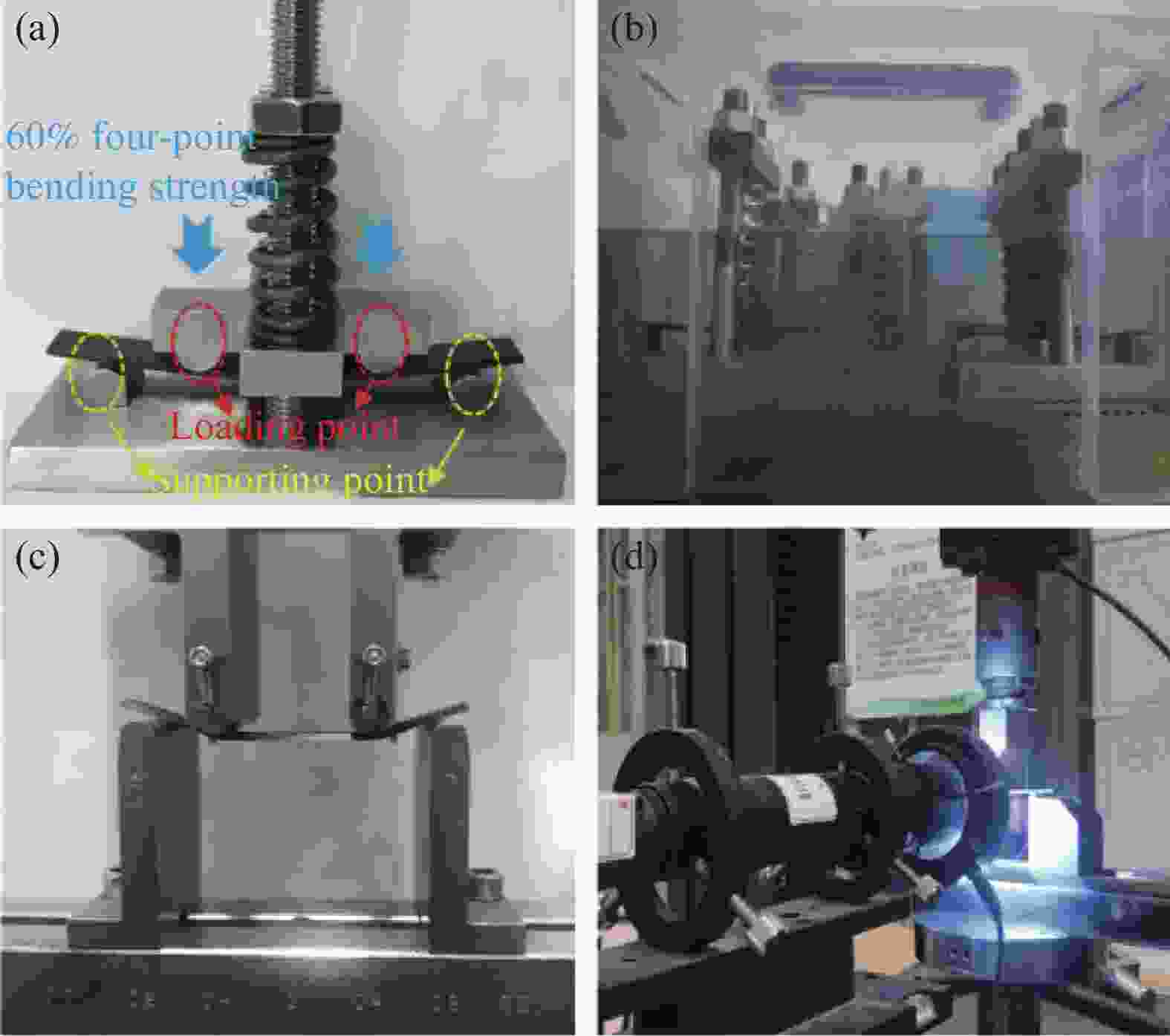

图 1 (a)自行设计的四点弯曲夹具载荷施加实验;(b)吸湿耦合四点弯曲载荷条件预处理实验;(c)四点弯曲力学实验;(d)原位裂纹观测实验

Figure 1. (a)Self-designed four-point bending fixture loading experiment; (b)Moisture absorption coupling four-point bending loading pretreatment experiment; (c)Four-point bending mechanical experiment; (d)In-situ crack observation experiment

图 8 T800级碳纤维复合材料层合板的四点弯曲载荷位移对比图:(a)未经预处理、(b)预处理7天后、(c)预处理14天后、(d)预处理21天后

Figure 8. Comparison of four-point bending load displacement of T800 carbon fiber composite laminate: (a) without pretreatment, (b) with pretreatment for 7 days, (c) with pretreatment for 14 days, (d) with pretreatment for 21 days.

图 9 5倍盐水+60%四点弯曲载荷条件下处理7天,T800级碳纤维复合材料层合板四点失效形貌特征(a)左侧加载处,(b)右侧加载处

Figure 9. Four-point failure morphology characteristics of T800 carbon fiber composite laminate after 7 days pretreatment under 5 times seawater moisture coupled with 60% four-point bending load (a)the left loading position, (b)the right loading position

图 10 5倍盐水+60%四点弯曲载荷条件下处理14天,T800级碳纤维复合材料层合板四点失效形貌特征(a)左侧加载处,(b)右侧加载处

Figure 10. Four-point failure morphology characteristics of T800 carbon fiber composite laminate after 14 days pretreatment under 5 times seawater moisture coupled with 60% four-point bending load (a)the left loading position, (b)the right loading position

图 11 5倍盐水+60%四点弯曲载荷条件下处理21天,T800级碳纤维复合材料层合板四点失效形貌特征(a)左侧加载处,(b)等弯矩段,(c)右侧加载处

Figure 11. Four-point failure morphology characteristics of T800 carbon fiber composite laminate after 21 days pretreatment under 5 times seawater moisture coupled with 60% four-point bending load (a)the left loading position, (b) the equal bending moment area, (c)the right loading position

表 1 未经预处理,T800级碳纤维复合材料层合板四点弯曲性能

Table 1. Four-point bending properties of untreated T800 carbon fiber composite laminate

Width/

mmThickness/

mmBending

load/NBending

strength/MPaBending

modulus/GPa13.1 1.95 1197 1441 223 -

[1] AFSHAR A, LIAO H T, CHIANG F P, KORACH C S. Time-dependent changes in mechanical properties of carbon fiber vinyl ester composites exposed to marine environments[J]. Composite Structures, 2016, 144(1): 80-85. [2] ALAM P, ROBERT C, Ó BRÁDAIGH C M. Tidal turbine blade composites-A review on the effects of hygrothermal aging on the properties of CFRP[J]. Composites Part B. Engineering, 2018, 149: 248-259. doi: 10.1016/j.compositesb.2018.05.003 [3] GARGANO A, GALOS J, MOURITZ A P. Importance of fibre sizing on the seawater durability of carbon fibre laminates[J]. Composite Communications, 2020, 19: 11-15. doi: 10.1016/j.coco.2020.02.002 [4] JESTHI D K, NAYAK R K. Evaluation of mechanical properties and morphology of seawater aged carbon and glass fiber reinforced polymer hybrid composites[J]. Composites Part B: Engineering, 2019, 174: 106980. doi: 10.1016/j.compositesb.2019.106980 [5] MINAKUCHI S, NAKAMURA K, MIZUTANI T, et al. Life-cycle evaluation of the moisture absorption and desorption behaviors of prepreg-based carbon fiber reinforced plastic[J]. Advanced Functional Materials, 2020, 30: 17-33. [6] WONG K J, JOHAR M, KOLOOR S S R, et al. Moisture absorption effects on mode II delamination of carbon/epoxy composites[J]. Polymers, 2020, 12(9): 2162. doi: 10.3390/polym12092162 [7] JOHAR M, CHONG W W F, KANG H S, WONG K J. Effects of moisture absorption on the different modes of carbon/epoxy composites delamination[J]. Polymer Degradation and Stability, 2019, 165: 117-125. doi: 10.1016/j.polymdegradstab.2019.05.007 [8] LIU L, ZHAO Z, CHEN W, et al. An experimental investigation on high velocity impact behavior of hygrothermal aged CFRP composites[J]. Composite Structures, 2018, 204: 645-657. doi: 10.1016/j.compstruct.2018.08.009 [9] HUMEAU C, DAVIES P, JACQUEMIN F. An experimental study of water diffusion in carbon/epoxy composites under static tensile stress[J]. Composites Part A: Applied Science and Manufacturing, 2018, 107: 94-104. doi: 10.1016/j.compositesa.2017.12.016 [10] ABDEL-MAGID B, ZIAEE S, GASS K, et al. The combined effects of load, moisture and temperature on the properties of E-glass/epoxy composites[J]. Composite Structures, 2005, 71: 320-326. doi: 10.1016/j.compstruct.2005.09.022 [11] ARGUELLES A, FERNANDEZ-CANTELI A, VINA J, et al. Evolution of the impact strength of carbon fiber-reinforced PEI following exposure to mechanical, hygrothermal and hygrothermomechanical aging[J]. Journal of Composite Materials, 2007, 41: 2337-2346. doi: 10.1177/0021998307075446 [12] MOROKOV E, LEVIN V, RYZHOVA T, et al. Bending damage evolution from micro to macro level in CFRP laminates studied by high-frequency acoustic microscopy and acoustic emission[J]. Composite Structures, 2022, (288): 115427. [13] 董晓龙. 原位四点弯曲测试装置的设计分析与试验研究[D]. 吉林大学, 2015.DONG Xiaolong. Development of an in-situ Four-point Bending Instrument and Corresponding Experimental Research[D]. Jilin University, 2015 (in Chinese). [14] MARTIN R H, DAVIDSON B D. Mode II fracture toughness evaluation using four point bend, end notched flexure test[J]. Plastics, Rubber and Composites, 1999, 28(8): 401-406. doi: 10.1179/146580199101540565 [15] MURAT K, SONMEZ F O, ERSOY N, et al. Failure behavior of composite laminates under four-point bending[J]. Journal of Composite Materials, 2016, 50: 1-19. [16] ABBADI A, AZARI Z, BELOUETTAR S. Modelling the fatigue behaviour of composites honeycomb materials (aluminium/aramide fibre core) using four-point bending tests[J]. International Journal of Fatigue. 2010, 32: 11: 1739-1747. [17] Rojas-Sanchez J F, Schmack T, BOESL B, et al. Strain rate-dependent characterization of carbon fibre-reinforced composite laminates using four-point bending tests[J]. Journal of Reinforced Plastics and Composites, 2019, 39: 165-174. [18] SYED ABDULLAH S I B, BOKTI S K, WONG K J. Mode II and mode III delamination of carbon fiber/epoxy composite laminates subjected to a four-point bending mechanism[J]. Composites Part B: Engineering, 2024, 270: 111110. doi: 10.1016/j.compositesb.2023.111110 [19] COCCHI A, MONTAGNIER O, HOCHARD C. Study of hourglass-shaped specimens for the analysis of compression behaviour in fibre direction of FRP composites using compression and four-point bending tests[J]. Composites Part A: Applied Science and Manufacturing, 2021, 144: 106332. doi: 10.1016/j.compositesa.2021.106332 [20] AWAD Z K, ARAVINTHAN T, MANALO A. Geometry effect on the behaviour of single and glue-laminated glass fibre reinforced polymer composite sandwich beams loaded in four-point bending[J]. Materials & Design, 2012, 39: 93-103. [21] 郝敏娟, 谢中朋, 岳忠. 四点弯曲载荷作用下复合材料分层演化行为探索[J]. 玻璃钢/复合材料, 2017, 8: 25-29.HAO Minjuan, XIE Zhongpeng, YUE Zhong. Experimental studyu for evolution behavior of composite materials with delamination defect by four-point bending[J]. Fiber Reinforced Plastics/Composites, 2017, 8: 25-29 (in Chinese). [22] 赵玉卿, 姜峰, 黄争鸣. 纤维复合材料层合板在四点弯曲载荷下的损伤分析[J]. 复合材料科学与工程, 2020, 2: 10-18.ZHAO Yuqing, JIANG Feng, HUANG Zhengming. Damage analysis of fiber composite laminates under four-point bending load[J]. Composites Science and Engineering, 2020, 2: 10-18 (in Chinese). [23] 马丽婷, 陈新文, 王翔, 等. 碳纤维复合材料曲梁冲击后四点弯曲强度及损伤失效模式研究[J]. 玻璃钢/复合材料, 2017, 3: 17-20.MA Liting, CHEN Xinwen, WANG Xiang, GUO Guangping. Study on the post impact curved beam strength and failure mode of carbon/epoxy laminate[J]. Fiber Reinforced Plastics/Composites, 2017, 3: 17-20 (in Chinese). [24] WANG Y, CHAI Y, SOUTIS C, et al. Evolution of kink bands in a notched unidirectional carbon fibre-epoxy composite under four-point bending[J]. Composites Science and Technology, 2019, 172: 143-152. doi: 10.1016/j.compscitech.2019.01.014 [25] COCCHI A, MONTAGNIER O, HOCHARD C. Study of hourglass-shaped specimens for the analysis of compression behaviour in fibre direction of FRP composites using compression and four-point bending tests[J]. Composites Part A Applied Science and Manufacturing, 2021, 144(4): 106332. [26] AWAD Z K, ARAVINTHAN T, MANALO A. Geometry effect on the behaviour of single and glue-laminated glass fibre reinforced polymer composite sandwich beams loaded in four-point bending[J]. Materials & Design, 2012, 39(8): 93-103. [27] American Society for Testing and Materials. ASTM D5229/D5229M-20 Standard Test Method for Moisture Absorption Properties and Equilibrium Conditioning of Polymer Matrix Composite Materials[S]. West Conshohocken: ASTM International, 2020. [28] 中国国家标准化管理委员会(标准制定单位). 定向纤维增强聚合物基复合材料弯曲性能试验方法: GB/T 3356-2014[S]. 北京: 中国标准出版社, 2014.Standardization Administration of the People’s Republic of China. Test method for flexural properties of orientational fiber reinforced polymer metrix composite materials: GB/T 7314—1987[S]. Beijing: China Standards Press, 2014 (in Chinese). -

点击查看大图

点击查看大图

计量

- 文章访问数: 68

- HTML全文浏览量: 22

- 被引次数: 0

下载:

下载: